lock MERCEDES-BENZ SPRINTER 2011 MY11 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2011Pages: 292, PDF Size: 6.75 MB

Page 150 of 292

G

Warning

Do not attempt to modify or repair the lashing

points, cargo tie-down

rings or tie downs. The

load or the cargo tie-down rings could work

loose and cause serious injury to you and

other people as well as material damage.

Spread the load evenly between the lashing

points or cargo tie-down rings.

Observe the loading guidelines.

i Secure loose loads with a tested lashing

net or a tarpaulin.

X Always fasten the lashing net or tarpaulin

to all available

cargo tie-down points. Make

sure that the retaining hooks are secured

against accidental opening.

! Observe the information

on the maximum

loading capacity of the lashing points.

If you use multiple lashing points to secure

a load, you should observe the maximum

loading capacity of the weakest lashing

point.

When you brake hard, for example, forces

apply that can be far higher than the weight

force of the transported load. Always use

multiple lashing points to distribute these

forces, and distribute the load equally

among them.

Information about the maximum loading

capacity of the cargo tie-down points can be

found in the "Technical data" section

(Y page 283).

i If your vehicle is equipped with loading

rails in the cargo floor, you should place

lashing rods directly in front of and behind

the load. The lashing rods directly absorb

the potential shifting forces. G

Warning

If you

tension the lashing straps between the

side walls, or between a side wall and the

cargo floor, the

maximum permissible load for

the loading rails or lashing points or eyelets

could be exceeded if the brakes are applied suddenly, if

the vehicle's direction is changed

abruptly or in the event of an accident.

The load would no longer be secured,

resulting in a risk of serious injury being

caused by the load slipping.

For this reason,

do not tension a lashing strap

between the side walls or between a side wall

and the cargo floor.

Only lashing rods are to be used between the

loading rails on the side walls. Observe the

operating instructions of the lashing rod

manufacturer.

i Securing loads on the cargo floor by

lashing them down is only recommended

for lightweight loads. Place non-slip mats

(anti-slip mats) on the cargo floor to

increase load security. G

Warning

Before releasing

the lashing straps, you must

make sure that

the load is standing firmly and

that it cannot tip over once the straps have

been removed. Otherwise, you or others could

be injured by the load slipping.

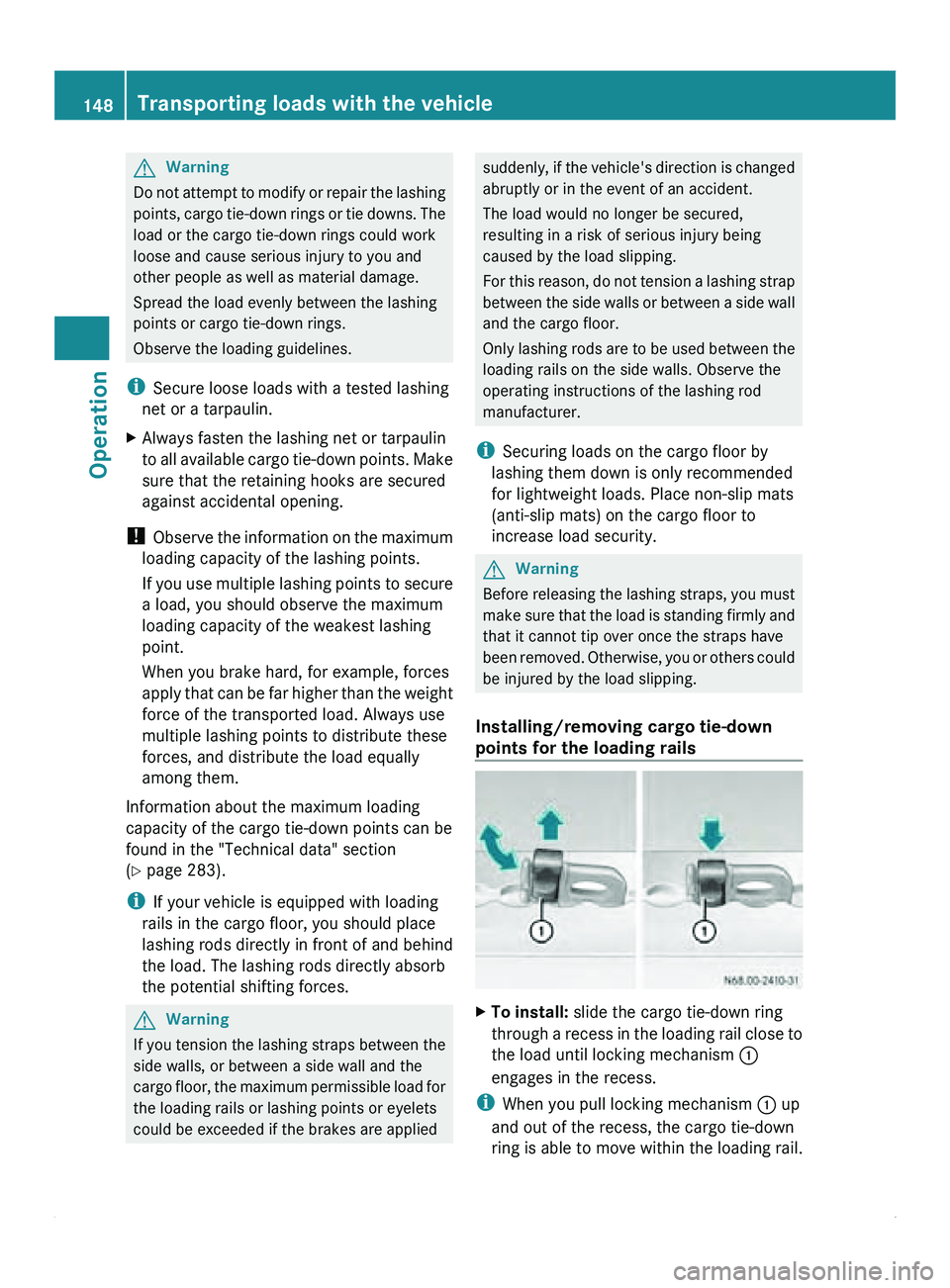

Installing/removing cargo tie-down

points for the loading rails X

To install: slide the cargo tie-down ring

through a recess

in the loading rail close to

the load until locking mechanism 0046

engages in the recess.

i When you pull locking mechanism 0046 up

and out of the recess, the cargo tie-down

ring is able to move within the loading rail. 148

Transporting loads with the vehicle

Operation

Page 151 of 292

Make sure that locking mechanism 0046 is

always engaged in a recess.

G

Warning

If not firmly anchored in the loading rail, the

cargo tie-down ring

may slip or be torn out of

the loading rail in the event of sudden braking.

The load would no longer be secured,

resulting in a risk of serious injury being

caused by the load slipping. For this reason,

always check the cargo tie-down ring for firm

seating after installing.

X Check the cargo tie-down ring for firm

seating.

