transmission MERCEDES-BENZ SPRINTER 2015 MY15 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2015Pages: 334, PDF Size: 5.94 MB

Page 198 of 334

Resetting the trip computer

Using the steering wheel buttons

X Press the 0080or007F button to select

After start

After start.

X Press the 0063or0064 button to select the

function you would like to reset.

X Press and hold the 0045reset button until the

values are reset to "0". Telephone menu

Introduction G

WARNING

If you operate information systems and com-

munication equipment integrated in the vehi- cle while driving, you will be distracted from

traffic conditions. You could also lose control of the vehicle. There is a risk of an accident.

Only operate the equipment when the traffic

situation permits. If you are not sure that this

is possible, park the vehicle paying attention

to traffic conditions and operate the equip-

ment when the vehicle is stationary.

You must observe the legal requirements of

the country in which you are currently driving when operating a mobile phone in the vehicle.

If it is permitted to operate a mobile phone

while the vehicle is in motion, only operate it

when road and traffic conditions permit.

If you have connected a mobile phone to the

Sprinter hands-free system, you can operate

it using the functions in the TEL

TEL menu.

X Switch on the mobile phone (see the sep-

arate operating instructions).

X Switch on the audio equipment (see the

separate operating instructions).

X Establish a Bluetooth ®

connection

between the mobile phone and the audio

equipment (see the separate operating

instructions). X

Press the 0080or007F button on the steer-

ing wheel to select the TEL TELmenu.

X When Please enter PIN:

Please enter PIN: appears in the

display, enter the PIN using the mobile

phone or audio equipment.

The mobile phone will search for a network. The display remains blank during this time.

You will see the mobile phone operational

readiness display once the mobile phone

has found a network.

i You can obtain further information about

suitable mobile phones and connecting

mobile phones via Bluetooth ®

at any quali-

fied specialist workshop.

i If the mobile phone operational readiness

symbol goes out, your vehicle is outside of

the transmission and reception range.

Accepting a call X

Press the 0061button on the steering

wheel to accept an incoming call.

The display shows the call duration.

Rejecting or ending a call X

Press 0076button on the steering wheel to

reject or end a call.

The caller then hears the engaged tone.

The display shows the mobile phone opera- tional readiness symbol again.

Dialing a number from the phone book You can enter new telephone numbers into

the phone book via the mobile phone (see the

separate operating instructions). If your

mobile phone is able to receive calls, you can

search for and dial a number from the phone book. 196

On-board computer (vehicles with steering wheel buttons)On-board computer and displays

Page 279 of 334

R

Only use jumper cables that have a suffi-

cient cross-section and insulated terminal

clamps.

R If the battery is fully discharged, attach the

battery of another vehicle for a few minutes before attempting to start. This charges the

empty battery a little.

R Make sure that the two vehicles do not

touch.

Make sure that:

R the jumper cables are not damaged.

R bare parts of the terminal clamps do not

come into contact with other metal parts

while the jumper cables are connected to

the battery.

R the jumper cables cannot come into con-

tact with parts such as the V-belt pulley or

the fan. These parts move when the engine

is started and while it is running.

i Jumper cables and further information

regarding jump starting can be obtained at any qualified specialist workshop. Before connecting the jumper cables

On vehicles with a battery main switch, check whether the battery main switch is switched

on (Y page 137).

X Apply the parking brake.

X Move the selector lever of the automatic

transmission to position P.

X Switch off all electrical consumers, e.g.

audio equipment, blower.

X Turn the key to position 0in the ignition

lock and remove it (Y page 138).

X Open the hood (Y page 248). Tow-starting and towing away

Important safety notes

G

WARNING

Functions relevant to safety are restricted or

no longer available if:

R the engine is not running.

R the brake system or the power steering is

malfunctioning.

R there is a malfunction in the voltage supply

or the vehicle's electrical system.

If your vehicle is being towed, much more

force may be necessary to steer or brake.

There is a risk of an accident.

In such cases, use a tow bar. Before towing,

make sure that the steering moves freely. G

WARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged. There is a risk of an accident.

Always switch off the ignition when towing the

vehicle with a tow cable or a tow bar. G

WARNING

When towing or tow-starting another vehicle

and its weight is greater than the permissible gross weight of your vehicle, the:

R the towing eye could detach itself

R the vehicle/trailer combination could roll-

over.

There is a risk of an accident.

When towing or tow-starting another vehicle,

its weight should not be greater than the per- missible gross weight of your vehicle.

Information on the gross vehicle weight can

be found on the vehicle identification plate

(Y page 316).

