boot MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 18 of 1232

MAINTENANCE - WITH ASSYST MAINTENANCE

COMPUTER

ASSYST provides information on the best possible

timing for maintenance work.

NOTE: The engine manufacturer strongly recom-

mends the use of synthetic engine oils, such as

TMobil 1 SAE 0W-40.

When the next maintenance service is due, this

will be indicated in the multi-function display with

the wrench icon symbol displayed in km/miles or

days.

²One wrench icon showing indicates Oil Service

is necessary.

²Two wrench icons showing indicates Mainte-

nance Service is necessary ± displayed in km/miles or

days.

If the display shows the number of days, a clock

symbol will also appear in the multi-function display.

You should have the maintenance performed

within the stated period/distance.

The service indicator should be reset after an oil

service and/or maintenance service has been per-

formed.

REGULAR CHECK-UPS

To maintain the safe operation of the vehicle, it is

recommended that the following tasks be performed

on a regular basis (i.e. weekly or whenever the vehi-

cle is refueled). Check:

²Engine oil level

²Brake system, clutch mechanism ± fluid level

²Battery ± acid level

²Windshield washer system and headlamp clean-

ing system ± fluid level

²Mechanical assemblies (e. g. engine, transmis-

sion, etc.) ± check for leaks

²Condition of tires and tires pressures

²All exterior lights

SPECIAL MAINTENANCE REQUIREMENTS

If bodies built by manufacturers other than

DaimlerChrysler Corporation are fitted to the vehi-

cle, the maintenance requirements and lubrication

intervals specified by the body manufacturer must be

adhered to, in addition to all standard maintenance

requirements.

Brake Fluid

Only use brake fluids approved by the manufac-

turer (DOT 4 plus).

Coolant

Corrosion inhibitor/antifreeze concentration in the

coolant should be checked before the onset of winter

(once year in countries with high prevailing temper-

atures).Replace the coolant every five years or 100,000

miles.

Dust Filter for Heating/Ventilation Replace-

ment

The dust filter and the tailgate interior filter are to

be renewed during routine maintenance service. If

operating conditions are dusty, these filters should be

renewed more frequently.

ENGINE OIL CHANGE AND FILTER REPLACEMENT

At the minimum, change the engine oil and oil fil-

ter once a year ± even if the vehicle mileage per year

is extremely low. For standard oil service schedules

refer to the chapter oil service and maintenance ser-

vice.

Once a Year

Select the viscosity of the engine oil (SAE classes)

according to the outside air temperature.

Only use engine oil approved by DaimlerChrysler

Corporation if following the ASSYST system guide-

lines.

If the fuel used has a sulphur content exceeding

0.05% by weight, the service intervals should be split

in half.

SCOPE OF WORK FOR MAINTENANCE SERVICE

Oil Service

²Engine:

Oil change and filter replacement

Check fluid levels of the following system,

refill as necessary.

²If fluid is lost, trace and eliminate cause ± as a

separate order.

²Power-assisted steering

Lubrication work:

²Trailer tow hitch (original equipment)

Maintenance

²ASSYST maintenance computer reset

Function check

²Signalling system, warning and indicator lamps

²Headlamps, exterior lighting

²Windshield wipers, windshield washer system

Check for leaks and damage.

²Check for abrasion points and ensure that lines

are correctly routed!

²All lines and hoses, sensor cables

²Rubber boots on front axle drive shafts, rubber

boots on front axle suspension ball joints, shock

absorbers

Check fluid levels for the following systems,

correct as necessary.

NOTE: Should there be a loss of fluid which cannot

be explained by regular use, trace and eliminate the

cause.

0 - 8 LUBRICATION & MAINTENANCEVA

MAINTENANCE SCHEDULES (Continued)