X To remove:

pull locking

mechanism 0046 up

and pull the cargo tie-down ring towards

the locking mechanism and out of the

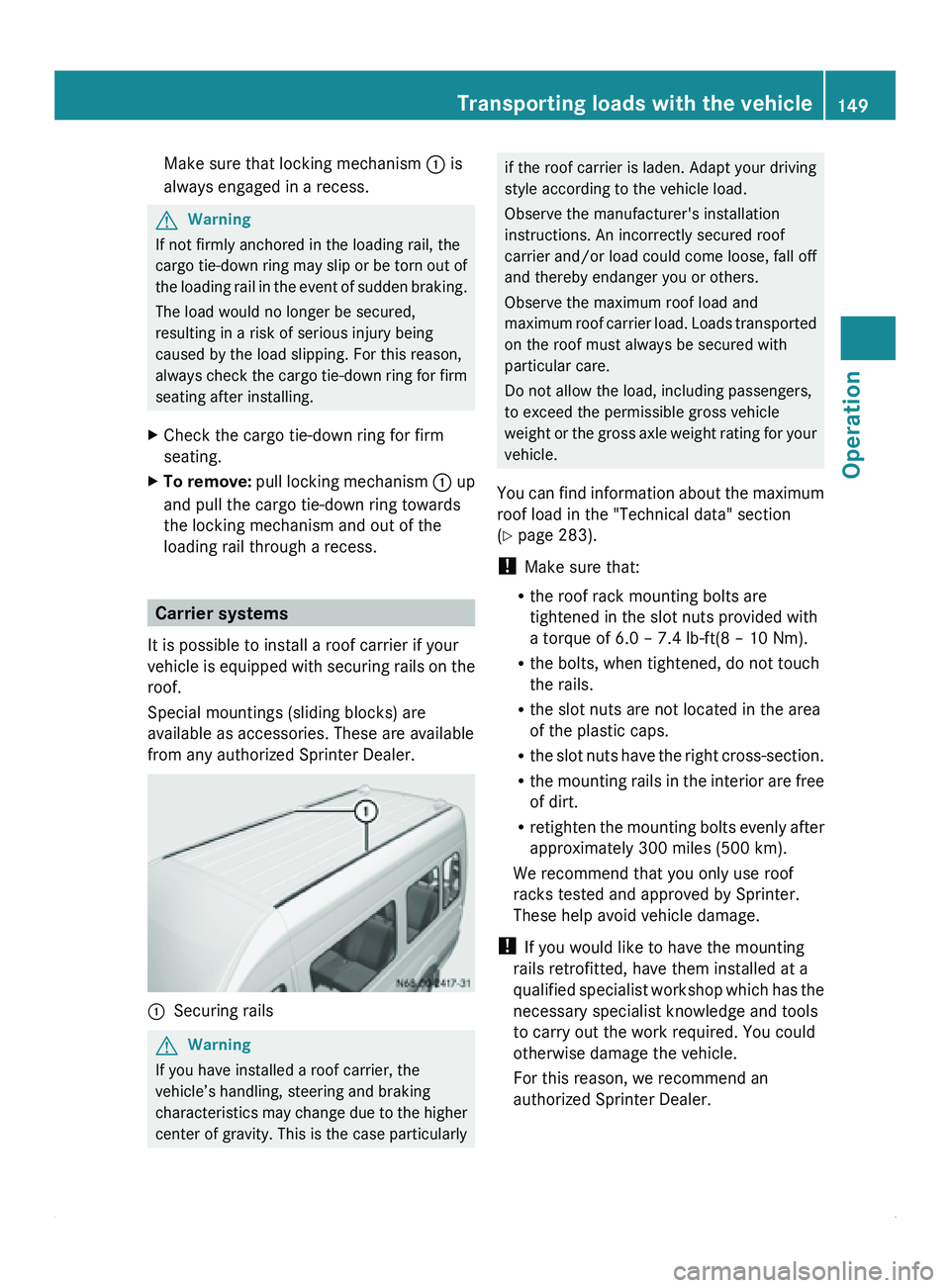

loading rail through a recess. Carrier systems

It is possible to install a roof carrier if your

vehicle is equipped

with securing rails on the

roof.

Special mountings (sliding blocks) are

available as accessories. These are available

from any authorized Sprinter Dealer. 0046

Securing rails G

Warning

If you have installed a roof carrier, the

vehicle’s handling, steering and braking

characteristics may change

due to the higher

center of gravity. This is the case particularly if the roof carrier is laden. Adapt your driving

style according to the vehicle load.

Observe the manufacturer's installation

instructions. An incorrectly secured roof

carrier and/or

load

could come loose, fall off

and thereby endanger you or others.

Observe the maximum roof load and

maximum roof carrier load. Loads transported

on the roof must always be secured with

particular care.

Do not allow the load, including passengers,

to exceed the permissible gross vehicle

weight or the gross axle weight rating for your

vehicle.

You can find information about the maximum

roof load in the "Technical data" section

(Y page 283).

! Make sure that:

R the roof rack mounting bolts are

tightened in the slot nuts provided with

a torque of 6.0 – 7.4 lb-ft(8 – 10 Nm).

R the bolts, when tightened, do not touch

the rails.

R the slot nuts are not located in the area

of the plastic caps.

R the slot nuts have the right cross-section.

R the mounting rails in the interior are free

of dirt.

R retighten the mounting bolts evenly after

approximately 300 miles (500 km).

We recommend that you only use roof

racks tested and approved by Sprinter.

These help avoid vehicle damage.

! If you would like to have the mounting

rails retrofitted, have them installed at a

qualified specialist workshop which has the

necessary specialist knowledge and tools

to carry out the work required. You could

otherwise damage the vehicle.

For this reason, we recommend an

authorized Sprinter Dealer. Transporting loads with the vehicle

149

Operation Z

Page 165 of 292

!

In order to avoid consequential damage,

repair damage caused by loose chippings

and remove any dirt immediately, in

particular:

R insect remains

R bird droppings

R flash rust

R tree resin

R oils and grease

R fuels

R tar stains

R salt residue

Wash your vehicle

more frequently if it gets

dirty more often.

! Do not park the vehicle for an extended

period right after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. Generally, park the

vehicle at operating temperature after

cleaning.

