headlamp MERCEDES-BENZ SPRINTER 2012 MY12 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2012Pages: 292, PDF Size: 6.75 MB

Page 166 of 292

The windshield wipers may otherwise move

and injure you.

X Turn the key to position 0 in the ignition

lock or remove it.

! Do not fold the windshield wipers away

from the windshield unless the hood is

closed. Otherwise, you could damage the

hood.

X Fold the wiper arms away from the

windshield until you feel them engage.

X Clean the windshield and the wiper blades.

X Fold the windshield wipers back again

before switching on the ignition.

Headlamps Wipe the headlamp lenses with a wet sponge.

! Only use washer

fluid which is suitable for

plastic lamp lenses. Unsuitable washer

fluid could damage the plastic lamp lenses

of the headlamps.

Therefore, do not use:

R dry cloths

R abrasive products

R solvents

R cleaning products containing solvents

You could otherwise scratch or damage the

surface of the lenses.

Sliding door Clean the contact plates and the tips of the

contact pins around the sliding door with

water, shampoo and a soft cloth.

Do not oil or grease the contact plates and

contact pins.

Remove foreign objects. Power washers

! Maintain the following minimum

distances between the high-pressure

nozzle and the object being cleaned:

R approximately 2.2 ft (70 cm)

when using

round-jet nozzles

R approximately 1 ft (30 cm) when using

25° flat-spray jets and concentrated-

power jets

Keep the water jet moving while cleaning.

To avoid causing damage, do not point the

water jet directly at:

R door joints

R brake hoses

R electrical components

R plug connections

R seals

R the drive train, especially not at the

intermediate bearing of the propeller

shaft

R the rear-view camera or the microphone

opening on the bottom of the rear-view

camera. Keep a minimum distance of

1.6 ft (50 cm). G

Warning

Do not

use round-jet nozzles to clean the tires.

The pulsating water jet can cause damage to

the substructure of

the tires that is not visible

from the outside. This type of damage only

becomes noticeable at a much later stage and

can cause the tires to burst. This could cause

you to lose control of the vehicle, resulting in

an accident and injuring yourself or others.

Replace damaged tires immediately. Automatic car wash

If the vehicle is very dirty, prewash it before

you put it through an automatic car wash. G

Warning

If a wax preservative is applied after the

vehicle is washed,

you should remove the wax164

Cleaning and care

Operation

Page 173 of 292

Have the system checked immediately at a

qualified specialist workshop, e.g. at an

authorized Sprinter Dealer.

