TEST ACTION APPLICABILITY

2 With the DRBIIIt, read Transmission DTCs.

Are there any Improper Gear and/or Improper Ratio DTCs present?All

Ye s!Refer to the Transmission category and perform the appropriate

symptom.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 3

3 Verify the correct axle gear ratio and make sure there are no mechanical problems.

Refer to the Service Information for the proper procedures.

Were there any problems found?All

Ye s!Refer to the Service Information for proper repair procedures.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 4

4 Determine if the Transmission is mechanically slipping.

Is the transmission slipping?All

Ye s!Repair internal transmission as necessary. Refer to the Service

Information for the proper repair procedure.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

126

TRANSMISSION - NAG1

TRANSMISSION SLIPPING ÐContinued

Verification Tests

NAG1 TRANSMISSION VERIFICATION TEST - VER 1 APPLICABILITY

1. Reconnect any disconnected components.

2. Connect the DRBIIItto the Data Link Connector.

3. With the DRBIIIt, erase ABS DTCs.

4. With the DRBIIIt, erase ECM DTCs.

5. With the DRBIIIt, erase Transmission DTCs.

6. With the DRBIIIt, display Transmission Temperature. Start and run the engine until the

Transmission Temperature is HOT, above 43É C (110É F).

7. Check the Transmission fluid and adjust if necessary. Refer to the Service Information for the

proper Fluid Fill procedure.

8. NOTE: If internal repairs were performed and the shift quality is still poor, it may

be necessary to check the internal repair. Also check for any TSBs and/or Controller

Flash updates that may apply.

9. ROAD TEST PROCEDURE

10. Road test the vehicle. Make fifteen to twenty 1-2, 2-3, 3-4 and 4-5 upshifts.

11. Perform these shifts from a standing start to 72 km/h (45 MPH) with a constant throttle

opening of 20 to 25 degrees.

12. With speeds below 40 km/h (25 MPH), make five to eight wide open throttle kickdowns to

1st gear. Allow at least 5 seconds each in 2nd and 3rd gear between each kickdown.

13. With the DRBIIIt, read Transmission DTCs.

Were there any Diagnostic Trouble Codes set?All

Ye s!Repair is not complete, refer to appropriate symptom.

No!Repair is complete.

