MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1661 of 2305

²Reduction in exhaust emissions as a result of an

improvement in the air supply of the engine.

²Increased power output as a result of the higher

charge pressure combined with a reduced exhaust

backpressure and thus improved charge cycle.

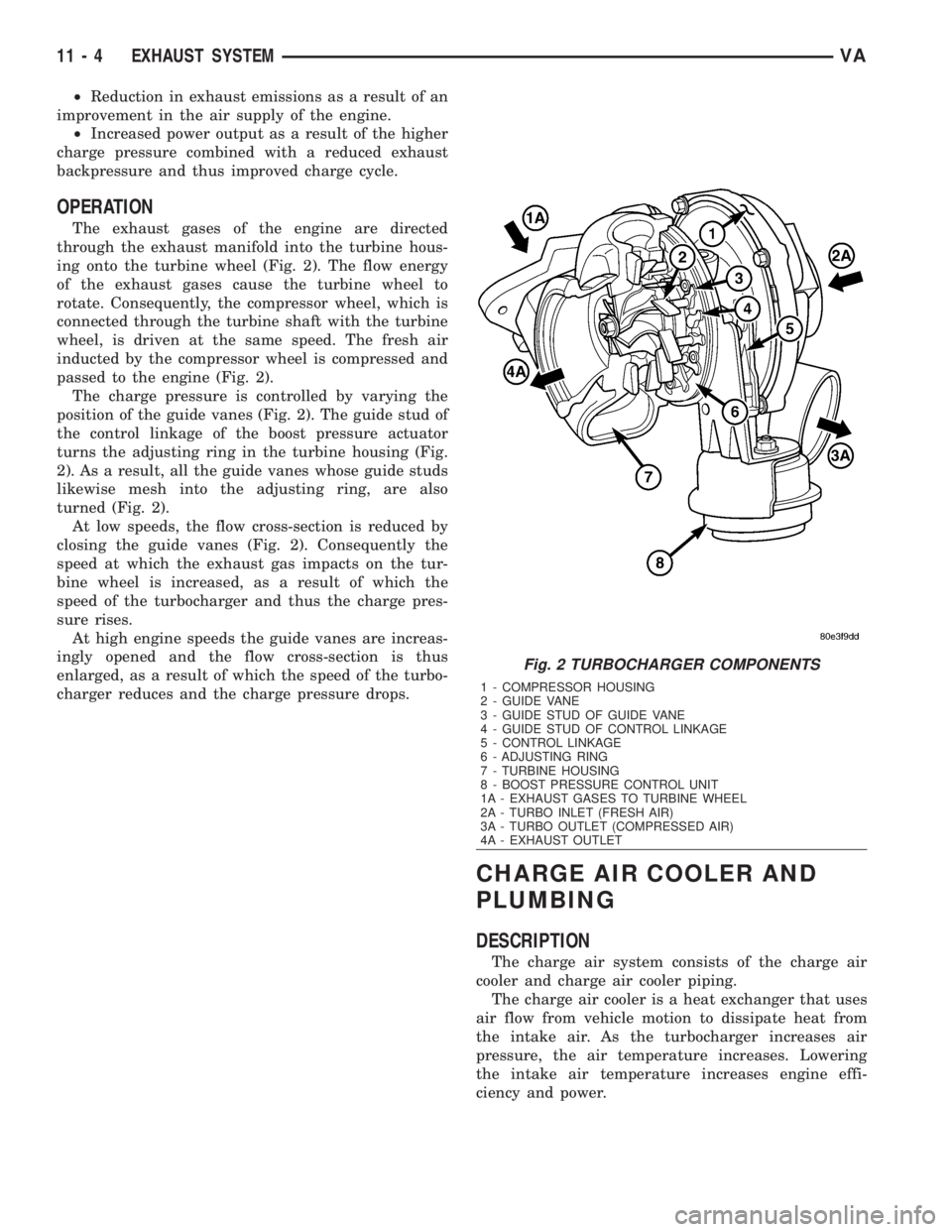

OPERATION

The exhaust gases of the engine are directed

through the exhaust manifold into the turbine hous-

ing onto the turbine wheel (Fig. 2). The flow energy

of the exhaust gases cause the turbine wheel to

rotate. Consequently, the compressor wheel, which is

connected through the turbine shaft with the turbine

wheel, is driven at the same speed. The fresh air

inducted by the compressor wheel is compressed and

passed to the engine (Fig. 2).

The charge pressure is controlled by varying the

position of the guide vanes (Fig. 2). The guide stud of

the control linkage of the boost pressure actuator

turns the adjusting ring in the turbine housing (Fig.

2). As a result, all the guide vanes whose guide studs

likewise mesh into the adjusting ring, are also

turned (Fig. 2).

At low speeds, the flow cross-section is reduced by

closing the guide vanes (Fig. 2). Consequently the

speed at which the exhaust gas impacts on the tur-

bine wheel is increased, as a result of which the

speed of the turbocharger and thus the charge pres-

sure rises.

At high engine speeds the guide vanes are increas-

ingly opened and the flow cross-section is thus

enlarged, as a result of which the speed of the turbo-

charger reduces and the charge pressure drops.

CHARGE AIR COOLER AND

PLUMBING

DESCRIPTION

The charge air system consists of the charge air

cooler and charge air cooler piping.

The charge air cooler is a heat exchanger that uses

air flow from vehicle motion to dissipate heat from

the intake air. As the turbocharger increases air

pressure, the air temperature increases. Lowering

the intake air temperature increases engine effi-

ciency and power.