i There is usually a notice in the engine

compartment to remind

you when the next

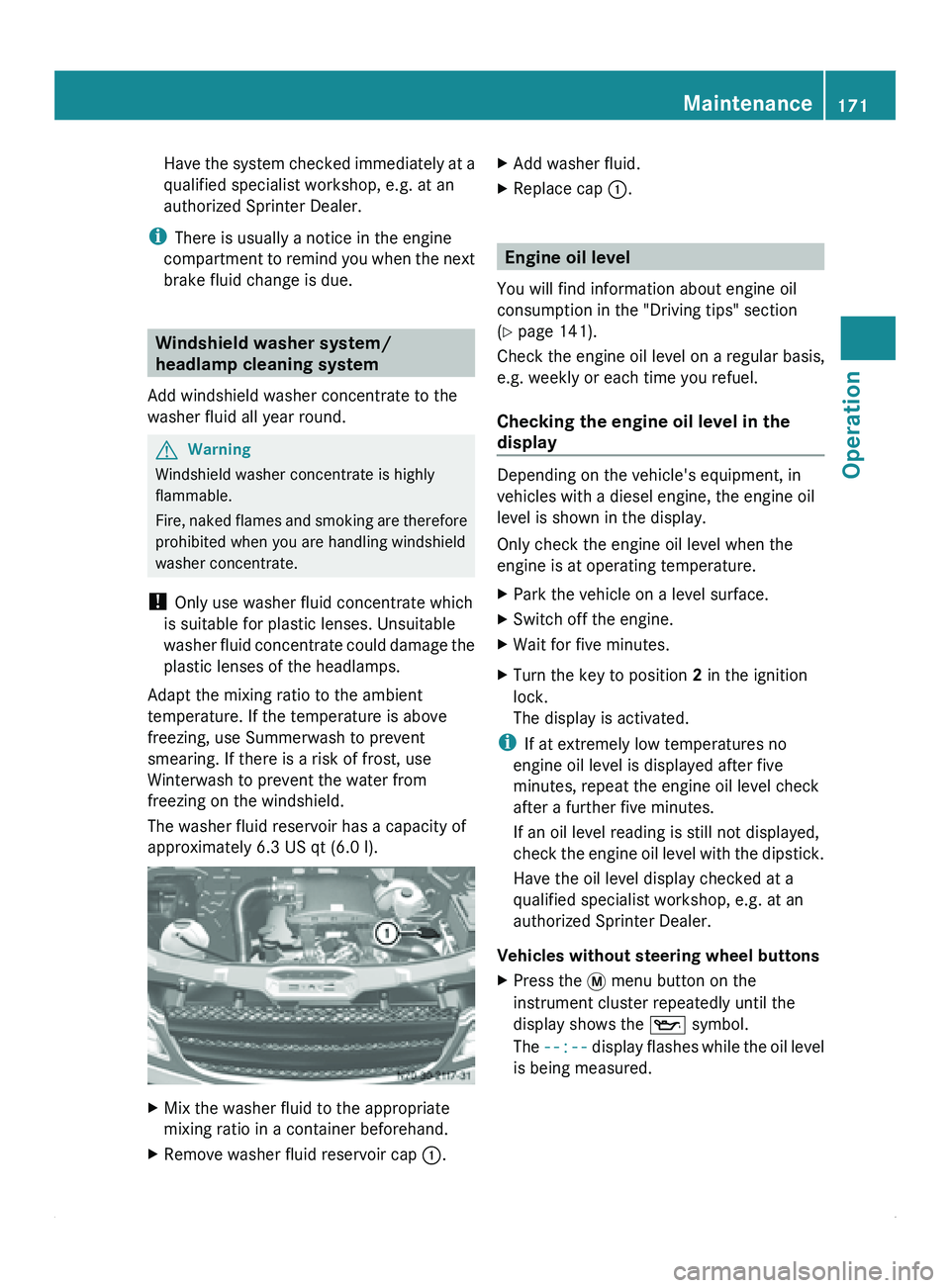

brake fluid change is due. Windshield washer system/

headlamp cleaning system

Add windshield washer concentrate to the

washer fluid all year round. G

Warning

Windshield washer concentrate is highly

flammable.

Fire, naked flames

and smoking are therefore

prohibited when you are handling windshield

washer concentrate.

! Only use washer fluid concentrate which

is suitable for plastic lenses. Unsuitable

washer fluid concentrate could damage the

plastic lenses of the headlamps.

Adapt the mixing ratio to the ambient

temperature. If the temperature is above

freezing, use Summerwash to prevent

smearing. If there is a risk of frost, use

Winterwash to prevent the water from

freezing on the windshield.

The washer fluid reservoir has a capacity of

approximately 6.3 US qt (6.0 l). X

Mix the washer fluid to the appropriate

mixing ratio in a container beforehand.

X Remove washer fluid reservoir cap 0046.X

Add washer fluid.

X Replace cap 0046. Engine oil level

You will find information about engine oil

consumption in the "Driving tips" section

(Y page 141).

Check the engine oil level on a regular basis,

e.g. weekly or each time you refuel.

Checking the engine oil level in the

display Depending on the vehicle's equipment, in

vehicles with a diesel engine, the engine oil

level is shown in the display.

Only check the engine oil level when the

engine is at operating temperature.

X

Park the vehicle on a level surface.

X Switch off the engine.

X Wait for five minutes.

X Turn the key to position 2 in the ignition

lock.

The display is activated.

i If at extremely low temperatures no

engine oil level is displayed after five

minutes, repeat the engine oil level check

after a further five minutes.

If an oil level reading is still not displayed,

check the engine

oil level with the dipstick.

Have the oil level display checked at a

qualified specialist workshop, e.g. at an

authorized Sprinter Dealer.

Vehicles without steering wheel buttons

X Press the 007B menu button on the

instrument cluster repeatedly until the

display shows the 00B1 symbol.