127

VERIFICATION TESTS

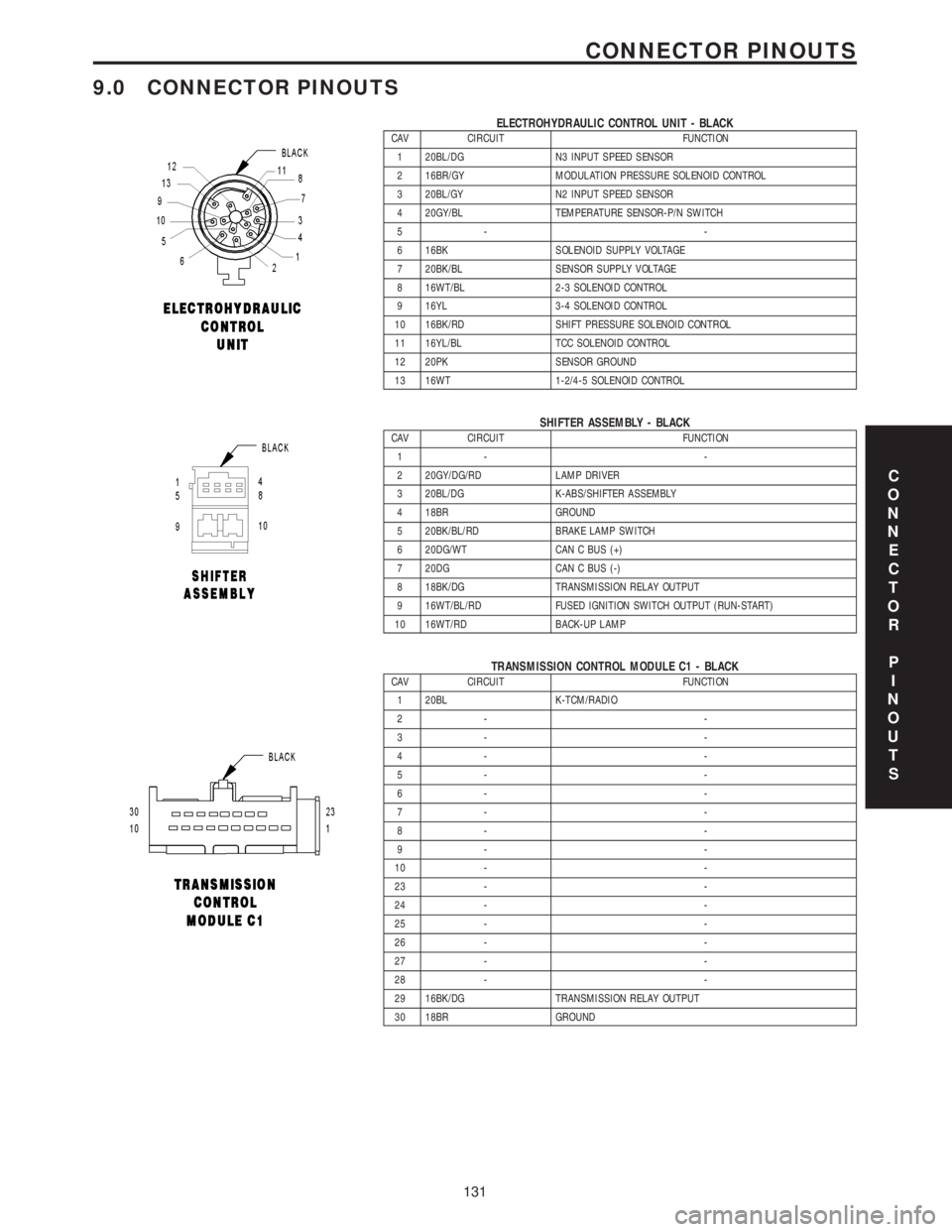

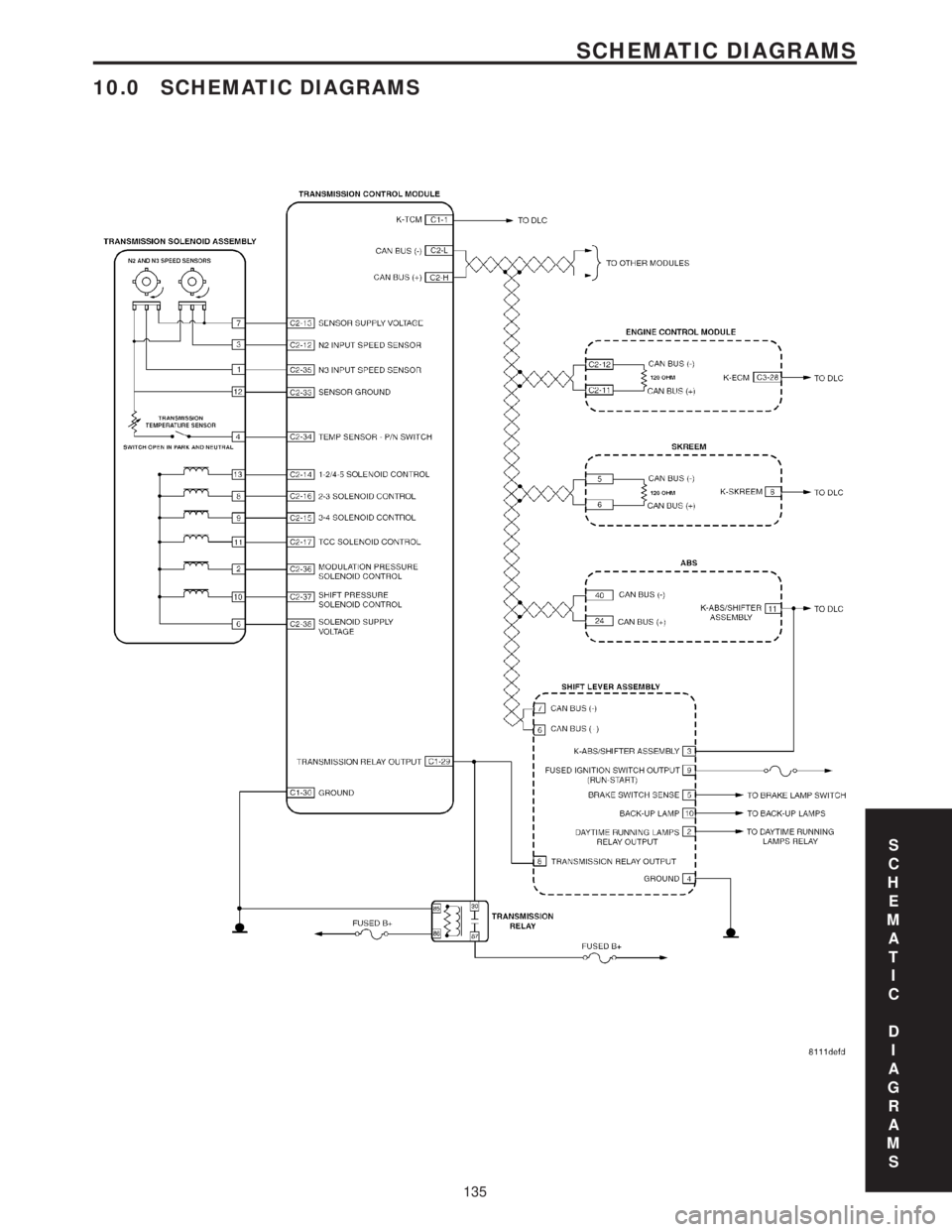

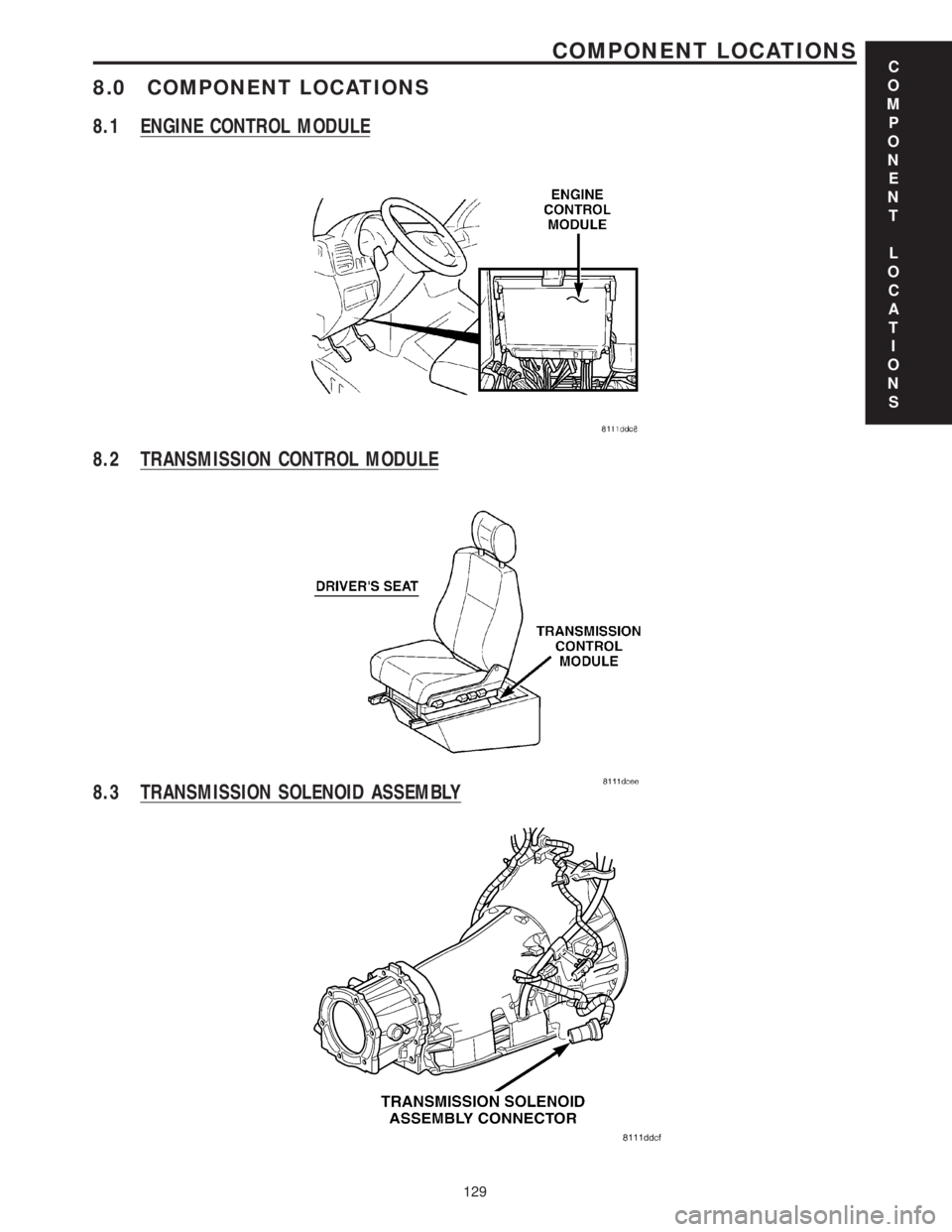

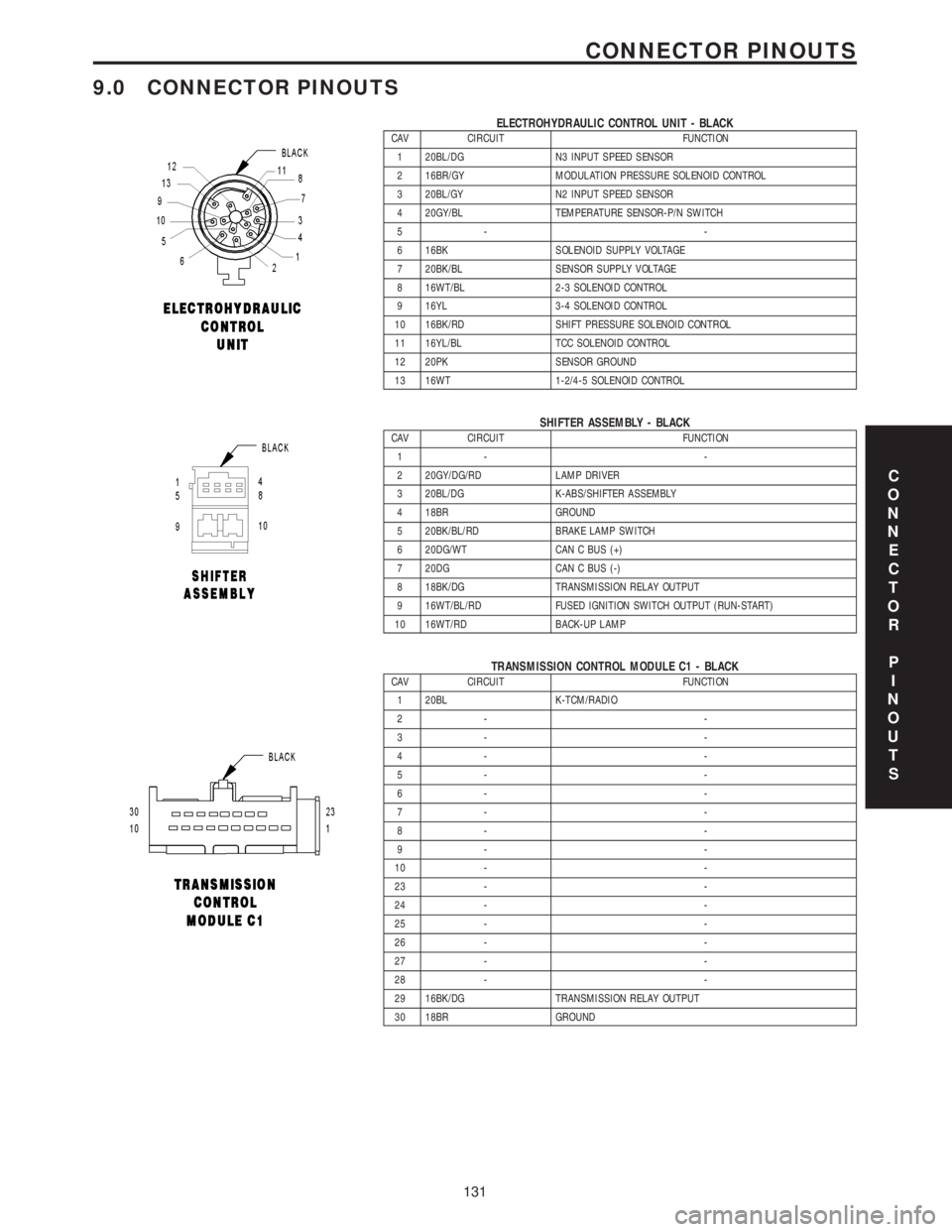

9.0 CONNECTOR PINOUTS