Fig. 2 TURBOCHARGER COMPONENTS

1 - COMPRESSOR HOUSING

2 - GUIDE VANE

3 - GUIDE STUD OF GUIDE VANE

4 - GUIDE STUD OF CONTROL LINKAGE

5 - CONTROL LINKAGE

6 - ADJUSTING RING

7 - TURBINE HOUSING

8 - BOOST PRESSURE CONTROL UNIT

1A - EXHAUST GASES TO TURBINE WHEEL

2A - TURBO INLET (FRESH AIR)

3A - TURBO OUTLET (COMPRESSED AIR)

4A - EXHAUST OUTLET

11 - 4 EXHAUST SYSTEMVA

Page 1662 of 2305

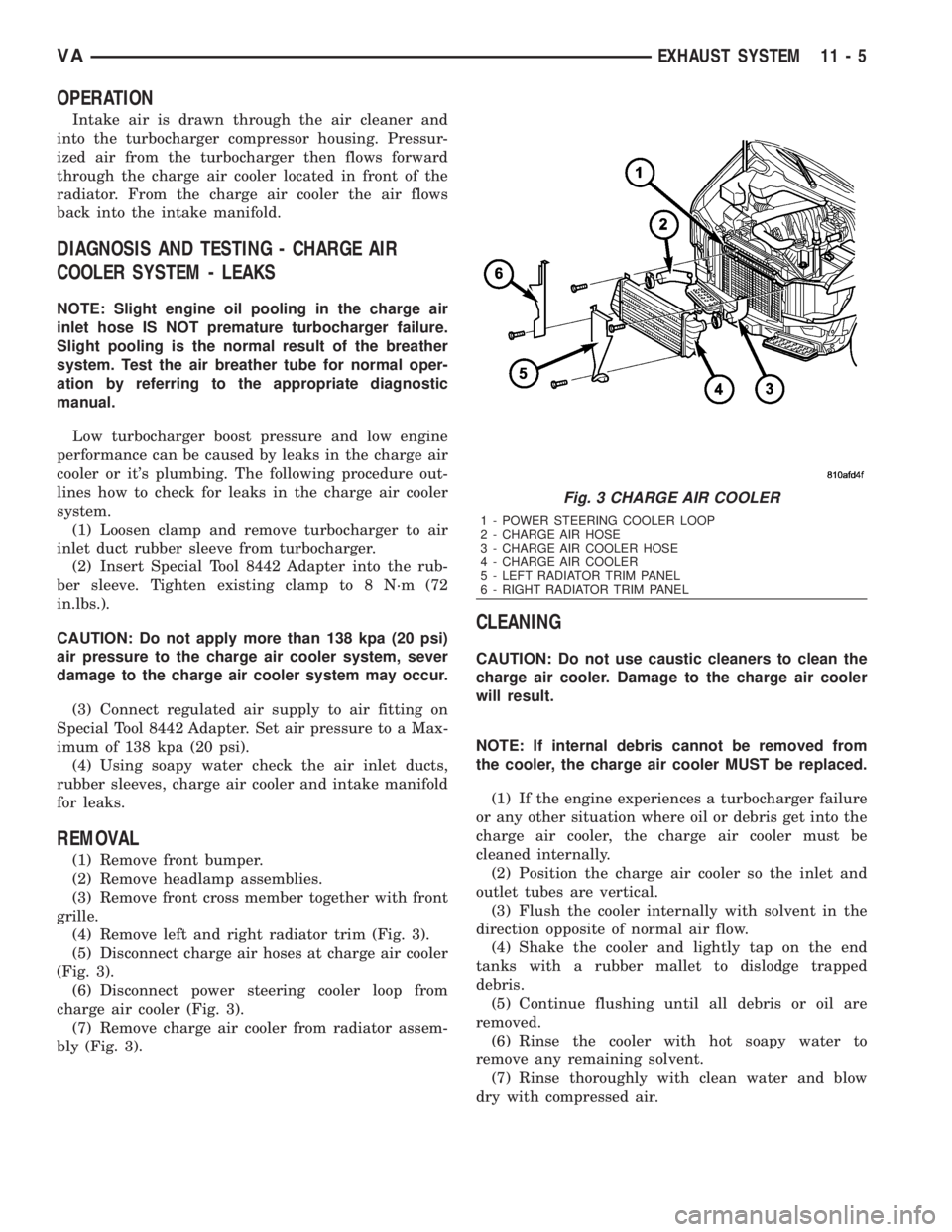

OPERATION

Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressur-

ized air from the turbocharger then flows forward

through the charge air cooler located in front of the

radiator. From the charge air cooler the air flows

back into the intake manifold.

DIAGNOSIS AND TESTING - CHARGE AIR

COOLER SYSTEM - LEAKS

NOTE: Slight engine oil pooling in the charge air

inlet hose IS NOT premature turbocharger failure.

Slight pooling is the normal result of the breather

system. Test the air breather tube for normal oper-

ation by referring to the appropriate diagnostic

manual.

Low turbocharger boost pressure and low engine

performance can be caused by leaks in the charge air

cooler or it's plumbing. The following procedure out-

lines how to check for leaks in the charge air cooler

system.

(1) Loosen clamp and remove turbocharger to air

inlet duct rubber sleeve from turbocharger.

(2) Insert Special Tool 8442 Adapter into the rub-

ber sleeve. Tighten existing clamp to 8 N´m (72

in.lbs.).

CAUTION: Do not apply more than 138 kpa (20 psi)

air pressure to the charge air cooler system, sever

damage to the charge air cooler system may occur.

(3) Connect regulated air supply to air fitting on

Special Tool 8442 Adapter. Set air pressure to a Max-

imum of 138 kpa (20 psi).