! Only secure the tow rope or tow bar at the

towing eyes. Otherwise, the vehicle could

be damaged. Tow-starting and towing away

277Roadside Assistance Z

Page 280 of 334

!

Observe the following points when towing

with a tow rope:

R Secure the tow rope on the same side on

both vehicles.

R Ensure that the tow cable is not longer

than legally permitted. Mark the tow

cable in the middle, e.g. with a white

cloth (30 x 30 cm). This will make other

road users aware that the vehicle is being towed.

R Only secure the tow cable to the towing

eye.

R Observe the brake lamps of the towing

vehicle while driving. Always maintain a

distance so that the tow rope does not

sag.

R Do not use steel cables or chains to tow

your vehicle. You could otherwise dam-

age the vehicle.

! Do not use the towing eye for recovery,

this could damage the vehicle. If in doubt,

recover the vehicle with a crane.

! When towing, pull away slowly and

smoothly. If the tractive power is too high,

the vehicles could be damaged.

When towing away, you must observe the

legal requirements for the country in which

you are currently driving.

It is preferable to have the vehicle transpor-

ted on a transporter or trailer instead of tow-

ing it.

The automatic transmission selector lever

must be in the Nposition when towing the

vehicle.

The battery must be connected and charged.

Otherwise, you:

R cannot turn the key in the ignition lock to

position 2

R cannot move the selector lever to position

N on vehicles with automatic transmission

Before the vehicle is towed, switch off the

automatic locking feature (Y page 71). You

could otherwise lock yourself out of the vehi-

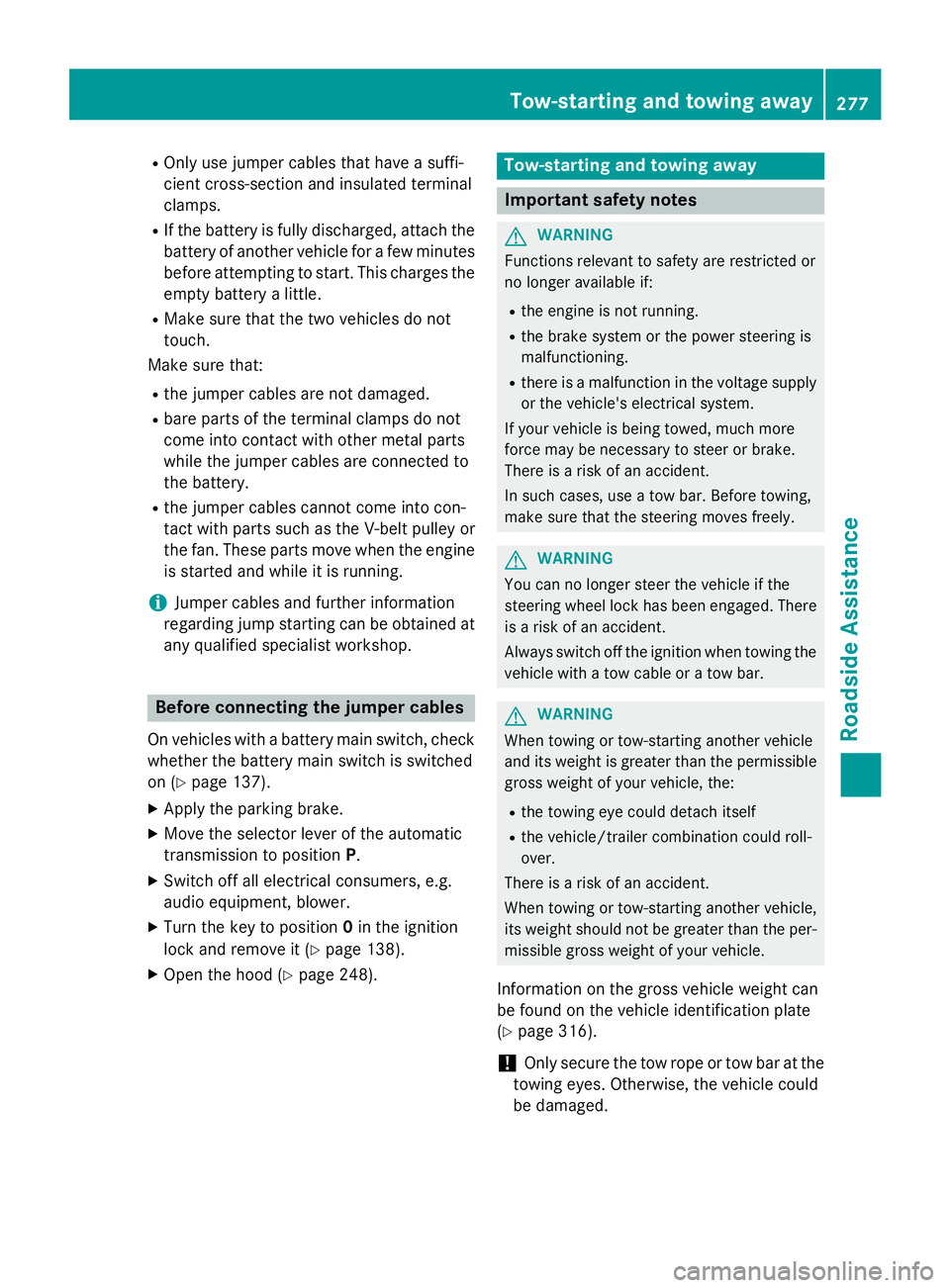

cle when pushing or towing away the vehicle. Installing/removing the towing eye

The fixture for the front towing eye is located in the

bumper. Rear towing eye under the bumper, attached to the

chassis

Your vehicle may be equipped with rear tow-

ing eye 0044. If you tow or tow-start a vehicle,

attach the towing device to rear towing

eye 0044.

If your vehicle is equipped with a trailer tow

hitch, attach the towing device to the trailer

tow hitch (Y page 173).

Installing the front towing eye

X Take the towing eye and screwdriver from

the vehicle tool kit (Y page 274).

X Press cover 0043and remove cover 0043from

the opening.

You will see the fixture for the towing eye.

X Screw in the towing eye clockwise to the

stop.

