light MERCEDES-BENZ SPRINTER 2006 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 637 of 2305

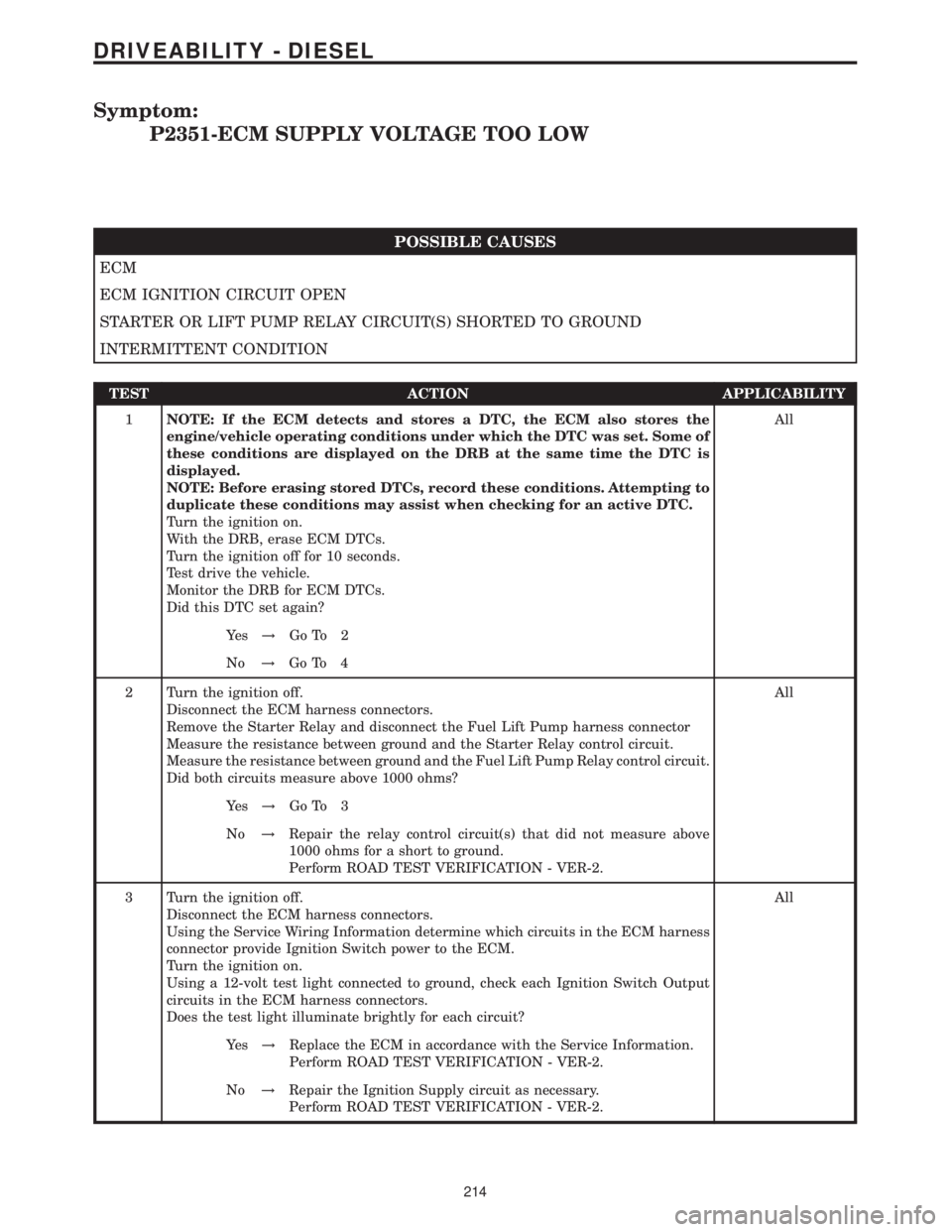

Symptom:

P2351-ECM SUPPLY VOLTAGE TOO LOW

POSSIBLE CAUSES

ECM

ECM IGNITION CIRCUIT OPEN

STARTER OR LIFT PUMP RELAY CIRCUIT(S) SHORTED TO GROUND

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1NOTE: If the ECM detects and stores a DTC, the ECM also stores the

engine/vehicle operating conditions under which the DTC was set. Some of

these conditions are displayed on the DRB at the same time the DTC is

displayed.

NOTE: Before erasing stored DTCs, record these conditions. Attempting to

duplicate these conditions may assist when checking for an active DTC.

Turn the ignition on.

With the DRB, erase ECM DTCs.

Turn the ignition off for 10 seconds.

Test drive the vehicle.

Monitor the DRB for ECM DTCs.

Did this DTC set again?All

Ye s!Go To 2

No!Go To 4

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay and disconnect the Fuel Lift Pump harness connector

Measure the resistance between ground and the Starter Relay control circuit.

Measure the resistance between ground and the Fuel Lift Pump Relay control circuit.

Did both circuits measure above 1000 ohms?All

Ye s!Go To 3

No!Repair the relay control circuit(s) that did not measure above

1000 ohms for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the ECM harness connectors.

Using the Service Wiring Information determine which circuits in the ECM harness

connector provide Ignition Switch power to the ECM.

Turn the ignition on.

Using a 12-volt test light connected to ground, check each Ignition Switch Output

circuits in the ECM harness connectors.

Does the test light illuminate brightly for each circuit?All

Ye s!Replace the ECM in accordance with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Ignition Supply circuit as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

