light MERCEDES-BENZ SPRINTER 2006 Manual Online

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 818 of 2305

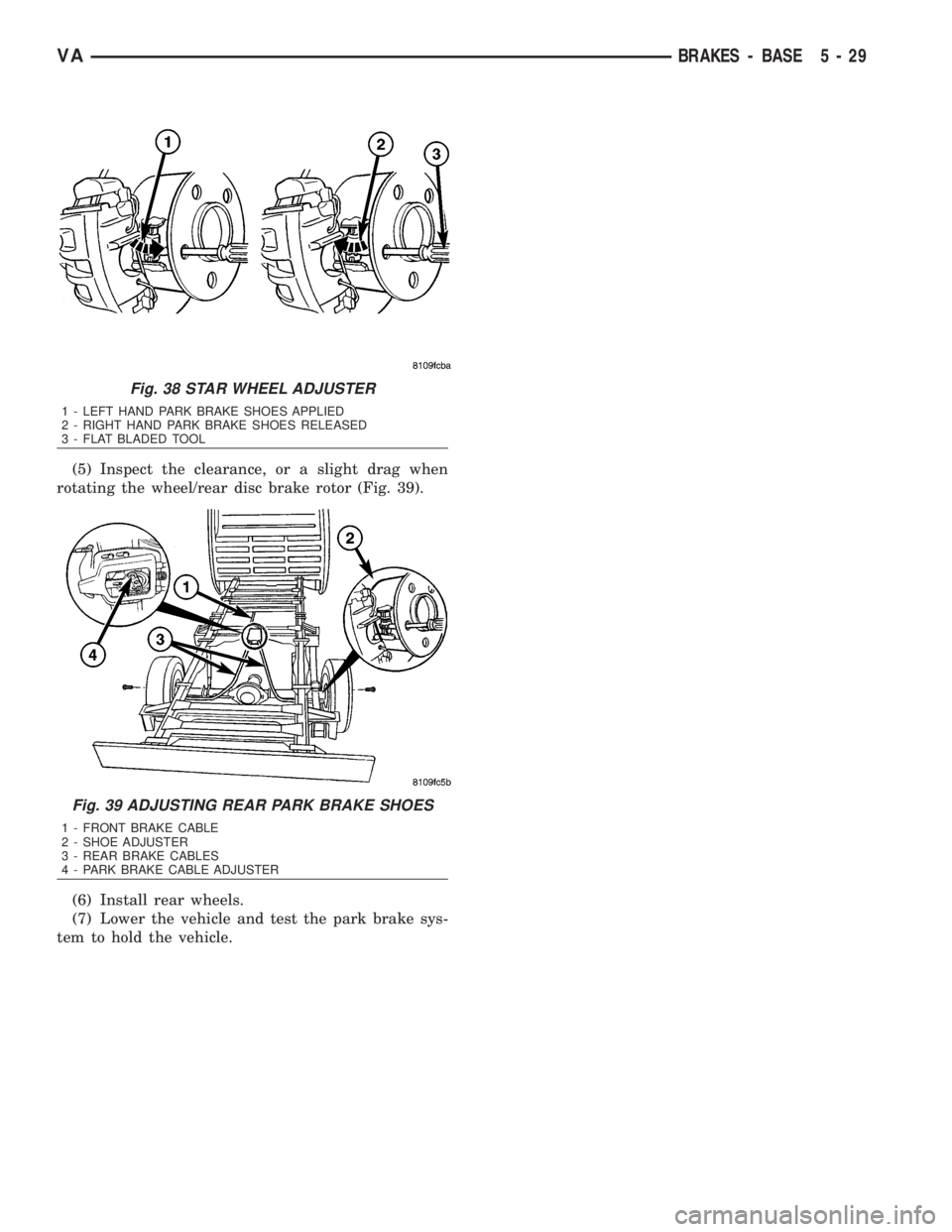

(5) Inspect the clearance, or a slight drag when

rotating the wheel/rear disc brake rotor (Fig. 39).

(6) Install rear wheels.

(7) Lower the vehicle and test the park brake sys-

tem to hold the vehicle.

