MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1711 of 2305

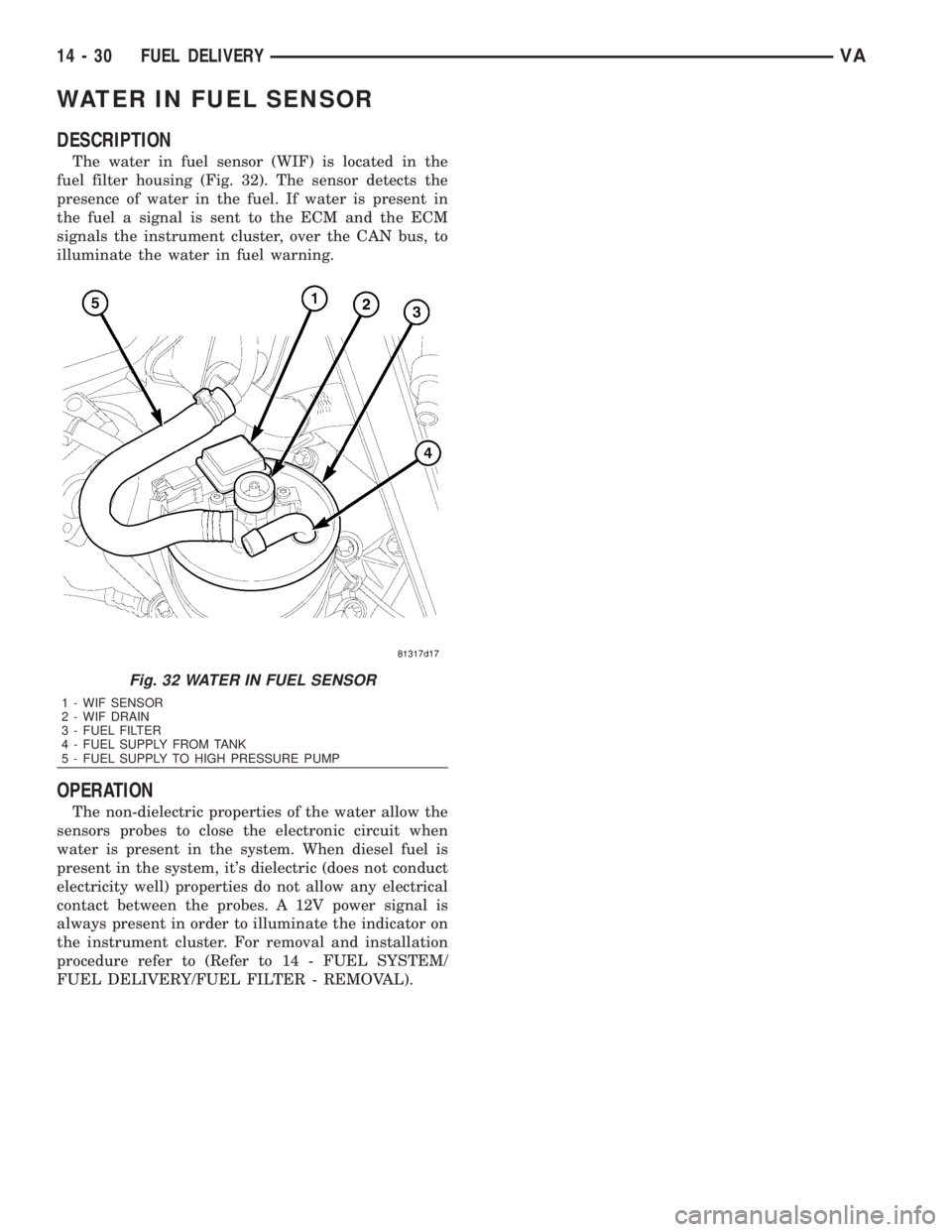

WATER IN FUEL SENSOR

DESCRIPTION

The water in fuel sensor (WIF) is located in the

fuel filter housing (Fig. 32). The sensor detects the

presence of water in the fuel. If water is present in

the fuel a signal is sent to the ECM and the ECM

signals the instrument cluster, over the CAN bus, to

illuminate the water in fuel warning.

OPERATION

The non-dielectric properties of the water allow the

sensors probes to close the electronic circuit when

water is present in the system. When diesel fuel is

present in the system, it's dielectric (does not conduct

electricity well) properties do not allow any electrical

contact between the probes. A 12V power signal is

always present in order to illuminate the indicator on

the instrument cluster. For removal and installation

procedure refer to (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL FILTER - REMOVAL).

Fig. 32 WATER IN FUEL SENSOR

1 - WIF SENSOR

2 - WIF DRAIN

3 - FUEL FILTER

4 - FUEL SUPPLY FROM TANK

5 - FUEL SUPPLY TO HIGH PRESSURE PUMP

14 - 30 FUEL DELIVERYVA

Page 1712 of 2305

FUEL INJECTION

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................32

REMOVAL.............................32

INSTALLATION.........................32

BOOST PRESSURE SENSOR

DESCRIPTION.........................33

OPERATION...........................33

DIAGNOSIS AND TESTING - BOOST

PRESSURE SENSOR..................33

REMOVAL.............................33

INSTALLATION.........................33

CAMSHAFT POSITION SENSOR

DESCRIPTION.........................33

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................34

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................35

OPERATION...........................35

REMOVAL.............................35

INSTALLATION.........................35

FUEL INJECTOR

DESCRIPTION

FUEL INJECTOR......................35

OPERATION...........................36

STANDARD PROCEDURE

STANDARD PROCEDURE - INJECTOR

CLASSIFICATION.....................37

CLEANING FUEL INJECTORS............38

REMOVAL.............................38

INSTALLATION.........................39

FUEL PRESSURE SENSOR

DESCRIPTION.........................39

OPERATION...........................39REMOVAL.............................39

INSTALLATION.........................40

FUEL PRESSURE SOLENOID

DESCRIPTION.........................40

OPERATION...........................40

STANDARD PROCEDURE - FUEL PRESSURE

SOLENOID TEST......................41

REMOVAL.............................41

INSTALLATION.........................41

FUEL TEMPERATURE SENSOR

DESCRIPTION.........................42

OPERATION...........................42

REMOVAL.............................42

INSTALLATION.........................42

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................42

OPERATION...........................43

REMOVAL.............................43

INSTALLATION.........................43

INTAKE AIR PRESSURE SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................43

