MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 2281 of 2305

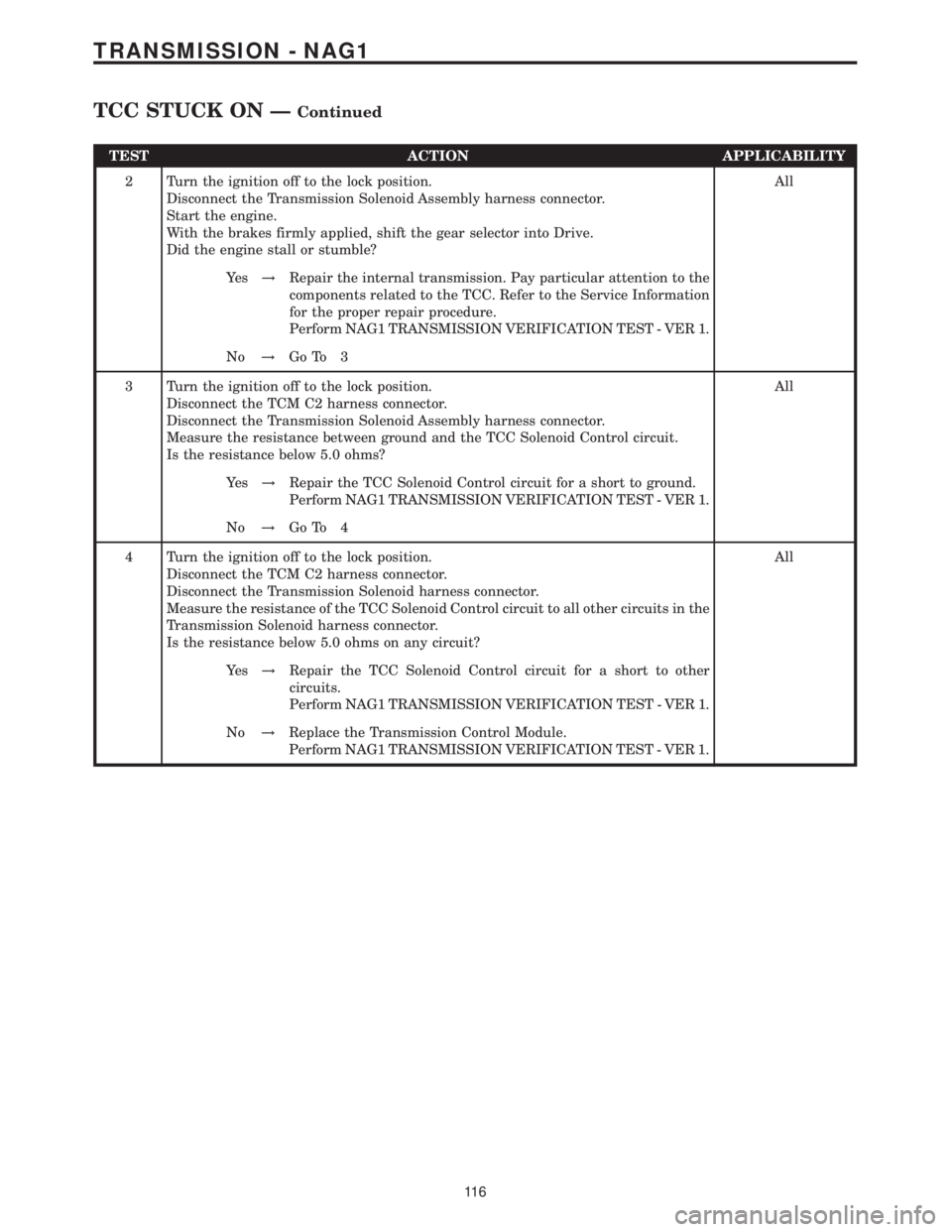

TEST ACTION APPLICABILITY

2 Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid Assembly harness connector.

Start the engine.

With the brakes firmly applied, shift the gear selector into Drive.

Did the engine stall or stumble?All

Ye s!Repair the internal transmission. Pay particular attention to the

components related to the TCC. Refer to the Service Information

for the proper repair procedure.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance between ground and the TCC Solenoid Control circuit.

Is the resistance below 5.0 ohms?All

Ye s!Repair the TCC Solenoid Control circuit for a short to ground.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 4

4 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

Disconnect the Transmission Solenoid harness connector.

Measure the resistance of the TCC Solenoid Control circuit to all other circuits in the

Transmission Solenoid harness connector.

