water pump MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 8 of 2305

TABLE OF CONTENTS - Continued

FLAME SENSOR SHORTED..............................................91

GLOW PIN OPEN.......................................................91

GLOW PIN SHORTED...................................................91

HEATER IN LOCKOUT MODE.............................................93

HEATER OVERHEATED..................................................93

SUCCESSIVE OVERHEATING............................................93

OVER VOLTAGE........................................................96

OVERHEATING SENSOR OPEN...........................................97

OVERHEATING SENSOR SHORTED.......................................97

TEMP SENSOR OPEN...................................................98

TEMP SENSOR SHORTED...............................................98

UNDER VOLTAGE......................................................99

COMMUNICATION

*NO RESPONSE FROM AIRBAG CONTROL MODULE.......................102

*NO RESPONSE FROM AUTOMATIC TEMPERATURE CONTROL..............104

*NO RESPONSE FROM CABIN HEATER MODULE..........................106

*NO RESPONSE FROM CENTRAL TIMER MODULE.........................108

*NO RESPONSE FROM CONTROLLER ANTILOCK BRAKE...................110

*NO RESPONSE FROM ENGINE CONTROL MODULE.......................112

*NO RESPONSE FROM HEATER BOOSTER MODULE.......................114

*NO RESPONSE FROM INSTRUMENT CLUSTER...........................116

*NO RESPONSE FROM RADIO..........................................118

*NO RESPONSE FROM SECURITY SYSTEM MODULE......................120

*NO RESPONSE FROM SENTRY KEY REMOTE ENTRY MODULE.............122

*NO RESPONSE FROM SHIFTER ASSEMBLY..............................124

*NO RESPONSE FROM TRANSMISSION CONTROL MODULE................126

HEATING & A/C

A/C COMPRESSOR CONTROL HIGH OR OPEN (ACTIVE)....................128

A/C COMPRESSOR CONTROL HIGH OR OPEN (STORED)...................130

A/C COMPRESSOR CONTROL SHORTED LOW (STORED)...................130

AIR OUTLET TEMP SENSOR HIGH OR OPEN (STORED)....................130

AIR OUTLET TEMP SENSOR SHORTED LOW (STORED)....................130

AUX FAN RELAY CONTROL HIGH OR OPEN (STORED).....................130

AUX FAN RELAY CONTROL SHORTED LOW (STORED).....................130

BLOWER STAGE 1 HIGH OR OPEN (STORED).............................130

BLOWER STAGE 1 SHORTED LOW (STORED).............................130

CABIN HEATER CONTROL HIGH OR OPEN (STORED)......................130

CABIN HEATER CONTROL SHORTED LOW (STORED)......................130

CIRC PUMP CONTROL HIGH OR OPEN (STORED).........................130

CIRC PUMP CONTROL SHORTED LOW (STORED).........................130

EVAP TEMP SENSOR HIGH OR OPEN (STORED)..........................130

EVAP TEMP SENSOR SHORTED LOW (STORED)..........................130

NO COMMUNICATION BUS (STORED)....................................130

NO COMMUNICATION WITH ECM (STORED)..............................130

NO COMMUNICATION WITH IC (STORED).................................130

RECIRC AIR SOLENOID CONTROL HIGH OR OPEN (STORED)...............130

RECIRC AIR SOLENOID CONTROL SHORTED LOW (STORED)...............130

REFRIG PRESS SENSOR HIGH OR OPEN (STORED).......................130

REFRIG PRESS SENSOR SHORTED LOW (STORED).......................130

WATER CYCLE VALVE CONTROL HIGH OR OPEN (STORED)................130

WATER CYCLE VALVE CONTROL SHORTED LOW (STORED)................130

iii

Page 9 of 2305

TABLE OF CONTENTS - Continued

A/C COMPRESSOR CONTROL SHORTED LOW (ACTIVE)....................132

AIR OUTLET TEMP SENSOR HIGH OR OPEN (ACTIVE).....................134

AIR OUTLET TEMP SENSOR SHORTED LOW (ACTIVE).....................136

ATC FUNCTION TEST COOL FAILURE....................................138

ATC FUNCTION TEST FAILURE..........................................138

ATC FUNCTION TEST HEAT FAILURE.....................................138

AUX FAN RELAY CONTROL HIGH OR OPEN (ACTIVE)......................140

AUX FAN RELAY CONTROL SHORTED LOW (ACTIVE)......................142

BLOWER STAGE 1 HIGH OR OPEN (ACTIVE)..............................144

BLOWER STAGE 1 SHORTED LOW (ACTIVE)..............................146

CABIN HEATER CONTROL HIGH OR OPEN (ACTIVE).......................148

CABIN HEATER CONTROL SHORTED LOW (ACTIVE).......................150

CIRC PUMP CONTROL HIGH OR OPEN (ACTIVE)..........................152

CIRC PUMP CONTROL SHORTED LOW (ACTIVE)..........................154

EVAP TEMP SENSOR HIGH OR OPEN (ACTIVE)...........................156

EVAP TEMP SENSOR SHORTED LOW (ACTIVE)...........................158

NO COMMUNICATION BUS (ACTIVE).....................................160

NO COMMUNICATION WITH ECM (ACTIVE)...............................163

NO COMMUNICATION WITH IC (ACTIVE)..................................165

RECIRC AIR SOLENOID CONTROL HIGH OR OPEN (ACTIVE)................167

RECIRC AIR SOLENOID CONTROL SHORTED LOW (ACTIVE)................169

REFRIG PRESS SENSOR HIGH OR OPEN (ACTIVE)........................171

REFRIG PRESS SENSOR SHORTED LOW (ACTIVE)........................173

WATER CYCLE VALVE CONTROL HIGH OR OPEN (ACTIVE).................175