X Insert screwdriver into the towing eye and

tighten it. 278

Tow-starting and towing awayRoadside Assistance

Page 281 of 334

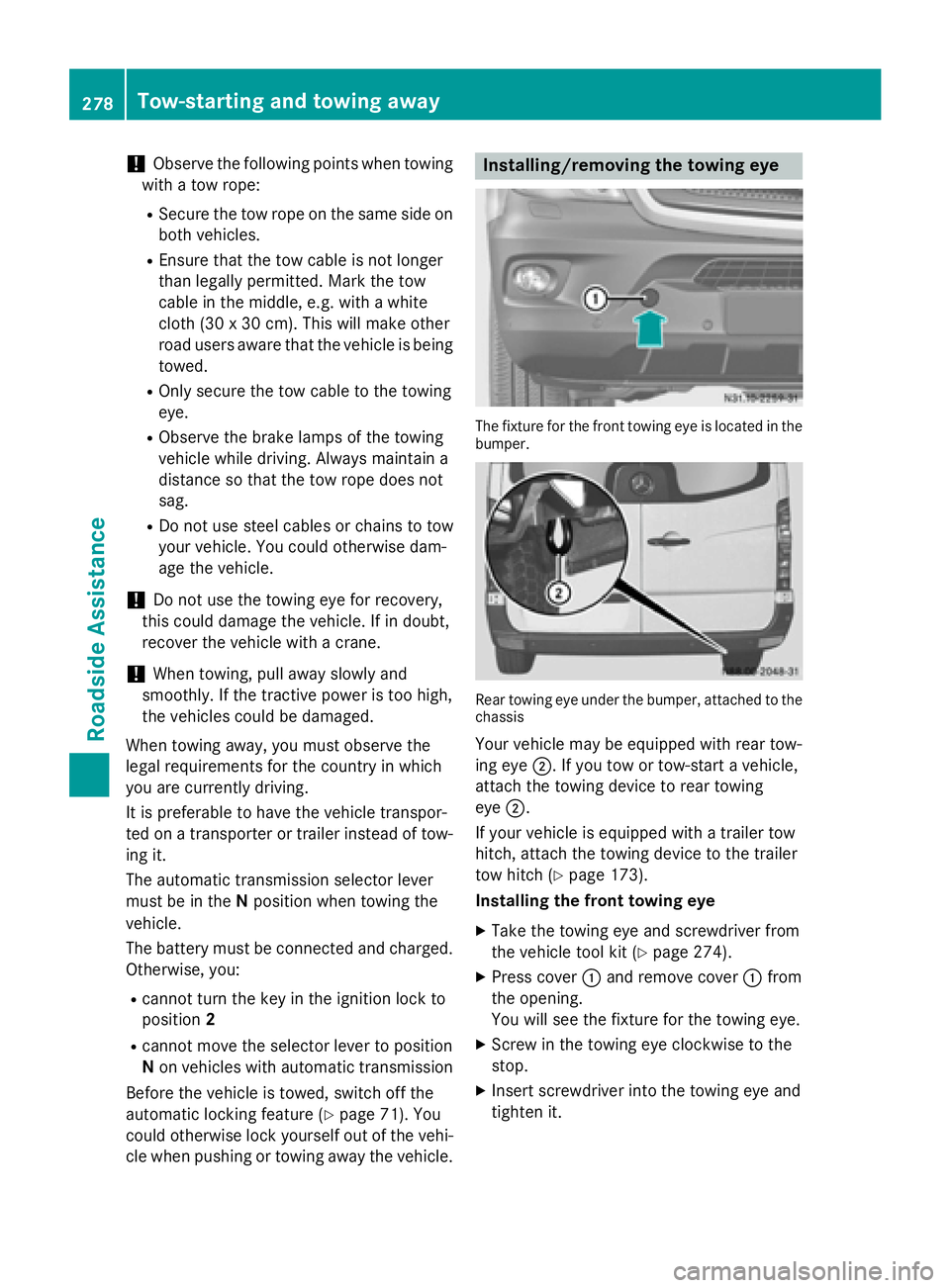

Removing the front towing eye

X

Remove the screwdriver from the vehicle

tool kit.

X Insert the screwdriver into the towing eye

and turn the screwdriver counter-clock-

wise.

X Unscrew the towing eye.

X Insert cover 0043with the lug at the bottom

and press it in at the top until it engages.

X Place the towing eye and screwdriver back

in the vehicle tool kit. Towing away in the event of malfunc-

tions

With transmission damage !

Always use new bolts when installing the

propeller shafts.

i Only have the propeller shafts fitted/

removed by qualified, skilled personnel.

If the vehicle has transmission damage, have

the propeller shaft removed before towing

away. Towing with the front or rear axle

raised

General notes !

The ignition must be switched off if the

vehicle is being towed with the front or rear

axle raised. Otherwise, ESP ®

may intervene

and damage the brake system.

! Always use new bolts when installing the

propeller shafts.

i Only have the propeller shafts fitted/

removed by qualified, skilled personnel.

Observe the following before towing a vehicle

with a raised front or rear axle:

R the information on towing in the event of

malfunctions (Y page 279) and

R the important safety notes (Y page 277).If the front axle is damaged, raise the vehicle

at the front axle and if the rear axle is dam-

aged, raise the vehicle at the rear axle.

Towing If the front axle is raised, the vehicle may be

towed a maximum of 30 miles (50 km). For a

towing distance of over 30 miles (50 km), the propeller shafts to the driven axles must be

removed.

X Turn the key to position 2in the ignition

lock.

X Depress the brake pedal and keep it

depressed.

X Shift the automatic transmission to posi-

tion N.

X Release the brake pedal.

X Release the parking brake.

