MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1741 of 2305

(4) Slowly turn the steering wheel lock-to-lock 20

times with the engine off while checking the fluid

level.

NOTE: For vehicles with long return lines or oil

coolers turn wheel 40 times.

(5) Start the engine. With the engine idling main-

tain the fluid level.

(6) Lower the front wheels and let the engine idle

for two minutes.

(7) Turn the steering wheel in both direction and

verify power assist and quiet operation of the pump.

If the fluid is extremely foamy or milky looking,

allow the vehicle to stand a few minutes and repeat

the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - FLUSHING POWER

STEERING SYSTEM

Flushing is required when the power steering/hy-

draulic booster system fluid has become contami-

nated. Contaminated fluid in the steering/booster

system can cause seal deterioration and affect steer-

ing gear/booster spool valve operation.

(1) Raise the front end of the vehicle off the

ground until the wheels are free to turn.

(2) Remove the return line from the pump.

NOTE: If vehicle is equipped with a hydraulic

booster remove both return lines from the pump.

(3) Plug the return line port/ports at the pump.

(4) Position the return line/lines into a large con-

tainer to catch the fluid.

(5) While an assistant is filling the pump reservoir

start the engine.

(6) With the engine running at idle turn the wheel

back and forth.

NOTE: Do not contact or hold the wheel against the

steering stops.

(7) Run a quart of fluid through the system then

stop the engine and install the return line/lines.

(8) Fill the system with fluid and perform Steering

Pump Initial Operation, (Refer to 19 - STEERING/

PUMP - STANDARD PROCEDURE).

(9) Start the engine and run it for fifteen minutes

then stop the engine.

(10) Remove the return line/lines from the pump

and plug the pump port/ports.

(11) Pour fresh fluid into the reservoir and check

the draining fluid for contamination. If the fluid is

still contaminated, then flush the system again.(12) Install the return line/lines and perform

Steering Pump Initial Operation, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

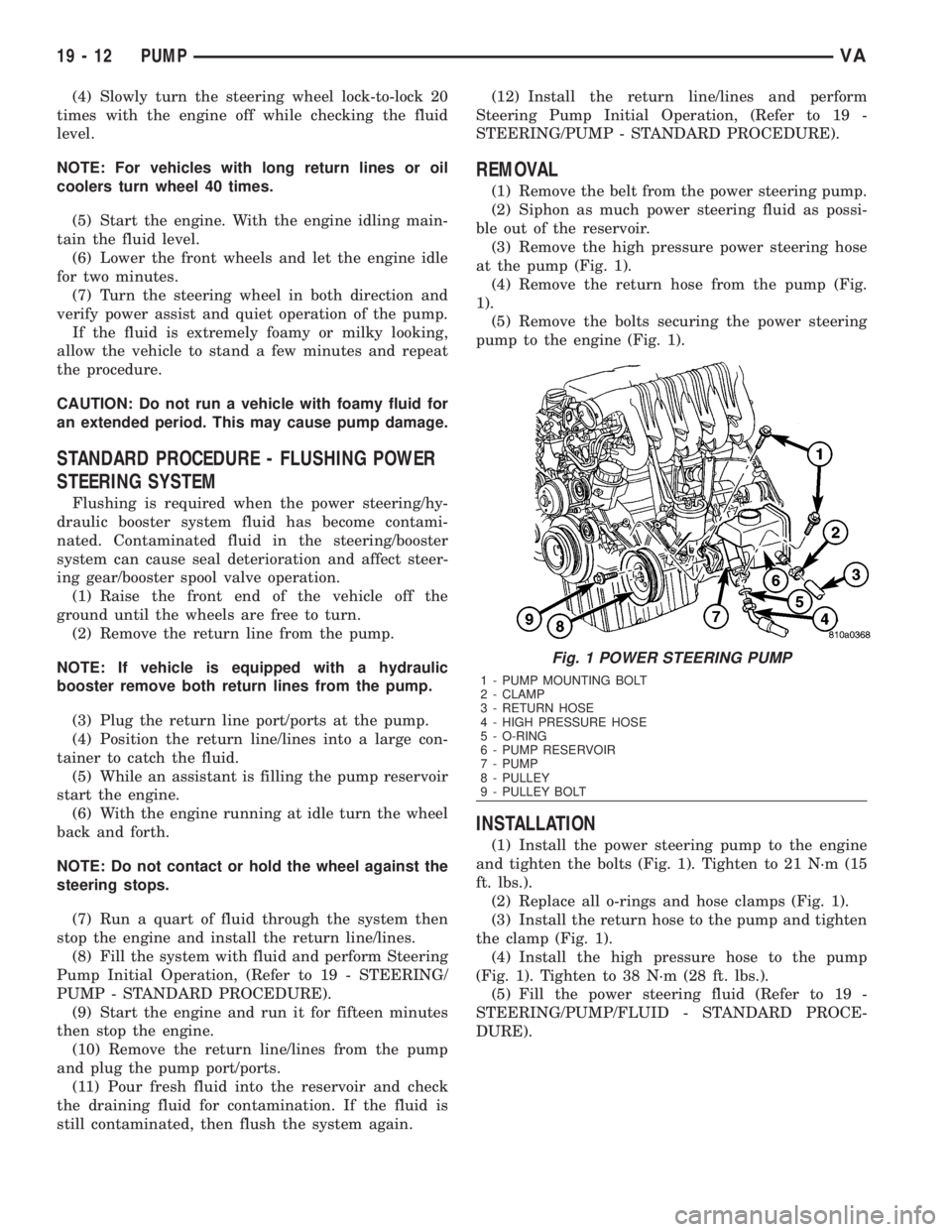

REMOVAL

(1) Remove the belt from the power steering pump.