Fig. 38 STAR WHEEL ADJUSTER

1 - LEFT HAND PARK BRAKE SHOES APPLIED

2 - RIGHT HAND PARK BRAKE SHOES RELEASED

3 - FLAT BLADED TOOL

Fig. 39 ADJUSTING REAR PARK BRAKE SHOES

1 - FRONT BRAKE CABLE

2 - SHOE ADJUSTER

3 - REAR BRAKE CABLES

4 - PARK BRAKE CABLE ADJUSTER

VABRAKES - BASE 5 - 29

Page 821 of 2305

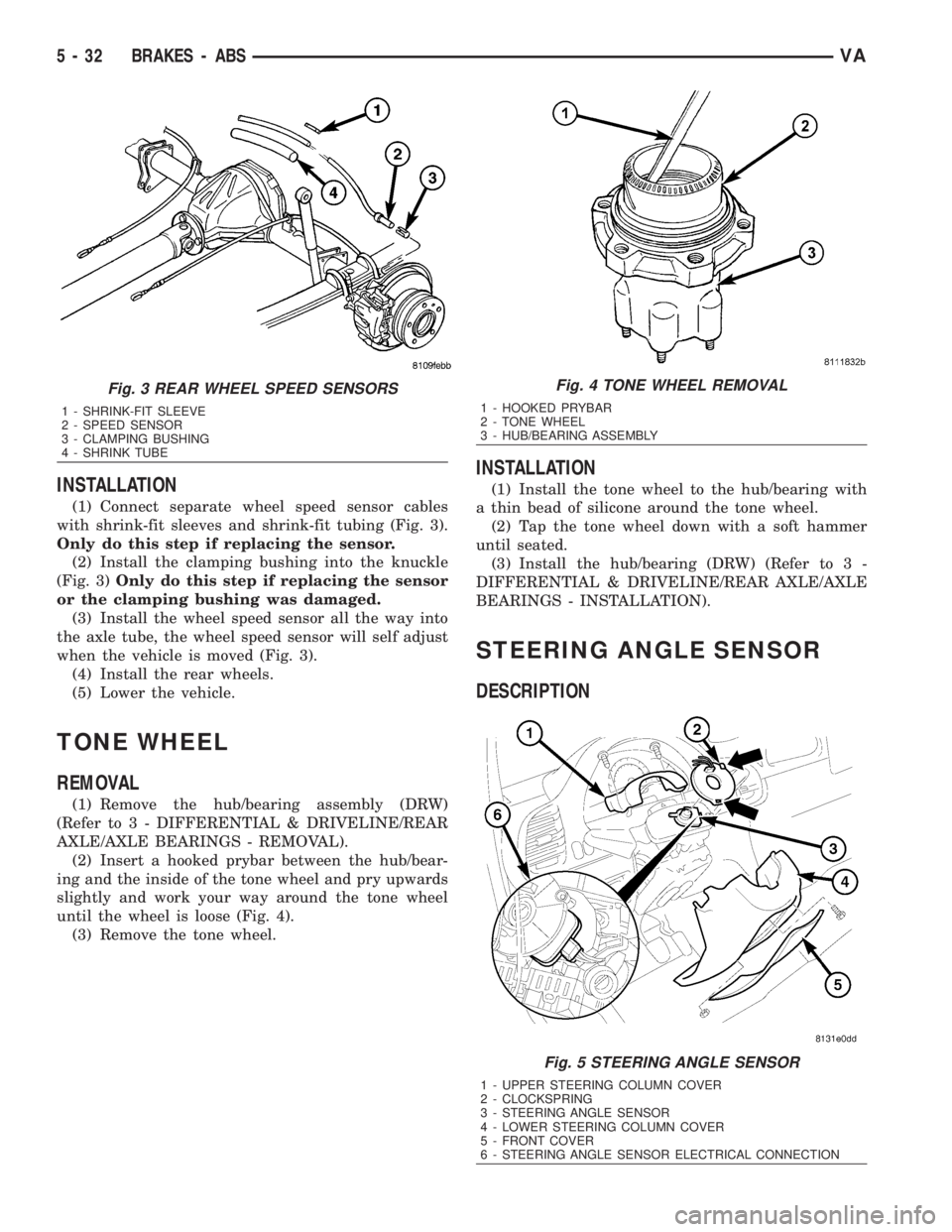

INSTALLATION

(1) Connect separate wheel speed sensor cables

with shrink-fit sleeves and shrink-fit tubing (Fig. 3).

Only do this step if replacing the sensor.

(2) Install the clamping bushing into the knuckle

(Fig. 3)Only do this step if replacing the sensor

or the clamping bushing was damaged.

(3) Install the wheel speed sensor all the way into

the axle tube, the wheel speed sensor will self adjust

when the vehicle is moved (Fig. 3).

(4) Install the rear wheels.

(5) Lower the vehicle.

TONE WHEEL

REMOVAL

(1) Remove the hub/bearing assembly (DRW)

(Refer to 3 - DIFFERENTIAL & DRIVELINE/REAR

AXLE/AXLE BEARINGS - REMOVAL).

(2) Insert a hooked prybar between the hub/bear-

ing and the inside of the tone wheel and pry upwards

slightly and work your way around the tone wheel

until the wheel is loose (Fig. 4).

(3) Remove the tone wheel.

INSTALLATION

(1) Install the tone wheel to the hub/bearing with

a thin bead of silicone around the tone wheel.

(2) Tap the tone wheel down with a soft hammer

until seated.

(3) Install the hub/bearing (DRW) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE/AXLE

BEARINGS - INSTALLATION).

STEERING ANGLE SENSOR

DESCRIPTION

Fig. 3 REAR WHEEL SPEED SENSORS

1 - SHRINK-FIT SLEEVE

2 - SPEED SENSOR

3 - CLAMPING BUSHING

4 - SHRINK TUBE

Fig. 4 TONE WHEEL REMOVAL

1 - HOOKED PRYBAR

2 - TONE WHEEL

3 - HUB/BEARING ASSEMBLY

Fig. 5 STEERING ANGLE SENSOR

1 - UPPER STEERING COLUMN COVER

2 - CLOCKSPRING

3 - STEERING ANGLE SENSOR

4 - LOWER STEERING COLUMN COVER

5 - FRONT COVER

6 - STEERING ANGLE SENSOR ELECTRICAL CONNECTION

5 - 32 BRAKES - ABSVA

Page 828 of 2305

COOLING

TABLE OF CONTENTS

page page

COOLING

OPERATION - COOLING SYSTEM...........1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS.............................1COOLING SYSTEM.....................2

ACCESSORY DRIVE.......................5

ENGINE.................................9

COOLING

OPERATION - COOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED OR STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.²Increasing engine speed for more air flow is rec-

ommended.

TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

AIR CONDITIONING; ADD - ON OR AFTER MARKET:

A maximum cooling package should have been

ordered with vehicle if add-on or after market A/C is

installed. If not, maximum cooling system compo-

nents should be installed for model involved per

manufacturer's specifications.

RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, (Refer to 7 - COOLING - DIAGNOSIS AND

TESTING)

VACOOLING 7 - 1

Page 837 of 2305

Propylene - glycol / Ethylene - glycol Mixtures - Should Not

Be Used in Chrysler Vehicles

Propylene-glycol/ethylene-glycol Mixtures can

cause the destabilization of various corrosion inhibi-

tors, causing damage to the various cooling system

components. Also, once ethylene-glycol and propy-

lene-glycol based coolants are mixed in the vehicle,

conventional methods of determining freeze point will

not be accurate. Both the refractive index and spe-

cific gravity differ between ethylene glycol and propy-

lene glycol.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

DIAGNOSIS AND TESTING

COOLING SYSTEM LEAKS

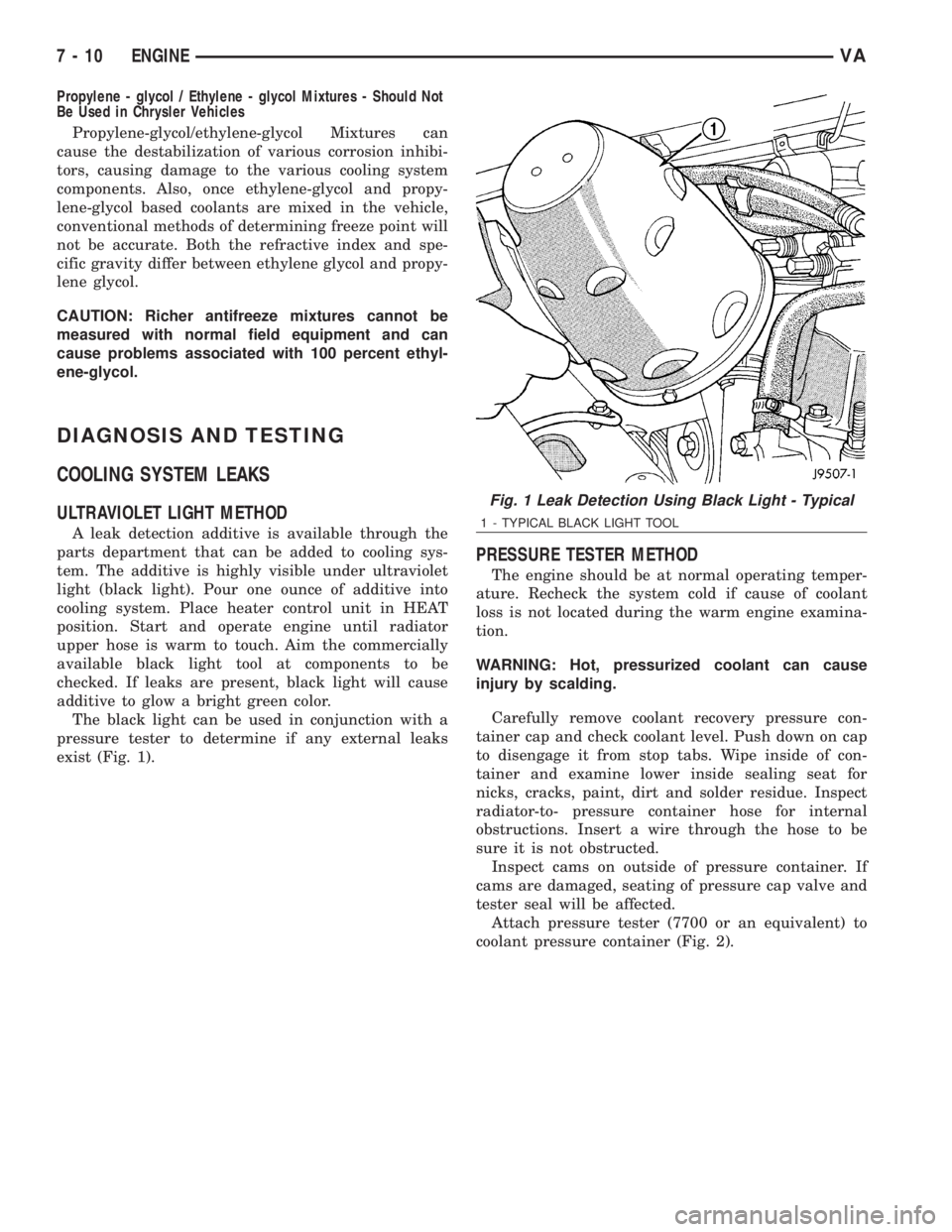

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 1).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: Hot, pressurized coolant can cause

injury by scalding.