214

DRIVEABILITY - DIESEL

Page 642 of 2305

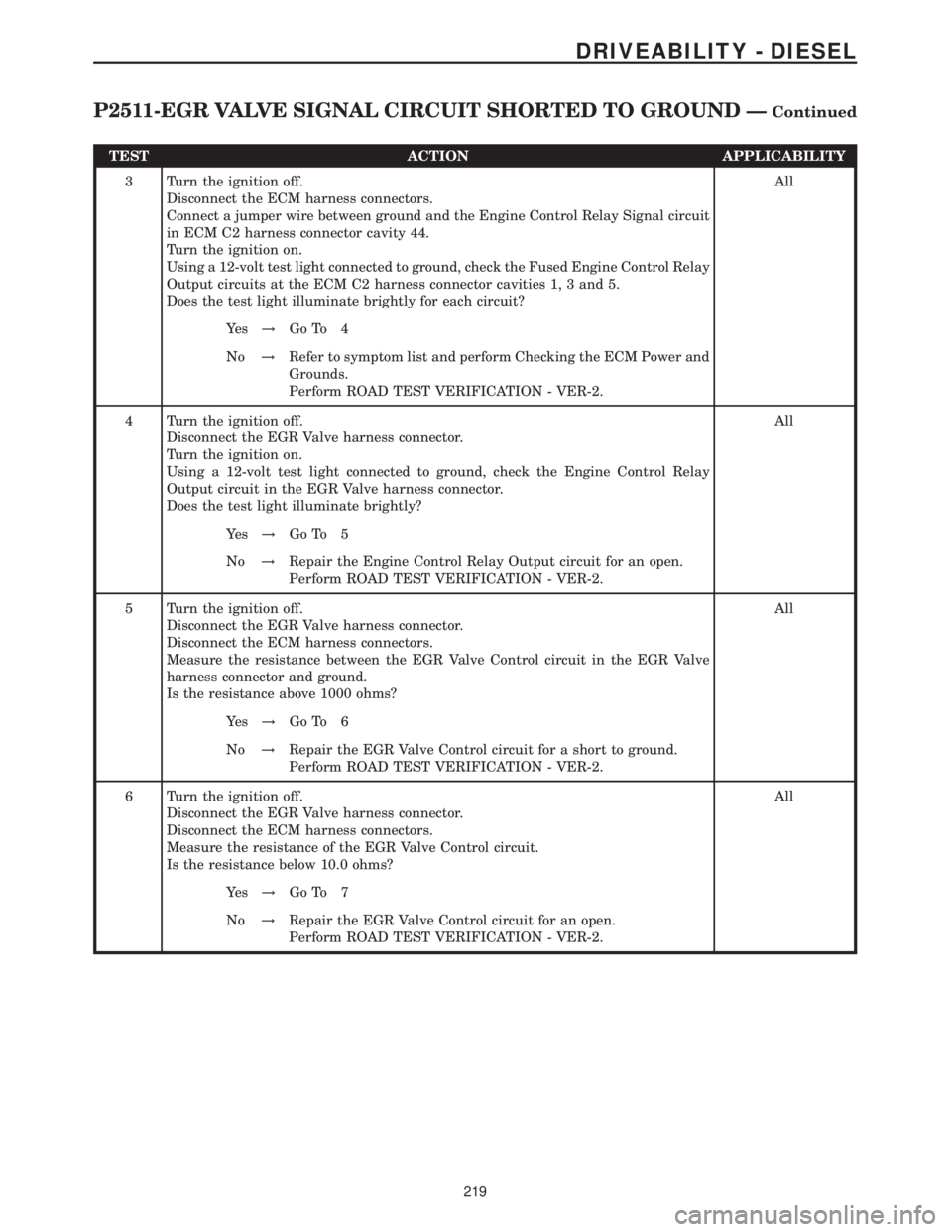

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Signal circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Does the test light illuminate brightly for each circuit?All

Ye s!Go To 4

No!Refer to symptom list and perform Checking the ECM Power and

Grounds.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the EGR Valve harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Engine Control Relay

Output circuit in the EGR Valve harness connector.

Does the test light illuminate brightly?All

Ye s!Go To 5

No!Repair the Engine Control Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

5 Turn the ignition off.

Disconnect the EGR Valve harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between the EGR Valve Control circuit in the EGR Valve

harness connector and ground.

Is the resistance above 1000 ohms?All

Ye s!Go To 6

No!Repair the EGR Valve Control circuit for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

6 Turn the ignition off.

Disconnect the EGR Valve harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the EGR Valve Control circuit.

Is the resistance below 10.0 ohms?All

Ye s!Go To 7

No!Repair the EGR Valve Control circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