Is the resistance below 5.0 ohms on any circuit?All

Ye s!Repair the TCC Solenoid Control circuit for a short to other

circuits.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

11 6

TRANSMISSION - NAG1

TCC STUCK ON ÐContinued

Page 2282 of 2305

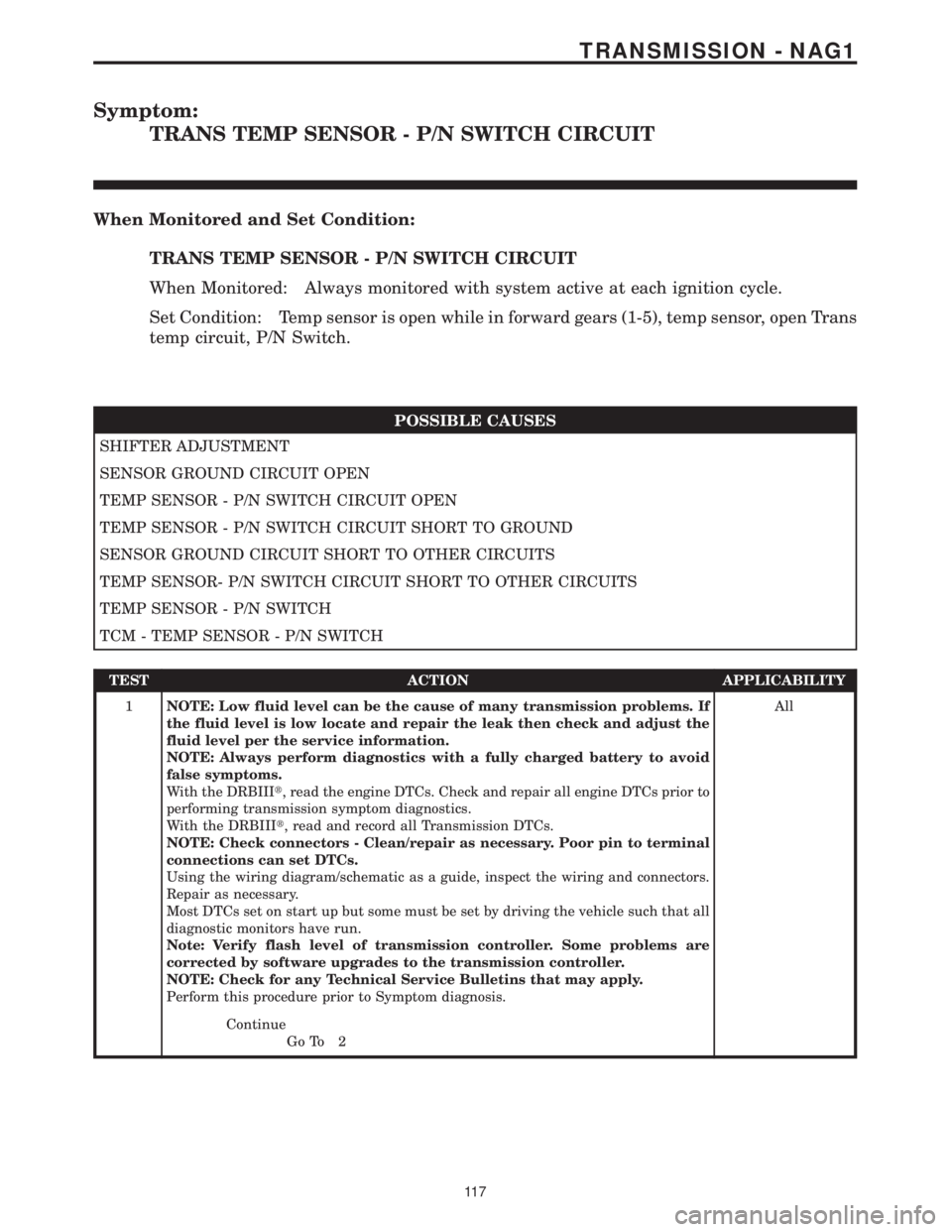

Symptom:

TRANS TEMP SENSOR - P/N SWITCH CIRCUIT

When Monitored and Set Condition:

TRANS TEMP SENSOR - P/N SWITCH CIRCUIT

When Monitored: Always monitored with system active at each ignition cycle.

Set Condition: Temp sensor is open while in forward gears (1-5), temp sensor, open Trans

temp circuit, P/N Switch.