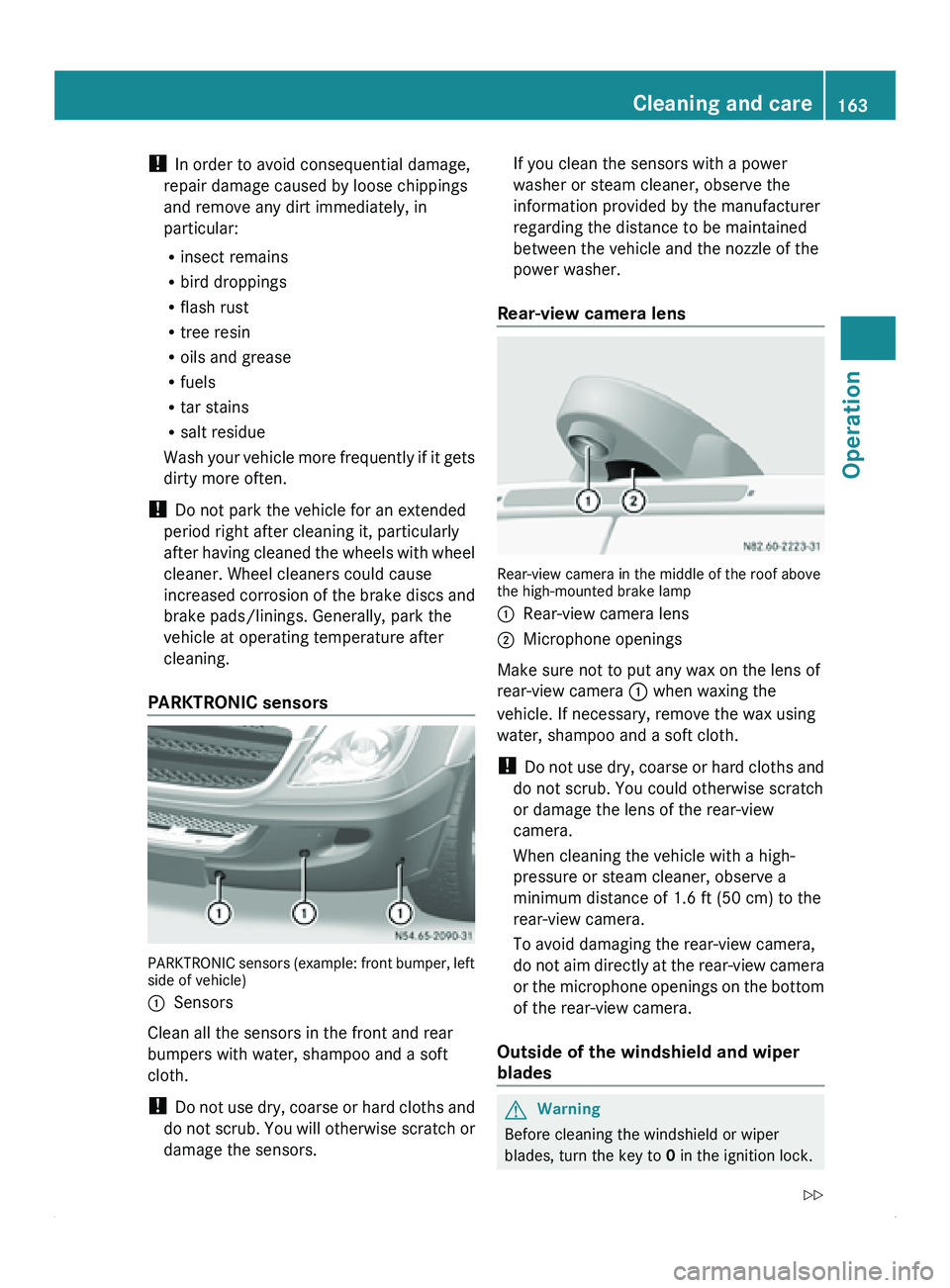

PARKTRONIC sensors PARKTRONIC sensors (example: front bumper, left

side of vehicle)

0046

Sensors

Clean all the sensors in the front and rear

bumpers with water, shampoo and a soft

cloth.

! Do not

use

dry, coarse or hard cloths and

do not scrub. You will otherwise scratch or

damage the sensors. If you clean the sensors with a power

washer or steam cleaner, observe the

information provided by the manufacturer

regarding the distance to be maintained

between the vehicle and the nozzle of the

power washer.

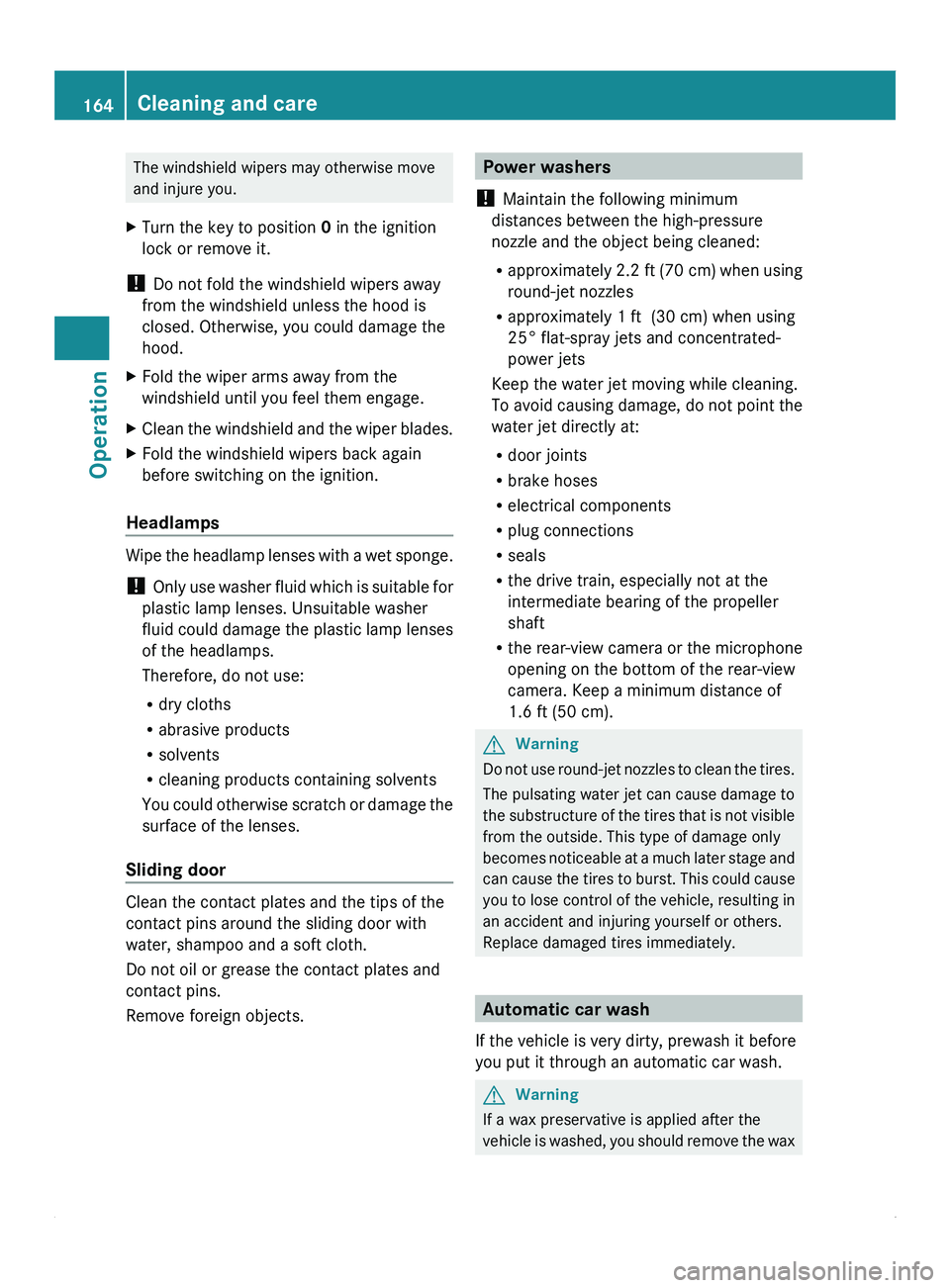

Rear-view camera lens Rear-view camera in the middle of the roof above

the high-mounted brake lamp

0046

Rear-view camera lens

0047 Microphone openings

Make sure not to put any wax on the lens of

rear-view camera 0046 when waxing the

vehicle. If necessary, remove the wax using

water, shampoo and a soft cloth.

! Do not

use

dry, coarse or hard cloths and

do not scrub. You could otherwise scratch

or damage the lens of the rear-view

camera.

When cleaning the vehicle with a high-

pressure or steam cleaner, observe a

minimum distance of 1.6 ft (50 cm) to the

rear-view camera.

To avoid damaging the rear-view camera,

do not aim directly at the rear-view camera

or the microphone openings on the bottom

of the rear-view camera.

Outside of the windshield and wiper

blades G

Warning

Before cleaning the windshield or wiper

blades, turn the key to 0 in the ignition lock. Cleaning and care

163

Operation

Z

Page 166 of 292

The windshield wipers may otherwise move

and injure you.

X Turn the key to position 0 in the ignition

lock or remove it.

