fuse MERCEDES-BENZ SPRINTER 2005 Service Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 218 of 1232

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Reinstall the speed control switch onto the

back of the multi-function switch. (Refer to 8 - ELEC-

TRICAL/SPEED CONTROL/SWITCH - INSTALLA-

TION).

(2) Position the multi-function switch onto the

steering column (Fig. 37).

(3) Install and tighten the two screws that secure

the multi-function switch to the steering column.

(4) Position the upper shroud onto the top of the

multi-function switch.

(5) Install and tighten the two screws that secure

the upper shroud to the top of the multi-function

switch.

(6) Reinstall the clockspring onto the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - INSTALLATION).

(7) Reinstall the fuse block onto the underside of

the steering column. (Refer to 8 - ELECTRICAL/

POWER DISTRIBUTION/FUSE BLOCK - INSTAL-

LATION).

(8) Reconnect the battery negative cable.

PARK BRAKE SWITCH

REMOVAL

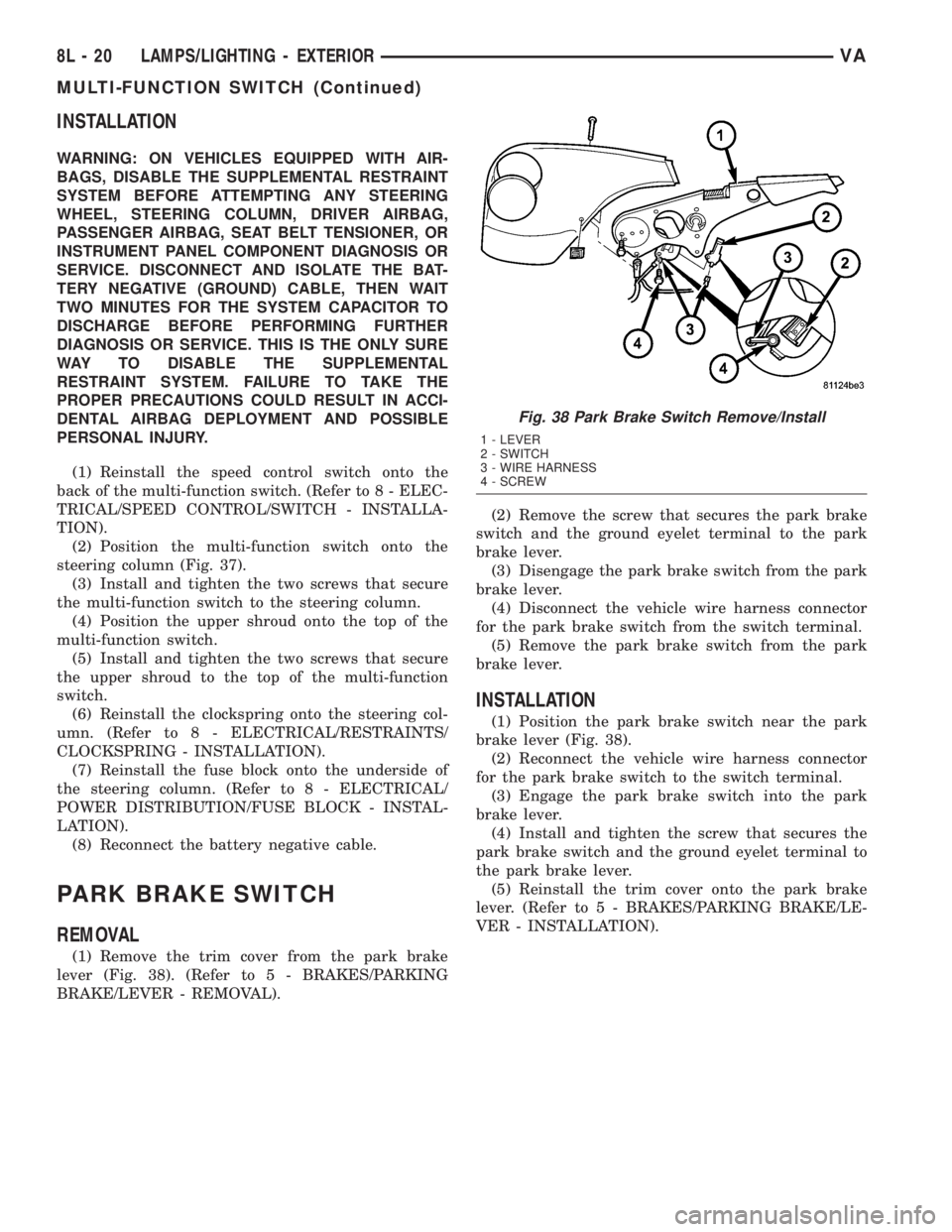

(1) Remove the trim cover from the park brake

lever (Fig. 38). (Refer to 5 - BRAKES/PARKING

BRAKE/LEVER - REMOVAL).(2) Remove the screw that secures the park brake

switch and the ground eyelet terminal to the park

brake lever.

(3) Disengage the park brake switch from the park

brake lever.

(4) Disconnect the vehicle wire harness connector

for the park brake switch from the switch terminal.

(5) Remove the park brake switch from the park

brake lever.

INSTALLATION

(1) Position the park brake switch near the park

brake lever (Fig. 38).

(2) Reconnect the vehicle wire harness connector

for the park brake switch to the switch terminal.

(3) Engage the park brake switch into the park

brake lever.

(4) Install and tighten the screw that secures the

park brake switch and the ground eyelet terminal to

the park brake lever.

(5) Reinstall the trim cover onto the park brake

lever. (Refer to 5 - BRAKES/PARKING BRAKE/LE-

VER - INSTALLATION).

