light MERCEDES-BENZ SPRINTER 2015 MY15 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2015Pages: 334, PDF Size: 5.94 MB

Page 302 of 334

0087

Maximum tire pressure (Y page 290)

0085 Manufacturer

0083 Tire material (Y page 302)

0084 Tire size designation, load-bearing capa-

city and speed index (Y page 300)

006B Tire name

The markings described above are on the tire in addition to the tire name (sales designa-

tion) and the manufacturer's name.

i Tire data is vehicle-specific and may devi-

ate from the data in the example.

Tire size designation, load bearing index and speed index G

WARNING

Exceeding the stated tire load-bearing capa-

city and the approved maximum speed could

lead to tire damage or the tire bursting. There is a risk of accident.

Therefore, only use tire types and sizes

approved for your vehicle model. Observe the

tire load rating and speed rating required for

your vehicle. 0043

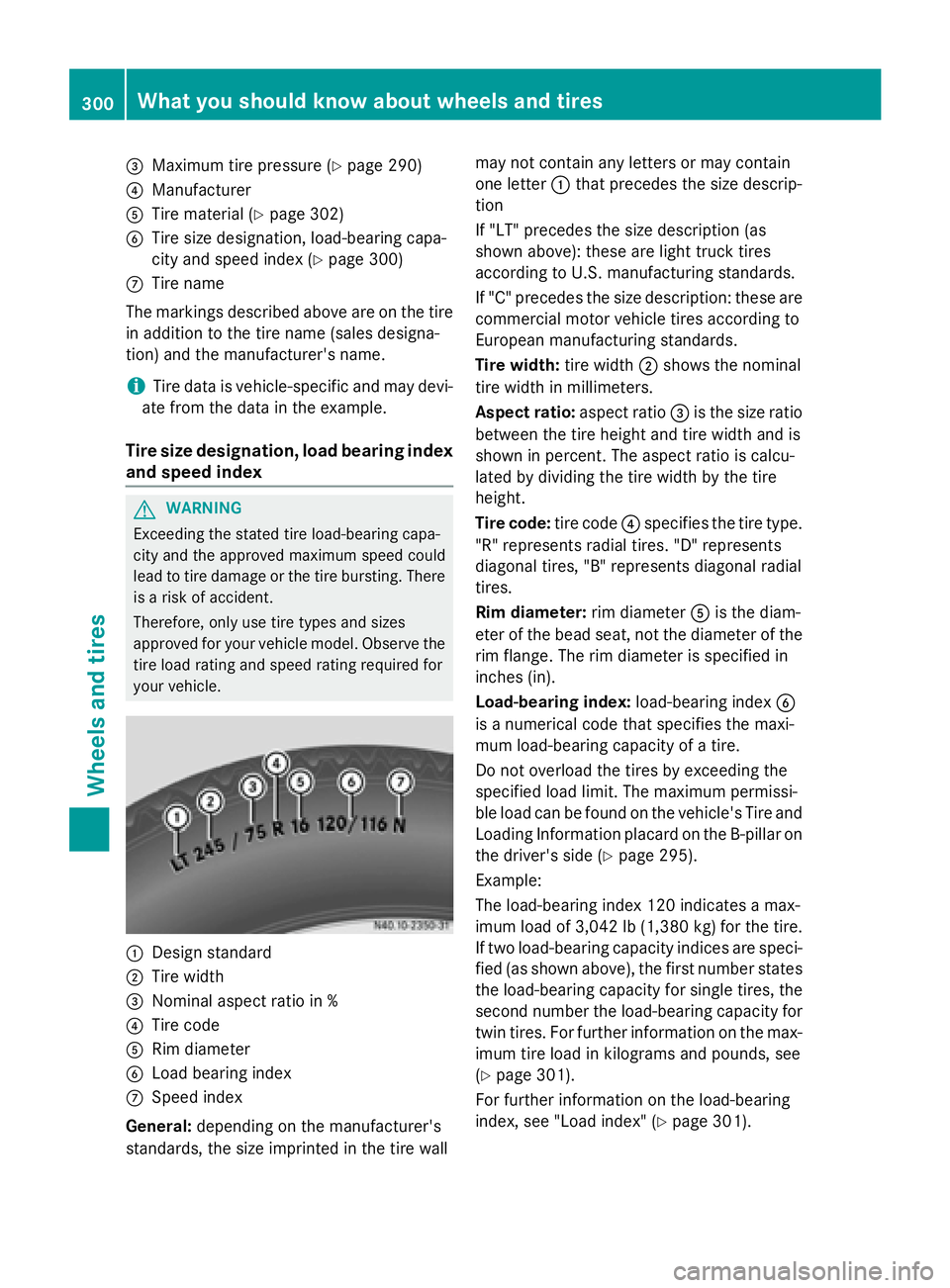

Design standard

0044 Tire width

0087 Nominal aspect ratio in %

0085 Tire code

0083 Rim diameter

0084 Load bearing index

006B Speed index

General: depending on the manufacturer's

standards, the size imprinted in the tire wall may not contain any letters or may contain

one letter

0043that precedes the size descrip-

tion

If "LT" precedes the size description (as

shown above): these are light truck tires

according to U.S. manufacturing standards.

If "C" precedes the size description: these are

commercial motor vehicle tires according to

European manufacturing standards.

Tire width: tire width0044shows the nominal

tire width in millimeters.

Aspect ratio: aspect ratio0087is the size ratio

between the tire height and tire width and is

shown in percent. The aspect ratio is calcu-

lated by dividing the tire width by the tire

height.

Tire code: tire code0085specifies the tire type.

"R" represents radial tires. "D" represents

diagonal tires, "B" represents diagonal radial

tires.

Rim diameter: rim diameter0083is the diam-