WATER CYCLE VALVE CONTROL SHORTED LOW (ACTIVE).................177

INSTRUMENT CLUSTER

AMBIENT TEMP SENSOR OPEN/SHORT TO BATTERY......................179

AMBIENT TEMP SENSOR SHORT TO GROUND............................181

FUEL LEVEL SENSOR OPEN/SHORT TO BATTERY.........................182

FUEL LEVEL SENSOR SHORT TO GROUND...............................184

INSTRUMENT CLUSTER INTERNAL FAILURE B1043........................185

INSTRUMENT CLUSTER INTERNAL FAILURE B1053........................186

INSTRUMENT CLUSTER OVERVOLTAGE..................................187

NO CAN COMMUNICATION WITH ABS....................................188

NO CAN COMMUNICATION WITH ECM...................................190

NO CAN COMMUNICATION WITH TCM....................................192

PREGLOW INDICATOR LAMP FAILURE...................................194

SRS INDICATOR LAMP FAILURE.........................................195

POWER DOOR LOCKS/RKE

DRIVER DOOR AJAR INDICATOR DRIVER CIRCUIT SHORT TO GROUND......196

PASSENGER DOOR AJAR INDICATOR DRIVER CIRCUIT SHORT TO GROUND .198

REPLACE CONTROL MODULE..........................................200

RKE INTERFACE CIRCUIT SHORT TO GROUND - CTM......................201

RKE INTERFACE CIRCUIT SHORT TO GROUND - SKREEM..................203

RKE INTERFACE CIRCUIT SHORT TO VOLTAGE - CTM.....................205

RKE INTERFACE CIRCUIT SHORT TO VOLTAGE - SKREEM..................206

THE ACM HAS UNLOCKED THE DOORS..................................208

UNKNOWN TROUBLE CODE UNKNOWN DTC TYPE 2......................209

*RKE INOPERATIVE....................................................210

*RKE POOR RANGE...................................................211

iv

Page 12 of 2305

TABLE OF CONTENTS - Continued

FUSES (FUSE BLOCK NO. 2)............................................274

FUSES (FUSE BLOCK NO. 3)............................................276

FUSES (FUSE/RELAY BLOCK)...........................................278

HOOD AJAR SWITCH - BLACK...........................................278

HORN (VTSS).........................................................278

IGNITION LOCK SWITCH - BLACK........................................278

INSTRUMENT CLUSTER C1.............................................279

INSTRUMENT CLUSTER C2 - WHITE.....................................279

INTRUSION SENSOR NO. 1 - BLACK.....................................279

INTRUSION SENSOR NO. 2 - BLACK.....................................279

INTRUSION SENSOR NO. 3 - BLACK.....................................280

MASTER DOOR LOCK SWITCH..........................................280

PANIC ALARM SWITCH - BLACK.........................................280

FUSES (PDC).........................................................281

RADIO C1 - BLACK....................................................282

RADIO C2............................................................282

RECIRCULATED AIR SOLENOID VALVE...................................282

REFRIGERANT PRESSURE SENSOR.....................................282

A/C AUXILIARY FAN RELAY (RELAY BLOCK)...............................284

CIRCULATION PUMP RELAY-CABIN HEATER MODULE (RELAY BLOCK).......284

D+ RELAY NO. 2 (RELAY BLOCK)........................................284

FAN STAGE 1 RELAY (RELAY BLOCK)....................................284

OPTIONAL EQUIPMENT RELAY (RELAY BLOCK)...........................284

REMOTE KEYLESS ENTRY ANTENNA....................................284

SEAT BELT SWITCH...................................................284

SEAT BELT TENSIONER-DRIVER - YELLOW...............................285

SEAT BELT TENSIONER-PASSENGER - YELLOW...........................285

SECURITY SYSTEM MODULE C1 - BROWN...............................285

SECURITY SYSTEM MODULE C2 - LT. GREEN.............................286

SENTRY KEY REMOTE ENTRY MODULE (SKREEM)........................286

SHIFTER ASSEMBLY - BLACK...........................................286

SIREN - BLACK.......................................................286

STEERING ANGLE SENSOR............................................287

TOWING/INTRUSION SENSOR ON/OFF SWITCH...........................287

TRANSMISSION CONTROL MODULE C1 - BLACK..........................287

TRANSMISSION CONTROL MODULE C2 - BLACK..........................288

WATER CYCLE VALVE..................................................288

WINDOW DEFOGGER-LEFT REAR.......................................288

WINDOW DEFOGGER-RIGHT REAR......................................288

10.0 SCHEMATIC DIAGRAMS................................................289

10.1AIRBAG SYSTEM.................................................289

10.2COMMUNICATION................................................290

10.2.1COMMUNICATION K-LINES................................290

10.2.2CAN BUS NETWORK......................................291

10.3HEATING & A/C...................................................292

10.3.1AUTOMATIC TEMPERATURE CONTROL (ATC)................292

10.3.2CABIN HEATER MODULE (CHM)............................293

10.3.3HEATER BOOSTER MODULE (HBM).........................294

10.4INSTRUMENT CLUSTER...........................................295

vii

Page 143 of 2305

Symptom List:

A/C COMPRESSOR CONTROL HIGH OR OPEN (STORED)

A/C COMPRESSOR CONTROL SHORTED LOW (STORED)

AIR OUTLET TEMP SENSOR HIGH OR OPEN (STORED)

AIR OUTLET TEMP SENSOR SHORTED LOW (STORED)

AUX FAN RELAY CONTROL HIGH OR OPEN (STORED)

AUX FAN RELAY CONTROL SHORTED LOW (STORED)

BLOWER STAGE 1 HIGH OR OPEN (STORED)

BLOWER STAGE 1 SHORTED LOW (STORED)

CABIN HEATER CONTROL HIGH OR OPEN (STORED)

CABIN HEATER CONTROL SHORTED LOW (STORED)

CIRC PUMP CONTROL HIGH OR OPEN (STORED)

CIRC PUMP CONTROL SHORTED LOW (STORED)

EVAP TEMP SENSOR HIGH OR OPEN (STORED)

EVAP TEMP SENSOR SHORTED LOW (STORED)

NO COMMUNICATION BUS (STORED)

NO COMMUNICATION WITH ECM (STORED)

NO COMMUNICATION WITH IC (STORED)

RECIRC AIR SOLENOID CONTROL HIGH OR OPEN (STORED)

RECIRC AIR SOLENOID CONTROL SHORTED LOW (STORED)

REFRIG PRESS SENSOR HIGH OR OPEN (STORED)

REFRIG PRESS SENSOR SHORTED LOW (STORED)

WATER CYCLE VALVE CONTROL HIGH OR OPEN (STORED)

WATER CYCLE VALVE CONTROL SHORTED LOW (STORED)

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be A/C COMPRESSOR CONTROL

HIGH OR OPEN (STORED).

When Monitored and Set Condition:

NO COMMUNICATION BUS (STORED)

When Monitored: With the ignition on.

Set Condition: This DTC will set if the Automatic Temperature Control (ATC) fails to

receive all module messages.

NO COMMUNICATION WITH ECM (STORED)

When Monitored: With the ignition on.

Set Condition: This DTC will set if the Automatic Temperature Control (ATC) fails to

receive all messages from the ECM.