The --:-- display flashes

while the oil level

is being measured. Maintenance

171

Operation Z

Page 198 of 292

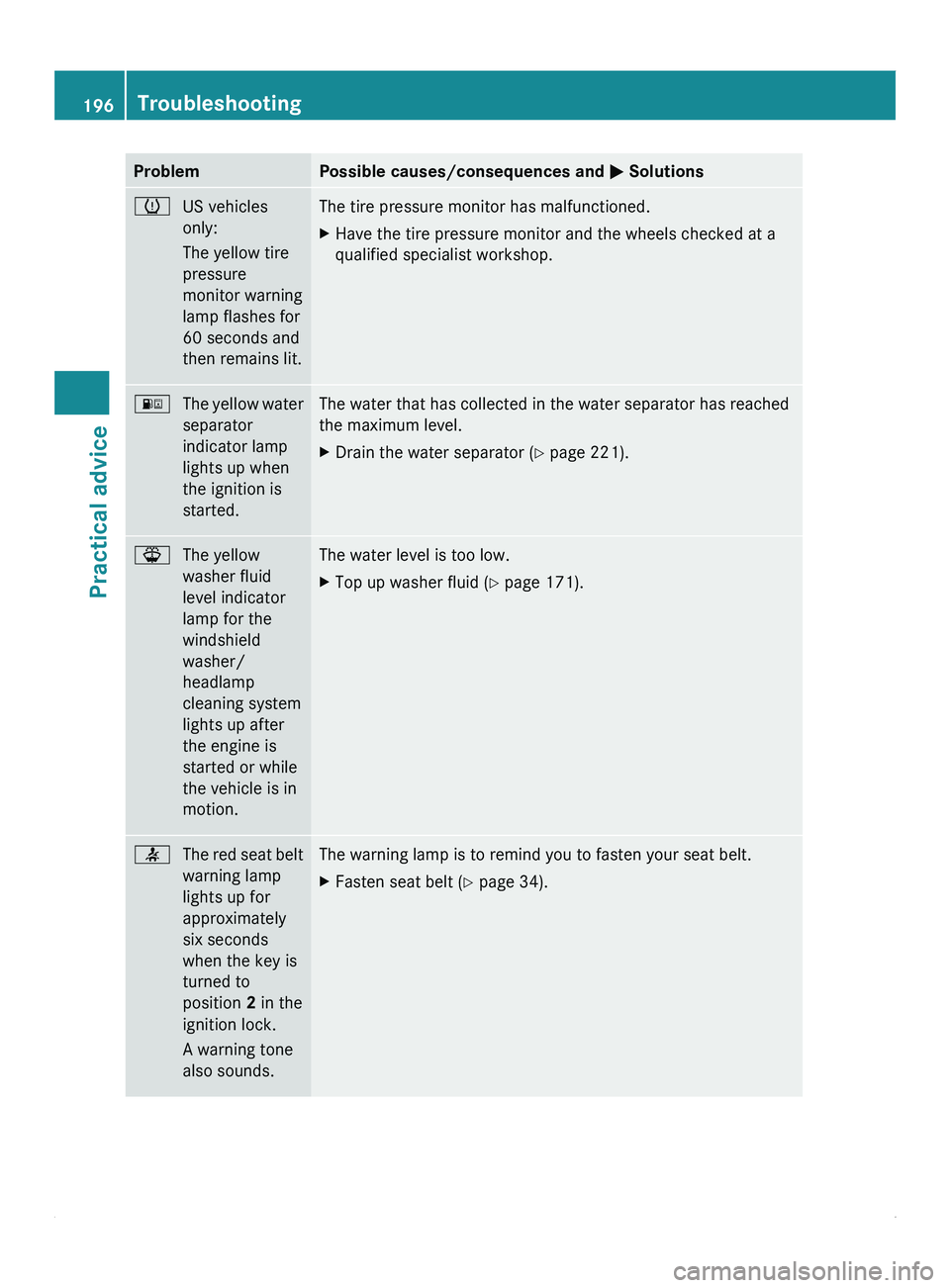

Problem Possible causes/consequences and

0050 Solutions0077

US vehicles

only:

The yellow tire

pressure

monitor warning

lamp flashes for

60 seconds and

then remains lit. The tire pressure monitor has malfunctioned.

X

Have the tire pressure monitor and the wheels checked at a

qualified specialist workshop. 00BA

The yellow water

separator

indicator lamp

lights up when

the ignition is

started. The water that has collected in the water separator has reached

the maximum level.

X

Drain the water separator ( Y page 221).00BD

The yellow

washer fluid

level indicator

lamp for the

windshield

washer/

headlamp

cleaning system

lights up after

the engine is

started or while

the vehicle is in

motion. The water level is too low.

X

Top up washer fluid ( Y page 171).0082

The red seat belt

warning lamp

lights up for

approximately

six seconds

when the key is

turned to

position 2 in the

ignition lock.

A warning tone

also sounds. The warning lamp is to remind you to fasten your seat belt.