Page 46 of 1232

PROPELLER SHAFT

REMOVAL

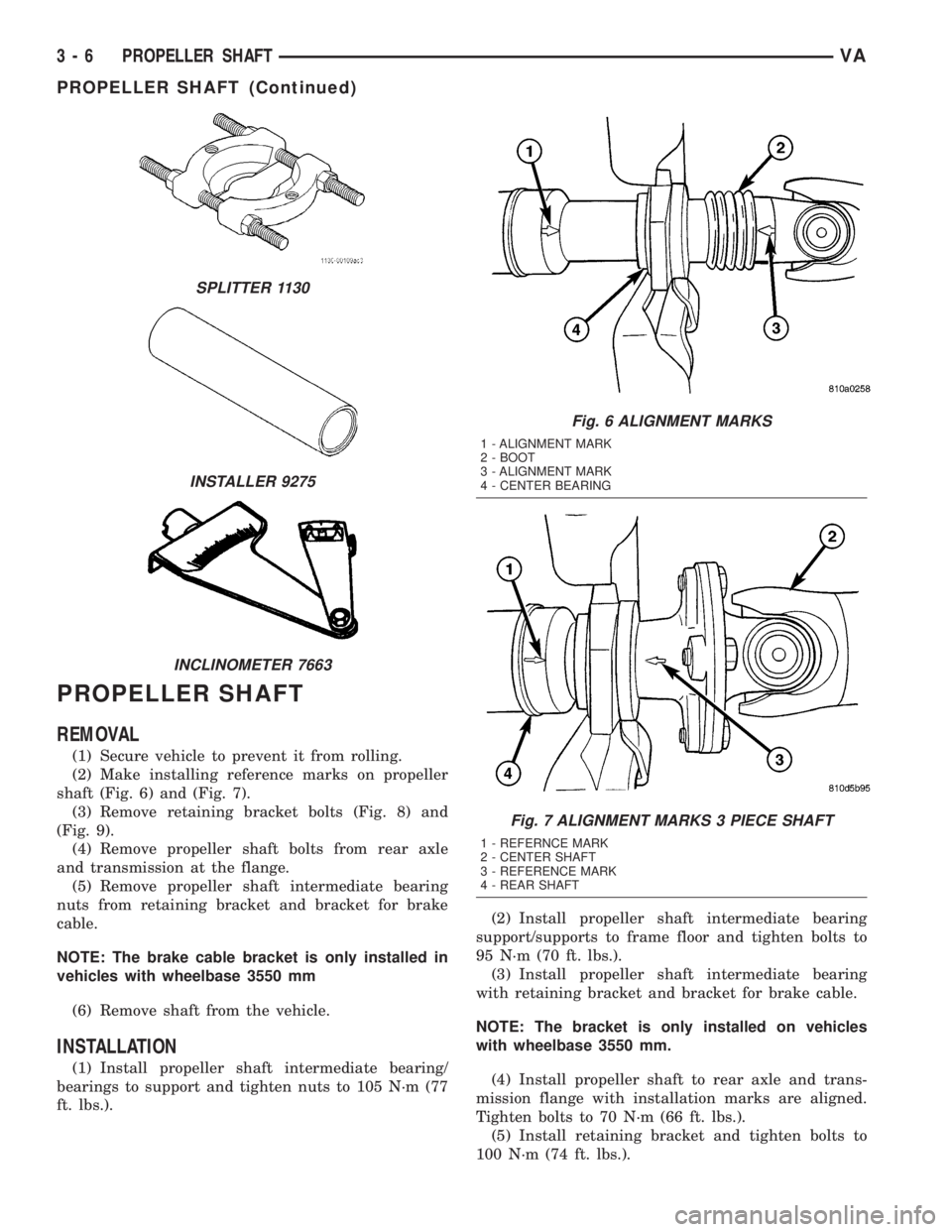

(1) Secure vehicle to prevent it from rolling.

(2) Make installing reference marks on propeller

shaft (Fig. 6) and (Fig. 7).

(3) Remove retaining bracket bolts (Fig. 8) and

(Fig. 9).

(4) Remove propeller shaft bolts from rear axle

and transmission at the flange.

(5) Remove propeller shaft intermediate bearing

nuts from retaining bracket and bracket for brake

cable.

NOTE: The brake cable bracket is only installed in

vehicles with wheelbase 3550 mm

(6) Remove shaft from the vehicle.

INSTALLATION

(1) Install propeller shaft intermediate bearing/

bearings to support and tighten nuts to 105 N´m (77

ft. lbs.).(2) Install propeller shaft intermediate bearing

support/supports to frame floor and tighten bolts to

95 N´m (70 ft. lbs.).

(3) Install propeller shaft intermediate bearing

with retaining bracket and bracket for brake cable.

NOTE: The bracket is only installed on vehicles

with wheelbase 3550 mm.

(4) Install propeller shaft to rear axle and trans-

mission flange with installation marks are aligned.

Tighten bolts to 70 N´m (66 ft. lbs.).

(5) Install retaining bracket and tighten bolts to

100 N´m (74 ft. lbs.).

SPLITTER 1130

INSTALLER 9275

INCLINOMETER 7663

Fig. 6 ALIGNMENT MARKS

1 - ALIGNMENT MARK

2 - BOOT

3 - ALIGNMENT MARK

4 - CENTER BEARING

Fig. 7 ALIGNMENT MARKS 3 PIECE SHAFT

1 - REFERNCE MARK

2 - CENTER SHAFT

3 - REFERENCE MARK

4 - REAR SHAFT

3 - 6 PROPELLER SHAFTVA

PROPELLER SHAFT (Continued)