! Do not fold the windshield wipers away

from the windshield unless the hood is

closed. Otherwise, you could damage the

hood.

X Fold the wiper arms away from the

windshield until you feel them engage.

X Clean the windshield and the wiper blades.

X Fold the windshield wipers back again

before switching on the ignition.

Headlamps Wipe the headlamp lenses with a wet sponge.

! Only use washer

fluid which is suitable for

plastic lamp lenses. Unsuitable washer

fluid could damage the plastic lamp lenses

of the headlamps.

Therefore, do not use:

R dry cloths

R abrasive products

R solvents

R cleaning products containing solvents

You could otherwise scratch or damage the

surface of the lenses.

Sliding door Clean the contact plates and the tips of the

contact pins around the sliding door with

water, shampoo and a soft cloth.

Do not oil or grease the contact plates and

contact pins.

Remove foreign objects. Power washers

! Maintain the following minimum

distances between the high-pressure

nozzle and the object being cleaned:

R approximately 2.2 ft (70 cm)

when using

round-jet nozzles

R approximately 1 ft (30 cm) when using

25° flat-spray jets and concentrated-

power jets

Keep the water jet moving while cleaning.

To avoid causing damage, do not point the

water jet directly at:

R door joints

R brake hoses

R electrical components

R plug connections

R seals

R the drive train, especially not at the

intermediate bearing of the propeller

shaft

R the rear-view camera or the microphone

opening on the bottom of the rear-view

camera. Keep a minimum distance of

1.6 ft (50 cm). G

Warning

Do not

use round-jet nozzles to clean the tires.

The pulsating water jet can cause damage to

the substructure of

the tires that is not visible

from the outside. This type of damage only

becomes noticeable at a much later stage and

can cause the tires to burst. This could cause

you to lose control of the vehicle, resulting in

an accident and injuring yourself or others.

Replace damaged tires immediately. Automatic car wash

If the vehicle is very dirty, prewash it before

you put it through an automatic car wash. G

Warning

If a wax preservative is applied after the

vehicle is washed,

you should remove the wax164

Cleaning and care

Operation

Page 170 of 292

service. You will also see a minus sign before

the service due date.

Calling up the service due date

X

Turn the key to position 2 in the ignition

lock.

The display is activated.

Vehicles with steering wheel buttons

X Press the 0059 or 0058 button on the

steering wheel repeatedly

until you see the

standard display (Y page 77).

X Press the 0029 or 002D button on the

steering wheel repeatedly

until you see the

following in the display, for example:

R 009B Service A in ... days

R 009B Service A in ... mi (km)

Vehicles without steering wheel buttons

X Press the 007B menu button on the

instrument cluster repeatedly until the

009B or 009C symbol for the service

appears.

Additionally you will see the remaining

distance in miles ( mi) or kilometers ( km) or

the remaining time in days ( d).Hood

Opening the hood G

Warning

Do not pull the release lever while the vehicle

is in motion.

If you do so, the hood may open

up and block your view. G

Warning!

There is a risk of injury if the hood is open,

even if the engine is not running.

Some engine components can become very

hot.

To avoid the risk of burns, only touch those

components described in the Operator's

Manual and observe

the relevant safety notes. G

Warning

The radiator fan between the radiator and the

engine can start

automatically, even if the key

has been removed from the ignition lock.

Keep away from the area of rotation of the fan

blades. You could otherwise be injured.

The electronic injector control operates at

high voltage. For this reason, you must never

touch injection system components while:

R the engine is running.

R the engine is being started.

R the ignition is switched on.

You could otherwise receive an electric shock

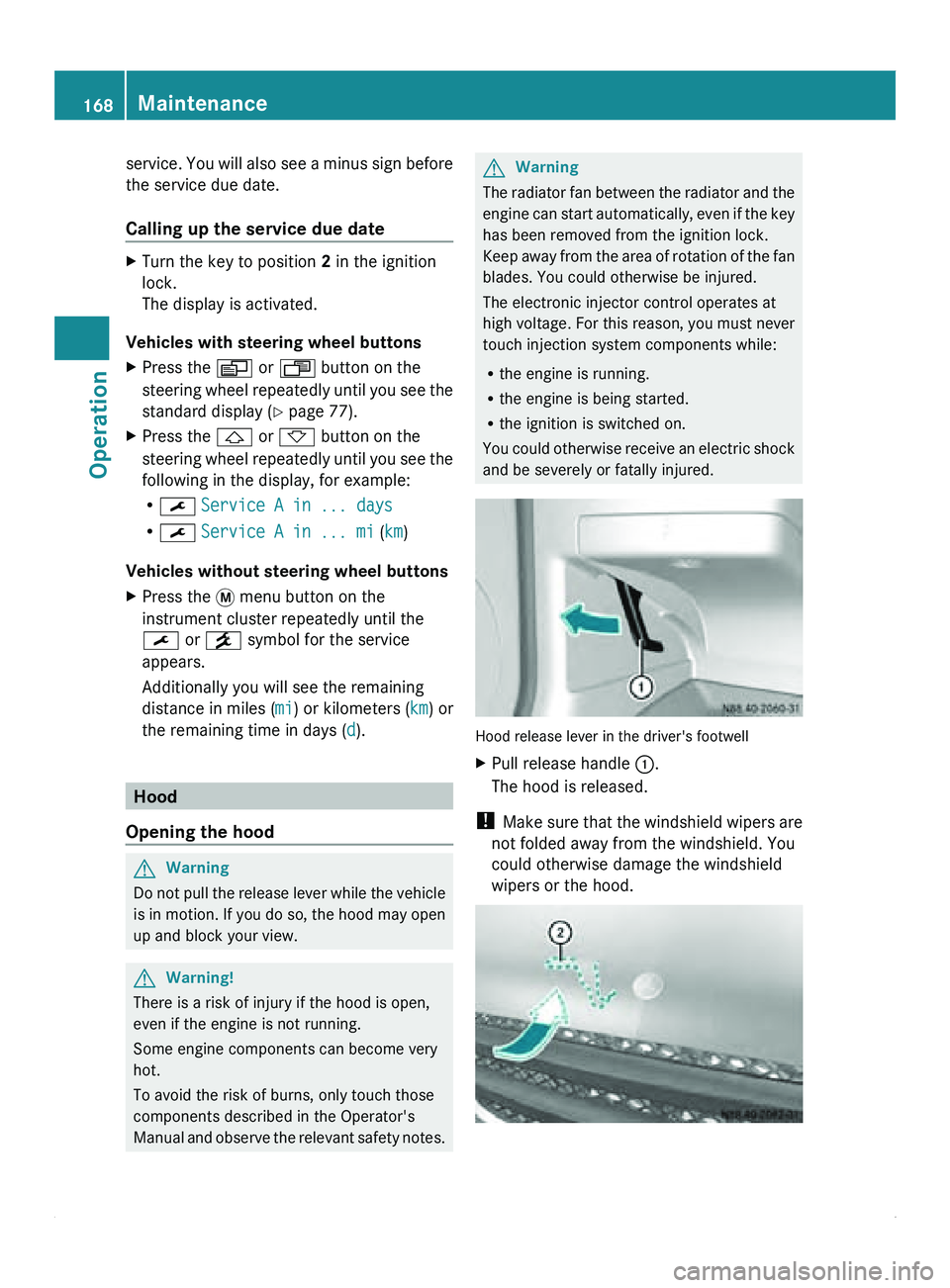

and be severely or fatally injured. Hood release lever in the driver's footwell

X

Pull release handle 0046.

