fuse MERCEDES-BENZ SPRINTER 2005 Service Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 286 of 1232

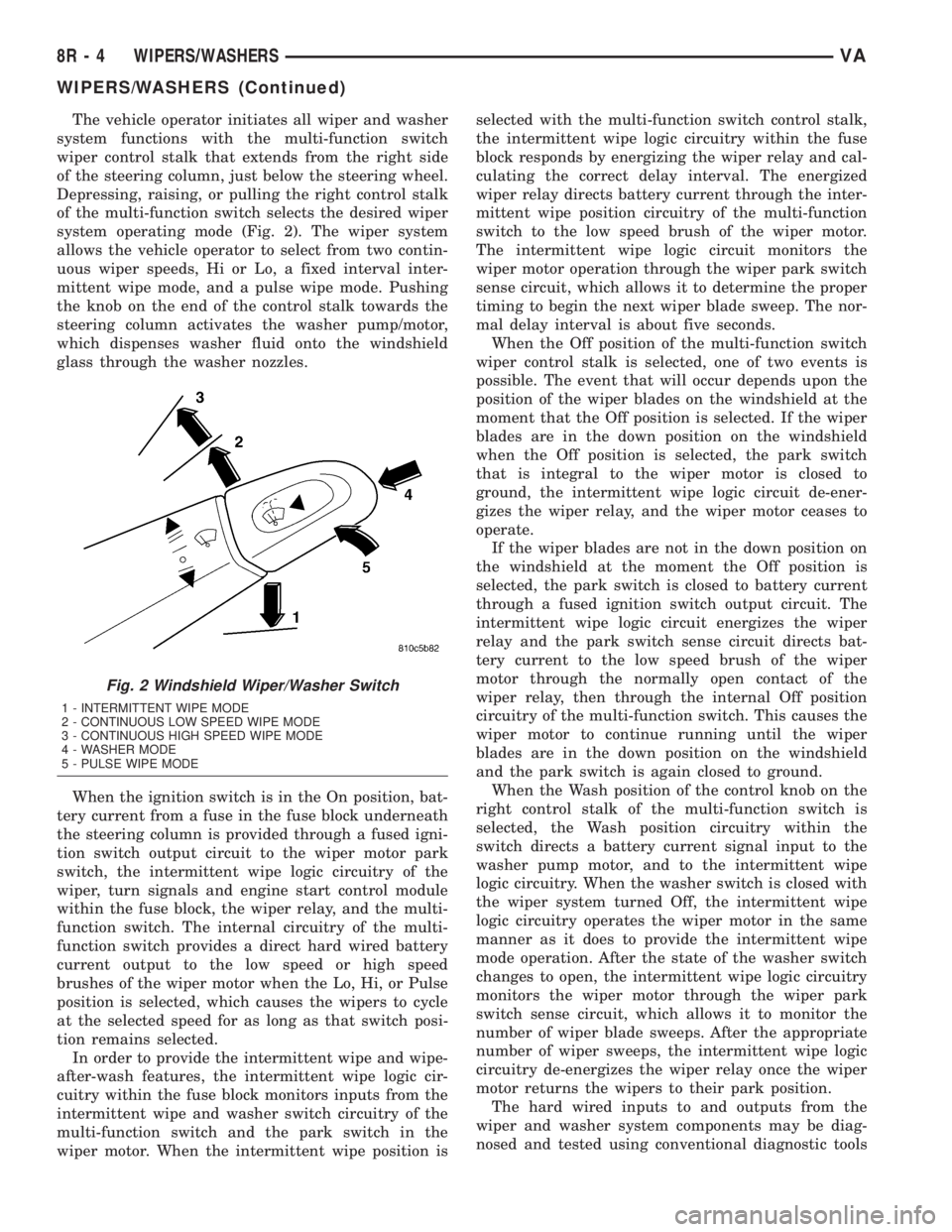

The vehicle operator initiates all wiper and washer

system functions with the multi-function switch

wiper control stalk that extends from the right side

of the steering column, just below the steering wheel.

Depressing, raising, or pulling the right control stalk

of the multi-function switch selects the desired wiper

system operating mode (Fig. 2). The wiper system

allows the vehicle operator to select from two contin-

uous wiper speeds, Hi or Lo, a fixed interval inter-

mittent wipe mode, and a pulse wipe mode. Pushing

the knob on the end of the control stalk towards the

steering column activates the washer pump/motor,

which dispenses washer fluid onto the windshield

glass through the washer nozzles.

When the ignition switch is in the On position, bat-

tery current from a fuse in the fuse block underneath

the steering column is provided through a fused igni-

tion switch output circuit to the wiper motor park

switch, the intermittent wipe logic circuitry of the

wiper, turn signals and engine start control module

within the fuse block, the wiper relay, and the multi-

function switch. The internal circuitry of the multi-

function switch provides a direct hard wired battery

current output to the low speed or high speed

brushes of the wiper motor when the Lo, Hi, or Pulse

position is selected, which causes the wipers to cycle

at the selected speed for as long as that switch posi-

tion remains selected.

In order to provide the intermittent wipe and wipe-

after-wash features, the intermittent wipe logic cir-

cuitry within the fuse block monitors inputs from the

intermittent wipe and washer switch circuitry of the

multi-function switch and the park switch in the

wiper motor. When the intermittent wipe position isselected with the multi-function switch control stalk,

the intermittent wipe logic circuitry within the fuse

block responds by energizing the wiper relay and cal-

culating the correct delay interval. The energized

wiper relay directs battery current through the inter-

mittent wipe position circuitry of the multi-function

switch to the low speed brush of the wiper motor.

The intermittent wipe logic circuit monitors the

wiper motor operation through the wiper park switch

sense circuit, which allows it to determine the proper

timing to begin the next wiper blade sweep. The nor-

mal delay interval is about five seconds.

When the Off position of the multi-function switch

wiper control stalk is selected, one of two events is

possible. The event that will occur depends upon the

position of the wiper blades on the windshield at the

moment that the Off position is selected. If the wiper

blades are in the down position on the windshield

when the Off position is selected, the park switch

that is integral to the wiper motor is closed to

ground, the intermittent wipe logic circuit de-ener-

gizes the wiper relay, and the wiper motor ceases to

operate.

