ESP MERCEDES-BENZ SPRINTER 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2017Pages: 286, PDF Size: 4.36 MB

Page 232 of 286

!Make sure that:

Rthe side windows and the roof are com-

pletely closed

Rthe climate control blower is switched off

Rthe windshield wiper switch is at position0

The vehicle could otherwise be damaged.

You can wash the vehicle in an automatic car

wash from the very start.

Wash off excess dirt before cleaning the vehicle

in an automatic car wash.

After putting the vehicle through an automatic

car wash, wipe off wax from:

Rthe rear view camera lens (Ypage 232)

Rthe windshield

Rthe windshield wiper blades

This will prevent smears and reduce wiping

noises caused by residue on the windshield.

Washing by hand

In some countries, washing by hand is only

allowed at specially equipped washing bays.

Observe the legal requirements of the country

you are currently in when washing by hand.

XDo not use hot water and do not wash the

vehicle in direct sunlight.

XUse a soft car sponge.

XUse a mild cleaning agent, e.g. a car shampoo

approved for use with Sprinter vehicles.

XThoroughly hose down the vehicle with a gen-

tle jet of water.

XDo not point the water jet directly towards the

air inlets.

XUse plenty of water and rinse out the sponge

frequently.

XRinse the vehicle with clean water and dry

thoroughly with a chamois.

XDo not let the cleaning agents dry on the

paintwork.

When using the vehicle in winter, remove all

traces of road salt deposits carefully and as

soon as possible.

Power washers

GWARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior damage

to the tires or chassis components. Compo-

nents damaged in this way may fail unexpect-

edly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced imme-

diately.

!Under no circumstances use power washers

in the vehicle interior. The pressurized water

and associated spray produced by the power washer could cause extensive damage to the

vehicle.

!Observe the minimum distance to be main-

tained between the nozzle of the high-pres-

sure cleaner and the object to be cleaned:

Rapproximately 2.2 ft(70 cm) when using

round-jet nozzles

Rapproximately 1 ft (30 cm) when using 25°

flat-spray jets and concentrated-power jets

Keep the water jet moving while cleaning. To

avoid causing damage, do not point the water jet directly at:

Rdoor joints

Rbrake hoses

Relectrical components

Relectrical connections

Rseals

Rdrive train, especially not at the intermedi-

ate bearing of the propeller shaft

Rrear view camera

Keep a minimum distance of 1.6 ft(50 cm).

Cleaning the engine

!Water must not enter intake or ventilation

openings. When cleaning with high pressure

water or steam cleaners, the spray must not

be aimed directly at electrical components or

the terminals of electrical lines.

Preserve the engine after the engine has been

cleaned. Protect the belt drive system from

exposure to the preservative agent.

Also observe the information under "Power

washers" (

Ypage 230).

230Care

Maintenance and care

Page 243 of 286

Towing with the front or rear axle

raised

General notes

!The ignition must be switched off if the vehi-

cle is being towed with the front or rear axle

raised. Otherwise, ESP

®may intervene and

damage the brake system.

!Always use new bolts when installing the

propeller shafts.

iOnly have the propeller shafts installed and

removed by qualified, skilled personnel.

Observe the following before towing a vehicle

with a raised front or rear axle:

Rthe information on towing in the event of mal-

functions (Ypage 240) and

Rthe important safety notes (Ypage 239).

If the front axle is damaged, raise the vehicle at

the front axle and if the rear axle is damaged,

raise the vehicle at the rear axle.

Towing

If the front axle is raised, the vehicle may be

towed a maximum of 30 miles (50 km). For a

towing distance of over 30 miles (50 km), the

propeller shafts to the driven axles must be

removed.

XTurn the key to position 2in the ignition lock.

XDepress the brake pedal and keep it

depressed.

XShift the automatic transmission to position

N.

XTurn the key to position 1in the ignition lock

and leave it in this position.

XSwitch on the hazard warning lamps

(Ypage 83).

XRelease the brake pedal.

XRelease the parking brake.

XIf the front axle is raised, do not exceed the

towing speed of 30 mph (50 km/h) and the

towing distance of 30 miles (50 km).

Towing the vehicle with both axles on

the ground

Important safety notes

GWARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged. There

is a risk of an accident.

Always switch off the ignition when towing the

vehicle with a tow cable or a tow bar.

!Do not exceed a towing speed of 31 mph

(50 km/h). You could otherwise damage the

transmission.

iOnly have the propeller shafts fitted and

removed by qualified, skilled personnel.

Before towing the vehicle, observe the follow-

ing:

Rthe information on towing in the event of mal-

functions (Ypage 240) and

Rthe important safety notes (Ypage 239).

Towing

You may only tow the vehicle a maximum dis-

tance of 30 miles (50 km). For a towing distance

of over 30 miles (50 km), the propeller shafts to the driven axles must be removed.

XTurn the key to position 2in the ignition lock.

XDepress the brake pedal and keep it

depressed.