INSTALLATION.........................44

MANIFOLD AIR FLOW (MAF) SENSOR

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................45

O2 SENSOR

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................48

INSTALLATION.........................48

VAFUEL INJECTION 14 - 31

Page 1713 of 2305

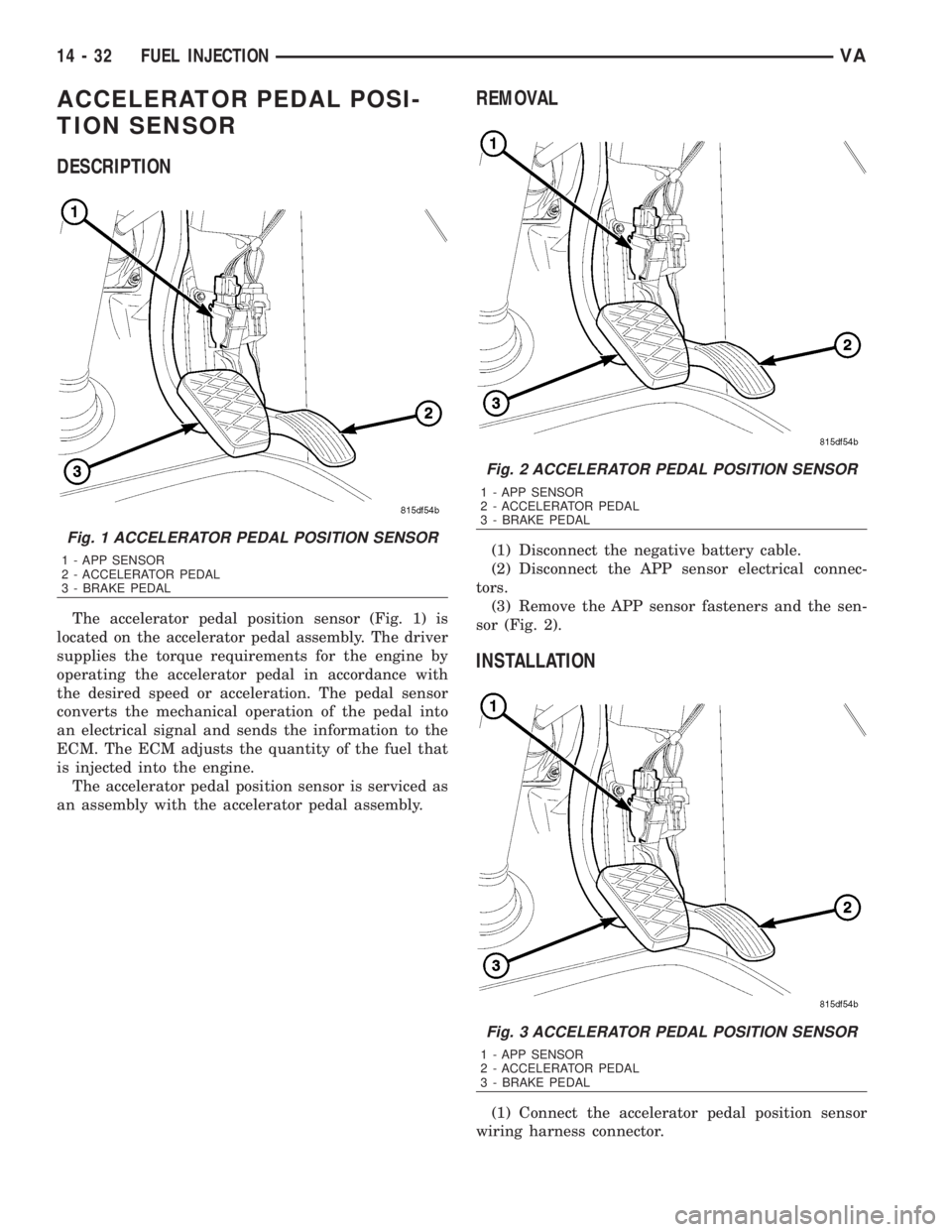

ACCELERATOR PEDAL POSI-

TION SENSOR

DESCRIPTION

The accelerator pedal position sensor (Fig. 1) is

located on the accelerator pedal assembly. The driver

supplies the torque requirements for the engine by

operating the accelerator pedal in accordance with

the desired speed or acceleration. The pedal sensor

converts the mechanical operation of the pedal into

an electrical signal and sends the information to the

ECM. The ECM adjusts the quantity of the fuel that

is injected into the engine.

The accelerator pedal position sensor is serviced as

an assembly with the accelerator pedal assembly.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the APP sensor electrical connec-

tors.

(3) Remove the APP sensor fasteners and the sen-

sor (Fig. 2).

INSTALLATION

(1) Connect the accelerator pedal position sensor

wiring harness connector.

Fig. 1 ACCELERATOR PEDAL POSITION SENSOR

1 - APP SENSOR

2 - ACCELERATOR PEDAL

3 - BRAKE PEDAL

Fig. 2 ACCELERATOR PEDAL POSITION SENSOR

1 - APP SENSOR

2 - ACCELERATOR PEDAL

3 - BRAKE PEDAL

Fig. 3 ACCELERATOR PEDAL POSITION SENSOR

1 - APP SENSOR

2 - ACCELERATOR PEDAL

3 - BRAKE PEDAL

14 - 32 FUEL INJECTIONVA

Page 1714 of 2305

(2) Position the sensor (Fig. 3) and install the fas-

teners.

(3) Connect the negative battery cable.