If the wiper blades are not in the down position on

the windshield at the moment the Off position is

selected, the park switch is closed to battery current

through a fused ignition switch output circuit. The

intermittent wipe logic circuit energizes the wiper

relay and the park switch sense circuit directs bat-

tery current to the low speed brush of the wiper

motor through the normally open contact of the

wiper relay, then through the internal Off position

circuitry of the multi-function switch. This causes the

wiper motor to continue running until the wiper

blades are in the down position on the windshield

and the park switch is again closed to ground.

When the Wash position of the control knob on the

right control stalk of the multi-function switch is

selected, the Wash position circuitry within the

switch directs a battery current signal input to the

washer pump motor, and to the intermittent wipe

logic circuitry. When the washer switch is closed with

the wiper system turned Off, the intermittent wipe

logic circuitry operates the wiper motor in the same

manner as it does to provide the intermittent wipe

mode operation. After the state of the washer switch

changes to open, the intermittent wipe logic circuitry

monitors the wiper motor through the wiper park

switch sense circuit, which allows it to monitor the

number of wiper blade sweeps. After the appropriate

number of wiper sweeps, the intermittent wipe logic

circuitry de-energizes the wiper relay once the wiper

motor returns the wipers to their park position.

The hard wired inputs to and outputs from the

wiper and washer system components may be diag-

nosed and tested using conventional diagnostic tools

Fig. 2 Windshield Wiper/Washer Switch

1 - INTERMITTENT WIPE MODE

2 - CONTINUOUS LOW SPEED WIPE MODE

3 - CONTINUOUS HIGH SPEED WIPE MODE

4 - WASHER MODE

5 - PULSE WIPE MODE

8R - 4 WIPERS/WASHERSVA

WIPERS/WASHERS (Continued)

Page 287 of 1232

and methods. Proper testing of the intermittent wipe

logic circuitry within the fuse block requires the use

of a DRBIIItscan tool. Refer to the appropriate diag-

nostic information. Refer to the owner's manual in

the vehicle glove box for more information on the fea-

tures and operation of the wiper and washer system.

DIAGNOSIS AND TESTING - WIPER &

WASHER SYSTEM

If the wiper motor operates, but the wipers do not

move on the windshield, replace the faulty wiper

linkage module. If the washer pump/motor operates,

but no washer fluid is dispensed on the glass; or, if

the wipers operate, but chatter, lift, or do not clear

the glass, clean and inspect the wiper and washer

system components as required. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS - CLEANING) and

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS -

INSPECTION). For diagnosis and testing of the

multi-function switch (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/MULTI-FUNC-

TION SWITCH - DIAGNOSIS AND TESTING).

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

The hard wired circuits and components of the

wiper and washer system may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the

intermittent wipe logic circuitry contained within the

fuse block underneath the steering column. The most

reliable, efficient, and accurate means to diagnose

the intermittent wipe logic circuitry requires the use

of a DRBIIItscan tool. Refer to the appropriate diag-

nostic information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CLEANING - WIPER & WASHER SYSTEM

WIPER SYSTEM

The squeegees of wiper blades exposed to the ele-

ments for a long time tend to lose their wiping effec-

tiveness. Periodic cleaning of the squeegees is

suggested to remove any deposits of salt or road film.

The wiper blades, arms, and windshield glass should

only be cleaned using a sponge or soft cloth and

windshield washer fluid, a mild detergent, or a non-

abrasive cleaner. If the wiper blades continue to

leave streaks, smears, hazing, or beading on the

glass after thorough cleaning of the squeegees and

the glass, the entire wiper blade assembly must be

replaced.

CAUTION: Protect the rubber squeegees of the

wiper blades from any petroleum-based cleaners,

solvents, or contaminants. These products can rap-

idly deteriorate the rubber squeegees.

WASHER SYSTEM

If the washer system is contaminated with foreign

material, drain the washer reservoir by removing the

washer pump/motor from the reservoir. Clean foreign

material from the inside of the washer pump/motor

inlet nipple and the washer reservoir using clean

washer fluid, a mild detergent, or a non-abrasive

cleaner. Flush foreign material from the washer sys-

tem plumbing by first disconnecting the washer

hoses from the washer nozzles, then running the

washer pump/motor to run clean washer fluid or

water through the system. Plugged or restricted

washer nozzles should be carefully back-flushed

using compressed air. If the washer nozzle obstruc-

tion cannot be cleared, replace the washer nozzle.

CAUTION: Never introduce petroleum-based clean-

ers, solvents, or contaminants into the washer sys-

tem. These products can rapidly deteriorate the

rubber seals and hoses of the washer system, as

well as the rubber squeegees of the wiper blades.

CAUTION: Never use compressed air to flush the

washer system plumbing. Compressed air pres-

sures are too great for the washer system plumbing

components and will result in further system dam-

age. Never use sharp instruments to clear a

plugged washer nozzle or damage to the nozzle ori-

fice and improper nozzle spray patterns will result.

VAWIPERS/WASHERS 8R - 5

WIPERS/WASHERS (Continued)

Page 301 of 1232

WASHERS/FRONT WIPER MOTOR -

INSTALLATION).

(2) Carefully position the wiper linkage module

and wiper motor to the underside of the cowl top

panel as a unit (Fig. 22).

(3) Install and tighten the two screws that secure

the wiper linkage module motor bracket to the flange

on the underside of the cowl top panel. Tighten the

screws to 6 N´m (50 in. lbs.).

(4) Install and tighten the nut and washer that

secures each wiper pivot housing to the outside of the

cowl top panel.

(5) Reconnect the wiper motor pigtail wire connec-

tor to the vehicle wire harness connector.

(6) Reinstall the ventilation housing onto the dash

panel and the underside of the cowl top panel (Fig.

21).

(7) Reinstall the wiper arms onto the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - INSTALLATION).

(8) Reconnect the battery negative cable.