219

DRIVEABILITY - DIESEL

P2511-EGR VALVE SIGNAL CIRCUIT SHORTED TO GROUND ÐContinued

Page 645 of 2305

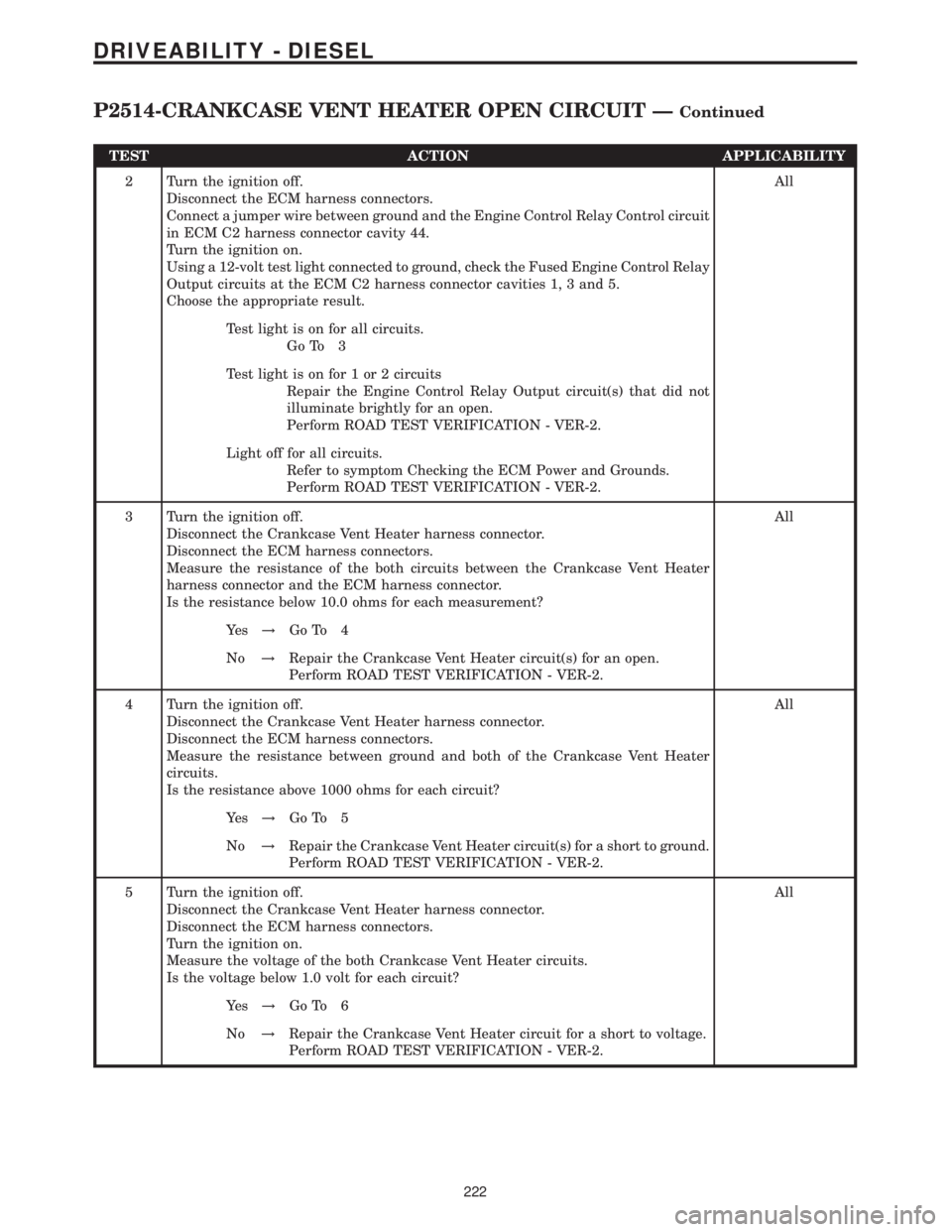

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Choose the appropriate result.All

Test light is on for all circuits.

Go To 3

Test light is on for 1 or 2 circuits

Repair the Engine Control Relay Output circuit(s) that did not

illuminate brightly for an open.

Perform ROAD TEST VERIFICATION - VER-2.

Light off for all circuits.

Refer to symptom Checking the ECM Power and Grounds.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the Crankcase Vent Heater harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the both circuits between the Crankcase Vent Heater

harness connector and the ECM harness connector.

Is the resistance below 10.0 ohms for each measurement?All

Ye s!Go To 4

No!Repair the Crankcase Vent Heater circuit(s) for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the Crankcase Vent Heater harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and both of the Crankcase Vent Heater

circuits.

Is the resistance above 1000 ohms for each circuit?All

Ye s!Go To 5

No!Repair the Crankcase Vent Heater circuit(s) for a short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

5 Turn the ignition off.

Disconnect the Crankcase Vent Heater harness connector.

Disconnect the ECM harness connectors.

Turn the ignition on.

Measure the voltage of the both Crankcase Vent Heater circuits.

Is the voltage below 1.0 volt for each circuit?All

Ye s!Go To 6

No!Repair the Crankcase Vent Heater circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

222

DRIVEABILITY - DIESEL

P2514-CRANKCASE VENT HEATER OPEN CIRCUIT ÐContinued

Page 658 of 2305

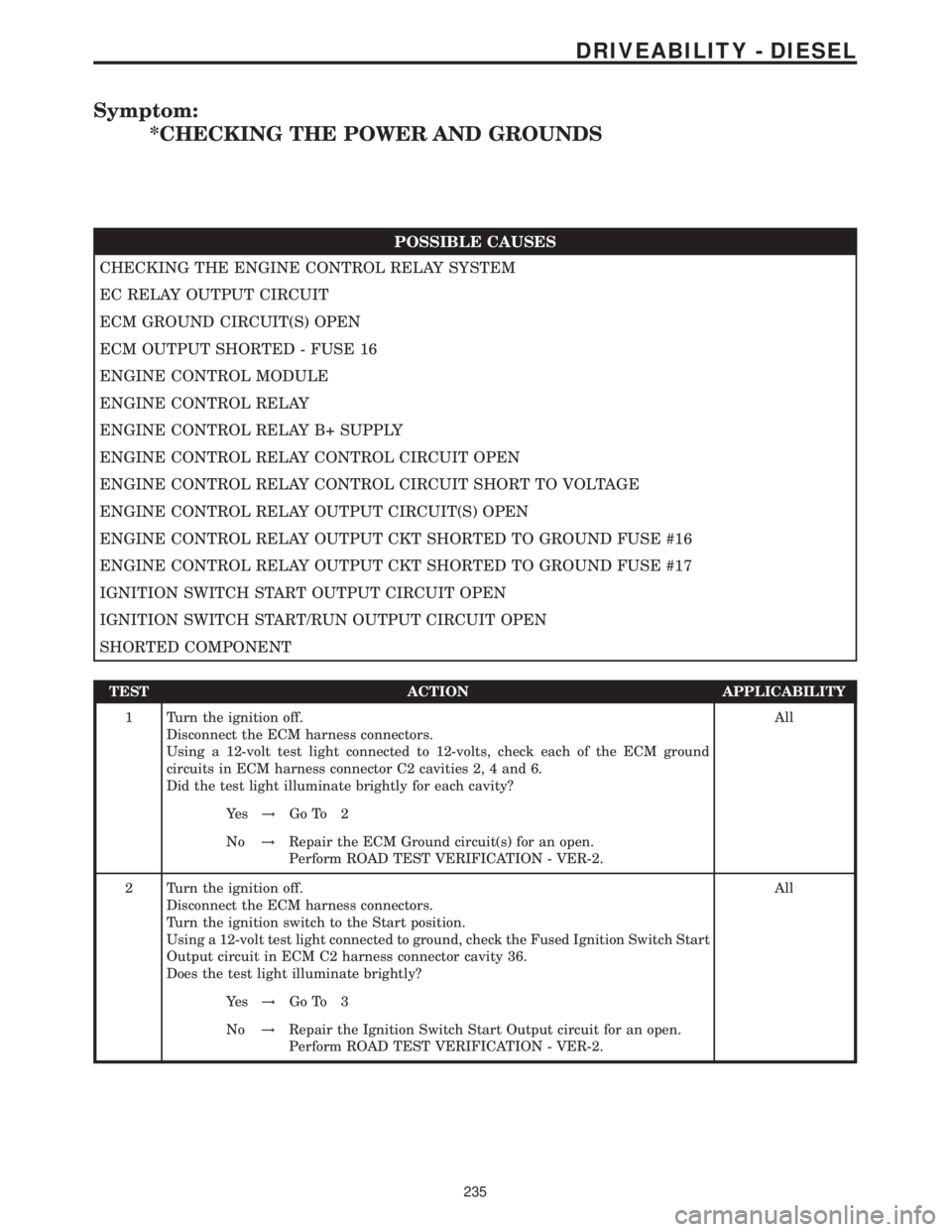

Symptom:

*CHECKING THE POWER AND GROUNDS

POSSIBLE CAUSES

CHECKING THE ENGINE CONTROL RELAY SYSTEM

EC RELAY OUTPUT CIRCUIT

ECM GROUND CIRCUIT(S) OPEN

ECM OUTPUT SHORTED - FUSE 16

ENGINE CONTROL MODULE

ENGINE CONTROL RELAY

ENGINE CONTROL RELAY B+ SUPPLY

ENGINE CONTROL RELAY CONTROL CIRCUIT OPEN

ENGINE CONTROL RELAY CONTROL CIRCUIT SHORT TO VOLTAGE

ENGINE CONTROL RELAY OUTPUT CIRCUIT(S) OPEN

ENGINE CONTROL RELAY OUTPUT CKT SHORTED TO GROUND FUSE #16

ENGINE CONTROL RELAY OUTPUT CKT SHORTED TO GROUND FUSE #17

IGNITION SWITCH START OUTPUT CIRCUIT OPEN

IGNITION SWITCH START/RUN OUTPUT CIRCUIT OPEN

SHORTED COMPONENT

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to 12-volts, check each of the ECM ground

circuits in ECM harness connector C2 cavities 2, 4 and 6.

Did the test light illuminate brightly for each cavity?All

Ye s!Go To 2

No!Repair the ECM Ground circuit(s) for an open.

Perform ROAD TEST VERIFICATION - VER-2.

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Turn the ignition switch to the Start position.

Using a 12-volt test light connected to ground, check the Fused Ignition Switch Start

Output circuit in ECM C2 harness connector cavity 36.

Does the test light illuminate brightly?All

Ye s!Go To 3

No!Repair the Ignition Switch Start Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

235

DRIVEABILITY - DIESEL

Page 659 of 2305

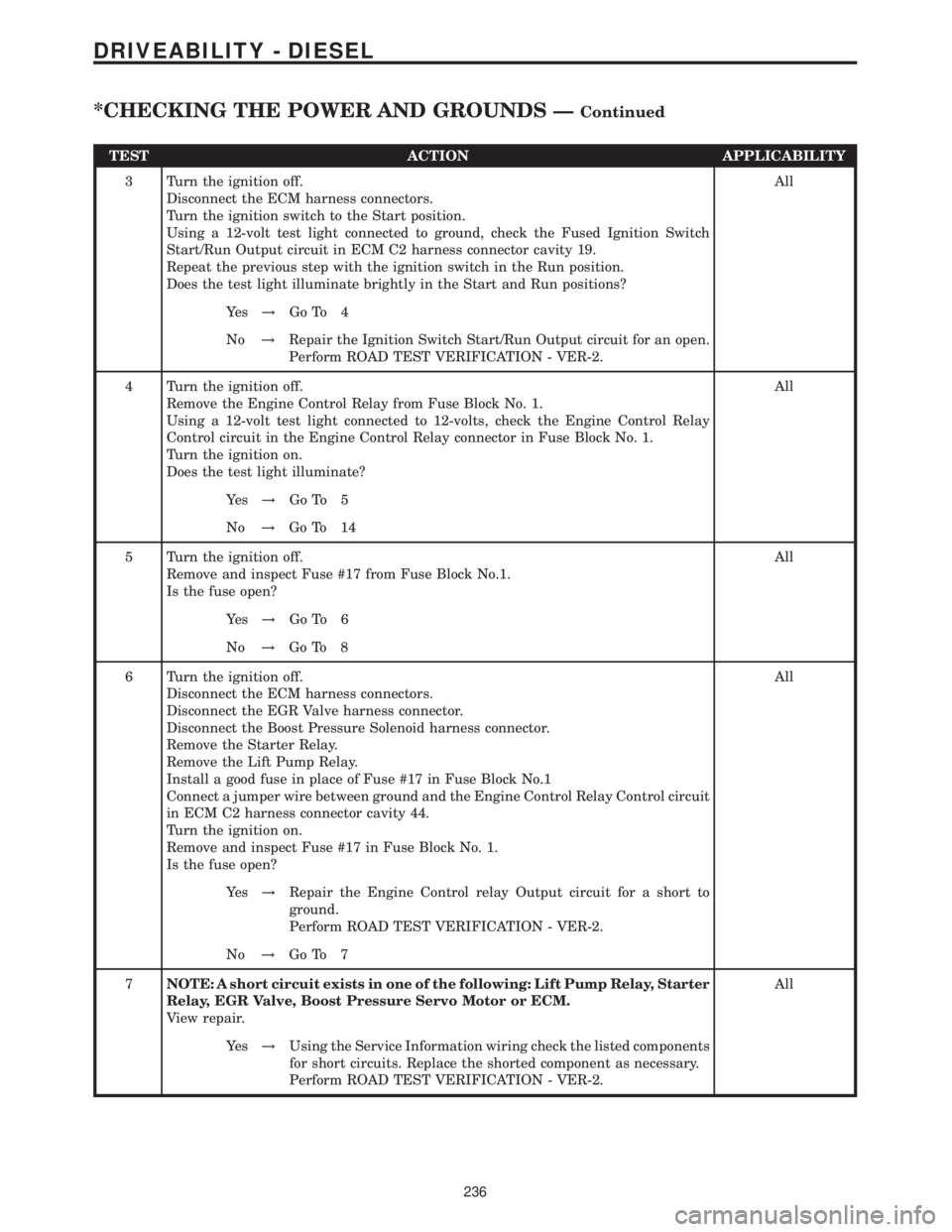

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the ECM harness connectors.

Turn the ignition switch to the Start position.

Using a 12-volt test light connected to ground, check the Fused Ignition Switch

Start/Run Output circuit in ECM C2 harness connector cavity 19.

Repeat the previous step with the ignition switch in the Run position.

Does the test light illuminate brightly in the Start and Run positions?All

Ye s!Go To 4

No!Repair the Ignition Switch Start/Run Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Remove the Engine Control Relay from Fuse Block No. 1.

Using a 12-volt test light connected to 12-volts, check the Engine Control Relay

Control circuit in the Engine Control Relay connector in Fuse Block No. 1.

Turn the ignition on.

Does the test light illuminate?All

Ye s!Go To 5

No!Go To 14

5 Turn the ignition off.

Remove and inspect Fuse #17 from Fuse Block No.1.

