light MERCEDES-BENZ SPRINTER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 165 of 2305

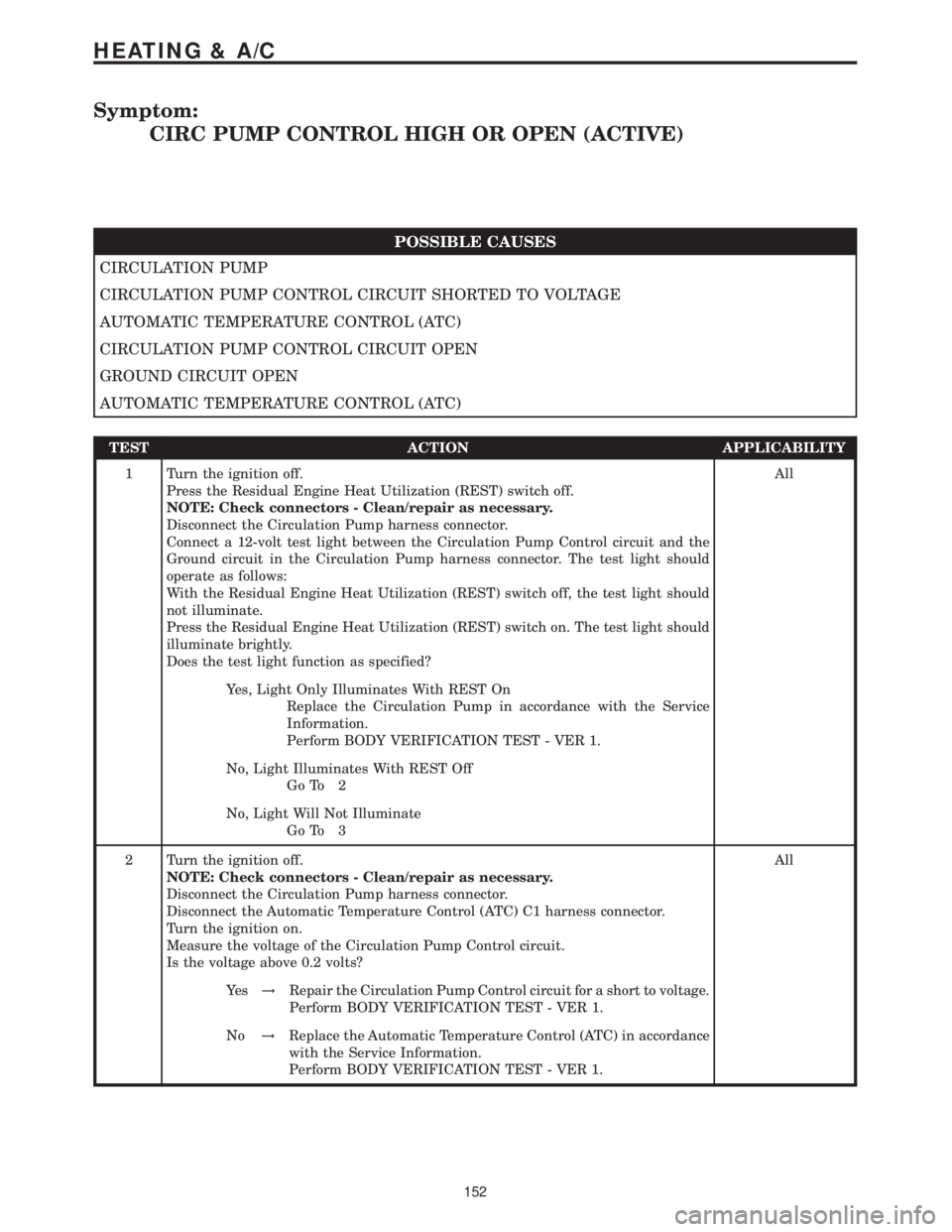

Symptom:

CIRC PUMP CONTROL HIGH OR OPEN (ACTIVE)

POSSIBLE CAUSES

CIRCULATION PUMP

CIRCULATION PUMP CONTROL CIRCUIT SHORTED TO VOLTAGE

AUTOMATIC TEMPERATURE CONTROL (ATC)

CIRCULATION PUMP CONTROL CIRCUIT OPEN

GROUND CIRCUIT OPEN

AUTOMATIC TEMPERATURE CONTROL (ATC)

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Press the Residual Engine Heat Utilization (REST) switch off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Circulation Pump harness connector.

Connect a 12-volt test light between the Circulation Pump Control circuit and the

Ground circuit in the Circulation Pump harness connector. The test light should

operate as follows:

With the Residual Engine Heat Utilization (REST) switch off, the test light should

not illuminate.

Press the Residual Engine Heat Utilization (REST) switch on. The test light should

illuminate brightly.

Does the test light function as specified?All

Yes, Light Only Illuminates With REST On

Replace the Circulation Pump in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No, Light Illuminates With REST Off

Go To 2

No, Light Will Not Illuminate

Go To 3

2 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Circulation Pump harness connector.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Turn the ignition on.

Measure the voltage of the Circulation Pump Control circuit.