POSSIBLE CAUSES

SHIFTER ADJUSTMENT

SENSOR GROUND CIRCUIT OPEN

TEMP SENSOR - P/N SWITCH CIRCUIT OPEN

TEMP SENSOR - P/N SWITCH CIRCUIT SHORT TO GROUND

SENSOR GROUND CIRCUIT SHORT TO OTHER CIRCUITS

TEMP SENSOR- P/N SWITCH CIRCUIT SHORT TO OTHER CIRCUITS

TEMP SENSOR - P/N SWITCH

TCM - TEMP SENSOR - P/N SWITCH

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

11 7

TRANSMISSION - NAG1

Page 2283 of 2305

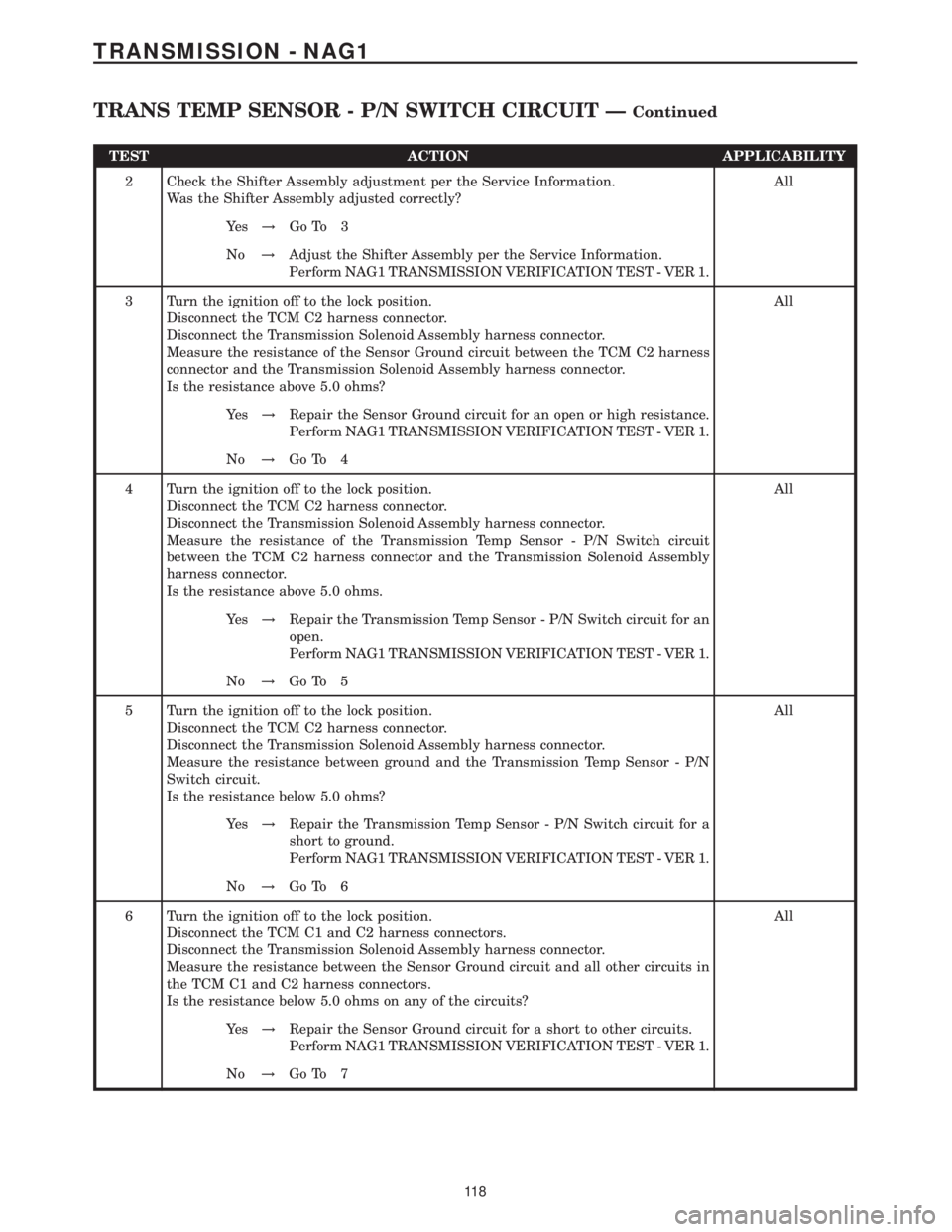

TEST ACTION APPLICABILITY

2 Check the Shifter Assembly adjustment per the Service Information.

Was the Shifter Assembly adjusted correctly?All

Ye s!Go To 3

No!Adjust the Shifter Assembly per the Service Information.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

3 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance of the Sensor Ground circuit between the TCM C2 harness

connector and the Transmission Solenoid Assembly harness connector.

Is the resistance above 5.0 ohms?All

Ye s!Repair the Sensor Ground circuit for an open or high resistance.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 4

4 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance of the Transmission Temp Sensor - P/N Switch circuit

between the TCM C2 harness connector and the Transmission Solenoid Assembly

harness connector.

Is the resistance above 5.0 ohms.All

Ye s!Repair the Transmission Temp Sensor - P/N Switch circuit for an

open.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 5

5 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance between ground and the Transmission Temp Sensor - P/N

Switch circuit.

Is the resistance below 5.0 ohms?All

Ye s!Repair the Transmission Temp Sensor - P/N Switch circuit for a

short to ground.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 6

6 Turn the ignition off to the lock position.

Disconnect the TCM C1 and C2 harness connectors.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance between the Sensor Ground circuit and all other circuits in

the TCM C1 and C2 harness connectors.