XShift the automatic transmission to position

N.

XRelease the brake pedal.

XRelease the parking brake.

XLeave the key in position 2in the ignition lock.

XSwitch on the hazard warning lamps

(Ypage 83).

XDo not exceed the towing speed of 30 mph

(50 km/h) and the towing distance of

30 miles (50 km).

Recovering a vehicle that is stuck

!

When recovering a vehicle that has become

stuck, pull it as smoothly and evenly as pos-

sible. Excessive tractive power could damage

the vehicles.

Tow-starting and towing away241

Breakdown assistance

Z

Page 244 of 286

If the drive wheels get trapped on loose or

muddy ground, recover the vehicle with the

utmost care. This is especially the case if the

vehicle is laden.

Never attempt to recover a vehicle with a trailer

attached.

Pull out the vehicle backwards, if possible, using

the tracks it made when it became stuck.

Transporting the vehicle

!

You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise, the

vehicle could be damaged.

Tow-starting (emergency engine

starting)

Vehicles with automatic transmission

!Vehicles with automatic transmission must

not be tow-started. You could otherwise dam-

age the automatic transmission.

You can find information on jump-starting under

"Jump-starting“ (

Ypage 238).

Electrical fuses

The fuse allocation chart and further information

on the electric fuses and relays can be found in the "Fuse allocation chart" supplement.

242Electrical fuses

Breakdown assistance

Page 247 of 286

RDo not drive with tires which have too little

tread depth, as this significantly reduces the

traction on wet roads (hydroplaning).

RReplace the tires after 6 years at the latest,

regardless of wear. This also applies to the

spare wheel.

Operation in winter

General notes

Have your vehicle winterproofed at a qualified

specialist workshop at the onset of winter.

Prior to the onset of winter, ensure that snow

chains are stowed in the vehicle (

Ypage 246).

Also observe the notes in the "Changing a

wheel" section (

Ypage 262).

Regularly check the vehicle and remove snow or ice when traveling in wintry conditions.

An accumulation of snow and ice, particularly

when frozen, caught in the area around the air

intake slots, moving parts, the axles and the

wheel arches may:

Rrestrict air intake

Rdamage vehicle parts

Rcause malfunctions by restricting the mobility

intended by the design (e.g. reduced possible

steering input).

If there is any damage, inform a qualified spe-

cialist workshop.

Driving with summer tires

At temperatures below 45 ‡ (+7 †), summer

tires lose elasticity and therefore traction and

braking power. Change the tires on your vehicle

to M+S tire. Using summer tires at very cold

temperatures could cause tears to form,

thereby damaging the tires permanently. We

cannot accept responsibility for this type of

damage.

M+S tires

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may

be severely affected. There is a risk of an acci- dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

GWARNING

M+S tires with a tire tread depth of less than

ã in (4 mm) are not suitable for use in winter

and do not provide sufficient traction. There is

a risk of an accident.

M+S tires with a tread depth of less than ãin

(4 mm) must be replaced immediately.

Use winter tires or all-season tires at tempera-

tures below 45 ‡ (+7 †). Both types of tire are

identified by the M+S marking.

Only winter tires bearing the isnowflake

symbol in addition to the M+S marking provide

the best possible grip in wintry road conditions.

Only these tires will allow driving safety systems

such as ABS and ESP

®to function optimally in

winter. These tires have been developed specif-

ically for driving in snow.

For safe driving, use M+S tire sof the same make

and tread pattern on all wheels.

Always observe the maximum permissible

speed specified for the M+S tires you have

mounted.

If you install M+S tires that have a lower maxi-

mum permissible speed than the maximum per-

missible speed of the vehicle, affix an appropri-

ate warning sign in the driver's field of vision.

You can obtain this at a qualified specialist work-

shop.

Operation in winter245

Wheels and tires

Z

Page 248 of 286

Once you have mounted the winter tires:

XCheck the tire pressure (Ypage 246).

XReactivate the tire pressure moni-

tor* (

Ypage 251).

Snow chains

GWARNING

If you drive too fast with snow chains moun-

ted, they may snap. As a result, you could

injure others and damage the vehicle. There is

a risk of an accident.

Observe the maximum permissible speed for

operation with snow chains.

When driving with snow chains installed, do not

exceed the maximum permissible speed of

30 mph (50 km/h). Observe the country-spe-

cific laws and regulations for operation with

snow chains.

!Check the snow chains for damage before

mounting them. Damaged or worn snow

chains may snap and damage the following

components:

Rwheel

Rwheel housing

Rwheel suspension

For this reason, you must use only snow

chains that are free of defects. Observe the

manufacturer's mounting instructions.

!Vehicles with steel wheels: if you mount

snow chains on steel wheels, you may dam-

age the hub caps. Remove the hub caps from

the relevant wheels before mounting the

snow chains.

Snow chains increase traction on roads in wintry

conditions.