Is the fuse open?All

Ye s!Go To 6

No!Go To 8

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the EGR Valve harness connector.

Disconnect the Boost Pressure Solenoid harness connector.

Remove the Starter Relay.

Remove the Lift Pump Relay.

Install a good fuse in place of Fuse #17 in Fuse Block No.1

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Remove and inspect Fuse #17 in Fuse Block No. 1.

Is the fuse open?All

Ye s!Repair the Engine Control relay Output circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 7

7NOTE: A short circuit exists in one of the following: Lift Pump Relay, Starter

Relay, EGR Valve, Boost Pressure Servo Motor or ECM.

View repair.All

Ye s!Using the Service Information wiring check the listed components

for short circuits. Replace the shorted component as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

236

DRIVEABILITY - DIESEL

*CHECKING THE POWER AND GROUNDS ÐContinued

Page 660 of 2305

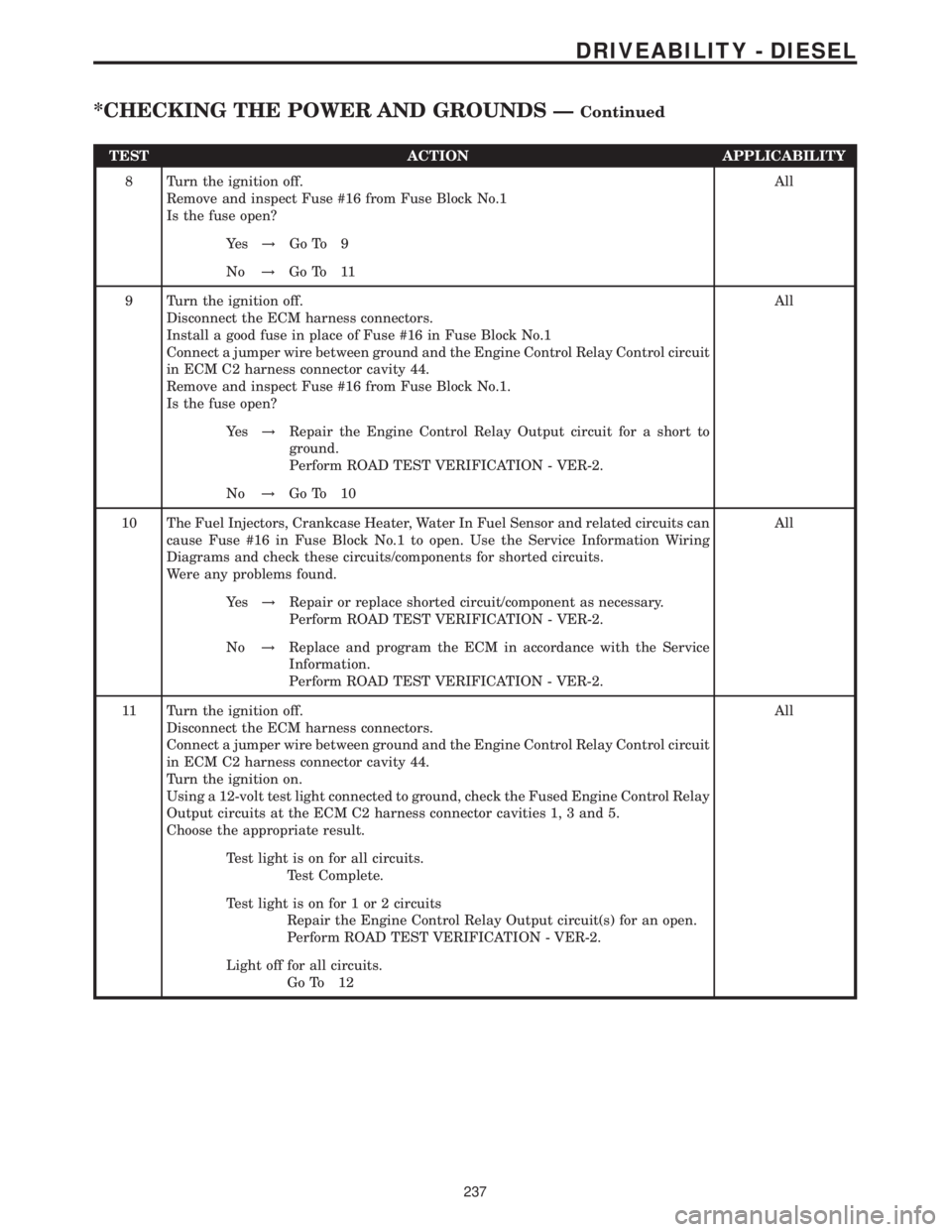

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Remove and inspect Fuse #16 from Fuse Block No.1

Is the fuse open?All

Ye s!Go To 9

No!Go To 11

9 Turn the ignition off.

Disconnect the ECM harness connectors.

Install a good fuse in place of Fuse #16 in Fuse Block No.1

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Remove and inspect Fuse #16 from Fuse Block No.1.

Is the fuse open?All

Ye s!Repair the Engine Control Relay Output circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 10

10 The Fuel Injectors, Crankcase Heater, Water In Fuel Sensor and related circuits can

cause Fuse #16 in Fuse Block No.1 to open. Use the Service Information Wiring

Diagrams and check these circuits/components for shorted circuits.

Were any problems found.All

Ye s!Repair or replace shorted circuit/component as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No!Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

11 Turn the ignition off.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Choose the appropriate result.All

Test light is on for all circuits.

Test Complete.

Test light is on for 1 or 2 circuits

Repair the Engine Control Relay Output circuit(s) for an open.

Perform ROAD TEST VERIFICATION - VER-2.

Light off for all circuits.