X Turn the key to position 1in the ignition

lock and leave it in this position.

X Switch on the hazard warning lamps

(Y page 95).

X If the front axle is raised, do not exceed the

towing speed of 30 mph (50 km/h) and the towing distance of 30 miles (50 km). Towing the vehicle with both axles on

the ground

Important safety notes G

WARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged. There is a risk of an accident.

Always switch off the ignition when towing the

vehicle with a tow cable or a tow bar.

! Do not exceed a towing speed of 31 mph

(50 km/h). You could otherwise damage

the transmission.

! Always use new bolts when installing the

propeller shafts. Tow-starting and towing away

279Roadside Assistance Z

Page 282 of 334

i

Only have the propeller shafts fitted/

removed by qualified, skilled personnel.

Before towing the vehicle, observe the fol-

lowing:

R the information on towing in the event of

malfunctions (Y page 279) and

R the important safety notes (Y page 277).

Towing You may only tow the vehicle a maximum dis-

tance of 30 miles (50 km). For a towing dis-

tance of over 30 miles (50 km), the propeller

shafts to the driven axles must be removed.

X Turn the key to position 2in the ignition

lock.

X Depress the brake pedal and keep it

depressed.

X Shift the automatic transmission to posi-

tion N.

X Release the brake pedal.

X Release the parking brake.

X Leave the key in position 2in the ignition

lock.

X Switch on the hazard warning lamps

(Y page 95).

X Do not exceed the towing speed of 30 mph

(50 km/h) and the towing distance of

30 miles (50 km). Recovering a vehicle that is stuck

! When recovering a vehicle that has

become stuck, pull it as smoothly and

evenly as possible. Excessive tractive

power could damage the vehicles.

If the drive wheels get trapped on loose or

muddy ground, recover the vehicle with the

utmost care. This is especially the case if the

vehicle is laden.