Fig. 38 Park Brake Switch Remove/Install

1 - LEVER

2 - SWITCH

3 - WIRE HARNESS

4 - SCREW

8L - 20 LAMPS/LIGHTING - EXTERIORVA

MULTI-FUNCTION SWITCH (Continued)

Page 222 of 1232

TURN SIGNAL RELAY

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, DRIVER AIRBAG, PASSENGER

AIRBAG, SEAT BELT TENSIONER, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE. DIS-

CONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE SUP-

PLEMENTAL RESTRAINT SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

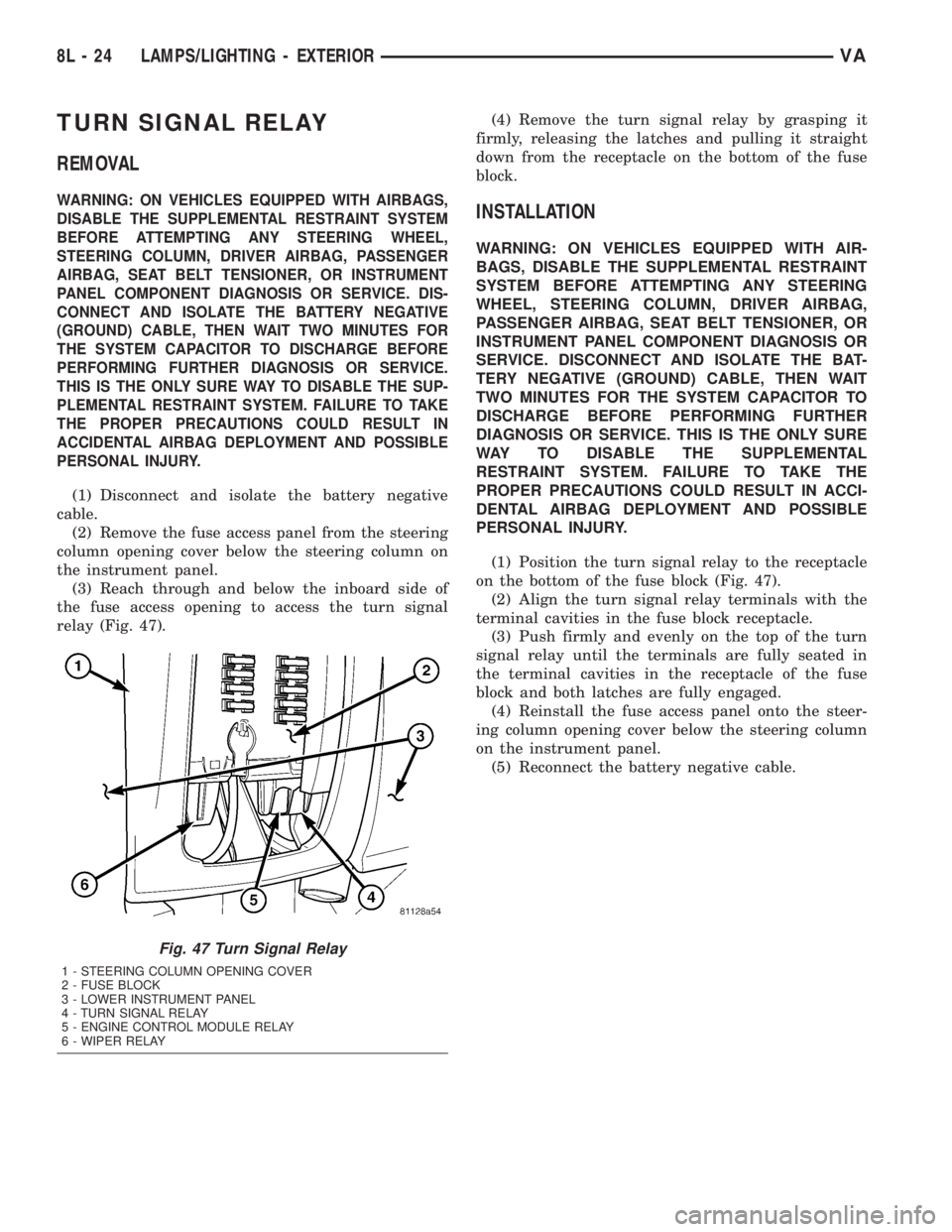

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel from the steering

column opening cover below the steering column on

the instrument panel.

(3) Reach through and below the inboard side of

the fuse access opening to access the turn signal

relay (Fig. 47).(4) Remove the turn signal relay by grasping it

firmly, releasing the latches and pulling it straight

down from the receptacle on the bottom of the fuse

block.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the turn signal relay to the receptacle

on the bottom of the fuse block (Fig. 47).

(2) Align the turn signal relay terminals with the

terminal cavities in the fuse block receptacle.

(3) Push firmly and evenly on the top of the turn

signal relay until the terminals are fully seated in

the terminal cavities in the receptacle of the fuse

block and both latches are fully engaged.

(4) Reinstall the fuse access panel onto the steer-

ing column opening cover below the steering column

on the instrument panel.

(5) Reconnect the battery negative cable.

Fig. 47 Turn Signal Relay

1 - STEERING COLUMN OPENING COVER

2 - FUSE BLOCK

3 - LOWER INSTRUMENT PANEL

4 - TURN SIGNAL RELAY

5 - ENGINE CONTROL MODULE RELAY

6 - WIPER RELAY

8L - 24 LAMPS/LIGHTING - EXTERIORVA

Page 224 of 1232

A door jamb switch for each sliding side door and the

right rear door is standard equipment on wagon mod-

els. The sliding and rear door jamb switches are not

available for van models.

²Entry/Exit Lamp- An entry/exit lamp to illu-

minate each front and sliding side door step well is

optional equipment on wagon models.

²Time Delay Relay- Vehicles equipped with the

optional remote cargo lamp switches also have a time

delay relay located in the electrical center within the

driver side front seat riser.

Hard wired circuitry connects the interior lighting

system components to the electrical system of the

vehicle. These hard wired circuits are integral to sev-

eral wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the interior lighting

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

The interior lighting systems can be divided into

two general classifications based upon the circuit

that controls their operation: The interior lighting

circuit, or the exterior lighting circuit. The hard

wired circuits and components of the interior lighting

systems may be diagnosed and tested using conven-

tional diagnostic tools and procedures.

INTERIOR LIGHTING CIRCUIT

Depending upon the vehicle model (van or wagon)

and the selected vehicle options the interior lighting

circuit may include dome/cargo lamps located over-

head in the front and rear of the vehicle, a dome/

reading lamp located in the header area above the

windshield between the sun visors, and entry/exit

lamps located in the front and sliding side door step

wells.

WAGON MODELS

In all wagon models, the lamps in the interior

lighting circuit are provided with battery current at

all times by a fuse in the fuse block beneath the

steering column. The front, side, and rear door jamb

switches control a ground path for each of these

lamps, except for the optional reading lamp. If the

lamp has an optional integral switch, that switch has

three separate positions. The first position provides aground path independent of the door jamb switches

to turn the lamp On. The second, or center position

allows the door jamb switches to control the lamp.

The third position segregates that lamp from the

door jamb switch input, turning the lamp Off. In the

case of the optional dome/reading lamp, the integral

lamp switch has a fourth position which will illumi-

nate only the reading lamp bulb.