ELECTROHYDRAULIC CONTROL UNIT - BLACKCAV CIRCUIT FUNCTION

1 20BL/DG N3 INPUT SPEED SENSOR

2 16BR/GY MODULATION PRESSURE SOLENOID CONTROL

3 20BL/GY N2 INPUT SPEED SENSOR

4 20GY/BL TEMPERATURE SENSOR-P/N SWITCH

5- -

6 16BK SOLENOID SUPPLY VOLTAGE

7 20BK/BL SENSOR SUPPLY VOLTAGE

8 16WT/BL 2-3 SOLENOID CONTROL

9 16YL 3-4 SOLENOID CONTROL

10 16BK/RD SHIFT PRESSURE SOLENOID CONTROL

11 16YL/BL TCC SOLENOID CONTROL

12 20PK SENSOR GROUND

13 16WT 1-2/4-5 SOLENOID CONTROL

SHIFTER ASSEMBLY - BLACKCAV CIRCUIT FUNCTION

1- -

2 20GY/DG/RD LAMP DRIVER

3 20BL/DG K-ABS/SHIFTER ASSEMBLY

4 18BR GROUND

5 20BK/BL/RD BRAKE LAMP SWITCH

6 20DG/WT CAN C BUS (+)

7 20DG CAN C BUS (-)