Never attempt to recover a vehicle with a

trailer attached. Pull out the vehicle backwards, if possible,

using the tracks it made when it became

stuck. Transporting the vehicle

! You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise,

the vehicle could be damaged. Tow-starting (emergency engine

starting)

Vehicles with automatic transmission !

Vehicles with automatic transmission

must not be tow-started. You could other-

wise damage the automatic transmission.

You can find information on jump-starting

under "Jump-starting“ (Y page 276). Electrical fuses

G

WARNING

If you manipulate or bridge a faulty fuse or if

you replace it with a fuse with a higher amper- age, the electric cables could be overloaded.

This could result in a fire. There is a risk of an

accident and injury.

Always replace faulty fuses with the specified

new fuses having the correct amperage.

! Only use fuses that have been approved

for Sprinter vehicles and that have the

required fuse rating for the systems con-

cerned. Components or systems could oth- erwise be damaged.

The fuses in your vehicle switch off defective power circuits. If a fuse blows, all the com-

ponents on the circuit and their functions will

cease to operate.

Blown fuses must be replaced with fuses of

the same rating, which you can recognize by

the color and fuse rating. Observe the infor- 280

Electrical fusesRoadside Assistance

Page 308 of 334

Single tires:

if the tires are of identical

dimensions, you can rotate both wheels on

both the front and rear axles so that the tires'

original direction of rotation is maintained. On unidirectional tires, an arrow on the sidewall

shows the prescribed direction of rotation of

the tire.

Twin rear tires: if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear

axle in pairs such that the original direction of

tire rotation is retained. With unidirectional

tires, you may rotate the outside wheels at

the rear axle from one side to the other. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed limi-

tation specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool, dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Mounting a wheel

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake. X

Turn the front wheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not endan-

gered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed. Any-

one who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements.

X Secure the vehicle to prevent it from rolling

away.

i Observe the safety notes on parking in the

section on "Driving and parking"

(Y page 149).

X On level terrain: place chocks or other

suitable objects under the front and rear of the wheel that is diagonally opposite the

wheel to be changed.

X On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed.

X Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 274).

X Remove the spare wheel from the spare

wheel bracket (Y page 313). Observe the

safety notes in the "Spare wheel" section

(Y page 312).

X On wheels with wheel bolts, remove the

hub caps. 306

Changing wheelsWheels and tires

Page 311 of 334

Removing a wheel

!

Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the

wheel bolts and wheel nuts could otherwise

be damaged when being tightened.

X Unscrew the wheel bolts or nuts.

X On front wheels with wheel nuts, remove

the wheel nut cover.

X Remove the wheel.

Installing the adapter G

WARNING

If you tighten the adapter bolts when the vehi- cle is raised, the jack could tip over. There is a risk of injury.

Make sure that the vehicle is properly pre-

pared for a wheel change. Tighten the adapter

bolts with particular care and attention.

Always observe the instructions and safety

notes on "Changing a wheel" (Y page 305).G

WARNING

If you do not tighten the bolts of the adapter to the specified tightening torque, the adapter

may come loose with the spare wheel. There

is a risk of an accident.

Tighten the bolts of the adapter to the speci-

fied tightening torque. Have the spare wheel

replaced with a complete wheel and an extra- wide tire at a qualified specialist workshop

immediately.

! Vehicles with Super Single tires:

if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and

do not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

On vehicles with Super Single tires, you must

attach the narrow spare wheel to the rear axle by means of an adapter. The adapter is bolted

to the spare wheel using the adapter bolts for transportation. The handling characteristics of your vehicle

are affected when driving with a spare wheel

installed. After changing a wheel, drive to the

nearest specialist workshop and have the

spare wheel replaced with a wheel and tire

assembly that has a Super Single tire.

X Clean the wheel and wheel hub contact

surfaces.

X Unscrew the six adapter bolts on the spare

wheel and remove the adapter.

X Tighten the adapter with the six adapter

bolts evenly in a crosswise pattern through

the outer holes on the wheel hub.

X Tighten the six adapter bolts on the wheel

hub to a tightening torque of 177 lb-ft

(240 Nm).