(4) Using soapy water check the air inlet ducts,

rubber sleeves, charge air cooler and intake manifold

for leaks.

REMOVAL

(1) Remove front bumper.

(2) Remove headlamp assemblies.

(3) Remove front cross member together with front

grille.

(4) Remove left and right radiator trim (Fig. 3).

(5) Disconnect charge air hoses at charge air cooler

(Fig. 3).

(6) Disconnect power steering cooler loop from

charge air cooler (Fig. 3).

(7) Remove charge air cooler from radiator assem-

bly (Fig. 3).

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.

(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4) Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped

debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

Fig. 3 CHARGE AIR COOLER

1 - POWER STEERING COOLER LOOP

2 - CHARGE AIR HOSE

3 - CHARGE AIR COOLER HOSE

4 - CHARGE AIR COOLER

5 - LEFT RADIATOR TRIM PANEL

6 - RIGHT RADIATOR TRIM PANEL

VAEXHAUST SYSTEM 11 - 5

Page 1663 of 2305

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit.

INSTALLATION

(1) Install charge air cooler to radiator (Fig. 3).

(2) Connect power steering cooler loop to charge

air cooler (Fig. 3).

(3) Connect charge air hoses (Fig. 3).

(4) Install both radiator trim pieces (Fig. 3).

(5) Install front grille with front cross member.

(6) Install headlamp assemblies.

(7) Install front bumper.

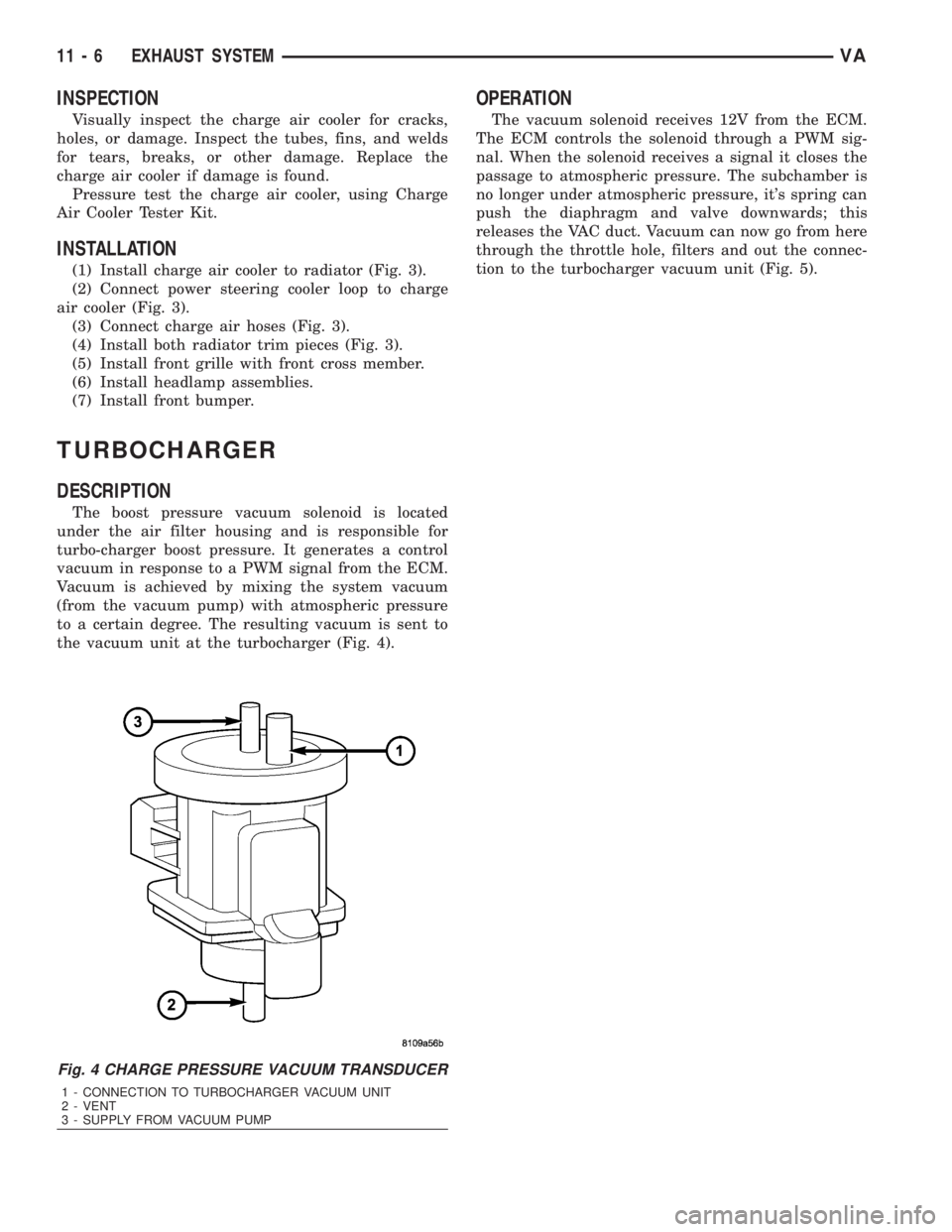

TURBOCHARGER

DESCRIPTION

The boost pressure vacuum solenoid is located

under the air filter housing and is responsible for

turbo-charger boost pressure. It generates a control

vacuum in response to a PWM signal from the ECM.

Vacuum is achieved by mixing the system vacuum

(from the vacuum pump) with atmospheric pressure

to a certain degree. The resulting vacuum is sent to

the vacuum unit at the turbocharger (Fig. 4).

