MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 661 of 2305

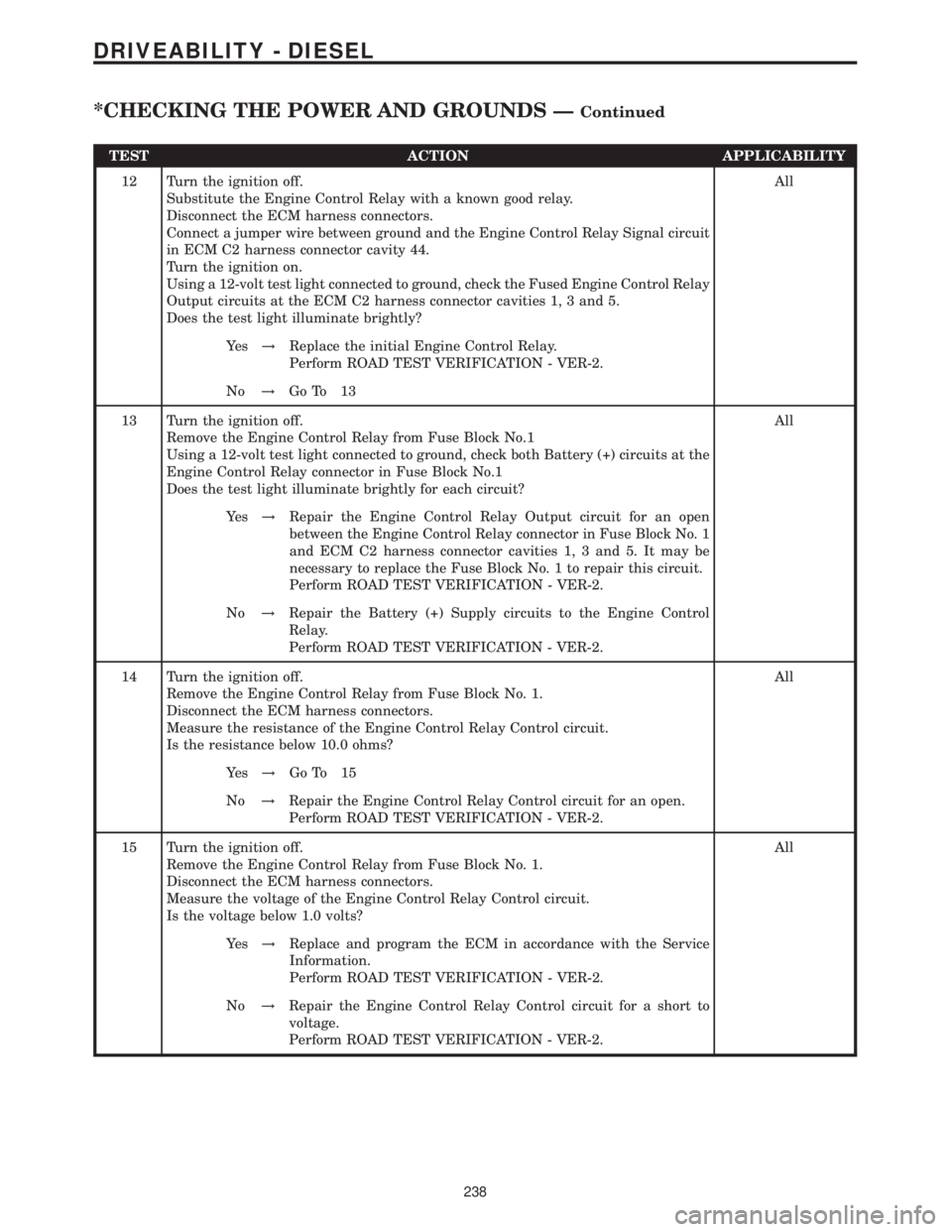

TEST ACTION APPLICABILITY

12 Turn the ignition off.

Substitute the Engine Control Relay with a known good relay.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Signal circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Does the test light illuminate brightly?All

Ye s!Replace the initial Engine Control Relay.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 13

13 Turn the ignition off.

Remove the Engine Control Relay from Fuse Block No.1

Using a 12-volt test light connected to ground, check both Battery (+) circuits at the

Engine Control Relay connector in Fuse Block No.1

Does the test light illuminate brightly for each circuit?All

Ye s!Repair the Engine Control Relay Output circuit for an open

between the Engine Control Relay connector in Fuse Block No. 1

and ECM C2 harness connector cavities 1, 3 and 5. It may be

necessary to replace the Fuse Block No. 1 to repair this circuit.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Battery (+) Supply circuits to the Engine Control

Relay.

Perform ROAD TEST VERIFICATION - VER-2.

14 Turn the ignition off.

Remove the Engine Control Relay from Fuse Block No. 1.

Disconnect the ECM harness connectors.

Measure the resistance of the Engine Control Relay Control circuit.

Is the resistance below 10.0 ohms?All

Ye s!Go To 15

No!Repair the Engine Control Relay Control circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

15 Turn the ignition off.

Remove the Engine Control Relay from Fuse Block No. 1.

Disconnect the ECM harness connectors.

Measure the voltage of the Engine Control Relay Control circuit.

Is the voltage below 1.0 volts?All

Ye s!Replace and program the ECM in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Engine Control Relay Control circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

