tow MERCEDES-BENZ SPRINTER 2015 MY15 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2015Pages: 334, PDF Size: 5.94 MB

Page 307 of 334

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are dis-

tributed over the tire tread. If the tire tread is level with the bars, the wear limit of 00CDin

(1.6 mm) has been reached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over

designated seat positions in a vehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle. Flat tire

General notes

If your vehicle is equipped with a spare wheel, the spare wheel is under the rear of the vehi-

cle (Y page 312).

Information about installing a wheel can be

found in the "Wheel change" section

(Y page 306).

When you replace a tire, we recommend that

you also replace the tire valve. Please observe

the safety-relevant information on tire valve

(Y page 290). Changing wheels

Rotating the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent. Rotate front and rear wheels only if the wheels

and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are loca-

ted in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec- tronic components.

Only have tires changed at a qualified spe-cialist workshop.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y page 306).

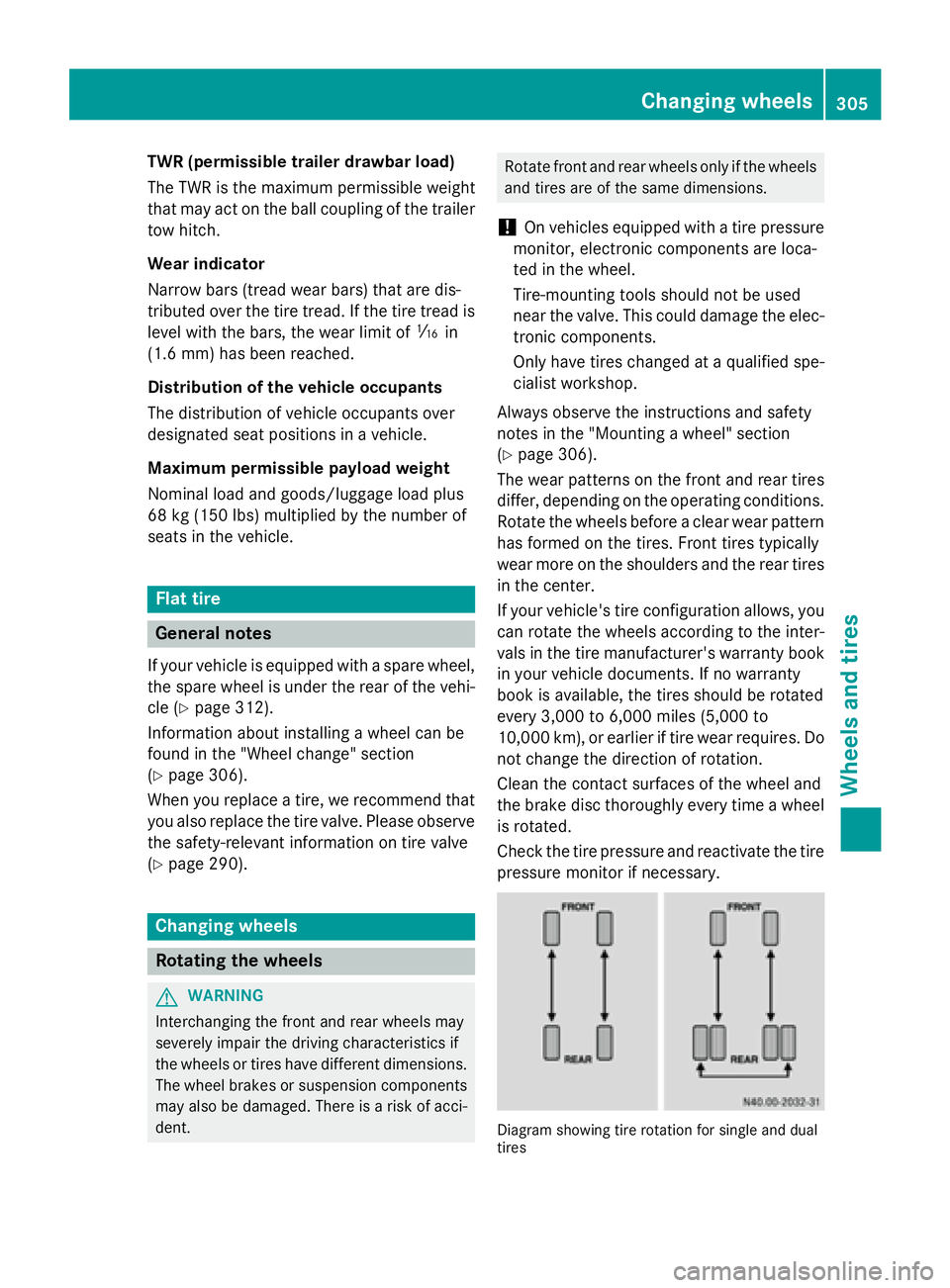

The wear patterns on the front and rear tires

differ, depending on the operating conditions. Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in the center.

If your vehicle's tire configuration allows, you can rotate the wheels according to the inter-

vals in the tire manufacturer's warranty book

in your vehicle documents. If no warranty

book is available, the tires should be rotated

every 3,000 to 6,000 miles (5,000 to

10,000 km), or earlier if tire wear requires. Do

not change the direction of rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated.

Check the tire pressure and reactivate the tire pressure monitor if necessary. Diagram showing tire rotation for single and dual