(2) Siphon as much power steering fluid as possi-

ble out of the reservoir.

(3) Remove the high pressure power steering hose

at the pump (Fig. 1).

(4) Remove the return hose from the pump (Fig.

1).

(5) Remove the bolts securing the power steering

pump to the engine (Fig. 1).

INSTALLATION

(1) Install the power steering pump to the engine

and tighten the bolts (Fig. 1). Tighten to 21 N´m (15

ft. lbs.).

(2) Replace all o-rings and hose clamps (Fig. 1).

(3) Install the return hose to the pump and tighten

the clamp (Fig. 1).

(4) Install the high pressure hose to the pump

(Fig. 1). Tighten to 38 N´m (28 ft. lbs.).

(5) Fill the power steering fluid (Refer to 19 -

STEERING/PUMP/FLUID - STANDARD PROCE-

DURE).

Fig. 1 POWER STEERING PUMP

1 - PUMP MOUNTING BOLT

2 - CLAMP

3 - RETURN HOSE

4 - HIGH PRESSURE HOSE

5 - O-RING

6 - PUMP RESERVOIR

7 - PUMP

8 - PULLEY

9 - PULLEY BOLT

19 - 12 PUMPVA

Page 1742 of 2305

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Power Steering Pump To

Timing Case Cover/Sup-

port21 15 185

High Pressure Flexible

Hose To Power Steering

Pump38 28 336

Power Steering Pulley To

Pump30 22 265

FLUID

STANDARD PROCEDURE

POWER STEERING PUMP FILL AND BLEED

PROCEDURE

(1) Remove the cap from the fluid reservoir.

Check cap seal for damage and replace if

needed.

(2) Fill the power steering pump with approved

fluid (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION).Do not fill fluid

beyond the MAX mark.

(3) Raise the vehicles front wheels off the ground.

(4) With the engine off turn the steering wheel

from right to left.Perform this step until all the

bubble formations can no longer be seen in the

power steering reservoir.

(5) Start the engine and turn the steering wheel

with the engine at idle speed then shut the engine off

and check for correct oil level and no bubble in the

system.

(6) Reinstall power steering cap tightly.

(7) Test the system for leaks and proper operation.

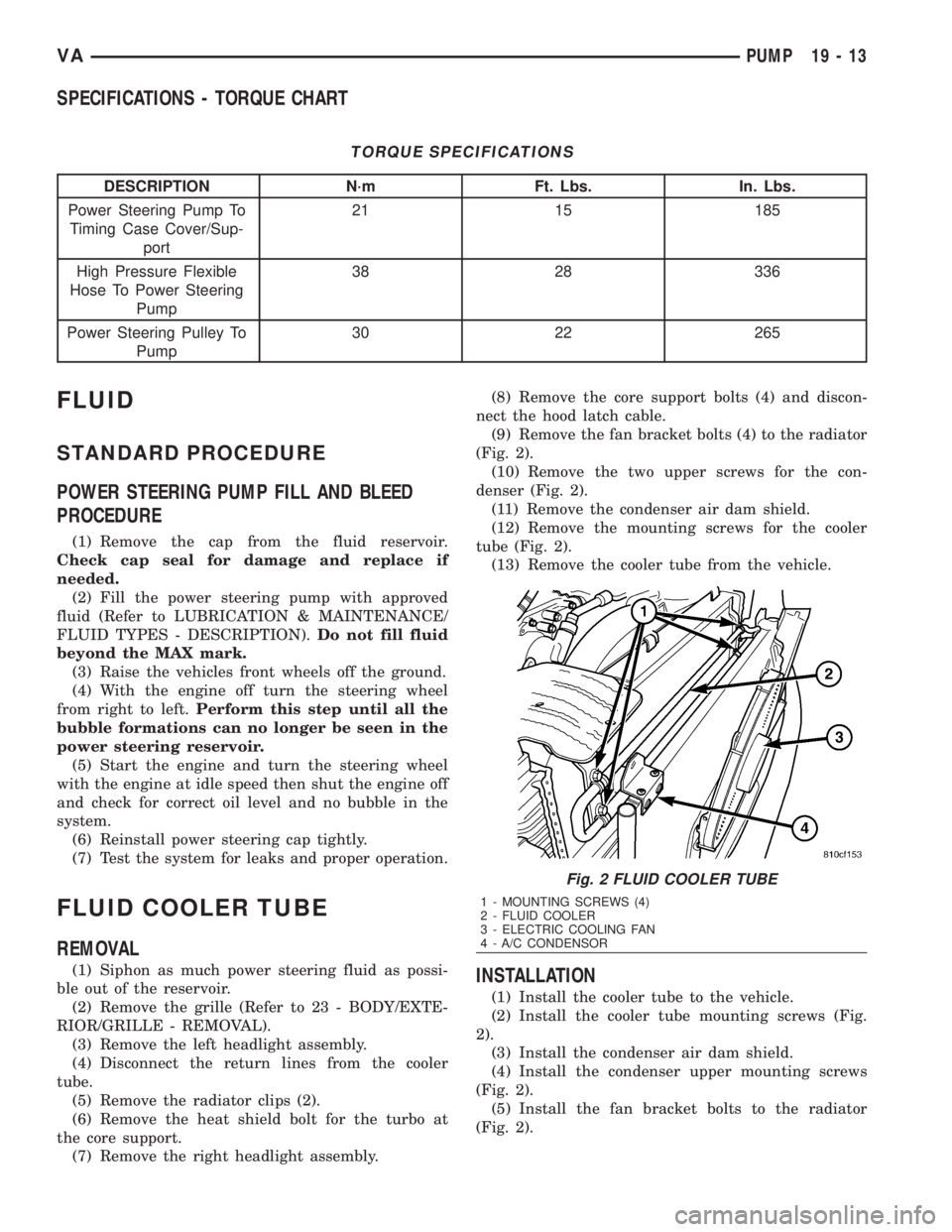

FLUID COOLER TUBE

REMOVAL

(1) Siphon as much power steering fluid as possi-

ble out of the reservoir.