Go To 12

237

DRIVEABILITY - DIESEL

*CHECKING THE POWER AND GROUNDS ÐContinued

Page 661 of 2305

TEST ACTION APPLICABILITY

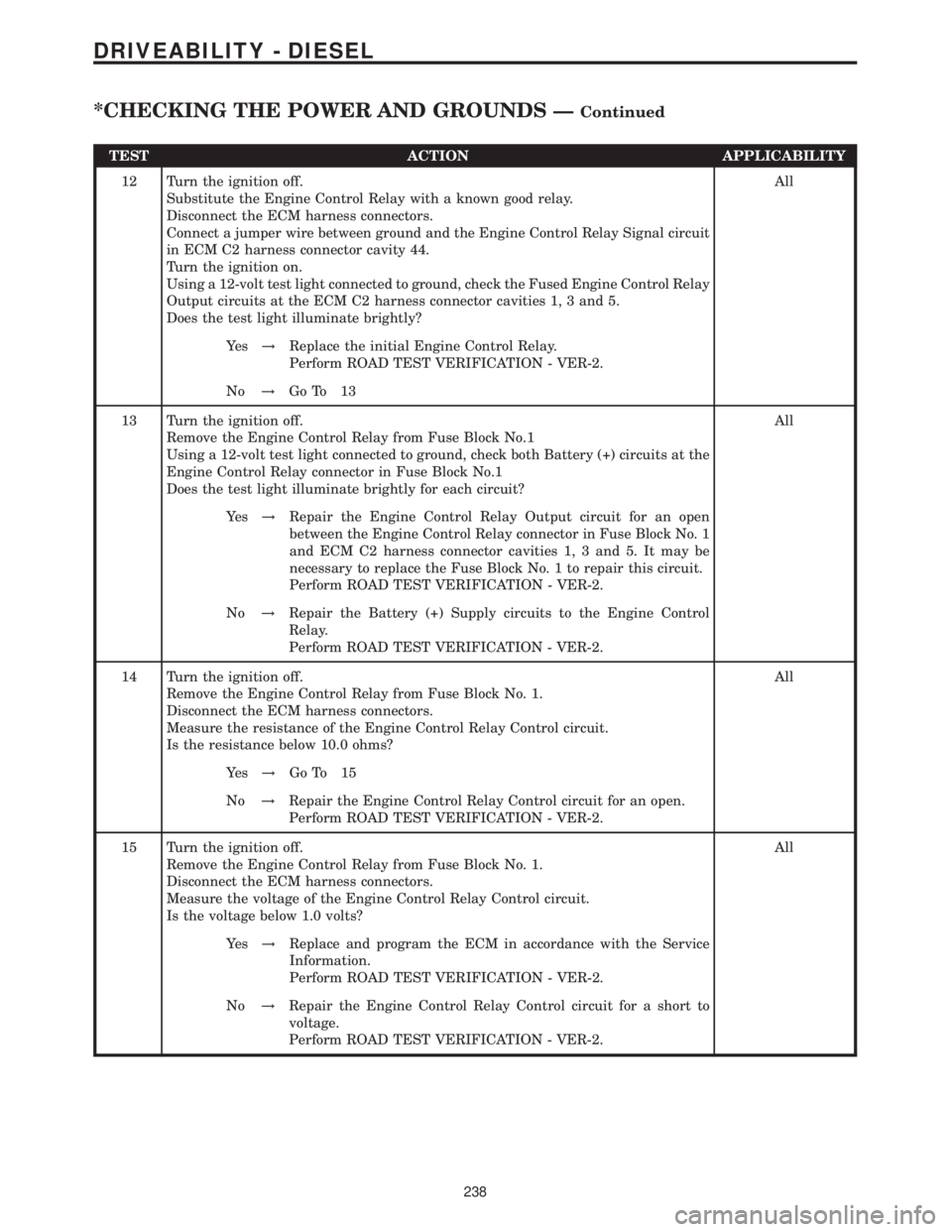

12 Turn the ignition off.

Substitute the Engine Control Relay with a known good relay.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Signal circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Does the test light illuminate brightly?All

Ye s!Replace the initial Engine Control Relay.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 13

13 Turn the ignition off.

Remove the Engine Control Relay from Fuse Block No.1

Using a 12-volt test light connected to ground, check both Battery (+) circuits at the

Engine Control Relay connector in Fuse Block No.1

Does the test light illuminate brightly for each circuit?All

Ye s!Repair the Engine Control Relay Output circuit for an open

between the Engine Control Relay connector in Fuse Block No. 1

and ECM C2 harness connector cavities 1, 3 and 5. It may be

necessary to replace the Fuse Block No. 1 to repair this circuit.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Battery (+) Supply circuits to the Engine Control

Relay.

Perform ROAD TEST VERIFICATION - VER-2.

14 Turn the ignition off.

Remove the Engine Control Relay from Fuse Block No. 1.

Disconnect the ECM harness connectors.

Measure the resistance of the Engine Control Relay Control circuit.

Is the resistance below 10.0 ohms?All

Ye s!Go To 15

No!Repair the Engine Control Relay Control circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

15 Turn the ignition off.

Remove the Engine Control Relay from Fuse Block No. 1.

Disconnect the ECM harness connectors.

Measure the voltage of the Engine Control Relay Control circuit.

Is the voltage below 1.0 volts?All

Ye s!Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Engine Control Relay Control circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