WIPER MOTOR

DESCRIPTION

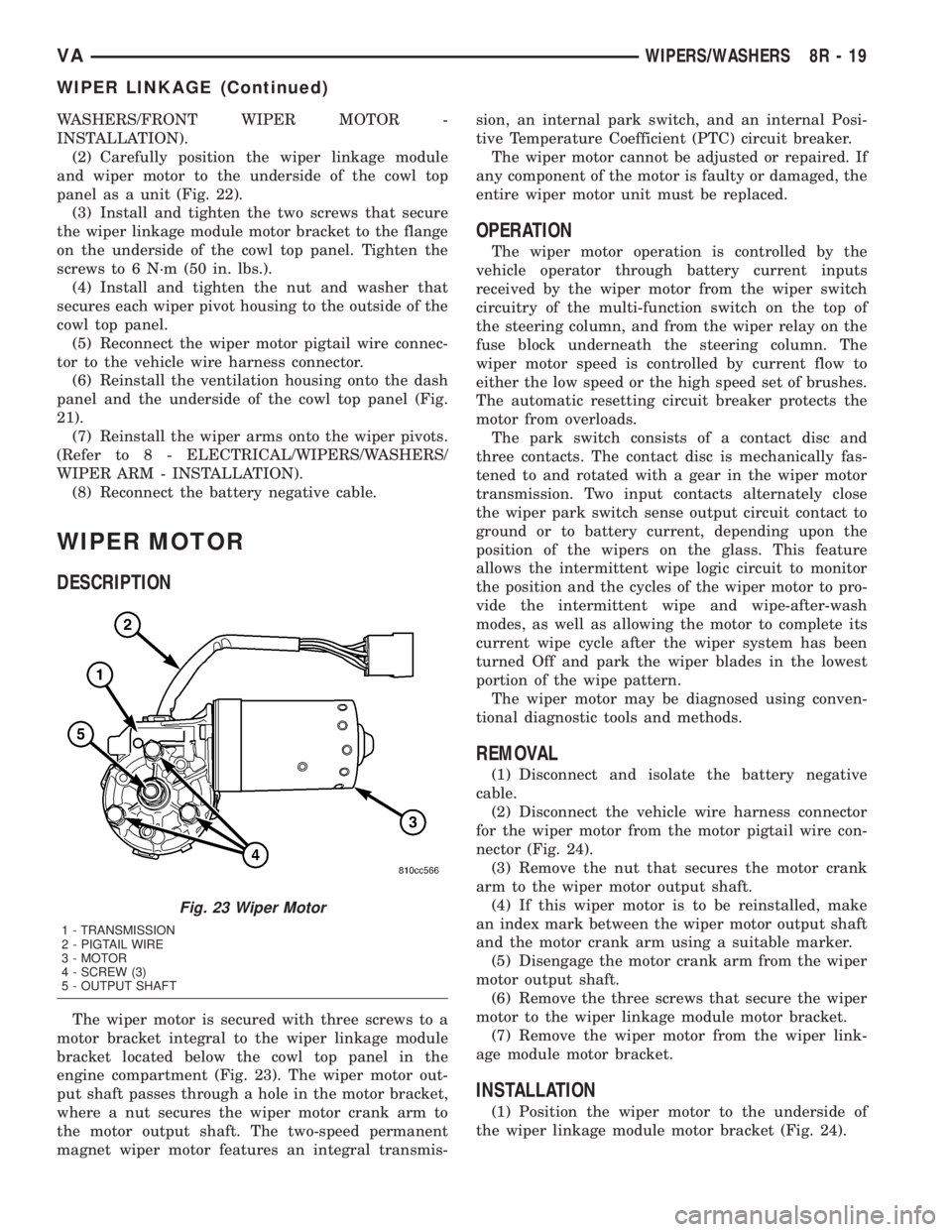

The wiper motor is secured with three screws to a

motor bracket integral to the wiper linkage module

bracket located below the cowl top panel in the

engine compartment (Fig. 23). The wiper motor out-

put shaft passes through a hole in the motor bracket,

where a nut secures the wiper motor crank arm to

the motor output shaft. The two-speed permanent

magnet wiper motor features an integral transmis-sion, an internal park switch, and an internal Posi-

tive Temperature Coefficient (PTC) circuit breaker.

The wiper motor cannot be adjusted or repaired. If

any component of the motor is faulty or damaged, the

entire wiper motor unit must be replaced.

OPERATION

The wiper motor operation is controlled by the

vehicle operator through battery current inputs

received by the wiper motor from the wiper switch

circuitry of the multi-function switch on the top of

the steering column, and from the wiper relay on the

fuse block underneath the steering column. The

wiper motor speed is controlled by current flow to

either the low speed or the high speed set of brushes.

The automatic resetting circuit breaker protects the

motor from overloads.

The park switch consists of a contact disc and

three contacts. The contact disc is mechanically fas-

tened to and rotated with a gear in the wiper motor

transmission. Two input contacts alternately close

the wiper park switch sense output circuit contact to

ground or to battery current, depending upon the

position of the wipers on the glass. This feature

allows the intermittent wipe logic circuit to monitor

the position and the cycles of the wiper motor to pro-

vide the intermittent wipe and wipe-after-wash

modes, as well as allowing the motor to complete its

current wipe cycle after the wiper system has been

turned Off and park the wiper blades in the lowest

portion of the wipe pattern.

The wiper motor may be diagnosed using conven-

tional diagnostic tools and methods.