tires Changing wheels

305Wheels and tires Z

Page 313 of 334

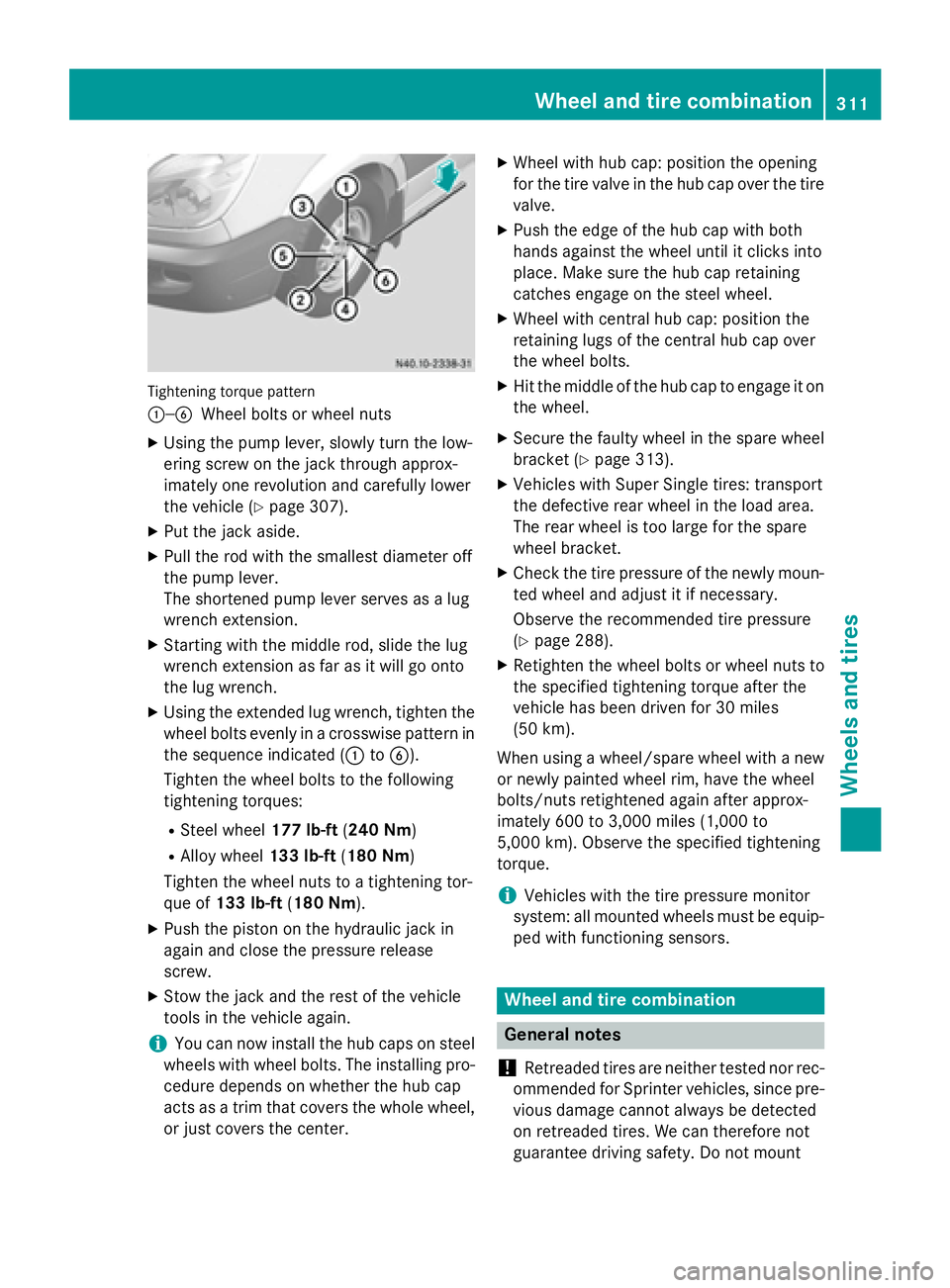

Tightening torque pattern

0043—0084

Wheel bolts or wheel nuts

X Using the pump lever, slowly turn the low-

ering screw on the jack through approx-

imately one revolution and carefully lower

the vehicle (Y page 307).

X Put the jack aside.

X Pull the rod with the smallest diameter off

the pump lever.

The shortened pump lever serves as a lug

wrench extension.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in the sequence indicated (0043 to0084).

Tighten the wheel bolts to the following

tightening torques:

R Steel wheel 177 lb-ft(240 Nm)

R Alloy wheel 133 lb-ft(180 Nm)

Tighten the wheel nuts to a tightening tor-

que of 133 lb-ft (180 Nm).

X Push the piston on the hydraulic jack in

again and close the pressure release

screw.

X Stow the jack and the rest of the vehicle

tools in the vehicle again.

i You can now install the hub caps on steel

wheels with wheel bolts. The installing pro-

cedure depends on whether the hub cap

acts as a trim that covers the whole wheel,

or just covers the center. X

Wheel with hub cap: position the opening

for the tire valve in the hub cap over the tire

valve.

X Push the edge of the hub cap with both

hands against the wheel until it clicks into

place. Make sure the hub cap retaining

catches engage on the steel wheel.

X Wheel with central hub cap: position the

retaining lugs of the central hub cap over