X

Fasten seat belt (Y page 34).196

TroubleshootingPractical advice

Page 211 of 292

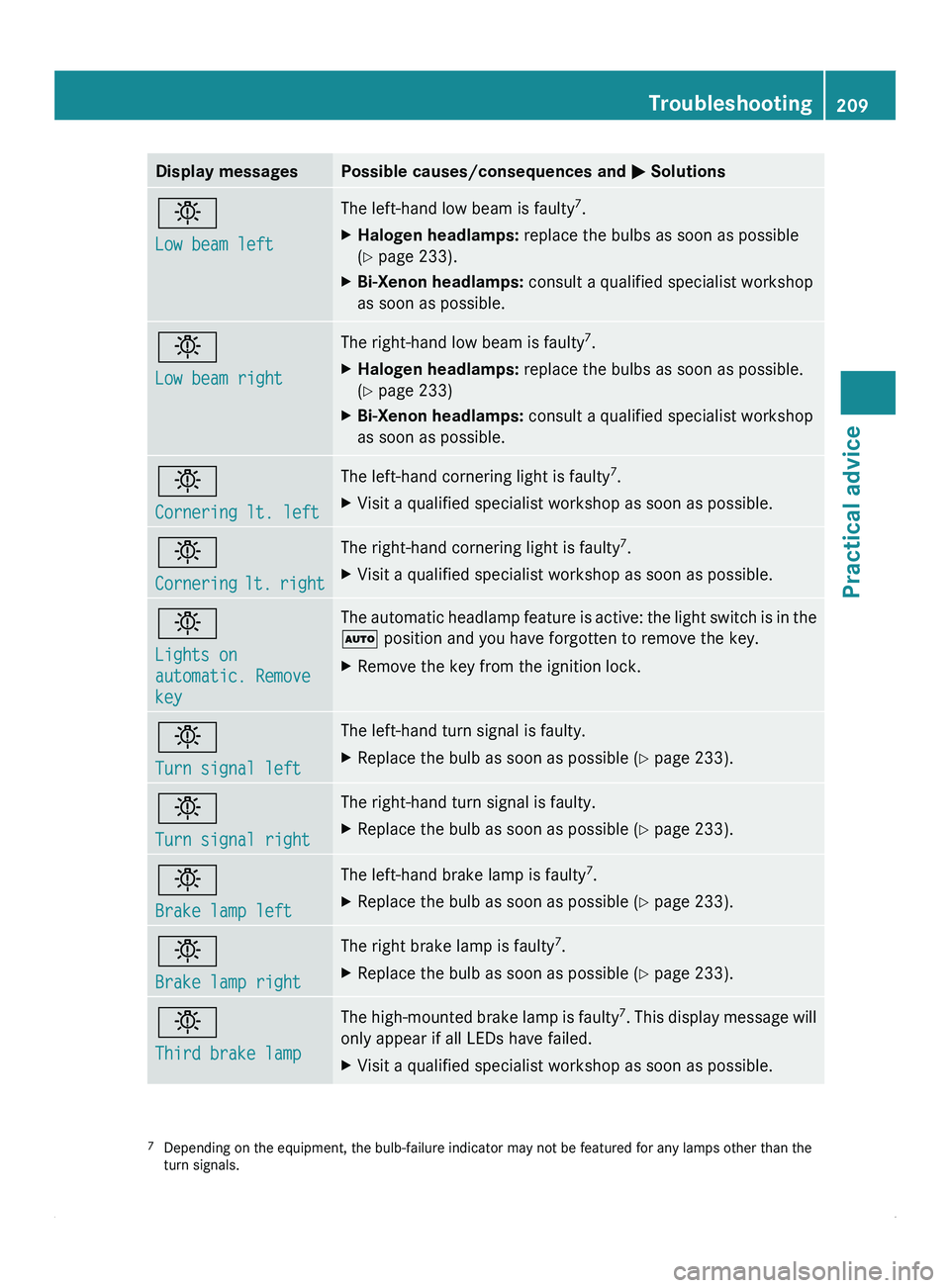

Display messages Possible causes/consequences and

0050 Solutions0055

Low beam left The left-hand low beam is faulty

7

.

X Halogen headlamps: replace the bulbs as soon as possible

(Y page 233).

X Bi-Xenon headlamps: consult a qualified specialist workshop

as soon as possible. 0055

Low beam right The right-hand low beam is faulty

7

.

X Halogen headlamps: replace the bulbs as soon as possible.

(Y page 233)

X Bi-Xenon headlamps: consult a qualified specialist workshop

as soon as possible. 0055

Cornering lt. left The left-hand cornering light is faulty

7

.

X Visit a qualified specialist workshop as soon as possible. 0055

Cornering lt.

right The right-hand cornering light is faulty

7

.

X Visit a qualified specialist workshop as soon as possible. 0055

Lights on

automatic. Remove

key The automatic headlamp feature is active: the light switch is in the

005A position and you have forgotten to remove the key.

X

Remove the key from the ignition lock. 0055

Turn signal left The left-hand turn signal is faulty.

X

Replace the bulb as soon as possible (Y page 233). 0055

Turn signal right The right-hand turn signal is faulty.

X

Replace the bulb as soon as possible (Y page 233). 0055

Brake lamp left The left-hand brake lamp is faulty

7

.

X Replace the bulb as soon as possible (Y page 233). 0055

Brake lamp right The right brake lamp is faulty

7

.

X Replace the bulb as soon as possible (Y page 233). 0055

Third brake lamp The high-mounted brake lamp is faulty

7

. This display message will

only appear if all LEDs have failed.

X Visit a qualified specialist workshop as soon as possible. 7

Depending on the equipment, the bulb-failure indicator may not be featured for any lamps other than the

turn signals. Troubleshooting

209

Practical advice Z

Page 221 of 292

Problem Possible causes/consequences and

0050 SolutionsThe key cannot be

turned in the ignition

lock. The vehicle voltage is too low.

X

Switch off all non-essential consumers, e.g. the seat heating,

interior lighting, and try to turn the key again.

If this does not work:

X Check and, if necessary, replace the starter battery.

or

X Jump-start the vehicle.

or

X Consult a qualified specialist workshop. The key cannot be

turned in the ignition

lock. The steering lock has jammed mechanically.

X

Remove the key and insert it again into the ignition lock. Turn

the steering wheel from side to side while doing so. Headlamps and turn signals

G

Warning

The operating safety of your vehicle could be jeopardized if maintenance work is carried out

incorrectly. As a

result, you could lose control of the vehicle and cause an accident. In addition,

the safety systems may no longer be able to protect you or others as they are designed to do.

Always have maintenance work carried out at a qualified specialist workshop. The qualified

specialist workshop must have the necessary specialist knowledge and tools to carry out the

work required. We recommend visiting an authorized Sprinter Dealer. In particular, work relevant

to safety or on safety-related systems must be carried out at a qualified specialist workshop. Problem Possible causes/consequences and

0050 SolutionsThe headlamps are

fogged up

on

the inside. Air humidity is very high.

X

Drive with the headlamps switched on.

The headlamps are clear after a short distance. The headlamps are

fogged up

on

the inside. The headlamp housing is not sealed and moisture has been able

to enter.

X

Have the headlamps checked at a qualified specialist workshop. Windshield wipers

G

Warning

The operating safety of your vehicle could be jeopardized if maintenance work is carried out

incorrectly. As a

result, you could lose control of the vehicle and cause an accident. In addition,

the safety systems may no longer be able to protect you or others as they are designed to do. Troubleshooting

219

Practical advice

Z

Page 236 of 292

Do not change Xenon bulbs yourself, but have

them replaced at a qualified specialist

workshop which has

the necessary specialist

knowledge and tools to carry out the work

required.

We recommend an authorized Sprinter Dealer

for this purpose. In particular, work relevant

to safety or on safety-related systems must

be carried out at a qualified specialist

workshop.