130

HEATING & A/C

Page 272 of 2305

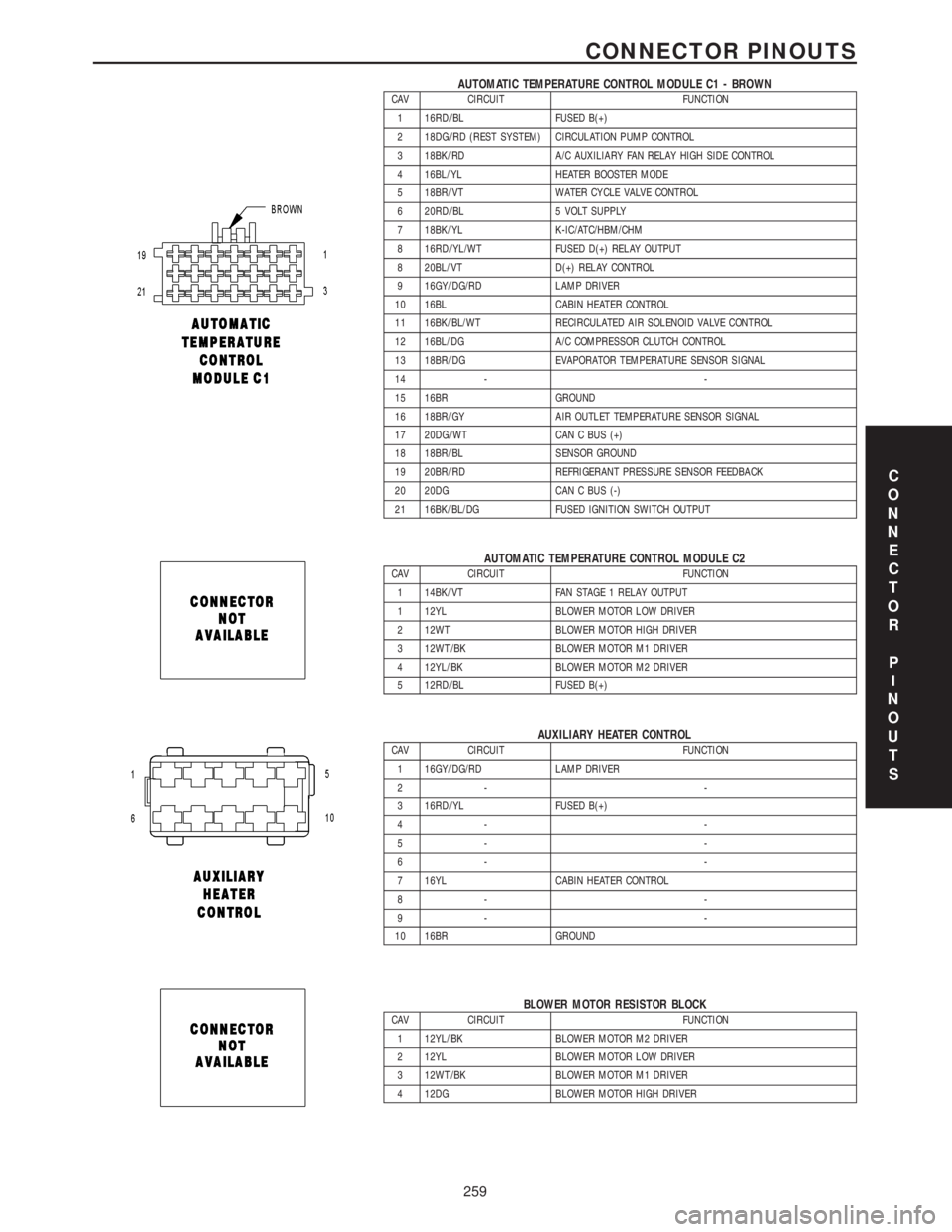

AUTOMATIC TEMPERATURE CONTROL MODULE C1 - BROWNCAV CIRCUIT FUNCTION

1 16RD/BL FUSED B(+)

2 18DG/RD (REST SYSTEM) CIRCULATION PUMP CONTROL

3 18BK/RD A/C AUXILIARY FAN RELAY HIGH SIDE CONTROL

4 16BL/YL HEATER BOOSTER MODE

5 18BR/VT WATER CYCLE VALVE CONTROL

6 20RD/BL 5 VOLT SUPPLY

7 18BK/YL K-IC/ATC/HBM/CHM

8 16RD/YL/WT FUSED D(+) RELAY OUTPUT

8 20BL/VT D(+) RELAY CONTROL

9 16GY/DG/RD LAMP DRIVER

10 16BL CABIN HEATER CONTROL

11 16BK/BL/WT RECIRCULATED AIR SOLENOID VALVE CONTROL

12 16BL/DG A/C COMPRESSOR CLUTCH CONTROL

13 18BR/DG EVAPORATOR TEMPERATURE SENSOR SIGNAL

14 - -

15 16BR GROUND

16 18BR/GY AIR OUTLET TEMPERATURE SENSOR SIGNAL

17 20DG/WT CAN C BUS (+)

18 18BR/BL SENSOR GROUND

19 20BR/RD REFRIGERANT PRESSURE SENSOR FEEDBACK

20 20DG CAN C BUS (-)

21 16BK/BL/DG FUSED IGNITION SWITCH OUTPUT

AUTOMATIC TEMPERATURE CONTROL MODULE C2CAV CIRCUIT FUNCTION

1 14BK/VT FAN STAGE 1 RELAY OUTPUT

1 12YL BLOWER MOTOR LOW DRIVER

2 12WT BLOWER MOTOR HIGH DRIVER

3 12WT/BK BLOWER MOTOR M1 DRIVER

4 12YL/BK BLOWER MOTOR M2 DRIVER

5 12RD/BL FUSED B(+)

AUXILIARY HEATER CONTROLCAV CIRCUIT FUNCTION

1 16GY/DG/RD LAMP DRIVER

2- -

3 16RD/YL FUSED B(+)