Carefully remove coolant recovery pressure con-

tainer cap and check coolant level. Push down on cap

to disengage it from stop tabs. Wipe inside of con-

tainer and examine lower inside sealing seat for

nicks, cracks, paint, dirt and solder residue. Inspect

radiator-to- pressure container hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of pressure container. If

cams are damaged, seating of pressure cap valve and

tester seal will be affected.

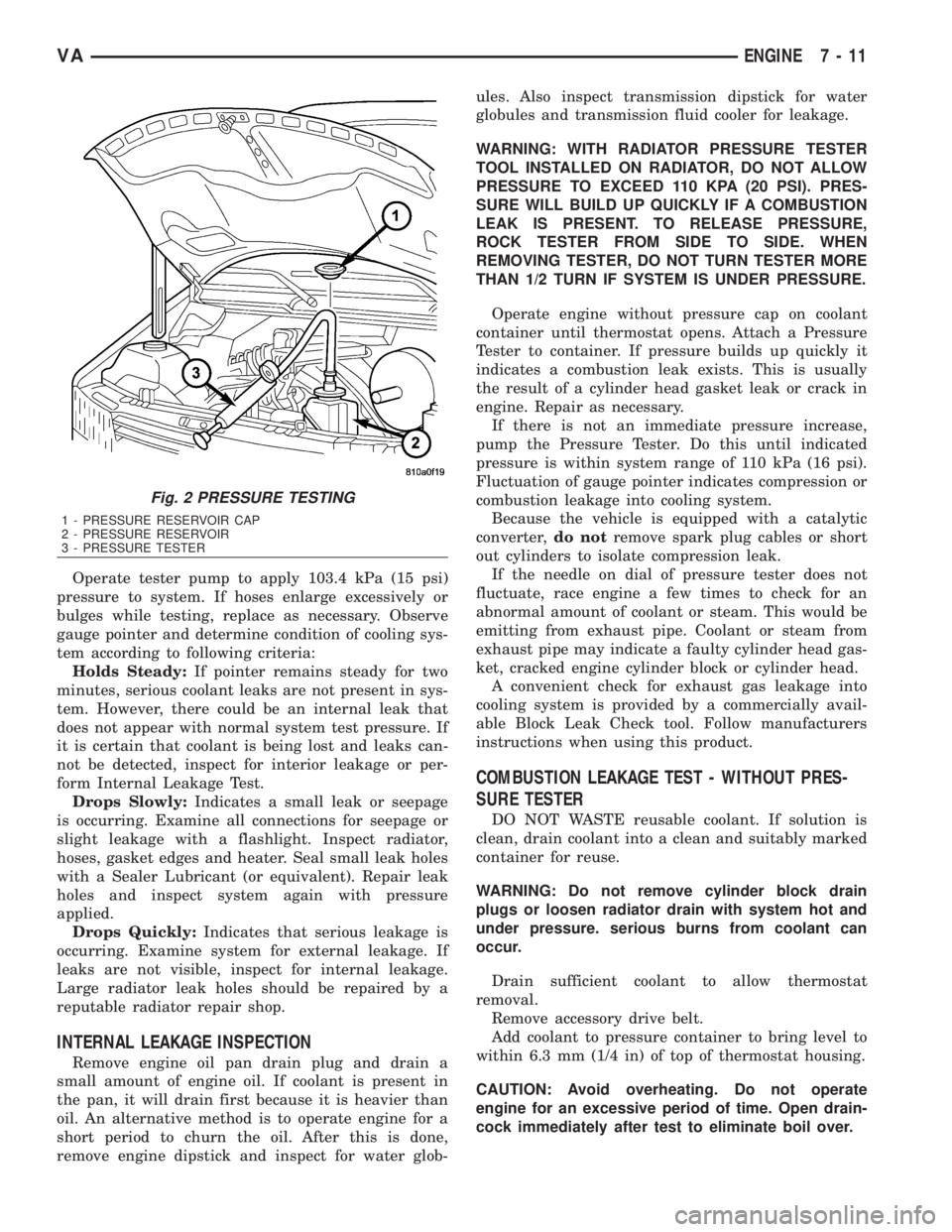

Attach pressure tester (7700 or an equivalent) to

coolant pressure container (Fig. 2).

Fig. 1 Leak Detection Using Black Light - Typical

1 - TYPICAL BLACK LIGHT TOOL

7 - 10 ENGINEVA

Page 838 of 2305

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on coolant

container until thermostat opens. Attach a Pressure

Tester to container. If pressure builds up quickly it

indicates a combustion leak exists. This is usually

the result of a cylinder head gasket leak or crack in

engine. Repair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT PRES-

SURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean and suitably marked

container for reuse.

WARNING: Do not remove cylinder block drain

plugs or loosen radiator drain with system hot and

under pressure. serious burns from coolant can

occur.

Drain sufficient coolant to allow thermostat

removal.

Remove accessory drive belt.