For reasons of safety we only recommend using snow chains or traction aids that are approved

for the Sprinter. The snow chains or traction aids

must be of class U or meet the SAE type U

specification. Information on snow chains is

available at any qualified specialist workshop.

When mounting snow chains, please bear the

following points in mind:

RSnow chains cannot be mounted on all

wheel/tire combinations. When mounting the snow chains, note the permissible tire and

snow chain dimensions.

RMount snow chains only in pairs and only to

the rear wheels. On vehicles with twin tires,

mount the snow chains to the outer wheels.

Observe the manufacturer's mounting

instructions.

RVehicles with all-wheel-drive:

snow chains

are not permitted on the front axle. There is

not sufficient space for commercially-availa-

ble snow chains. Information about snow

chains for all-wheel-drive vehicles can be

obtained from an authorized Sprinter Dealer.

ROnly use snow chains when the road is cov-

ered by a layer of snow. Remove the snow

chains as soon as possible when you come to

a road that is not snow-covered.

RThe use of snow chains may be restricted by

local regulations. Observe the appropriate

regulations before mounting snow chains.

RActivate all-wheel drive before driving off with

snow chains (Ypage 145).

RWhen driving with snow chains installed, do

not exceed the maximum permissible speed

of 30 mph (50 km/h).

RCheck the tension of the chains after a dis-

tance of approximately 0.5 miles (1.0 km).

You can deactivate ASR (

Ypage 54) when pull-

ing away with snow chains mounted. This allows

the wheels to spin in a controlled manner, ach-

ieving an increased driving force (cutting

action).

Tire pressure

Tire pressure specifications

Important safety notes

GWARNING

Underinflated or overinflated tires pose the

following risks:

Rthe tires may burst, especially as the load

and vehicle speed increase.

Rthe tires may wear excessively and/or

unevenly, which may greatly impair tire

traction.

Rthe driving characteristics, as well as steer-

ing and braking, may be greatly impaired.

246Tire pressure

Wheels and tires

* optional

Page 252 of 286

flated tire causes the tire to overheat and canlead to tire failure. Underinflation also

reduces fuel efficiency and tire tread life, and

may affect the vehicle's handling and stop-

ping ability.

Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the driv-

er's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the vehi-

cle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal

low tire pressure as intended. TPMS malfunc-

tions may occur for a variety of reasons,

including the mounting of incompatible

replacement or alternate tires or wheels on

the vehicle that prevent the TPMS from func-

tioning properly. Always check the TPMS mal-

function telltale after replacing one or more

tires or wheels on your vehicle to ensure that

the replacement or alternate tires and wheels

allow the TPMS to continue to function prop-

erly.

Vehicles with a tire pressure monitor are equip-

ped with sensors in the wheels that monitor the

tire pressure of all four tires. The tire pressure

monitor monitors the pressure in all four tires;

you set this pressure when you activate the tire pressure monitor. The tire pressure monitor

warns you when the pressure drops in one or

more of the ti

res. The tire pressure monitor only

functions if the corresponding sensors are

installed on all wheels. You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire pres-

sure.

The tire pressure monitor does not warn you if a

tire pressure is incorrect. Observe the notes on the recommended tire pressure (

Ypage 246).

The tire pressure monitor is not able to warn you

of a sudden loss of pressure, e.g. following pen- etration by a foreign object. In this event, brake

the vehicle until it comes to a standstill. Do not

carry out any sudden steering maneuvers.

The tire pressure monitor has a yellow h

warning lamp in the instrument cluster for indi-

cating pressure loss/malfunctions (USA) or

pressure loss (Canada). Depending on how the

warning lamp flashes or lights up, an underin-

flated tire or a malfunction in the tire pressure

monitor is displayed:

Rif the h warning lamp is lit continuously,

the tire pressure on one or more tires is sig-

nificantly too low. The tire pressure monitor is

not malfunctioning.

RUSA only: if the hwarning lamp flashes for

60 seconds and then remains lit constantly,

the tire pressure monitor is malfunctioning.

Only vehicles with steering wheel buttons: the

on-board computer displays information on tire

pressure. After a few minutes of driving, the cur-

rent tire pressure of each tire is shown in the on-

board computer.

USA only: if the tire pressure monitor is mal-

functioning, it may be more than 10 minutes

before the malfunction is shown. The htire

pressure warning lamp flashes for 60 seconds

and then remains lit. When the malfunction has been rectified, the htire pressure warning

lamp goes ou

t after a few minutes of driving.

The tire pressure values indicated by the on-

board computer may differ from those meas-

ured at a gas station with a pressure gage. The

tire pressures shown by the on-board computer

refer to those measured at sea level. At high

altitudes, the tire pressure values indicated by a pressure gage are higher than those shown by

the on-board computer. In this case, do not

reduce the tire pressures.

If radio transmitting equipment (e.g. wireless

headphones, two-way radios) is operated inside

the vehicle or in the vicinity of the vehicle, this

can interfere with the operation of the tire pres-

sure monitor.

