clock MERCEDES-BENZ SPRINTER 2019 MY19 with 7” screen

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2019Pages: 354, PDF Size: 6.15 MB

Page 195 of 354

Information about Mercedes PRO

When you log in with a user account tothe

Mercedes PRO por tal,th en services and of fers

from Mercedes-Benz Vans will be available to

yo u.

Av ailability is countr y-dependent. You can check

th eav ailability of Mercedes PRO in your country

at thefo llowing page: http://www.me rcedes.pro

Fo r more information on Mercedes PRO contact

an authorized Mercedes-Benz Center or visit the

Mercedes PRO por tal. Information about Mercedes PRO connect

Mercedes PRO connect pr ovides thefo llowing

services:

R Accident and breakdown mana gement

(breakdown assi stance call button or auto‐

matic accident or breakd own de tection)

Use the breakdown assis tance call button in

th eov erhead cont rol panel tomake a call to

th e Mercedes-Benz Cus tomer Center

(/ page 171).

Yo u can also select a menu ent ryinthe multi‐

media sy stem (/ page171).

R Emergency Call Sy stem

Use the0053 button (SOS button) in the

ove rhead cont rol panel tomake a call tothe

Mercedes-Benz emer gency call center

(/ page 171).

Mercedes PRO connect accident and breakdown

management and the Mercedes-Benz emer gency

call center are available foryo u around the clock

fo rth e use of the services.

Please no tethat Mercedes PRO connect is a

Mercedes-Benz service. In emer gencies, al ways

call the national emer gency services firs t using

th est andard national emer gency service phone

numbers. In emergencies, you can also use the

Emergency Call Sy stem (/ page216).

The following conditions must be met touse

Mercedes PRO connect services in theve hicle:

R You ha veaccess toa GSM network

R The contract partner's GSM network co ver‐

age is available in there spective region

R The ignition is switched on, so that vehicle

data can be transfer red automatically Calling the Mercedes-Benz Cus

tomer Center

using the multimedia sy stem

Multimedia sy stem:

4 © 5

Phone 5

g #

Call Mercedes PRO connect.