R To prevent short circuits, switch off the

lighting system before changing a bulb.

R Only touch new bulbs with a clean, lint-free

cloth or similar. Do not work with wet or

greasy fingers.

R Only install 12 V bulbs of the same type and

of the correct wattage.

R Have the headlamp setting checked

regularly.

R If the new bulb still does not light up consult

a qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

R Have the following LEDs and bulbs replaced

at a qualified specialist workshop, e.g. an

authorized Sprinter Dealer:

-the additional turn signals in the exterior

mirrors

- the high-mounted brake lamp

- the Bi-Xenon bulbs

- the fog lamps

! Make sure the bulbs are always securely

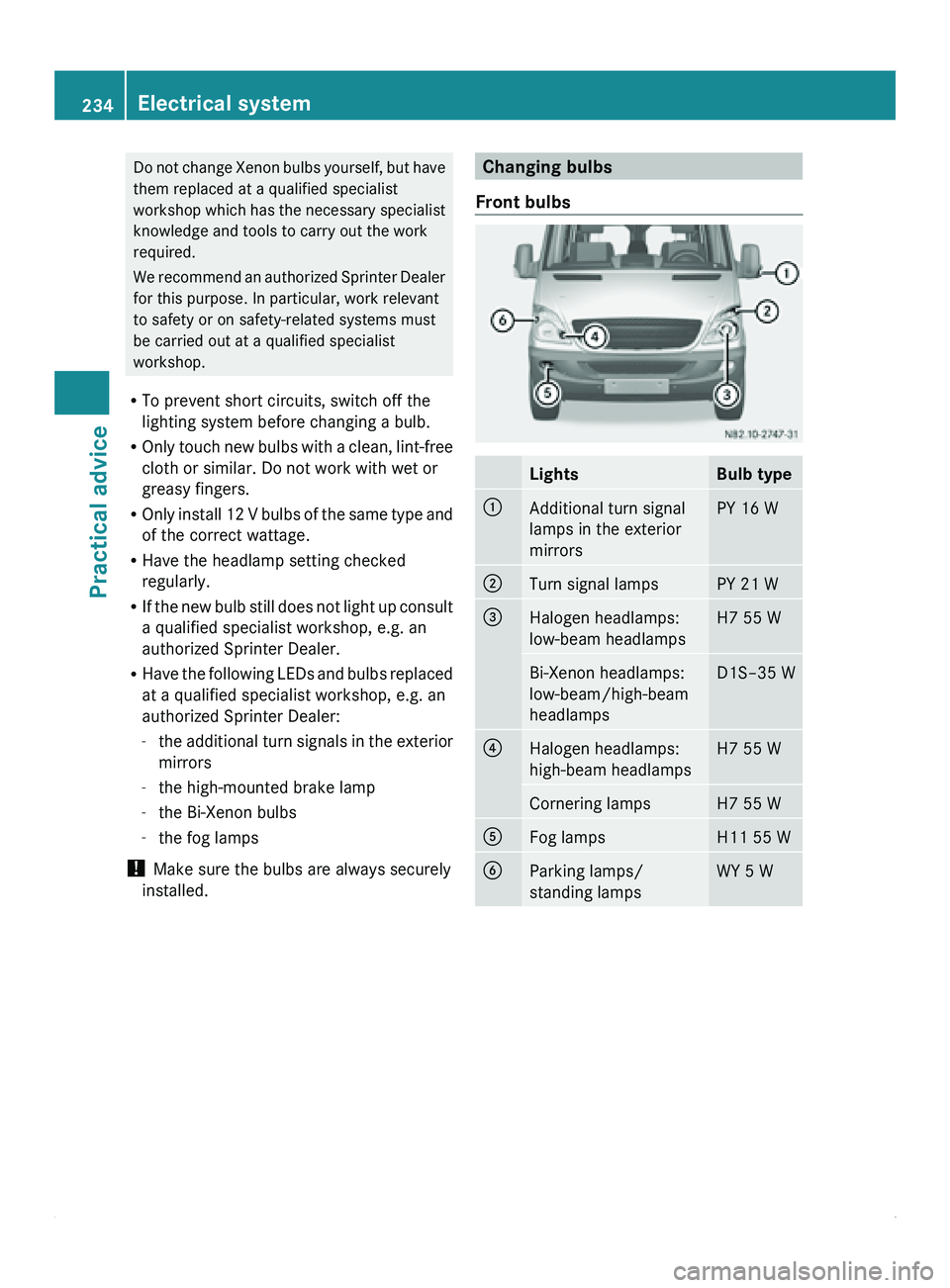

installed. Changing bulbs

Front bulbs Lights Bulb type

0046

Additional turn signal

lamps in the exterior

mirrors PY 16 W

0047

Turn signal lamps PY 21 W

008A

Halogen headlamps:

low-beam headlamps H7 55 W

Bi-Xenon headlamps:

low-beam/high-beam

headlamps D1S–35 W

0088

Halogen headlamps:

high-beam headlamps H7 55 W

Cornering lamps H7 55 W

0086

Fog lamps H11 55 W

0087

Parking lamps/

standing lamps WY 5 W234

Electrical system

Practical advice

Page 237 of 292

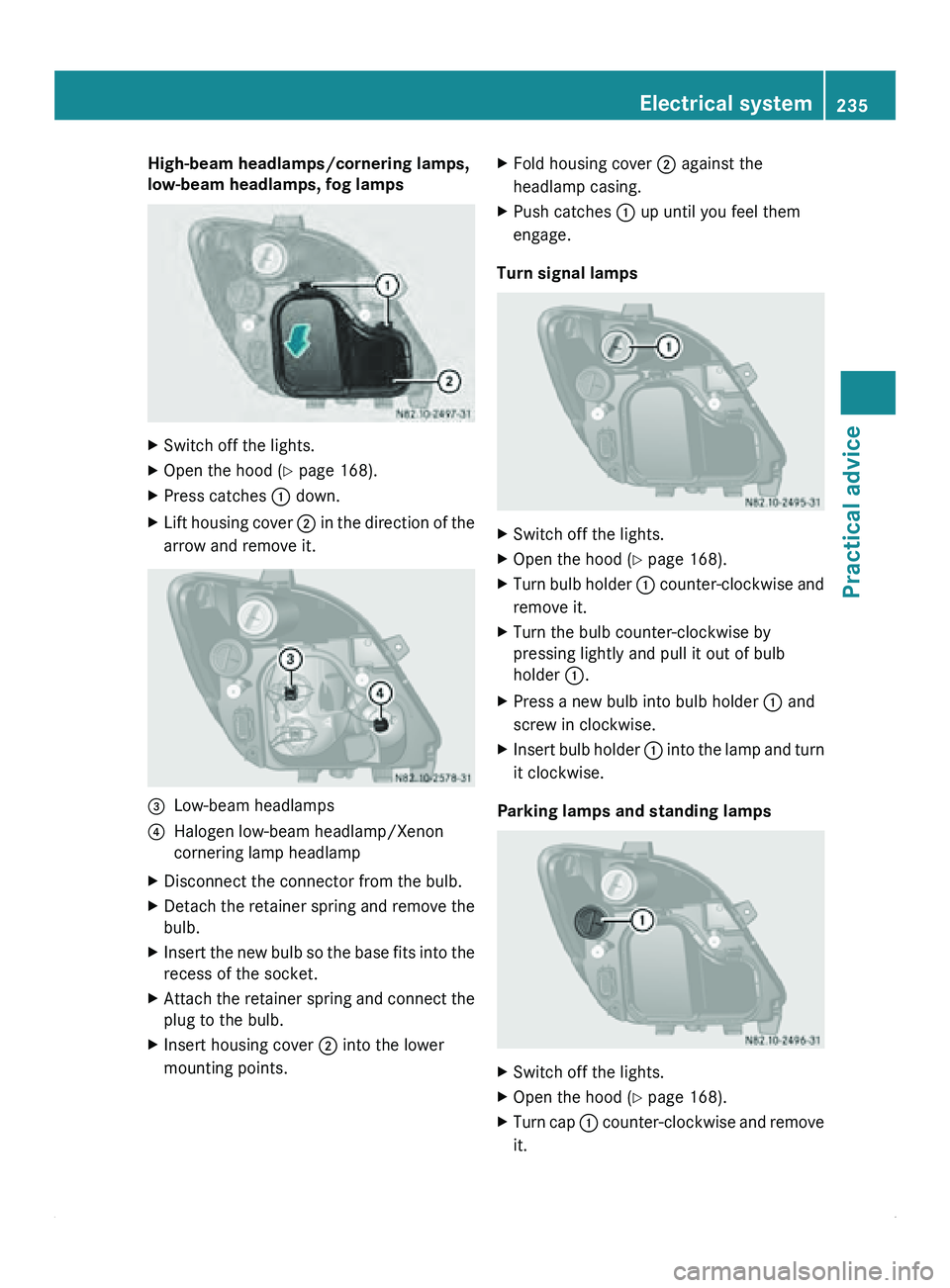

High-beam headlamps/cornering lamps,

low-beam headlamps, fog lamps

X

Switch off the lights.

X Open the hood (Y page 168).

X Press catches 0046 down.

X Lift housing cover 0047 in the direction of the

arrow and remove it. 008A

Low-beam headlamps

0088 Halogen low-beam headlamp/Xenon

cornering lamp headlamp

X Disconnect the connector from the bulb.

X Detach the retainer spring and remove the

bulb.

X Insert the new bulb so the base fits into the

recess of the socket.

X Attach the retainer spring and connect the

plug to the bulb.

X Insert housing cover 0047 into the lower

mounting points. X

Fold housing cover 0047 against the

headlamp casing.

X Push catches 0046 up until you feel them

engage.

Turn signal lamps X

Switch off the lights.

X Open the hood (Y page 168).

X Turn bulb holder 0046 counter-clockwise and

remove it.

X Turn the bulb counter-clockwise by

pressing lightly and pull it out of bulb

holder 0046

.

X Press a new bulb into bulb holder 0046 and

screw in clockwise.

X Insert bulb holder 0046 into the

lamp and turn

it clockwise.

Parking lamps and standing lamps X

Switch off the lights.

X Open the hood (Y page 168).