Is the resistance below 5.0 ohms on any of the circuits?All

Ye s!Repair the Sensor Ground circuit for a short to other circuits.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 7

11 8

TRANSMISSION - NAG1

TRANS TEMP SENSOR - P/N SWITCH CIRCUIT ÐContinued

Page 2284 of 2305

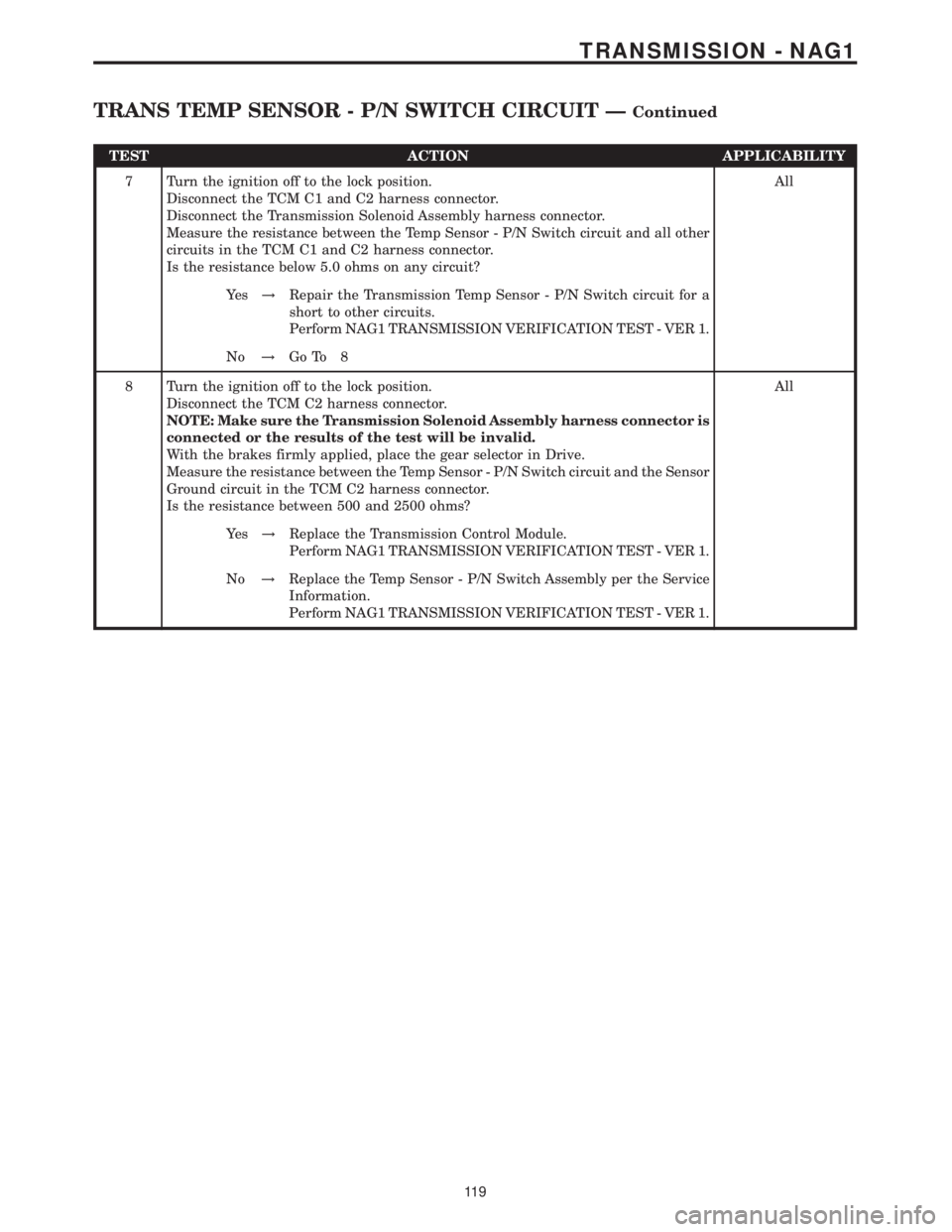

TEST ACTION APPLICABILITY

7 Turn the ignition off to the lock position.

Disconnect the TCM C1 and C2 harness connector.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance between the Temp Sensor - P/N Switch circuit and all other

circuits in the TCM C1 and C2 harness connector.

Is the resistance below 5.0 ohms on any circuit?All

Ye s!Repair the Transmission Temp Sensor - P/N Switch circuit for a

short to other circuits.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 8

8 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

NOTE: Make sure the Transmission Solenoid Assembly harness connector is

connected or the results of the test will be invalid.

With the brakes firmly applied, place the gear selector in Drive.

Measure the resistance between the Temp Sensor - P/N Switch circuit and the Sensor

Ground circuit in the TCM C2 harness connector.