Then, you can select a service and be connec ted

to a specialist at the Mercedes-Benz Cus tomer

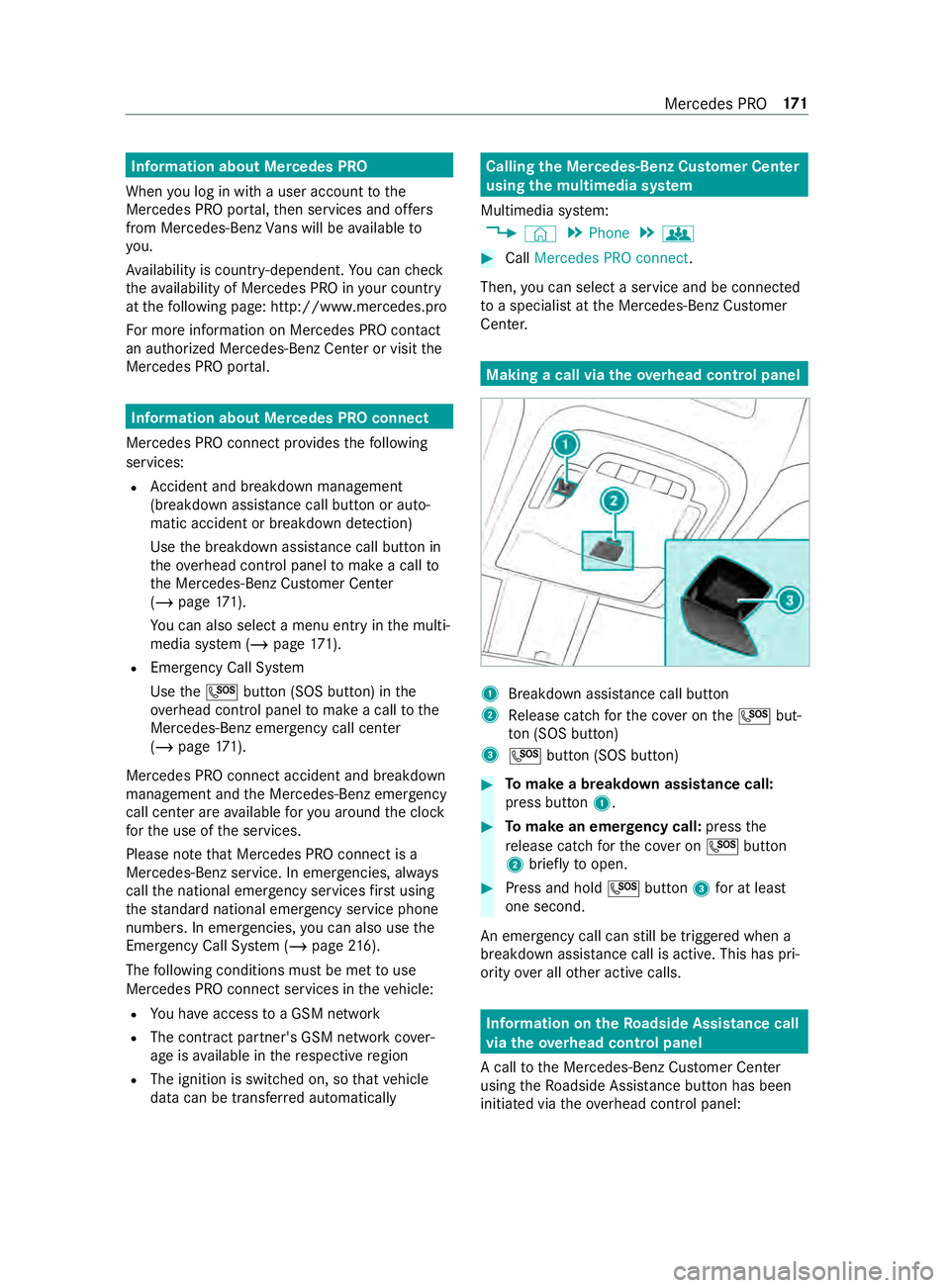

Center. Making a call via the

overhead control panel 1

Breakdown assis tance call button

2 Release cat chforth e co ver on the0053 but‐

to n (SOS button)

3 0053 button (SOS button) #

Tomake a breakdown assistance call:

press button 1. #

Tomake an eme rgency call: pressthe

re lease cat chforth e co ver on 0053 button

2 brief lyto open. #

Press and hold 0053button 3for at least

one second.

An emer gency call can still be triggered when a

breakdown assis tance call is acti ve. This has pri‐

ority over all other active calls. Information on

theRo adside Assistance call

via the overhead control panel

A call tothe Mercedes-Benz Cus tomer Center

using theRo adside Assis tance button has been

initia ted via theove rhead cont rol panel: Mercedes PRO

171

Page 224 of 354

#

Tomo vetherack ra ils:unsc rew star knobs

7 coun ter-clockwise until they are slightly

loose. #

Slide rack rail2 along roof rail1 tothe

desired position. #

Screw star knobs 7tight clo ckwise. #

Check that thera ck rail is seated securely.