eter of the bead seat, not the diameter of the rim flange. The rim diameter is specified in

inches (in).

Load-bearing index: load-bearing index0084

is a numerical code that specifies the maxi-

mum load-bearing capacity of a tire.

Do not overload the tires by exceeding the

specified load limit. The maximum permissi-

ble load can be found on the vehicle's Tire and

Loading Information placard on the B-pillar on the driver's side (Y page 295).

Example:

The load-bearing index 120 indicates a max-

imum load of 3,042 lb (1,380 kg) for the tire.

If two load-bearing capacity indices are speci- fied (as shown above), the first number states

the load-bearing capacity for single tires, the second number the load-bearing capacity for

twin tires. For further information on the max- imum tire load in kilograms and pounds, see

(Y page 301).

For further information on the load-bearing

index, see "Load index" (Y page 301).300

What you should know about wheels and tiresWheels and tires

Page 303 of 334

Speed rating:

speed rating006Bspecifies the

approved maximum speed of the tire.

Regardless of the speed index always observe the speed limits. Drive carefully and adapt

your driving style to the traffic conditions.

i Tire data is vehicle-specific and may devi-

ate from the data in the example. Index Speed rating

F up to 50 mph (80 km/h)

G up to 56 mph (90 km/h)

J up to 62 mph (100 km/h)

K up to 68 mph (110 km/h)

L up to 74 mph (120 km/h)

M up to 80 mph (130 km/h)

N up to 87 mph (140 km/h)

P up to 93 mph (150 km/h)

Q up to 100 mph (160 km/h)

R over 106 mph (170 km/h)

i

Not all tires that have the M+S identifica-

tion offer the driving characteristics of win-

ter tires. In addition to the M+S marking,

winter tires also have the 004Dsnowflake

symbol on the tire wall. Tires with this mark- ing fulfill the requirements of the Rubber

Manufacturers Association (RMA) and the

Rubber Association of Canada (RAC)

regarding the tire traction on snow. They

have been especially developed for driving

on snow.