Is the voltage above 0.2 volts?All

Ye s!Repair the Circulation Pump Control circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Automatic Temperature Control (ATC) in accordance

with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

152

HEATING & A/C

Page 180 of 2305

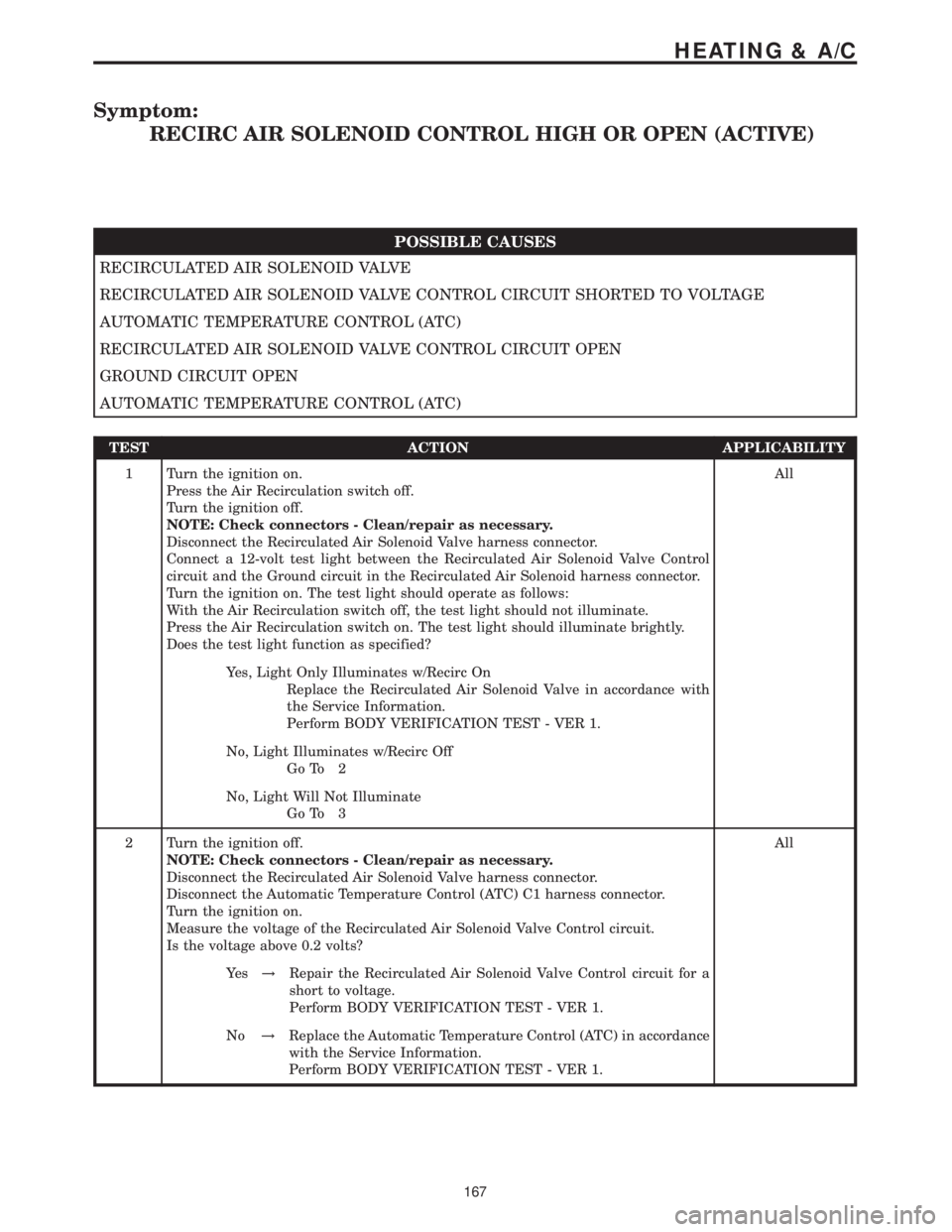

Symptom:

RECIRC AIR SOLENOID CONTROL HIGH OR OPEN (ACTIVE)

POSSIBLE CAUSES

RECIRCULATED AIR SOLENOID VALVE

RECIRCULATED AIR SOLENOID VALVE CONTROL CIRCUIT SHORTED TO VOLTAGE

AUTOMATIC TEMPERATURE CONTROL (ATC)

RECIRCULATED AIR SOLENOID VALVE CONTROL CIRCUIT OPEN

GROUND CIRCUIT OPEN

AUTOMATIC TEMPERATURE CONTROL (ATC)

TEST ACTION APPLICABILITY

1 Turn the ignition on.

Press the Air Recirculation switch off.

Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Recirculated Air Solenoid Valve harness connector.

Connect a 12-volt test light between the Recirculated Air Solenoid Valve Control

circuit and the Ground circuit in the Recirculated Air Solenoid harness connector.

Turn the ignition on. The test light should operate as follows:

With the Air Recirculation switch off, the test light should not illuminate.

Press the Air Recirculation switch on. The test light should illuminate brightly.

Does the test light function as specified?All

Yes, Light Only Illuminates w/Recirc On

Replace the Recirculated Air Solenoid Valve in accordance with

the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

No, Light Illuminates w/Recirc Off

Go To 2

No, Light Will Not Illuminate

Go To 3

2 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Recirculated Air Solenoid Valve harness connector.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Turn the ignition on.

Measure the voltage of the Recirculated Air Solenoid Valve Control circuit.