Page 48 of 1232

CENTER BEARING

REMOVAL

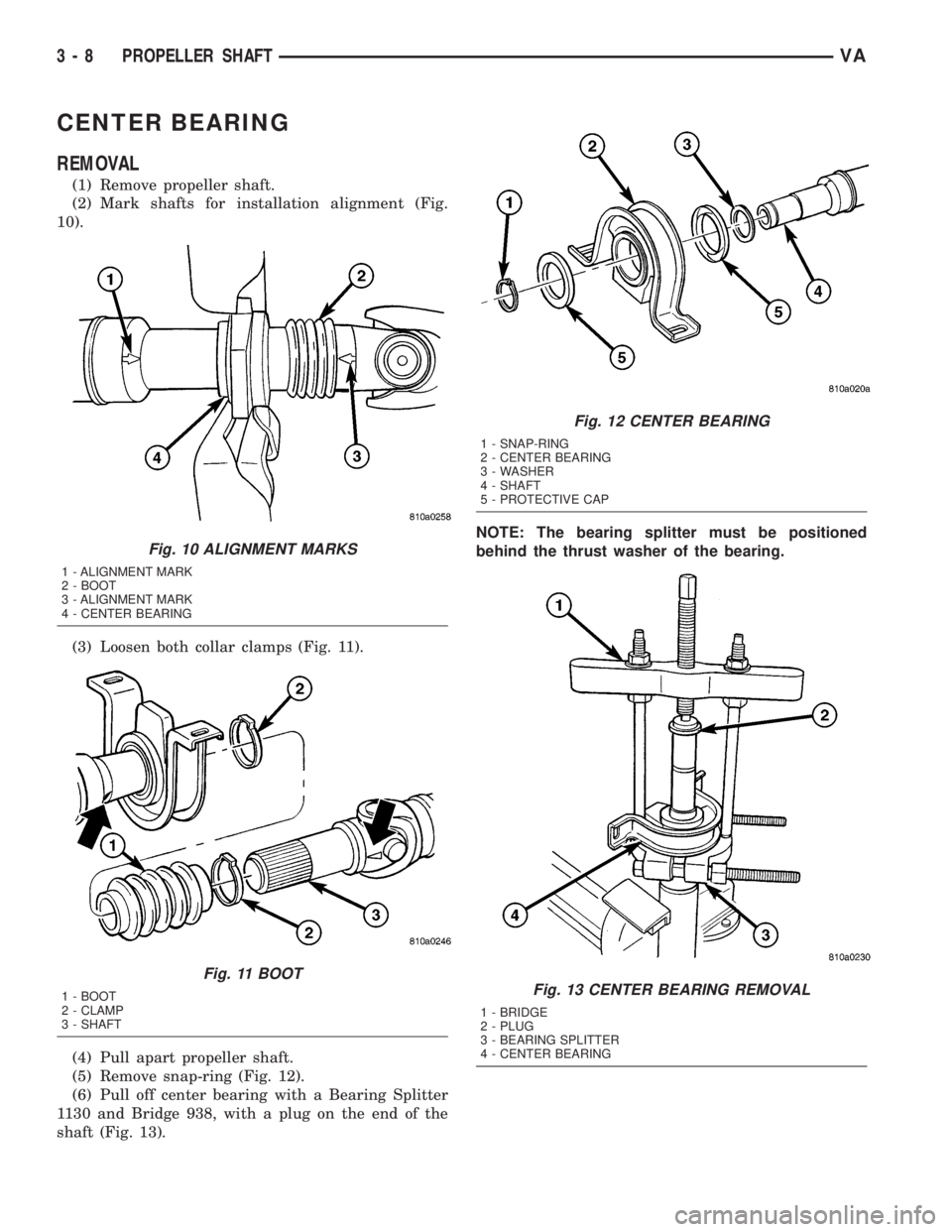

(1) Remove propeller shaft.

(2) Mark shafts for installation alignment (Fig.

10).

(3) Loosen both collar clamps (Fig. 11).

(4) Pull apart propeller shaft.

(5) Remove snap-ring (Fig. 12).

(6) Pull off center bearing with a Bearing Splitter

1130 and Bridge 938, with a plug on the end of the

shaft (Fig. 13).NOTE: The bearing splitter must be positioned

behind the thrust washer of the bearing.