4- -

5- -

6- -

7 16YL CABIN HEATER CONTROL

8- -

9- -

10 16BR GROUND

BLOWER MOTOR RESISTOR BLOCKCAV CIRCUIT FUNCTION

1 12YL/BK BLOWER MOTOR M2 DRIVER

2 12YL BLOWER MOTOR LOW DRIVER

3 12WT/BK BLOWER MOTOR M1 DRIVER

4 12DG BLOWER MOTOR HIGH DRIVER

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

259

CONNECTOR PINOUTS

Page 428 of 2305

ecm internal error 3

ecm internal error 4

ecm internal error 4

ecm internal error 5

ecm internal fault

ecm invalid coding

ecm invalid data

ecm read error

ecm read/write error

ecm supply voltage too low

ecm voltage supply is too high

ecm voltage supply is too low

ecm write error

egr flow rate is too high

egr flow rate is too low

egr valve excessive current

egr valve signal circuit open circuit

egr valve signal circuit shorted to ground

egr valve signal circuit shorted to ground

egr valve signal circuit shorted to voltage

engine control relay plausibility

engine control relay shuts off too early

engine control relay shuts off too late

engine coolant temp sensor circuit plausibility

engine coolant temp sensor circuit plausibility

engine coolant temp sensor circuit plausibility with

engine oil sensor

engine coolant temp sensor circuit signal voltage too

high

engine coolant temp sensor circuit signal voltage too

high

engine coolant temp sensor circuit signal voltage too

low

engine coolant temp sensor circuit signal voltage too

low

*engine cranks but will not start

engine oil sensor circuit invalid level

engine oil sensor circuit level out of range

engine oil sensor circuit level out of range

engine oil sensor monitoring error

engine oil sensor oil temperature plausibility

engine oil sensor open circuit

engine oil sensor poor oil quality

engine oil sensor quality measurement error

engine oil sensor quality plausibility

engine oil sensor signal error

engine oil sensor signal plausibility

engine oil sensor signal voltage is too high

engine oil sensor signal voltage is too low

engine oil sensor synchronization error

engine oil sensor water contamination

*engine will not crank

esm can message missing or incorrect

etc can message missing or incorrect

fuel injector 1 read too large

fuel injector 1 read too large

fuel injector 1 read too small

fuel injector 1 read too smallfuel injector 2 read too large

fuel injector 2 read too large

fuel injector 2 read too small

fuel injector 2 read too small

fuel injector 3 read too large

fuel injector 3 read too large

fuel injector 3 read too small

fuel injector 3 read too small

fuel injector 4 read too large

fuel injector 4 read too large

fuel injector 4 read too small

fuel injector 4 read too small

fuel injector 5 read too large

fuel injector 5 read too large

fuel injector 5 read too small

fuel injector 5 read too small

fuel press sensor circuit malf signal voltage too high

fuel press sensor circuit malf signal voltage too low

fuel press solenoid signal plausibility high

fuel press solenoid signal plausibility low

fuel pressure sensor circuit signal voltage too high

fuel pressure sensor circuit signal voltage too low

fuel pressure solenoid circuit excessive current

fuel pressure solenoid circuit open circuit

fuel pressure solenoid circuit shorted to ground or

b+

fuel pump relay circuit open circuit