250Tire pressure

Wheels and tires

Page 256 of 286

Loading the vehicle

Instruction labels for tires and loads

GWARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair the steering and driving characteristics and lead

to brake failure. There is a risk of accident.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load.

The Tire and Loading Information placard on the

driver’s door B-pillar

Two instruction labels on your vehicle show themaximum possible load.

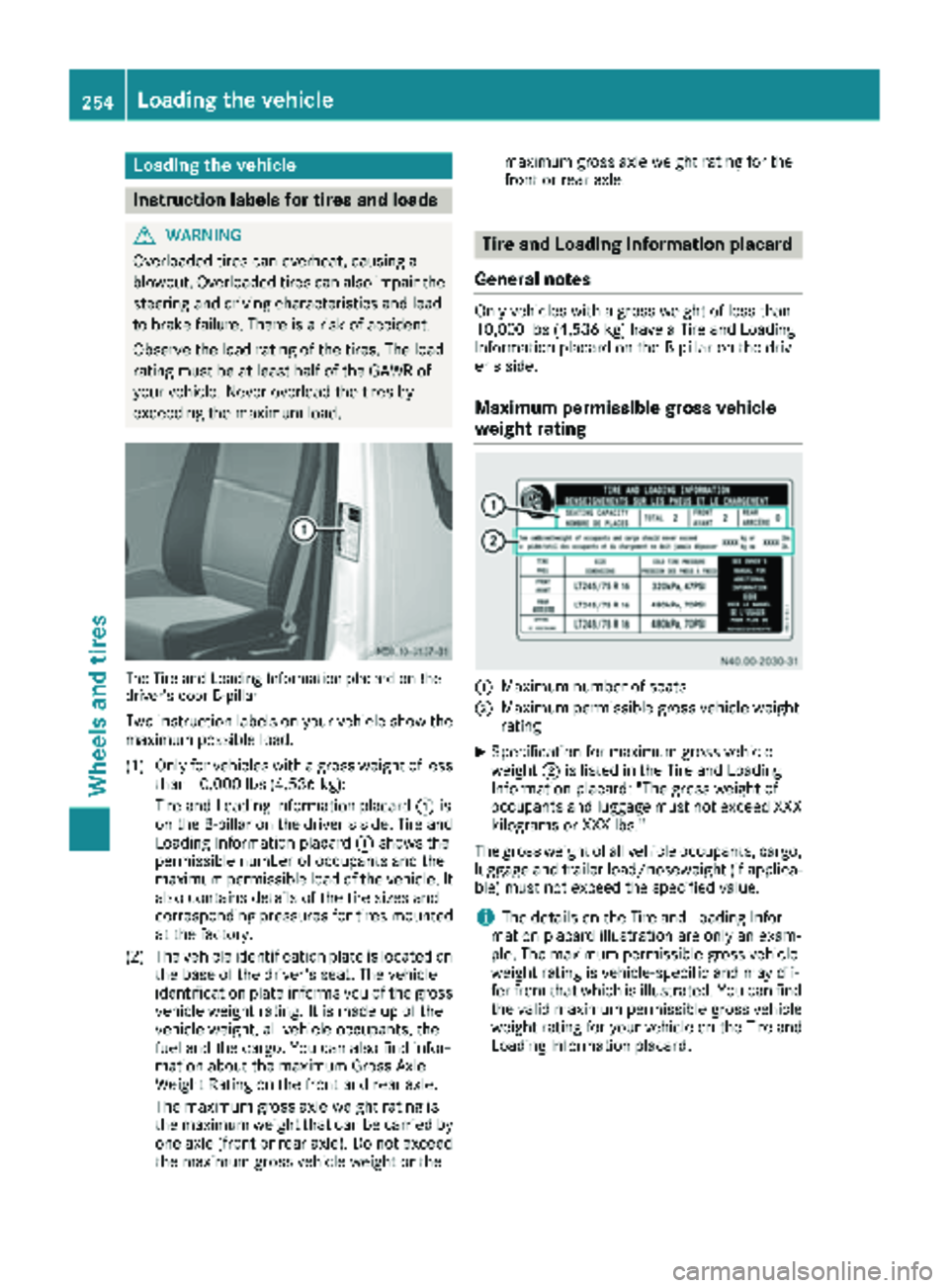

(1) Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg):

Tire and Loading Information placard :is

on the B-pillar on the driver's side. Tire and

Loading Information placard :shows the

permissible number of occupants and the

maximum permissible load of the vehicle. It

also contains details of the tire sizes and

corresponding pressures for tires mounted

at the factory.

(2) The vehicle identification plate is located on the base of the driver's seat. The vehicle

identification plate informs you of the gross

vehicle weight rating. It is made up of the

vehicle weight, all vehicle occupants, the

fuel and the cargo. You can also find infor-

mation about the maximum Gross Axle

Weight Rating on the front and rear axle.

The maximum gross axle weight rating is

the maximum weight that can be carried by

one axle (front or rear axle). Do not exceed

the maximum gross vehicle weight or the maximum gross axle weight rating for the

front or rear axle.