VAN MODELS

Unless a van model is equipped with an optional

remote cargo lamp switch, all of the lamps in the

interior lighting circuit operate the same way as the

wagon models except that there are only two door

jamb switches, one for each front door. If the vehicle

is equipped with an optional remote cargo lamp

switch, the lamps in the rear of the vehicle on the

interior lighting circuit are provided with battery

current by the time delay relay. The time delay relay

is a smart relay containing active electronic elements

that comprise an electronic timer logic circuit. When

the remote cargo lamp switches provide the proper

input to the time delay relay, the relay logic responds

by energizing the relay control coil. The energized

relay control coil provides battery current to all of

the lamps on the rear interior lighting circuit and to

the indicator Light-Emitting Diode (LED) units in

the remote cargo switches causing each to illuminate.

If a remote cargo lamp switch remains On for more

than about fifteen minutes, the time delay relay will

then automatically de-energize the rear interior

lighting circuits until the remote cargo lamp switch

is cycled Off and then back On.

EXTERIOR LIGHTING CIRCUIT

The exterior lighting circuit provides battery cur-

rent to the optional ash receiver/cigar lighter lamp

and to the illumination Light-Emitting Diode (LED)

unit within the remote cargo lamp switch in the

instrument panel accessory switch bezel whenever

the exterior lamps are turned On.

SPECIFICATIONS - INTERIOR LIGHTING

BULB SPECIFICATIONS

LAMP BULB

Cargo/Dome Lamp K - 12V 18W

Dome/Reading Lamp K - 12V 10W

Dome Lamp w/Intrusion

SensorK - 12V 6W

Entry/Exit Lamp W5W - 12V 5W

8L - 26 LAMPS/LIGHTING - INTERIORVA

LAMPS/LIGHTING - INTERIOR (Continued)

Page 235 of 1232

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION..........................3

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH.............................3REMOVAL.............................3

INSTALLATION..........................4

POWER MIRRORS

DESCRIPTION

The power operated outside rear view mirrors

allow the driver to adjust both outside mirrors elec-

trically from the driver side front seat position by

operating a switch on the driver side front door trim

panel. The power mirrors receive a non-switched bat-

tery feed through a fuse so that the system will

remain operational, regardless of the ignition switch

position.

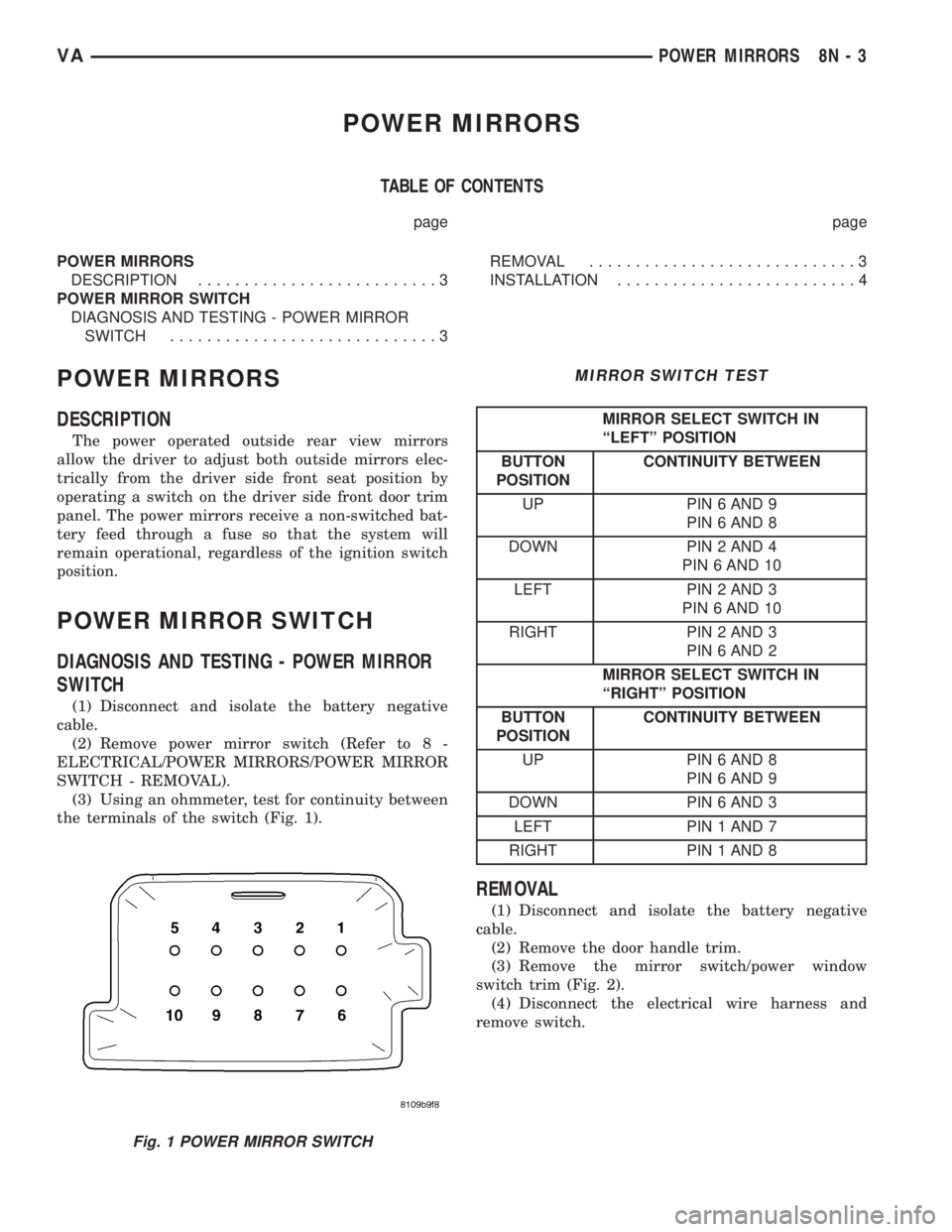

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH

(1) Disconnect and isolate the battery negative

cable.

(2) Remove power mirror switch (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(3) Using an ohmmeter, test for continuity between

the terminals of the switch (Fig. 1).

MIRROR SWITCH TEST

MIRROR SELECT SWITCH IN

ªLEFTº POSITION

BUTTON

POSITIONCONTINUITY BETWEEN

UP PIN 6 AND 9

PIN 6 AND 8

DOWN PIN 2 AND 4

PIN 6 AND 10

LEFT PIN 2 AND 3

PIN 6 AND 10

RIGHT PIN 2 AND 3

PIN 6 AND 2

MIRROR SELECT SWITCH IN

ªRIGHTº POSITION

BUTTON

POSITIONCONTINUITY BETWEEN

UP PIN 6 AND 8

PIN 6 AND 9

DOWN PIN 6 AND 3

LEFT PIN 1 AND 7

RIGHT PIN 1 AND 8

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door handle trim.