Further information on the reading of tire

information can be obtained at any qualified

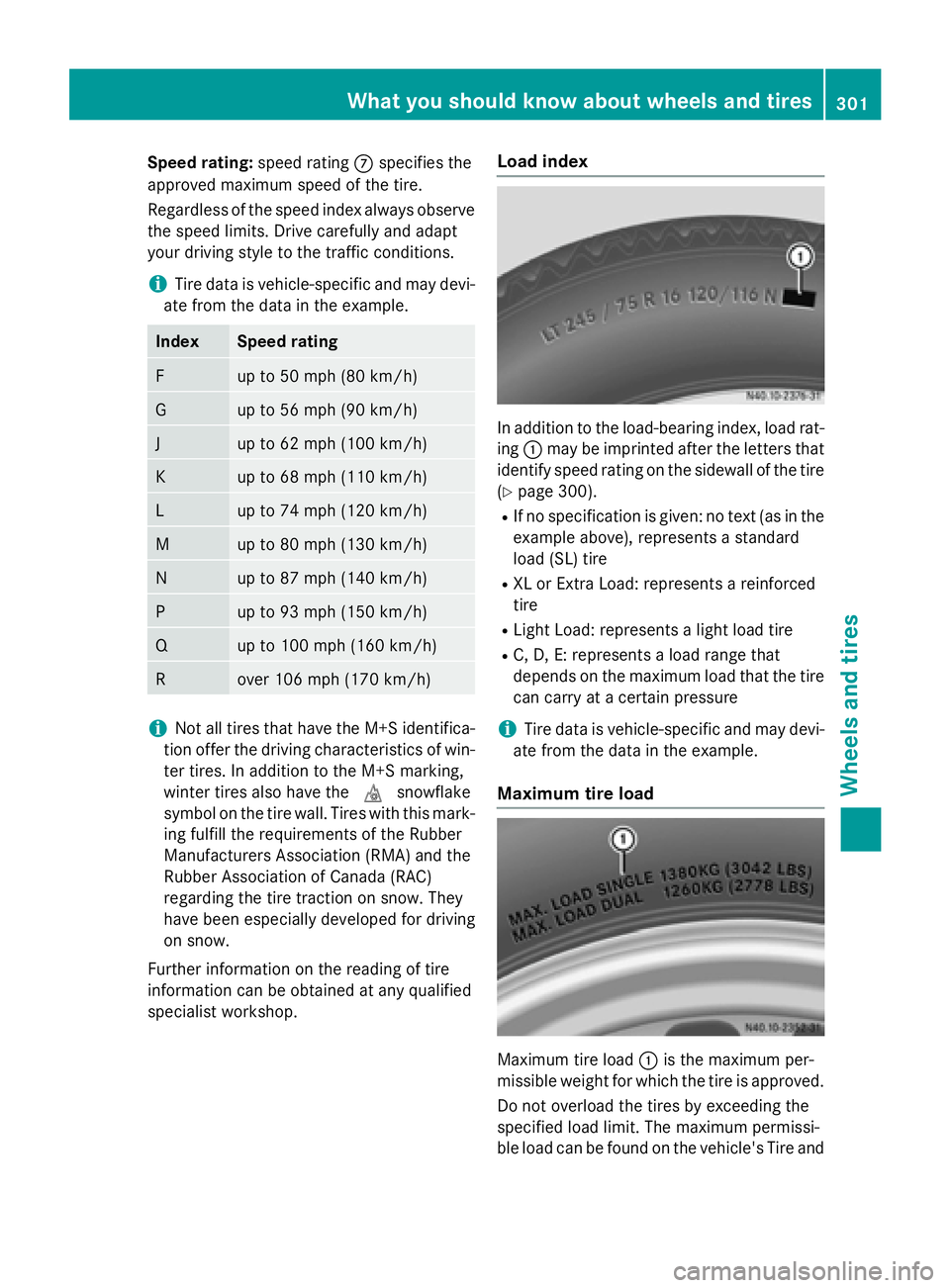

specialist workshop. Load index In addition to the load-bearing index, load rat-

ing 0043may be imprinted after the letters that

identify speed rating on the sidewall of the tire (Y page 300).

R If no specification is given: no text (as in the

example above), represents a standard

load (SL) tire

R XL or Extra Load: represents a reinforced

tire

R Light Load: represents a light load tire

R C, D, E: represents a load range that

depends on the maximum load that the tire

can carry at a certain pressure

i Tire data is vehicle-specific and may devi-

ate from the data in the example.

Maximum tire load Maximum tire load

0043is the maximum per-

missible weight for which the tire is approved.

Do not overload the tires by exceeding the

specified load limit. The maximum permissi-

ble load can be found on the vehicle's Tire and What you should know about wheels and tires

301Wheels and tires Z

Page 306 of 334

is bar. 100 kilopascals (kPa) are the equiva-

lent of 1 bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of

the tire more precisely.

Curb weight

The weight of a vehicle with standard equip-

ment including the maximum filling capacity

of fuel, oil, and coolant. It also includes the

air-conditioning system and optional equip-

ment if these are installed on the vehicle, but

does not include passengers or luggage.

Maximum tire load

The maximum tire load in kilograms or

pounds is the maximum weight for which a

tire is approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one

tire.

Maximum load on one tire

Maximum load on one tire. This is calculated

by dividing the maximum axle load of one axle by two.

PSI (Pounds per square inch)

Standard unit of measurement for tire pres-

sure.