Moving the sliders &

WARNING Risk of inju rydue toinade‐

qu ately secured loads

If th e slider of the interior roof rack system is

not engaged proper ly,th e load may come

loose, fall down and injure people, for

ins tance when they enter or load and unload

th e cargo compartment. #

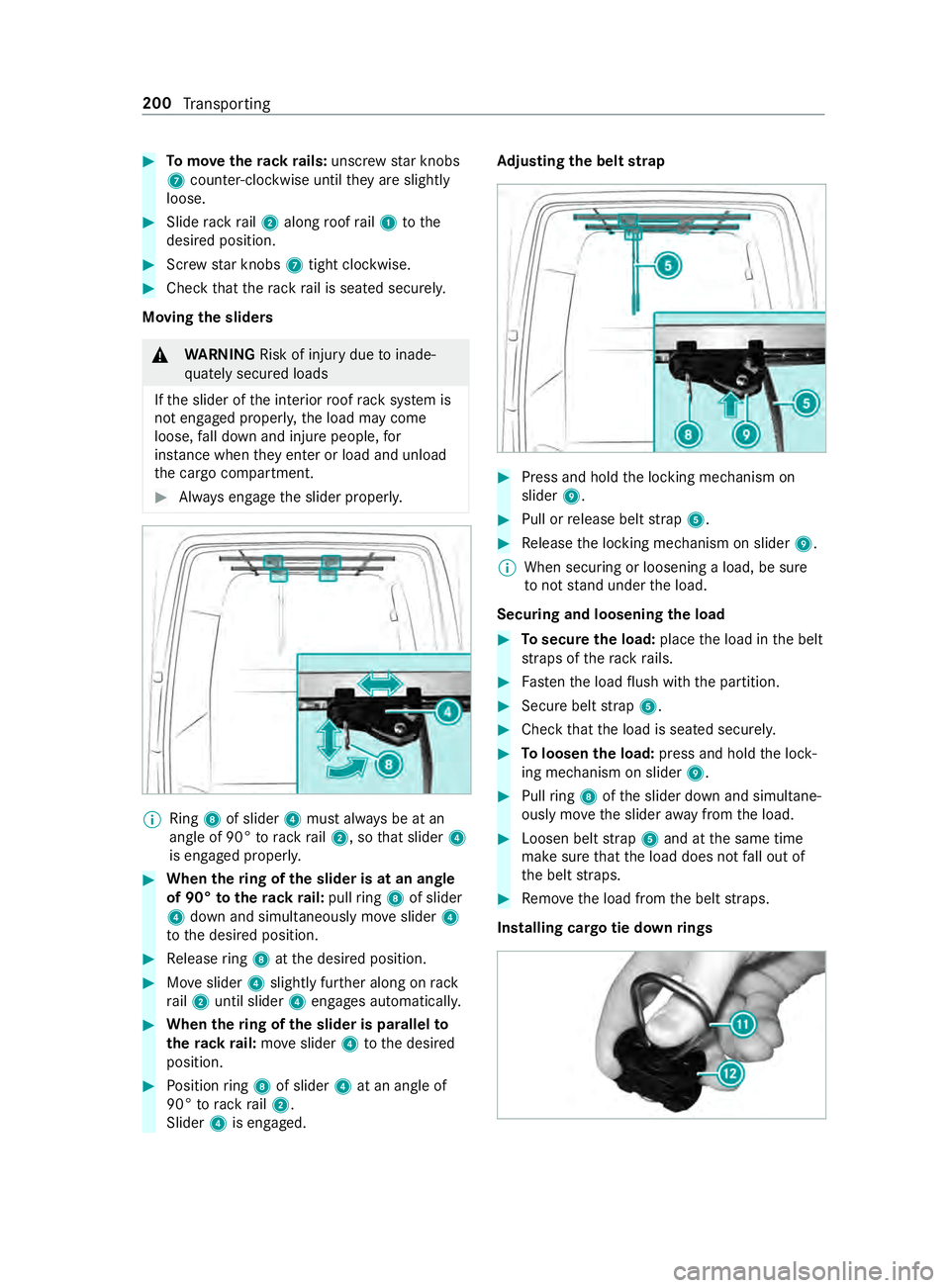

Always engage the slider properly. %

Ring

8of slider 4must alw ays be at an

angle of 90° torack rail2, so that slider 4

is engaged proper ly. #

When thering of the slider is at an angle

of 90° totherack ra il:pull ring 8 of slider

4 down and simul taneously mo veslider 4

to the desired position. #

Release ring 8 atthe desired position. #

Moveslider 4slightly fur ther along on rack

ra il2 until slider 4engages automaticall y. #

When thering of the slider is pa rallel to

th erack ra il:mo veslider 4tothe desired

position. #

Position ring 8 of slider 4at an angle of

90° torack rail2.

Slider 4is engaged. Ad

justing the belt strap #

Press and hold the locking mechanism on

slider 9. #

Pull or release belt stra p5. #

Release the locking mechanism on slider 9.

% When securing or loosening a load, be sure

to not stand under the load.

Securing and loosening the load #

Tosecure the load: placethe load in the belt

st ra ps of thera ck rails. #

Fasten the load flush with the partition. #

Secure belt stra p5. #

Check that the load is seated securel y. #

Toloosen the load: press and hold the lock‐

ing mechanism on slider 9. #

Pull ring 8 ofthe slider down and simultane‐

ously mo vethe slider away from the load. #

Loosen belt stra p5 and at the same time

make sure that the load does not fall out of

th e belt stra ps. #

Remo vethe load from the belt stra ps.

Installing cargo tie down rings 200

Transporting

Page 230 of 354

&

WARNING Risk offire and injury from

engine oil

If engine oil comes into con tact wi thhot com‐

ponent parts in the engine compartment, it

may ignite. #

Make sure that no engine oil is spilled

next tothefiller opening. #

Allow the engine tocool off and thor‐

oughly clean the engine oil from compo‐

nent parts before starting theve hicle. *

NO

TEEngine damage due toincor rect oil

fi lter, incor rect oil or additi ve #

Do not use engine oil or an oil filter with

specifications deviating from those

re qu ired forth e prescribed service

inter vals.