Is the voltage above 0.2 volts?All

Ye s!Repair the Recirculated Air Solenoid Valve Control circuit for a

short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Automatic Temperature Control (ATC) in accordance

with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

167

HEATING & A/C

Page 183 of 2305

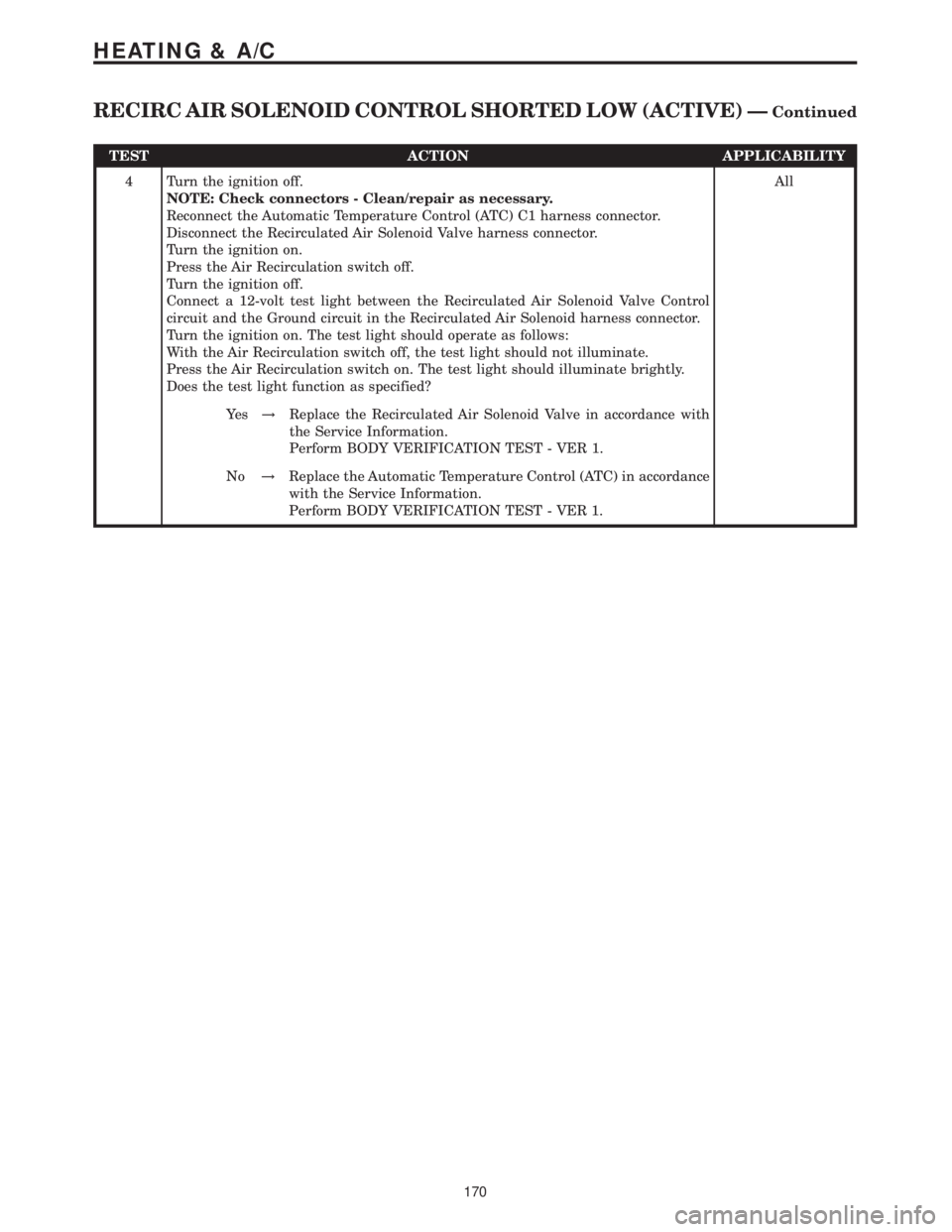

TEST ACTION APPLICABILITY

4 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Reconnect the Automatic Temperature Control (ATC) C1 harness connector.

Disconnect the Recirculated Air Solenoid Valve harness connector.

Turn the ignition on.

Press the Air Recirculation switch off.

Turn the ignition off.

Connect a 12-volt test light between the Recirculated Air Solenoid Valve Control

circuit and the Ground circuit in the Recirculated Air Solenoid harness connector.

Turn the ignition on. The test light should operate as follows:

With the Air Recirculation switch off, the test light should not illuminate.

Press the Air Recirculation switch on. The test light should illuminate brightly.

Does the test light function as specified?All

Ye s!Replace the Recirculated Air Solenoid Valve in accordance with

the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Automatic Temperature Control (ATC) in accordance