Fig. 10 ALIGNMENT MARKS

1 - ALIGNMENT MARK

2 - BOOT

3 - ALIGNMENT MARK

4 - CENTER BEARING

Fig. 11 BOOT

1 - BOOT

2 - CLAMP

3 - SHAFT

Fig. 12 CENTER BEARING

1 - SNAP-RING

2 - CENTER BEARING

3 - WASHER

4 - SHAFT

5 - PROTECTIVE CAP

Fig. 13 CENTER BEARING REMOVAL

1 - BRIDGE

2 - PLUG

3 - BEARING SPLITTER

4 - CENTER BEARING

3 - 8 PROPELLER SHAFTVA

Page 49 of 1232

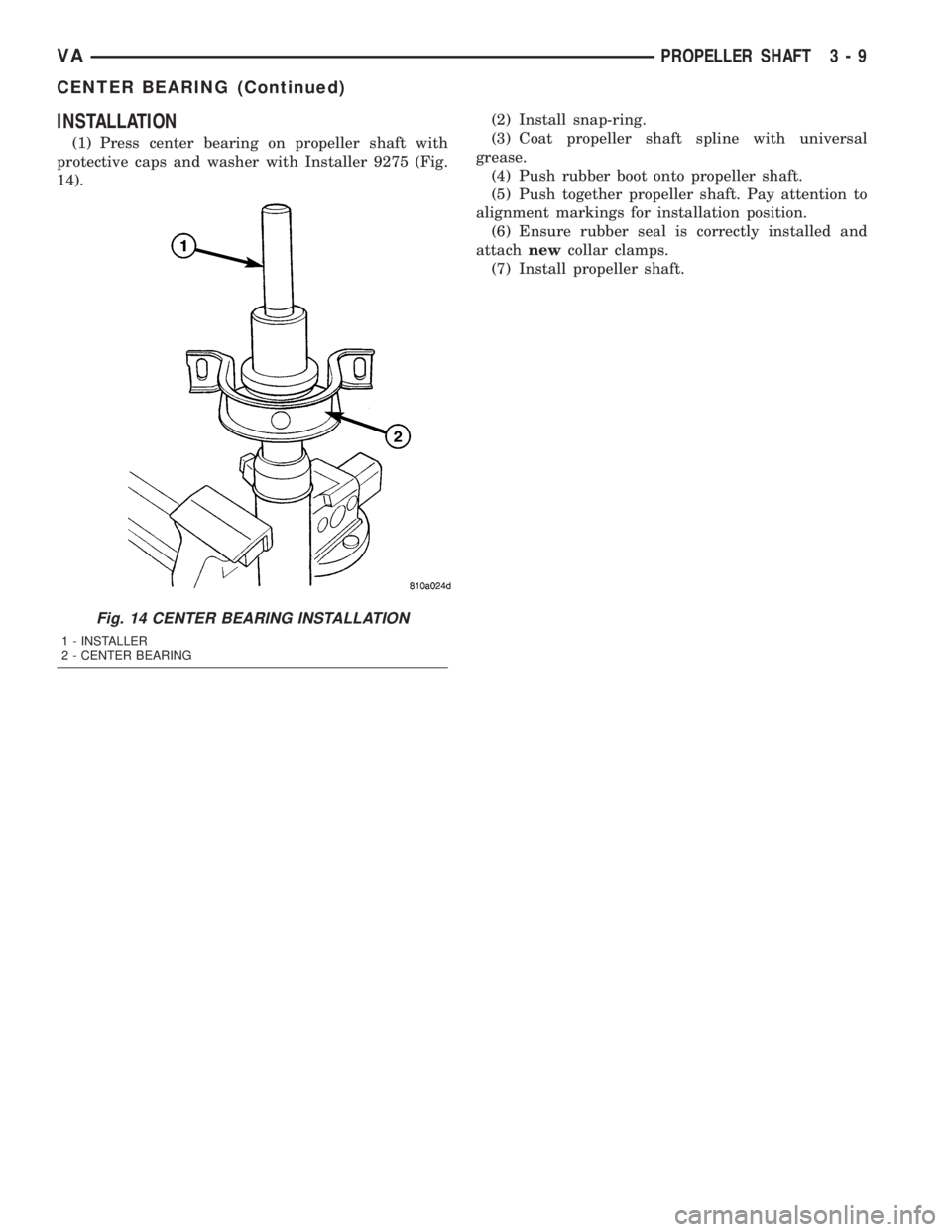

INSTALLATION

(1) Press center bearing on propeller shaft with

protective caps and washer with Installer 9275 (Fig.

14).(2) Install snap-ring.

(3) Coat propeller shaft spline with universal

grease.

(4) Push rubber boot onto propeller shaft.

(5) Push together propeller shaft. Pay attention to

alignment markings for installation position.

(6) Ensure rubber seal is correctly installed and

attachnewcollar clamps.

(7) Install propeller shaft.

Fig. 14 CENTER BEARING INSTALLATION

1 - INSTALLER

2 - CENTER BEARING

VAPROPELLER SHAFT 3 - 9

CENTER BEARING (Continued)

Page 870 of 1232

LINKAGE

TABLE OF CONTENTS

page page

LINKAGE

DIAGNOSIS AND TESTING - OUTER TIE ROD

END ................................10

SPECIFICATIONS - TORQUE CHART........10

SPECIAL TOOLS

FRONT SUSPENSION..................11TIE ROD END

REMOVAL.............................11

INSTALLATION.........................11

LINKAGE

DIAGNOSIS AND TESTING - OUTER TIE ROD

END

NOTE: If the outer tie rod end is equipped with a

lubrication fitting, grease the joint then road test

the vehicle before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.

(3) Mount a dial indicator solidly to the vehicle

steering knuckle and then zero the dial indicator.(4) Position indicator plunger on the topside of the

outer tie rod end.

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the outer tie rod

end.

(5) Position a pry bar in order to pry downwards

on the outer tie rod end.

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the outer tie rod end (Refer to 19 - STEERING/

LINKAGE/TIE ROD END - REMOVAL).

(7) If the outer tie rod end is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