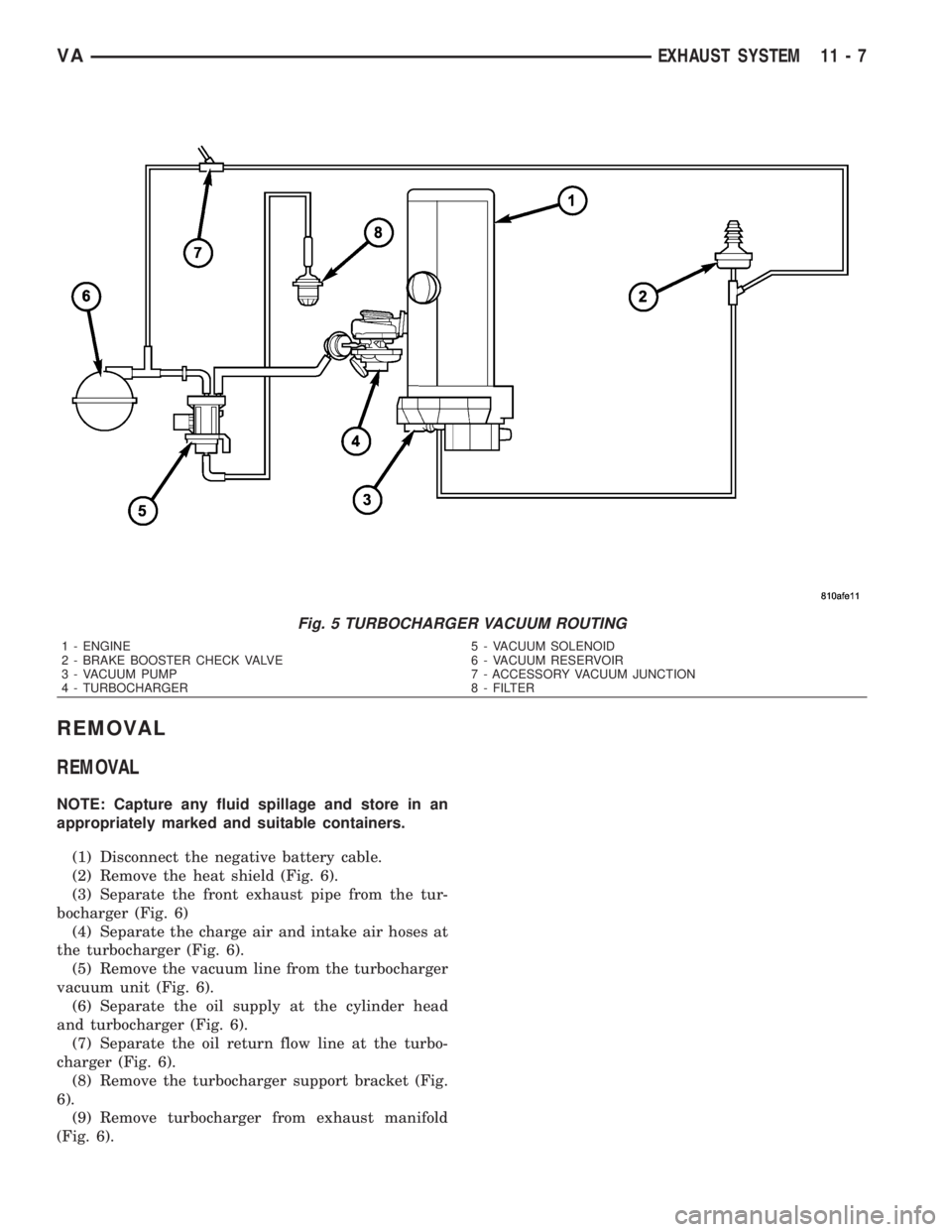

OPERATION

The vacuum solenoid receives 12V from the ECM.

The ECM controls the solenoid through a PWM sig-

nal. When the solenoid receives a signal it closes the

passage to atmospheric pressure. The subchamber is

no longer under atmospheric pressure, it's spring can

push the diaphragm and valve downwards; this

releases the VAC duct. Vacuum can now go from here

through the throttle hole, filters and out the connec-

tion to the turbocharger vacuum unit (Fig. 5).