X Push the wheel onto the adapter and attach

it.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (Y page 305).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you

only use wheel bolts or wheel nuts which have Changing wheels

309Wheels and tires Z

Page 312 of 334

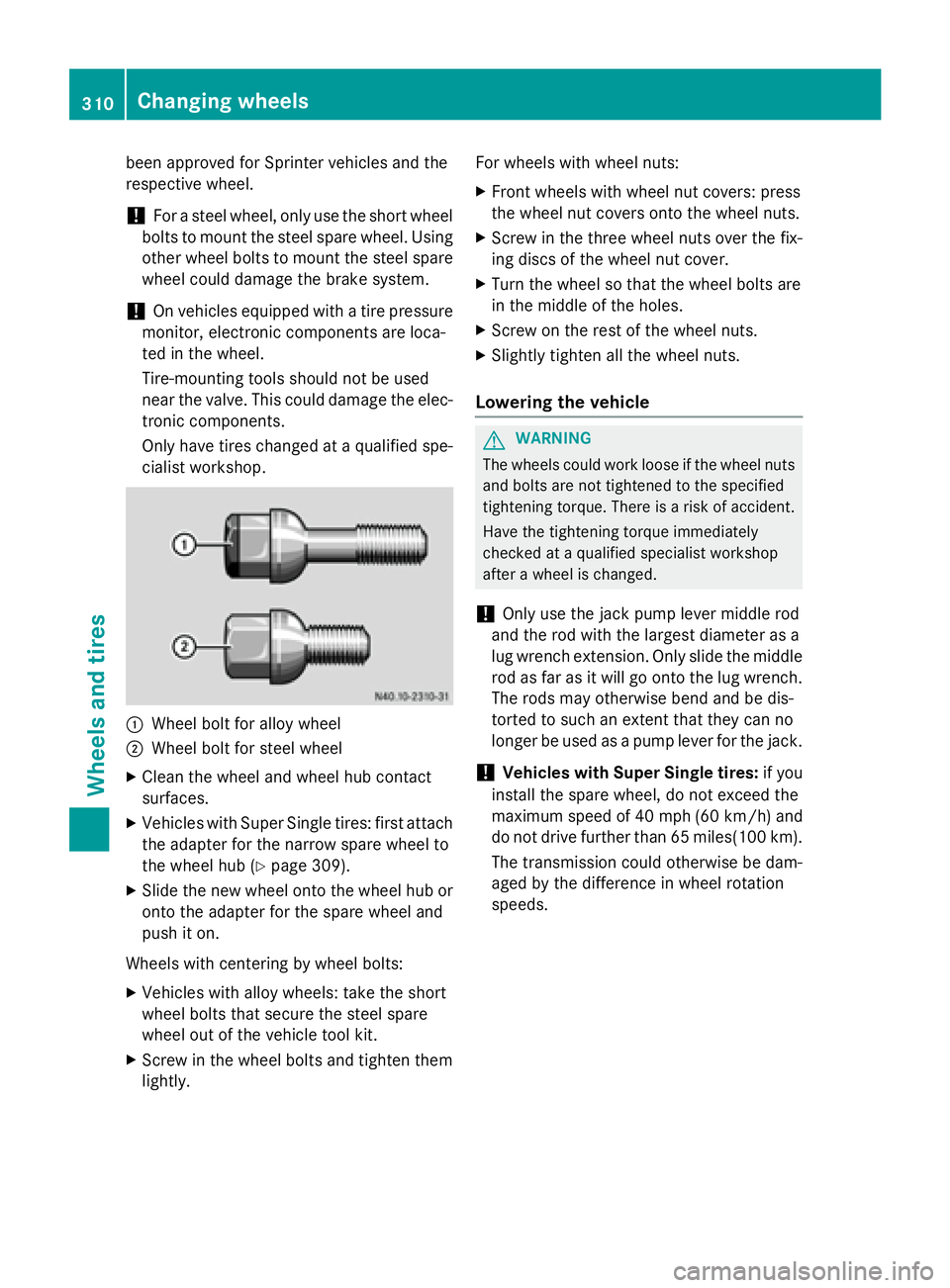

been approved for Sprinter vehicles and the

respective wheel.

! For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using other wheel bolts to mount the steel spare wheel could damage the brake system.

! On vehicles equipped with a tire pressure

monitor, electronic components are loca-

ted in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec-

tronic components.

Only have tires changed at a qualified spe- cialist workshop. 0043

Wheel bolt for alloy wheel

0044 Wheel bolt for steel wheel

X Clean the wheel and wheel hub contact

surfaces.

X Vehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to

the wheel hub (Y page 309).

X Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and

push it on.

Wheels with centering by wheel bolts:

X Vehicles with alloy wheels: take the short

wheel bolts that secure the steel spare

wheel out of the vehicle tool kit.

X Screw in the wheel bolts and tighten them

lightly. For wheels with wheel nuts:

X Front wheels with wheel nut covers: press

the wheel nut covers onto the wheel nuts.