Tire and Loading Information placard

General notes

Only vehicles with a gross weight of less than

10,000 lbs (4,536 kg) have a Tire and Loading

Information placard on the B-pillar on the driv-

er's side.

Maximum permissible gross vehicle

weight rating

:Maximum number of seats

;Maximum permissible gross vehicle weight

rating

XSpecification for maximum gross vehicle

weight ;is listed in the Tire and Loading

Information placard: "The gross weight of

occupants and luggage must not exceed XXX

kilograms or XXX lbs."

The gross weight of all vehicle occupants, cargo,

luggage and trailer load/noseweight (if applica-

ble) must not exceed the specified value.

iThe details on the Tire and Loading Infor-

mation placard illustration are only an exam-

ple. The maximum permissible gross vehicle

weight rating is vehicle-specific and may dif-

fer from that which is illustrated. You can find

the valid maximum permissible gross vehicle

weight rating for your vehicle on the Tire and

Loading Information placard.

254Loading the vehicle

Wheels and tires

Page 260 of 286

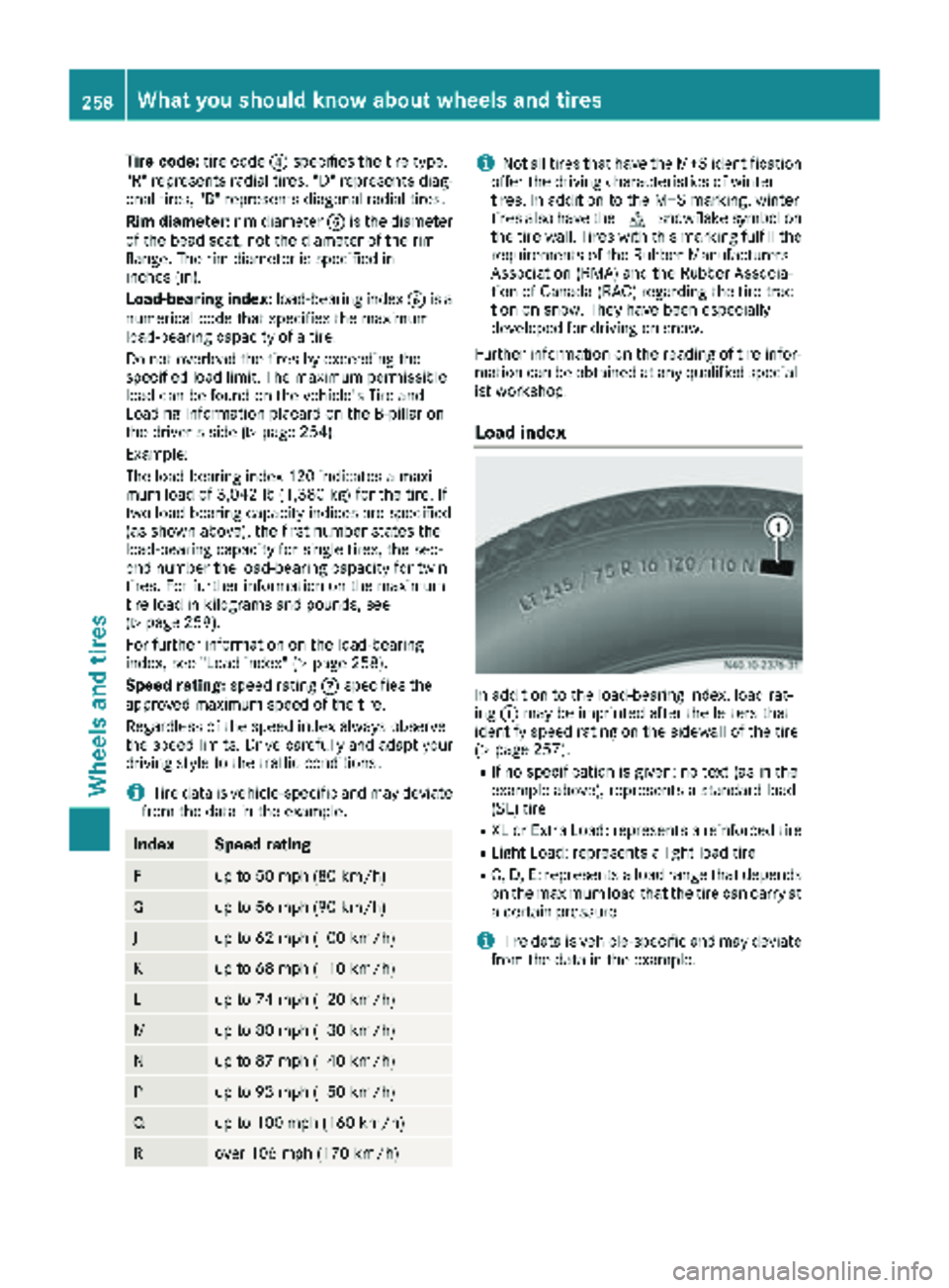

Tire code:tire code?specifies the tire type.