Fig. 4 CHARGE PRESSURE VACUUM TRANSDUCER

1 - CONNECTION TO TURBOCHARGER VACUUM UNIT

2 - VENT

3 - SUPPLY FROM VACUUM PUMP

11 - 6 EXHAUST SYSTEMVA

Page 1664 of 2305

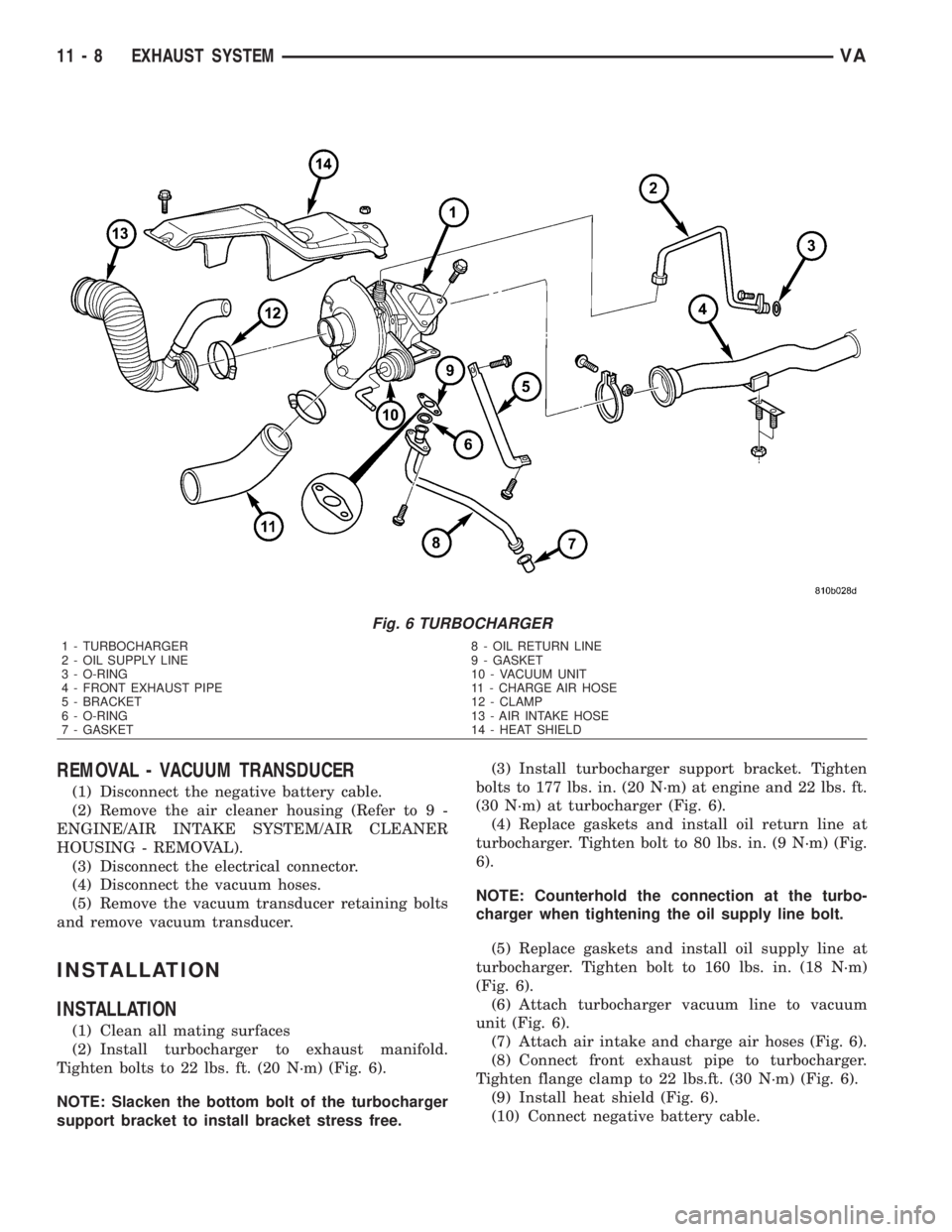

REMOVAL

REMOVAL

NOTE: Capture any fluid spillage and store in an

appropriately marked and suitable containers.

(1) Disconnect the negative battery cable.

(2) Remove the heat shield (Fig. 6).

(3) Separate the front exhaust pipe from the tur-

bocharger (Fig. 6)

(4) Separate the charge air and intake air hoses at

the turbocharger (Fig. 6).

(5) Remove the vacuum line from the turbocharger

vacuum unit (Fig. 6).

(6) Separate the oil supply at the cylinder head

and turbocharger (Fig. 6).

(7) Separate the oil return flow line at the turbo-

charger (Fig. 6).

(8) Remove the turbocharger support bracket (Fig.

6).

(9) Remove turbocharger from exhaust manifold

(Fig. 6).

Fig. 5 TURBOCHARGER VACUUM ROUTING

1 - ENGINE 5 - VACUUM SOLENOID

2 - BRAKE BOOSTER CHECK VALVE 6 - VACUUM RESERVOIR

3 - VACUUM PUMP 7 - ACCESSORY VACUUM JUNCTION

4 - TURBOCHARGER 8 - FILTER

VAEXHAUST SYSTEM 11 - 7

Page 1665 of 2305

REMOVAL - VACUUM TRANSDUCER

(1) Disconnect the negative battery cable.

(2) Remove the air cleaner housing (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

(3) Disconnect the electrical connector.

(4) Disconnect the vacuum hoses.

(5) Remove the vacuum transducer retaining bolts

and remove vacuum transducer.

INSTALLATION

INSTALLATION

(1) Clean all mating surfaces

(2) Install turbocharger to exhaust manifold.

Tighten bolts to 22 lbs. ft. (20 N´m) (Fig. 6).

NOTE: Slacken the bottom bolt of the turbocharger

support bracket to install bracket stress free.(3) Install turbocharger support bracket. Tighten

bolts to 177 lbs. in. (20 N´m) at engine and 22 lbs. ft.

(30 N´m) at turbocharger (Fig. 6).

(4) Replace gaskets and install oil return line at

turbocharger. Tighten bolt to 80 lbs. in. (9 N´m) (Fig.

6).

NOTE: Counterhold the connection at the turbo-

charger when tightening the oil supply line bolt.

(5) Replace gaskets and install oil supply line at

turbocharger. Tighten bolt to 160 lbs. in. (18 N´m)

(Fig. 6).

(6) Attach turbocharger vacuum line to vacuum

unit (Fig. 6).

(7) Attach air intake and charge air hoses (Fig. 6).

(8) Connect front exhaust pipe to turbocharger.

Tighten flange clamp to 22 lbs.ft. (30 N´m) (Fig. 6).

(9) Install heat shield (Fig. 6).

(10) Connect negative battery cable.