Add coolant to pressure container to bring level to

within 6.3 mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Fig. 2 PRESSURE TESTING

1 - PRESSURE RESERVOIR CAP

2 - PRESSURE RESERVOIR

3 - PRESSURE TESTER

VAENGINE 7 - 11

Page 846 of 2305

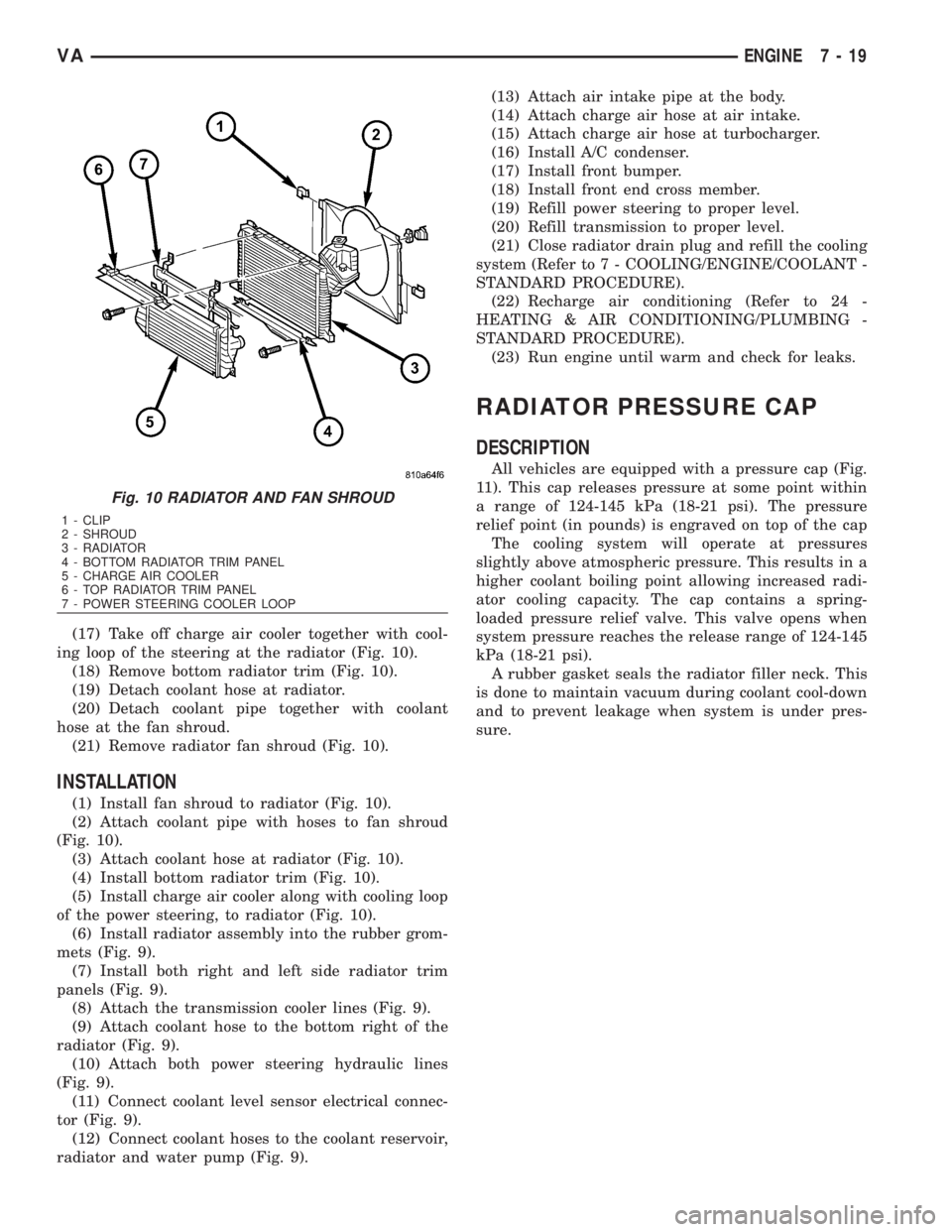

(17) Take off charge air cooler together with cool-

ing loop of the steering at the radiator (Fig. 10).

(18) Remove bottom radiator trim (Fig. 10).

(19) Detach coolant hose at radiator.

(20) Detach coolant pipe together with coolant

hose at the fan shroud.

(21) Remove radiator fan shroud (Fig. 10).

INSTALLATION

(1) Install fan shroud to radiator (Fig. 10).

(2) Attach coolant pipe with hoses to fan shroud

(Fig. 10).

(3) Attach coolant hose at radiator (Fig. 10).

(4) Install bottom radiator trim (Fig. 10).

(5) Install charge air cooler along with cooling loop

of the power steering, to radiator (Fig. 10).

(6) Install radiator assembly into the rubber grom-

mets (Fig. 9).

(7) Install both right and left side radiator trim

panels (Fig. 9).

(8) Attach the transmission cooler lines (Fig. 9).

(9) Attach coolant hose to the bottom right of the

radiator (Fig. 9).

(10) Attach both power steering hydraulic lines

(Fig. 9).

(11) Connect coolant level sensor electrical connec-

tor (Fig. 9).

(12) Connect coolant hoses to the coolant reservoir,

radiator and water pump (Fig. 9).(13) Attach air intake pipe at the body.

(14) Attach charge air hose at air intake.

(15) Attach charge air hose at turbocharger.