(2) Remove the grille (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL).

(3) Remove the left headlight assembly.

(4) Disconnect the return lines from the cooler

tube.

(5) Remove the radiator clips (2).

(6) Remove the heat shield bolt for the turbo at

the core support.

(7) Remove the right headlight assembly.(8) Remove the core support bolts (4) and discon-

nect the hood latch cable.

(9) Remove the fan bracket bolts (4) to the radiator

(Fig. 2).

(10) Remove the two upper screws for the con-

denser (Fig. 2).

(11) Remove the condenser air dam shield.

(12) Remove the mounting screws for the cooler

tube (Fig. 2).

(13) Remove the cooler tube from the vehicle.INSTALLATION

(1) Install the cooler tube to the vehicle.

(2) Install the cooler tube mounting screws (Fig.

2).

(3) Install the condenser air dam shield.

(4) Install the condenser upper mounting screws

(Fig. 2).

(5) Install the fan bracket bolts to the radiator

(Fig. 2).

Fig. 2 FLUID COOLER TUBE

1 - MOUNTING SCREWS (4)

2 - FLUID COOLER

3 - ELECTRIC COOLING FAN

4 - A/C CONDENSOR

VAPUMP 19 - 13

Page 1743 of 2305

(6) Install the core support bolts and reconnect the

hood latch cable.

(7) Install the right headlight assembly.

(8) Install the bolt for the turbo shield at the core

support.

(9) Install the radiator clips.

(10) Install the return lines to the cooler tube.

(11) Install the left headlight assembly.

(12) Install the grille assembly (Refer to 23 -

BODY/EXTERIOR/GRILLE - INSTALLATION).

(13) Fill the power steering fluid (Refer to 19 -

STEERING/PUMP/FLUID - STANDARD PROCE-

DURE).

HOSES

REMOVAL

REMOVAL - PRESSURE HOSE

(1) Siphon as much power steering fluid as possi-

ble out of the reservoir.

(2) Disconnect the pressure hose at the pump.

(3) Disconnect the pressure hose at the steering

gear.

(4) Remove the pressure hose mounting bracket

from the gear.

(5) Remove the pressure hose from the vehicle.

REMOVAL - RETURN LINE FROM PUMP TO

COOLER TUBE

(1) Siphon as much power steering fluid as possi-

ble out of the reservoir.

(2) Disconnect the return line at the pump.

(3) Remove the grille (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL).

(4) Remove the left headlight assembly.

(5) Disconnect the return line at the cooler tube.

(6) Remove the return line from the vehicle.

REMOVAL - RETURN HOSE FROM GEAR TO

COOLER TUBE

(1) Siphon as much power steering fluid as possi-

ble out of the reservoir.

(2) Disconnect the return hose from the gear.

(3) Remove the grille (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL).

(4) Remove the left headlight assembly.

(5) Disconnect the return line at the cooler tube.

(6) Remove the return line from the vehicle.

INSTALLATION

INSTALLATION - PRESSURE HOSE

(1) Install the pressure hose to the vehicle.(2) Reconnect the pressure hose at the steering

gear. Tighten to 37 N´m (27 ft.lbs.).

(3) Install the pressure hose mounting bracket to

the steering gear.

(4) Reconnect the pressure hose at the power

steering pump. Tighten to 38 N´m (28 ft.lbs.).

(5) Fill the power steering fluid (Refer to 19 -

STEERING/PUMP/FLUID - STANDARD PROCE-

DURE).

INSTALLATION - RETURN LINE FROM PUMP

TO COOLER TUBE

(1) Install the return line to the vehicle.

(2) Reconnect the return line at the cooler tube.

(3) Install the left headlight assembly.

(4) Install the grille assembly (Refer to 23 - BODY/

EXTERIOR/GRILLE - INSTALLATION).

(5) Reconnect the return line at the power steering

pump.

(6) Fill the power steering fluid (Refer to 19 -

STEERING/PUMP/FLUID - STANDARD PROCE-

DURE).

INSTALLATION - RETURN HOSE FROM GEAR

TO COOLER TUBE

(1) Install the return line to the vehicle.

(2) Reconnect the return line at the cooler tube.

(3) Install the left headlight assembly.

(4) Install the grille assembly (Refer to 23 - BODY/

EXTERIOR/GRILLE - INSTALLATION).

(5) Reconnect the return line at the power steering

gear.

(6) Fill the power steering fluid (Refer to 19 -

STEERING/PUMP/FLUID - STANDARD

PROCEDURE).