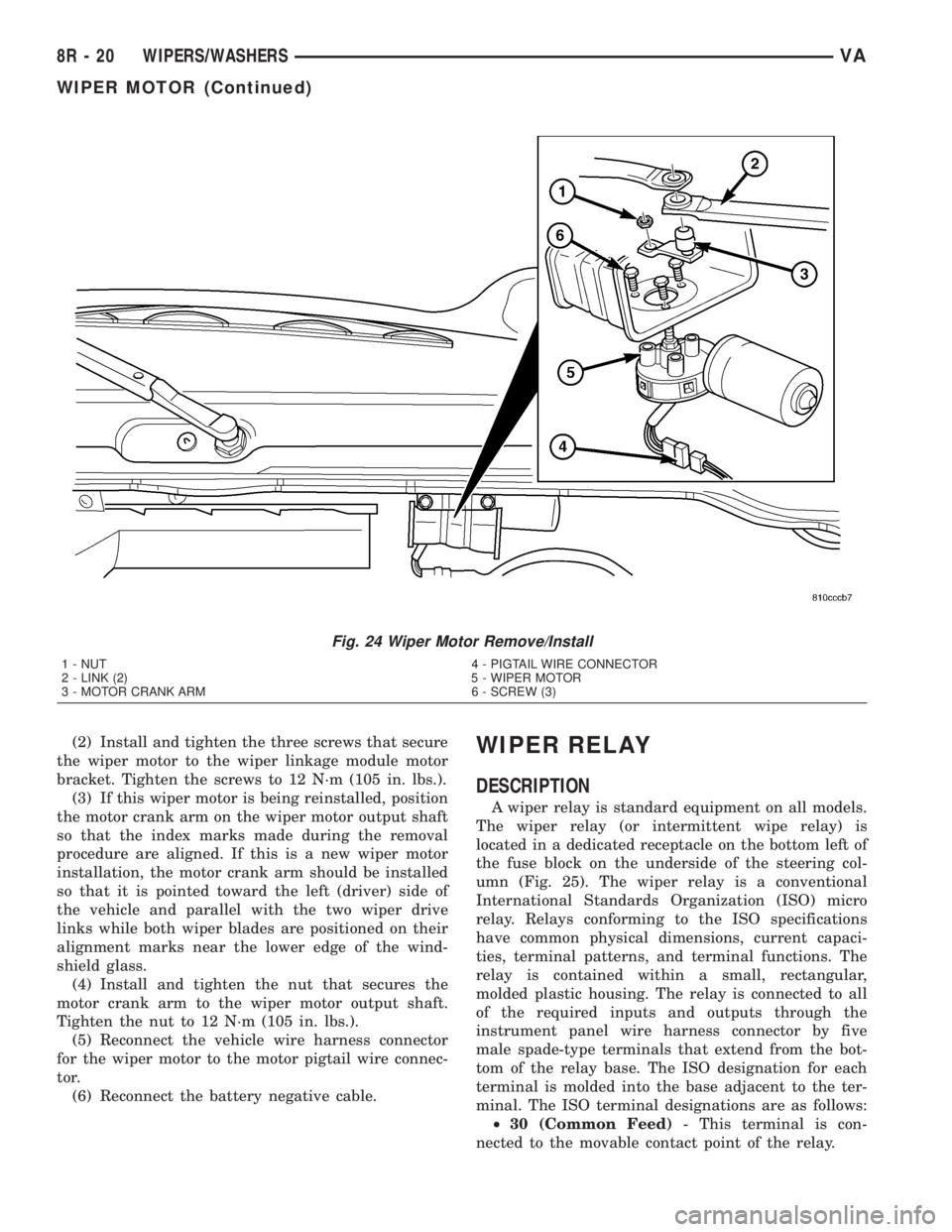

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the vehicle wire harness connector

for the wiper motor from the motor pigtail wire con-

nector (Fig. 24).

(3) Remove the nut that secures the motor crank

arm to the wiper motor output shaft.

(4) If this wiper motor is to be reinstalled, make

an index mark between the wiper motor output shaft

and the motor crank arm using a suitable marker.

(5) Disengage the motor crank arm from the wiper

motor output shaft.

(6) Remove the three screws that secure the wiper

motor to the wiper linkage module motor bracket.

(7) Remove the wiper motor from the wiper link-

age module motor bracket.

INSTALLATION

(1) Position the wiper motor to the underside of

the wiper linkage module motor bracket (Fig. 24).

Fig. 23 Wiper Motor

1 - TRANSMISSION

2 - PIGTAIL WIRE

3 - MOTOR

4 - SCREW (3)

5 - OUTPUT SHAFT

VAWIPERS/WASHERS 8R - 19

WIPER LINKAGE (Continued)

Page 302 of 1232

(2) Install and tighten the three screws that secure

the wiper motor to the wiper linkage module motor

bracket. Tighten the screws to 12 N´m (105 in. lbs.).

(3) If this wiper motor is being reinstalled, position

the motor crank arm on the wiper motor output shaft

so that the index marks made during the removal

procedure are aligned. If this is a new wiper motor

installation, the motor crank arm should be installed

so that it is pointed toward the left (driver) side of

the vehicle and parallel with the two wiper drive

links while both wiper blades are positioned on their

alignment marks near the lower edge of the wind-

shield glass.

(4) Install and tighten the nut that secures the

motor crank arm to the wiper motor output shaft.

Tighten the nut to 12 N´m (105 in. lbs.).

(5) Reconnect the vehicle wire harness connector

for the wiper motor to the motor pigtail wire connec-

tor.