Aspect ratio

Relationship between tire height and width in

percent.

tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's sur-

face. Tire pressure is specified in pounds per square inch (psi), in kilopascal (kPa) or in bar.

Tire pressure should only be corrected when

the tires are cold. Cold tire pressure

The tires are cold:

R if the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

R if the vehicle has not been driven further

than 1 mile (1.6 km)

Tire tread

The part of the tire th at comes into contact

with the road.

Tire bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel wires in the bead to prevent the tire from

coming loose from the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance

battery, are not included in the curb weight

and the weight of the accessories.

TIN (Tire Identification Number)

A unique identification number which can be

used by a tire manufacturer to identify tires,

for example for a product recall, and thus

identify the purchasers. The TIN is composed of the manufacturer identification code, tire

size, tire model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing capacity of a tire.

Traction

Traction is the result of friction between the

tires and the road surface. 304

What you should know about wheels and tiresWheels and tires

Page 308 of 334

Single tires:

if the tires are of identical

dimensions, you can rotate both wheels on

both the front and rear axles so that the tires'

original direction of rotation is maintained. On unidirectional tires, an arrow on the sidewall

shows the prescribed direction of rotation of

the tire.

Twin rear tires: if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear

axle in pairs such that the original direction of

tire rotation is retained. With unidirectional

tires, you may rotate the outside wheels at

the rear axle from one side to the other. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed limi-

tation specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool, dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Mounting a wheel

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake. X

Turn the front wheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not endan-

gered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed. Any-

one who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements.

X Secure the vehicle to prevent it from rolling

away.

i Observe the safety notes on parking in the

section on "Driving and parking"

(Y page 149).

X On level terrain: place chocks or other

suitable objects under the front and rear of the wheel that is diagonally opposite the

wheel to be changed.

X On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed.

X Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 274).

X Remove the spare wheel from the spare

wheel bracket (Y page 313). Observe the

safety notes in the "Spare wheel" section

(Y page 312).

X On wheels with wheel bolts, remove the

hub caps. 306

Changing wheelsWheels and tires

Page 312 of 334

been approved for Sprinter vehicles and the

respective wheel.

! For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using other wheel bolts to mount the steel spare wheel could damage the brake system.

! On vehicles equipped with a tire pressure

monitor, electronic components are loca-

ted in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec-

tronic components.