238

DRIVEABILITY - DIESEL

*CHECKING THE POWER AND GROUNDS ÐContinued

Page 662 of 2305

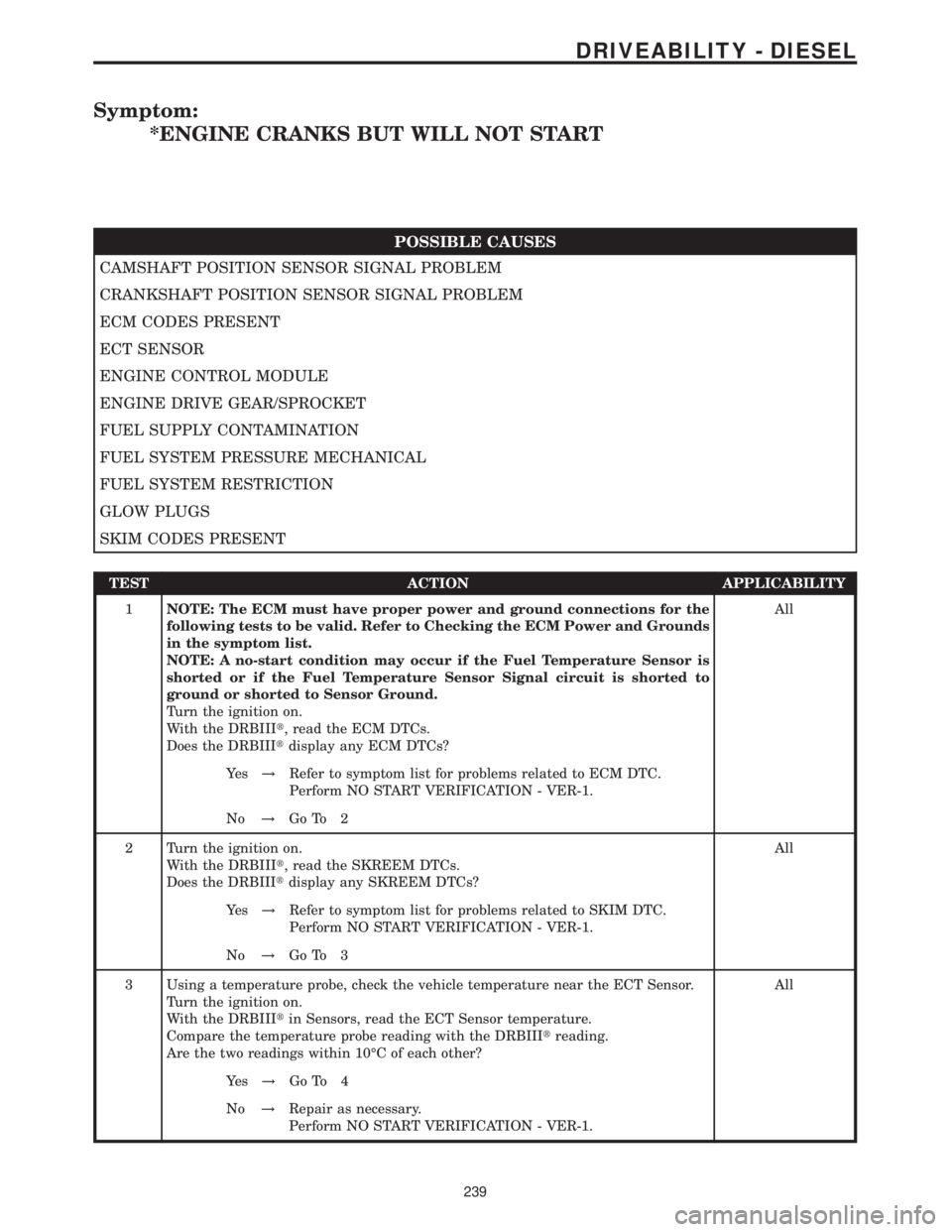

Symptom:

*ENGINE CRANKS BUT WILL NOT START

POSSIBLE CAUSES

CAMSHAFT POSITION SENSOR SIGNAL PROBLEM

CRANKSHAFT POSITION SENSOR SIGNAL PROBLEM

ECM CODES PRESENT

ECT SENSOR

ENGINE CONTROL MODULE

ENGINE DRIVE GEAR/SPROCKET

FUEL SUPPLY CONTAMINATION

FUEL SYSTEM PRESSURE MECHANICAL

FUEL SYSTEM RESTRICTION

GLOW PLUGS

SKIM CODES PRESENT

TEST ACTION APPLICABILITY

1NOTE: The ECM must have proper power and ground connections for the

following tests to be valid. Refer to Checking the ECM Power and Grounds

in the symptom list.

NOTE: A no-start condition may occur if the Fuel Temperature Sensor is

shorted or if the Fuel Temperature Sensor Signal circuit is shorted to

ground or shorted to Sensor Ground.

Turn the ignition on.

With the DRBIIIt, read the ECM DTCs.

Does the DRBIIItdisplay any ECM DTCs?All

Ye s!Refer to symptom list for problems related to ECM DTC.

Perform NO START VERIFICATION - VER-1.

No!Go To 2

2 Turn the ignition on.

With the DRBIIIt, read the SKREEM DTCs.

Does the DRBIIItdisplay any SKREEM DTCs?All

Ye s!Refer to symptom list for problems related to SKIM DTC.

Perform NO START VERIFICATION - VER-1.

No!Go To 3

3 Using a temperature probe, check the vehicle temperature near the ECT Sensor.

Turn the ignition on.

With the DRBIIItin Sensors, read the ECT Sensor temperature.

Compare the temperature probe reading with the DRBIIItreading.