(3) Remove the mirror switch/power window

switch trim (Fig. 2).

(4) Disconnect the electrical wire harness and

remove switch.

Fig. 1 POWER MIRROR SWITCH

VAPOWER MIRRORS 8N - 3

Page 247 of 1232

an electronic impact sensor, and an energy storage

capacitor. The ACM housing has three integral

mounting tabs. A stamped metal cover plate is per-

manently secured to the bottom of the ACM housing

to enclose and protect the internal electronic circuitry

and components. An arrow printed on a label on the

top of the ACM housing near the rear provides a

visual verification of the proper orientation of the

unit, and should always be pointed toward the front

of the vehicle. A molded plastic electrical connector

receptacle containing numerous terminal pins is inte-

gral to the left facing side of the ACM housing. These

terminal pins connect the ACM to the vehicle electri-

cal system through a dedicated take out and connec-

tor of the vehicle wire harness.

The impact sensor internal to the ACM is cali-

brated for the specific vehicle, and is only serviced as

a unit with the ACM. The ACM cannot be repaired or

adjusted and, if damaged or faulty, it must be

replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the supplemental restraint system

logic circuits and controls all of the supplemental

restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with the DRBIIItscan tool using a diagnostic Serial

Communication Interface (SCI) data bus line for sup-

plemental restraint system programming or diagno-

sis and testing through the 16-way Data Link

Connector (DLC) located on the dash panel below the

driver side end of the instrument panel. A hard wired

output from the ACM is used for control of the airbag

indicator in the ElectroMechanical Instrument Clus-

ter (EMIC). (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER/AIRBAG INDICATOR -

OPERATION).

The ACM microprocessor continuously monitors all

of the supplemental restraint system electrical cir-

cuits to determine the system readiness. If the ACM

detects a monitored system fault, it sets an appropri-

ate Diagnostic Trouble Code (DTC) and sends an out-

put to the EMIC to turn on the airbag indicator. The

ACM illuminates the indicator for about four seconds

each time the ignition switch is turned to the On

position as a bulb test. If the indicator remains illu-

minated for about ten seconds after the ignition

switch is turned to the On position, the ACM has

detected a non-critical fault that poses no danger to

the vehicle occupants. If the airbag indicator illumi-

nates solid (not flashing) while driving or stays on

longer than ten seconds following the bulb test, the

ACM has detected a critical fault that may cause the

airbags not to deploy when required or to deploy

when not required. An active fault only remains forthe duration of the fault, or in some cases, for the

duration of the current ignition switch cycle, while a

stored fault causes a DTC to be stored in memory by

the ACM.

The ACM receives battery current through a fused

ignition switch output circuit. The ACM receives

ground through a ground circuit and take out of the

vehicle wire harness. This take out has an eyelet ter-

minal connector secured by a nut to a ground stud on

the floor panel directly below the ACM within the

driver side seat riser. A case ground is also provided

for the ACM through a ground circuit and eyelet ter-

minal connector secured under the left rear ACM

mounting screw. These connections allow the ACM to

be operational whenever the ignition switch is in the

On position. The ACM also contains an energy-stor-

age capacitor. When the ignition switch is in the On

position, this capacitor is continually being charged

with enough electrical energy to deploy the supple-

mental restraint components for up to one second fol-

lowing a battery disconnect or failure. The purpose of

the capacitor is to provide backup supplemental

restraint system protection in case there is a loss of

battery current supply to the ACM during an impact.

An electronic impact sensor is contained within the

ACM. The electronic impact sensor is an accelerome-

ter that senses the rate of vehicle deceleration, which

provides verification of the direction and severity of

an impact. A pre-programmed decision algorithm in

the ACM microprocessor determines when the decel-

eration rate as signaled by the impact sensor indi-

cates an impact that is severe enough to require

supplemental restraint system protection. When the

programmed conditions are met, the ACM sends the

proper electrical signals to deploy the seat belt ten-

sioners and front airbags.

The ACM also provides a hard wired electrical

crash signal output following a supplemental

restraint deployment event. This output is used to

signal other electronic modules in the vehicle to pro-

vide their enhanced accident response features,

which include automatically disabling the engine

from running and unlocking all of the doors. How-

ever, these responses are each dependent upon the

circuits, components, and modules controlling these

features remaining intact from collateral damage

incurred during the vehicle impact.

A single ACM is used for all variations of the sup-

plemental restraint system available in this vehicle.

This ACM is programmable and in order to function

properly it must be programmed for the correct vehi-

cle supplemental restraint system equipment using

an initialization procedure. The initialization proce-

dure requires the use of a DRBIIItscan tool. Refer to

the appropriate diagnostic information. The hard

wired inputs and outputs for the ACM may be diag-

VARESTRAINTS 8O - 9

AIRBAG CONTROL MODULE (Continued)