Mercedes-Benz recommends using original or

te sted replacement and service parts. #

Do not change the engine oil or oil filter

in order toset change inter vals longer

th an those prescribed. #

Do not use any additive. #

Follow the instructions on the service

inter val display forch anging the engine

oil. *

NO

TEDama gecaused byadding too

much engine oil To

o much engine oil can damage the engine

or the catalytic con verter. #

Have excess engine oil remo ved at a

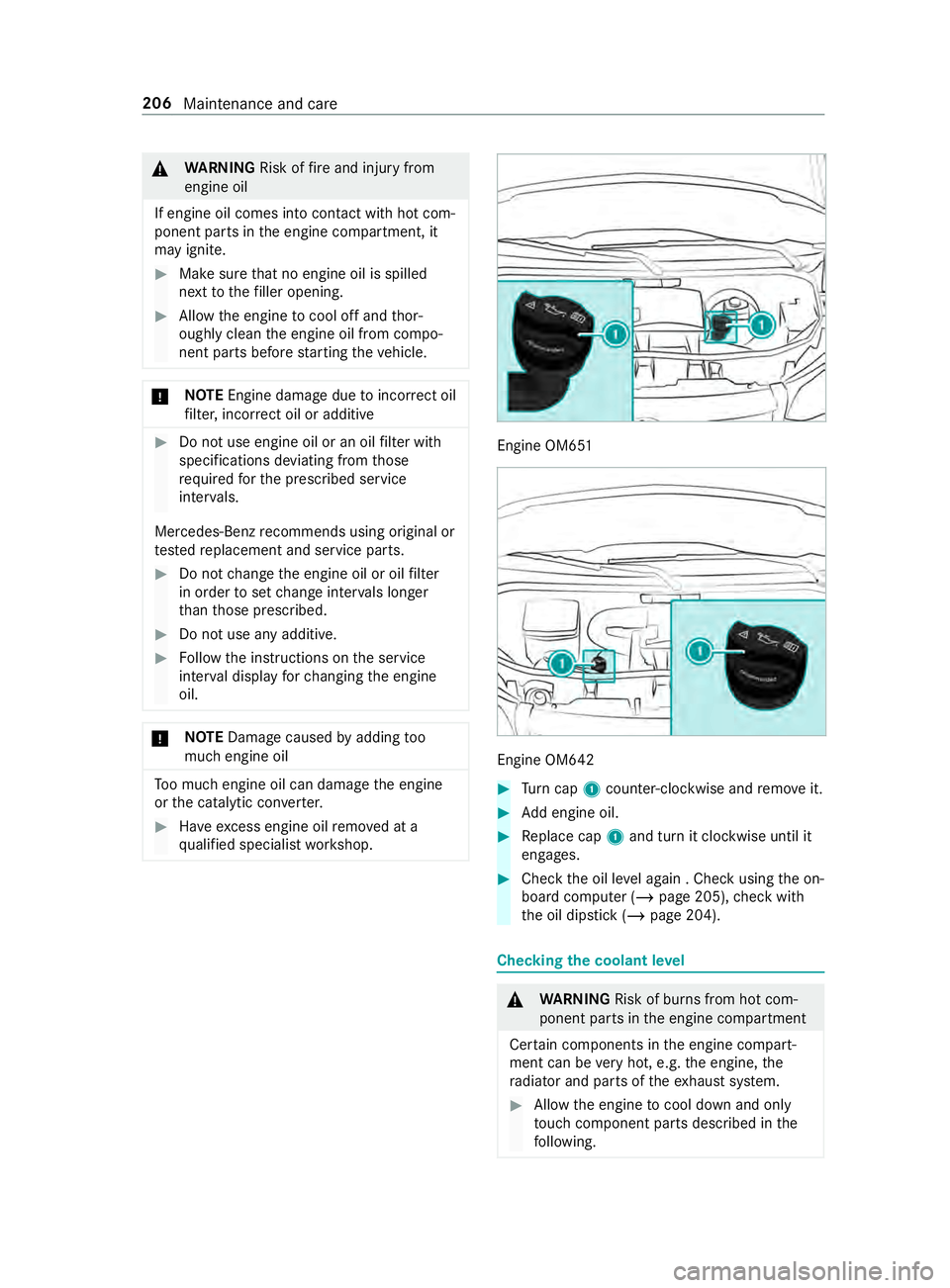

qu alified specialist workshop. Engine OM651

Engine OM642

#

Turn cap 1counter-clockwise and remo veit. #

Add engine oil. #

Replace cap 1and turn it clockwise until it

engages. #

Check the oil le vel again . Check using the on-

board computer (/ page 205),check with

th e oil dipstick (/ page 204). Checking

the coolant le vel &

WARNING Risk of bu rns from hot com‐

ponent parts in the engine compartment

Cer tain components in the engine compart‐

ment can be very hot, e.g. the engine, the

ra diator and parts of theex haust sy stem. #

Allow the engine tocool down and only

to uch component parts desc ribed in the

fo llowing. 206

Maintenance and care

Page 231 of 354

If

yo u ha vetocar ryout any workinthe engine

compartment, touch only thefo llowing compo‐

nents:

R Hood

R Engine oil filler opening cap

R Washer fluid reser voir cap

R Coolant expansion reser voir cap &

WARNING Danger of bu rns when open‐

ing the hood

If yo u open the hood when the engine has

ove rheated or during a fire inthe engine com‐

partment, you could come into con tact wi th

hot gases or other escaping operating fluids. #

Before opening the hood, allow the

engine tocool down. #

Intheeve nt of a fire inthe engine com‐

partment, keep the hood closed and call

th efire service. &

WARNING Risk of scalding from hot

coolant

The engine cooling sy stem is pressurized,

particular lywhen the engine is warm. If you

open the cap, you could be scalded byhot

coolant spr aying out. #

Let the engine cool down before open‐

ing the cap. #

When opening the cap, wear pr otective

gl ove s and saf etygl asses. #

Open the cap slowly torelease pres‐

sure. Allow

the engine and the engine cooling sy stem

to cool down before checking the coolant le vel or

re filling coolant.