(6) Reconnect the battery negative cable.WIPER RELAY

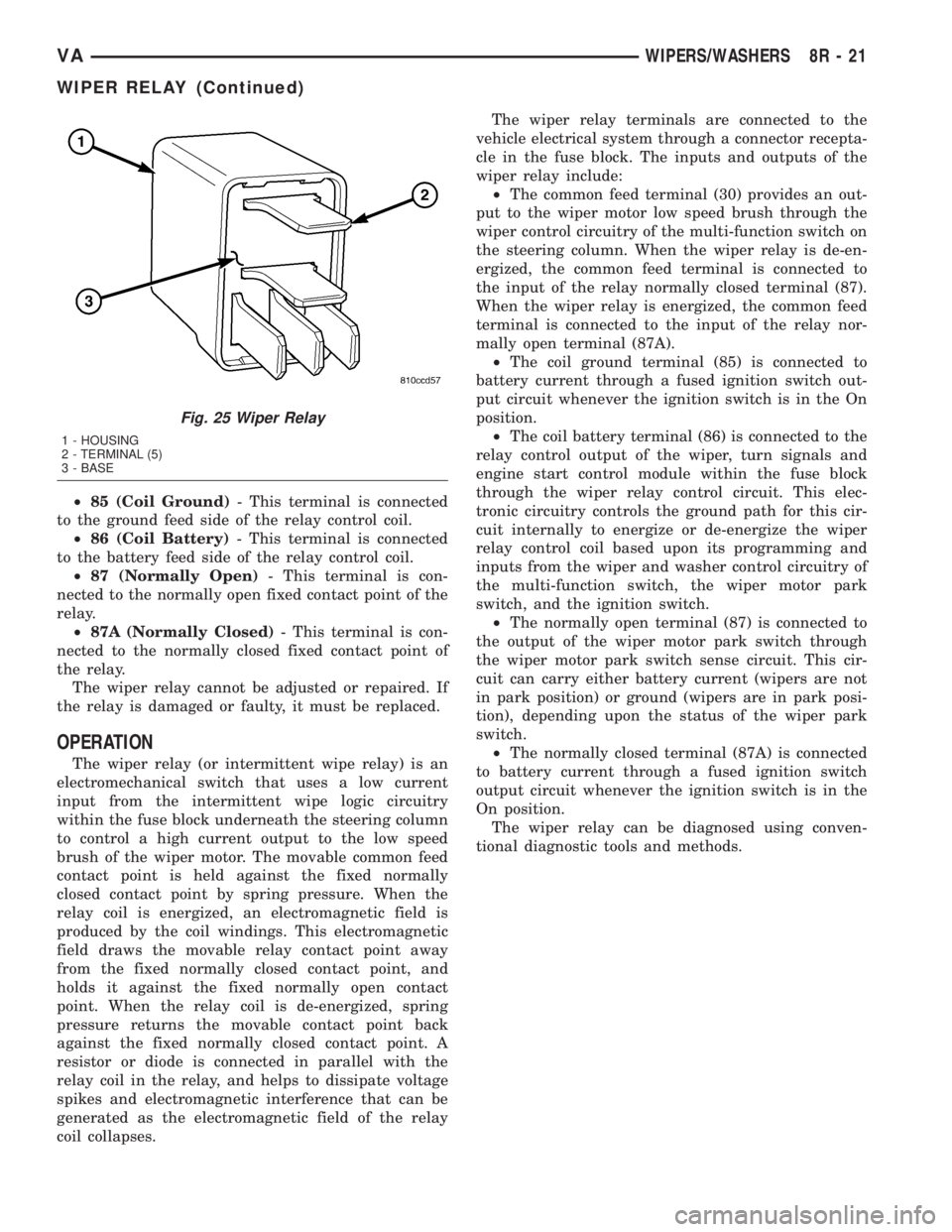

DESCRIPTION

A wiper relay is standard equipment on all models.

The wiper relay (or intermittent wipe relay) is

located in a dedicated receptacle on the bottom left of

the fuse block on the underside of the steering col-

umn (Fig. 25). The wiper relay is a conventional

International Standards Organization (ISO) micro

relay. Relays conforming to the ISO specifications

have common physical dimensions, current capaci-

ties, terminal patterns, and terminal functions. The

relay is contained within a small, rectangular,

molded plastic housing. The relay is connected to all

of the required inputs and outputs through the

instrument panel wire harness connector by five

male spade-type terminals that extend from the bot-

tom of the relay base. The ISO designation for each

terminal is molded into the base adjacent to the ter-

minal. The ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

Fig. 24 Wiper Motor Remove/Install

1 - NUT 4 - PIGTAIL WIRE CONNECTOR

2 - LINK (2) 5 - WIPER MOTOR

3 - MOTOR CRANK ARM 6 - SCREW (3)

8R - 20 WIPERS/WASHERSVA

WIPER MOTOR (Continued)

Page 303 of 1232

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The wiper relay cannot be adjusted or repaired. If

the relay is damaged or faulty, it must be replaced.

OPERATION

The wiper relay (or intermittent wipe relay) is an

electromechanical switch that uses a low current

input from the intermittent wipe logic circuitry

within the fuse block underneath the steering column

to control a high current output to the low speed

brush of the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor or diode is connected in parallel with the

relay coil in the relay, and helps to dissipate voltage

spikes and electromagnetic interference that can be

generated as the electromagnetic field of the relay

coil collapses.The wiper relay terminals are connected to the

vehicle electrical system through a connector recepta-

cle in the fuse block. The inputs and outputs of the

wiper relay include:

²The common feed terminal (30) provides an out-

put to the wiper motor low speed brush through the

wiper control circuitry of the multi-function switch on

the steering column. When the wiper relay is de-en-

ergized, the common feed terminal is connected to

the input of the relay normally closed terminal (87).

When the wiper relay is energized, the common feed

terminal is connected to the input of the relay nor-

mally open terminal (87A).

²The coil ground terminal (85) is connected to

battery current through a fused ignition switch out-

put circuit whenever the ignition switch is in the On

position.

²The coil battery terminal (86) is connected to the

relay control output of the wiper, turn signals and

engine start control module within the fuse block

through the wiper relay control circuit. This elec-

tronic circuitry controls the ground path for this cir-

cuit internally to energize or de-energize the wiper

relay control coil based upon its programming and

inputs from the wiper and washer control circuitry of

the multi-function switch, the wiper motor park

switch, and the ignition switch.

²The normally open terminal (87) is connected to

the output of the wiper motor park switch through

the wiper motor park switch sense circuit. This cir-

cuit can carry either battery current (wipers are not

in park position) or ground (wipers are in park posi-

tion), depending upon the status of the wiper park

switch.

²The normally closed terminal (87A) is connected

to battery current through a fused ignition switch

output circuit whenever the ignition switch is in the

On position.

The wiper relay can be diagnosed using conven-

tional diagnostic tools and methods.

Fig. 25 Wiper Relay

1 - HOUSING

2 - TERMINAL (5)

3 - BASE

VAWIPERS/WASHERS 8R - 21

WIPER RELAY (Continued)