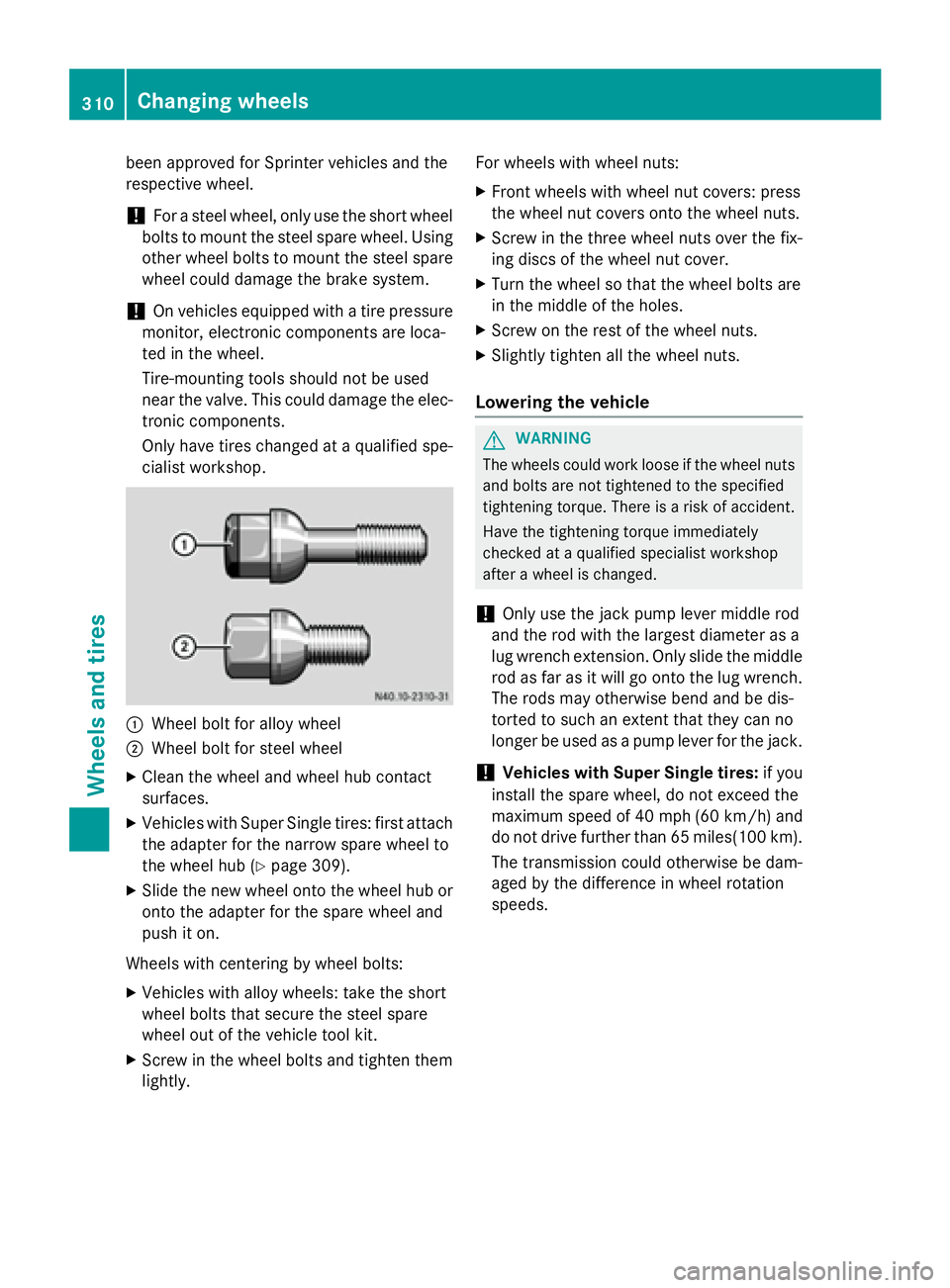

Only have tires changed at a qualified spe- cialist workshop. 0043

Wheel bolt for alloy wheel

0044 Wheel bolt for steel wheel

X Clean the wheel and wheel hub contact

surfaces.

X Vehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to

the wheel hub (Y page 309).

X Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and

push it on.

Wheels with centering by wheel bolts:

X Vehicles with alloy wheels: take the short

wheel bolts that secure the steel spare

wheel out of the vehicle tool kit.

X Screw in the wheel bolts and tighten them

lightly. For wheels with wheel nuts:

X Front wheels with wheel nut covers: press

the wheel nut covers onto the wheel nuts.

X Screw in the three wheel nuts over the fix-

ing discs of the wheel nut cover.

X Turn the wheel so that the wheel bolts are

in the middle of the holes.

X Screw on the rest of the wheel nuts.

X Slightly tighten all the wheel nuts.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle rod as far as it will go onto the lug wrench. The rods may otherwise bend and be dis-

torted to such an extent that they can no

longer be used as a pump lever for the jack.

! Vehicles with Super Single tires:

if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/ h)and

do not drive further than 65 miles(100 km ).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds. 310