with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

170

HEATING & A/C

RECIRC AIR SOLENOID CONTROL SHORTED LOW (ACTIVE) ÐContinued

Page 188 of 2305

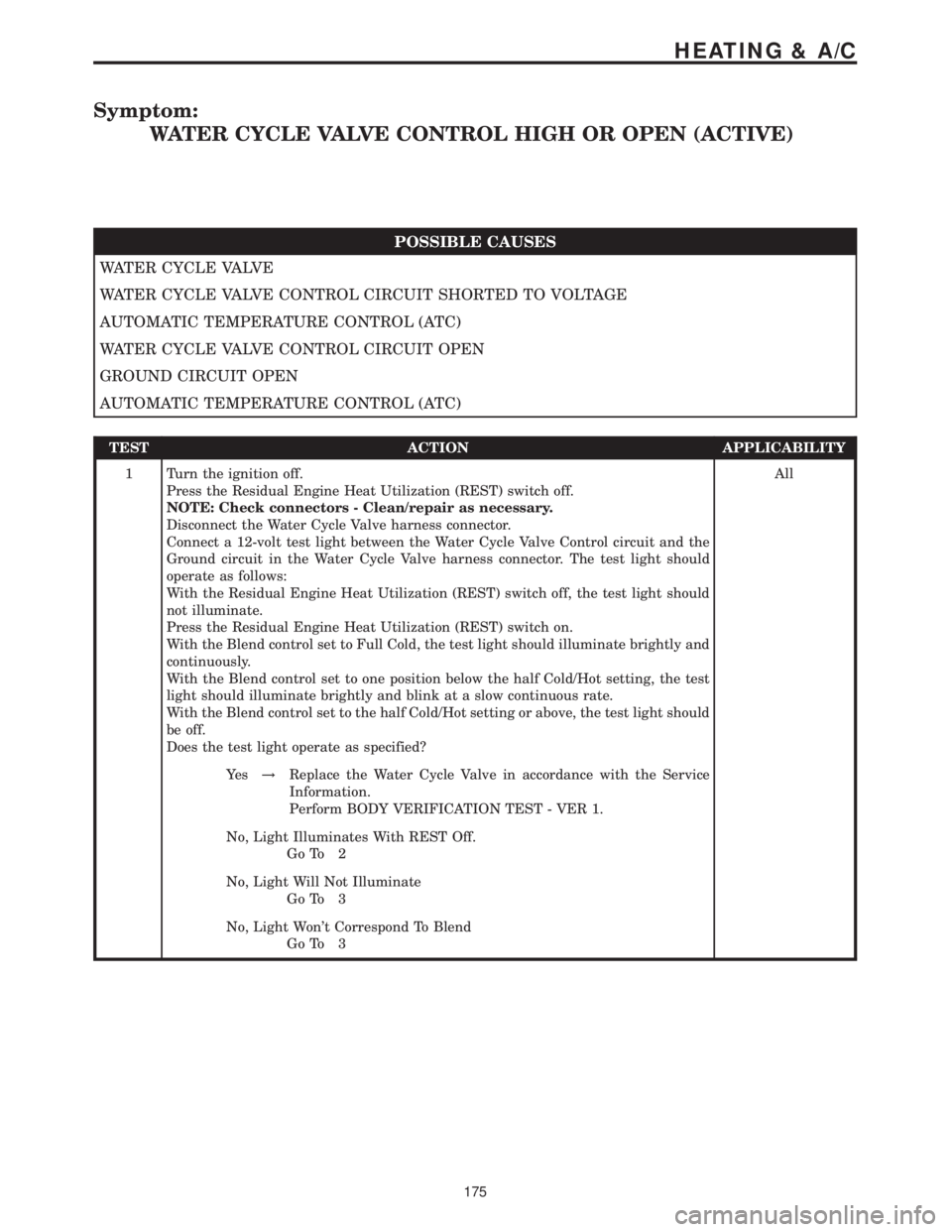

Symptom:

WATER CYCLE VALVE CONTROL HIGH OR OPEN (ACTIVE)

POSSIBLE CAUSES

WATER CYCLE VALVE

WATER CYCLE VALVE CONTROL CIRCUIT SHORTED TO VOLTAGE

AUTOMATIC TEMPERATURE CONTROL (ATC)

WATER CYCLE VALVE CONTROL CIRCUIT OPEN

GROUND CIRCUIT OPEN

AUTOMATIC TEMPERATURE CONTROL (ATC)

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Press the Residual Engine Heat Utilization (REST) switch off.

NOTE: Check connectors - Clean/repair as necessary.

Disconnect the Water Cycle Valve harness connector.

Connect a 12-volt test light between the Water Cycle Valve Control circuit and the

Ground circuit in the Water Cycle Valve harness connector. The test light should

operate as follows:

With the Residual Engine Heat Utilization (REST) switch off, the test light should

not illuminate.

Press the Residual Engine Heat Utilization (REST) switch on.

With the Blend control set to Full Cold, the test light should illuminate brightly and

continuously.

With the Blend control set to one position below the half Cold/Hot setting, the test

light should illuminate brightly and blink at a slow continuous rate.

With the Blend control set to the half Cold/Hot setting or above, the test light should

be off.

Does the test light operate as specified?All

Ye s!Replace the Water Cycle Valve in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No, Light Illuminates With REST Off.

Go To 2

No, Light Will Not Illuminate

Go To 3

No, Light Won't Correspond To Blend

Go To 3

175

HEATING & A/C

Page 191 of 2305

TEST ACTION APPLICABILITY

4 Turn the ignition off.

NOTE: Check connectors - Clean/repair as necessary.

Reconnect the Automatic Temperature Control (ATC) C1 harness connector.

Press the Residual Engine Heat Utilization (REST) switch off.

Disconnect the Water Cycle Valve harness connector.

Connect a 12-volt test light between the Water Cycle Valve Control circuit and the

Ground circuit in the Water Cycle Valve harness connector. The test light should

operate as follows:

With the Residual Engine Heat Utilization (REST) switch off, the test light should

not illuminate.

Press the Residual Engine Heat Utilization (REST) switch on.

With the Blend control set to Full Cold, the test light should illuminate brightly and

continuously.

With the Blend control set to one position below the half Cold/Hot setting, the test

light should illuminate brightly and blink at a slow continuous rate.

With the Blend control set to the half Cold/Hot setting or above, the test light should

be off.