the wheel bolts.

X Hit the middle of the hub cap to engage it on

the wheel.

X Secure the faulty wheel in the spare wheel

bracket (Y page 313).

X Vehicles with Super Single tires: transport

the defective rear wheel in the load area.

The rear wheel is too large for the spare

wheel bracket.

X Check the tire pressure of the newly moun-

ted wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 288).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

(50 km).

When using a wheel/spare wheel with a new

or newly painted wheel rim, have the wheel

bolts/nuts retightened again after approx-

imately 600 to 3,000 miles (1,000 to

5,000 km). Observe the specified tightening

torque.

i Vehicles with the tire pressure monitor

system: all mounted wheels must be equip- ped with functioning sensors. Wheel and tire combination

General notes

! Retreaded tires are neither tested nor rec-

ommended for Sprinter vehicles, since pre-

vious damage cannot always be detected

on retreaded tires. We can therefore not

guarantee driving safety. Do not mount Wheel and tire combination

311Wheels and tires Z

Page 322 of 334

i

Malfunctions resulting from paraffin sep-

aration can only be rectified by heating the

entire fuel system. Park the vehicle in a

heated garage, for example.

To prevent operating problems, diesel with

better flow qualities is available during the

winter months. You can obtain information at the gas station or from your fuel supplier.