Are the two readings within 10ÉC of each other?All

Ye s!Go To 4

No!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

239

DRIVEABILITY - DIESEL

Page 663 of 2305

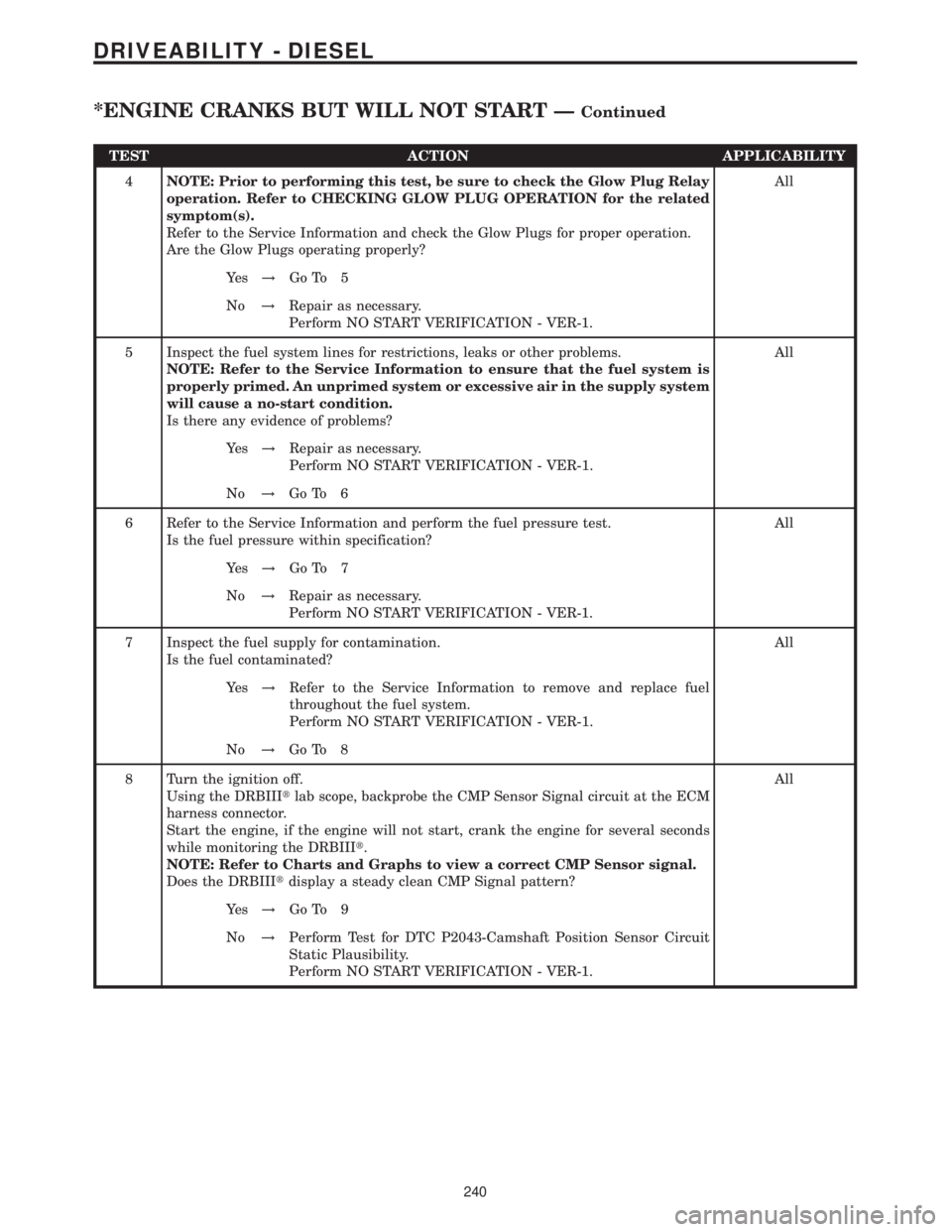

TEST ACTION APPLICABILITY

4NOTE: Prior to performing this test, be sure to check the Glow Plug Relay

operation. Refer to CHECKING GLOW PLUG OPERATION for the related

symptom(s).

Refer to the Service Information and check the Glow Plugs for proper operation.

Are the Glow Plugs operating properly?All

Ye s!Go To 5

No!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

5 Inspect the fuel system lines for restrictions, leaks or other problems.

NOTE: Refer to the Service Information to ensure that the fuel system is

properly primed. An unprimed system or excessive air in the supply system

will cause a no-start condition.

Is there any evidence of problems?All

Ye s!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No!Go To 6

6 Refer to the Service Information and perform the fuel pressure test.

Is the fuel pressure within specification?All

Ye s!Go To 7

No!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

7 Inspect the fuel supply for contamination.

Is the fuel contaminated?All

Ye s!Refer to the Service Information to remove and replace fuel

throughout the fuel system.

Perform NO START VERIFICATION - VER-1.

No!Go To 8

8 Turn the ignition off.

Using the DRBIIItlab scope, backprobe the CMP Sensor Signal circuit at the ECM

harness connector.

Start the engine, if the engine will not start, crank the engine for several seconds

while monitoring the DRBIIIt.

NOTE: Refer to Charts and Graphs to view a correct CMP Sensor signal.

Does the DRBIIItdisplay a steady clean CMP Signal pattern?All

Ye s!Go To 9

No!Perform Test for DTC P2043-Camshaft Position Sensor Circuit

Static Plausibility.

Perform NO START VERIFICATION - VER-1.

240

DRIVEABILITY - DIESEL

*ENGINE CRANKS BUT WILL NOT START ÐContinued

Page 664 of 2305

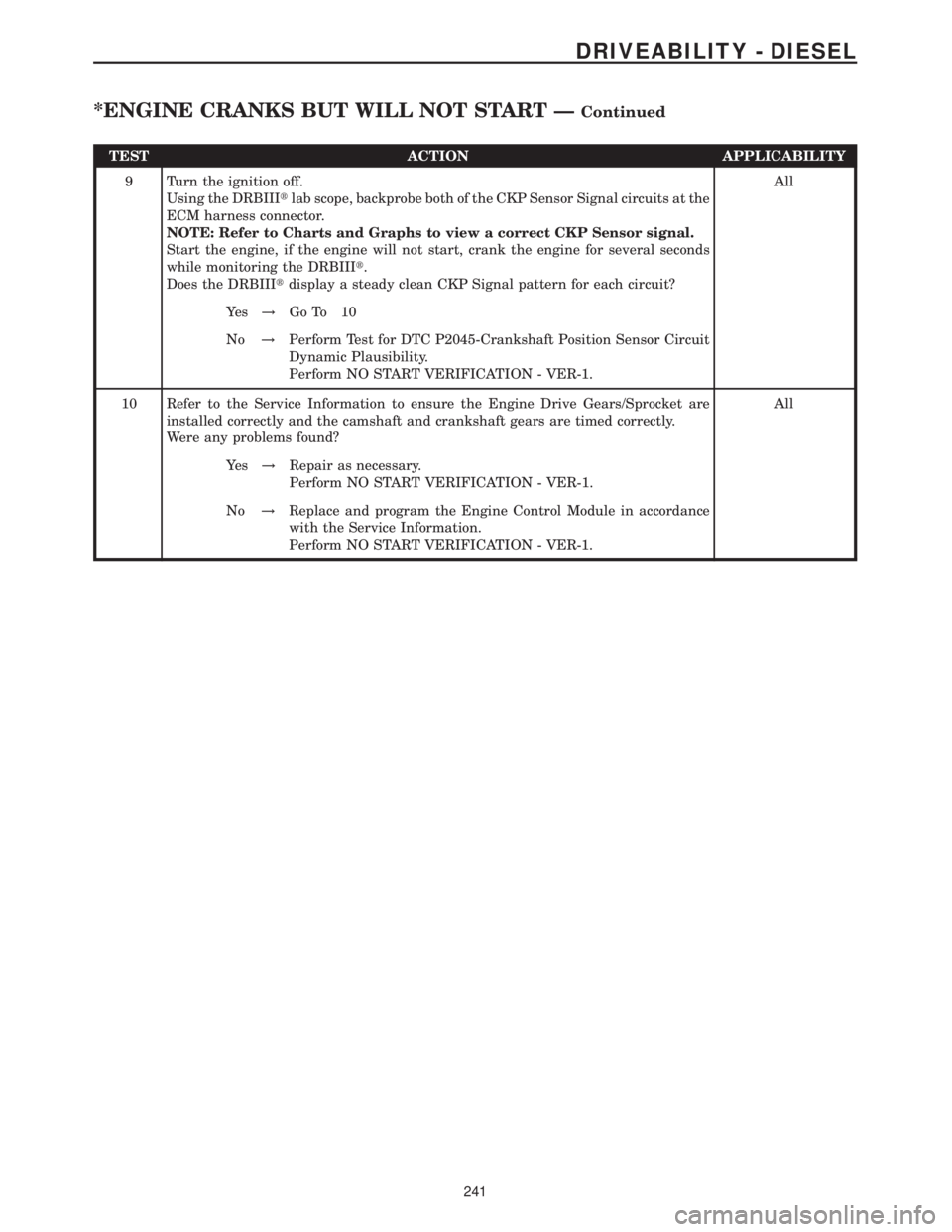

TEST ACTION APPLICABILITY

9 Turn the ignition off.

Using the DRBIIItlab scope, backprobe both of the CKP Sensor Signal circuits at the

ECM harness connector.

NOTE: Refer to Charts and Graphs to view a correct CKP Sensor signal.

Start the engine, if the engine will not start, crank the engine for several seconds

while monitoring the DRBIIIt.

Does the DRBIIItdisplay a steady clean CKP Signal pattern for each circuit?All

Ye s!Go To 10

No!Perform Test for DTC P2045-Crankshaft Position Sensor Circuit

Dynamic Plausibility.

Perform NO START VERIFICATION - VER-1.