238

DRIVEABILITY - DIESEL

*CHECKING THE POWER AND GROUNDS ÐContinued

Page 665 of 2305

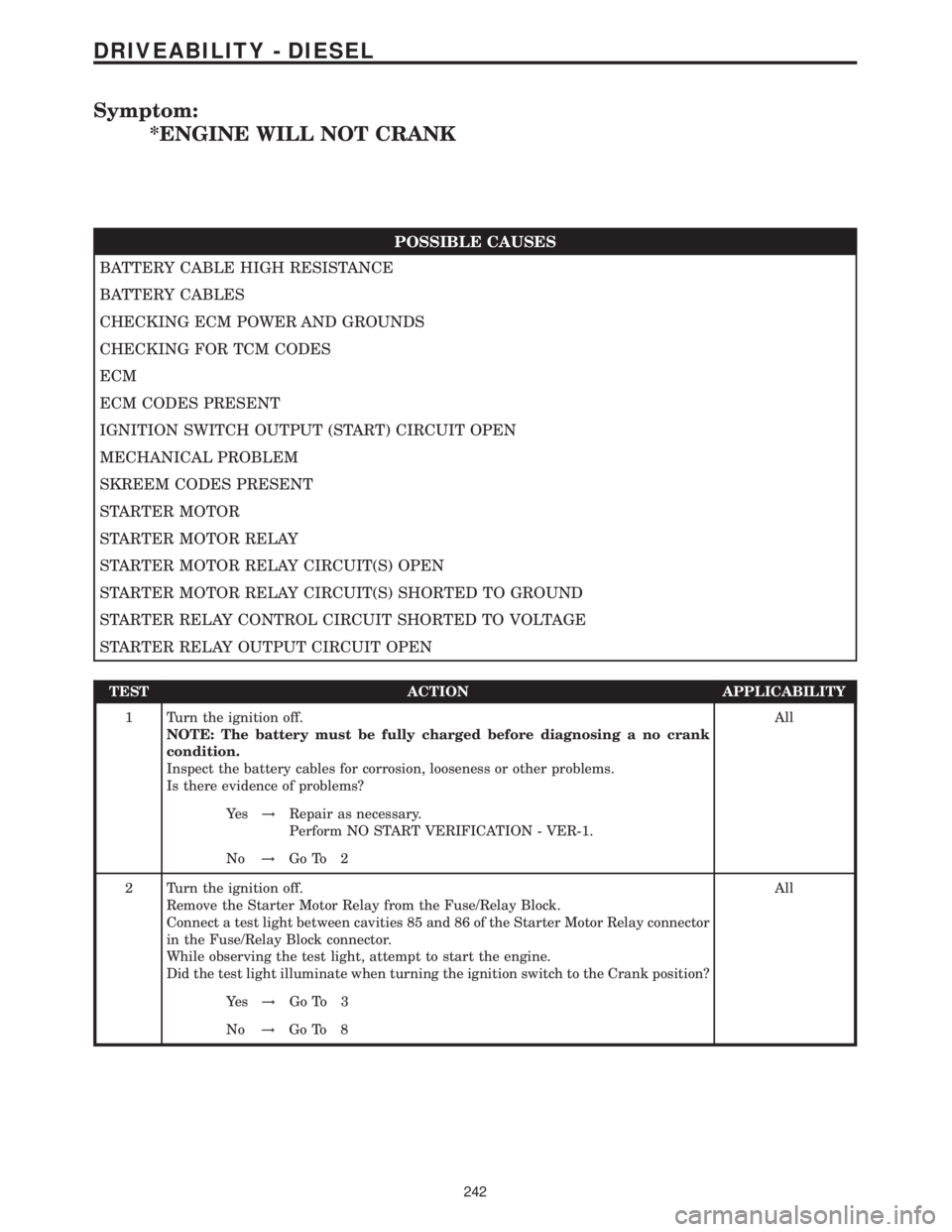

Symptom:

*ENGINE WILL NOT CRANK

POSSIBLE CAUSES

BATTERY CABLE HIGH RESISTANCE

BATTERY CABLES

CHECKING ECM POWER AND GROUNDS

CHECKING FOR TCM CODES

ECM

ECM CODES PRESENT

IGNITION SWITCH OUTPUT (START) CIRCUIT OPEN

MECHANICAL PROBLEM

SKREEM CODES PRESENT

STARTER MOTOR

STARTER MOTOR RELAY

STARTER MOTOR RELAY CIRCUIT(S) OPEN

STARTER MOTOR RELAY CIRCUIT(S) SHORTED TO GROUND

STARTER RELAY CONTROL CIRCUIT SHORTED TO VOLTAGE

STARTER RELAY OUTPUT CIRCUIT OPEN

TEST ACTION APPLICABILITY

1 Turn the ignition off.

NOTE: The battery must be fully charged before diagnosing a no crank

condition.

Inspect the battery cables for corrosion, looseness or other problems.

Is there evidence of problems?All

Ye s!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No!Go To 2

2 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Connect a test light between cavities 85 and 86 of the Starter Motor Relay connector

in the Fuse/Relay Block connector.

While observing the test light, attempt to start the engine.

Did the test light illuminate when turning the ignition switch to the Crank position?All