* NO

TEPaint wo rkdamage due tocoolant If coolant

gets on painted sur faces, the paint‐

wo rkcan be damaged. #

Add coolant carefully. #

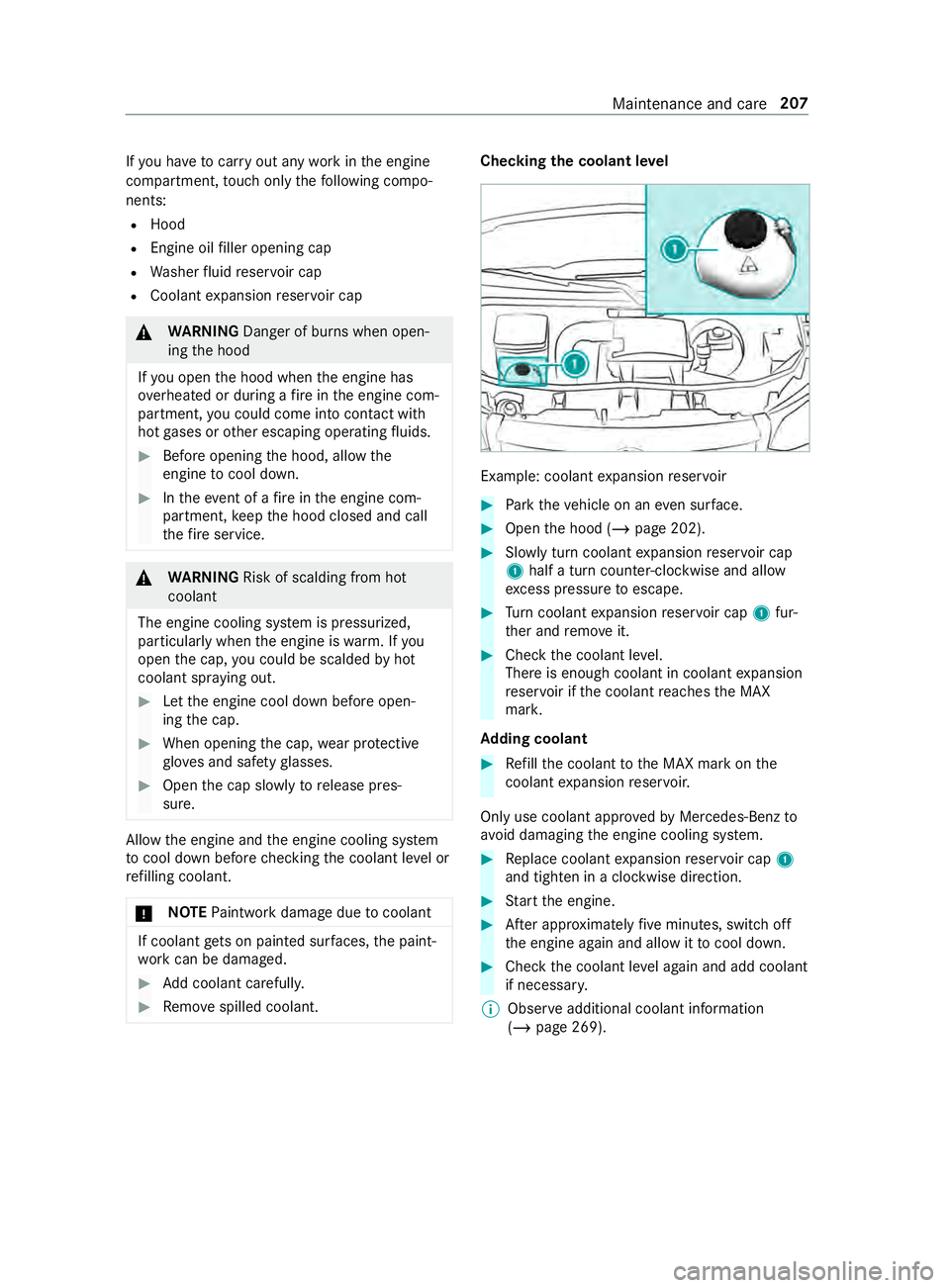

Remo vespilled coolant. Checking

the coolant le vel Example: coolant

expansion reser voir #

Park theve hicle on an even sur face. #

Open the hood (/ page 202). #

Slowly turn coolant expansion reser voir cap

1 half a turn coun ter-clockwise and allow

exc ess pressure toescape. #

Turn coolant expansion reser voir cap 1fur‐

th er and remo veit. #

Check the coolant le vel.