19 - 14 PUMPVA

Page 1744 of 2305

TRANSMISSION

TABLE OF CONTENTS

page

AUTOMATIC TRANSMISSION NAG1 - SERVICE

INFORMATION............................1

AUTOMATIC TRANSMISSION NAG1 - SERVICE

INFORMATION

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION NAG1 - SERVICE

INFORMATION

DESCRIPTION..........................3

OPERATION............................4

DIAGNOSIS AND TESTING

AUTOMATIC TRANSMISSION............39

PRELIMINARY........................39

ROAD TESTING......................39

AUTOMATIC TRANSMISSION............40

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR......................42

REMOVAL.............................42

DISASSEMBLY.........................46

ASSEMBLY............................52

INSTALLATION.........................60

SCHEMATICS AND DIAGRAMS............65

SPECIFICATIONS - NAG1 AUTOMATIC

TRANSMISSION......................86

SPECIAL TOOLS - AUTOMATIC

TRANSMISSION - NAG1................87

INPUT CLUTCHES

DESCRIPTION.........................90

OPERATION...........................91

INPUT CLUTCH K1

DISASSEMBLY.........................92

ASSEMBLY............................94

INPUT CLUTCH K2

DISASSEMBLY.........................97

ASSEMBLY............................99

INPUT CLUTCH K3

DISASSEMBLY........................102

ASSEMBLY...........................103

ELECTROHYDRAULIC UNIT

DESCRIPTION........................105

OPERATION..........................112

REMOVAL............................120

DISASSEMBLY........................121

ASSEMBLY...........................125INSTALLATION........................129

FLUID AND FILTER

DESCRIPTION........................131

OPERATION..........................131

DIAGNOSIS AND TESTING

EFFECTS OF INCORRECT FLUID LEVEL . . 131

CAUSES OF BURNT FLUID.............132

FLUID CONTAMINATION...............132

STANDARD PROCEDURE

CHECK OIL LEVEL...................132

TRANSMISSION FILL.................133

FLUID/FILTER SERVICE...............134

FREEWHEELING CLUTCH

DESCRIPTION........................135

OPERATION..........................135

DISASSEMBLY........................136

ASSEMBLY...........................138

GEARSHIFT CABLE

DIAGNOSIS AND TESTING

GEARSHIFT CABLE..................138

REMOVAL............................139

INSTALLATION........................140

HOLDING CLUTCHES

DESCRIPTION........................141

OPERATION..........................142

HOLDING CLUTCH B1

DISASSEMBLY........................143

ASSEMBLY...........................145

HOLDING CLUTCH B2

DISASSEMBLY........................148

ASSEMBLY...........................150

INPUT SPEED SENSORS

DESCRIPTION........................153

OPERATION..........................154

OIL PUMP

DESCRIPTION........................154

OPERATION..........................154

DISASSEMBLY........................155

VATRANSMISSION 21 - 1

Page 1745 of 2305

INSPECTION.........................155

ASSEMBLY...........................156

OUTPUT SHAFT BEARING

REMOVAL............................156

INSTALLATION........................158

OUTPUT SHAFT SEAL

REMOVAL............................159

INSTALLATION........................159

PARK LOCK CABLE

REMOVAL............................160

INSTALLATION........................161

PISTONS

DESCRIPTION........................163

OPERATION..........................163

PLANETARY GEARTRAIN

DESCRIPTION........................164

OPERATION..........................165

DISASSEMBLY........................166

ASSEMBLY...........................167

SHIFT MECHANISM

DESCRIPTION........................168

OPERATION..........................168REMOVAL............................169

INSTALLATION........................170

SOLENOID

DESCRIPTION........................171

OPERATION..........................174

TEMPERATURE SENSOR/PARK-NEUTRAL

CONTACT

DESCRIPTION

PARK/NEUTRAL CONTACT.............176

TRANSMISSION TEMPERATURE SENSOR . 176

OPERATION

PARK/NEUTRAL CONTACT.............177

TRANSMISSION TEMPERATURE SENSOR . 177

TORQUE CONVERTER

DESCRIPTION........................178

OPERATION..........................182

REMOVAL............................183

INSTALLATION........................184

TORQUE CONVERTER HUB SEAL

REMOVAL............................184

INSTALLATION........................184

21 - 2 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1746 of 2305

AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION

DESCRIPTION

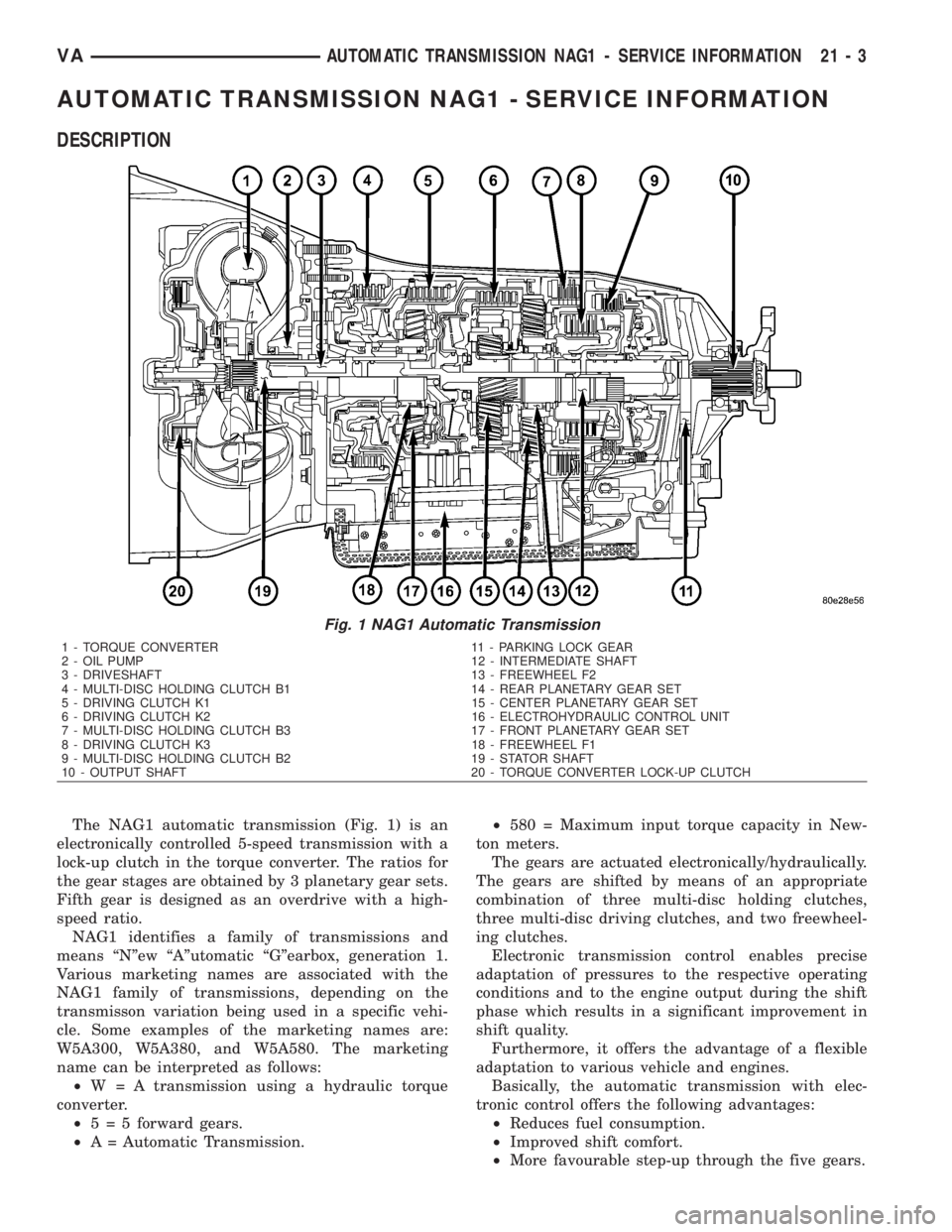

The NAG1 automatic transmission (Fig. 1) is an

electronically controlled 5-speed transmission with a

lock-up clutch in the torque converter. The ratios for

the gear stages are obtained by 3 planetary gear sets.

Fifth gear is designed as an overdrive with a high-

speed ratio.

NAG1 identifies a family of transmissions and

means ªNºew ªAºutomatic ªGºearbox, generation 1.

Various marketing names are associated with the

NAG1 family of transmissions, depending on the

transmisson variation being used in a specific vehi-

cle. Some examples of the marketing names are:

W5A300, W5A380, and W5A580. The marketing

name can be interpreted as follows:

²W = A transmission using a hydraulic torque

converter.

²5 = 5 forward gears.

²A = Automatic Transmission.²580 = Maximum input torque capacity in New-

ton meters.

The gears are actuated electronically/hydraulically.

The gears are shifted by means of an appropriate

combination of three multi-disc holding clutches,

three multi-disc driving clutches, and two freewheel-

ing clutches.

Electronic transmission control enables precise

adaptation of pressures to the respective operating

conditions and to the engine output during the shift

phase which results in a significant improvement in

shift quality.

Furthermore, it offers the advantage of a flexible

adaptation to various vehicle and engines.

Basically, the automatic transmission with elec-

tronic control offers the following advantages:

²Reduces fuel consumption.

²Improved shift comfort.

²More favourable step-up through the five gears.

Fig. 1 NAG1 Automatic Transmission

1 - TORQUE CONVERTER 11 - PARKING LOCK GEAR

2 - OIL PUMP 12 - INTERMEDIATE SHAFT

3 - DRIVESHAFT 13 - FREEWHEEL F2

4 - MULTI-DISC HOLDING CLUTCH B1 14 - REAR PLANETARY GEAR SET

5 - DRIVING CLUTCH K1 15 - CENTER PLANETARY GEAR SET

6 - DRIVING CLUTCH K2 16 - ELECTROHYDRAULIC CONTROL UNIT

7 - MULTI-DISC HOLDING CLUTCH B3 17 - FRONT PLANETARY GEAR SET

8 - DRIVING CLUTCH K3 18 - FREEWHEEL F1

9 - MULTI-DISC HOLDING CLUTCH B2 19 - STATOR SHAFT

10 - OUTPUT SHAFT 20 - TORQUE CONVERTER LOCK-UP CLUTCH

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 3

Page 1747 of 2305

²Increased service life and reliability.

²Lower maintenance costs.

TRANSMISSION IDENTIFICATION

The transmission can be generically identified

visually by the presence of a round 13-way connector

located near the front corner of the transmission oil

pan, on the right side. Specific transmission informa-

tion can be found stamped into a pad on the left side

of the transmission, above the oil pan rail.

TRANSMISSION GEAR RATIOS

The gear ratios for the NAG1 automatic transmis-

sion are as follows:

1st Gear............................3.59:1

2nd Gear............................2.19:1

3rd Gear............................1.41:1

4th Gear............................1.00:1

5th Gear............................0.83:1

Reverse.............................3.16:1

TRANSMISSION HOUSING

The converter housing and transmission are made

from a light alloy. These are bolted together and cen-

tered via the outer multi-disc carrier of multi-disc

holding clutch, B1. A coated intermediate plate pro-

vides the sealing. The oil pump and the outer multi-

disc carrier of the multi-disc holding clutch, B1, are

bolted to the converter housing. The stator shaft is

pressed into it and prevented from rotating by

splines. The electrohydraulic unit is bolted to the

transmission housing from underneath. A sheet

metal steel oil pan forms the closure.

MECHANICAL SECTION

The mechanical section consists of a input shaft,

output shaft, a sun gear shaft, and three planetary

gear sets which are coupled to each other. The plan-

etary gear sets each have four planetary pinion

gears. The oil pressure for the torque converter

lock-up clutch and clutch K2 is supplied through

bores in the input shaft. The oil pressure to clutch

K3 is transmitted through the output shaft. The

lubricating oil is distributed through additional bores

in both shafts. All the bearing points of the gear sets,

as well as the freewheeling clutches and actuators,

are supplied with lubricating oil. The parking lock

gear is connected to the output shaft via splines.