Does the test light operate as specified?All

Ye s!Replace the Water Cycle Valve in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No!Replace the Automatic Temperature Control (ATC) in accordance

with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

178

HEATING & A/C

WATER CYCLE VALVE CONTROL SHORTED LOW (ACTIVE) ÐContinued

Page 254 of 2305

TEST ACTION APPLICABILITY

8 Turn the ignition off.

NOTE: The Rain Sensor Module (RSM) is mounted above the accelerator

pedal assembly.

Disconnect the Rain Sensor Module harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Battery Supply circuit at the

Rain Sensor Module harness connector cavity A-1.

Does the test light illuminate brightly?All

Ye s!Go To 9

No!Repair the open 12 Volt Power Supply circuit.

9 Turn the ignition off.

Disconnect the Rain Sensor Module harness connector.

Using a 12-volt test light connected to 12 volts, check the Ground circuit at the Rain

Sensor Module harness connector cavity C-1.

Does the test light illuminate brightly?All

Ye s!Go To 10

No!Repair the open Ground circuit.

10 Turn the ignition off.

Disconnect the Rain Sensor Module harness connector.

Turn the ignition on.

Refer to the Wiper/Washer Switch Voltage Chart in Charts and Graphs to verify

correct wiper switch voltage signals to the Rain Sensor Module when the wiper

switch is adjusted to each of the four positions.

Do voltage readings at the RSM connector correspond correctly to voltages specified

in the chart?All

Ye s!Go To 11

No!Refer to the Rain Sensor/Wiper System Schematic in Charts and

Graphs to diagnose base wiper system problem with the circuit(s)

that did not have the correct corresponding voltage to the chart.

11 Turn the ignition off.

Disconnect the wiper motor harness connector.

Using a 12-volt test light connected to 12-volts, check the Ground circuit at the Wiper

Motor harness connector.

Does the test light illuminate brightly?All

Ye s!Go To 12

No!Repair the Wiper Motor Ground circuit for an open.

241

WINDSHIELD WIPER & WASHER

CHECKING THE RAIN SENSOR/WIPER OPERATION ÐContinued

Page 324 of 2305

²Four Wheel Speed Sensors/Tone Wheel assem-

blies

²ABS warning indicator

²TCS (ASR) event indicator

²TCS (ASR) warning indicator

²Steering Angle Sensor

²Lateral Acceleration/Yaw Rate Sensor

²Brake Pressure Sensor

²ESP event indicator

²Brake Fluid Level switch

²Brake Switch (BS)

²Brake Lamp Switch (BLS)

²TCS Switch (TCSS)

²K - ABS

²CAN C Bus

²Fuses, grounds, and wiring

3.7.1 ABS AND TCS (ASR) INDICATORS

This system is equipped with an ABS warning

indicator, TCS (ASR) warning indicator, and TCS

(ASR) event indicator to alert the driver of a

malfunction/event it has detected. The CAB can

request the illumination of the ABS warning indi-

cator, TCS (ASR) warning indicator, and TCS (ASR)

event indicator via CAN C BUS. The CAB controls

the ABS warning indicator by:

²Light steady during an initial test at the begin-

ning of an ignition cycle to function as a bulb

check

²Light steady when a system malfunction exists

(DTC)

²Light steady - If you have not met the speed

required to reset/retest the ABS components

The Instrument Cluster (IC) controls the indica-

tors. The Instrument Cluster transmits a message

over the CAN C Bus relating to diagnostics and

current lamp status for the ABS and TCS (ASR)

indicators. The CAB can control the operation of

TCS warning and TCS event indicators by:

²Both light steady with engine off and both go out

with engine running

²TCS warning indicator lights steady when a TCS

malfunction exists

²TCS event indicator will flash when TCS is in an

active event

3.7.2 CONTROLLER ANTILOCK BRAKE

(CAB)

The CAB is mounted directly to the Hydraulic

Control Unit (HCU) that includes a microprocessor

and twelve solenoids that control valves that con-trol brake pressure during antilock braking or trac-

tion control events. The CAB also has circuits that

monitor the following:

²Double brake switch outputs are monitored to

determine whether or not to prepare for possible

ABS braking

²Wheel Speed Sensors are monitored to determine

when a wheel is tending to lock up. The CAB will

operate the valves in the HCU to control braking

pressure during ABS braking

²Detect ABS system related problems and take

diagnostic action

²Able to execute self-tests and output control com-

mands

When equipped with Electronic Stability (ESP),

the CAB also monitors the following:

²The ESP looks at the Steering Angle Sensor value

and monitors the speed of the inner and outer

wheels to ensure that the values are plausible.

The Steering Angle Sensor also monitors the

speed that the steering wheel is turned.

²The Lateral Acceleration/Yaw Rate Sensor is con-

tained in one unit. The sensor measures side to

side (lateral) motion and rotational motion (how

fast the vehicle is turning).

²The ESP uses data from the Brake Pressure

Sensor to analyze how hard and fast that the

driver wants to brake.

3.7.3 HYDRAULIC CONTROL UNIT (HCU)

The HCU on the Bosch 5.7 has an integral valve

body for controlling the front and rear brakes.

Within the HCU are inlet, outlet, and shuttle

valves, to release brake pressure as required to

avoid wheel lockup, keeping the wheels rolling, and

maintain optimum deceleration with stability. The

Pump Motor is attached to the HCU which works

with the ABS and TCS and is controlled by the

CAB. The primary function is to provide extra

amount of fluid when needed.