(16) Install A/C condenser.

(17) Install front bumper.

(18) Install front end cross member.

(19) Refill power steering to proper level.

(20) Refill transmission to proper level.

(21) Close radiator drain plug and refill the cooling

system (Refer to 7 - COOLING/ENGINE/COOLANT -

STANDARD PROCEDURE).

(22) Recharge air conditioning (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(23) Run engine until warm and check for leaks.

RADIATOR PRESSURE CAP

DESCRIPTION

All vehicles are equipped with a pressure cap (Fig.

11). This cap releases pressure at some point within

a range of 124-145 kPa (18-21 psi). The pressure

relief point (in pounds) is engraved on top of the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

loaded pressure relief valve. This valve opens when

system pressure reaches the release range of 124-145

kPa (18-21 psi).

A rubber gasket seals the radiator filler neck. This

is done to maintain vacuum during coolant cool-down

and to prevent leakage when system is under pres-

sure.

Fig. 10 RADIATOR AND FAN SHROUD

1 - CLIP

2 - SHROUD

3 - RADIATOR

4 - BOTTOM RADIATOR TRIM PANEL

5 - CHARGE AIR COOLER

6 - TOP RADIATOR TRIM PANEL

7 - POWER STEERING COOLER LOOP

VAENGINE 7 - 19

Page 855 of 2305

the status of the driver side front seat belt. This

audible warning occurs independent of the visual

warning provided by the EMIC ªSeatbeltº indicator.

²Lights-On Warning- The EMIC chime tone

generator will generate repetitive chime tones at a

fast rate when either front door is opened with the

ignition switch in any position except On, and the

exterior lights are turned On. The EMIC uses inter-

nal programming and hard wired inputs from the left

(lighting) control stalk of the multi-function switch,

the ignition switch, and both front door jamb

switches to determine the current status of these

switches. This chime will continue to sound until the

exterior lighting is turned Off, until the ignition

switch is turned to the On position, or until both

front doors are closed, whichever occurs first.

²Key-In-Ignition Warning- The EMIC chime

tone generator will generate repetitive chime tones at

a fast rate when the key is in the ignition lock cylin-

der, the ignition switch is in any position except On,

and either front door is opened. The EMIC uses

internal programming and hard wired inputs from

the key-in ignition switch, the ignition switch, and

both front door jamb switches to determine the cur-

rent status of these switches. The chime will con-

tinue to sound until the key is removed from the

ignition lock cylinder, until the ignition switch is

turned to the On position, or until both front doors

are closed, whichever occurs first.

²Audible Turn Signal/Hazard Warning Sup-

port- The EMIC contactless relay will generate

repetitive clicks at a slow rate during normal turn

signal/hazard warning operation, or at a fast rate

when a turn signal lamp bulb or circuit is inopera-

tive, in concert with the operation of the turn signal

indicators in the cluster. These clicks are designed to

emulate the sound of the opening and closing of the

contact points in a conventional electromechanical

turn signal or hazard warning flasher. The EMIC

uses a hard wired input received from the turn sig-

nal relay in the fuse block beneath the steering col-

umn through the turn signal or hazard warning

switch circuitry of the multi-function switch to deter-

mine when to flash the turn signal indicators and

activate the contactless relay on the cluster electronic

circuit board. The turn signal clicks will continue to

sound until the turn signal switch is turned Off, or

until the ignition switch is turned to the Off position,

whichever occurs first. The hazard warning clicks

will continue to sound until the hazard warning

switch is turned Off.

The EMIC provides chime service for all available

features in the chime warning system. The EMIC relies

upon its internal programming and hard wired inputs

from the front door ajar switches, the key-in ignition

switch, the ignition switch, the seat belt switch, and the

turn signal/hazard warning (multi-function) switches.

The EMIC relies upon electronic message inputsreceived from other electronic modules over the CAN

data bus network to provide chime service for the low

engine oil level warning. Upon receiving the proper

inputs, the EMIC activates the chime tone generator or

the contactless relay to provide the audible warning to

the vehicle operator. The internal programming of the

EMIC determines the priority of each chime request

input that is received, as well as the rate and duration

of each tone that is to be generated. See the owner's

manual in the vehicle glove box for more information on

the features provided by the chime warning system.

The hard wired chime warning system inputs to

the EMIC, as well as other hard wired circuits for

this system may be diagnosed and tested using con-

ventional diagnostic tools and procedures. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the EMIC, the CAN data

bus network, or the electronic message inputs used

by the EMIC to provide chime warning system ser-

vice. The most reliable, efficient, and accurate means

to diagnose the EMIC, the CAN data bus network,

and the electronic message inputs for the chime

warning system requires the use of a diagnostic scan

tool. Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

The hard wired chime warning system inputs to

the ElectroMechanical Instrument Cluster (EMIC),

as well as other hard wired circuits for this system

may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods may not prove conclusive

in the diagnosis of the EMIC, the Controller Area

Network (CAN) data bus network, or the electronic

message inputs used by the EMIC to provide chime

warning system service. The most reliable, efficient,

and accurate means to diagnose the EMIC, the CAN

data bus network, and the electronic message inputs

for the chime warning system requires the use of a

diagnostic scan tool. Refer to the appropriate diag-

nostic information.