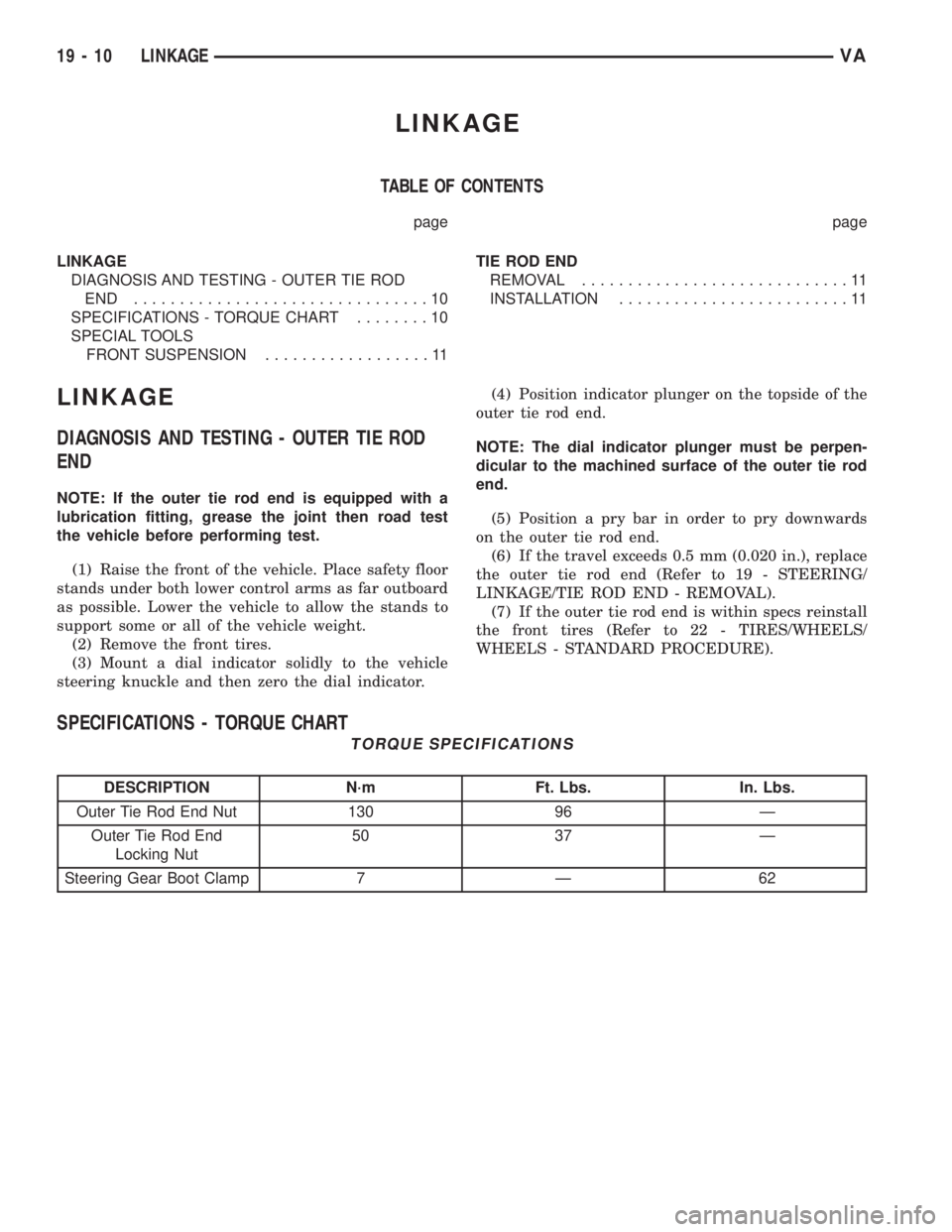

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Outer Tie Rod End Nut 130 96 Ð

Outer Tie Rod End

Locking Nut50 37 Ð

Steering Gear Boot Clamp 7 Ð 62

19 - 10 LINKAGEVA

Page 1052 of 1232

(2) Tighten door fasteners to 10 N´m (89 in. lbs.).

(3) Install bracket onto check and install bracket

bolt/nut.

(4) Tighten bracket bolt/nut to 6 N´m (53 in. lbs.).

(5) Install check bracket onto a-pillar.

(6) Apply Loctitet243 sealant check strap bolts

and install bolts.

(7) Tighten the M8 bolts to 35 N´m (26 ft. lbs.) or

tighten the M6 bolts to 10 N´m (89 in. lbs.).

(8) Install trim panel. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION)

(9) Connect battery negative cable.