Page 304 of 1232

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

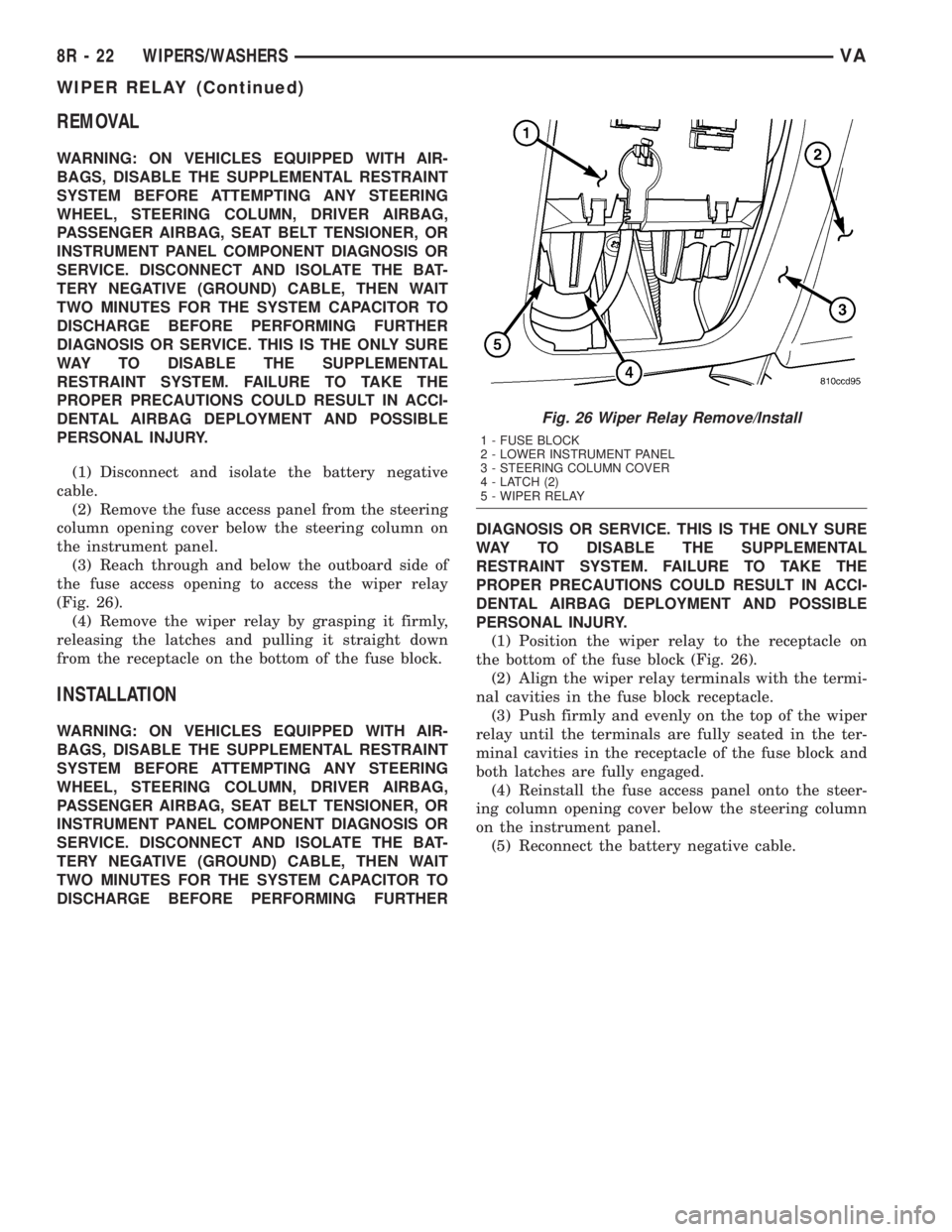

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel from the steering

column opening cover below the steering column on

the instrument panel.

(3) Reach through and below the outboard side of

the fuse access opening to access the wiper relay

(Fig. 26).

(4) Remove the wiper relay by grasping it firmly,

releasing the latches and pulling it straight down

from the receptacle on the bottom of the fuse block.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHERDIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the wiper relay to the receptacle on

the bottom of the fuse block (Fig. 26).

(2) Align the wiper relay terminals with the termi-

nal cavities in the fuse block receptacle.

(3) Push firmly and evenly on the top of the wiper

relay until the terminals are fully seated in the ter-

minal cavities in the receptacle of the fuse block and

both latches are fully engaged.

(4) Reinstall the fuse access panel onto the steer-

ing column opening cover below the steering column

on the instrument panel.

(5) Reconnect the battery negative cable.

Fig. 26 Wiper Relay Remove/Install

1 - FUSE BLOCK

2 - LOWER INSTRUMENT PANEL

3 - STEERING COLUMN COVER

4 - LATCH (2)

5 - WIPER RELAY

8R - 22 WIPERS/WASHERSVA

WIPER RELAY (Continued)

Page 305 of 1232

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

FUSE BLOCK........................ 8W-11-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER................ 8W-41-1

AIR CONDITIONER/HEATER............ 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1CENTRAL TIMER MODULE............. 8W-45-1

AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATIONS.... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 VAWIRING 8W - 1

Page 307 of 1232

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS...........................1

DESCRIPTION - CIRCUIT INFORMATION....5

DESCRIPTION - SECTION IDENTIFICATION

AND INFORMATION....................5

DESCRIPTION - CONNECTOR, GROUND

AND SPLICE INFORMATION..............5

WARNING

WARNINGS - GENERAL.................6

DIAGNOSIS AND TESTING - WIRING

HARNESS............................6

STANDARD PROCEDURE

STANDARD PROCEDURE -

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................7

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL...................7

STANDARD PROCEDURE - TESTING FOR

CONTINUITY..........................8STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND...................8