X Screw in the three wheel nuts over the fix-

ing discs of the wheel nut cover.

X Turn the wheel so that the wheel bolts are

in the middle of the holes.

X Screw on the rest of the wheel nuts.

X Slightly tighten all the wheel nuts.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle rod as far as it will go onto the lug wrench. The rods may otherwise bend and be dis-

torted to such an extent that they can no

longer be used as a pump lever for the jack.

! Vehicles with Super Single tires:

if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/ h)and

do not drive further than 65 miles(100 km ).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds. 310

Changing wheelsWheels and tires

Page 318 of 334

Vehicle electronics

Tampering with the engine electron-

ics G

WARNING

Always have work on the engine electronics

and related components carried out at a quali- fied specialist workshop. Otherwise, the vehi-cle's operating safety could be affected.

! Only have engine electronics and the cor-

responding parts, such as control units,

sensors or connector leads, serviced in a

qualified specialist workshop. Otherwise,

the vehicle parts may wear more quickly.

This can lead to loss of the New Vehicle

Limited Warranty. Installing electrical or electronic

equipment

G

WARNING

You and others may damage your health due

to excessive electromagnetic radiation. By

using an external antenna, the possible health risks of electromagnetic fields, which are

under discussion among the scientific com-

munity, should be largely prevented.

Therefore, only have the exterior antenna

installed at a qualified specialist workshop.

Electrical and electronic devices may have a

detrimental effect on both the comfort and

the operating safety of the vehicle. If equip-

ment of this kind is installed, its electromag-

netic compatibility must be checked and veri-

fied.

If these devices are linked to functions asso-

ciated with resistance to interference, they

must have type approval. This applies to the

device or its interfaces to the vehicle elec-

tronics, e.g. charging brackets.

A telephone or two-way radio to be installed in

the vehicle must be approved. Further infor-

mation can be obtained from any Sprinter

Dealer. For operation of mobile phones and two-way

radios, Mercedes Benz recommends connec- tion to an approved exterior antenna. This is

the only way to ensure optimum reception

quality inside the vehicle and to minimize

mutual interference between the vehicle elec-

tronics, mobile phones and two-way radios.