3.7.4 SWITCHES/SENSORS

BRAKE SWITCH (BS):This switch prepares the

CAB for a possible antilock event. The CAB uses an

output state voltage from the BS when the brake

pedal is either released/depressed. The Fused Igni-

tion Switch Output circuit supplies 12 volts to the

BS. A released brake pedal will close the BS circuit

and the BS Output circuit supplies 12 volts to the

CAB. When the driver depresses the brake pedal,

the BS Output circuit voltage drops to 0 volts and

the CAB senses the brake pedal state. This tells the

CAB what position the brake pedal is currently in to

make an ABS event possible. When using the

DRBIIItin Inputs/Outputs, the BS and BLS will

3

GENERAL INFORMATION

Page 326 of 2305

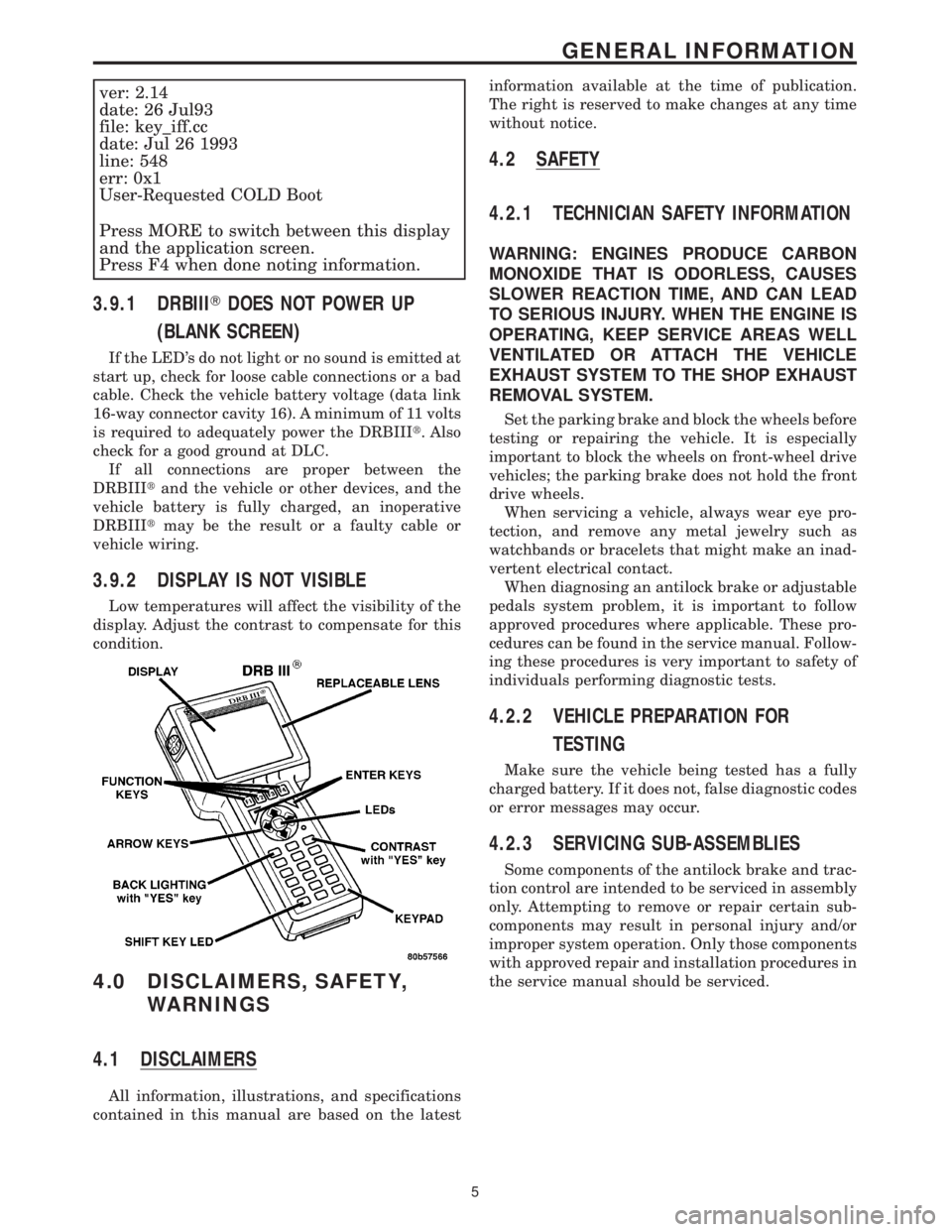

ver: 2.14

date: 26 Jul93

file: key_iff.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.9.1 DRBIIITDOES NOT POWER UP

(BLANK SCREEN)

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

16-way connector cavity 16). A minimum of 11 volts

is required to adequately power the DRBIIIt. Also

check for a good ground at DLC.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result or a faulty cable or

vehicle wiring.

3.9.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latestinformation available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially

important to block the wheels on front-wheel drive

vehicles; the parking brake does not hold the front

drive wheels.

When servicing a vehicle, always wear eye pro-

tection, and remove any metal jewelry such as

watchbands or bracelets that might make an inad-

vertent electrical contact.

When diagnosing an antilock brake or adjustable

pedals system problem, it is important to follow

approved procedures where applicable. These pro-

cedures can be found in the service manual. Follow-

ing these procedures is very important to safety of

individuals performing diagnostic tests.