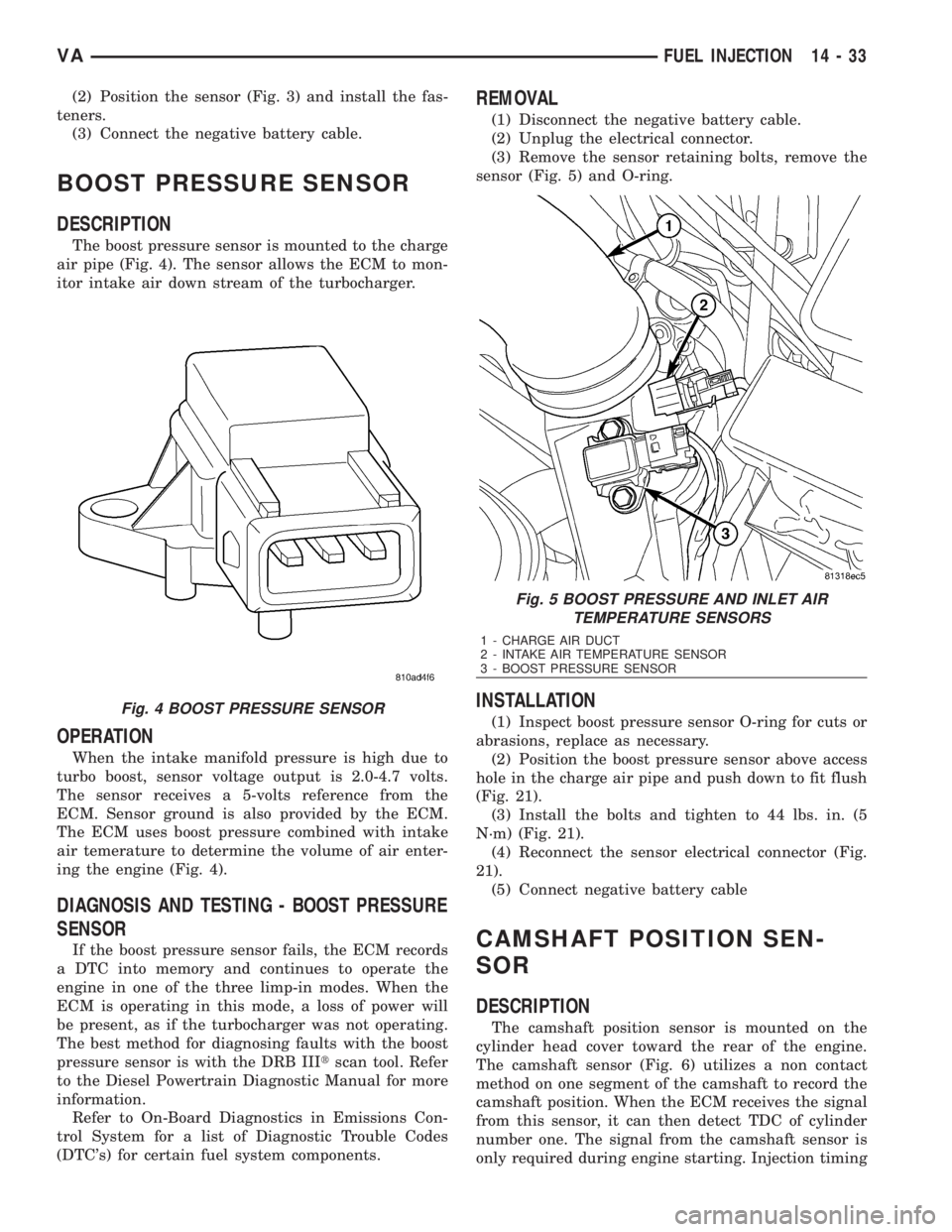

BOOST PRESSURE SENSOR

DESCRIPTION

The boost pressure sensor is mounted to the charge

air pipe (Fig. 4). The sensor allows the ECM to mon-

itor intake air down stream of the turbocharger.

OPERATION

When the intake manifold pressure is high due to

turbo boost, sensor voltage output is 2.0-4.7 volts.

The sensor receives a 5-volts reference from the

ECM. Sensor ground is also provided by the ECM.

The ECM uses boost pressure combined with intake

air temerature to determine the volume of air enter-

ing the engine (Fig. 4).

DIAGNOSIS AND TESTING - BOOST PRESSURE

SENSOR

If the boost pressure sensor fails, the ECM records

a DTC into memory and continues to operate the

engine in one of the three limp-in modes. When the

ECM is operating in this mode, a loss of power will

be present, as if the turbocharger was not operating.

The best method for diagnosing faults with the boost

pressure sensor is with the DRB IIItscan tool. Refer

to the Diesel Powertrain Diagnostic Manual for more

information.

Refer to On-Board Diagnostics in Emissions Con-

trol System for a list of Diagnostic Trouble Codes

(DTC's) for certain fuel system components.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Unplug the electrical connector.

(3) Remove the sensor retaining bolts, remove the

sensor (Fig. 5) and O-ring.

INSTALLATION

(1) Inspect boost pressure sensor O-ring for cuts or

abrasions, replace as necessary.

(2) Position the boost pressure sensor above access

hole in the charge air pipe and push down to fit flush

(Fig. 21).

(3) Install the bolts and tighten to 44 lbs. in. (5

N´m) (Fig. 21).

(4) Reconnect the sensor electrical connector (Fig.

21).

(5) Connect negative battery cable

CAMSHAFT POSITION SEN-

SOR

DESCRIPTION

The camshaft position sensor is mounted on the

cylinder head cover toward the rear of the engine.

The camshaft sensor (Fig. 6) utilizes a non contact

method on one segment of the camshaft to record the

camshaft position. When the ECM receives the signal

from this sensor, it can then detect TDC of cylinder

number one. The signal from the camshaft sensor is

only required during engine starting. Injection timing

Fig. 4 BOOST PRESSURE SENSOR

Fig. 5 BOOST PRESSURE AND INLET AIR

TEMPERATURE SENSORS

1 - CHARGE AIR DUCT

2 - INTAKE AIR TEMPERATURE SENSOR

3 - BOOST PRESSURE SENSOR

VAFUEL INJECTION 14 - 33

Page 1715 of 2305

is synchronized by means of the camshaft signal and

the crankshaft signal.