Changing wheelsWheels and tires

Page 315 of 334

i

If you have mounted a spare wheel, the

tire pressure monitor (Y page 291) will not

function for this wheel. The spare wheel is

not equipped with a sensor for monitoring

tire pressure. Removing and installing the spare

wheel

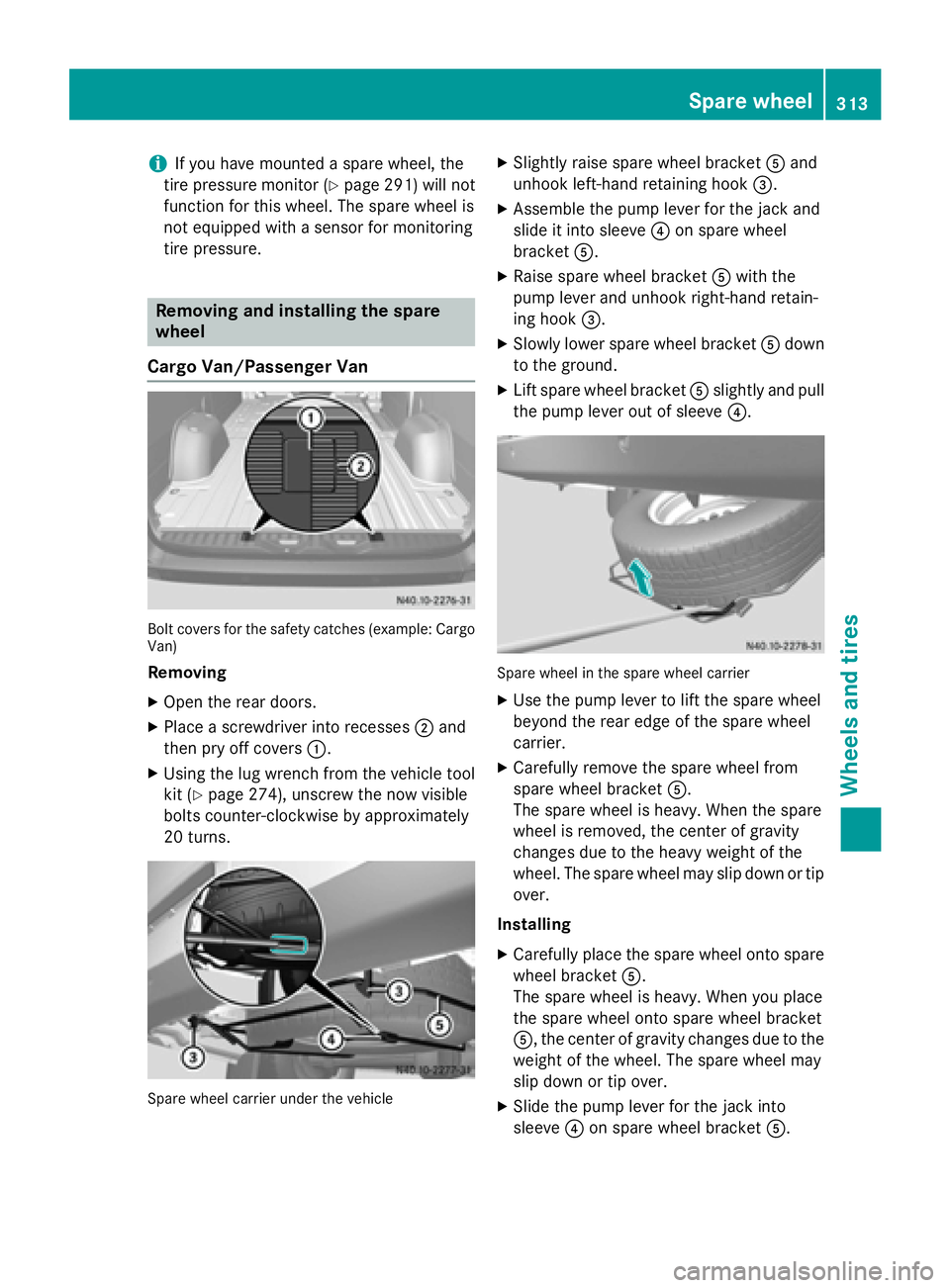

Cargo Van/Passenger Van Bolt covers for the safety catches (example: Cargo

Van)

Removing

X Open the rear doors.

X Place a screwdriver into recesses 0044and

then pry off covers 0043.

X Using the lug wrench from the vehicle tool

kit (Y page 274), unscrew the now visible

bolts counter-clockwise by approximately

20 turns. Spare wheel carrier under the vehicle X

Slightly raise spare wheel bracket 0083and

unhook left-hand retaining hook 0087.

X Assemble the pump lever for the jack and

slide it into sleeve 0085on spare wheel

bracket 0083.

X Raise spare wheel bracket 0083with the

pump lever and unhook right-hand retain-

ing hook 0087.

X Slowly lower spare wheel bracket 0083down

to the ground.