Is the resistance between 500 and 2500 ohms?All

Ye s!Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Replace the Temp Sensor - P/N Switch Assembly per the Service

Information.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

11 9

TRANSMISSION - NAG1

TRANS TEMP SENSOR - P/N SWITCH CIRCUIT ÐContinued

Page 2285 of 2305

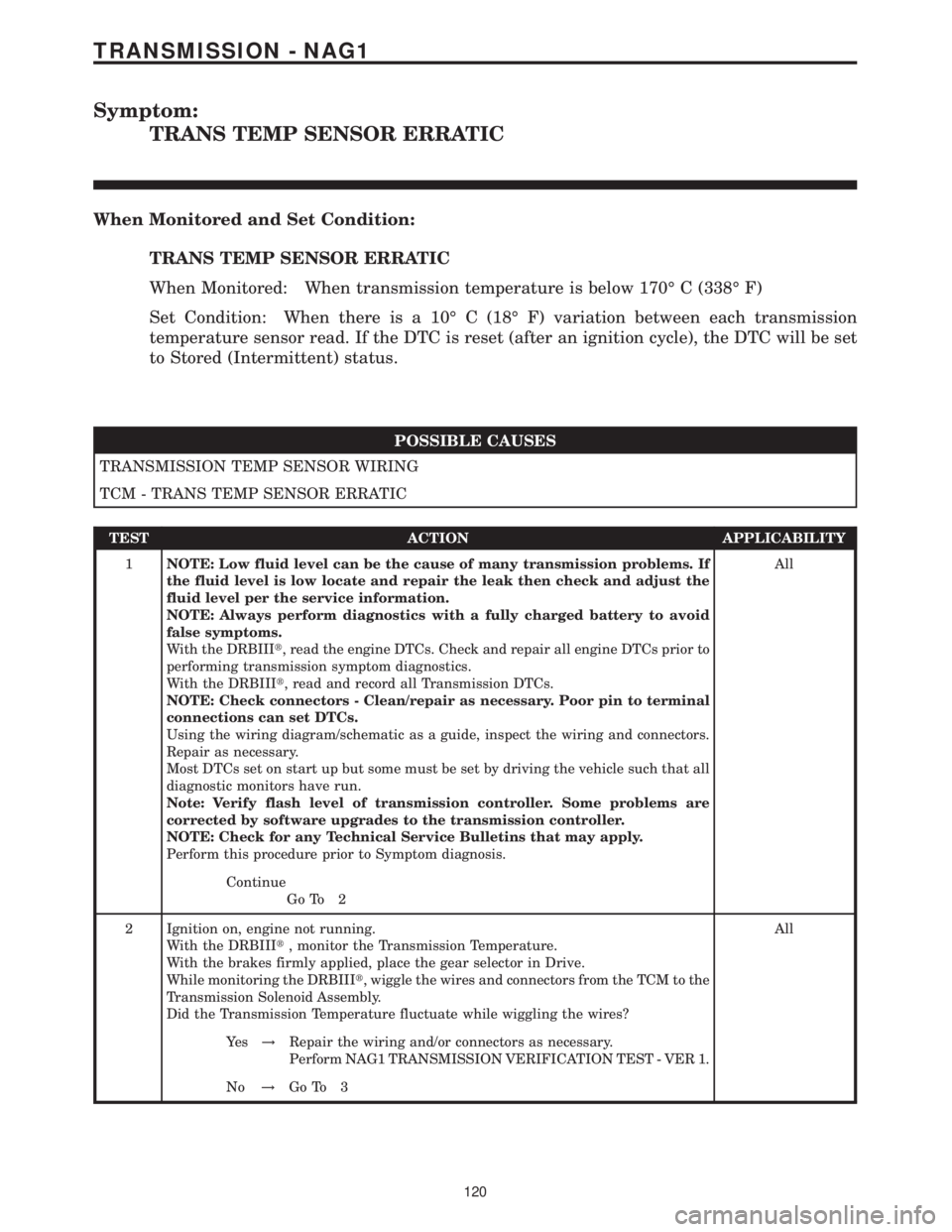

Symptom:

TRANS TEMP SENSOR ERRATIC

When Monitored and Set Condition:

TRANS TEMP SENSOR ERRATIC

When Monitored: When transmission temperature is below 170É C (338É F)

Set Condition: When there is a 10É C (18É F) variation between each transmission

temperature sensor read. If the DTC is reset (after an ignition cycle), the DTC will be set

to Stored (Intermittent) status.

POSSIBLE CAUSES

TRANSMISSION TEMP SENSOR WIRING

TCM - TRANS TEMP SENSOR ERRATIC

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

2 Ignition on, engine not running.

With the DRBIIIt, monitor the Transmission Temperature.

With the brakes firmly applied, place the gear selector in Drive.

While monitoring the DRBIIIt, wiggle the wires and connectors from the TCM to the

Transmission Solenoid Assembly.

Did the Transmission Temperature fluctuate while wiggling the wires?All

Ye s!Repair the wiring and/or connectors as necessary.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 3