Your vehicle is equipped with a fuel preheat-

ing system. This improves the flow properties

of the diesel by approximately 46 ‡ (8 †).

ULTRA-LOW SULFUR DIESEL can be used

without risk of malfunction down to an out-

side temperature of approximately 14 ‡

(00F810 †).

Fuel additives

! Do not add gasoline or kerosene to diesel

fuel to improve its flow characteristics.

Gasoline or kerosene impairs the lubricat-

ing properties of the diesel fuel. This can

result in damage to the fuel injection sys-

tem, for example.

Information on fuel consumption H

Environmental note

CO 2(carbon dioxide) is the gas which scien-

tists believe to be principally responsible for

global warming (the greenhouse effect). Your

vehicle's CO 2emissions are directly related to

fuel consumption and therefore depend on:

R efficient use of the fuel by the engine

R driving style

R other non-technical factors, such as envi-

ronmental influences, road conditions or

traffic flow

You can minimize your vehicle's CO 2emis-

sions by driving carefully and having it serv-

iced regularly.

Fuel consumption depends on: R the vehicle version

R the style of driving R

the operating conditions

R the type or quality of the fuel used

The vehicle will use more fuel than usual in the following situations:

R at very low outside temperatures

R in city traffic

R during short journeys

R on mountainous terrain

R when towing a trailer

To keep fuel consumption low, observe the

advice in the "Protection of the environment" section (Y page 23).

The following components of the different

vehicle versions influence fuel consumption:

R tire sizes, tire tread, tire pressure, tire con-

dition

R body

R transmission ratios for the drive assem-

blies

R additional equipment (e.g. air-conditioning

system, auxiliary heating system)

For these reasons, the actual consumption

figures for your vehicle may deviate from the

consumption figures determined according

to EU Directive 80/1268/EEC.

Data concerning fuel consumption are recor- ded in the on-board computer; use the steer-

ing wheel buttons to call up the Trip com-

puter menu (Y page 195).

Diesel Exhaust Fluid (DEF) General notes

! Only use DEF in accordance with

ISO 22241. The exhaust gas aftertreatment system may otherwise be damaged.

Observe the MB Specifications for Service

Products, Sheet No. 352.0.

Damage caused by the use of other reduc-

ing agents will invalidate the New Vehicle

Limited Warranty. 320

Service products and capacitiesTechnical data

Page 330 of 334

Load rails

The maximum tensile loads of the cargo tie

down points in the cargo compartment are: Cargo tie down

point Permissible nomi-

nal tensile load Load rails on cargo

compartment floor 1124.0 lbf

(5000 N) Lower load rail on

sidewall 562.0 lbf

(2500 N) Upper load rail on

sidewall 337.0 lbf

(1500 N) The values specified apply only to loads

placed on the cargo compartment floor if:

R the load is secured to 2 cargo tie down

points on the rail and

R the distance to the nearest load-securing

point on the same rail is approximately 3 ft

(1 m).

Roof carrier G

WARNING

When you load the roof, the center of gravity

of the vehicle rises and the driving character- istics change. If you exceed the maximum roof

load, the driving characteristics, as well as

steering and braking, will be greatly impaired. There is a risk of an accident.

Never exceed the maximum roof load and

adjust your driving style. G

WARNING

If you distribute the load unevenly in the vehi- cle, the handling as well as the steering and

braking characteristics are severely affected.

There is a risk of an accident.

Distribute the load evenly in the vehicle.

Secure the load to prevent it from slipping.

! The weight of any load carried on the roof,

including the roof carrier, must not exceed the maximum permissible roof load. The roof carrier supports must be mounted

at equal distances.

We recommend that you have a stabilizer

installed on the front axle.

! For safety reasons, we recommend that

you only use roof carrier systems that have

been tested and approved for the Sprinter.

This will help to avoid damage.