Fig. 6 TURBOCHARGER

1 - TURBOCHARGER 8 - OIL RETURN LINE

2 - OIL SUPPLY LINE 9 - GASKET

3 - O-RING 10 - VACUUM UNIT

4 - FRONT EXHAUST PIPE 11 - CHARGE AIR HOSE

5 - BRACKET 12 - CLAMP

6 - O-RING 13 - AIR INTAKE HOSE

7 - GASKET 14 - HEAT SHIELD

11 - 8 EXHAUST SYSTEMVA

Page 1666 of 2305

INSTALLATION - VACUUM TRANSDUCER

(1) Position vacuum transducer and install the

retaining bolts. Tighten bolts to 70 lbs.in (8 N´m).

(2) Connect vacuum hoses.

(3) Connect electrical connector

(4) Install air cleaner housing (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION)

(5) Connect negative battery cable.

VAEXHAUST SYSTEM 11 - 9

Page 1667 of 2305

Page 1668 of 2305

FRAME & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT BUMPER - STEPS

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................2

INSTALLATION..........................2

REAR BUMPER - STEP

REMOVAL.............................2

INSTALLATION..........................3

REAR FASCIA

REMOVAL.............................3

INSTALLATION..........................3FRAME

SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS . . . 3

SPECIFICATIONS - TORQUE.............8

ENGINE CRADLE CROSSMEMBER

REMOVAL.............................8

INSTALLATION.........................10

REAR CROSSMEMBER - TRANSMISSION