120

TRANSMISSION - NAG1

Page 2286 of 2305

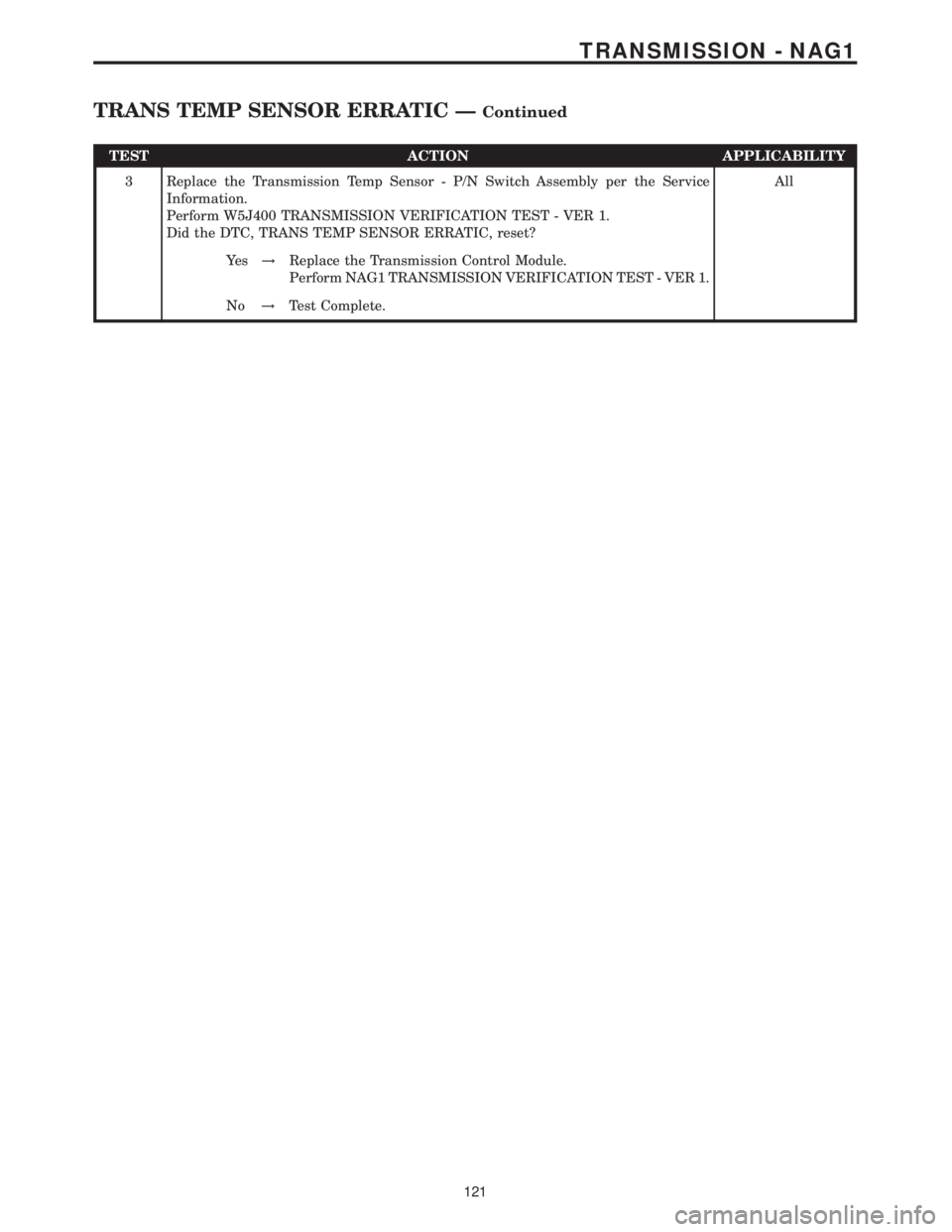

TEST ACTION APPLICABILITY

3 Replace the Transmission Temp Sensor - P/N Switch Assembly per the Service

Information.

Perform W5J400 TRANSMISSION VERIFICATION TEST - VER 1.

Did the DTC, TRANS TEMP SENSOR ERRATIC, reset?All

Ye s!Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Test Complete.