The hood is released.

! Make sure

that

the windshield wipers are

not folded away from the windshield. You

could otherwise damage the windshield

wipers or the hood. 168

Maintenance

Operation

Page 172 of 292

Only open the coolant expansion tank when

the coolant temperature is below 122 ‡

(50 †).

G

Warning

Coolant contains glycol and is therefore toxic.

Do not swallow the coolant. See a doctor

immediately if you swallow coolant.

Make sure that coolant does not come into

contact with skin,

eyes or clothing. In case of

contact with eyes, rinse immediately with

plenty of clean water. Clean affected areas of

skin and clothing with soap and water

immediately. Change any affected clothing

immediately.

X Slowly turn cap 0046 counter-clockwise and

allow the excess pressure to escape.

X Turn cap 0046 further and remove it.

X Add coolant until it is at the MAX mark.

Observe the correct coolant mixture ratio

and the required water quality

(Y page 160).

X Replace cap 0046 and tighten

it until the stop.

! Check the cooling and heating system

regularly for leaks.

If a large quantity of coolant is lost, have

the cause traced

and rectified at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. Clutch mechanism and brake system

G

Warning

Brake fluid is hazardous to health. Do not

swallow brake fluid.

See a doctor immediately

if you swallow brake fluid.

Make sure that brake fluid does not come into

contact with skin, clothing or eyes. Rinse

affected areas with plenty of clean water and

consult a doctor if necessary.

Always wear gloves and eye protection when

topping up brake fluid. Store brake fluid only in the original closed

container and keep it out of the reach of

children. Comply with safety regulations

when handling brake fluid.

G

Warning

If the

boiling point of the brake fluid is too low,

vapor pockets may form in the brake system

when the brakes

are subjected to a heavy load

(e.g. on long downhill stretches). This would

impair braking efficiency. The vehicle's

stopping distance may then be longer. This

increases the risk of an accident.

Have the brake fluid renewed every two years.

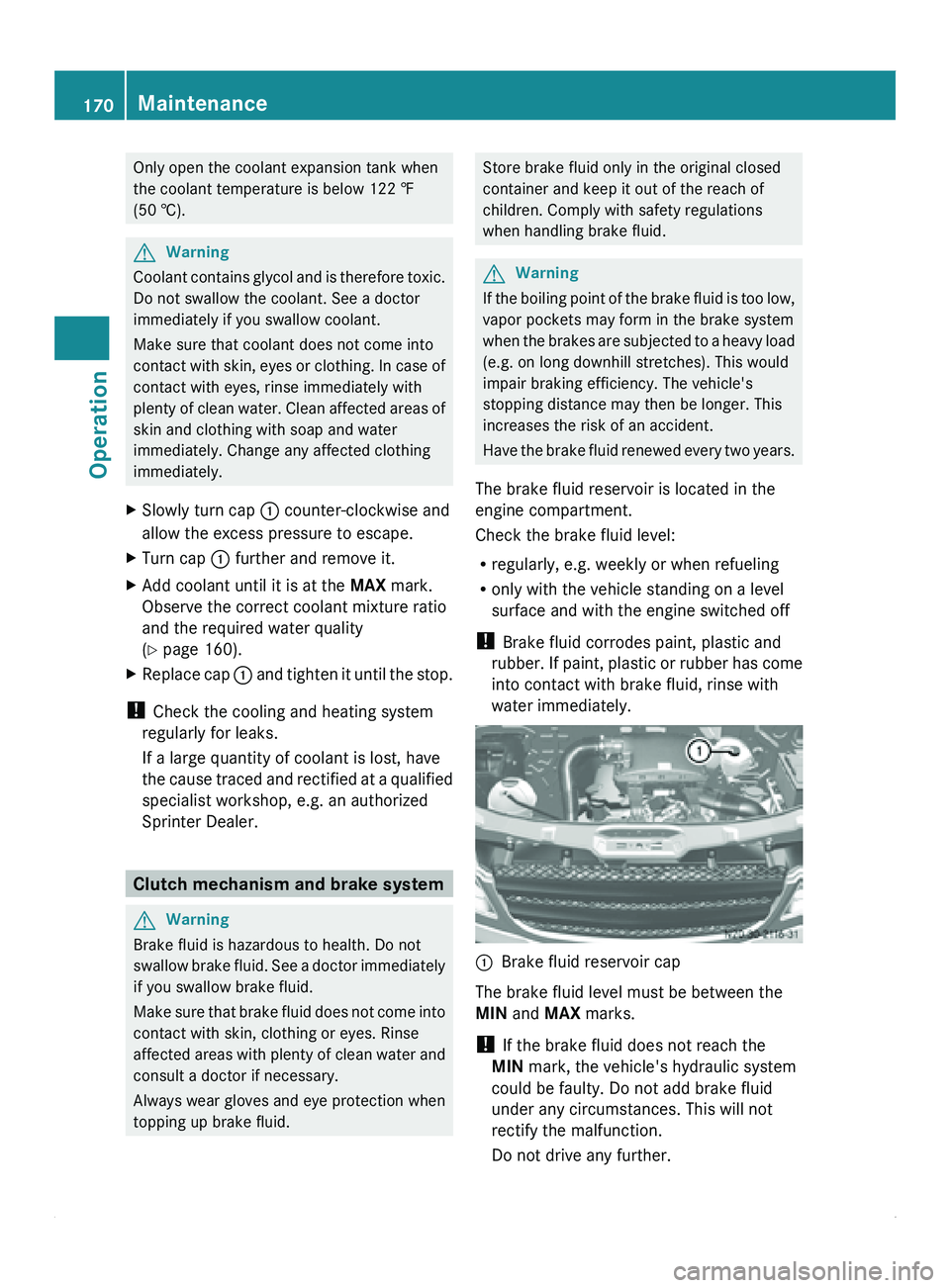

The brake fluid reservoir is located in the

engine compartment.

Check the brake fluid level:

R regularly, e.g. weekly or when refueling

R only with the vehicle standing on a level

surface and with the engine switched off

! Brake fluid corrodes paint, plastic and

rubber. If paint, plastic or rubber has come

into contact with brake fluid, rinse with

water immediately. 0046

Brake fluid reservoir cap

The brake fluid level must be between the

MIN and

MAX marks.

! If the brake fluid does not reach the

MIN mark, the vehicle's hydraulic system

could be faulty. Do not add brake fluid

under any circumstances. This will not

rectify the malfunction.

Do not drive any further. 170

Maintenance

Operation

Page 173 of 292

Have the system checked immediately at a

qualified specialist workshop, e.g. at an

authorized Sprinter Dealer.

i There is usually a notice in the engine

compartment to remind

you when the next

brake fluid change is due. Windshield washer system/

headlamp cleaning system

Add windshield washer concentrate to the

washer fluid all year round. G

Warning

Windshield washer concentrate is highly

flammable.

Fire, naked flames

and smoking are therefore

prohibited when you are handling windshield

washer concentrate.

! Only use washer fluid concentrate which

is suitable for plastic lenses. Unsuitable

washer fluid concentrate could damage the

plastic lenses of the headlamps.

Adapt the mixing ratio to the ambient

temperature. If the temperature is above

freezing, use Summerwash to prevent

smearing. If there is a risk of frost, use

Winterwash to prevent the water from

freezing on the windshield.