The transmission output of the mobile phone

or two-way radio may not exceed the follow-

ing maximum transmission output (PEAK): Frequency range Maximum trans-

mission output

(PEAK) Shortwave

(f < 50 MHz) 100 W

4 m waveband 30 W

2 m waveband 50 W

Trunked radio/Tetra 35 W

70 cm waveband 35 W

GSM/UMTS/LTE 10 W

Identification plates

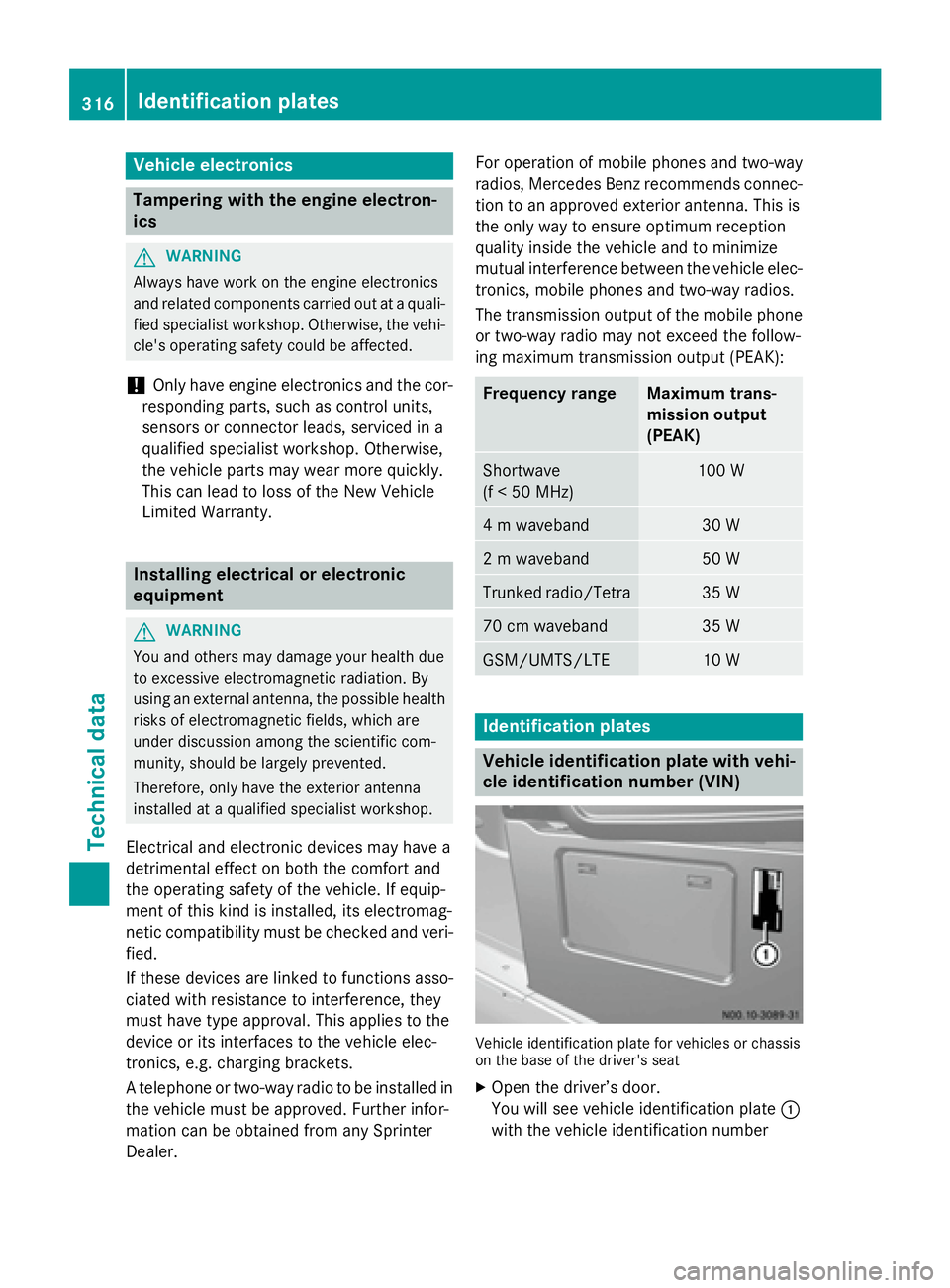

Vehicle identification plate with vehi-

cle identification number (VIN)

Vehicle identification plate for vehicles or chassis

on the base of the driver's seat

X Open the driver’s door.

You will see vehicle identification plate 0043

with the vehicle identification number 316

Identification platesTechnical data

Page 320 of 334

Service products and capacities

Important safety notes

G

WARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels of the respective original containers. Always

store service products sealed in their original containers. Always keep service products out

of the reach of children. H

Environmental note

Dispose of service products in an environ-

mentally responsible manner.

Service products include the following:

R Fuels, e.g. diesel

R Additives for the exhaust gas aftertreat-

ment, e.g. Diesel Exhaust Fluid (DEF)

R Lubricants, e.g. engine oil, transmission oil

R Coolant

R Brake fluid

R Washer fluid

R Climate control system refrigerants

Approved service products comply with the

highest quality standards and are listed in the MB Specifications for Service Products. Only

use service products approved for the vehi-

cle. This is an important condition for the war-

ranty.

You will recognize the approved service prod- ucts by the inscription on the container: MB

Approval (e.g. MB Approval 228.5)

Other identifications and recommendations

refer to quality level or a specification accord-

ing to an MB Sheet Number (e.g. MB 228.5).

They are therefore not necessarily approved.

Further information can be obtained at any

qualified specialist workshop.

Additives for approved service products are

neither required nor permitted. Approved fuel additives are the exception. Additives can cause engine damage and must therefore not

be added to the service products.

The use of additives is always the responsi-

bility of the vehicle operator. The use of addi- tives may result in the restriction or loss of

your Limited Warranty entitlements. Fuel

Important safety notes G

WARNING

Fuel is highly flammable. Improper handling of fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creatingsparks under all circumstances. Switch off the

engine and, if applicable, the auxiliary heating before refueling. G

WARNING

Fuel is poisonous and hazardous to health.

There is a risk of injury.

You must make sure that fuel does not come into contact with your skin, eyes or clothing

and that it is not swallowed. Do not inhale fuel

vapors. Keep fuel away from children.

If you or others come into contact with fuel,

observe the following:

R Wash away fuel from skin immediately

using soap and water.

R If fuel comes into contact with your eyes,

immediately rinse them thoroughly with

clean water. Seek medical assistance with-

out delay.

R If fuel is swallowed, seek medical assis-

tance without delay. Do not induce vomit-

ing.

R Immediately change out of clothing which

has come into contact with fuel.

When handling, storing and disposing of fuels,

please observe the relevant regulations. 318

Service products and capacitiesTechnical data