8B - 2 CHIME/BUZZERVA

Page 862 of 2305

²Position of selector lever.

²Selected shift range.

²CAN signals.

²Engine Status.

Engine speed limits may be reached in all gears

with full throttle or in kick-down operation. In for-

ward driving, the shift range of the forward gears

can be adjusted by the operator by tipping the selec-

tor lever to the left or right (AutoStick). However, the

TCM features a downshift inhibitor to prevent the

engine from overspeeding.

OPERATION

The transmission control module (TCM) deter-

mines the current operating conditions of the vehicle

and controls the shifting process for shift comfort and

driving situations. It receives this operating data

from sensors and broadcast messages from other

modules.

The TCM uses inputs from several sensors that are

directly hardwired to the controller and it uses sev-

eral indirect inputs that are used to control shifts.

This information is used to actuate the proper sole-

noids in the valve body to achieve the desired gear.

The shift lever assembly (SLA) has several items

that are monitored by the TCM to calculate shift

lever position. The reverse light switch, an integral

part of the SLA, controls the reverse light relay con-

trol circuit. The Brake/Transmission Shift Interlock

(BTSI) solenoid and the park lockout solenoid (also

part of the SLA) are controlled by the TCM.

The ECM and ABS broadcast messages over the

controller area network (CAN C) bus for use by the

TCM. The TCM uses this information, with other

inputs, to determine the transmission operating con-

ditions.

The TCM:

²determines the momentary operating conditions

of the vehicle.

²controls all shift processes.

²considers shift comfort and the driving situation.

The TCM controls the solenoid valves for modulat-

ing shift pressures and gear changes. Relative to the

torque being transmitted, the required pressures are

calculated from load conditions, engine rpm, vehicle

speed, and ATF temperature.

The following functions are contained in the TCM:

²Shift Program

²Downshift Safety

²Torque Converter Lock-Up Clutch.

²Adaptation.

This transmission does not have a TCM relay.

Power is supplied to the SLA and the TCM directly

from the ignition.

The TCM continuously checks for electrical prob-

lems, mechanical problems, and some hydraulic prob-

lems. When a problem is sensed, the TCM stores a

diagnostic trouble code (DTC). Some of these codescause the transmission to go into ªLimp-Inº or

ªdefaultº mode. Some DTCs cause permanent

Limp-In and others cause temporary Limp-In. The

NAG1 defaults in the current gear position if a DTC

is detected, then after a key cycle the transmission

will go into Limp-in, which is mechanical 2nd gear.

Some DTCs may allow the transmission to resume

normal operation (recover) if the detected problem

goes away. A permanent Limp-In DTC will recover

when the key is cycled, but if the same DTC is

detected for three key cycles the system will not

recover and the DTC must be cleared from the TCM

with the DRBIIItscan tool.

TCM SIGNALS

The TCM registers one part of the input signals by

direct inputs, the other part by CAN C bus. In addi-

tion to the direct control of the actuators, the TCM

sends various output signals by CAN C bus to other

control modules.

Selector Lever Position

The TCM monitors the SLA for all shift lever posi-

tions via the CAN bus.

ATF Temperature Sensor

The ATF temperature sensor is a positive temper-

ature co-efficient (PTC) thermistor. It measures the

temperature of the transmission fluid and is a direct

input signal for the TCM. The temperature of the

ATF has an influence on the shifttime and resulting

shift quality. As the temperature rises, resistance

rises, and therefore, the probing voltage is decreas-

ing. Because of its registration, the shifting process

can be optimized in all temperature ranges.

The ATF temperature sensor is wired in series

with the park/neutral contact. The temperature sig-

nal is transmitted to the TCM only when the reed

contact of the park/neutral contact is closed because

the TCM only reads ATF temperature while in any

forward gear, or REVERSE. When the transmission

is in PARK or NEUTRAL, the TCM will substitute

the engine temperature for the ATF temperature.

Starter Interlock

The TCM monitors a contact switch wired in series

with the transmission temperature sensor to deter-

mine PARK and NEUTRAL positions. The contact

switch is open in PARK and NEUTRAL. The TCM

senses transmission temperature as high (switch

supply voltage), confirming switch status as open.

The TCM then broadcasts a message over CAN bus

to confirm switch status. The PCM receives this

information and allows operation of the starter cir-

cuit.

VAELECTRONIC CONTROL MODULES 8E - 7

Page 864 of 2305

little longer before the next upshift. If the driving

style is still aggressive, the shift point is modified up

to ten steps. If the driving returns to normal, then

the shift point modification also returns to the base

position.

This adaptation has no memory. The adaptation to

driving style is nothing more than a shift point mod-

ification meant to assist an aggressive driver. The

shift points are adjusted for the moment and return

to base position as soon as the inputs are controlled

in a more rational manner.

Shift Time Adaptation (Shift Overlap Adaptation, Working

Pressure)

Shift time adaptation is the ability of the TCM to

electronically alter the time it takes to go from one

gear to another. Shift time is defined as the time it

takes to disengage one shift member while another is

being applied. Shift time adaptation is divided into

four categories:

1. Accelerating upshift, which is an upshift under

a load. For shift time adaptation for the 1-2 upshift

to take place, the transmission must shift from 1st to

2nd in six different engine load ranges vs. transmis-

sion output speed ranges.