10 Refer to the Service Information to ensure the Engine Drive Gears/Sprocket are

installed correctly and the camshaft and crankshaft gears are timed correctly.

Were any problems found?All

Ye s!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No!Replace and program the Engine Control Module in accordance

with the Service Information.

Perform NO START VERIFICATION - VER-1.

241

DRIVEABILITY - DIESEL

*ENGINE CRANKS BUT WILL NOT START ÐContinued

Page 665 of 2305

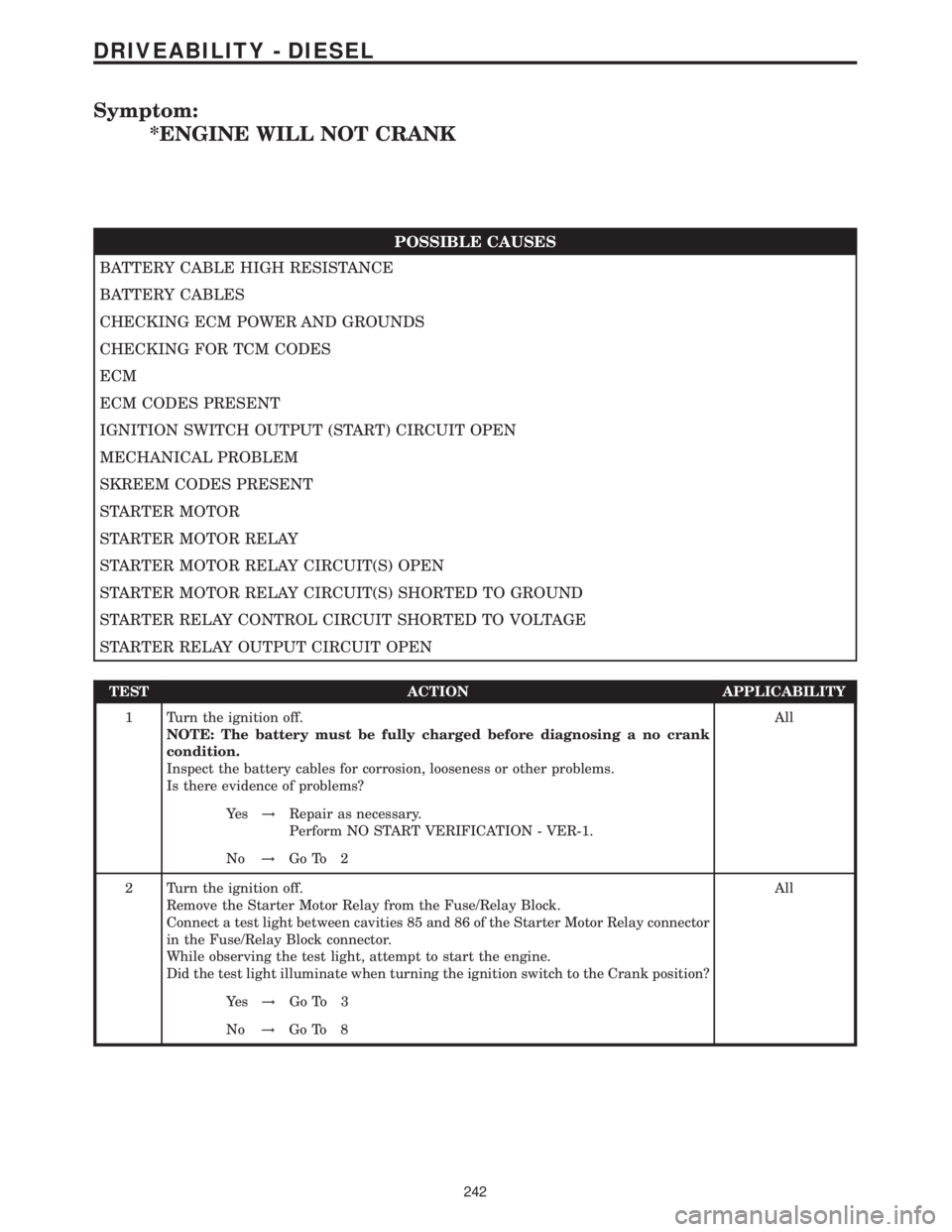

Symptom:

*ENGINE WILL NOT CRANK

POSSIBLE CAUSES

BATTERY CABLE HIGH RESISTANCE

BATTERY CABLES

CHECKING ECM POWER AND GROUNDS

CHECKING FOR TCM CODES

ECM

ECM CODES PRESENT

IGNITION SWITCH OUTPUT (START) CIRCUIT OPEN

MECHANICAL PROBLEM

SKREEM CODES PRESENT

STARTER MOTOR

STARTER MOTOR RELAY

STARTER MOTOR RELAY CIRCUIT(S) OPEN

STARTER MOTOR RELAY CIRCUIT(S) SHORTED TO GROUND

STARTER RELAY CONTROL CIRCUIT SHORTED TO VOLTAGE

STARTER RELAY OUTPUT CIRCUIT OPEN

TEST ACTION APPLICABILITY

1 Turn the ignition off.

NOTE: The battery must be fully charged before diagnosing a no crank

condition.

Inspect the battery cables for corrosion, looseness or other problems.

Is there evidence of problems?All

Ye s!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No!Go To 2

2 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Connect a test light between cavities 85 and 86 of the Starter Motor Relay connector

in the Fuse/Relay Block connector.

While observing the test light, attempt to start the engine.

Did the test light illuminate when turning the ignition switch to the Crank position?All