The data is valid for a load distributed evenly

over the entire roof area. Maximum roof load

and minimum number of pairs of roof carrier

supports on vehicles with: Maximum

roof load Minimum

number of pairs of

supports Standard

roof 660 lbs

(300 kg) 6

High roof 330 lbs

(150 kg) 3

Reduce the load on shorter roof carriers pro-

portionately. The maximum load per pair of

roof carrier supports is 110 lbs (50 kg).

Loading directions and other information con- cerning load distribution and load securing

can be found in the "Transporting" section

(Y page 240). Trailer tow hitch

General notes We recommend that you have the trailer tow

hitch mounted at an authorized Sprinter

Dealer.

Use only a trailer tow hitch that has been tes- ted and approved specially for your vehicle by

the distributor named on the inside of the

front cover. Only use a ball coupling that is

approved for your vehicle and Sprinter trailer

tow hitch. You can also find information on

the permitted dimensions of the ball coupling 328

Vehicle dataTechnical data

Page 331 of 334

on the identification plate of the trailer tow

hitch.

You can obtain advice from a qualified spe-

cialist workshop. Also observe the informa-

tion on towing a trailer in the "Driving and

parking" section (Y page 173). Vehicle data

329Technical data Z

Page 332 of 334

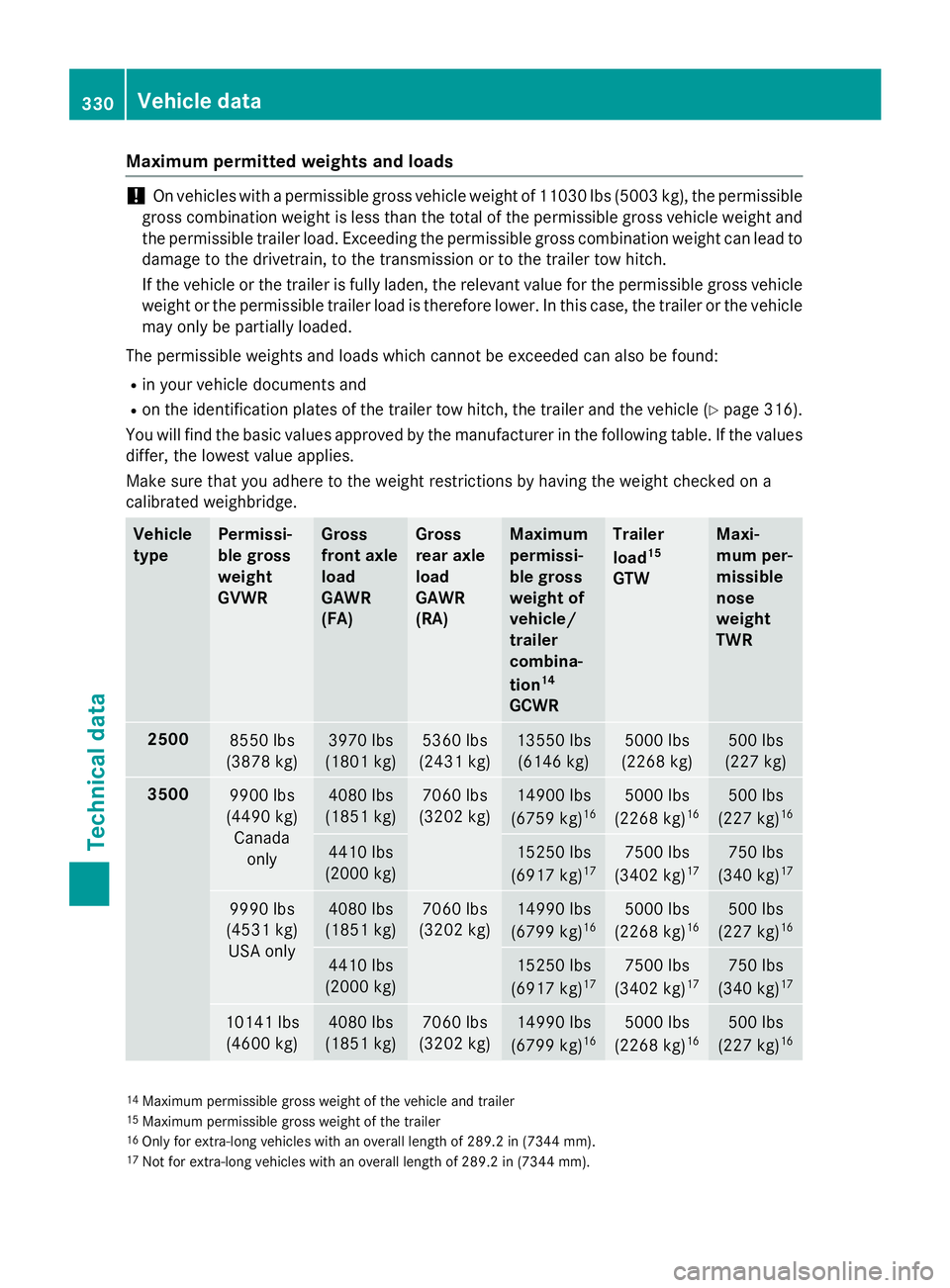

Maximum permitted weights and loads

!

On vehicles with a permissible gross vehicle weight of 11030 lbs (5003 kg), the permissible

gross combination weight is less than the total of the permissible gross vehicle weight and the permissible trailer load. Exceeding the permissible gross combination weight can lead to

damage to the drivetrain, to the transmission or to the trailer tow hitch.