121

TRANSMISSION - NAG1

TRANS TEMP SENSOR ERRATIC ÐContinued

Page 2287 of 2305

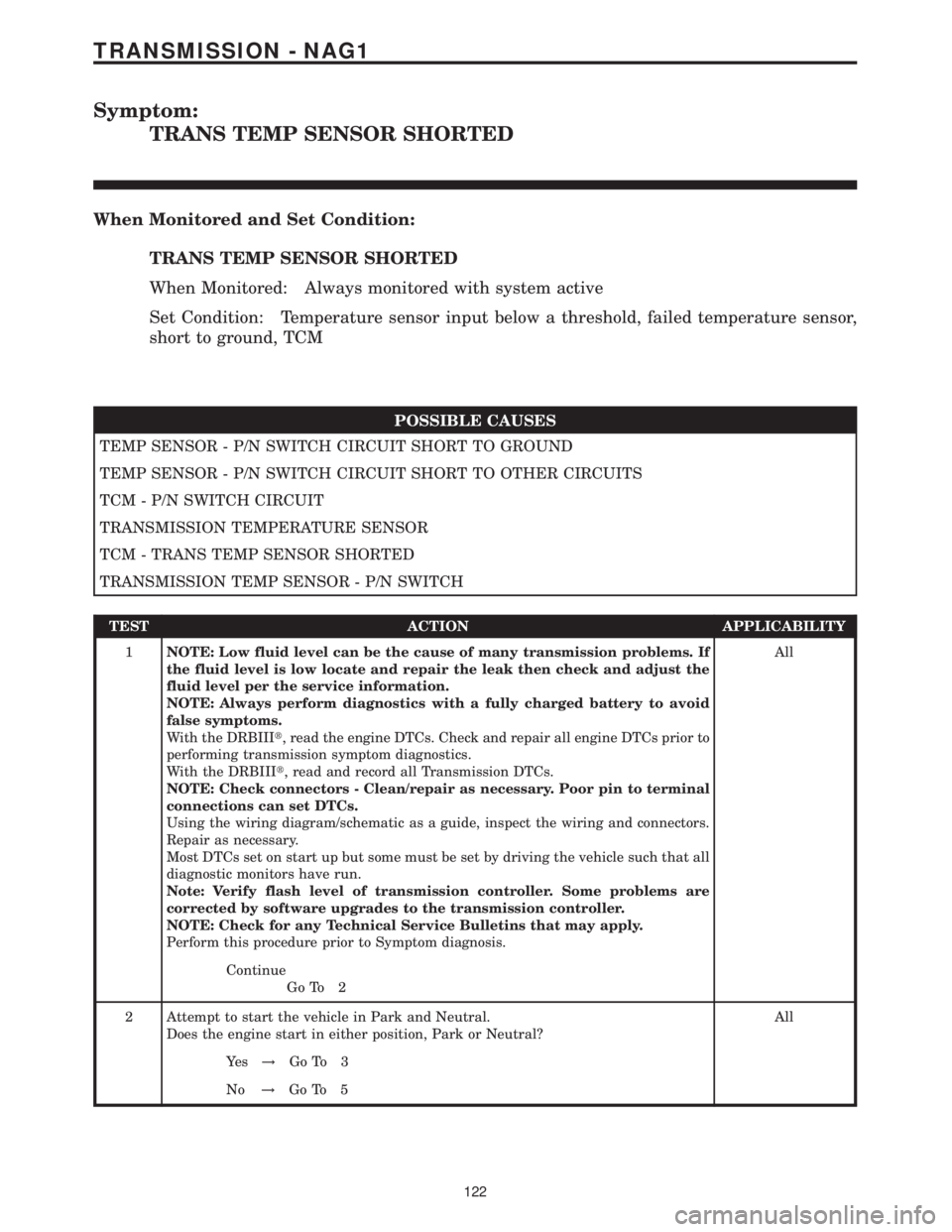

Symptom:

TRANS TEMP SENSOR SHORTED

When Monitored and Set Condition:

TRANS TEMP SENSOR SHORTED

When Monitored: Always monitored with system active

Set Condition: Temperature sensor input below a threshold, failed temperature sensor,