Ye s!Go To 3

No!Go To 8

242

DRIVEABILITY - DIESEL

Page 666 of 2305

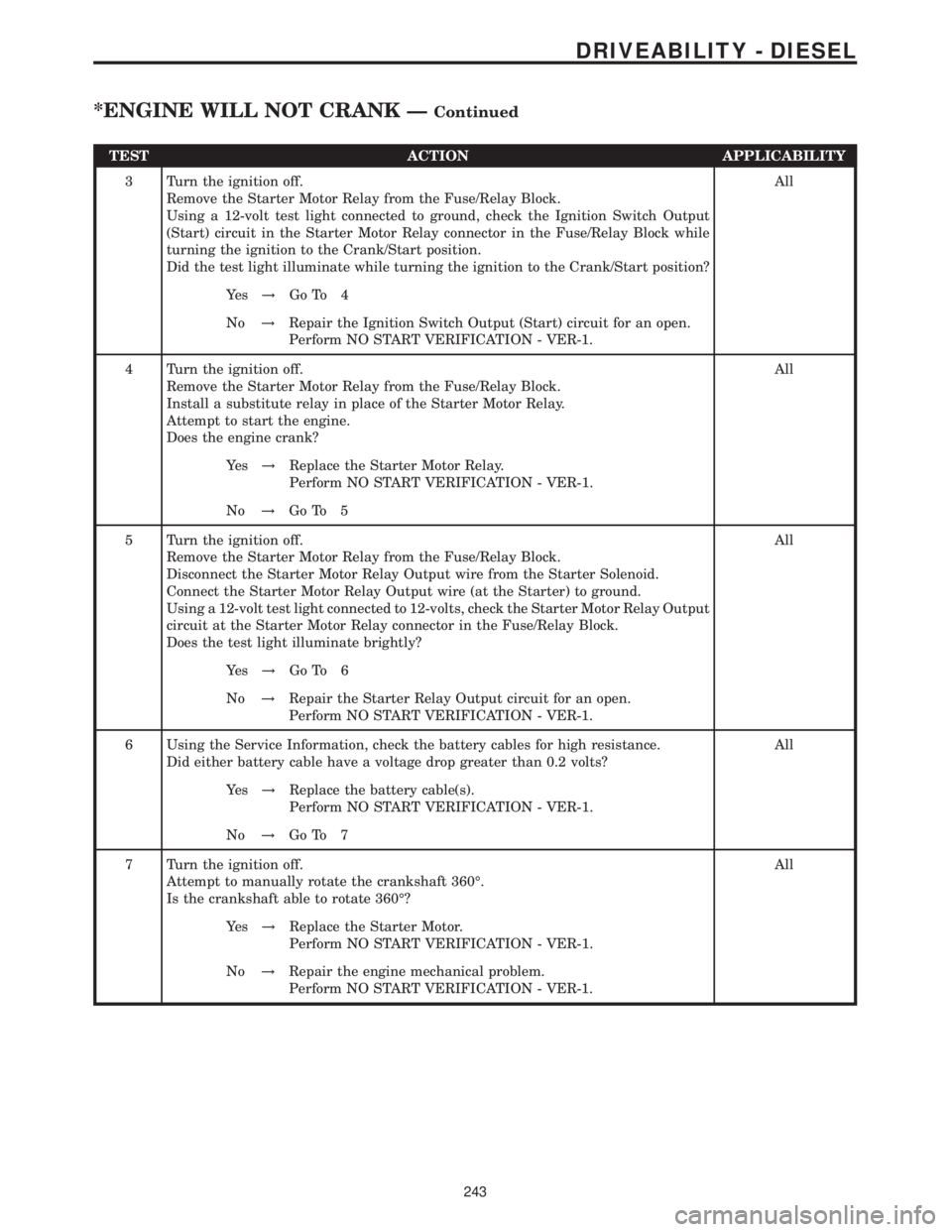

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Using a 12-volt test light connected to ground, check the Ignition Switch Output

(Start) circuit in the Starter Motor Relay connector in the Fuse/Relay Block while

turning the ignition to the Crank/Start position.

Did the test light illuminate while turning the ignition to the Crank/Start position?All

Ye s!Go To 4

No!Repair the Ignition Switch Output (Start) circuit for an open.

Perform NO START VERIFICATION - VER-1.

4 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Install a substitute relay in place of the Starter Motor Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s!Replace the Starter Motor Relay.

Perform NO START VERIFICATION - VER-1.

No!Go To 5

5 Turn the ignition off.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Disconnect the Starter Motor Relay Output wire from the Starter Solenoid.

Connect the Starter Motor Relay Output wire (at the Starter) to ground.

Using a 12-volt test light connected to 12-volts, check the Starter Motor Relay Output

circuit at the Starter Motor Relay connector in the Fuse/Relay Block.

Does the test light illuminate brightly?All

Ye s!Go To 6

No!Repair the Starter Relay Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

6 Using the Service Information, check the battery cables for high resistance.

Did either battery cable have a voltage drop greater than 0.2 volts?All

Ye s!Replace the battery cable(s).

Perform NO START VERIFICATION - VER-1.

No!Go To 7

7 Turn the ignition off.

Attempt to manually rotate the crankshaft 360É.

Is the crankshaft able to rotate 360É?All

Ye s!Replace the Starter Motor.

Perform NO START VERIFICATION - VER-1.

No!Repair the engine mechanical problem.

Perform NO START VERIFICATION - VER-1.

243

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 667 of 2305

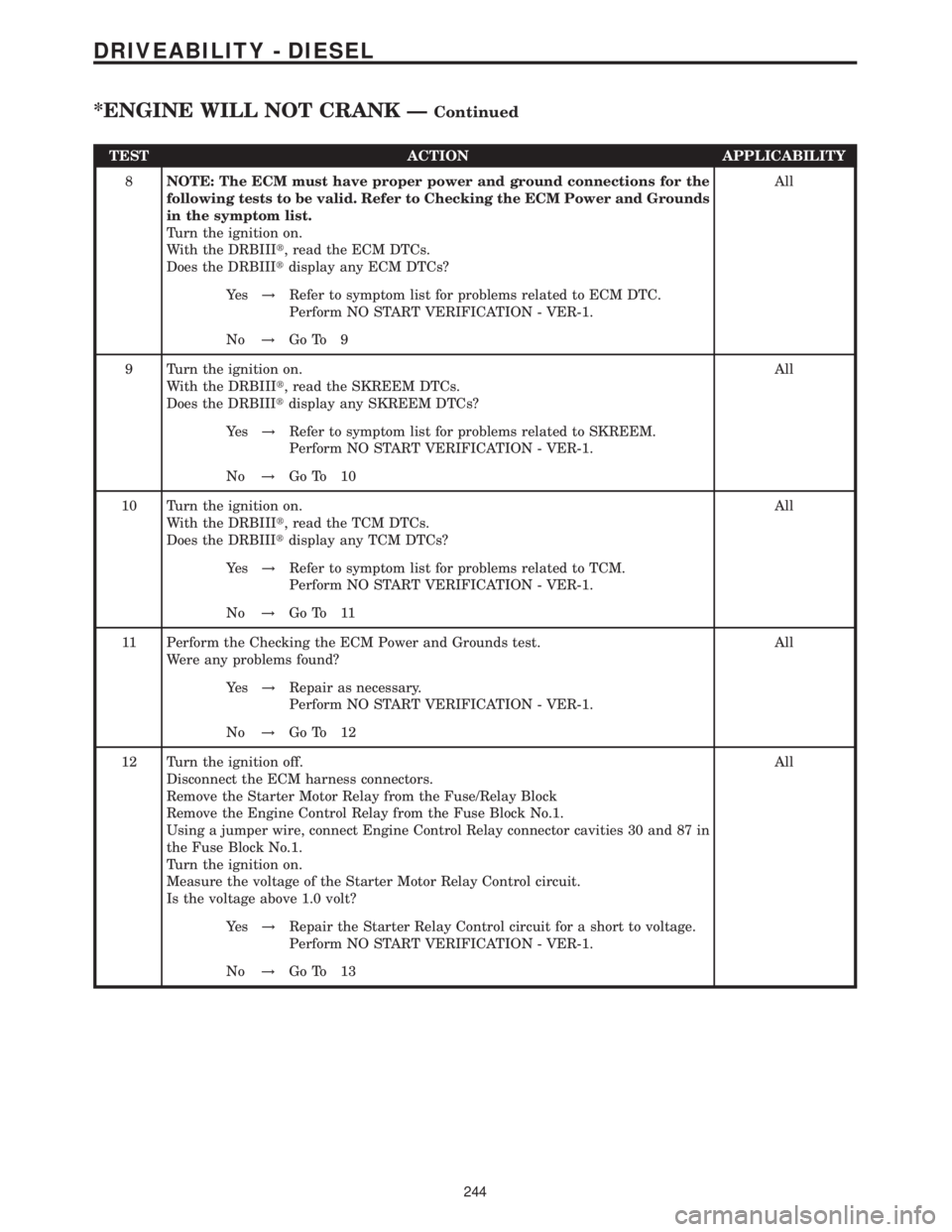

TEST ACTION APPLICABILITY

8NOTE: The ECM must have proper power and ground connections for the

following tests to be valid. Refer to Checking the ECM Power and Grounds

in the symptom list.