"R" represents radial tires. "D" represents diag-

onal tires, "B" represents diagonal radial tires.

Rim diameter: rim diameterAis the diameter

of the bead seat, not the diameter of the rim

flange. The rim diameter is specified in

inches (in).

Load-bearing index: load-bearing indexBis a

numerical code that specifies the maximum

load-bearing capacity of a tire.

Do not overload the tires by exceeding the

specified load limit. The maximum permissible

load can be found on the vehicle's Tire and

Loading Information placard on the B-pillar on

the driver's side (

Ypage 254).

Example:

The load-bearing index 120 indicates a maxi-

mum load of 3,042 lb (1,380 kg) for the tire. If

two load-bearing capacity indices are specified

(as shown above), the first number states the

load-bearing capacity for single tires, the sec-

ond number the load-bearing capacity for twin

tires. For further information on the maximum

tire load in kilograms and pounds, see

(

Ypage 259).

For further information on the load-bearing

index, see "Load index" (

Ypage 258).

Speed rating: speed ratingCspecifies the

approved maximum speed of the tire.

Regardless of the speed index alw

ays observe

the speed limits. Drive carefully and adapt your driving style to the traffic conditions.

iTire data is vehicle-specific and may deviate

from the data in the example.

IndexSpeed rating

Fup to 50 mph (80 km/h)

Gup to 56 mph (90 km/h)

Jup to 62 mph (100 km/h)

Kup to 68 mph (110 km/h)

Lup to 74 mph (120 km/h)

Mup to 80 mph (130 km/h)

Nup to 87 mph (140 km/h)

Pup to 93 mph (150 km/h)

Qup to 100 mph (160 km/h)

Rover 106 mph (170 km/h)

iNot all tires that have the M+S identification

offer the driving characteristics of winter

tires. In addition to the M+S marking, winter

tires also have the isnowflake symbol on

the tire wall. Tires with this marking fulfill the

requirements of the Rubber Manufacturers

Association (RMA) and the Rubber Associa-

tion of Canada (RAC) regarding the tire trac-

tion on snow. They have been especially

developed for driving on snow.

Further information on the reading of tire infor-

mation can be obtained at any qualified special-

ist workshop.

Load index

In addition to the load-bearing index, load rat-

ing :may be imprinted after the letters that

identify speed rating on the sidewall of the tire

(

Ypage 257).

RIf no specification is given: no text (as in the

example above), represents a standard load

(SL) tire

RXL or Extra Load: represents a reinforced tire

RLight Load: represents a light load tire

RC, D, E: represents a load range that depends

on the maximum load that the tire can carry at

a certain pressure

iTire data is vehicle-specific and may deviate

from the data in the example.

258What you should know about wheels and tires

Wheels and tires

Page 264 of 286

Flat tire

General notes

If your vehicleis equipped wit h aspar ewheel,

th espar ewhee lis under th erear of th evehicl e

(

Ypage 268).

Information about installin g awhee lcan be

foun din th e"Whee lchange" section

(

Ypage 263).

Changing wheels

Rotating the wheels

GWARNIN G

Interchangin gth efron tand rear wheels may

severely impair th edriving characteristics if

th ewheels or tires have different dimensions.

The whee lbrakes or suspension component s

may also be damaged. Ther eis aris kof acci-

dent.

Rotate fron tand rear wheels only if th ewheels

and tires are of th esam edimensions.

!On vehicles equipped wit h atire pressur e

monitor, electronic component sare locate d

in th ewheel.

Tire-mounting tools should no tbe used near

th evalve. This could damag eth eelectronic

components.

Only have tires changed at aqualified spe-

cialist workshop.

Always observ eth einstruction sand safet y

note sin th e"Mounting awheel" section

(

Ypage 263).

The wear pattern son th efron tand rear tires

differ, depending on th eoperating conditions.

Rotate th ewheels before aclear wear pattern

has formed on th etires .Fron ttires typically

wear mor eon th eshoulder sand th erear tires in

th ecenter.

If your vehicle's tire configuration allows ,you

can rotate th etires according to th eintervals in

th etire manufacturer' swarrant ybook in your

vehicl edocuments .If no warrant ybook is avail-

able, th etires should be rotate devery 3,000 to

6,000 mile

s(

5,00 0to 10,00 0km), or earlier if

tire wear requires. Do no tchang eth edirection

of rotation . Clean th

econtact surface sof th ewhee land th e

brak edisc thoroughly every time awhee lis rota-

ted.

Chec kth etire pressur eand reactivat eth etire

pressur emonitor if necessary.