short to ground, TCM

POSSIBLE CAUSES

TEMP SENSOR - P/N SWITCH CIRCUIT SHORT TO GROUND

TEMP SENSOR - P/N SWITCH CIRCUIT SHORT TO OTHER CIRCUITS

TCM - P/N SWITCH CIRCUIT

TRANSMISSION TEMPERATURE SENSOR

TCM - TRANS TEMP SENSOR SHORTED

TRANSMISSION TEMP SENSOR - P/N SWITCH

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

2 Attempt to start the vehicle in Park and Neutral.

Does the engine start in either position, Park or Neutral?All

Ye s!Go To 3

No!Go To 5

122

TRANSMISSION - NAG1

Page 2288 of 2305

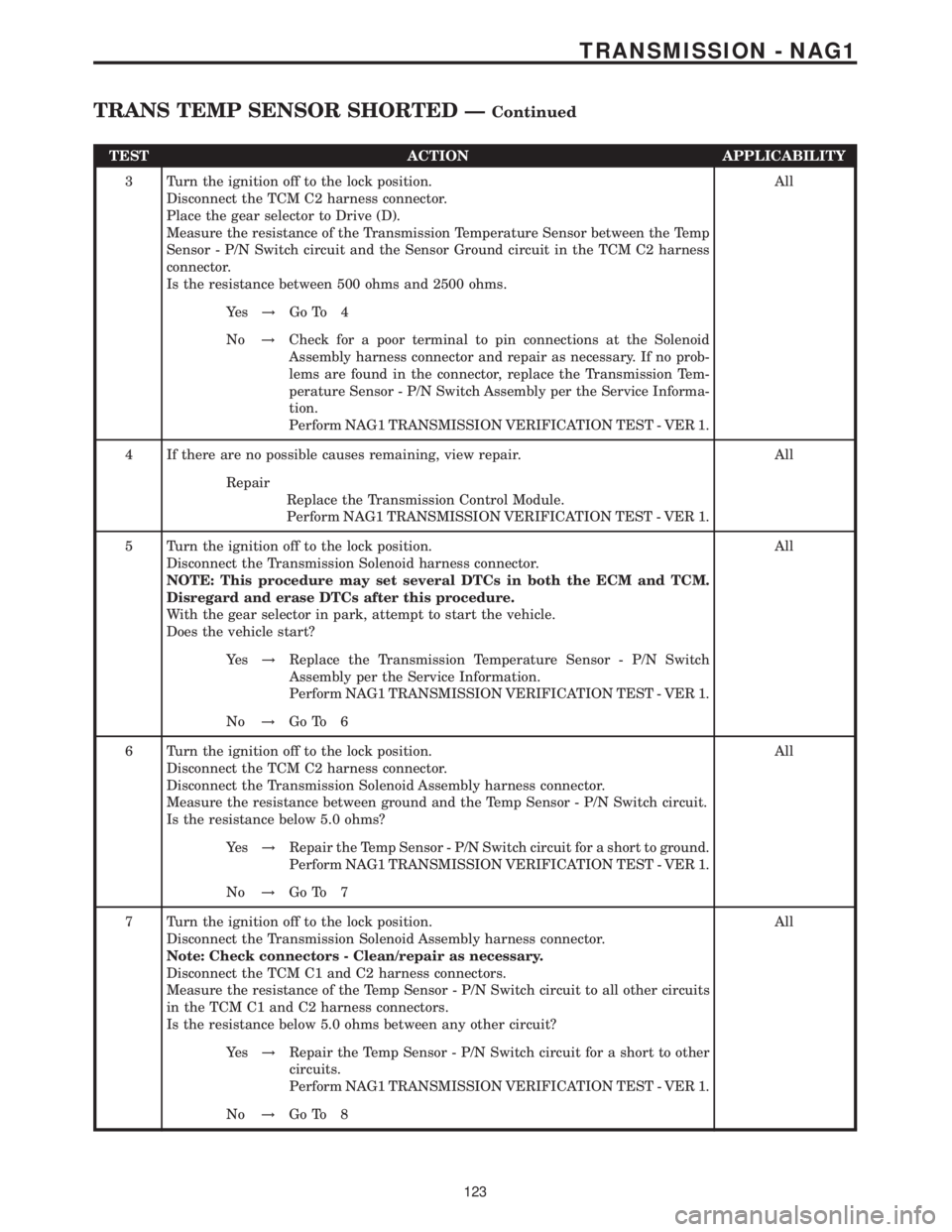

TEST ACTION APPLICABILITY

3 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

Place the gear selector to Drive (D).

Measure the resistance of the Transmission Temperature Sensor between the Temp

Sensor - P/N Switch circuit and the Sensor Ground circuit in the TCM C2 harness

connector.

Is the resistance between 500 ohms and 2500 ohms.All

Ye s!Go To 4

No!Check for a poor terminal to pin connections at the Solenoid

Assembly harness connector and repair as necessary. If no prob-

lems are found in the connector, replace the Transmission Tem-

perature Sensor - P/N Switch Assembly per the Service Informa-

tion.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

4 If there are no possible causes remaining, view repair. All

Repair

Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

5 Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid harness connector.

NOTE: This procedure may set several DTCs in both the ECM and TCM.

Disregard and erase DTCs after this procedure.

With the gear selector in park, attempt to start the vehicle.

Does the vehicle start?All

Ye s!Replace the Transmission Temperature Sensor - P/N Switch

Assembly per the Service Information.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 6

6 Turn the ignition off to the lock position.

Disconnect the TCM C2 harness connector.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance between ground and the Temp Sensor - P/N Switch circuit.

Is the resistance below 5.0 ohms?All

Ye s!Repair the Temp Sensor - P/N Switch circuit for a short to ground.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 7

7 Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid Assembly harness connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the TCM C1 and C2 harness connectors.

Measure the resistance of the Temp Sensor - P/N Switch circuit to all other circuits

in the TCM C1 and C2 harness connectors.

Is the resistance below 5.0 ohms between any other circuit?All

Ye s!Repair the Temp Sensor - P/N Switch circuit for a short to other

circuits.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 8

123

TRANSMISSION - NAG1

TRANS TEMP SENSOR SHORTED ÐContinued

Page 2289 of 2305

TEST ACTION APPLICABILITY

8 If there are no possible causes remaining, view repair. All

Repair

Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

124

TRANSMISSION - NAG1

TRANS TEMP SENSOR SHORTED ÐContinued

Page 2290 of 2305

Symptom:

TRANSMISSION SLIPPING

When Monitored and Set Condition:

TRANSMISSION SLIPPING

When Monitored: Engine rpm greater than 450 rpm, output speed greater than 180 rpm,

no N2 - N3 input speed sensor errors present, no gear selector lever errors present, no ABS

system errors, no transfer case errors present, and all wheel speeds between 70 - 380 rpm

with no wheel slip detected. Set Condition: Calculated ratio not within allowable range for

the engaged gear. No shifting operation.

Set Condition: The TCM constantly calculates the transmission ratio based on the N2 -

N3 input speed signals and the calculated output shaft speed (CAN message from the

ABS). The TCM will detect if the transmission is slipping or an invalid gear ratio is present

POSSIBLE CAUSES

OTHER DTCS PRESENT

AXLE - MECHANICAL - GEAR RATIO

INTERNAL TRANSMISSION

TCM - TRANSMISSION SLIPPING

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

125

TRANSMISSION - NAG1