Ye s!Go To 3

No!Go To 8

242

DRIVEABILITY - DIESEL

Page 666 of 2305

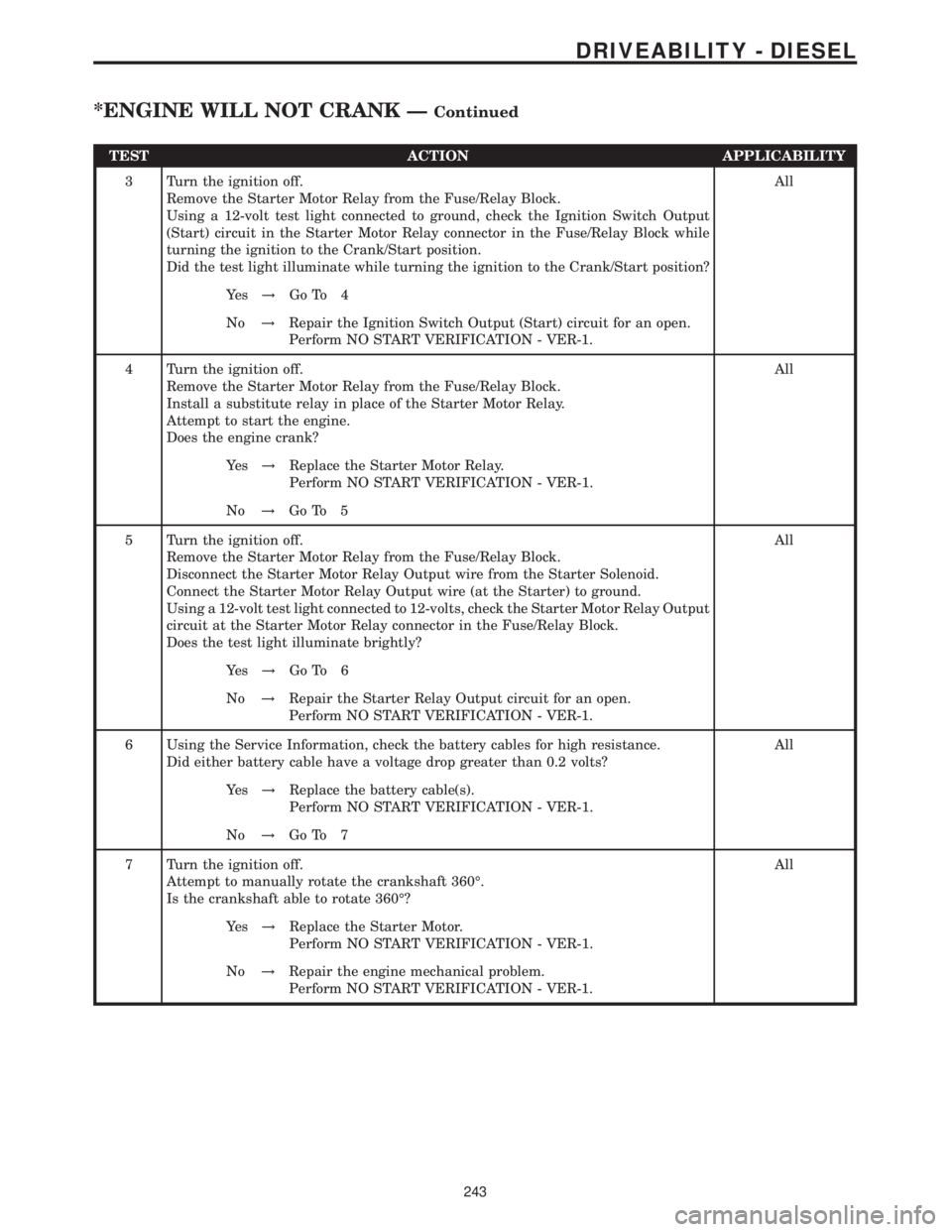

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Using a 12-volt test light connected to ground, check the Ignition Switch Output

(Start) circuit in the Starter Motor Relay connector in the Fuse/Relay Block while

turning the ignition to the Crank/Start position.

Did the test light illuminate while turning the ignition to the Crank/Start position?All

Ye s!Go To 4

No!Repair the Ignition Switch Output (Start) circuit for an open.

Perform NO START VERIFICATION - VER-1.

4 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Install a substitute relay in place of the Starter Motor Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s!Replace the Starter Motor Relay.

Perform NO START VERIFICATION - VER-1.

No!Go To 5

5 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Disconnect the Starter Motor Relay Output wire from the Starter Solenoid.

Connect the Starter Motor Relay Output wire (at the Starter) to ground.

Using a 12-volt test light connected to 12-volts, check the Starter Motor Relay Output

circuit at the Starter Motor Relay connector in the Fuse/Relay Block.

Does the test light illuminate brightly?All

Ye s!Go To 6

No!Repair the Starter Relay Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

6 Using the Service Information, check the battery cables for high resistance.

Did either battery cable have a voltage drop greater than 0.2 volts?All

Ye s!Replace the battery cable(s).

Perform NO START VERIFICATION - VER-1.

No!Go To 7

7 Turn the ignition off.

Attempt to manually rotate the crankshaft 360É.

Is the crankshaft able to rotate 360É?All

Ye s!Replace the Starter Motor.

Perform NO START VERIFICATION - VER-1.

No!Repair the engine mechanical problem.

Perform NO START VERIFICATION - VER-1.

243

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 708 of 2305

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

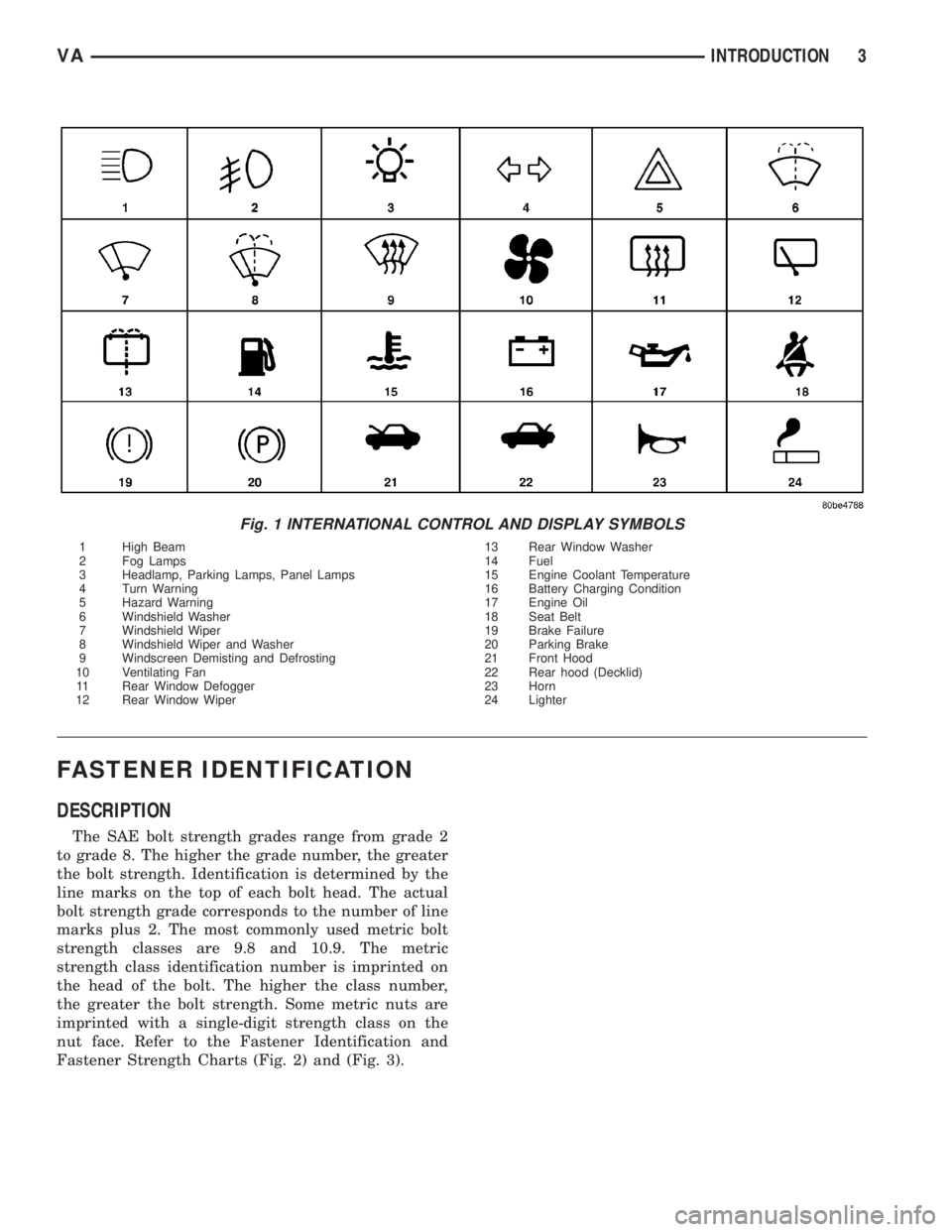

Fig. 1 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

VAINTRODUCTION 3