X Lift spare wheel bracket 0083slightly and pull

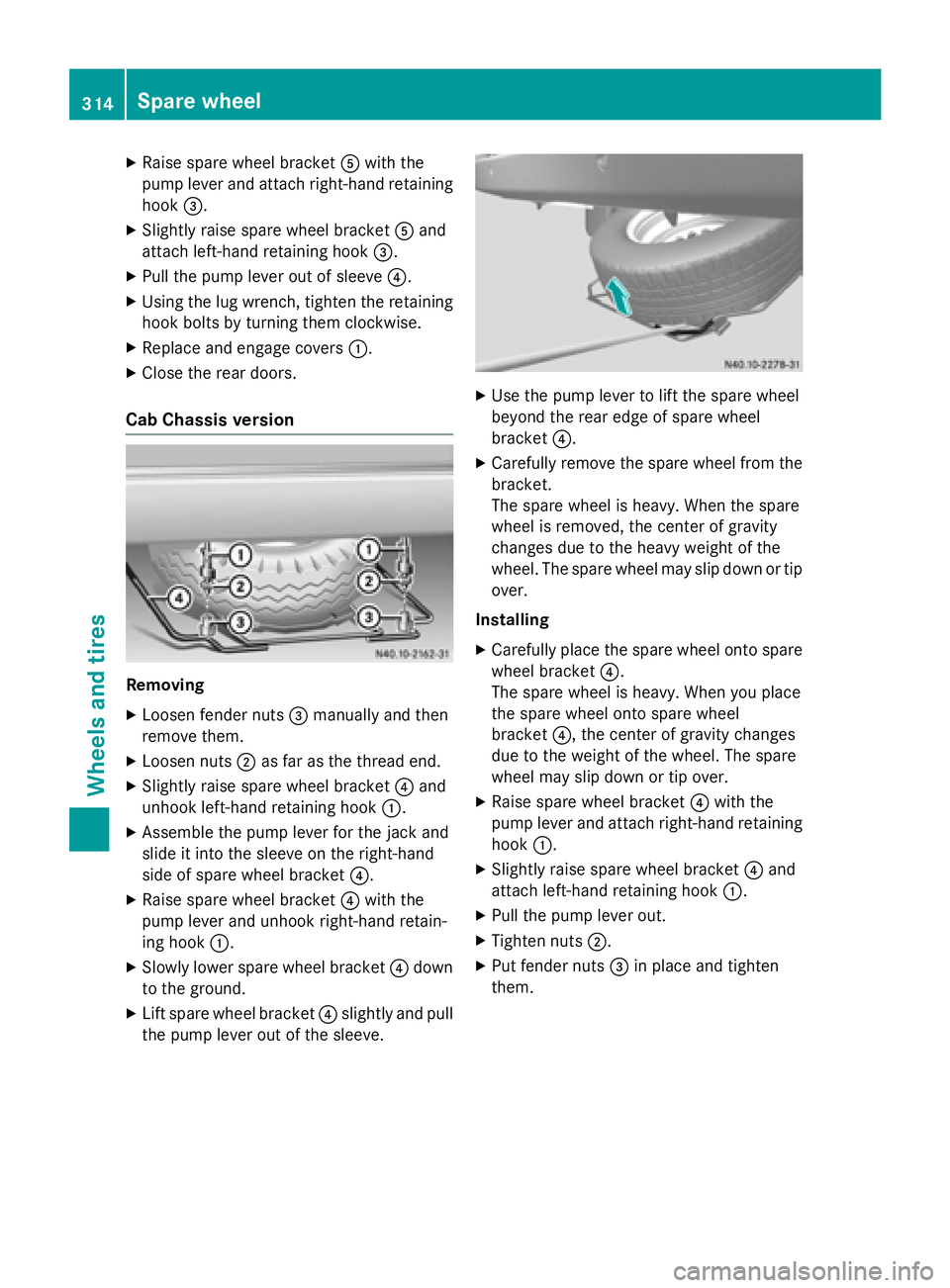

the pump lever out of sleeve 0085. Spare wheel in the spare wheel carrier

X Use the pump lever to lift the spare wheel

beyond the rear edge of the spare wheel

carrier.

X Carefully remove the spare wheel from

spare wheel bracket 0083.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the

wheel. The spare wheel may slip down or tip over.

Installing X Carefully place the spare wheel onto spare

wheel bracket 0083.

The spare wheel is heavy. When you place

the spare wheel onto spare wheel bracket

0083, the center of gravity changes due to the

weight of the wheel. The spare wheel may

slip down or tip over.

X Slide the pump lever for the jack into

sleeve 0085on spare wheel bracket 0083. Spare wheel

313Wheels and tires Z

Page 316 of 334

X

Raise spare wheel bracket 0083with the

pump lever and attach right-hand retaining hook 0087.

X Slightly raise spare wheel bracket 0083and

attach left-hand retaining hook 0087.

X Pull the pump lever out of sleeve 0085.

X Using the lug wrench, tighten the retaining

hook bolts by turning them clockwise.

X Replace and engage covers 0043.

X Close the rear doors.

Cab Chassis version Removing

X Loosen fender nuts 0087manually and then

remove them.