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS............8

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP.......................8

CONNECTOR

REMOVAL.............................8

INSTALLATION..........................9

DIODE

REMOVAL.............................9

INSTALLATION..........................9

TERMINAL

REMOVAL.............................9

INSTALLATION.........................10

WIRE

STANDARD PROCEDURE - WIRE SPLICING . . 10

WIRING DIAGRAM

INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

VA8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 1

Page 314 of 1232

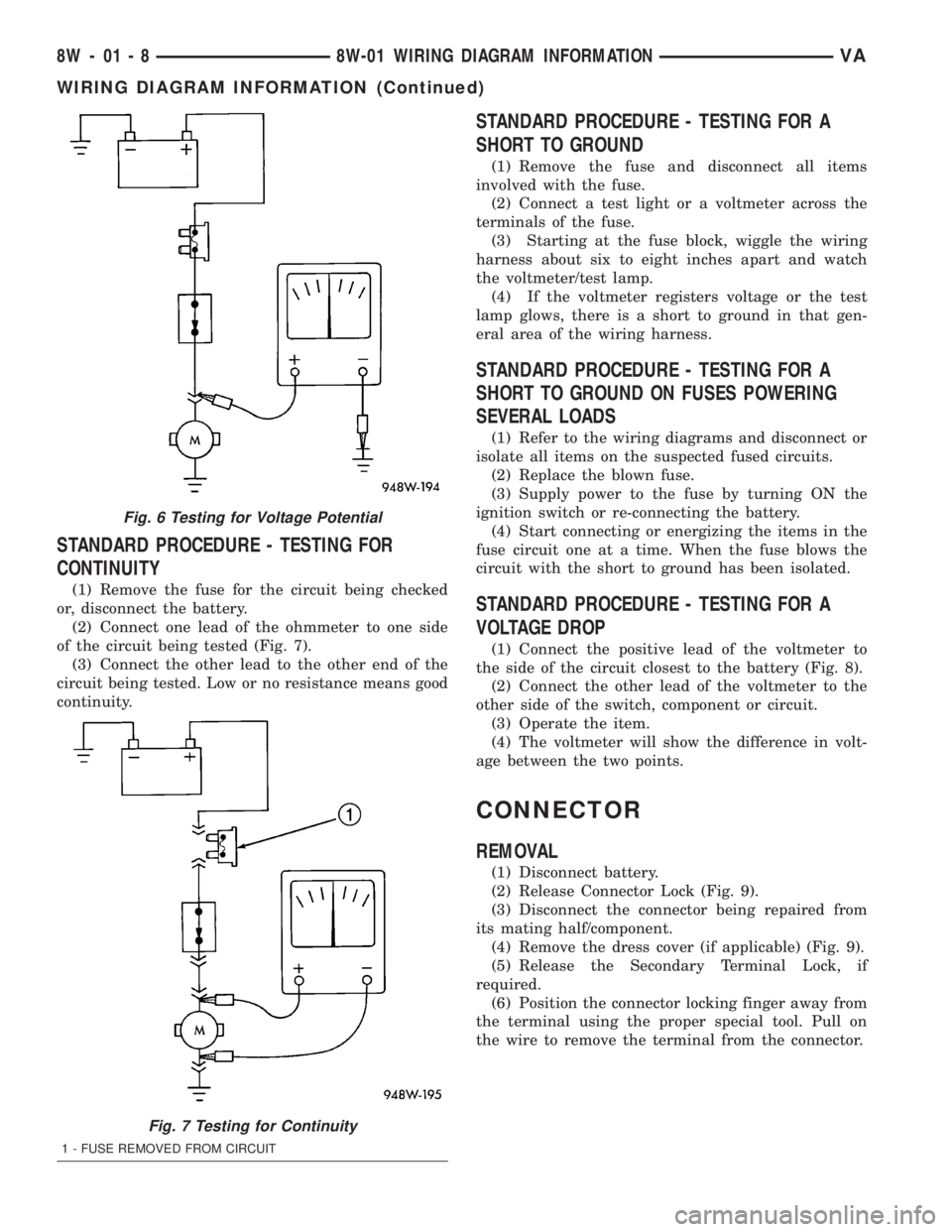

STANDARD PROCEDURE - TESTING FOR

CONTINUITY

(1) Remove the fuse for the circuit being checked

or, disconnect the battery.

(2) Connect one lead of the ohmmeter to one side

of the circuit being tested (Fig. 7).

(3) Connect the other lead to the other end of the

circuit being tested. Low or no resistance means good

continuity.

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES POWERING

SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting or energizing the items in the

fuse circuit one at a time. When the fuse blows the

circuit with the short to ground has been isolated.

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 8).

(2) Connect the other lead of the voltmeter to the

other side of the switch, component or circuit.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

CONNECTOR

REMOVAL

(1) Disconnect battery.

(2) Release Connector Lock (Fig. 9).

(3) Disconnect the connector being repaired from

its mating half/component.

(4) Remove the dress cover (if applicable) (Fig. 9).

(5) Release the Secondary Terminal Lock, if

required.

(6) Position the connector locking finger away from

the terminal using the proper special tool. Pull on

the wire to remove the terminal from the connector.

Fig. 6 Testing for Voltage Potential

Fig. 7 Testing for Continuity

1 - FUSE REMOVED FROM CIRCUIT

8W - 01 - 8 8W-01 WIRING DIAGRAM INFORMATIONVA

WIRING DIAGRAM INFORMATION (Continued)