Freewheeling clutches F1 and F2 are used to opti-

mize the shifts. The front freewheel, F1, is supported

on the extension of the stator shaft on the transmis-

sion side and, in the locking direction, connects the

sun gear of the front planetary gear set to the trans-

mission housing. In the locking direction, the rear

freewheeling clutch, F2, connects the sun gear of the

center planetary gear set to the sun gear of the rear

planetary gear set.

ELECTROHYDRAULIC CONTROL UNIT

The electrohydraulic control unit comprises the

shift plate made from light alloy for the hydraulic

control and an electrical control unit. The electrical

control unit comprises of a supporting body made of

plastic, into which the electrical components are

assembled. The supporting body is mounted on the

shift plate and screwed to it.

Strip conductors inserted into the supporting body

make the connection between the electrical compo-

nents and a plug connector. The connection to the

wiring harness on the vehicle and the transmission

control module (TCM) is produced via this 13-pin

plug connector with a bayonet lock.

SHIFT GROUPS

The hydraulic control components (including actua-

tors) which are responsible for the pressure distribu-

tion before, during, and after a gear change are

described as a shift group. Each shift group contains

a command valve, a holding pressure shift valve, a

shift pressure shift valve, overlap regulating valve,

and a solenoid.

The hydraulic system contains three shift groups:

1-2/4-5, 2-3, and 3-4. Each shift group can also be

described as being in one of two possible states. The

active shift group is described as being in the shift

phase when it is actively engaging/disengaging a

clutch combination. The 1-2/4-5 shift group control

the B1 and K1 clutches. The 2-3 shift group controls

the K2 and K3 clutches. The 3-4 shift group controls

the K3 and B2 clutches.

OPERATION

The transmission control is divided into the elec-

tronic and hydraulic transmission control functions.

While the electronic transmission control is responsi-

ble for gear selection and for matching the pressures

to the torque to be transmitted, the transmission's

power supply control occurs via hydraulic elements

in the electrohydraulic control module. The oil supply

to the hydraulic elements, such as the hydrodynamic

torque converter, the shift elements and the hydrau-

lic transmission control, is provided by way of an oil

pump connected with the torque converter.

The Transmission Control Module (TCM) allows for

the precise adaptation of pressures to the correspond-

ing operating conditions and to the engine output

during the gearshift phase, resulting in a noticeable

improvement in shift quality. The engine speed limit

can be reached in the individual gears at full throttle

and kickdown. The shift range can be changed in the

forward gears while driving, but the TCM employs a

downshift safeguard to prevent over-revving the

engine. The system offers the additional advantage of

21 - 4 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1748 of 2305

flexible adaptation to different vehicle and engine

variants.

EMERGENCY RUNNING FUNCTION

In order to ensure a safe driving state and to pre-

vent damage to the automatic transmission, the TCM

control module switches to limp-home mode in the

event of critical faults. A diagnostic trouble code

(DTC) assigned to the fault is stored in memory. All

solenoid and regulating valves are thus de-energized.

The net effect is:

²The last engaged gear remains engaged.

²The modulating pressure and shift pressures

rise to the maximum levels.

²The torque converter lockup clutch is deacti-

vated.

In order to preserve the operability of the vehicle

to some extent, the hydraulic control can be used to

engage 2nd gear or reverse using the following pro-

cedure:²Stop the vehicle.

²Move selector lever to ªPº.

²Switch off engine.

²Wait at least 10 seconds.

²Start engine.

²Move selector lever to D: 2nd gear.

²Move selector lever to R: Reverse gear.

The limp-home function remains active until the

DTC is rectified or the stored DTC is erased with the

appropriate scan tool. Sporadic faults can be reset

via ignition OFF/ON.