Page 253 of 1232

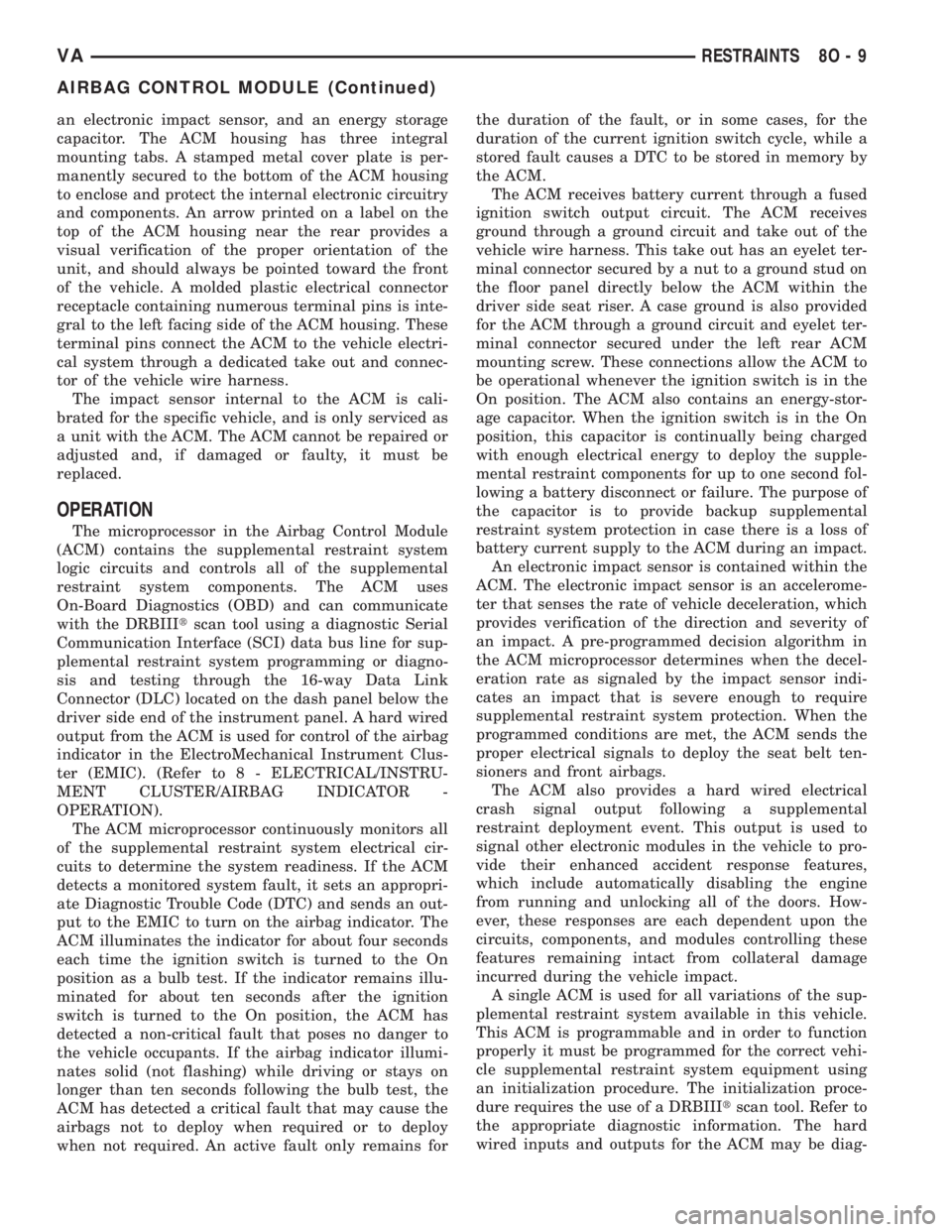

(3) Disconnect the clockspring upper pigtail wire

connectors from the terminals of the horn switch

located in the hub cavity of the steering wheel.

(4) Remove the steering wheel from the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - REMOVAL).

(5) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(6) Disconnect the two clockspring lower pigtail

connectors from the vehicle wire harness connectors

located between the steering column and the back of

the fuse block underneath the steering column (Fig.

16).

(7) Loosen the two screws that secure the clock-

spring to the multi-function switch housing far

enough to engage the clearance holes in the clock-

spring rotor and to disengage the clockspring case

from the switch housing.

(8) Remove the clockspring from the multi-function

switch housing. The clockspring cannot be repaired.

It must be replaced if faulty or damaged, or if the

driver airbag has been deployed.

(9) If the removed clockspring is to be reused, be

certain that the clockspring rotor is secured to the

clockspring case to maintain clockspring centering

until it is reinstalled on the steering column. If clock-

spring centering is not maintained, the clockspring

must be centered again before it is reinstalled. (Refer

to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING).INSTALLATION

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

If the clockspring is not properly centered in rela-

tion to the steering wheel, steering shaft and steer-

ing gear, it may be damaged. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING). Service replacement clocksprings are

shipped pre-centered and with the mounting screws

backed out from the case far enough to engage the

access holes in the upper surface of the rotor. The

clockspring mounting screws should not be tightened

into the clockspring case until the clockspring has

been installed on the steering column. If the screws

are tightened into or removed from the case before

the clockspring is installed on a steering column, the

clockspring centering procedure must be performed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: Before starting this procedure, be certain

that the front wheels are still in the straight-ahead

position.

(1) Carefully slide the centered clockspring down

over the steering column upper shaft until the screws

in the clockspring case are aligned with the mount-

ing holes on the multi-function switch housing.

(2) Tighten the two screws that secure the clock-

spring to the multi-function switch mounting hous-

ing. Tighten the screws to 2 N´m (18 in. lbs.).

(3) Reconnect the two clockspring lower pigtail

connectors to the vehicle wire harness connectors

located between the steering column and the back of

the fuse block underneath the steering column (Fig.

16).