There is enough coolant in coolant expansion

re ser voir if the coolant reaches the MAX

mar k.

Ad ding coolant #

Refill th e coolant tothe MAX mark on the

coolant expansion reser voir.

Only use coolant appr oved byMercedes-Benz to

avo id damaging the engine cooling sy stem. #

Replace coolant expansion reser voir cap 1

and tigh ten in a clo ckwise direction. #

Start the engine. #

After appro ximately five minutes, switch off

th e engine again and allow it tocool down. #

Che ckthe coolant le vel again and add coolant

if necessar y.

% Obser

veadditional coolant information

(/ page 269). Main

tenance and care 207

Page 245 of 354

R

vehicles with a gasoline engine: only per‐

fo rm starting assis tance when the engine and

ex haust sy stem are cold #

Vehicles with a battery main switch: check

whe ther the battery main switch is switched

on (/ page114). #

Secu retheve hicle using the parking brake. #

Vehicles with automatic transmission:

shift the transmission toposition 005D. #

Switch off the ignition and all electrical con‐

sumers. #

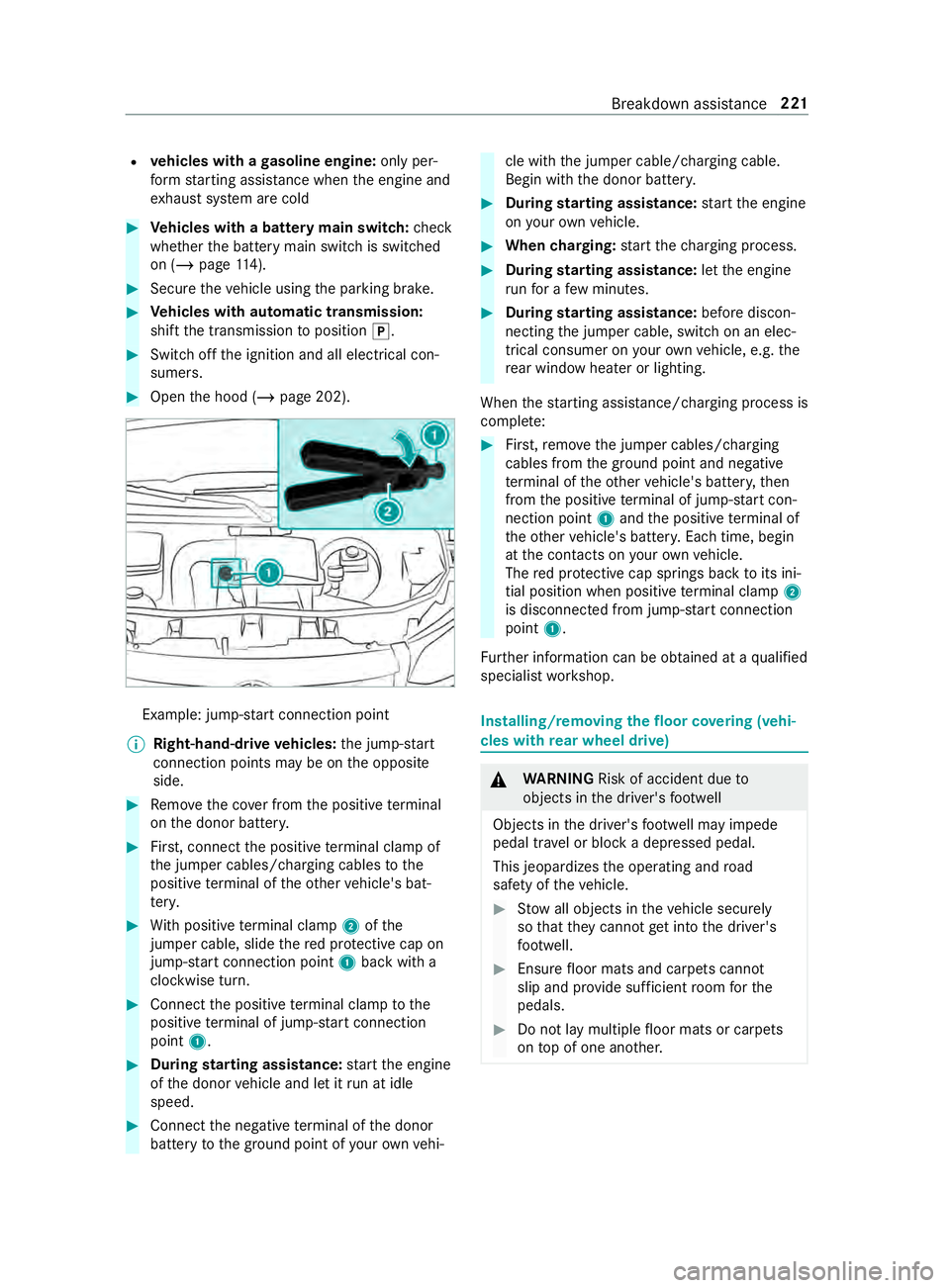

Open the hood (/ page 202). Example: jump-s

tart connection point

% Right-hand-drive

vehicles: the jump-s tart

connection points may be on the opposite

side. #

Remo vethe co ver from the positive term inal

on the donor batter y. #

First, connect the positive term inal clamp of

th e jumper cables/charging cables tothe

positive term inal of theot her vehicle's bat‐

te ry. #

With positive term inal clamp 2ofthe

jumper cable, slide there d pr otective cap on

jump-s tart connection point 1back with a

clockwise turn. #

Connect the positive term inal clamp tothe

positive term inal of jump-s tart connection

point 1. #

During starting assistance: start the engine

of the donor vehicle and let it run at idle

speed. #

Connect the negative term inal of the donor

battery tothe ground point of your ow nve hi‐ cle with

the jumper cable/charging cable.

Begin with the donor batter y. #

During starting assistance: start the engine

on your ow nve hicle. #

When charging: start thech arging process. #

During starting assistance: letthe engine

ru nfo r a few minutes. #

During starting assistance: before discon‐

necting the jumper cable, switch on an elec‐

trical consumer on your ow nve hicle, e.g. the