8 18BK/DG TRANSMISSION RELAY OUTPUT

9 16WT/BL/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

10 16WT/RD BACK-UP LAMP

TRANSMISSION CONTROL MODULE C1 - BLACKCAV CIRCUIT FUNCTION

1 20BL K-TCM/RADIO

2- -

3- -

4- -

5- -

6- -

7- -

8- -

9- -

10 - -

23 - -

24 - -

25 - -

26 - -

27 - -

28 - -

29 16BK/DG TRANSMISSION RELAY OUTPUT

30 18BR GROUND

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

131

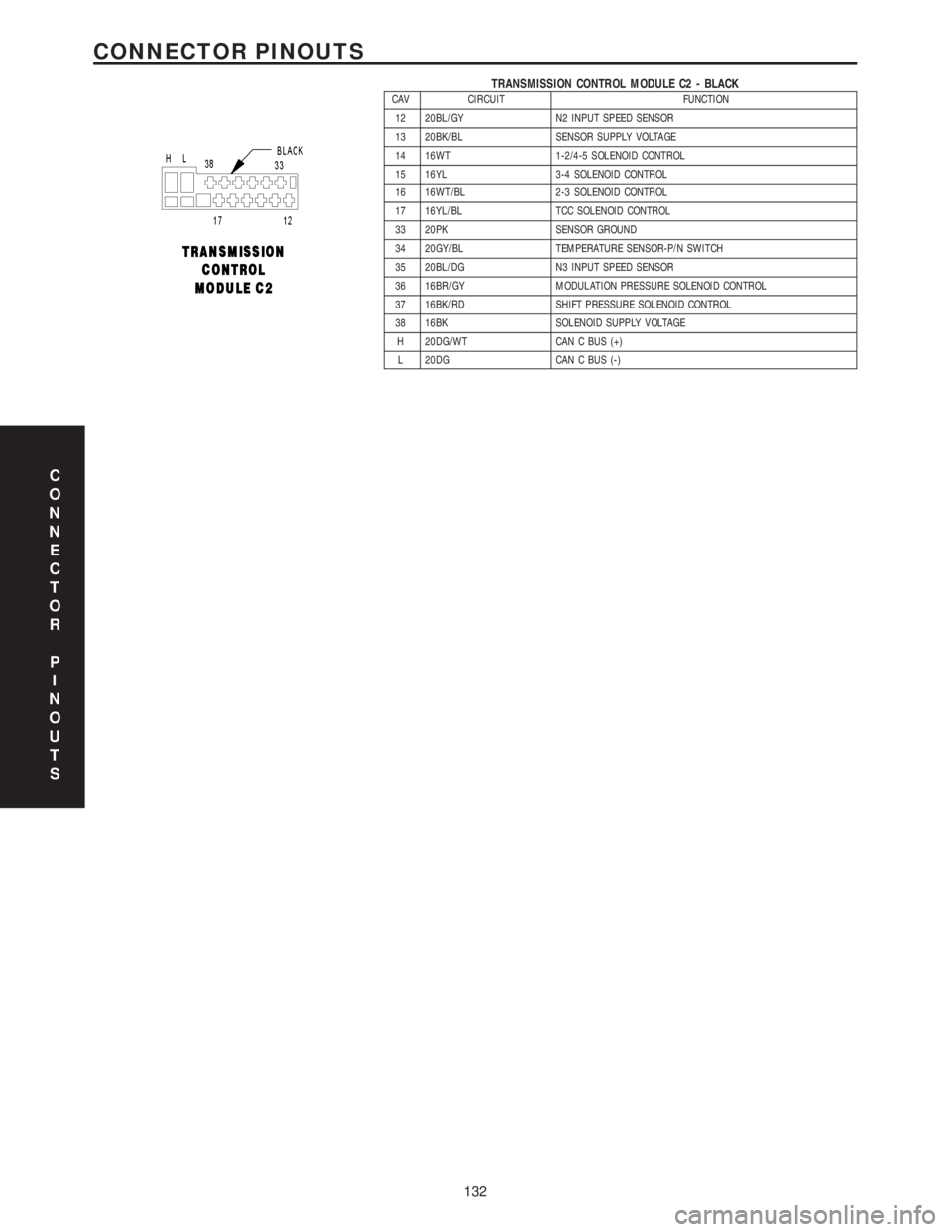

CONNECTOR PINOUTS

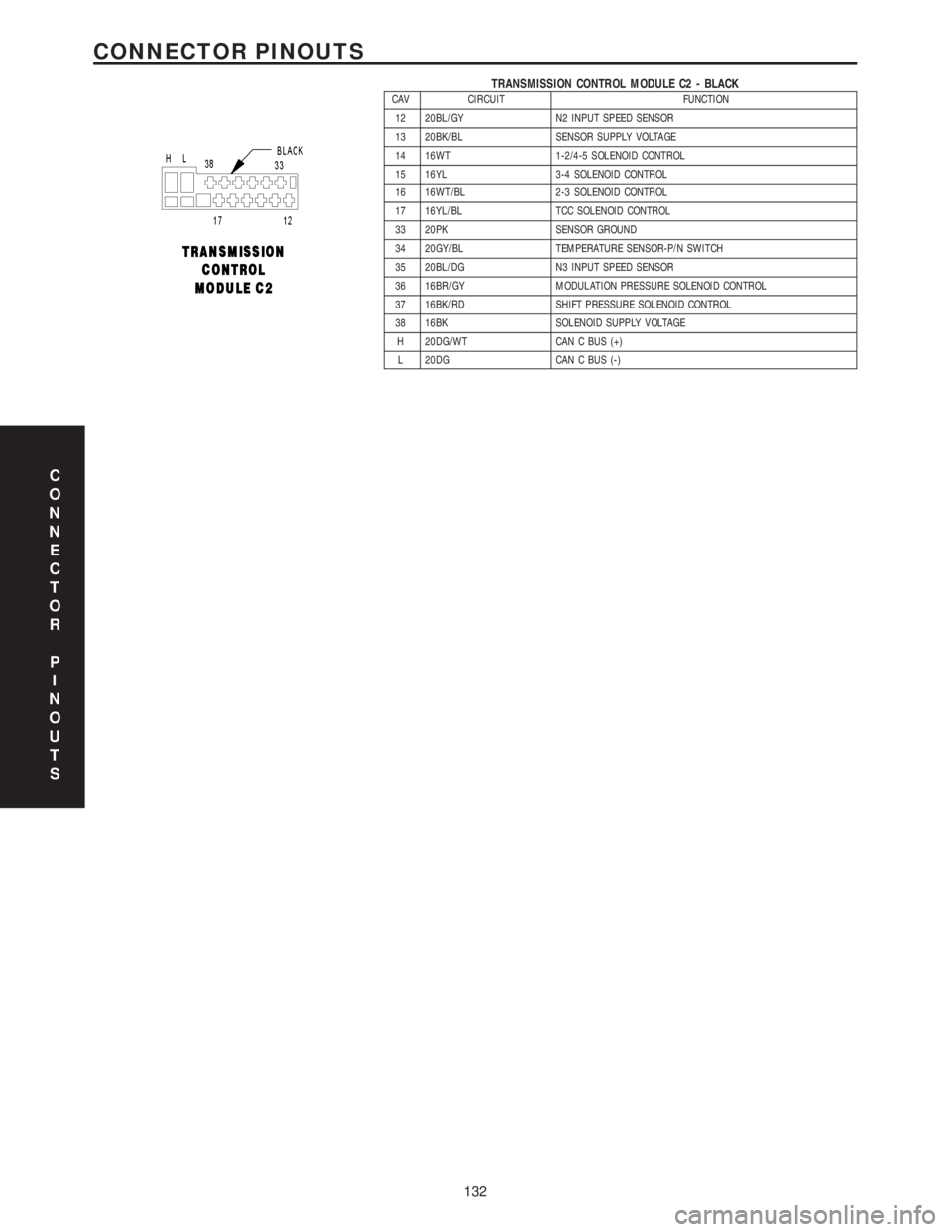

TRANSMISSION CONTROL MODULE C2 - BLACKCAV CIRCUIT FUNCTION

12 20BL/GY N2 INPUT SPEED SENSOR

13 20BK/BL SENSOR SUPPLY VOLTAGE

14 16WT 1-2/4-5 SOLENOID CONTROL

15 16YL 3-4 SOLENOID CONTROL

16 16WT/BL 2-3 SOLENOID CONTROL

17 16YL/BL TCC SOLENOID CONTROL

33 20PK SENSOR GROUND

34 20GY/BL TEMPERATURE SENSOR-P/N SWITCH

35 20BL/DG N3 INPUT SPEED SENSOR

36 16BR/GY MODULATION PRESSURE SOLENOID CONTROL

37 16BK/RD SHIFT PRESSURE SOLENOID CONTROL

38 16BK SOLENOID SUPPLY VOLTAGE

H 20DG/WT CAN C BUS (+)