Turn the ignition on.

With the DRBIIIt, read the ECM DTCs.

Does the DRBIIItdisplay any ECM DTCs?All

Ye s!Refer to symptom list for problems related to ECM DTC.

Perform NO START VERIFICATION - VER-1.

No!Go To 9

9 Turn the ignition on.

With the DRBIIIt, read the SKREEM DTCs.

Does the DRBIIItdisplay any SKREEM DTCs?All

Ye s!Refer to symptom list for problems related to SKREEM.

Perform NO START VERIFICATION - VER-1.

No!Go To 10

10 Turn the ignition on.

With the DRBIIIt, read the TCM DTCs.

Does the DRBIIItdisplay any TCM DTCs?All

Ye s!Refer to symptom list for problems related to TCM.

Perform NO START VERIFICATION - VER-1.

No!Go To 11

11 Perform the Checking the ECM Power and Grounds test.

Were any problems found?All

Ye s!Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No!Go To 12

12 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Motor Relay from the Fuse/Relay Block

Remove the Engine Control Relay from the Fuse Block No.1.

Using a jumper wire, connect Engine Control Relay connector cavities 30 and 87 in

the Fuse Block No.1.

Turn the ignition on.

Measure the voltage of the Starter Motor Relay Control circuit.

Is the voltage above 1.0 volt?All

Ye s!Repair the Starter Relay Control circuit for a short to voltage.

Perform NO START VERIFICATION - VER-1.

No!Go To 13

244

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 668 of 2305

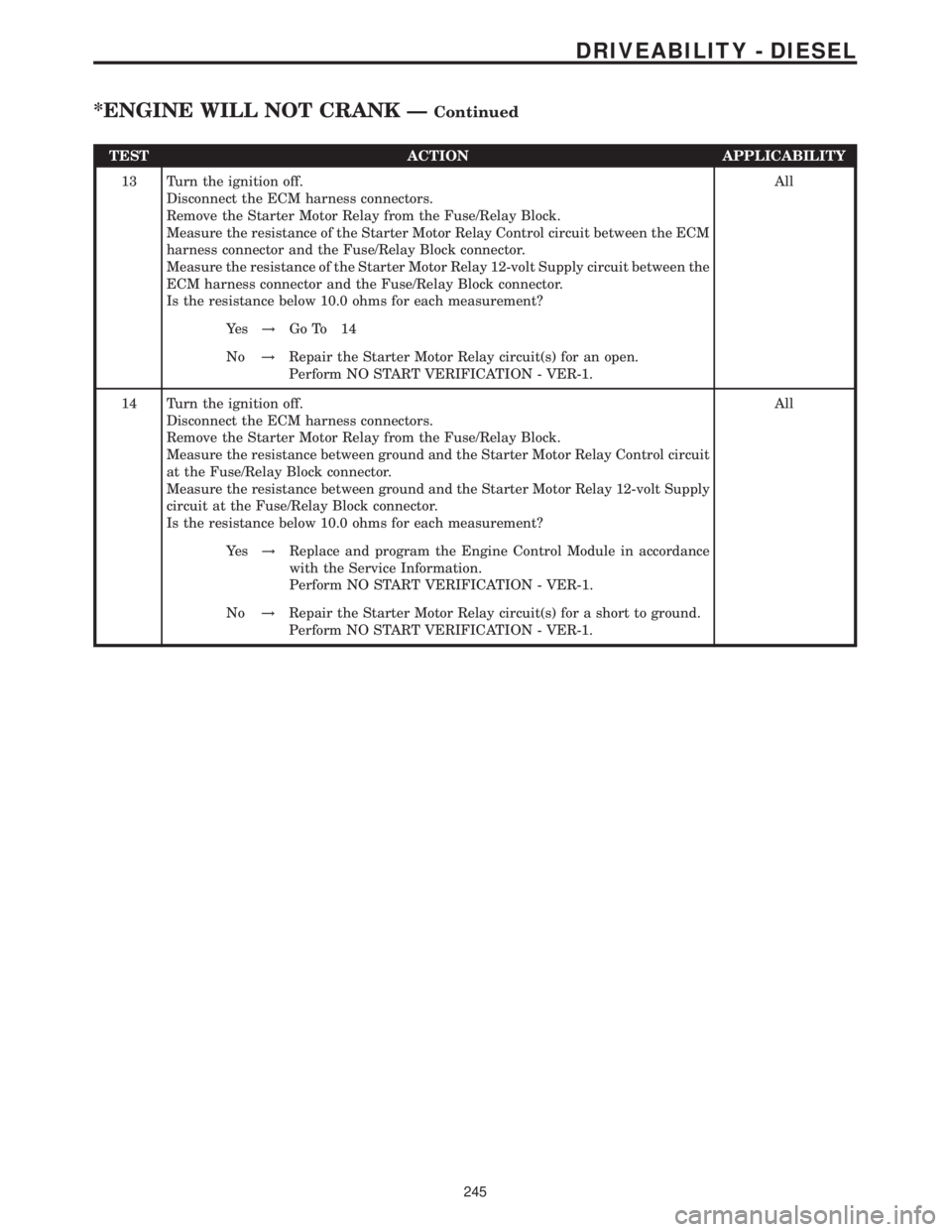

TEST ACTION APPLICABILITY

13 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Measure the resistance of the Starter Motor Relay Control circuit between the ECM

harness connector and the Fuse/Relay Block connector.

Measure the resistance of the Starter Motor Relay 12-volt Supply circuit between the

ECM harness connector and the Fuse/Relay Block connector.

Is the resistance below 10.0 ohms for each measurement?All

Ye s!Go To 14

No!Repair the Starter Motor Relay circuit(s) for an open.

Perform NO START VERIFICATION - VER-1.

14 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Motor Relay from the Fuse/Relay Block.

Measure the resistance between ground and the Starter Motor Relay Control circuit

at the Fuse/Relay Block connector.

Measure the resistance between ground and the Starter Motor Relay 12-volt Supply

circuit at the Fuse/Relay Block connector.

Is the resistance below 10.0 ohms for each measurement?All

Ye s!Replace and program the Engine Control Module in accordance

with the Service Information.