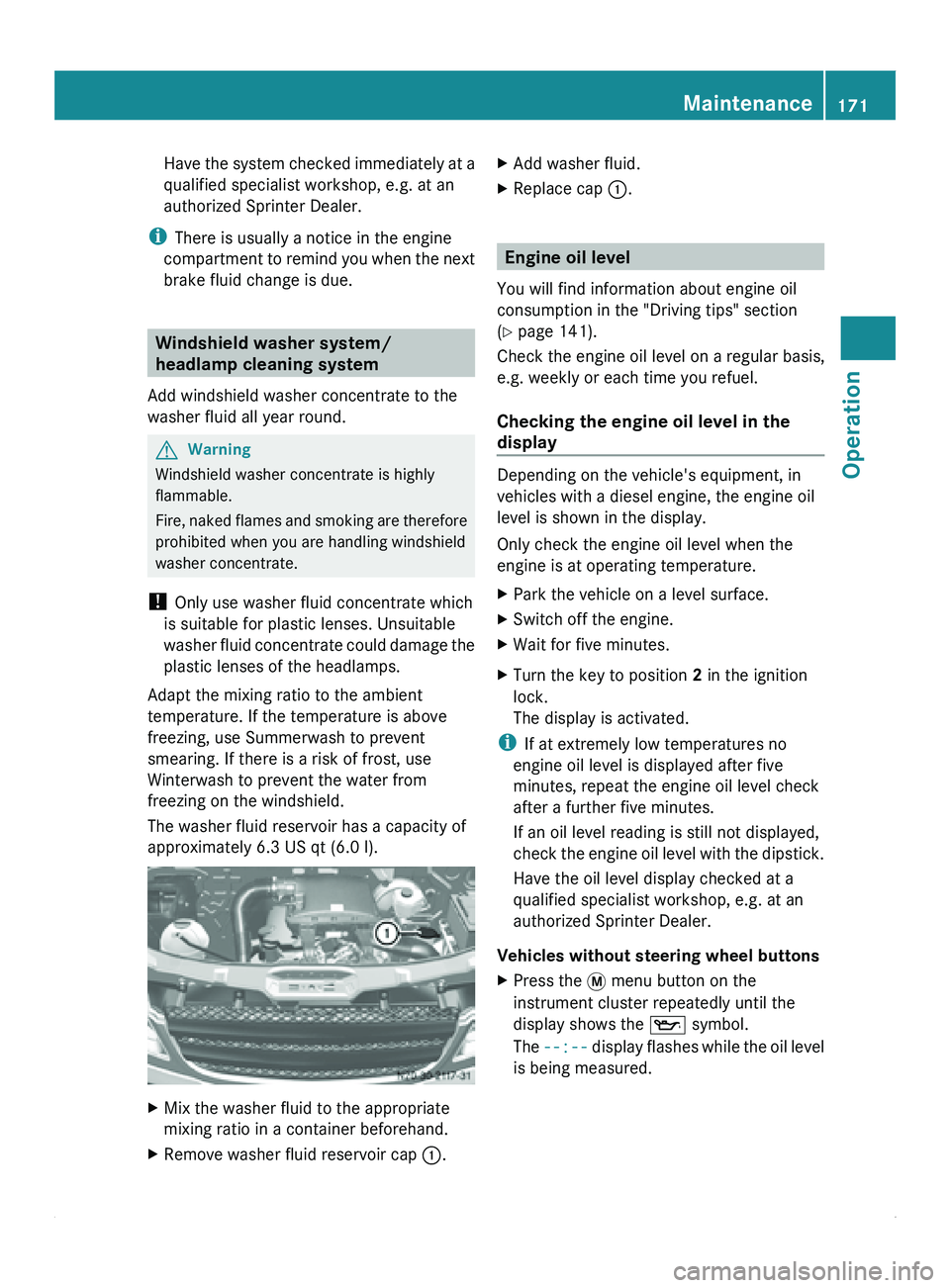

The washer fluid reservoir has a capacity of

approximately 6.3 US qt (6.0 l). X

Mix the washer fluid to the appropriate

mixing ratio in a container beforehand.

X Remove washer fluid reservoir cap 0046.X

Add washer fluid.

X Replace cap 0046. Engine oil level

You will find information about engine oil

consumption in the "Driving tips" section

(Y page 141).

Check the engine oil level on a regular basis,

e.g. weekly or each time you refuel.

Checking the engine oil level in the

display Depending on the vehicle's equipment, in

vehicles with a diesel engine, the engine oil

level is shown in the display.

Only check the engine oil level when the

engine is at operating temperature.

X

Park the vehicle on a level surface.

X Switch off the engine.

X Wait for five minutes.

X Turn the key to position 2 in the ignition

lock.

The display is activated.

i If at extremely low temperatures no

engine oil level is displayed after five

minutes, repeat the engine oil level check

after a further five minutes.

If an oil level reading is still not displayed,

check the engine

oil level with the dipstick.

Have the oil level display checked at a

qualified specialist workshop, e.g. at an

authorized Sprinter Dealer.

Vehicles without steering wheel buttons

X Press the 007B menu button on the

instrument cluster repeatedly until the

display shows the 00B1 symbol.