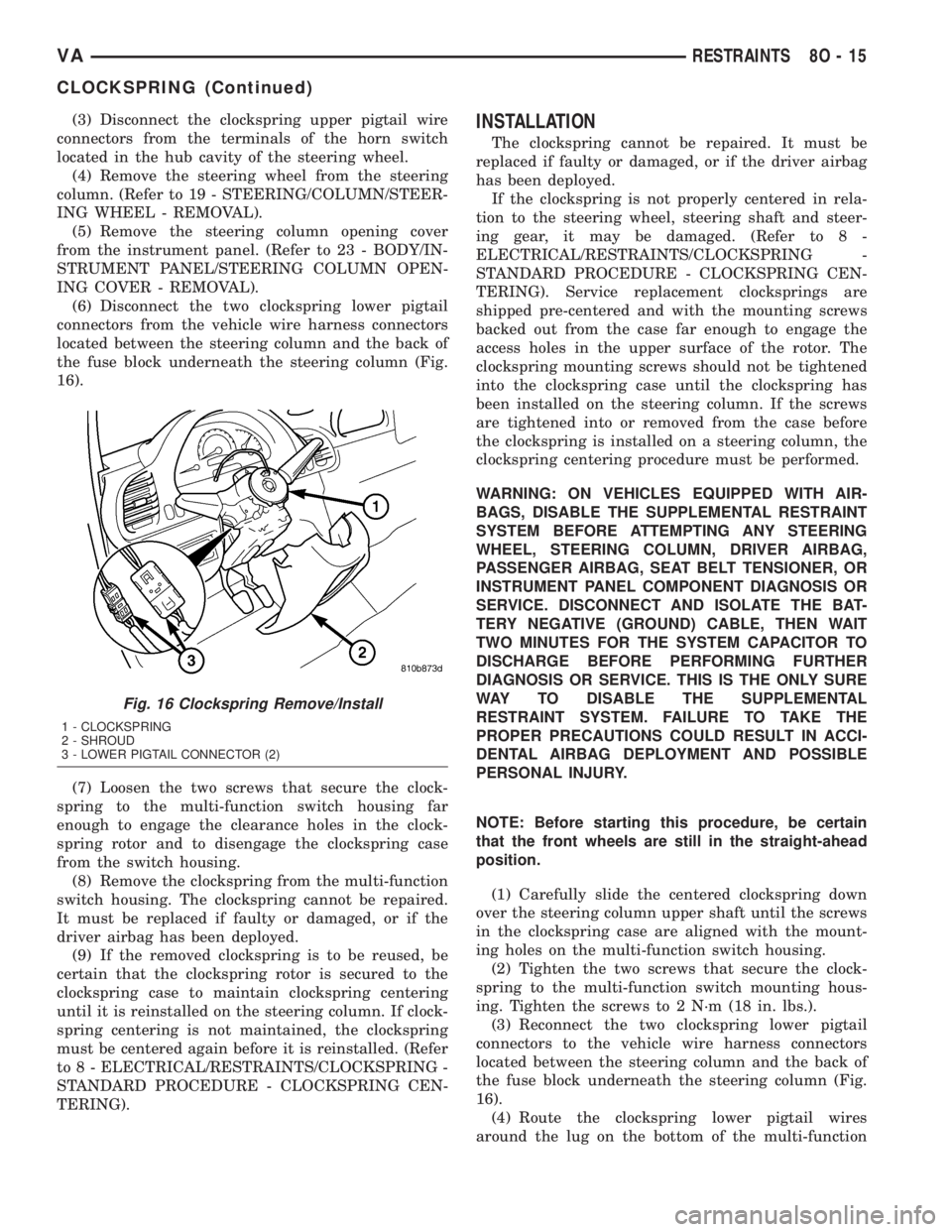

(4) Route the clockspring lower pigtail wires

around the lug on the bottom of the multi-function

Fig. 16 Clockspring Remove/Install

1 - CLOCKSPRING

2 - SHROUD

3 - LOWER PIGTAIL CONNECTOR (2)

VARESTRAINTS 8O - 15

CLOCKSPRING (Continued)

Page 254 of 1232

switch housing and behind the fuse block underneath

the steering column (Fig. 17).

(5) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(6) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

(7) Reconnect the clockspring upper pigtail wire

connectors to the terminals of the horn switch

located in the hub cavity of the steering wheel.

(8) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

DRIVER AIRBAG

DESCRIPTION

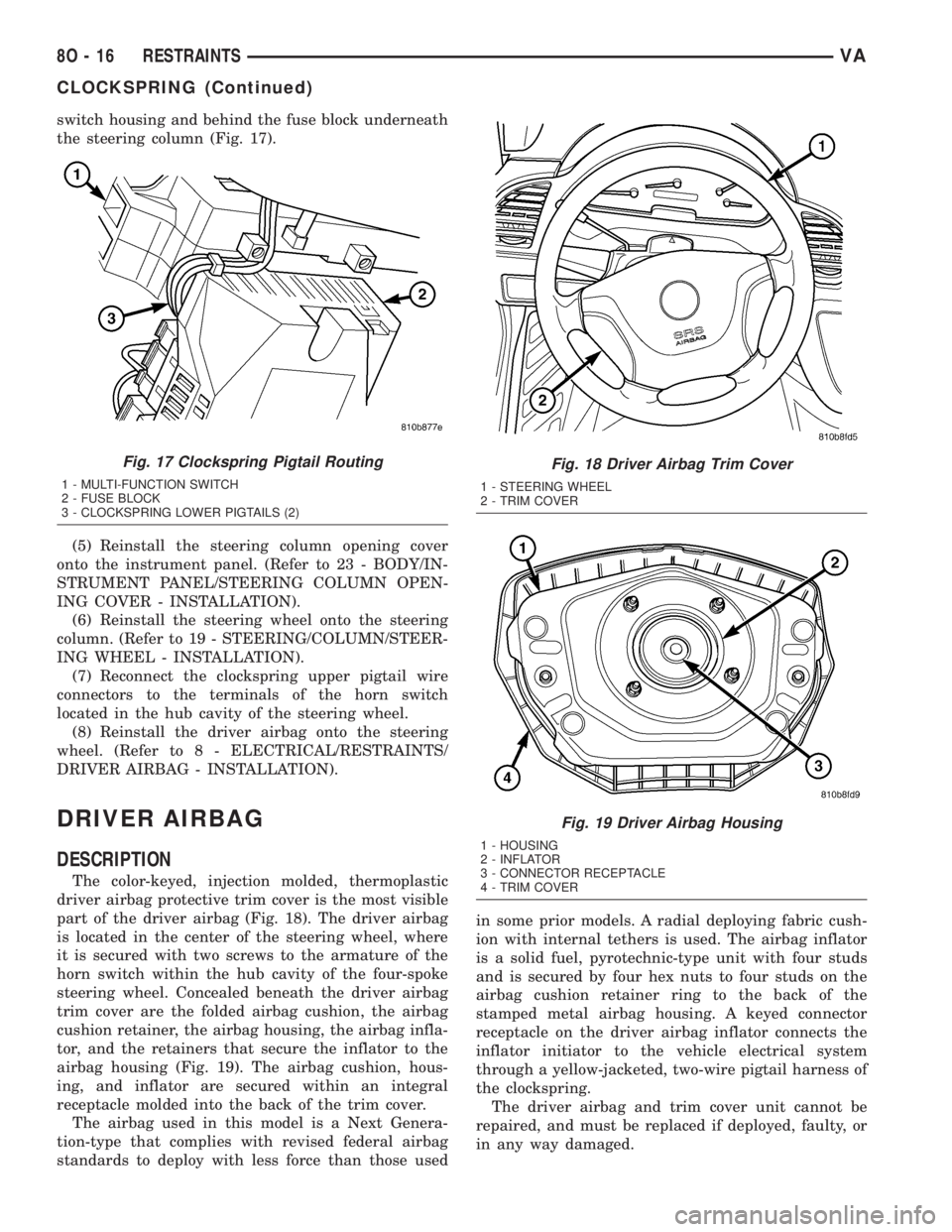

The color-keyed, injection molded, thermoplastic

driver airbag protective trim cover is the most visible

part of the driver airbag (Fig. 18). The driver airbag

is located in the center of the steering wheel, where

it is secured with two screws to the armature of the

horn switch within the hub cavity of the four-spoke

steering wheel. Concealed beneath the driver airbag

trim cover are the folded airbag cushion, the airbag

cushion retainer, the airbag housing, the airbag infla-

tor, and the retainers that secure the inflator to the

airbag housing (Fig. 19). The airbag cushion, hous-

ing, and inflator are secured within an integral

receptacle molded into the back of the trim cover.