fuel pump relay circuit shorted to ground

fuel pump relay circuit shorted to voltage

fuel pump relay excessive current

fuel quantity solenoid ecm thermal overload

fuel quantity solenoid open circuit

fuel quantity solenoid short to ground

fuel quantity solenoid short to ground

fuel quantity solenoid short to voltage

fuel rail pressure malfunction deceleration error

fuel rail pressure malfunction deceleration error

fuel rail pressure malfunction fuel flow below min-

imum quantity

fuel rail pressure malfunction maximum fuel flow

exceeded

fuel rail pressure malfunction maximum fuel pres-

sure exceeded

fuel rail pressure malfunction maximum fuel pres-

sure exceeded

fuel rail pressure malfunction maximum fuel pres-

sure exceeded

fuel rail pressure malfunction plausibility with fuel

pressure solenoid

fuel rail pressure malfunction rail pressure is too

high

fuel rail pressure malfunction rail pressure is too

low

fuel rail pressure malfunction rail pressure is too

low

fuel rail pressure malfunction rail pressure is too

low

fuel rail pressure malfunction rail pressure too high

5

GENERAL INFORMATION

Page 682 of 2305

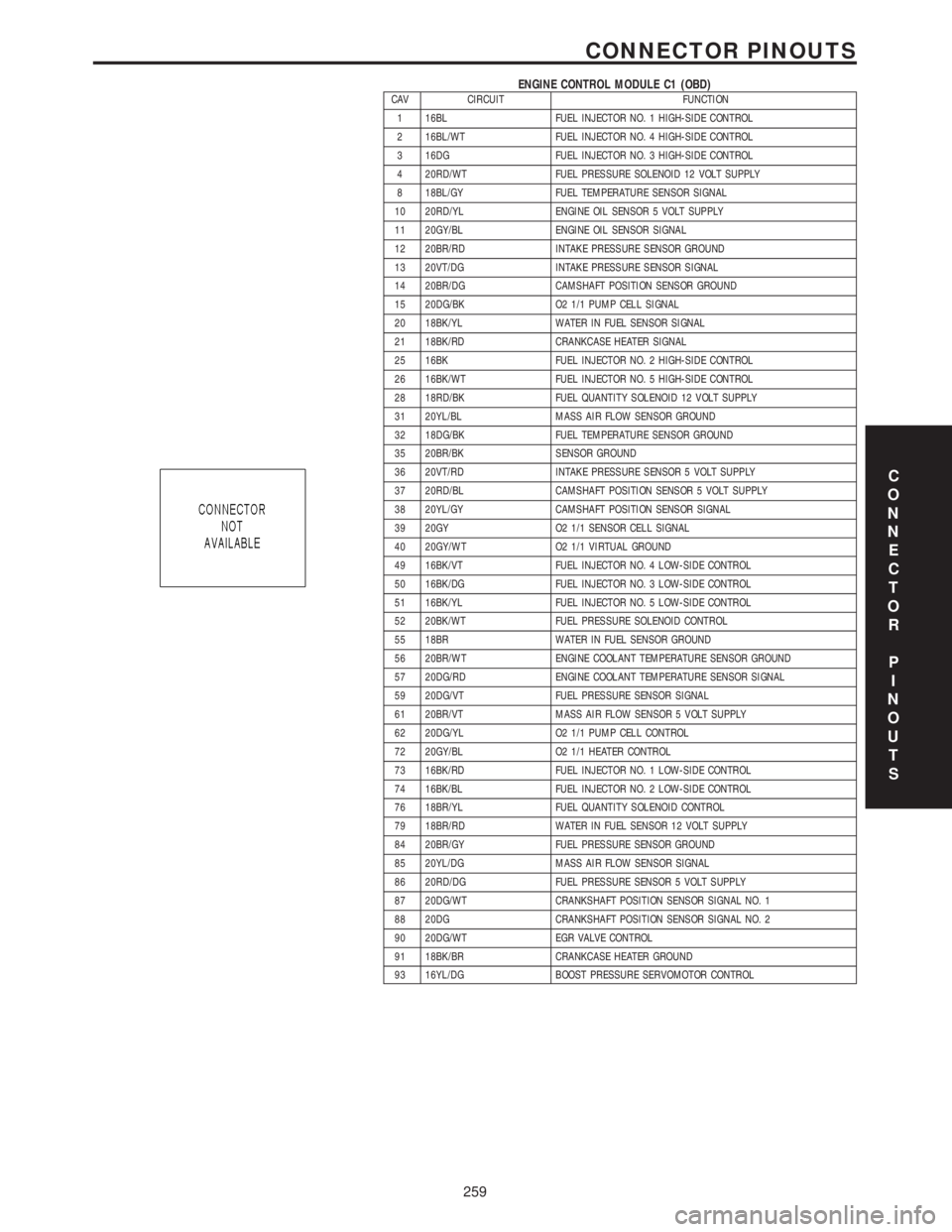

ENGINE CONTROL MODULE C1 (OBD)CAV CIRCUIT FUNCTION

1 16BL FUEL INJECTOR NO. 1 HIGH-SIDE CONTROL

2 16BL/WT FUEL INJECTOR NO. 4 HIGH-SIDE CONTROL

3 16DG FUEL INJECTOR NO. 3 HIGH-SIDE CONTROL

4 20RD/WT FUEL PRESSURE SOLENOID 12 VOLT SUPPLY

8 18BL/GY FUEL TEMPERATURE SENSOR SIGNAL

10 20RD/YL ENGINE OIL SENSOR 5 VOLT SUPPLY

11 20GY/BL ENGINE OIL SENSOR SIGNAL

12 20BR/RD INTAKE PRESSURE SENSOR GROUND

13 20VT/DG INTAKE PRESSURE SENSOR SIGNAL

14 20BR/DG CAMSHAFT POSITION SENSOR GROUND

15 20DG/BK O2 1/1 PUMP CELL SIGNAL

20 18BK/YL WATER IN FUEL SENSOR SIGNAL

21 18BK/RD CRANKCASE HEATER SIGNAL

25 16BK FUEL INJECTOR NO. 2 HIGH-SIDE CONTROL

26 16BK/WT FUEL INJECTOR NO. 5 HIGH-SIDE CONTROL

28 18RD/BK FUEL QUANTITY SOLENOID 12 VOLT SUPPLY

31 20YL/BL MASS AIR FLOW SENSOR GROUND

32 18DG/BK FUEL TEMPERATURE SENSOR GROUND

35 20BR/BK SENSOR GROUND

36 20VT/RD INTAKE PRESSURE SENSOR 5 VOLT SUPPLY

37 20RD/BL CAMSHAFT POSITION SENSOR 5 VOLT SUPPLY

38 20YL/GY CAMSHAFT POSITION SENSOR SIGNAL

39 20GY O2 1/1 SENSOR CELL SIGNAL

40 20GY/WT O2 1/1 VIRTUAL GROUND

49 16BK/VT FUEL INJECTOR NO. 4 LOW-SIDE CONTROL

50 16BK/DG FUEL INJECTOR NO. 3 LOW-SIDE CONTROL

51 16BK/YL FUEL INJECTOR NO. 5 LOW-SIDE CONTROL

52 20BK/WT FUEL PRESSURE SOLENOID CONTROL

55 18BR WATER IN FUEL SENSOR GROUND

56 20BR/WT ENGINE COOLANT TEMPERATURE SENSOR GROUND

57 20DG/RD ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

59 20DG/VT FUEL PRESSURE SENSOR SIGNAL

61 20BR/VT MASS AIR FLOW SENSOR 5 VOLT SUPPLY

62 20DG/YL O2 1/1 PUMP CELL CONTROL

72 20GY/BL O2 1/1 HEATER CONTROL

73 16BK/RD FUEL INJECTOR NO. 1 LOW-SIDE CONTROL

74 16BK/BL FUEL INJECTOR NO. 2 LOW-SIDE CONTROL

76 18BR/YL FUEL QUANTITY SOLENOID CONTROL

79 18BR/RD WATER IN FUEL SENSOR 12 VOLT SUPPLY

84 20BR/GY FUEL PRESSURE SENSOR GROUND

85 20YL/DG MASS AIR FLOW SENSOR SIGNAL

86 20RD/DG FUEL PRESSURE SENSOR 5 VOLT SUPPLY

87 20DG/WT CRANKSHAFT POSITION SENSOR SIGNAL NO. 1

88 20DG CRANKSHAFT POSITION SENSOR SIGNAL NO. 2

90 20DG/WT EGR VALVE CONTROL

91 18BK/BR CRANKCASE HEATER GROUND

93 16YL/DG BOOST PRESSURE SERVOMOTOR CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