Perform NO START VERIFICATION - VER-1.

No!Repair the Starter Motor Relay circuit(s) for a short to ground.

Perform NO START VERIFICATION - VER-1.

245

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 669 of 2305

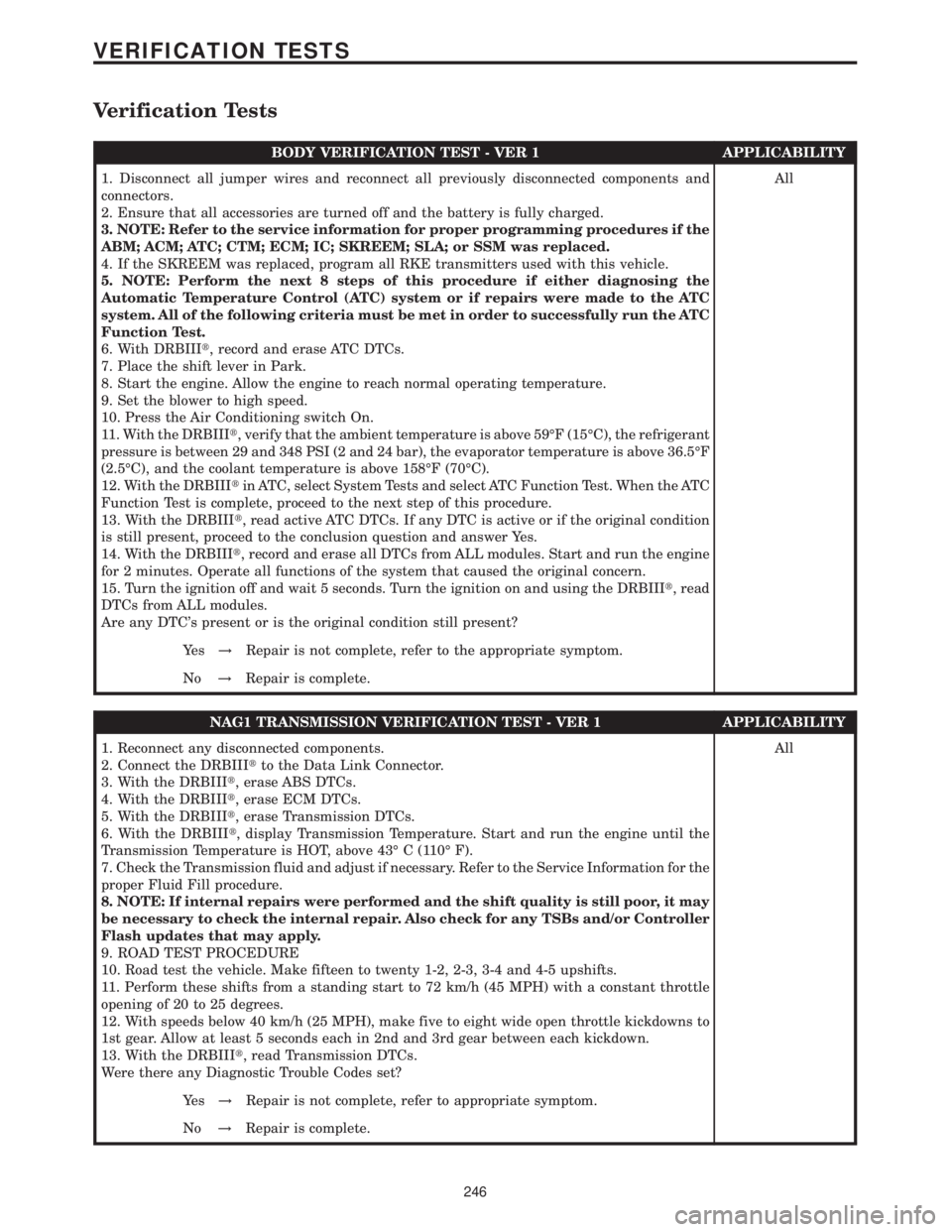

Verification Tests

BODY VERIFICATION TEST - VER 1 APPLICABILITY

1. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

2. Ensure that all accessories are turned off and the battery is fully charged.

3. NOTE: Refer to the service information for proper programming procedures if the

ABM; ACM; ATC; CTM; ECM; IC; SKREEM; SLA; or SSM was replaced.

4. If the SKREEM was replaced, program all RKE transmitters used with this vehicle.

5. NOTE: Perform the next 8 steps of this procedure if either diagnosing the

Automatic Temperature Control (ATC) system or if repairs were made to the ATC

system. All of the following criteria must be met in order to successfully run the ATC

Function Test.

6. With DRBIIIt, record and erase ATC DTCs.

7. Place the shift lever in Park.

8. Start the engine. Allow the engine to reach normal operating temperature.

9. Set the blower to high speed.

10. Press the Air Conditioning switch On.

11. With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the refrigerant

pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator temperature is above 36.5ÉF

(2.5ÉC), and the coolant temperature is above 158ÉF (70ÉC).

12. With the DRBIIItin ATC, select System Tests and select ATC Function Test. When the ATC

Function Test is complete, proceed to the next step of this procedure.

13. With the DRBIIIt, read active ATC DTCs. If any DTC is active or if the original condition

is still present, proceed to the conclusion question and answer Yes.

14. With the DRBIIIt, record and erase all DTCs from ALL modules. Start and run the engine

for 2 minutes. Operate all functions of the system that caused the original concern.

15. Turn the ignition off and wait 5 seconds. Turn the ignition on and using the DRBIIIt, read

DTCs from ALL modules.

Are any DTC's present or is the original condition still present?All

Ye s!Repair is not complete, refer to the appropriate symptom.

No!Repair is complete.

NAG1 TRANSMISSION VERIFICATION TEST - VER 1 APPLICABILITY

1. Reconnect any disconnected components.

2. Connect the DRBIIItto the Data Link Connector.

3. With the DRBIIIt, erase ABS DTCs.

4. With the DRBIIIt, erase ECM DTCs.

5. With the DRBIIIt, erase Transmission DTCs.

6. With the DRBIIIt, display Transmission Temperature. Start and run the engine until the

Transmission Temperature is HOT, above 43É C (110É F).

7. Check the Transmission fluid and adjust if necessary. Refer to the Service Information for the

proper Fluid Fill procedure.

8. NOTE: If internal repairs were performed and the shift quality is still poor, it may

be necessary to check the internal repair. Also check for any TSBs and/or Controller

Flash updates that may apply.

9. ROAD TEST PROCEDURE

10. Road test the vehicle. Make fifteen to twenty 1-2, 2-3, 3-4 and 4-5 upshifts.

11. Perform these shifts from a standing start to 72 km/h (45 MPH) with a constant throttle

opening of 20 to 25 degrees.

12. With speeds below 40 km/h (25 MPH), make five to eight wide open throttle kickdowns to

1st gear. Allow at least 5 seconds each in 2nd and 3rd gear between each kickdown.