4.2.2 VEHICLE PREPARATION FOR

TESTING

Make sure the vehicle being tested has a fully

charged battery. If it does not, false diagnostic codes

or error messages may occur.

4.2.3 SERVICING SUB-ASSEMBLIES

Some components of the antilock brake and trac-

tion control are intended to be serviced in assembly

only. Attempting to remove or repair certain sub-

components may result in personal injury and/or

improper system operation. Only those components

with approved repair and installation procedures in

the service manual should be serviced.

5

GENERAL INFORMATION

Page 328 of 2305

display does not match the state of the pedal,

perform the proper test. For a problem with the

ªABSº warning indicator, refer to the proper test.

6. If no other problems are found, it will be neces-

sary to road test the vehicle.THE DRBIIIt

MUST NOT BE CONNECTED TO THE

DATA LINK CONNECTOR WHEN ROAD

TESTING FOR PROPER ANTILOCK OP-

ERATION. THE SYSTEM IS DISABLED

WHILE IN DIAGNOSTIC MODE.Perform

several antilock stops from above 50 Km/h (30

mph) and then repeat steps 2, 3, and 4. If any

diagnostic trouble codes are present, proceed to

the appropriate test.

7. The following conditions should be considered

``NORMAL'' operation, and no repairs should be

attempted to correct them.

± Brake pedal feedback during an ABS stop

(clicking, vibrating)

± Clicking, groaning or buzzing at 12 Km/h (8

mph) (drive off self test)

± Groaning noise during an ABS stop

± Slight brake pedal drop and pop noise when

ignition is initially turned on

± Brake pedal ratcheting down at the end of an

ABS stop

8. If the complaint is ABS ``cycling'' at the end of a

stop at low speeds, it may be caused by a

marginal wheel speed sensor signal. The sensor

air gap, tone wheel condition, and/or brakes

hanging up are possible causes of this condition.

9. After a road test in which no problems were

found, refer to any Technical Service Bulletins

that may apply.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box)