259

CONNECTOR PINOUTS

Page 717 of 2305

AXLE FLUID

Use oils approved to MB 235.0 or 235.6, such as

Shell Spirax MB90, Caltex Hypoid LD, or MOPARt

part number 4874469, or equivalent. An API GL-5/

MIL-2105-E SAE 90 Hypoid Gear Oil may be substi-

tuted. Reduced axle durability may result if an

unapproved product is used.

BRAKE FLUID

Use brake fluid approved to MB 331.0, such as

Intac B026D, MOPARtBrake & Clutch Fluid, part

number 04549625AC, or equivalent. If the approved

product is not available, use a DOT 4 brake fluid:

minimum dry boiling point (ERBP) 500ÉF, minimum

wet boiling point (WERBP) 356ÉF, maximum viscos-

ity 1500 mm

2/s, conforming to FMVSS 116 and ISO

4925.

HOAT COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE-GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE-GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene-Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. Use coolant approved to MB 325.0, such

as EURO Peak Coolant/Anti-freeze (OLD WORLD

INDUSTRIES), Zerex G05 or G48 (The Valvoline

Company), Glysantin G05 (BASF AG), MOPARtpart

number 05066386AA, or an equivalent Extended LifeCoolant with the HOAT inhibitor system. This cool-

ant offers the best engine cooling without corrosion

when mixed with 50% anti-freeze and 50% distilled

water to obtain a freeze point of -37ÉC (-34ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: This coolant may not be mixed with any

other type of antifreeze. Mixing of coolants other

than specified (non-HOAT), may result in engine

damage that may not be covered under the new

vehicle warranty, and decreased corrosion protec-

tion.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion

inhibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise. The increased tempera-

ture can result in engine detonation. In addition, 100

percent ethylene-glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-34ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

0 - 2 LUBRICATION & MAINTENANCEVA

Page 792 of 2305

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin brake drums or substandard

brake lines and hoses can also cause a spongy pedal.

The proper course of action is to bleed the system,

and replace thin drums and substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation, or out of round brake drums. Other causes are

loose wheel bearings or calipers and worn, damaged

tires.

NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.Drag is a product of incomplete brake shoe release.

Drag can be minor or severe enough to overheat the

linings, rotors and drums.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat-cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In

severe cases, the lining may generate smoke as it

chars from overheating.

Common causes of brake drag are:

²Seized or improperly adjusted parking brake

cables.

²Loose/worn wheel bearing.

²Seized caliper or wheel cylinder piston.

²Caliper binding on corroded bushings or rusted

slide surfaces.

²Loose caliper mounting.

²Drum brake shoes binding on worn/damaged

support plates.

²Mis-assembled components.

²Long booster output rod.

If brake drag occurs at all wheels, the problem

may be related to a blocked master cylinder return

port, or faulty power booster (binds-does not release).

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Rusty caliper slide surfaces

²Improper brake pads

²Damaged rotor

A worn, damaged wheel bearing or suspension

component are further causes of pull. A damaged

front tire (bruised, ply separation) can also cause

pull.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at one of the brake units.