OPERATION

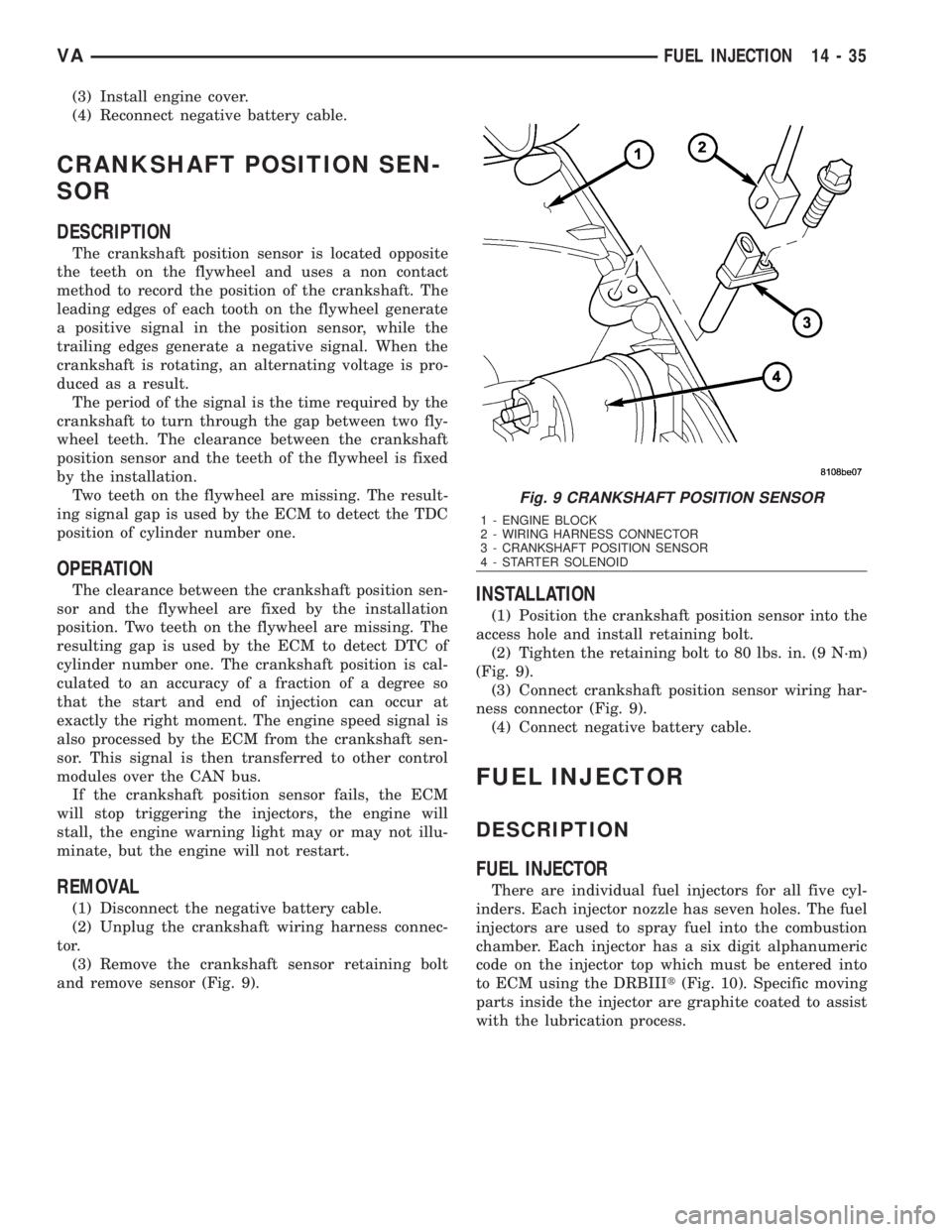

On the camshaft sensor's signal line, a high signal

correspons to a voltage of 0-5V. If the segment

machined into the exhaust camshaft sprocket is posi-

tioned opposite the camshaft sensor, the camshaft

signal is low, approximately 0V. This signal is used

by the engine control module (ECM) for detecting

ignition TDC of cylinder 1 as the engine rotates. If no

signal is supplied by the camshaft position sensor,

the vehicle will not start because cylinder order can

not be detected.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover

(3) Disconnect camshaft position sensor electrical

connector (Fig. 7).

(4) Remove retaining bolt and remove sensor (Fig.

7).

INSTALLATION

(1) Install camshaft position sensor and tighten

bolt (Fig. 8).

(2) Reconnect electrical connector (Fig. 8).

Fig. 6 CAMSHAFT POSITION SENSOR

Fig. 7 CAM POSITION SENSOR

1 - WIRING HARNESS CONNECTOR

2 - CAM POSITION SENSOR

3 - O-RING

4 - CYLINDER HEAD COVER

Fig. 8 CAM POSITION SENSOR

1 - WIRING HARNESS CONNECTOR

2 - CAM POSITION SENSOR

3 - O-RING

4 - CYLINDER HEAD COVER

14 - 34 FUEL INJECTIONVA

Page 1716 of 2305

(3) Install engine cover.

(4) Reconnect negative battery cable.

CRANKSHAFT POSITION SEN-

SOR

DESCRIPTION

The crankshaft position sensor is located opposite

the teeth on the flywheel and uses a non contact

method to record the position of the crankshaft. The

leading edges of each tooth on the flywheel generate

a positive signal in the position sensor, while the

trailing edges generate a negative signal. When the

crankshaft is rotating, an alternating voltage is pro-

duced as a result.

The period of the signal is the time required by the

crankshaft to turn through the gap between two fly-

wheel teeth. The clearance between the crankshaft

position sensor and the teeth of the flywheel is fixed

by the installation.

Two teeth on the flywheel are missing. The result-

ing signal gap is used by the ECM to detect the TDC

position of cylinder number one.

OPERATION

The clearance between the crankshaft position sen-

sor and the flywheel are fixed by the installation

position. Two teeth on the flywheel are missing. The

resulting gap is used by the ECM to detect DTC of

cylinder number one. The crankshaft position is cal-

culated to an accuracy of a fraction of a degree so

that the start and end of injection can occur at

exactly the right moment. The engine speed signal is

also processed by the ECM from the crankshaft sen-

sor. This signal is then transferred to other control

modules over the CAN bus.

If the crankshaft position sensor fails, the ECM

will stop triggering the injectors, the engine will

stall, the engine warning light may or may not illu-

minate, but the engine will not restart.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Unplug the crankshaft wiring harness connec-

tor.

(3) Remove the crankshaft sensor retaining bolt

and remove sensor (Fig. 9).

INSTALLATION

(1) Position the crankshaft position sensor into the

access hole and install retaining bolt.

(2) Tighten the retaining bolt to 80 lbs. in. (9 N´m)

(Fig. 9).

(3) Connect crankshaft position sensor wiring har-

ness connector (Fig. 9).

(4) Connect negative battery cable.

FUEL INJECTOR

DESCRIPTION

FUEL INJECTOR

There are individual fuel injectors for all five cyl-

inders. Each injector nozzle has seven holes. The fuel

injectors are used to spray fuel into the combustion

chamber. Each injector has a six digit alphanumeric

code on the injector top which must be entered into

to ECM using the DRBIIIt(Fig. 10). Specific moving

parts inside the injector are graphite coated to assist

with the lubrication process.