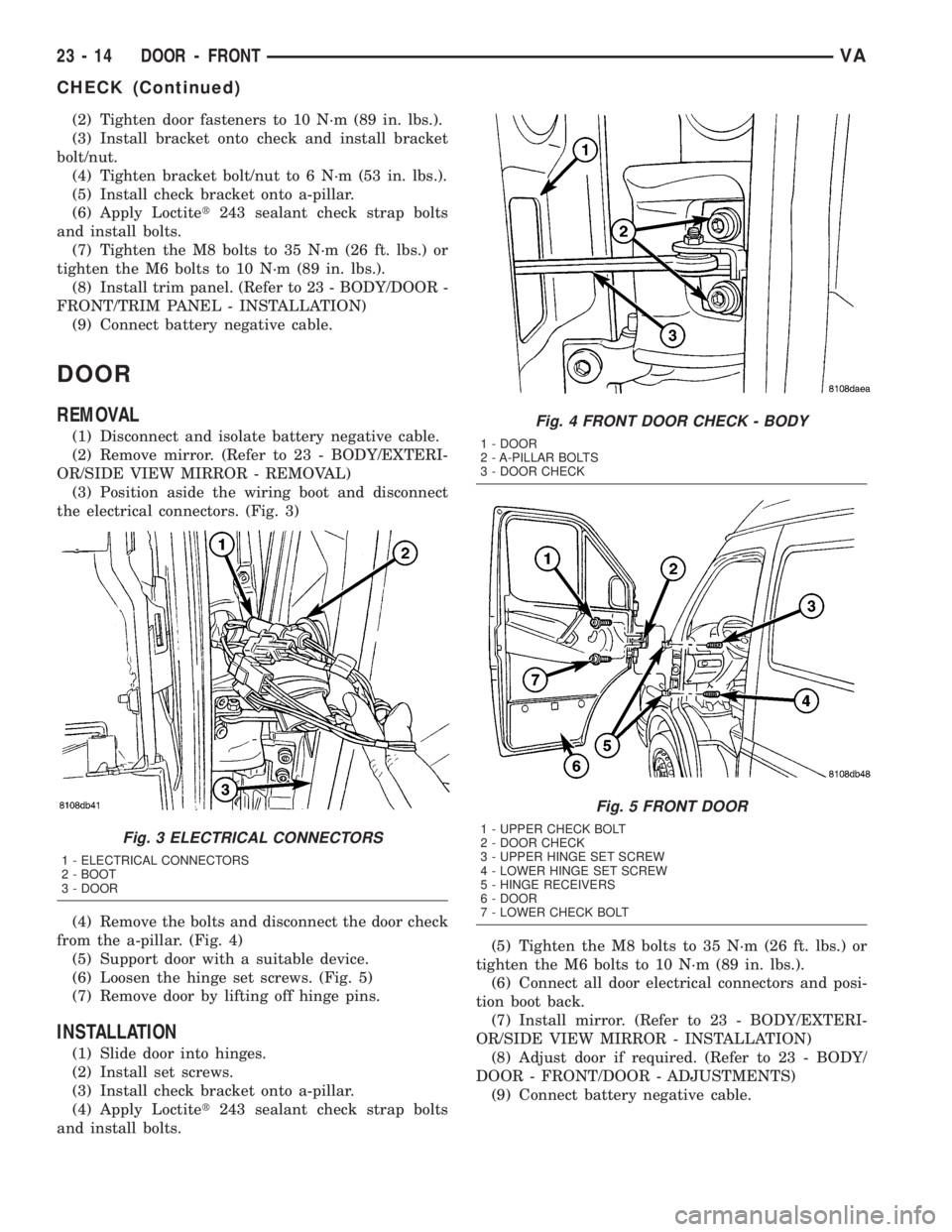

DOOR

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - REMOVAL)

(3) Position aside the wiring boot and disconnect

the electrical connectors. (Fig. 3)

(4) Remove the bolts and disconnect the door check

from the a-pillar. (Fig. 4)

(5) Support door with a suitable device.

(6) Loosen the hinge set screws. (Fig. 5)

(7) Remove door by lifting off hinge pins.

INSTALLATION

(1) Slide door into hinges.

(2) Install set screws.

(3) Install check bracket onto a-pillar.

(4) Apply Loctitet243 sealant check strap bolts

and install bolts.(5) Tighten the M8 bolts to 35 N´m (26 ft. lbs.) or

tighten the M6 bolts to 10 N´m (89 in. lbs.).

(6) Connect all door electrical connectors and posi-

tion boot back.

(7) Install mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - INSTALLATION)

(8) Adjust door if required. (Refer to 23 - BODY/

DOOR - FRONT/DOOR - ADJUSTMENTS)

(9) Connect battery negative cable.

Fig. 3 ELECTRICAL CONNECTORS

1 - ELECTRICAL CONNECTORS

2 - BOOT

3 - DOOR

Fig. 4 FRONT DOOR CHECK - BODY

1 - DOOR

2 - A-PILLAR BOLTS

3 - DOOR CHECK

Fig. 5 FRONT DOOR

1 - UPPER CHECK BOLT

2 - DOOR CHECK

3 - UPPER HINGE SET SCREW

4 - LOWER HINGE SET SCREW

5 - HINGE RECEIVERS

6 - DOOR

7 - LOWER CHECK BOLT

23 - 14 DOOR - FRONTVA

CHECK (Continued)