re ar wind owheater or lighting.

When thest arting assis tance/charging process is

comple te: #

First,re mo vethe jumper cables/charging

cables from the ground point and negative

te rm inal of theot her vehicle's batter y,then

from the positive term inal of jump-s tart con‐

nection point 1and the positive term inal of

th eot her vehicle's batter y.Each time, begin

at the contacts on your ow nve hicle.

The red pr otective cap springs back toits ini‐

tial position when positive term inal clamp 2

is disconnected from jump-s tart connection

point 1.

Fu rther information can be obtained at a qualified

specialist workshop. Installing/removing

thefloor co vering (vehi‐

cles with rear wheel drive) &

WARNING Risk of accident due to

objects in the driver's foot we ll

Objects in the driver's foot we ll may impede

pedal tr avel or block a depressed pedal.

This jeopardizes the operating and road

saf ety of theve hicle. #

Stow all objects in theve hicle securely

so that they cannot getinto the driver's

fo ot we ll. #

Ensure floor mats and carpets cannot

slip and pr ovide suf ficient room forthe

pedals. #

Do not lay multiple floor mats or carpets

on top of one ano ther. Breakdown assis

tance 221

Page 251 of 354

#

Obser vethe no tes on permissible towing

me thods (/ page 224). #

The propeller shafts tothe drive axles must

be remo ved if the maximum permissible tow‐

ing dis tance is exceeded. #

Vehicles with automatic transmission:

shift the automatic transmission toposition

005C. #

Release the parking brake. #

Switch off the ignition. Loading

theve hicle for transport #

Obser vethe no tes on towing away

( / page 225) (/ page 226). #

Connect theto w bar totheto wing eyeto load

th eve hicle. #

Vehicles with automatic transmission:

shift the automatic transmission toposition

005C.

% Ve

hicles with automatic transmission: in

th eeve nt of damage tothe electrics, the

automatic transmission may be loc ked in

position 005D.Toshift toposition 005C, provide

th e on-board electrical sy stem with po wer

( / page 219). #

Load theve hicle onto the transpor ter. #

Vehicles with automatic transmission:

shift the automatic transmission toposition

005D. #

Use the parking brake tosecure theve hicle

against rolling away. #

Only secure theve hicle bythe wheels.