Fig. 9 CRANKSHAFT POSITION SENSOR

1 - ENGINE BLOCK

2 - WIRING HARNESS CONNECTOR

3 - CRANKSHAFT POSITION SENSOR

4 - STARTER SOLENOID

VAFUEL INJECTION 14 - 35

Page 1717 of 2305

OPERATION

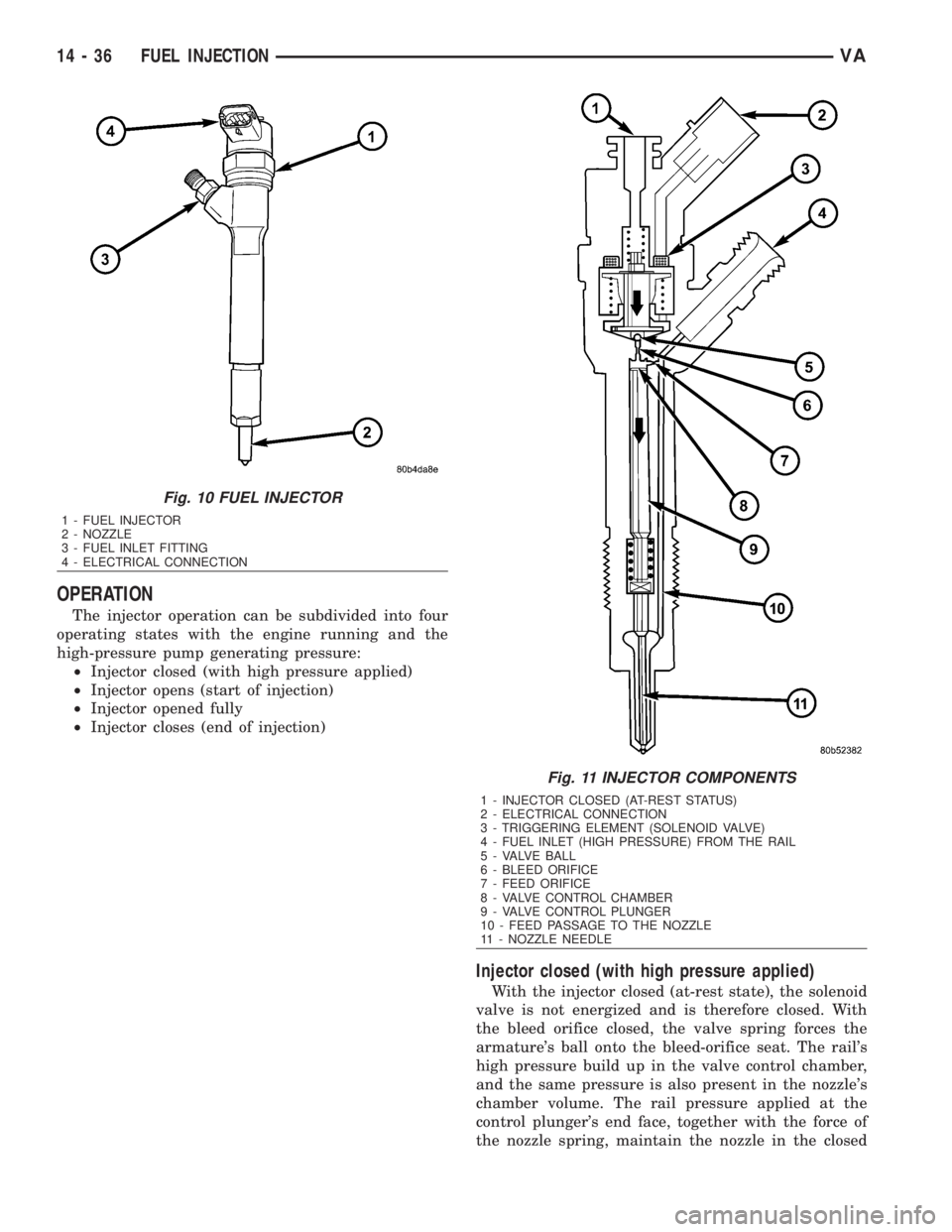

The injector operation can be subdivided into four

operating states with the engine running and the

high-pressure pump generating pressure:

²Injector closed (with high pressure applied)

²Injector opens (start of injection)

²Injector opened fully

²Injector closes (end of injection)

Injector closed (with high pressure applied)

With the injector closed (at-rest state), the solenoid

valve is not energized and is therefore closed. With

the bleed orifice closed, the valve spring forces the

armature's ball onto the bleed-orifice seat. The rail's

high pressure build up in the valve control chamber,

and the same pressure is also present in the nozzle's

chamber volume. The rail pressure applied at the

control plunger's end face, together with the force of

the nozzle spring, maintain the nozzle in the closed

Fig. 10 FUEL INJECTOR

1 - FUEL INJECTOR

2 - NOZZLE

3 - FUEL INLET FITTING

4 - ELECTRICAL CONNECTION

Fig. 11 INJECTOR COMPONENTS

1 - INJECTOR CLOSED (AT-REST STATUS)

2 - ELECTRICAL CONNECTION

3 - TRIGGERING ELEMENT (SOLENOID VALVE)

4 - FUEL INLET (HIGH PRESSURE) FROM THE RAIL

5 - VALVE BALL

6 - BLEED ORIFICE

7 - FEED ORIFICE

8 - VALVE CONTROL CHAMBER

9 - VALVE CONTROL PLUNGER

10 - FEED PASSAGE TO THE NOZZLE

11 - NOZZLE NEEDLE

14 - 36 FUEL INJECTIONVA

Page 1718 of 2305

position against the opening forces applied to its

pressure stage (Fig. 11).

Injector opens (start of injection)

The solenoid valve is energized with the pickup

current which serves to ensure that it open quickly.

The force exerted by the triggered solenoid now

exceeds that of the valve spring and the armature

opens the bleed orifice. Almost immediately, the high-

level pick-up current is reduced to the lower holding

current required for the electromagnet. This is possi-

ble due to the magnetic circuit's air gap now being

smaller. When the bleed orifice opens, fuel can flow

from the valve control chamber into the cavity situ-

ated above it, and from there via the fuel return to

the tank. The bleed orifice prevents complete pres-

sure balance, and the pressure in the valve control

chamber sinks as a result. This leads to the pressure

in the valve-control chamber being lower than that in

the nozzle's chamber volume which is still at the

same pressure level as the rail. The reduced pressure

in the valve-control chamber causes a reduction in

the force exerted on the control plunger, the nozzle

needle open as a result, and injection starts (Fig. 11).