The --:-- display flashes

while the oil level

is being measured. Maintenance

171

Operation Z

Page 174 of 292

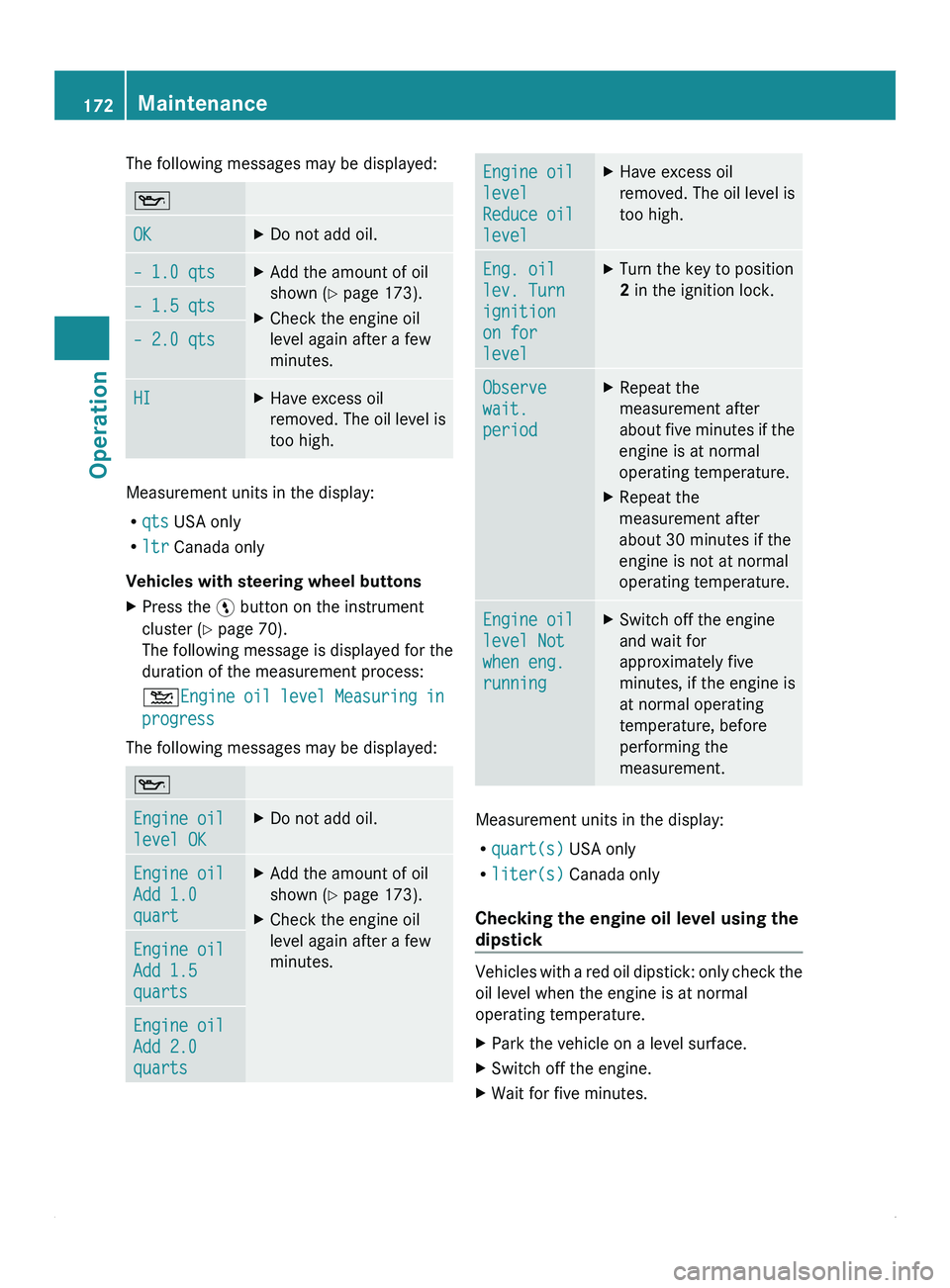

The following messages may be displayed:

00B1

OK X

Do not add oil. – 1.0 qts X

Add the amount of oil

shown (Y page 173).

X Check the engine oil

level again after a few

minutes. – 1.5 qts

– 2.0 qts

HI X

Have excess oil

removed. The oil

level is

too high. Measurement units in the display:

R

qts USA only

R ltr Canada only

Vehicles with steering wheel buttons

X Press the 00A4 button on the instrument

cluster (Y page 70).

The following message is displayed for the

duration of the measurement process:

00B4Engine oil

level

Measuring in

progress

The following messages may be displayed: 00B1

Engine oil

level OK X

Do not add oil. Engine oil

Add 1.0

quart X

Add the amount of oil

shown (Y page 173).

X Check the engine oil

level again after a few

minutes. Engine oil

Add 1.5

quarts

Engine oil

Add 2.0

quarts Engine oil

level

Reduce oil

level X

Have excess oil

removed. The oil

level is

too high. Eng. oil

lev. Turn

ignition

on for

level X

Turn the key to position

2 in the ignition lock. Observe

wait.

period X

Repeat the

measurement after

about five minutes

if the

engine is at normal

operating temperature.

X Repeat the

measurement after

about 30 minutes if the

engine is not at normal

operating temperature. Engine oil

level Not

when eng.

running X

Switch off the engine

and wait for

approximately five

minutes, if the engine is

at normal operating

temperature, before

performing the

measurement. Measurement units in the display:

R

quart(s) USA only

R liter(s) Canada only

Checking the engine oil level using the

dipstick Vehicles with a red oil dipstick: only check the

oil level when the engine is at normal

operating temperature.

X

Park the vehicle on a level surface.

X Switch off the engine.

X Wait for five minutes.172

Maintenance

Operation

Page 176 of 292

X

To install the air filter: insert the filter

mat.

X Put cover 0046 on. Vehicle assemblies

Check the assemblies regularly for leaks. If

fluid is being lost (e.g. there are oil stains

where the vehicle is parked), have the cause

found and rectified

immediately at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer.

0040Environmental note

When used improperly, service products are

harmful to the environment.

Do not allow service products to enter the

sewage system, surface

waters, ground water

or soil. Replacing the wiper blades

G

Warning

If the windshield wipers are set to intermittent

wipe or the rain/light sensor is active, the

windshield wipers could start moving at any

time and injure you or others.

Always remove the

key from the ignition lock

before replacing the wiper blades. G

Warning

Wiper blades are wear parts. Change the

wiper blades every six months, ideally in the

spring and fall.

Otherwise, the windshield and

rear window will not be wiped properly. This

may prevent you from observing the traffic

conditions, thereby causing an accident.

! Do not open the hood when a wiper arm

is folded away from the windshield.

Otherwise, you could damage the hood.

Do not fold the wiper arms back onto the

windshield without wiper blades fitted as

this could scratch the windshield. !

Only touch the windshield wiper where it

connects to the wiper arm. You could

otherwise damage the

wiper blade inserts.

Removing X

Apply the parking brake.

X On vehicles with automatic transmission,

move the selector lever to position P.