The airbag used in this model is a Next Genera-

tion-type that complies with revised federal airbag

standards to deploy with less force than those usedin some prior models. A radial deploying fabric cush-

ion with internal tethers is used. The airbag inflator

is a solid fuel, pyrotechnic-type unit with four studs

and is secured by four hex nuts to four studs on the

airbag cushion retainer ring to the back of the

stamped metal airbag housing. A keyed connector

receptacle on the driver airbag inflator connects the

inflator initiator to the vehicle electrical system

through a yellow-jacketed, two-wire pigtail harness of

the clockspring.

The driver airbag and trim cover unit cannot be

repaired, and must be replaced if deployed, faulty, or

in any way damaged.

Fig. 17 Clockspring Pigtail Routing

1 - MULTI-FUNCTION SWITCH

2 - FUSE BLOCK

3 - CLOCKSPRING LOWER PIGTAILS (2)

Fig. 18 Driver Airbag Trim Cover

1 - STEERING WHEEL

2 - TRIM COVER

Fig. 19 Driver Airbag Housing

1 - HOUSING

2 - INFLATOR

3 - CONNECTOR RECEPTACLE

4 - TRIM COVER

8O - 16 RESTRAINTSVA

CLOCKSPRING (Continued)

Page 255 of 1232

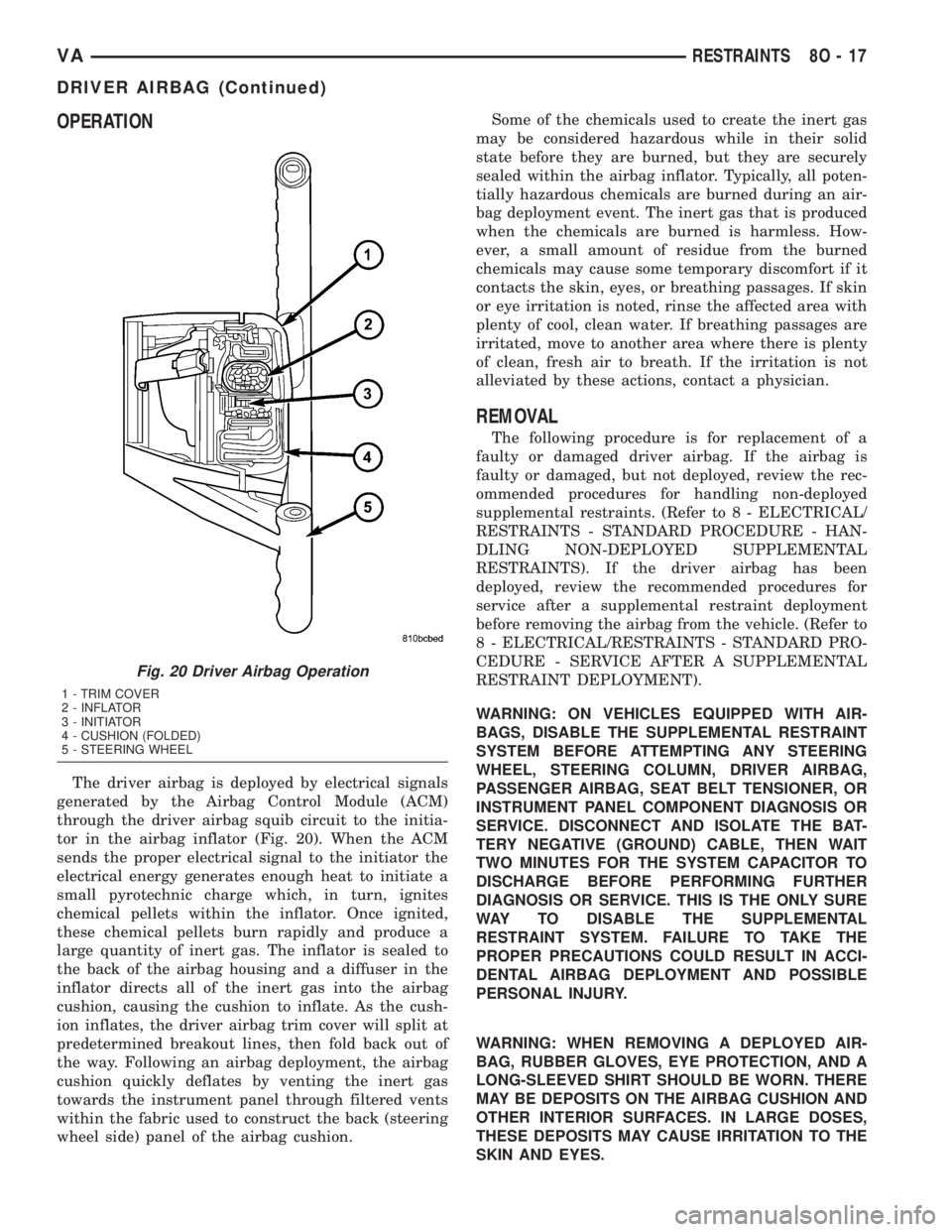

OPERATION

The driver airbag is deployed by electrical signals

generated by the Airbag Control Module (ACM)

through the driver airbag squib circuit to the initia-

tor in the airbag inflator (Fig. 20). When the ACM

sends the proper electrical signal to the initiator the

electrical energy generates enough heat to initiate a

small pyrotechnic charge which, in turn, ignites

chemical pellets within the inflator. Once ignited,

these chemical pellets burn rapidly and produce a

large quantity of inert gas. The inflator is sealed to

the back of the airbag housing and a diffuser in the

inflator directs all of the inert gas into the airbag

cushion, causing the cushion to inflate. As the cush-

ion inflates, the driver airbag trim cover will split at

predetermined breakout lines, then fold back out of

the way. Following an airbag deployment, the airbag

cushion quickly deflates by venting the inert gas

towards the instrument panel through filtered vents

within the fabric used to construct the back (steering

wheel side) panel of the airbag cushion.Some of the chemicals used to create the inert gas

may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. Typically, all poten-

tially hazardous chemicals are burned during an air-

bag deployment event. The inert gas that is produced

when the chemicals are burned is harmless. How-

ever, a small amount of residue from the burned

chemicals may cause some temporary discomfort if it

contacts the skin, eyes, or breathing passages. If skin

or eye irritation is noted, rinse the affected area with

plenty of cool, clean water. If breathing passages are

irritated, move to another area where there is plenty

of clean, fresh air to breath. If the irritation is not

alleviated by these actions, contact a physician.