Injector opens fully

The control plunger reaches its upper stop where it

remains supported by a cushion of fuel which is gen-

erated by the flow of fuel between the bleed and feed

orifices. The injector nozzle has now opened fully,

and the fuel is injected into the combustion chamber

at a pressure almost equal to that in the fuel rail

(Fig. 11).

Injector closes (end of injection)

As soon as the solenoid valve is no longer trig-

gered, the valve spring forces the armature down-

wards and the ball closes the bleed orifice. The

armature is a 2±piece design. Here, although the

armature plate is guided by a driver shoulder in its

downward movement, it can ªoverspringº with the

return spring so that it exerts no downwards-acting

forces on the armature and the ball. The closing of

the bleed orifice lead to pressure build up in the con-

trol chamber via the input from the feed orifice. This

pressure is the same as that in the rail and exerts an

increased force on the control plunger through its

end face. This force, together with that of the spring,

now exceeds the force exerted by the chamber volume

and the nozzle needle closes. Injection ceases as soon

as the nozzle needle comes up against its bottom stop

again (Fig. 11).

STANDARD PROCEDURE

STANDARD PROCEDURE - INJECTOR CLASSI-

FICATION

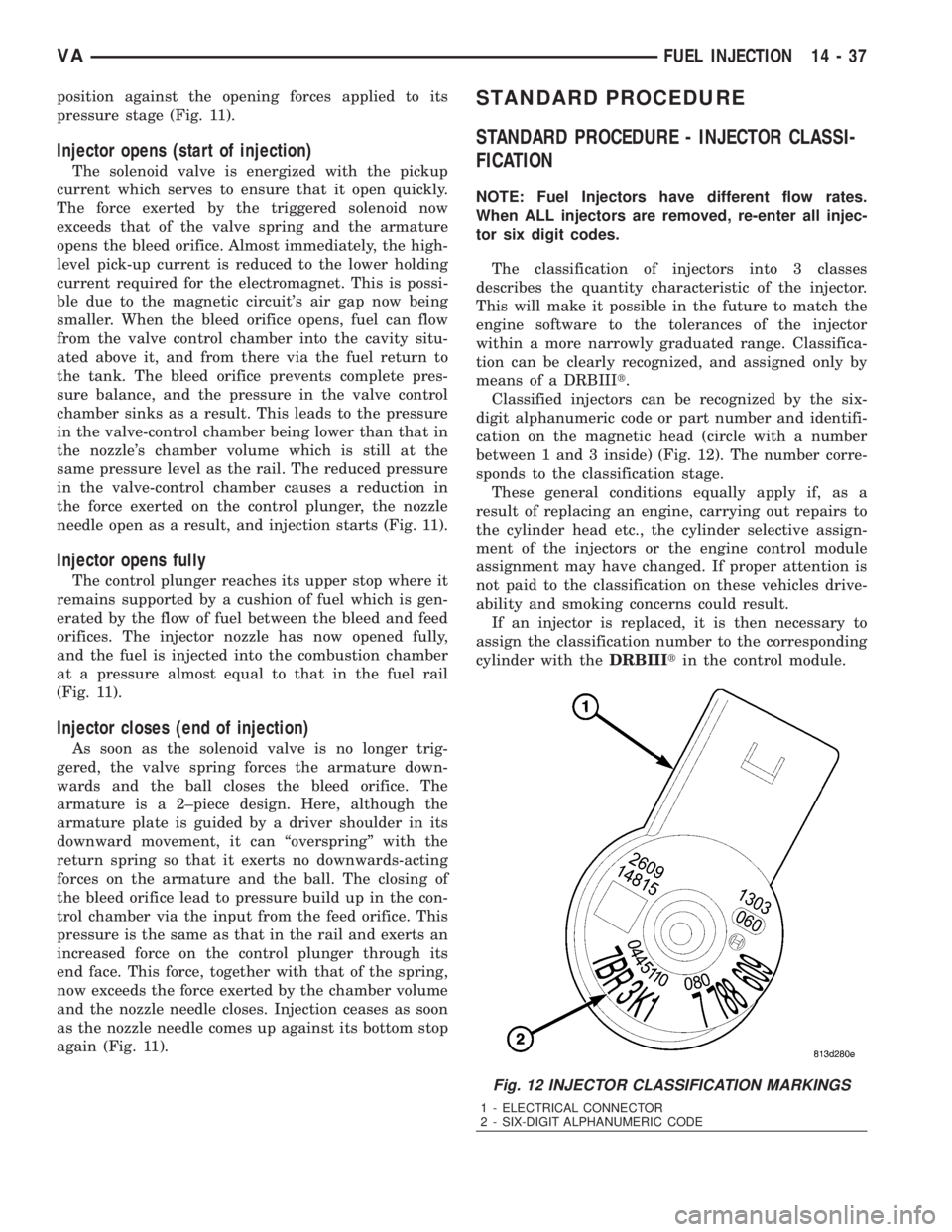

NOTE: Fuel Injectors have different flow rates.

When ALL injectors are removed, re-enter all injec-

tor six digit codes.

The classification of injectors into 3 classes

describes the quantity characteristic of the injector.

This will make it possible in the future to match the

engine software to the tolerances of the injector

within a more narrowly graduated range. Classifica-

tion can be clearly recognized, and assigned only by

means of a DRBIIIt.

Classified injectors can be recognized by the six-

digit alphanumeric code or part number and identifi-

cation on the magnetic head (circle with a number

between 1 and 3 inside) (Fig. 12). The number corre-

sponds to the classification stage.

These general conditions equally apply if, as a

result of replacing an engine, carrying out repairs to

the cylinder head etc., the cylinder selective assign-

ment of the injectors or the engine control module

assignment may have changed. If proper attention is

not paid to the classification on these vehicles drive-

ability and smoking concerns could result.

If an injector is replaced, it is then necessary to

assign the classification number to the corresponding

cylinder with theDRBIIItin the control module.

Fig. 12 INJECTOR CLASSIFICATION MARKINGS

1 - ELECTRICAL CONNECTOR

2 - SIX-DIGIT ALPHANUMERIC CODE

VAFUEL INJECTION 14 - 37

Page 1719 of 2305

INJECTOR CLASSIFICATION PROCEDURE

(1) Turn ignition switch ªONº.