Page 1086 of 1232

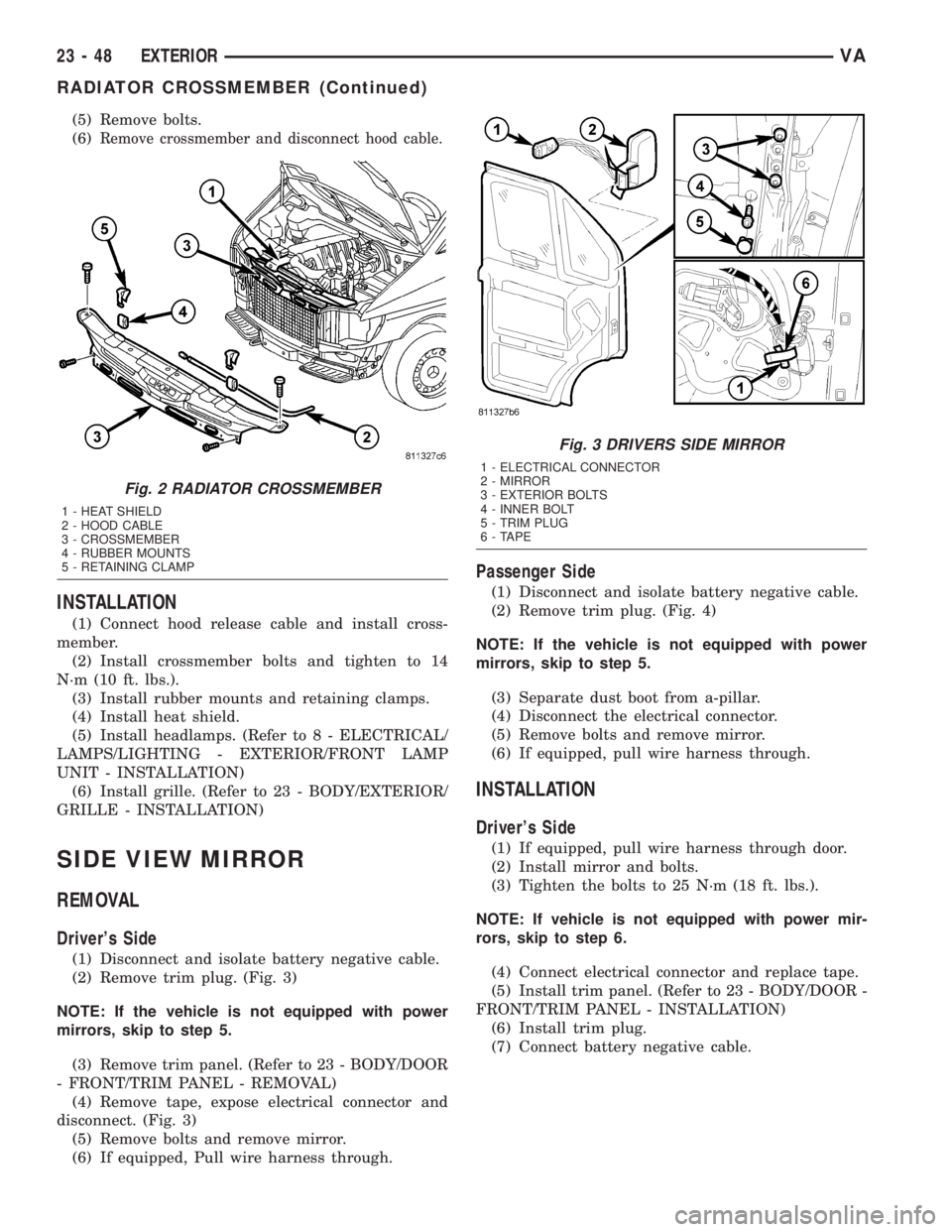

(5) Remove bolts.

(6)

Remove crossmember and disconnect hood cable.

INSTALLATION

(1) Connect hood release cable and install cross-

member.

(2) Install crossmember bolts and tighten to 14

N´m (10 ft. lbs.).

(3) Install rubber mounts and retaining clamps.

(4) Install heat shield.

(5) Install headlamps. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/FRONT LAMP

UNIT - INSTALLATION)

(6) Install grille. (Refer to 23 - BODY/EXTERIOR/

GRILLE - INSTALLATION)

SIDE VIEW MIRROR

REMOVAL

Driver's Side

(1) Disconnect and isolate battery negative cable.

(2) Remove trim plug. (Fig. 3)

NOTE: If the vehicle is not equipped with power

mirrors, skip to step 5.

(3) Remove trim panel. (Refer to 23 - BODY/DOOR

- FRONT/TRIM PANEL - REMOVAL)

(4) Remove tape, expose electrical connector and

disconnect. (Fig. 3)

(5) Remove bolts and remove mirror.

(6) If equipped, Pull wire harness through.

Passenger Side

(1) Disconnect and isolate battery negative cable.

(2) Remove trim plug. (Fig. 4)

NOTE: If the vehicle is not equipped with power

mirrors, skip to step 5.

(3) Separate dust boot from a-pillar.

(4) Disconnect the electrical connector.

(5) Remove bolts and remove mirror.

(6) If equipped, pull wire harness through.

INSTALLATION

Driver's Side

(1) If equipped, pull wire harness through door.

(2) Install mirror and bolts.

(3) Tighten the bolts to 25 N´m (18 ft. lbs.).

NOTE: If vehicle is not equipped with power mir-

rors, skip to step 6.

(4) Connect electrical connector and replace tape.

(5) Install trim panel. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION)

(6) Install trim plug.

(7) Connect battery negative cable.