REMOVAL

The following procedure is for replacement of a

faulty or damaged driver airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the driver airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: WHEN REMOVING A DEPLOYED AIR-

BAG, RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG CUSHION AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

Fig. 20 Driver Airbag Operation

1 - TRIM COVER

2 - INFLATOR

3 - INITIATOR

4 - CUSHION (FOLDED)

5 - STEERING WHEEL

VARESTRAINTS 8O - 17

DRIVER AIRBAG (Continued)

Page 262 of 1232

The passenger airbag unit used in this model is a

Next Generation-type that complies with revised fed-

eral airbag standards to deploy with less force than

those used in some prior models. The airbag housing

contains the folded airbag cushion, the airbag

retainer, and the airbag inflator. The airbag is a rect-

angular fabric cushion. The airbag inflator is a solid

fuel, pyrotechnic-type unit that is secured to and

sealed within the airbag housing along with the

folded airbag cushion. The inflator initiator connector

receptacle is connected to the vehicle electrical sys-

tem through a dedicated take out of the vehicle wire

harness with a yellow connector insulator.

The passenger airbag and airbag door unit cannot

be repaired, and must be replaced if deployed, faulty

or in any way damaged.

OPERATION

The passenger airbag is deployed by an electrical

signal generated by the Airbag Control Module

(ACM) through the passenger airbag squib circuits to

the initiator in the airbag inflator. When the ACM

sends the proper electrical signal to the initiator the

electrical energy generates enough heat to initiate a

small pyrotechnic charge which, in turn, ignites

chemical pellets within the inflator. Once ignited,

these chemical pellets burn rapidly and produce a

large quantity of inert gas. The inflator is sealed to

the back of the airbag housing and a diffuser in the

inflator directs all of the inert gas into the airbag

cushion, causing the cushion to inflate.

As the airbag cushion inflates, the passenger air-

bag door will unsnap from the clips that retain it to

the instrument panel at the top and bottom, then

pivot towards the top of the instrument panel and

out of the way on the woven straps. Following a pas-

senger airbag deployment, the airbag cushion quickly

deflates by venting the inert gas through the loose

weave of the fabric used to construct the back

(instrument panel side) of the airbag cushion.

Some of the chemicals used to create the inert gas

may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. However, the gas

that is produced when the chemicals are burned is

harmless. A small amount of residue from the burned

chemicals may cause some temporary discomfort if it

contacts the skin, eyes, or breathing passages. If skin

or eye irritation is noticed, rinse the affected area

with plenty of cool, clean water. If breathing pas-

sages are irritated, move to another area where there

is plenty of clean, fresh air to breath. If the irritation

is not alleviated by these actions, contact a physician

immediately.

REMOVAL

The following procedure is for replacement of a

faulty or damaged passenger airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the passenger airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: WHEN REMOVING A DEPLOYED AIR-

BAG, RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG UNIT AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the instrument panel top cover tray

from over the passenger airbag (Fig. 29). (Refer to 23

- BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - TRAY - REMOVAL).

(3) Remove the two screws that secure the passen-

ger airbag door upper clips to the instrument panel

base trim.

8O - 24 RESTRAINTSVA

PASSENGER AIRBAG (Continued)

Page 285 of 1232

The longer blade is installed on the left (driver) side

of the windshield.

²Wiper Linkage- The wiper pivots are the only

visible components of the wiper linkage. The remain-

der of the linkage is concealed within the engine

compartment just behind the hood opening. The

wiper linkage module includes the two wiper drive

links, the wiper motor crank arm, the two wiper piv-

ots, and the linkage and motor mounting bracket.

²Wiper Motor- The wiper motor is secured to

the wiper linkage module bracket on the underside of

the cowl panel within the engine compartment. The

wiper motor output shaft and crank arm extend

through a clearance hole in the mounting bracket,

where they are connected to a crank arm that drives

the wiper linkage.

²Wiper Relay- The wiper relay is located in a

dedicated receptacle on the lower left surface of the

fuse block underneath the steering column behind

the fuse access panel and the steering column open-

ing panel.

²Wiper, Turn Signals, Engine Start Control

Module- The wiper, turn signals and engine start

control module is integral to the fuse block located

underneath the steering column. The fuse block is

concealed behind the fuse access panel and the steer-

ing column opening panel, where it is secured with

screws to the steering column. The wiper, turn sig-

nals and engine start control module contains the

intermittent wipe logic circuitry, which includes

active electronic elements that allow it to provide the

intermittent wipe delay and the wipe-after-wash fea-

tures of the intermittent wipe system based upon

numerous hard wired inputs, then provides the

proper programmed hard wired control output to

operate the wiper motor through the wiper relay.

Hard wired circuitry connects the wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the wiper and washer

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.OPERATING MODES

The components of the wiper and washer system

are designed to provide the following operating

modes:

²Continuous Wipe Mode- The two-speed wiper

motor, the internal circuitry of the multi-function

switch, and the wiper relay work in concert to pro-

vide two continuous wipe cycles, low speed or high

speed.

²Intermittent Wipe Mode- The internal cir-

cuitry of the multi-function switch, the intermittent

wipe circuitry of the wiper, turn signals and engine

start control module in the fuse block, and the wiper

relay work in concert to provide an intermittent wipe

mode with a single, fixed delay interval.

²Pulse Wipe Mode- The internal circuitry of

the multi-function switch and the wiper relay work

in concert to provide a pulse wipe mode that will

allow the wiper motor to be operated for a single,

complete wipe cycle.

²Washer Mode- When the washer system is

activated with the multi-function switch while the

wiper system is operating, washer fluid will be dis-

pensed onto the windshield glass through the washer

nozzles for as long as the washer pump/motor is

energized.

²Wipe-After-Wash Mode- The intermittent

wipe circuitry of the wiper, turn signals and engine

start control module in the fuse block, and the wiper

relay provide a wipe-after-wash feature. If the wipers

are turned Off, this feature will operate the washer

pump/motor and the wipers for as long as the washer

system is activated, then provide several additional

wipe cycles after the washer system is deactivated

before parking the wiper blades near the base of the

windshield.

OPERATION

The wiper and washer system is designed to pro-

vide the vehicle operator with a convenient, safe, and

reliable means of maintaining visibility through the

windshield glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blades to wipe the

outside surface of the glass, as well as into the

hydraulic action of the washer system to apply

washer fluid stored in an on-board reservoir to the

area of the glass to be wiped. When combined, these

components provide the means to effectively main-

tain clear visibility for the vehicle operator by remov-

ing excess accumulations of rain, snow, bugs, mud, or

other minor debris from the outside windshield glass

surface that might be encountered while driving the

vehicle under numerous types of inclement operating

conditions.

VAWIPERS/WASHERS 8R - 3

WIPERS/WASHERS (Continued)