(2) Using a DRB IIItand select ENGINE then

MISCELLANEOUS.

(3) Select LEARN INJECTORS.

(4) Using the up and down arrows, scroll to the

appropriate injector.

(5) Using the right and left arrows, set injector to

proper classification.

(6) Once injectors are classified, cycle ignition to

complete.

CLEANING FUEL INJECTORS

NOTE: Before cleaning the injector recesses, seal

the injector holes in the injector recesses with the

appropriate pin to prevent debris from falling into

the recesses and entering the motor.

(1) Seal the injector holes inside the cylinder head

recesses.

(2) Wipe out injector recesses with a non-woven

cloth, then clean with a cylinder brush.

(3) Clean the bottom of the cylinder recess with a

round brush.

(4) Blow out the recess and clean again with a

non-woven cloth and cover over.

(5) Perform these steps for each injector recess.

NOTE: DO NOT clean the tip of the injector with a

wire brush. Use a non - woven cloth.

(6) Clean injector body with a wire brush.

(7) Clean injector tips with a non-woven cloth.

NOTE: Do Not apply antiseize lubricant to the injec-

tor nozzle area.

(8) Grease injector body with anti seize lubricant.

NOTE: Always replace the seals that seal off the

injectors at the cylinder head to the combustion

chamber and replace the retaining screws.

REMOVAL

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

NOTE: When removing injectors, the seal rings and

retaining stretch bolts must always be replaced.

Coat the injector body with the anti-seize com-pound before installing. Keep lubricant away from

the injector nozzle.

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove the fuel return hose locking clamps at

the injector and remove return hose.

(4) Disconnect the injector electrical connector

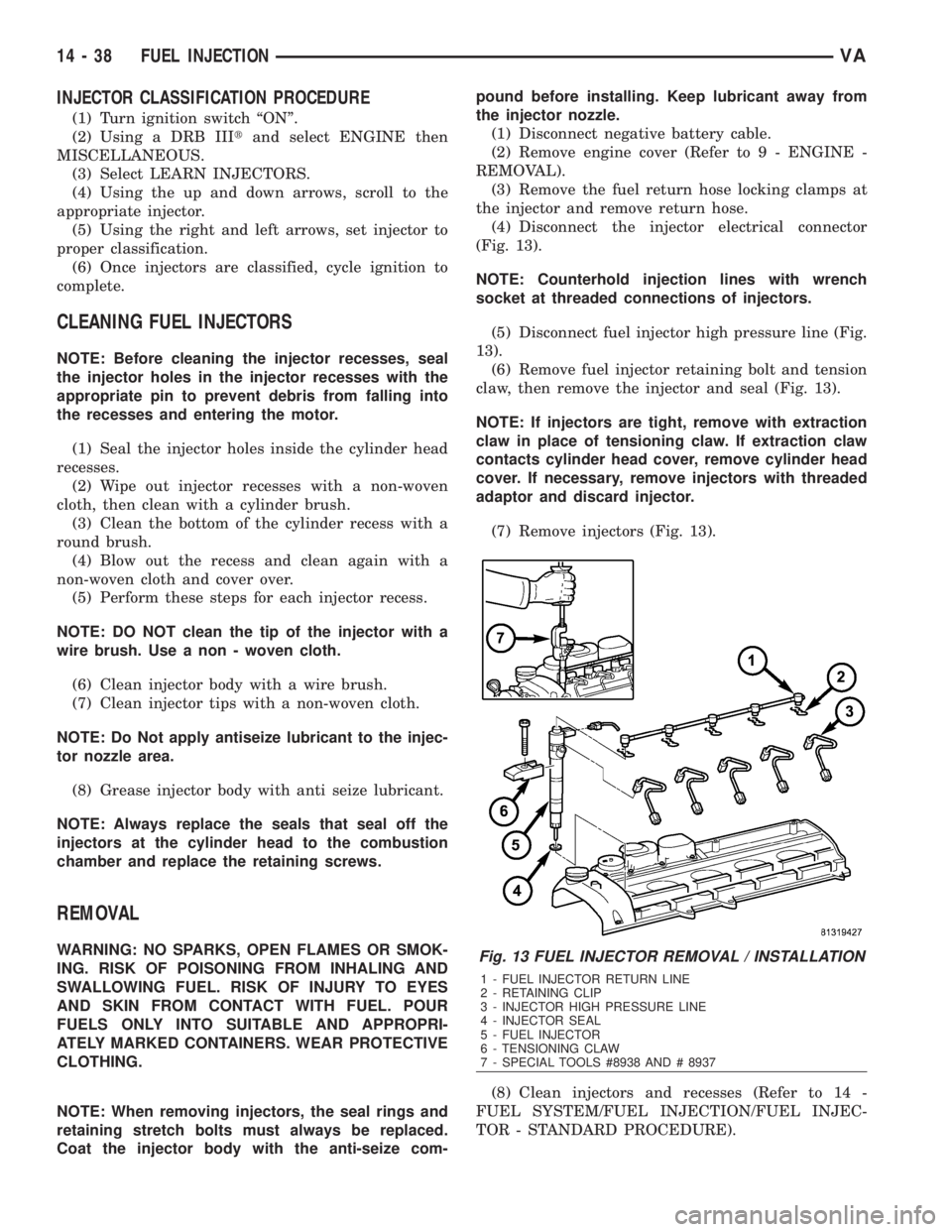

(Fig. 13).

NOTE: Counterhold injection lines with wrench

socket at threaded connections of injectors.

(5) Disconnect fuel injector high pressure line (Fig.

13).

(6) Remove fuel injector retaining bolt and tension

claw, then remove the injector and seal (Fig. 13).

NOTE: If injectors are tight, remove with extraction

claw in place of tensioning claw. If extraction claw

contacts cylinder head cover, remove cylinder head

cover. If necessary, remove injectors with threaded

adaptor and discard injector.

(7) Remove injectors (Fig. 13).

(8) Clean injectors and recesses (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - STANDARD PROCEDURE).Fig. 13 FUEL INJECTOR REMOVAL / INSTALLATION

1 - FUEL INJECTOR RETURN LINE

2 - RETAINING CLIP

3 - INJECTOR HIGH PRESSURE LINE

4 - INJECTOR SEAL

5 - FUEL INJECTOR

6 - TENSIONING CLAW

7 - SPECIAL TOOLS #8938 AND # 8937

14 - 38 FUEL INJECTIONVA

Page 1720 of 2305

INSTALLATION

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

NOTE: When removing injectors, the seal rings and

retaining stretch bolts must always be replaced.