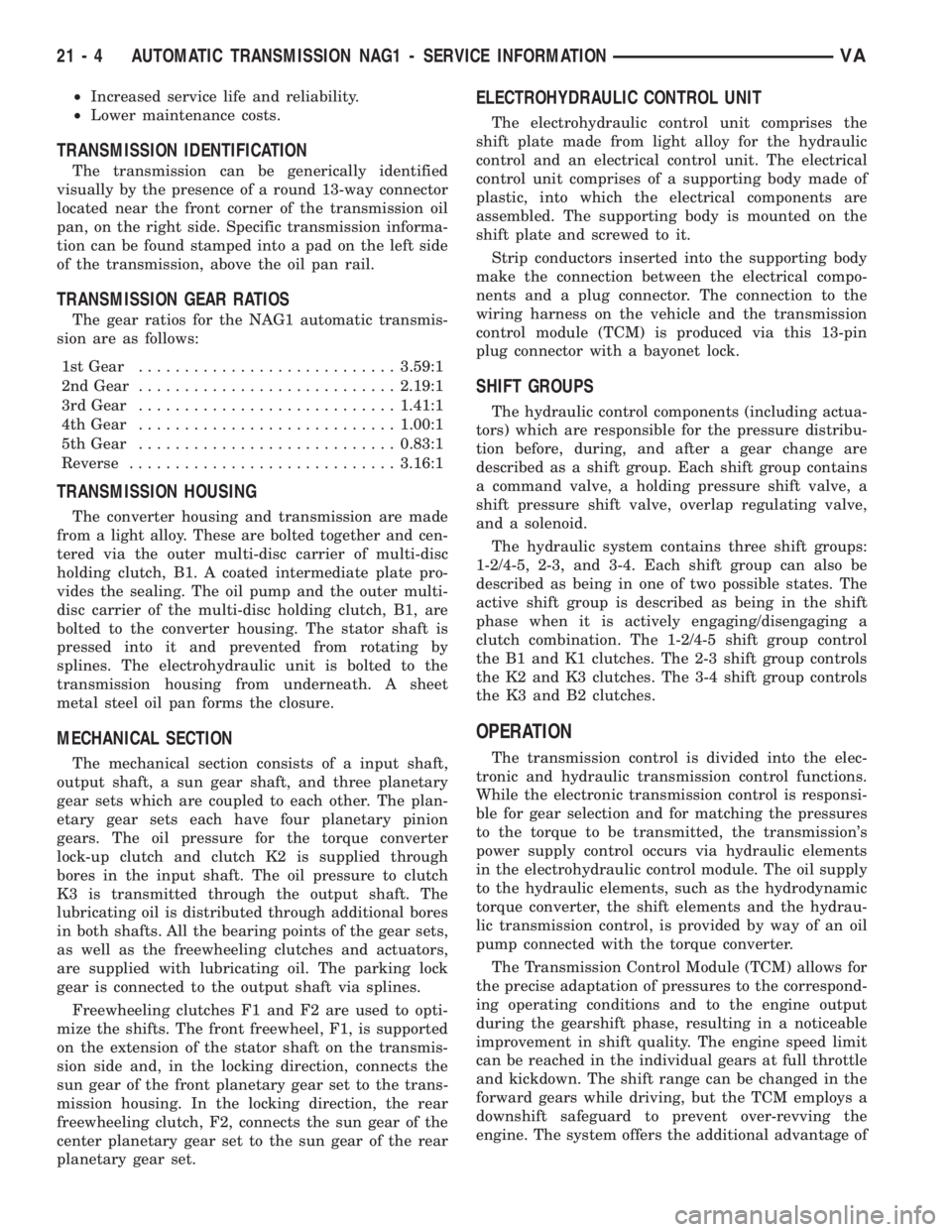

CLUTCH APPLICATION

Refer to CLUTCH APPLICATION for which shift

elements are applied in each gear position.

CLUTCH APPLICATION

GEAR RATIO B1 B2 B3 K1 K2 K3 F1 F2

1 3.59 X* X X* X X

2 2.19 X X X* X

3 1.41 X X X

4 1.00 X X X

5 0.83 X X X X*

N N/A X X

R 3.16 X* X X X

R - Limp

In1.93 X X X

* = The shift components required during coast.

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 5

Page 1749 of 2305

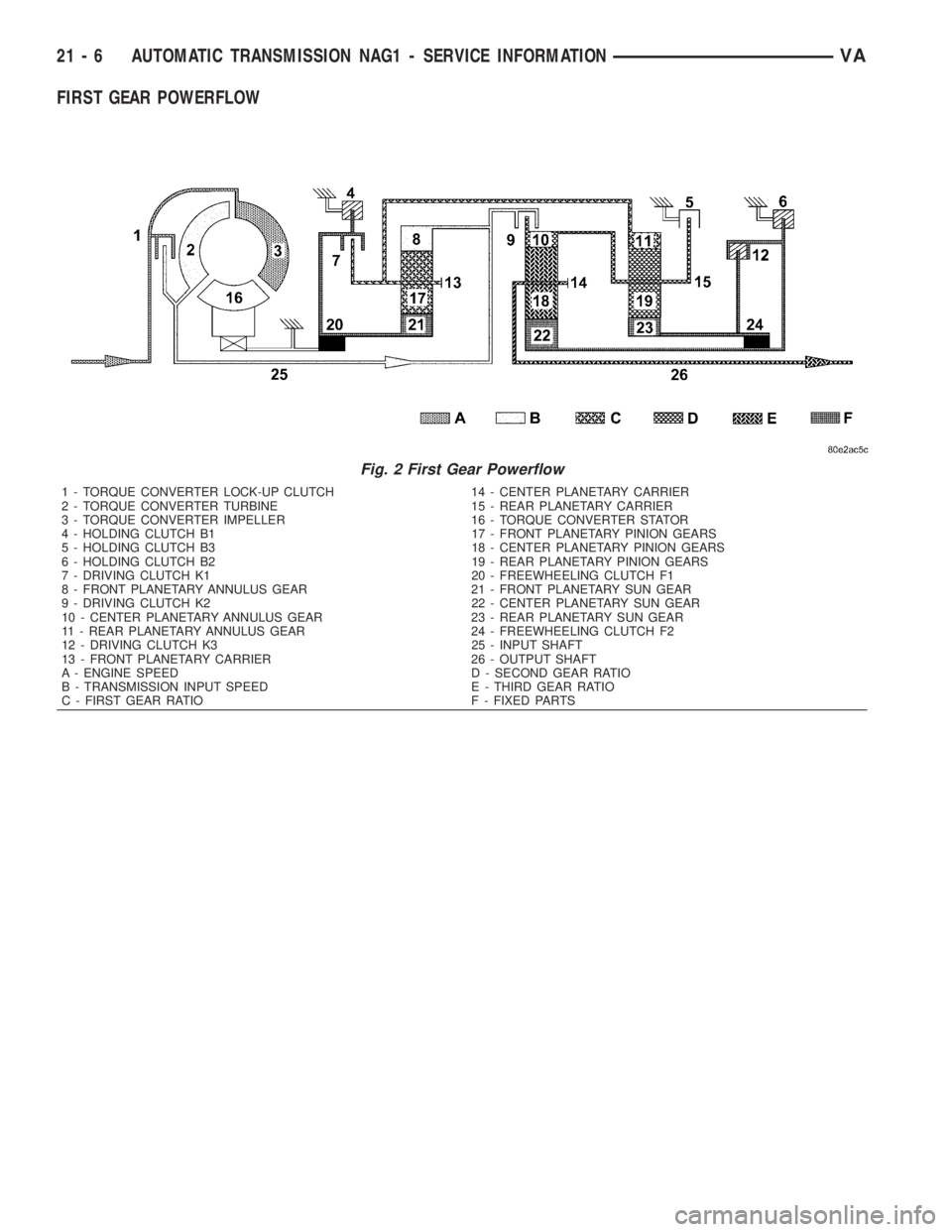

FIRST GEAR POWERFLOW

Fig. 2 First Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - INPUT SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - THIRD GEAR RATIO