L 20DG CAN C BUS (-)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

132

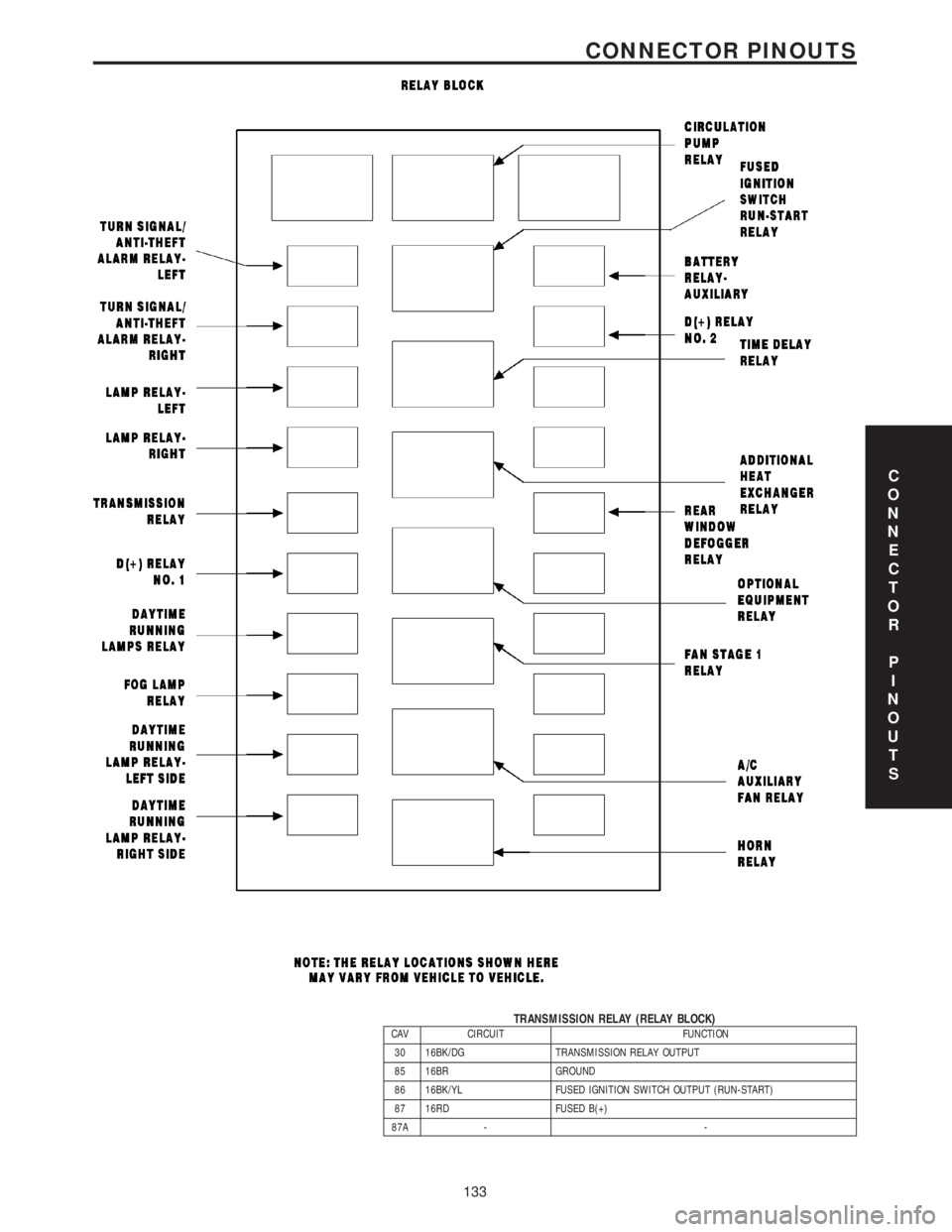

CONNECTOR PINOUTS