jumper wires

ohmmeter

voltmeter

test light

oscilloscope

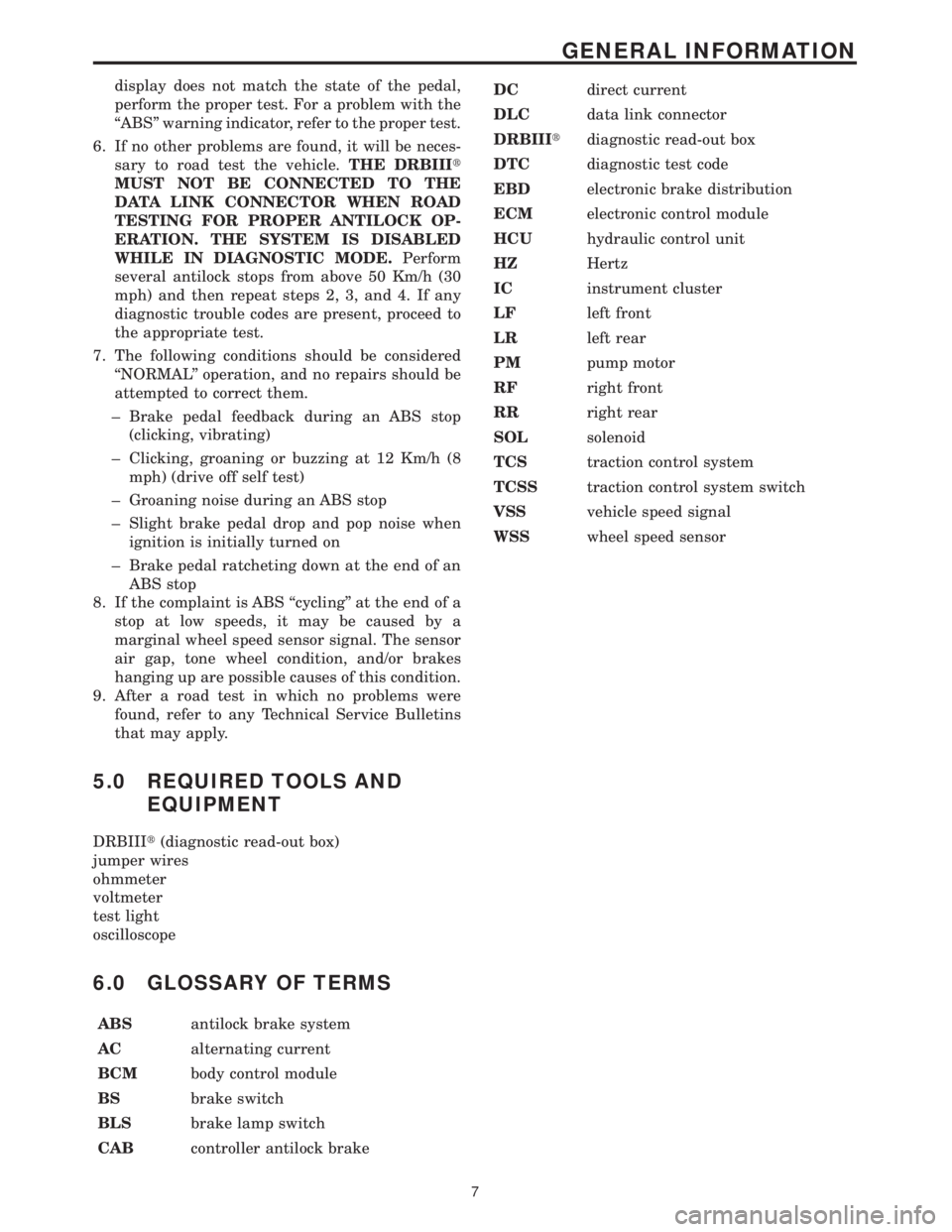

6.0 GLOSSARY OF TERMS

ABSantilock brake system

ACalternating current

BCMbody control module

BSbrake switch

BLSbrake lamp switch

CABcontroller antilock brakeDCdirect current

DLCdata link connector

DRBIIItdiagnostic read-out box

DTCdiagnostic test code

EBDelectronic brake distribution

ECMelectronic control module

HCUhydraulic control unit

HZHertz

ICinstrument cluster

LFleft front

LRleft rear

PMpump motor

RFright front

RRright rear

SOLsolenoid

TCStraction control system

TCSStraction control system switch

VSSvehicle speed signal

WSSwheel speed sensor

7

GENERAL INFORMATION

Page 332 of 2305

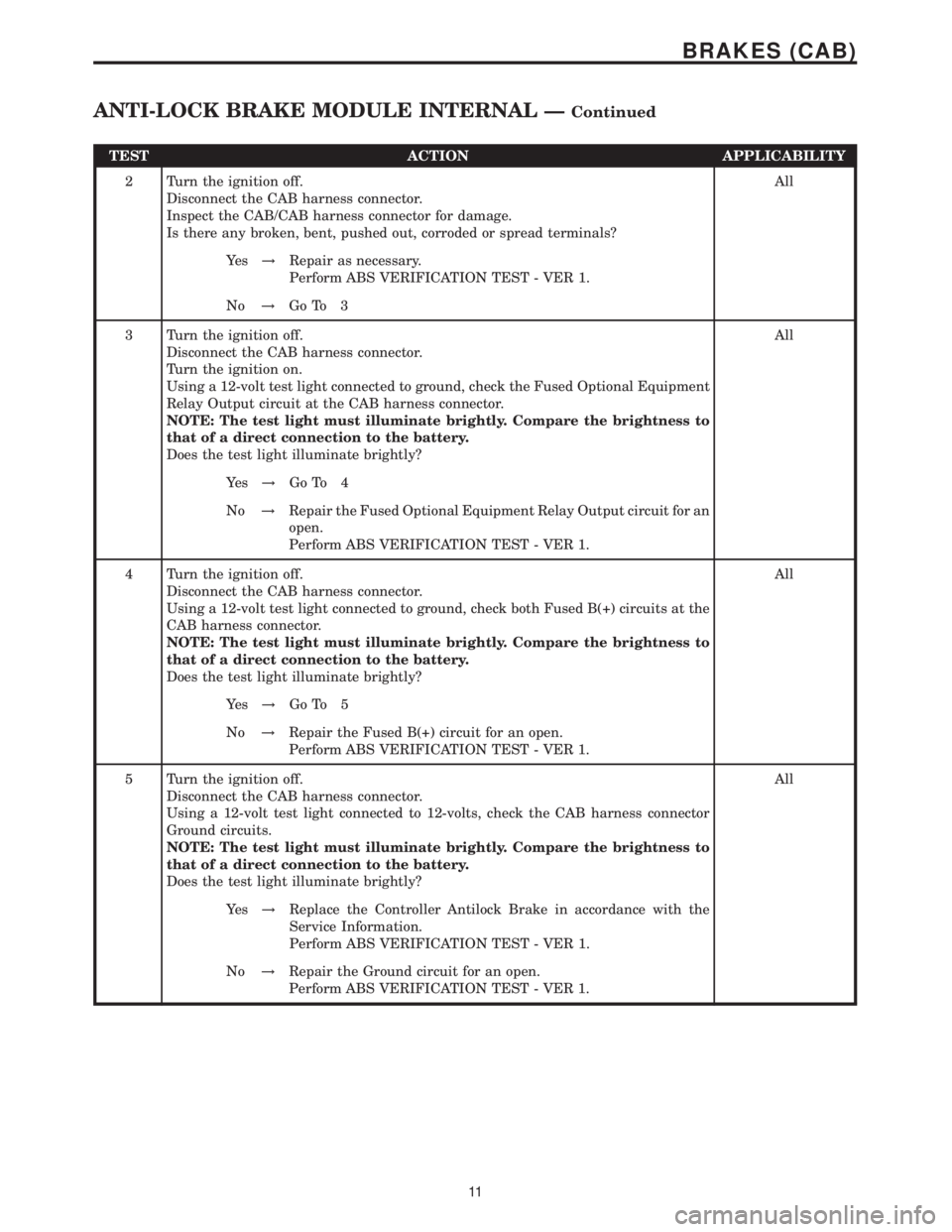

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the CAB harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Optional Equipment

Relay Output circuit at the CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 4

No!Repair the Fused Optional Equipment Relay Output circuit for an

open.

Perform ABS VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Disconnect the CAB harness connector.

Using a 12-volt test light connected to ground, check both Fused B(+) circuits at the

CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 5

No!Repair the Fused B(+) circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Disconnect the CAB harness connector.

Using a 12-volt test light connected to 12-volts, check the CAB harness connector

Ground circuits.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No!Repair the Ground circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

11

BRAKES (CAB)

ANTI-LOCK BRAKE MODULE INTERNAL ÐContinued