Fig. 2 RADIATOR CROSSMEMBER

1 - HEAT SHIELD

2 - HOOD CABLE

3 - CROSSMEMBER

4 - RUBBER MOUNTS

5 - RETAINING CLAMP

Fig. 3 DRIVERS SIDE MIRROR

1 - ELECTRICAL CONNECTOR

2 - MIRROR

3 - EXTERIOR BOLTS

4 - INNER BOLT

5 - TRIM PLUG

6 - TAPE

23 - 48 EXTERIORVA

RADIATOR CROSSMEMBER (Continued)

Page 1087 of 1232

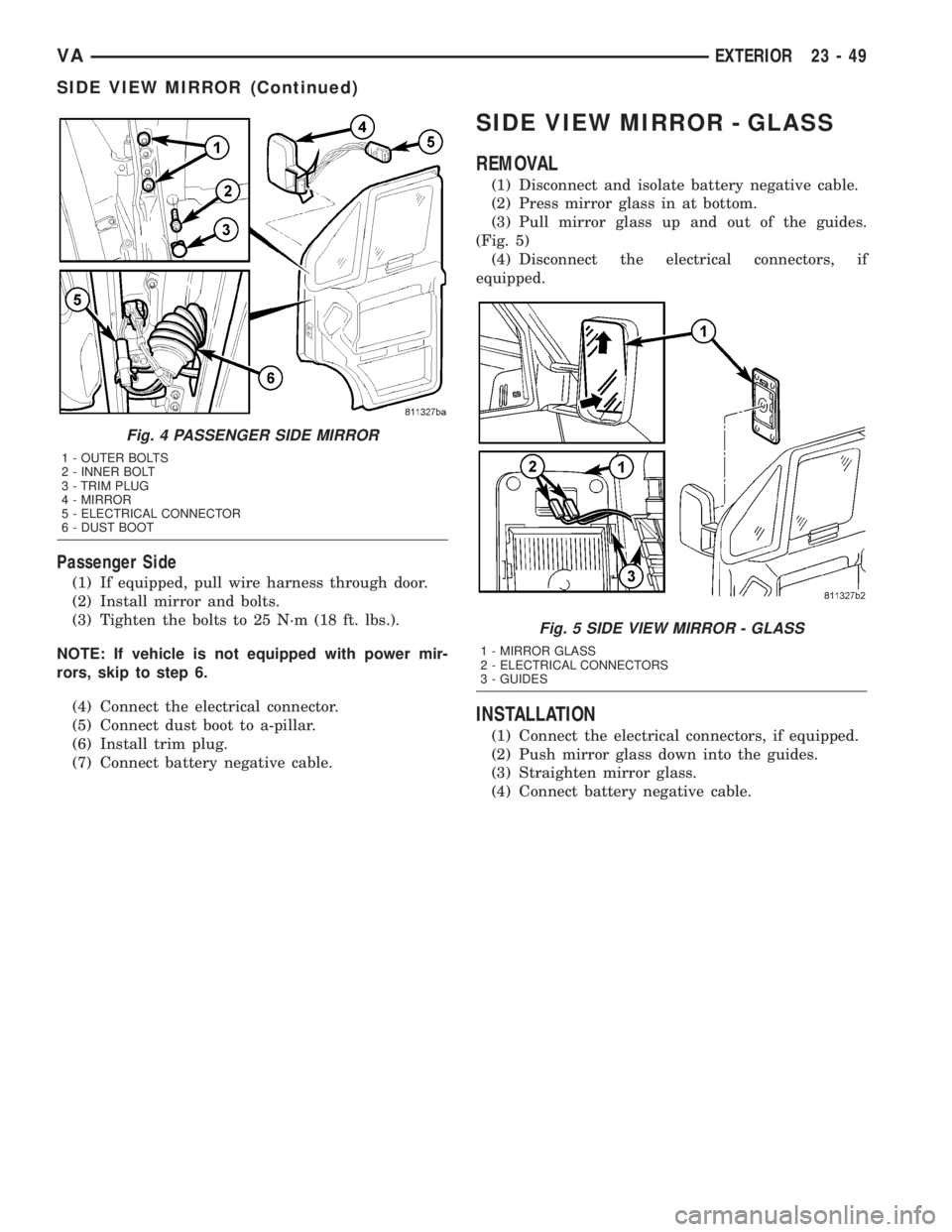

Passenger Side

(1) If equipped, pull wire harness through door.

(2) Install mirror and bolts.

(3) Tighten the bolts to 25 N´m (18 ft. lbs.).

NOTE: If vehicle is not equipped with power mir-

rors, skip to step 6.

(4) Connect the electrical connector.

(5) Connect dust boot to a-pillar.

(6) Install trim plug.

(7) Connect battery negative cable.

SIDE VIEW MIRROR - GLASS

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Press mirror glass in at bottom.

(3) Pull mirror glass up and out of the guides.

(Fig. 5)

(4) Disconnect the electrical connectors, if

equipped.

INSTALLATION

(1) Connect the electrical connectors, if equipped.

(2) Push mirror glass down into the guides.

(3) Straighten mirror glass.

(4) Connect battery negative cable.

Fig. 4 PASSENGER SIDE MIRROR

1 - OUTER BOLTS

2 - INNER BOLT

3 - TRIM PLUG

4 - MIRROR

5 - ELECTRICAL CONNECTOR

6 - DUST BOOT

Fig. 5 SIDE VIEW MIRROR - GLASS

1 - MIRROR GLASS

2 - ELECTRICAL CONNECTORS

3 - GUIDES

VAEXTERIOR 23 - 49

SIDE VIEW MIRROR (Continued)