REMOVAL.............................11

INSTALLATION.........................11

TRAILER HITCH

REMOVAL.............................11

INSTALLATION.........................12

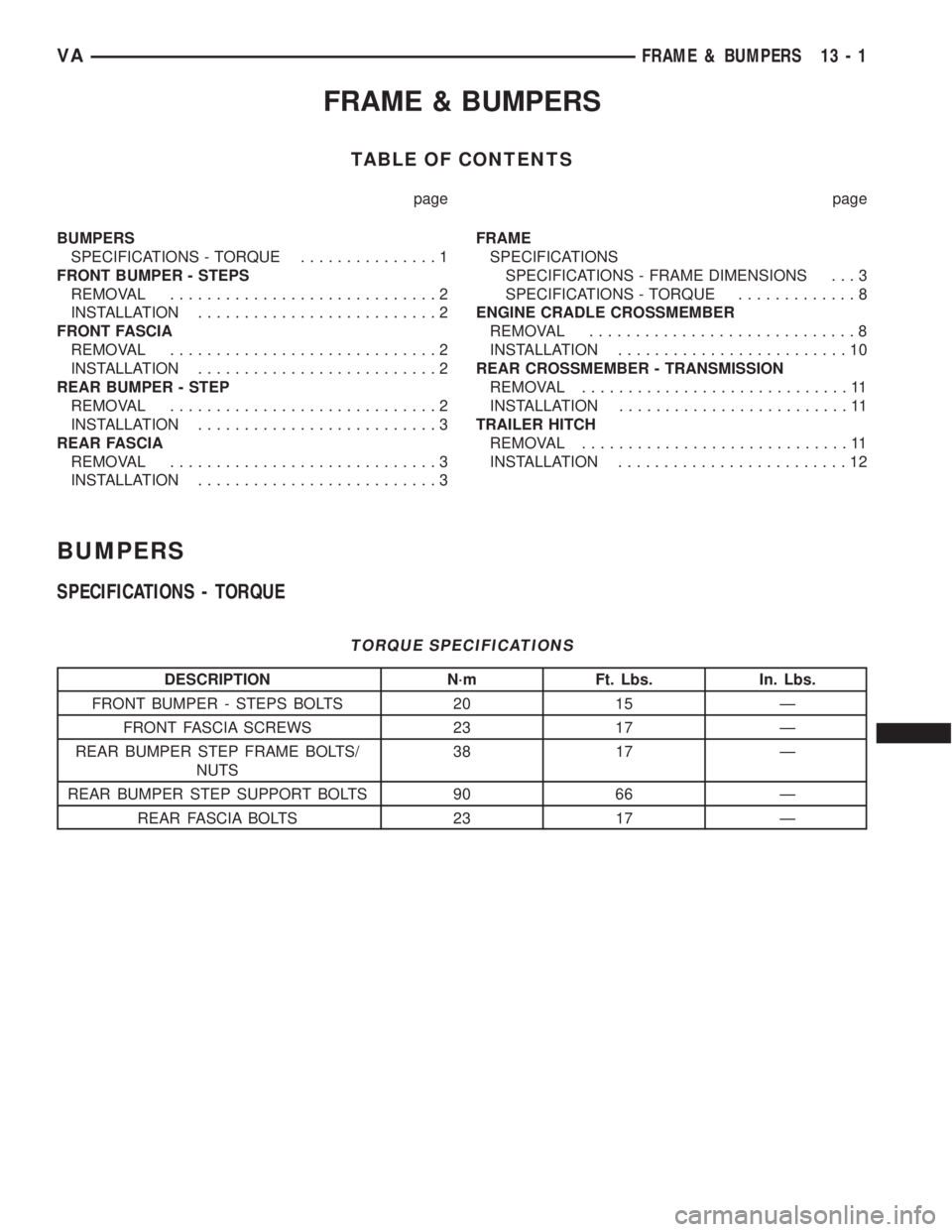

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

FRONT BUMPER - STEPS BOLTS 20 15 Ð

FRONT FASCIA SCREWS 23 17 Ð

REAR BUMPER STEP FRAME BOLTS/

NUTS38 17 Ð

REAR BUMPER STEP SUPPORT BOLTS 90 66 Ð

REAR FASCIA BOLTS 23 17 Ð

VAFRAME & BUMPERS 13 - 1

Page 1669 of 2305

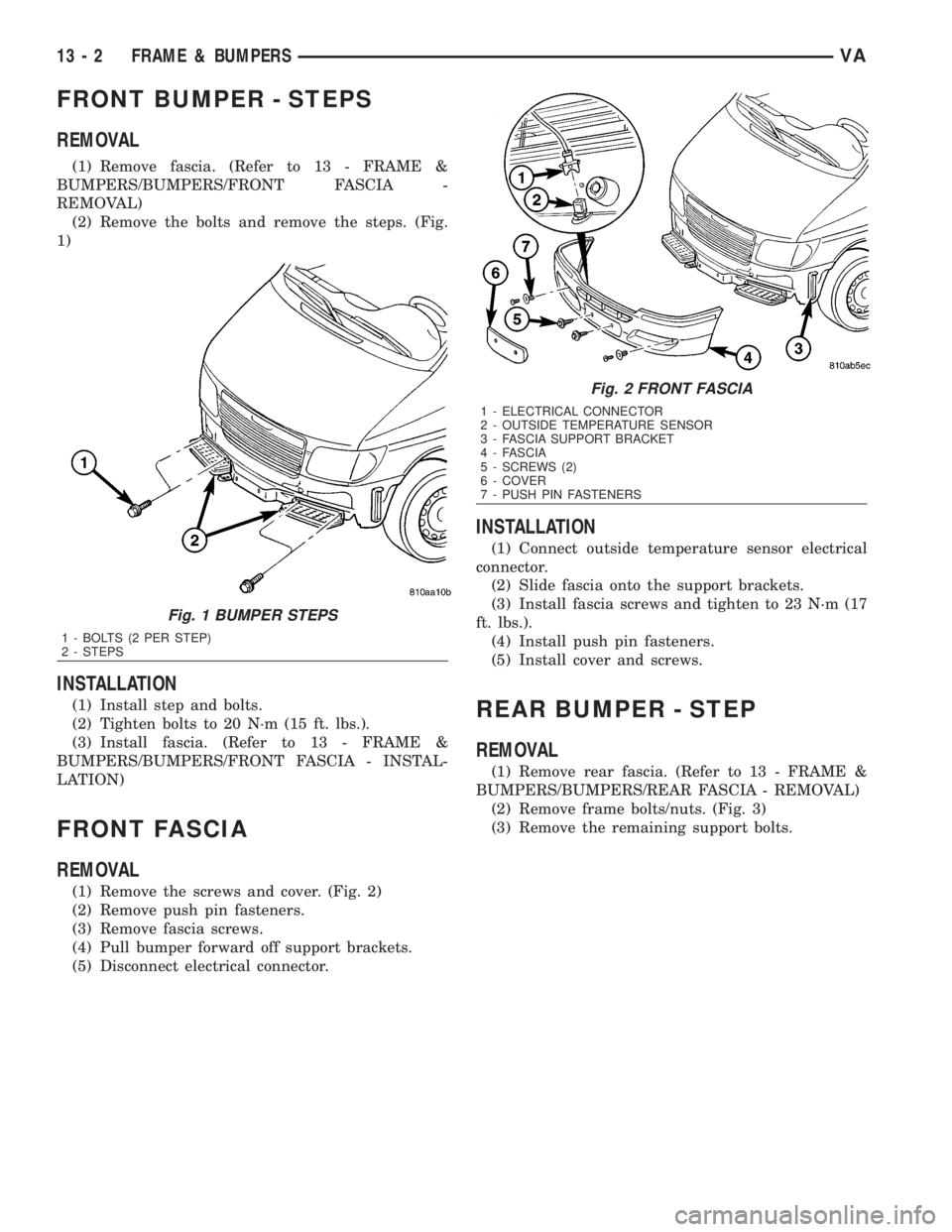

FRONT BUMPER - STEPS

REMOVAL

(1) Remove fascia. (Refer to 13 - FRAME &

BUMPERS/BUMPERS/FRONT FASCIA -

REMOVAL)

(2) Remove the bolts and remove the steps. (Fig.

1)

INSTALLATION

(1) Install step and bolts.

(2) Tighten bolts to 20 N´m (15 ft. lbs.).

(3) Install fascia. (Refer to 13 - FRAME &

BUMPERS/BUMPERS/FRONT FASCIA - INSTAL-

LATION)

FRONT FASCIA

REMOVAL

(1) Remove the screws and cover. (Fig. 2)

(2) Remove push pin fasteners.

(3) Remove fascia screws.

(4) Pull bumper forward off support brackets.

(5) Disconnect electrical connector.

INSTALLATION

(1) Connect outside temperature sensor electrical

connector.

(2) Slide fascia onto the support brackets.

(3) Install fascia screws and tighten to 23 N´m (17

ft. lbs.).

(4) Install push pin fasteners.

(5) Install cover and screws.