X Turn cap 0046 counter-clockwise and remove

it. Electrical system

235

Practical advice Z

Page 244 of 292

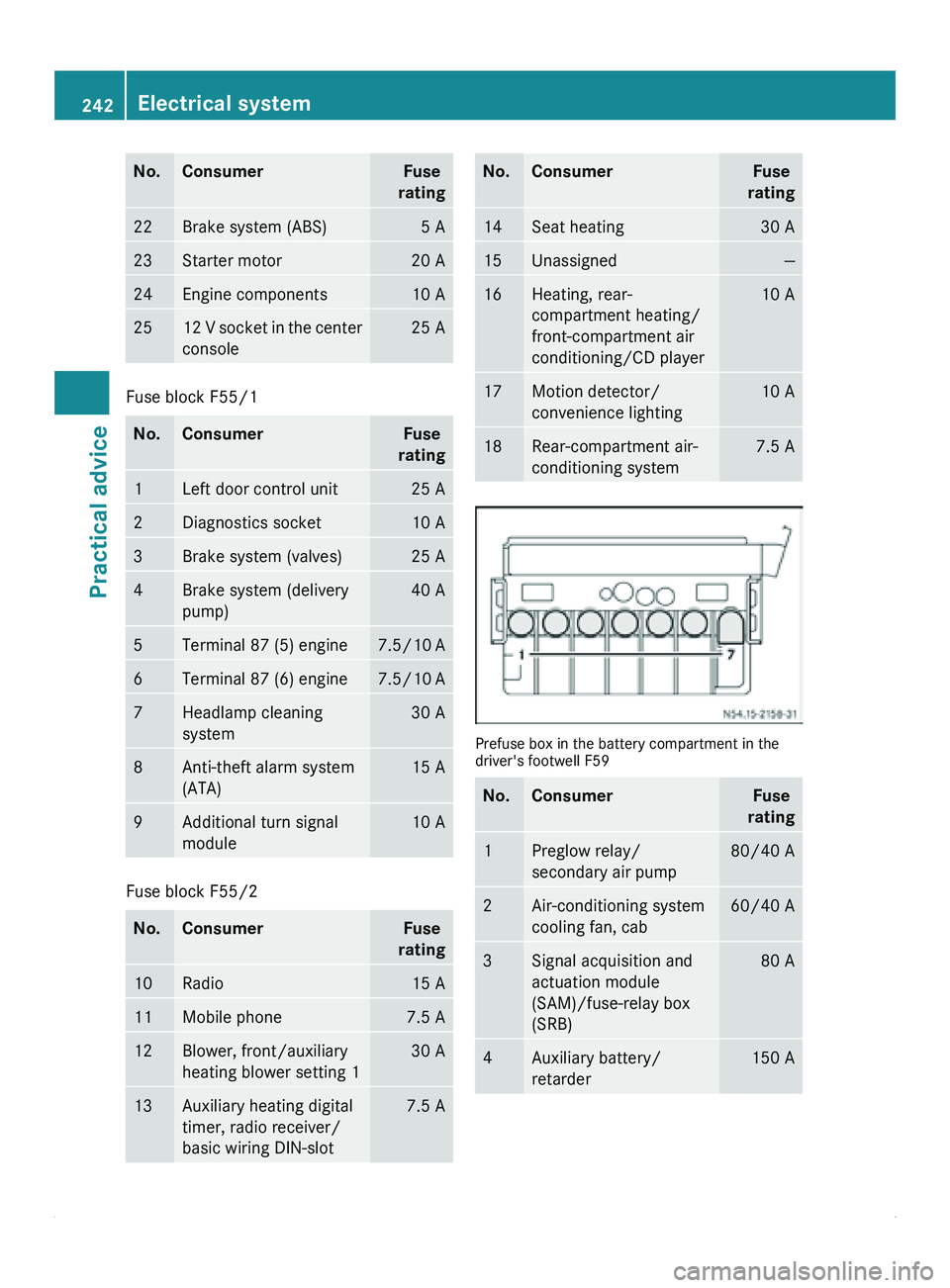

No. Consumer Fuse

rating 22 Brake system (ABS) 5 A

23 Starter motor 20 A

24 Engine components 10 A

25 12 V socket in the center

console 25 A

Fuse block F55/1

No. Consumer Fuse

rating 1 Left door control unit 25 A

2 Diagnostics socket 10 A

3 Brake system (valves) 25 A

4 Brake system (delivery

pump) 40 A

5 Terminal 87 (5) engine 7.5/10 A

6 Terminal 87 (6) engine 7.5/10 A

7 Headlamp cleaning

system 30 A

8 Anti-theft alarm system

(ATA) 15 A

9 Additional turn signal

module 10 A

Fuse block F55/2

No. Consumer Fuse

rating 10 Radio 15 A

11 Mobile phone 7.5 A

12 Blower, front/auxiliary

heating blower setting 1 30 A

13 Auxiliary heating digital

timer, radio receiver/

basic wiring DIN-

slot 7.5 A No. Consumer Fuse

rating 14 Seat heating 30 A

15 Unassigned —

16 Heating, rear-

compartment heating/

front-compartment air

conditioning/CD player 10 A

17 Motion detector/

convenience lighting 10 A

18 Rear-compartment air-

conditioning system 7.5 A

Prefuse box in the battery compartment in the

driver's footwell F59

No. Consumer Fuse

rating 1 Preglow relay/

secondary air pump 80/40 A