13. With the DRBIIIt, read Transmission DTCs.

Were there any Diagnostic Trouble Codes set?All

Ye s!Repair is not complete, refer to appropriate symptom.

No!Repair is complete.

246

VERIFICATION TESTS

Page 670 of 2305

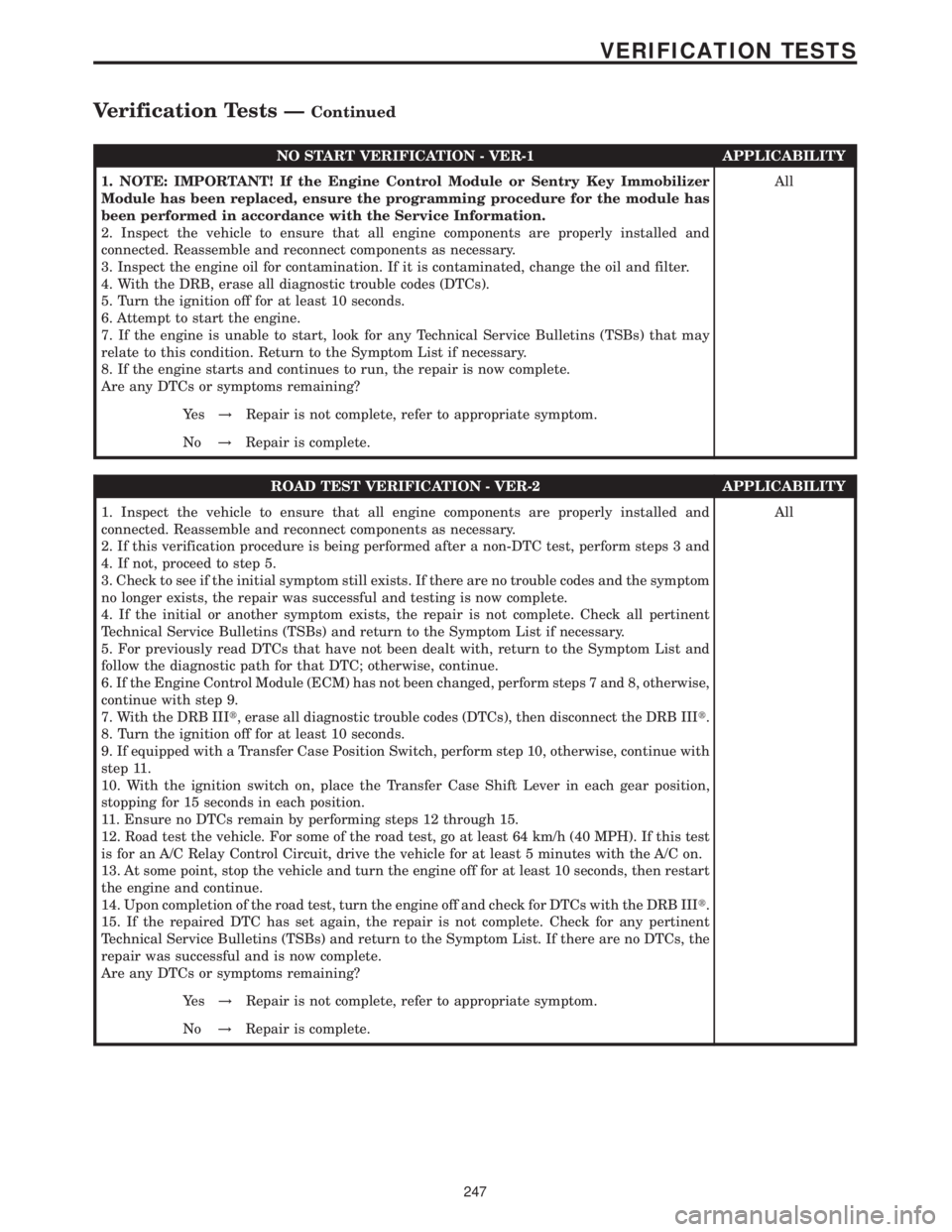

NO START VERIFICATION - VER-1 APPLICABILITY

1. NOTE: IMPORTANT! If the Engine Control Module or Sentry Key Immobilizer

Module has been replaced, ensure the programming procedure for the module has

been performed in accordance with the Service Information.

2. Inspect the vehicle to ensure that all engine components are properly installed and

connected. Reassemble and reconnect components as necessary.

3. Inspect the engine oil for contamination. If it is contaminated, change the oil and filter.

4. With the DRB, erase all diagnostic trouble codes (DTCs).

5. Turn the ignition off for at least 10 seconds.

6. Attempt to start the engine.

7. If the engine is unable to start, look for any Technical Service Bulletins (TSBs) that may

relate to this condition. Return to the Symptom List if necessary.

8. If the engine starts and continues to run, the repair is now complete.

Are any DTCs or symptoms remaining?All

Ye s!Repair is not complete, refer to appropriate symptom.

No!Repair is complete.

ROAD TEST VERIFICATION - VER-2 APPLICABILITY

1. Inspect the vehicle to ensure that all engine components are properly installed and

connected. Reassemble and reconnect components as necessary.

2. If this verification procedure is being performed after a non-DTC test, perform steps 3 and

4. If not, proceed to step 5.

3. Check to see if the initial symptom still exists. If there are no trouble codes and the symptom

no longer exists, the repair was successful and testing is now complete.

4. If the initial or another symptom exists, the repair is not complete. Check all pertinent

Technical Service Bulletins (TSBs) and return to the Symptom List if necessary.

5. For previously read DTCs that have not been dealt with, return to the Symptom List and

follow the diagnostic path for that DTC; otherwise, continue.

6. If the Engine Control Module (ECM) has not been changed, perform steps 7 and 8, otherwise,

continue with step 9.

7. With the DRB IIIt, erase all diagnostic trouble codes (DTCs), then disconnect the DRB IIIt.

8. Turn the ignition off for at least 10 seconds.

9. If equipped with a Transfer Case Position Switch, perform step 10, otherwise, continue with

step 11.

10. With the ignition switch on, place the Transfer Case Shift Lever in each gear position,

stopping for 15 seconds in each position.

11. Ensure no DTCs remain by performing steps 12 through 15.

12. Road test the vehicle. For some of the road test, go at least 64 km/h (40 MPH). If this test

is for an A/C Relay Control Circuit, drive the vehicle for at least 5 minutes with the A/C on.

13. At some point, stop the vehicle and turn the engine off for at least 10 seconds, then restart

the engine and continue.

14. Upon completion of the road test, turn the engine off and check for DTCs with the DRB IIIt.

15. If the repaired DTC has set again, the repair is not complete. Check for any pertinent

Technical Service Bulletins (TSBs) and return to the Symptom List. If there are no DTCs, the

repair was successful and is now complete.

Are any DTCs or symptoms remaining?All

Ye s!Repair is not complete, refer to appropriate symptom.

No!Repair is complete.

247

VERIFICATION TESTS

Verification Tests ÐContinued