If the vehicle or the trailer is fully laden, the relevant value for the permissible gross vehicle weight or the permissible trailer load is therefore lower. In this case, the trailer or the vehicle may only be partially loaded.

The permissible weights and loads which cannot be exceeded can also be found: R in your vehicle documents and

R on the identification plates of the trailer tow hitch, the trailer and the vehicle (Y page 316).

You will find the basic values approved by the manufacturer in the following table. If the values

differ, the lowest value applies.

Make sure that you adhere to the weight restrictions by having the weight checked on a

calibrated weighbridge. Vehicle

type Permissi-

ble gross

weight

GVWR Gross

front axle

load

GAWR

(FA) Gross

rear axle

load

GAWR

(RA) Maximum

permissi-

ble gross

weight of

vehicle/

trailer

combina-

tion

14

GCWR Trailer

load

15

GTW Maxi-

mum per-

missible

nose

weight

TWR

2500

8550 lbs

(3878 kg) 3970 lbs

(1801 kg) 5360 lbs

(2431 kg) 13550 lbs

(6146 kg) 5000 lbs

(2268 kg) 500 lbs

(227 kg) 3500

9900 lbs

(4490 kg) Canada only 4080 lbs

(1851 kg) 7060 lbs

(3202 kg) 14900 lbs

(6759 kg) 16 5000 lbs

(2268 kg) 16 500 lbs

(227 kg) 16 4410 lbs

(2000 kg) 15250 lbs

(6917 kg) 17 7500 lbs

(3402 kg) 17 750 lbs

(340 kg) 17 9990 lbs

(4531 kg) USA only 4080 lbs

(1851 kg) 7060 lbs

(3202 kg) 14990 lbs

(6799 kg) 16 5000 lbs

(2268 kg) 16 500 lbs

(227 kg) 16 4410 lbs

(2000 kg) 15250 lbs

(6917 kg) 17 7500 lbs

(3402 kg) 17 750 lbs

(340 kg) 17 10141 lbs

(4600 kg) 4080 lbs

(1851 kg) 7060 lbs

(3202 kg) 14990 lbs

(6799 kg) 16 5000 lbs

(2268 kg) 16 500 lbs

(227 kg) 16 14

Maximum permissible gross weight of the vehicle and trailer

15 Maximum permissible gross weight of the trailer

16 Only for extra-long vehicles with an overall length of 289.2 in (7344 mm).

17 Not for extra-long vehicles with an overall length of 289.2 in (7344 mm). 330

Vehicle dataTechnical data