Page 317 of 1232

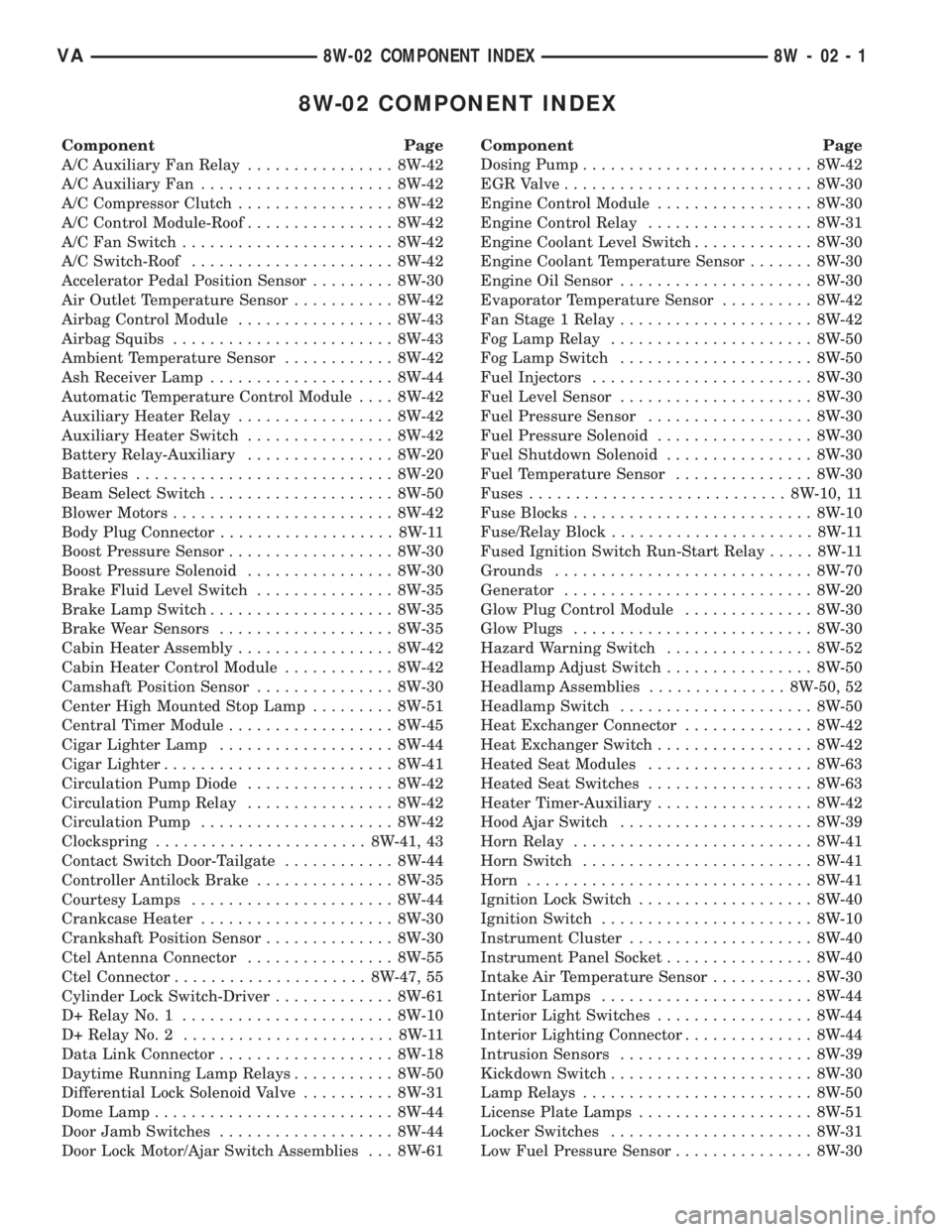

8W-02 COMPONENT INDEX

Component Page

A/C Auxiliary Fan Relay................ 8W-42

A/C Auxiliary Fan..................... 8W-42

A/C Compressor Clutch................. 8W-42

A/C Control Module-Roof................ 8W-42

A/C Fan Switch....................... 8W-42

A/C Switch-Roof...................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Air Outlet Temperature Sensor........... 8W-42

Airbag Control Module................. 8W-43

Airbag Squibs........................ 8W-43

Ambient Temperature Sensor............ 8W-42

Ash Receiver Lamp.................... 8W-44

Automatic Temperature Control Module.... 8W-42

Auxiliary Heater Relay................. 8W-42

Auxiliary Heater Switch................ 8W-42

Battery Relay-Auxiliary................ 8W-20

Batteries............................ 8W-20

Beam Select Switch.................... 8W-50

Blower Motors........................ 8W-42

Body Plug Connector................... 8W-11

Boost Pressure Sensor.................. 8W-30

Boost Pressure Solenoid................ 8W-30

Brake Fluid Level Switch............... 8W-35

Brake Lamp Switch.................... 8W-35

Brake Wear Sensors................... 8W-35

Cabin Heater Assembly................. 8W-42

Cabin Heater Control Module............ 8W-42

Camshaft Position Sensor............... 8W-30

Center High Mounted Stop Lamp......... 8W-51

Central Timer Module.................. 8W-45

Cigar Lighter Lamp................... 8W-44

Cigar Lighter......................... 8W-41

Circulation Pump Diode................ 8W-42

Circulation Pump Relay................ 8W-42

Circulation Pump..................... 8W-42

Clockspring....................... 8W-41, 43

Contact Switch Door-Tailgate............ 8W-44

Controller Antilock Brake............... 8W-35

Courtesy Lamps...................... 8W-44

Crankcase Heater..................... 8W-30

Crankshaft Position Sensor.............. 8W-30

Ctel Antenna Connector................ 8W-55

Ctel Connector..................... 8W-47, 55

Cylinder Lock Switch-Driver............. 8W-61

D+ Relay No. 1....................... 8W-10

D+ Relay No. 2....................... 8W-11

Data Link Connector................... 8W-18

Daytime Running Lamp Relays........... 8W-50

Differential Lock Solenoid Valve.......... 8W-31

Dome Lamp.......................... 8W-44

Door Jamb Switches................... 8W-44

Door Lock Motor/Ajar Switch Assemblies . . . 8W-61Component Page

Dosing Pump......................... 8W-42

EGR Valve........................... 8W-30

Engine Control Module................. 8W-30

Engine Control Relay.................. 8W-31

Engine Coolant Level Switch............. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Sensor..................... 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fan Stage 1 Relay..................... 8W-42

Fog Lamp Relay...................... 8W-50

Fog Lamp Switch..................... 8W-50

Fuel Injectors........................ 8W-30

Fuel Level Sensor..................... 8W-30

Fuel Pressure Sensor.................. 8W-30

Fuel Pressure Solenoid................. 8W-30

Fuel Shutdown Solenoid................ 8W-30

Fuel Temperature Sensor............... 8W-30

Fuses............................ 8W-10, 11

Fuse Blocks.......................... 8W-10

Fuse/Relay Block...................... 8W-11

Fused Ignition Switch Run-Start Relay..... 8W-11

Grounds............................ 8W-70

Generator........................... 8W-20

Glow Plug Control Module.............. 8W-30

Glow Plugs.......................... 8W-30

Hazard Warning Switch................ 8W-52

Headlamp Adjust Switch................ 8W-50

Headlamp Assemblies............... 8W-50, 52

Headlamp Switch..................... 8W-50

Heat Exchanger Connector.............. 8W-42

Heat Exchanger Switch................. 8W-42

Heated Seat Modules.................. 8W-63

Heated Seat Switches.................. 8W-63

Heater Timer-Auxiliary................. 8W-42

Hood Ajar Switch..................... 8W-39

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn............................... 8W-41

Ignition Lock Switch................... 8W-40

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Instrument Panel Socket................ 8W-40

Intake Air Temperature Sensor........... 8W-30

Interior Lamps....................... 8W-44

Interior Light Switches................. 8W-44

Interior Lighting Connector.............. 8W-44

Intrusion Sensors..................... 8W-39

Kickdown Switch...................... 8W-30

Lamp Relays......................... 8W-50

License Plate Lamps................... 8W-51

Locker Switches...................... 8W-31

Low Fuel Pressure Sensor............... 8W-30

VA8W-02 COMPONENT INDEX 8W - 02 - 1