C - FIRST GEAR RATIO F - FIXED PARTS

21 - 6 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1750 of 2305

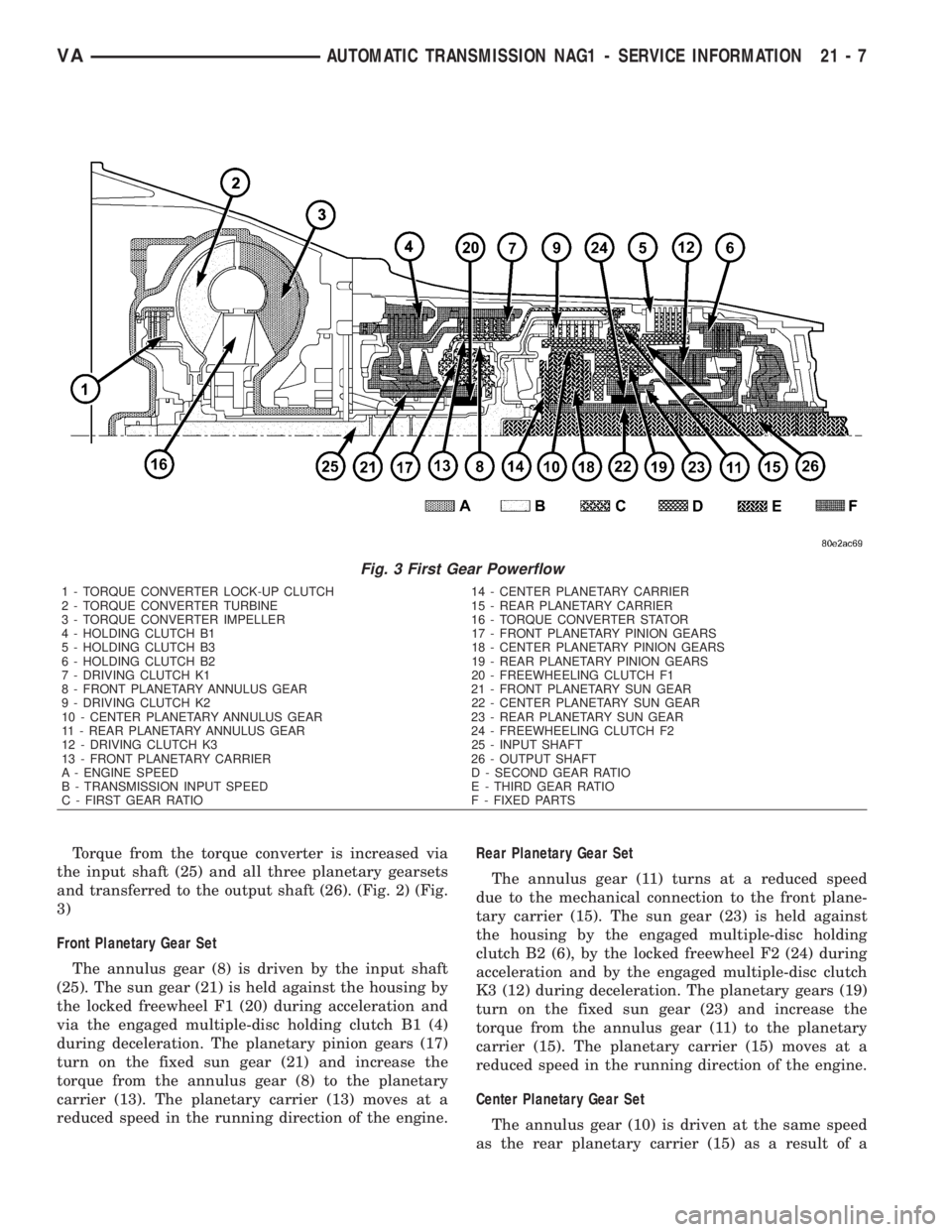

Torque from the torque converter is increased via

the input shaft (25) and all three planetary gearsets

and transferred to the output shaft (26). (Fig. 2) (Fig.

3)

Front Planetary Gear Set

The annulus gear (8) is driven by the input shaft

(25). The sun gear (21) is held against the housing by

the locked freewheel F1 (20) during acceleration and

via the engaged multiple-disc holding clutch B1 (4)

during deceleration. The planetary pinion gears (17)

turn on the fixed sun gear (21) and increase the

torque from the annulus gear (8) to the planetary

carrier (13). The planetary carrier (13) moves at a

reduced speed in the running direction of the engine.Rear Planetary Gear Set

The annulus gear (11) turns at a reduced speed

due to the mechanical connection to the front plane-

tary carrier (15). The sun gear (23) is held against

the housing by the engaged multiple-disc holding

clutch B2 (6), by the locked freewheel F2 (24) during

acceleration and by the engaged multiple-disc clutch

K3 (12) during deceleration. The planetary gears (19)

turn on the fixed sun gear (23) and increase the

torque from the annulus gear (11) to the planetary

carrier (15). The planetary carrier (15) moves at a

reduced speed in the running direction of the engine.

Center Planetary Gear Set

The annulus gear (10) is driven at the same speed

as the rear planetary carrier (15) as a result of a

Fig. 3 First Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - INPUT SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - THIRD GEAR RATIO

C - FIRST GEAR RATIO F - FIXED PARTS

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 7