X Loosen nuts 0044as far as the thread end.

X Slightly raise spare wheel bracket 0085and

unhook left-hand retaining hook 0043.

X Assemble the pump lever for the jack and

slide it into the sleeve on the right-hand

side of spare wheel bracket 0085.

X Raise spare wheel bracket 0085with the

pump lever and unhook right-hand retain-

ing hook 0043.

X Slowly lower spare wheel bracket 0085down

to the ground.

X Lift spare wheel bracket 0085slightly and pull

the pump lever out of the sleeve. X

Use the pump lever to lift the spare wheel

beyond the rear edge of spare wheel

bracket 0085.

X Carefully remove the spare wheel from the

bracket.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the

wheel. The spare wheel may slip down or tip over.

Installing X Carefully place the spare wheel onto spare

wheel bracket 0085.

The spare wheel is heavy. When you place

the spare wheel onto spare wheel

bracket 0085, the center of gravity changes

due to the weight of the wheel. The spare

wheel may slip down or tip over.

X Raise spare wheel bracket 0085with the

pump lever and attach right-hand retaining hook 0043.

X Slightly raise spare wheel bracket 0085and

attach left-hand retaining hook 0043.

X Pull the pump lever out.

X Tighten nuts 0044.

X Put fender nuts 0087in place and tighten

them. 314

Spare wheelWheels and

tires

Page 323 of 334

!

If DEF comes into contact with a painted

or aluminum surface, wash the surface off

immediately with plenty of water.

High ambient temperatures

When opening the DEF tank filler cap at high

outside temperatures, ammonia vapors may

escape. Ammonia vapors have a pungent

odor and are particularly irritating for your

skin, respiratory organs and eyes. This may

result in burning eyes, nose and throat, as

well as coughing and watering eyes. Do not

inhale ammonia vapors.

If DEF heats up, e.g. in direct sunlight, in the

DEF supply reservoir for some time to over

122 ‡ (50 †), ammonia vapor will develop.

Low ambient temperatures

DEF freezes at a temperature of approx-

imately 12 ‡(00F811 †). The vehicle is equipped

with a DEF preheating system at the factory.

Winter operation is therefore also guaranteed at temperatures under 12 ‡ (00F811 †).

Additives and tap water

! Do not mix DEF with any additives and do

not dilute DEF with tap water. Otherwise,

the exhaust gas aftertreatment may be

damaged.

Observe the MB Specifications for Service

Products, Sheet No. 352.0.

Damage that arises through the use of addi- tives or tap water will invalidate the New

Vehicle Limited Warranty.

Storage

! Containers made of aluminum, copper,

copper alloys as well as unalloyed or

galvanized steel are not suitable for storing

DEF. If stored in these types of containers, DEF could cause constituents of these met- als to dissolve and cause irreparable dam-

age to the exhaust gas aftertreatment.

Damage caused by such impurities in the

DEF will invalidate the New Vehicle Limited

Warranty. Only store DEF in containers made of high-

alloy Cr‑Ni steel or Mo‑Cr‑Ni steel in accord-

ance with DIN EN 10 088 ‑1/2/3 or plastic

containers made of polypropylene or poly-

ethylene.

Purity

! Impurities in DEF (e.g. caused by other

service products, cleaning agents, dust,

etc.) result in increased emissions, mal-

functions, catalytic converter damage or

engine damage.

The purity of DEF is essential to prevent mal-

functions in the exhaust gas aftertreatment.

If DEF is pumped out of the DEF tank, e.g.

during repair work, the same liquid must not

be used to refill the tank. Its purity is no longer guaranteed.

Disposal

Observe country-specific laws and regula-

tions when disposing of DEF.

003D Environmental note

Dispose of DEF in an environmentally respon- sible manner.

DEF supply reservoir content

Depending on equipment, the DEF supply res-

ervoir content may vary. Tank contents

Diesel Exhaust Fluid (DEF)

12 Approximately 4.7 US gal (18.0 l)

DEF consumption

For vehicles with a 4-cylinder, in-line

engine (OM 651), the DEF consumption of

the vehicle is:

R as a Cargo Van/Passenger Van, approx.

2322 MPG (0.2 l/100 km)

R as a Cab Chassis, approx. 1720 MPG

(0.35 l/100 km)

12 DEF according to ISO 22241. Observe MB Specifications for Service Products, Sheet 352.0. Service products and capacities

321Technical data Z