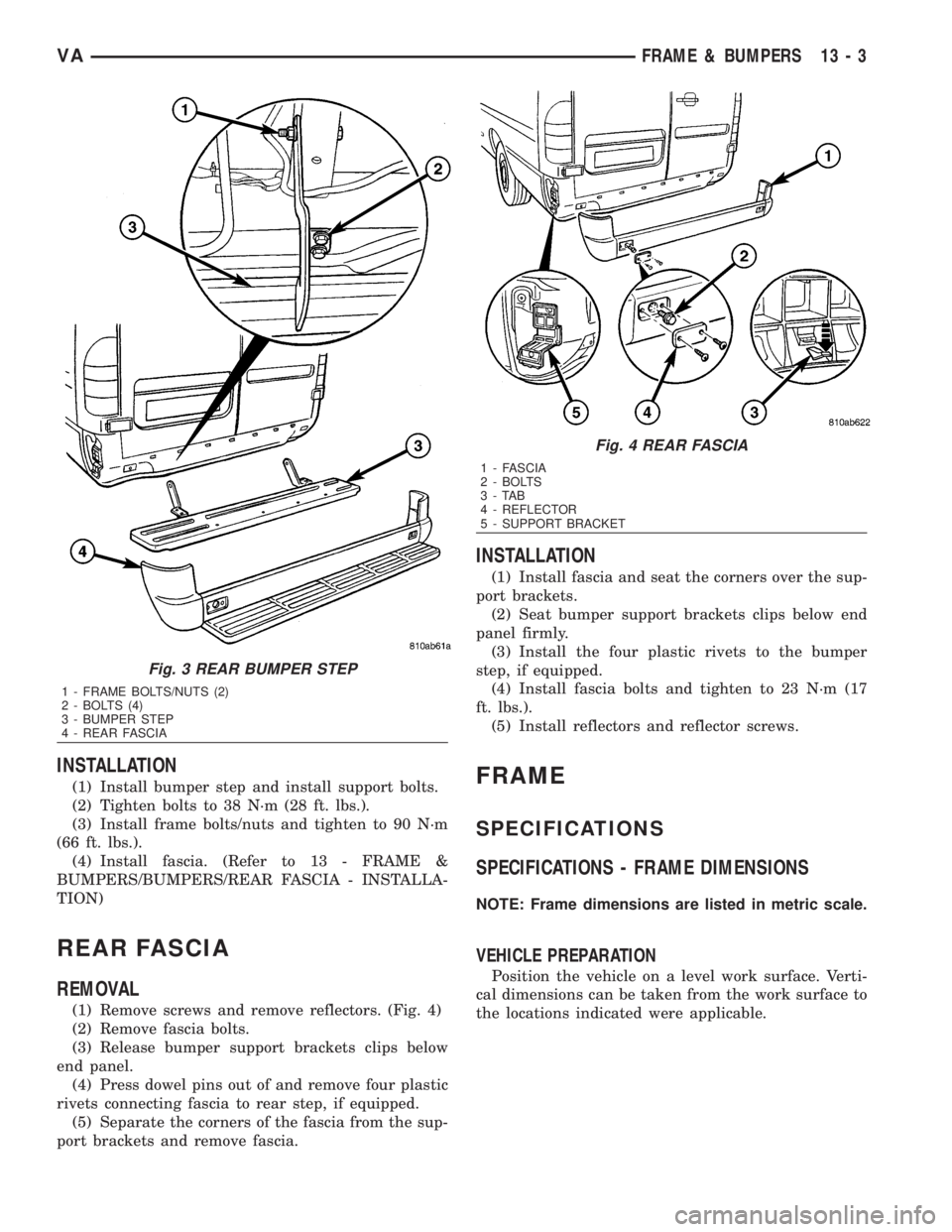

REAR BUMPER - STEP

REMOVAL

(1) Remove rear fascia. (Refer to 13 - FRAME &

BUMPERS/BUMPERS/REAR FASCIA - REMOVAL)

(2) Remove frame bolts/nuts. (Fig. 3)

(3) Remove the remaining support bolts.

Fig. 1 BUMPER STEPS

1 - BOLTS (2 PER STEP)

2 - STEPS

Fig. 2 FRONT FASCIA

1 - ELECTRICAL CONNECTOR

2 - OUTSIDE TEMPERATURE SENSOR

3 - FASCIA SUPPORT BRACKET

4 - FASCIA

5 - SCREWS (2)

6 - COVER

7 - PUSH PIN FASTENERS

13 - 2 FRAME & BUMPERSVA

Page 1670 of 2305

INSTALLATION

(1) Install bumper step and install support bolts.

(2) Tighten bolts to 38 N´m (28 ft. lbs.).

(3) Install frame bolts/nuts and tighten to 90 N´m

(66 ft. lbs.).

(4) Install fascia. (Refer to 13 - FRAME &

BUMPERS/BUMPERS/REAR FASCIA - INSTALLA-

TION)

REAR FASCIA

REMOVAL

(1) Remove screws and remove reflectors. (Fig. 4)

(2) Remove fascia bolts.

(3) Release bumper support brackets clips below

end panel.

(4) Press dowel pins out of and remove four plastic

rivets connecting fascia to rear step, if equipped.

(5) Separate the corners of the fascia from the sup-

port brackets and remove fascia.

INSTALLATION

(1) Install fascia and seat the corners over the sup-

port brackets.

(2) Seat bumper support brackets clips below end

panel firmly.

(3) Install the four plastic rivets to the bumper

step, if equipped.

(4) Install fascia bolts and tighten to 23 N´m (17

ft. lbs.).

(5) Install reflectors and reflector screws.

FRAME

SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS

NOTE: Frame dimensions are listed in metric scale.

VEHICLE PREPARATION

Position the vehicle on a level work surface. Verti-

cal dimensions can be taken from the work surface to

the locations indicated were applicable.

Fig. 3 REAR BUMPER STEP

1 - FRAME BOLTS/NUTS (2)

2 - BOLTS (4)

3 - BUMPER STEP

4 - REAR FASCIA

Fig. 4 REAR FASCIA

1 - FASCIA

2 - BOLTS

3-TAB

4 - REFLECTOR

5 - SUPPORT BRACKET

VAFRAME & BUMPERS 13 - 3