X Turn the key to position 1 in the ignition

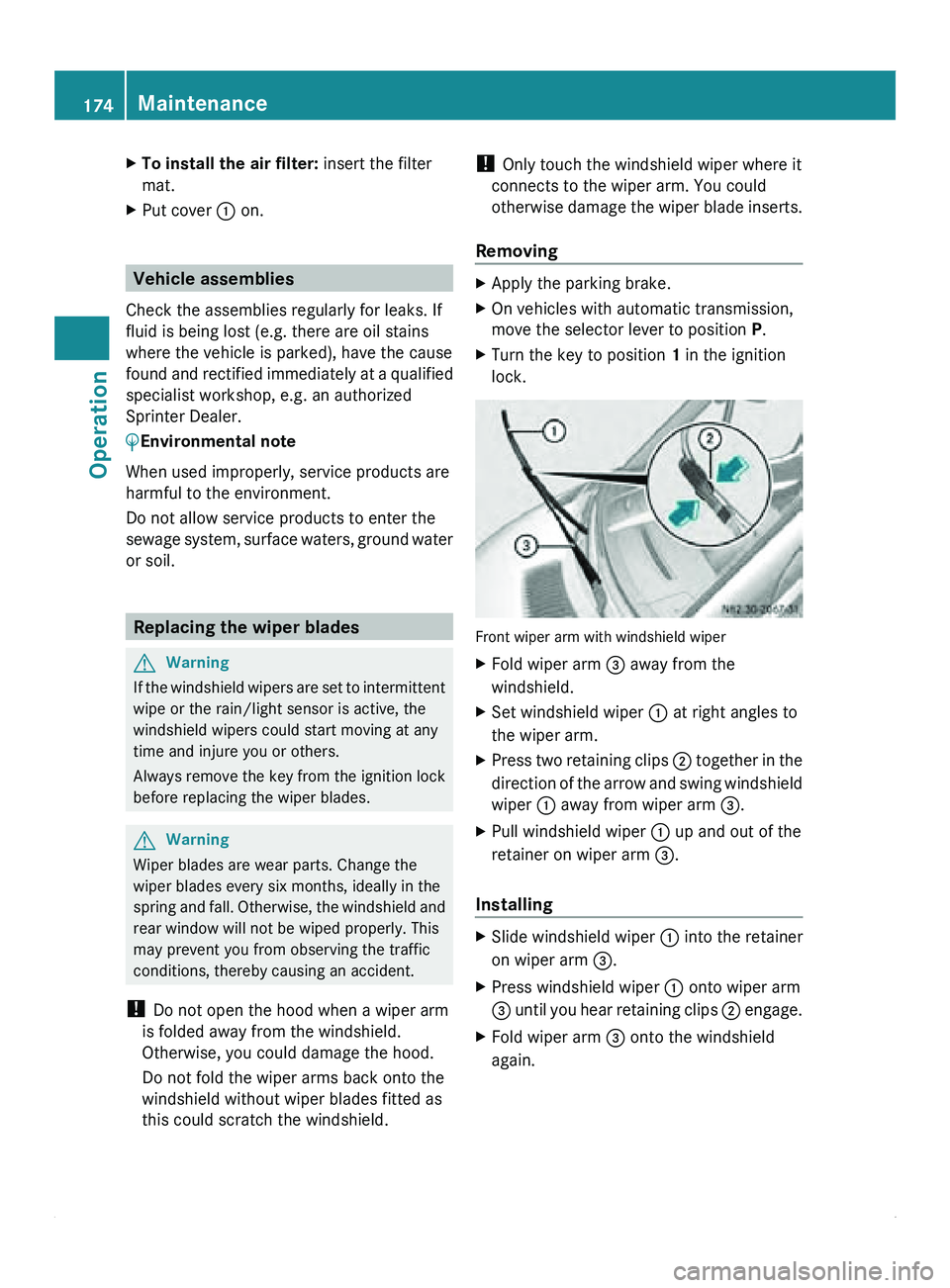

lock. Front wiper arm with windshield wiper

X

Fold wiper arm 008A away from the

windshield.

X Set windshield wiper 0046 at right angles to

the wiper arm.

X Press two retaining clips 0047 together

in

the

direction of the arrow and swing windshield

wiper 0046 away from wiper arm 008A.

X Pull windshield wiper 0046 up and out of the

retainer on wiper arm 008A.

Installing X

Slide windshield wiper 0046 into the retainer

on wiper arm 008A.

X Press windshield wiper 0046 onto wiper arm

008A until you

hear retaining clips 0047 engage.

X Fold wiper arm 008A onto the windshield

again. 174

Maintenance

Operation

Page 178 of 292

Disconnecting the battery

G

Warning

There is a risk of a short circuit if the positive

terminal of the

connected battery comes into

contact with any part of the vehicle. This could

cause the flammable gas mix to ignite. You

and others could be seriously injured.

R Do not place any metal objects or tools on

the batteries.

R When disconnecting the batteries, always

disconnect the negative terminal clamp

before the positive terminal clamp.

R When connecting the batteries, always

connect the positive terminal clamp before

the negative terminal clamp.

R Do not disconnect or connect the batteries

when the engine is running.

! Switch off the engine and remove the key

from the ignition lock before you loosen or

disconnect the terminal clamps. You may

otherwise destroy electronic components

such as the alternator.

Always disconnect the starter battery in the

battery case in the driver's footwell first.

! Always disconnect the battery in

the order described below. Never swap the

terminal clamps. You may otherwise

damage the vehicle electronics.

X Switch off all electrical consumers.

Disconnecting the starter battery

The starter battery is located in the battery

case in the driver's footwell. Removing/installing the floor covering in

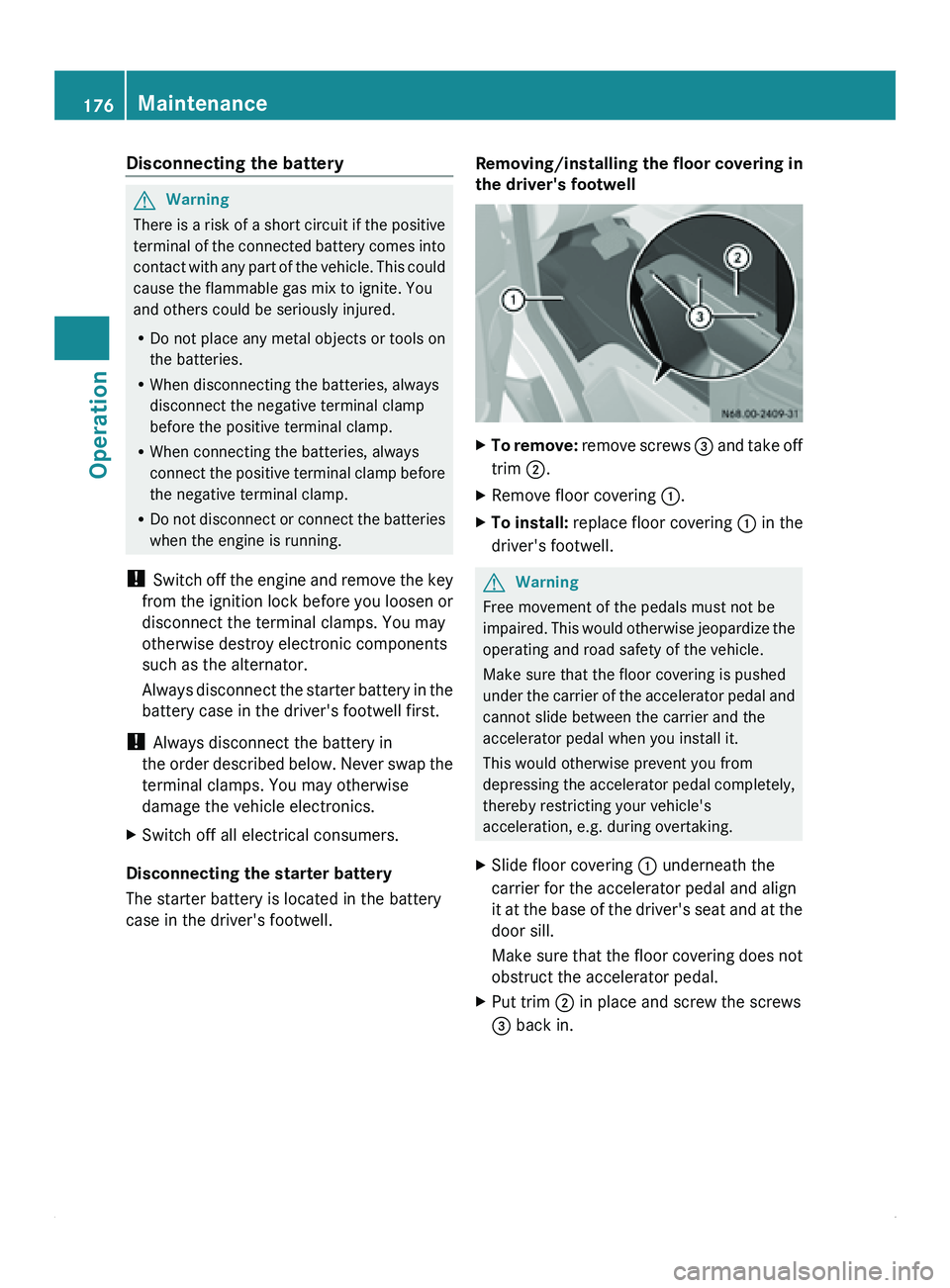

the driver's footwell X

To remove: remove screws 008A

and take off

trim 0047.

X Remove floor covering 0046.

X To install: replace floor covering

0046 in the

driver's footwell. G

Warning

Free movement of the pedals must not be

impaired. This would

otherwise jeopardize the

operating and road safety of the vehicle.

Make sure that the floor covering is pushed

under the carrier of the accelerator pedal and

cannot slide between the carrier and the

accelerator pedal when you install it.

This would otherwise prevent you from

depressing the accelerator pedal completely,

thereby restricting your vehicle's

acceleration, e.g. during overtaking.

X Slide floor covering 0046 underneath the

carrier for the accelerator pedal and align

it at the

base of the driver's seat and at the

door sill.

Make sure that the floor covering does not

obstruct the accelerator pedal.

X Put trim 0047 in place and screw the screws

008A back in.176

Maintenance

Operation