VABRAKES - BASE 5 - 3

Page 817 of 2305

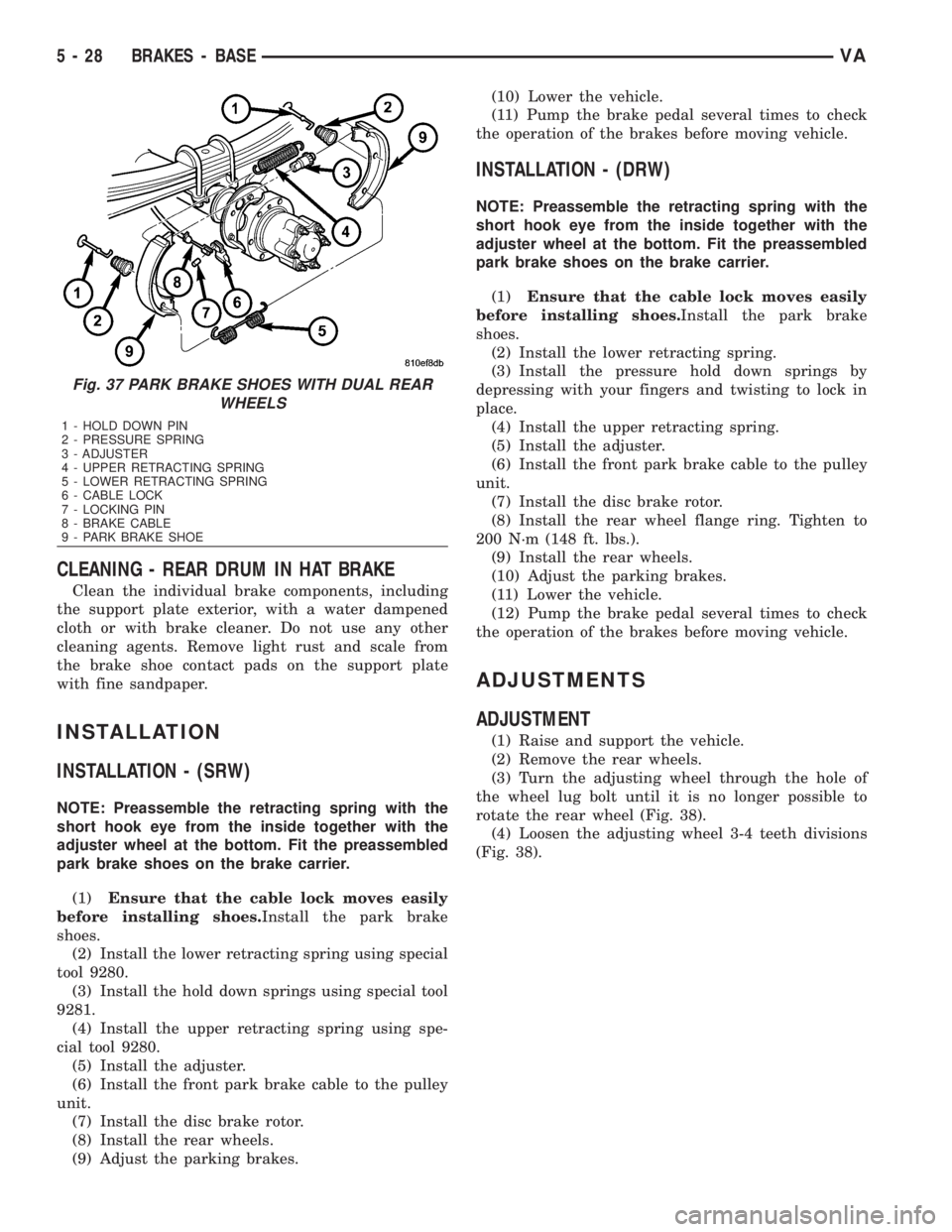

CLEANING - REAR DRUM IN HAT BRAKE

Clean the individual brake components, including

the support plate exterior, with a water dampened

cloth or with brake cleaner. Do not use any other

cleaning agents. Remove light rust and scale from

the brake shoe contact pads on the support plate

with fine sandpaper.

INSTALLATION

INSTALLATION - (SRW)

NOTE: Preassemble the retracting spring with the

short hook eye from the inside together with the

adjuster wheel at the bottom. Fit the preassembled

park brake shoes on the brake carrier.

(1)Ensure that the cable lock moves easily

before installing shoes.Install the park brake

shoes.

(2) Install the lower retracting spring using special

tool 9280.

(3) Install the hold down springs using special tool

9281.

(4) Install the upper retracting spring using spe-

cial tool 9280.

(5) Install the adjuster.

(6) Install the front park brake cable to the pulley

unit.

(7) Install the disc brake rotor.

(8) Install the rear wheels.

(9) Adjust the parking brakes.(10) Lower the vehicle.

(11) Pump the brake pedal several times to check

the operation of the brakes before moving vehicle.

INSTALLATION - (DRW)

NOTE: Preassemble the retracting spring with the

short hook eye from the inside together with the

adjuster wheel at the bottom. Fit the preassembled

park brake shoes on the brake carrier.

(1)Ensure that the cable lock moves easily

before installing shoes.Install the park brake

shoes.

(2) Install the lower retracting spring.

(3) Install the pressure hold down springs by

depressing with your fingers and twisting to lock in

place.

(4) Install the upper retracting spring.

(5) Install the adjuster.

(6) Install the front park brake cable to the pulley

unit.

(7) Install the disc brake rotor.

(8) Install the rear wheel flange ring. Tighten to

200 N´m (148 ft. lbs.).

(9) Install the rear wheels.

(10) Adjust the parking brakes.

(11) Lower the vehicle.

(12) Pump the brake pedal several times to check

the operation of the brakes before moving vehicle.

ADJUSTMENTS

ADJUSTMENT

(1) Raise and support the vehicle.

(2) Remove the rear wheels.

(3) Turn the adjusting wheel through the hole of

the wheel lug bolt until it is no longer possible to

rotate the rear wheel (Fig. 38).

(4) Loosen the adjusting wheel 3-4 teeth divisions

(Fig. 38).

Fig. 37 PARK BRAKE SHOES WITH DUAL REAR

WHEELS

1 - HOLD DOWN PIN

2 - PRESSURE SPRING

3 - ADJUSTER

4 - UPPER RETRACTING SPRING

5 - LOWER RETRACTING SPRING

6 - CABLE LOCK

7 - LOCKING PIN

8 - BRAKE CABLE

9 - PARK BRAKE SHOE

5 - 28 BRAKES - BASEVA