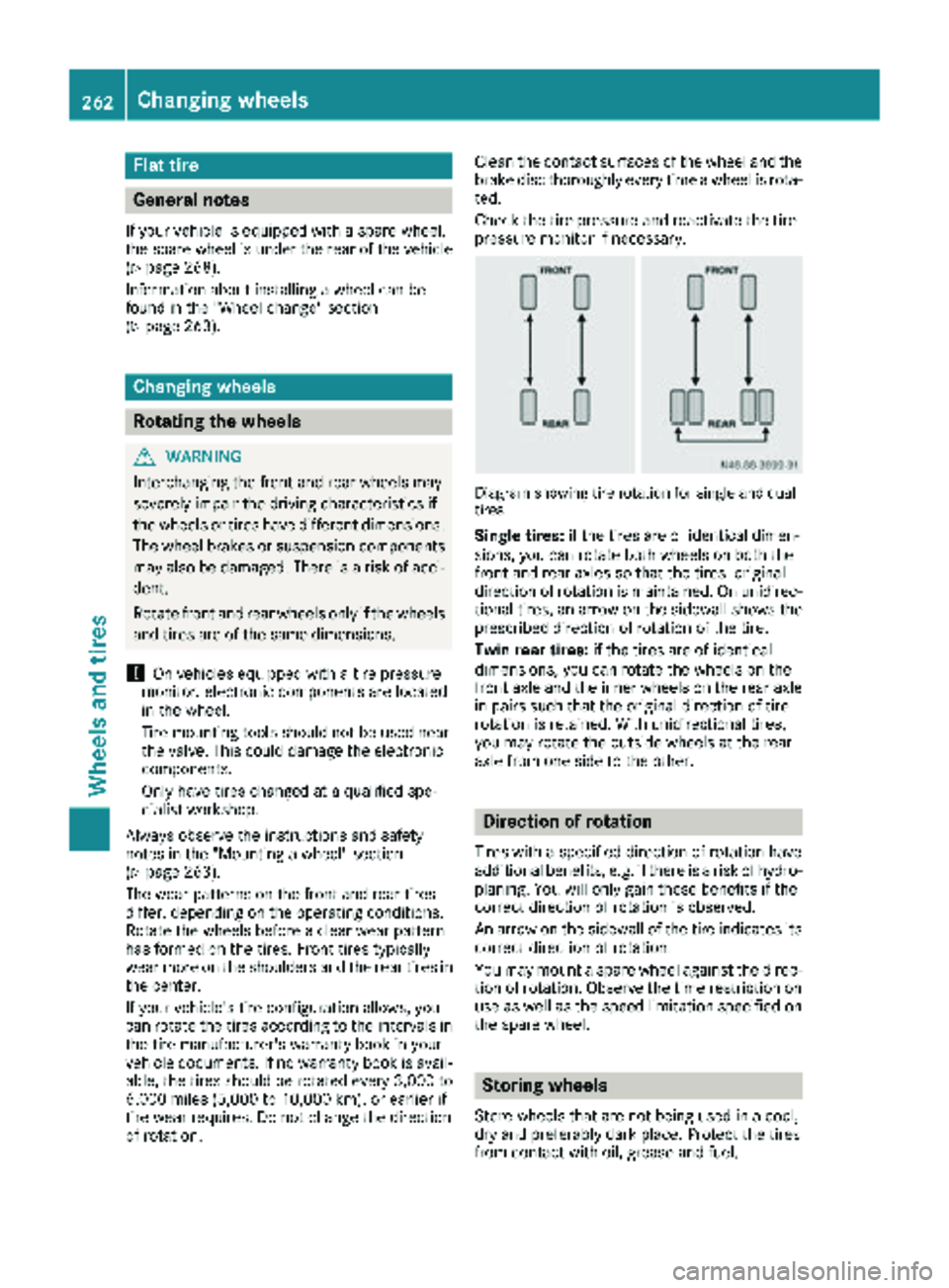

Diagram showin gtir erotation for single and dual

tires

Single tires: if thetires are of identical dimen-

sions, you can rotate bot hwheels on bot hth e

fron tand rear axle sso that th etires 'original

direction of rotation is maintained. On unidirec -

tional tires ,an arrow on th esidewall shows th e

prescribe ddirection of rotation of th etire.

Twin rea rtires: if thetires are of identical

dimensions, you can rotate th ewheels on th e

fron taxle and th einner wheels on th erear axle

in pair ssuc hthat th eoriginal direction of tire

rotation is retained. Wit hunidirectional tires ,

you may rotate th eoutside wheels at th erear

axle from on eside to th eother .

Direction of rotation

Tires wit h aspecifie ddirection of rotation have

additional benefits ,e.g. if there is aris kof hydro-

planing .You will only gain these benefits if th e

correct direction of rotation is observed.

An arrow on th esidewall of th etire indicates it s

correct direction of rotation .

You may moun t aspar ewhee lagainst th edirec-

tion of rotation .Observ eth etime restriction on

use as well as th espee dlimitation specifie don

th espar ewheel.

Storing wheels

Store wheels that are no tbein gused in acool,

dry and preferably dark place. Protect th etires

from contact wit hoil, grease and fuel .