Coat the injector body with the anti-seize com-

pound before installing. Keep lubricant away from

the injector nozzle.

(1) Clean injectors and recesses (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - STANDARD PROCEDURE).

(2) Coat injector body with anti seize lubricant

then install injectors with new seals.

(3) Install tensioning claws with new screws at

injectors. Tighten screws in two stages, 7 N´m (62

lbs. in.) then 90É (Fig. 13).

NOTE: If locking clamp has been pulled off at injec-

tor, the locking clamp must be replaced.

(4) Position fuel return line at injectors and secure

locking clamps (Fig. 13).

NOTE: Counterhold injection lines with wrench

socket at threaded connections of injectors. DO

NOT over tighten.

(5) Install high pressure injection lines (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- INSTALLATION).

(6) Reconnect injector electrical connectors (Fig.

13).

(7) Connect negative battery cable.

NOTE: Fuel Injectors have different flow rates.

When injectors are removed, re-enter all injector six

digit codes.

(8) Program all injector codes into the ECM using

the scan tool.

(9) Start engine, allow to run, turn engine off and

inspect for leaks (Refer to 14 - FUEL SYSTEM -

WARNING).

CAUTION: Care must be taken when installing the

engine cover. Assure the proper routing of the fuel

injector return fuel hose to the banjo bolt fitting in

the left rear corner of the cover. Failure to do so

may pinch or damage the hose causing fuel leakage

or a driveability concern.(10) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION)..

FUEL PRESSURE SENSOR

DESCRIPTION

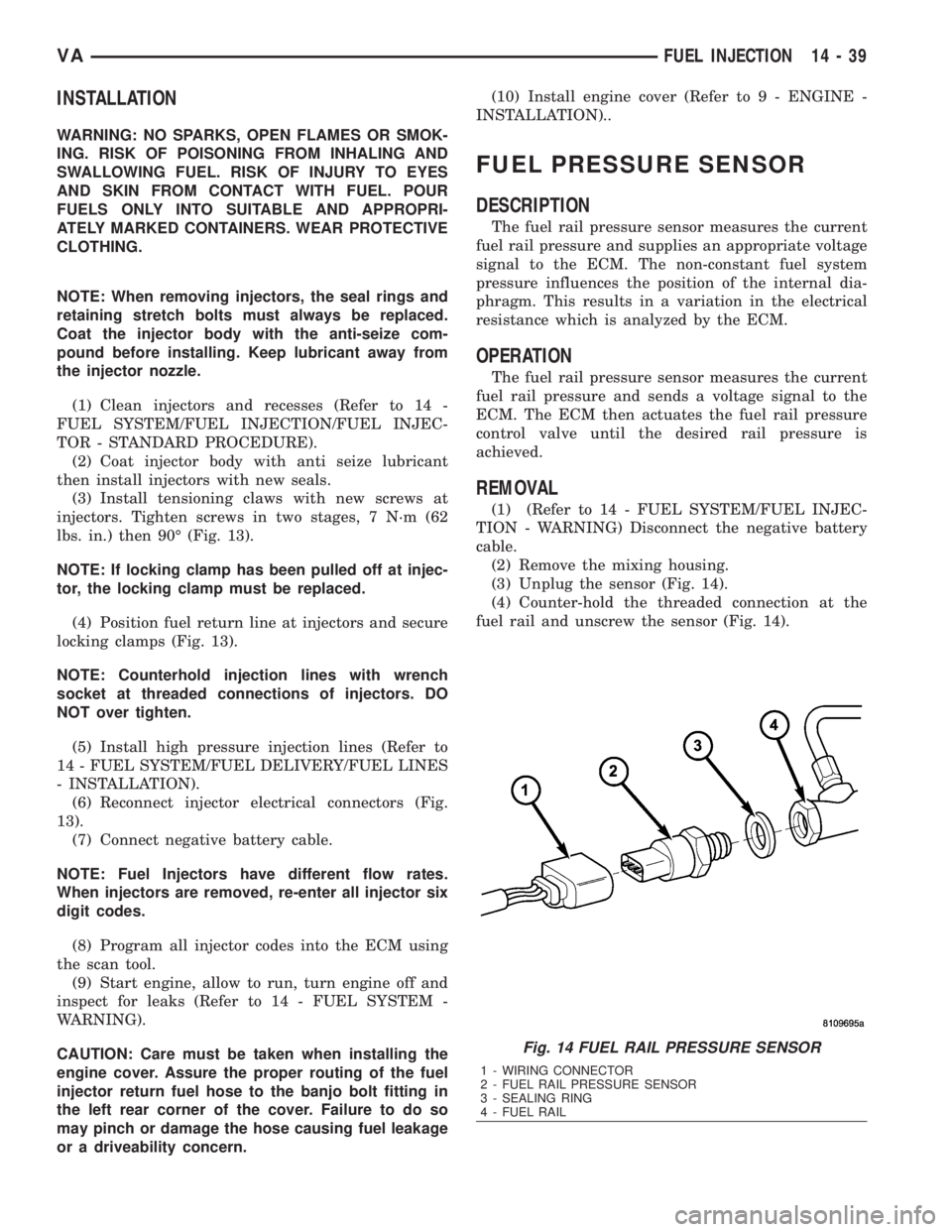

The fuel rail pressure sensor measures the current

fuel rail pressure and supplies an appropriate voltage

signal to the ECM. The non-constant fuel system

pressure influences the position of the internal dia-

phragm. This results in a variation in the electrical

resistance which is analyzed by the ECM.

OPERATION

The fuel rail pressure sensor measures the current

fuel rail pressure and sends a voltage signal to the

ECM. The ECM then actuates the fuel rail pressure

control valve until the desired rail pressure is

achieved.

REMOVAL

(1) (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION - WARNING) Disconnect the negative battery

cable.

(2) Remove the mixing housing.

(3) Unplug the sensor (Fig. 14).

(4) Counter-hold the threaded connection at the

fuel rail and unscrew the sensor (Fig. 14).

Fig. 14 FUEL RAIL PRESSURE SENSOR

1 - WIRING CONNECTOR

2 - FUEL RAIL PRESSURE SENSOR

3 - SEALING RING

4 - FUEL RAIL

VAFUEL INJECTION 14 - 39