2. Decelerating upshift, which is an upshift under

no load. This shift is a rolling upshift and is accom-

plished by letting the vehicle roll into the next gear.

3. Accelerating downshift, which is a downshift

under load. This shift can be initiated by the throttle,

with or without kickdown. The shift selector can also

be used.

4. Decelerating downshift, which is accomplished

by coasting down. As the speed of the vehicle

decreases, the transmission downshifts.

Fill Pressure Adaptation (Apply Pressure Adaptation, Modu-

lating Pressure)

Fill pressure adaptation is the ability of the TCM

to modify the pressure used to engage a shift mem-

ber. The value of this pressure determines how firm

the shift will be.

²If too much pressure is used, the shift will be

hard.

²If too little pressure is used, the transmission

may slip.

The pressure adjustment is needed to compensate

for the tolerances of the shift pressure solenoid valve.

The amount the solenoid valve opens as well as how

quickly the valve can move, has an effect on the pres-

sure. The return spring for the shift member pro-

vides a resistance that must be overcome by the

pressure in order for shift member to apply. These

return springs have slightly different values. This

also affects the application pressure and is compen-

sated for by fill pressure adaptation.Fill Time Adaptation (Engagement Time Adaptation)

Fill time is the time it takes to fill the piston cav-

ity and take up any clearances for a friction element

(clutch or brake). Fill time adaptation is the ability of

the TCM to modify the time it takes to fill the shift

member by applying a preload pressure.

CONTROLLER MODES OF OPERATION

Permanent Limp - In Mode

When the TCM determines there is a non-recover-

able condition present that does not allow proper

transmission operation, it places the transmission in

permanent Limp-In Mode. When the condition occurs

the TCM turns off all solenoids as well as the sole-

noid supply output circuit. If this occurs while the

vehicle is moving, the transmission remains in the

current gear position until the ignition is turned off

or the shifter is placed in the ªPº position. When the

shifter has been placed in ªP,º the transmission only

allows 2nd gear operation. If this occurs while the

vehicle is not moving, the transmission only allows

operation in 2nd gear.

Temporary Limp - In Mode

This mode is the same as the permanent Limp-In

Mode except if the condition is no longer present, the

system resumes normal operation.

Under Voltage Limp - In Mode

When the TCM detects that system voltage has

dropped below 8.5 volts, it disables voltage-depen-

dant diagnostics and places the transmission in the

temporary Limp-In Mode. When the TCM senses

that the voltage has risen above 9.0 volts, normal

transmission operation is resumed.

Hardware Error Mode

When the TCM detects a major internal error, the

transmission is placed in the permanent Limp-In

Mode and ceases all communication over the CAN

bus. When the TCM has entered this mode normal

transmission operation does not resume until all

DTCs are cleared from the TCM.

Loss of Drive

If the TCM detects a situation that has resulted or

may result in a catastrophic engine or transmission

problem, the transmission is placed in the neutral

position. Improper Ratio, Input Sensor Overspeed or

Engine Overspeed DTCs cause the loss of drive.

Controlled Limp - in Mode

When a failure does not require the TCM to shut

down the solenoid supply, but the failure is severe

enough that the TCM places the transmission into a

VAELECTRONIC CONTROL MODULES 8E - 9

Page 902 of 2305

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED GLASS........................... 1

HEATED MIRRORS......................... 9HEATED SEATS........................... 10

HEATED GLASS

TABLE OF CONTENTS

page page

HEATED GLASS

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

ELECTRIC BACKLIGHT (EBL) SYSTEM.....2

REAR WINDOW DEFOGGER RELAY

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................4REAR WINDOW DEFOGGER SWITCH

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING

REAR WINDOW DEFOGGER SWITCH......5

REMOVAL.............................6

INSTALLATION..........................6

REAR WINDOW DEFOGGER GRID

STANDARD PROCEDURE

GRID LINE AND TERMINAL REPAIR........7

HEATED GLASS

DESCRIPTION

CAUTION: Grid lines can be damaged or scraped

off with sharp instruments. Care should be taken in

cleaning glass or removing foreign materials,

decals or stickers. Normal glass cleaning solvents

or hot water used with rags or toweling is recom-

mended.

The rear window defogger system, also known as

the electric backlight (EBL), consists of a backglass

with two vertical bus bars linked by a series of grid

lines fired onto the inside surface of the rear window.

The EBL system is turned On or Off by a control

switch (Fig. 1) located in the instrument panel near

the right side of the steering wheel, which sends a

request signal to the rear window defogger module

that operates the left and right rear window defogger

relays located in the fuse/relay block under the driv-

ers seat.

Circuit protection is provided by a 30 amp fuse

also located in the fuse/relay block.

OPERATION

When the rear window defogger switch is pressed

to the On position, current is directed through the

switch to the rear window defogger module. The rear

window defogger module then grounds the control

side of the left and right rear window defogger (EBL)

Fig. 1 Rear Window Defogger Switch

1 - REAR WINDOW DEFOGGER SWITCH

2 - INSTRUMENT PANEL

VAHEATED SYSTEMS 8G - 1