2 Air-conditioning system

cooling fan, cab 60/40 A

3 Signal acquisition and

actuation module

(SAM)/fuse-relay box

(SRB) 80 A

4 Auxiliary battery/

retarder 150 A242

Electrical systemPractical advice

Page 289 of 292

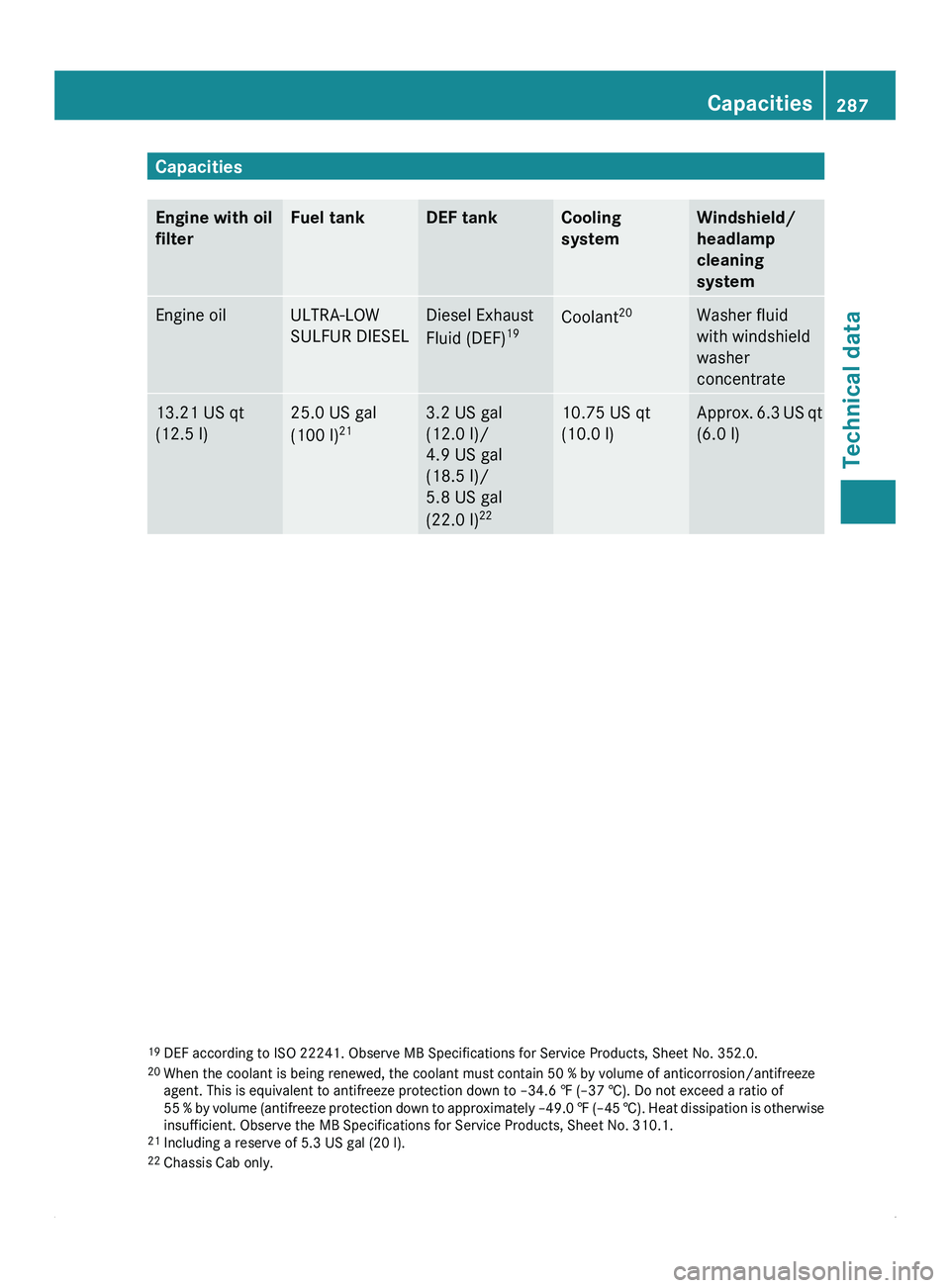

Capacities

Engine with oil

filter Fuel tank DEF tank Cooling

system Windshield/

headlamp

cleaning

system

Engine oil ULTRA-LOW

SULFUR DIESEL Diesel Exhaust

Fluid (DEF)

19 Coolant

20 Washer fluid

with windshield

washer

concentrate

13.21 US qt

(12.5 l) 25.0 US gal

(100 l)

21 3.2 US gal

(12.0 l)/

4.9 US gal

(18.5 l)/

5.8 US gal

(22.0 l)

22 10.75 US qt

(10.0 l) Approx. 6.3 US qt

(6.0 l) 19

DEF according to ISO 22241 . Observe MB Specifications for Service Products,

Sheet No. 352.0.

20 When the coolant is being renewed, the coolant must contain 50 % by volume of anticorrosion/antifreeze

agent. This is equivalent to antifreeze protection down to –34.6 ‡ (–37 †). Do not exceed a ratio of

55 % by volume (antifreeze protection down to approximately –49.0 ‡ (–45 †). Heat dissipation is otherwise

insufficient. Observe the MB Specifications for Service Products, Sheet No. 310.1.

21 Including a reserve of 5.3 US gal (20 l).

22 Chassis Cab only. Capacities

287

Technical data Z