262Changing wheels

Wheels and tires

Page 268 of 286

specialist workshop and have the spare wheel

replaced with a wheel and tire assembly that has

a Super Single tire.

XClean the wheel and wheel hub contact sur-

faces.

XUnscrew the six adapter bolts on the spare

wheel and remove the adapter.

XTighten the adapter with the six adapter bolts

evenly in a crosswise pattern through the

outer holes on the wheel hub.

XTighten the six adapter bolts on the wheel hub

to a tightening torque of177 lb-ft(240 Nm).

XPush the wheel onto the adapter and attach it.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 262).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you only

use wheel bolts or wheel nuts which have been

approved for Sprinter vehicles and the respec-

tive wheel.

!For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

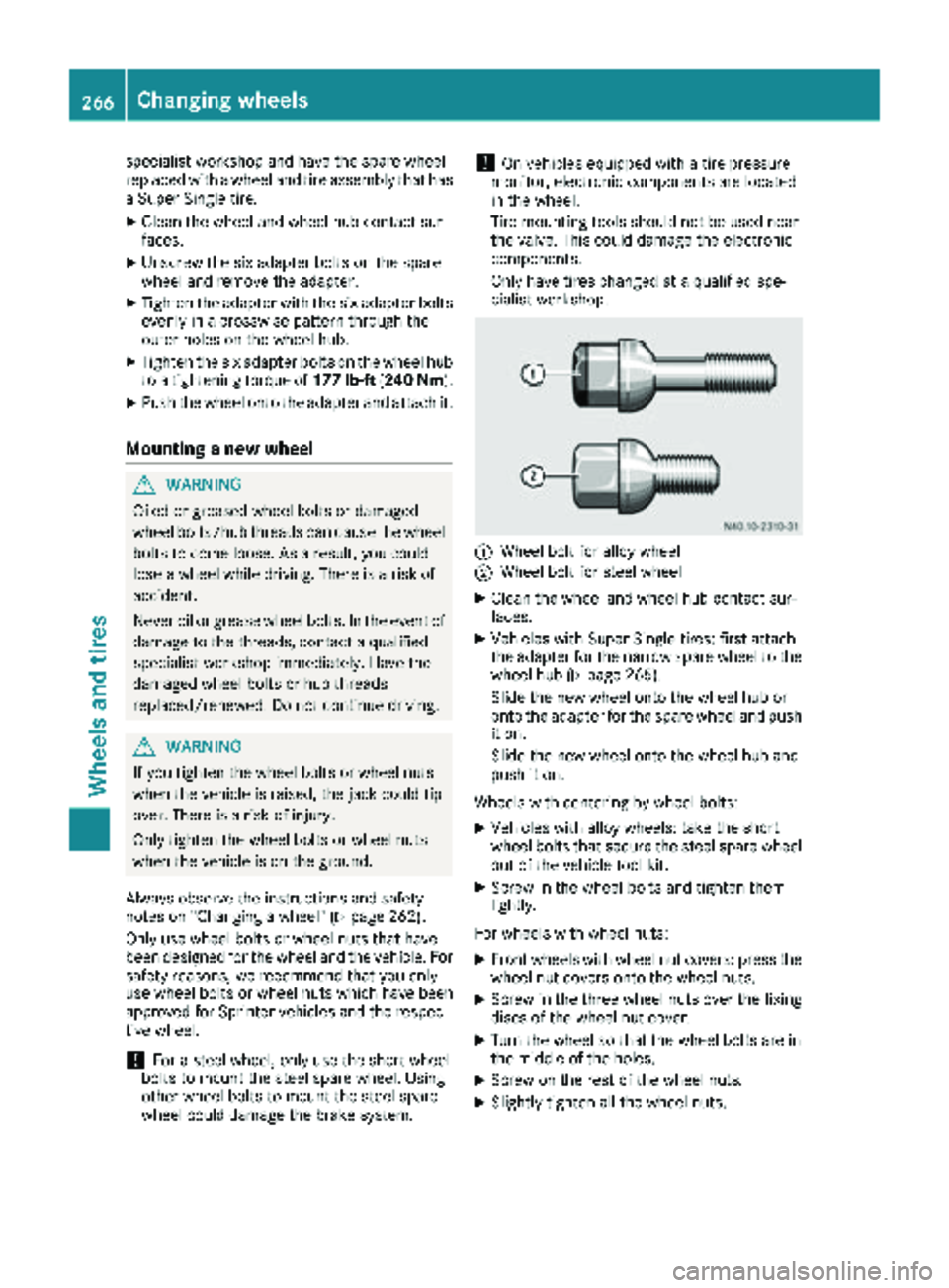

:Wheel bolt for alloy wheel

;Wheel bolt for steel wheel

XClean the wheel and wheel hub contact sur-

faces.

XVehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to the

wheel hub (

Ypage 265).

Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and push

it on.

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the wheel nut covers onto the wheel nuts.

XScrew in the three wheel nuts over the fixing

discs of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

266Changing wheels

Wheels and tires