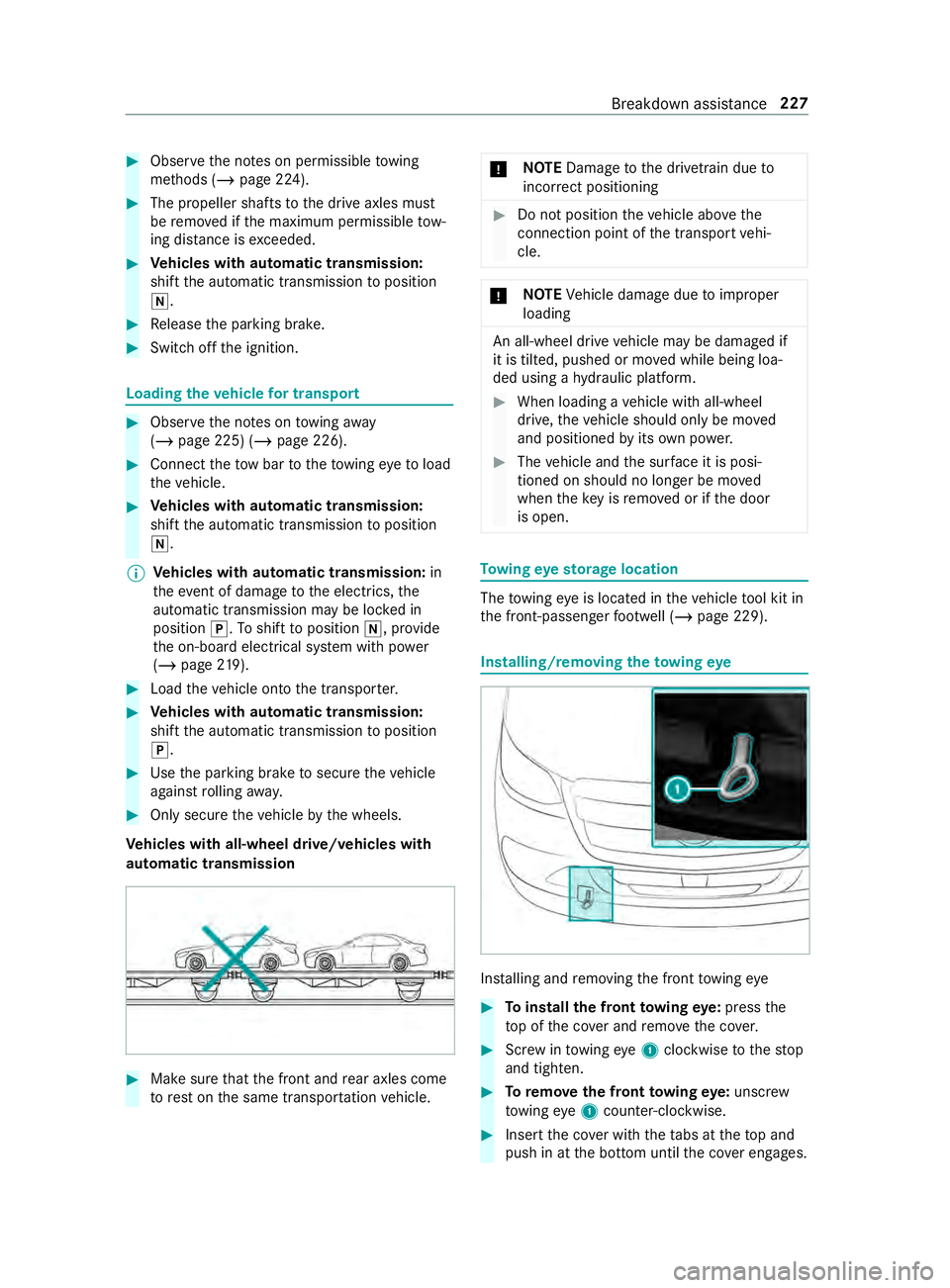

Ve hicles with all-wheel drive/vehicles with

automatic transmission #

Make sure that the front and rear axles come

to rest on the same transpor tation vehicle. *

NO

TEDama getothe driv etra in due to

incor rect positioning #

Do not position theve hicle abo vethe

connection point of the transport vehi‐

cle. *

NO

TEVehicle damage due toimproper

loading An all-wheel drive

vehicle may be damaged if

it is tilted, pushed or mo ved while being loa‐

ded using a hydraulic platform. #

When loading a vehicle with all-wheel

drive, theve hicle should only be mo ved

and positioned byits own po wer. #

The vehicle and the sur face it is posi‐

tioned on should no longer be mo ved

when theke y is remo ved or if the door

is open. To

wing eyesto rage location The

towing eye is located in theve hicle tool kit in

th e front-passen gerfo ot we ll (/ page 229). Installing/removing

theto wing eye Ins

talling and removing the front towing eye #

Toinstall the front towing eye: press the

to p of the co ver and remo vethe co ver. #

Screw intowing eye1clockwise tothestop

and tighten. #

Toremo vethe front towing eye: unsc rew

to wing eye1 counter-clockwise. #

Insert the co ver with theta bs at theto p and

push in at the bottom until the co ver engages. Breakdown assi

stance 227

Page 254 of 354

#

Remo vetheru bber mat from the front-

passenger foot we ll. #

Tounlo ck:turn thequ ick- re lease fastener 1

counter-clockwise toposition 0047. #

Slightly raise and pull out the co ver.

Inserting and locking the co ver #

Slide in the co ver and press it down wards. #

Press down thequ ick- re lease fastener 1

until it engages. #

Tolock: turnthequ ick- re lease fastener 1

clockwise toposition 0048. Re

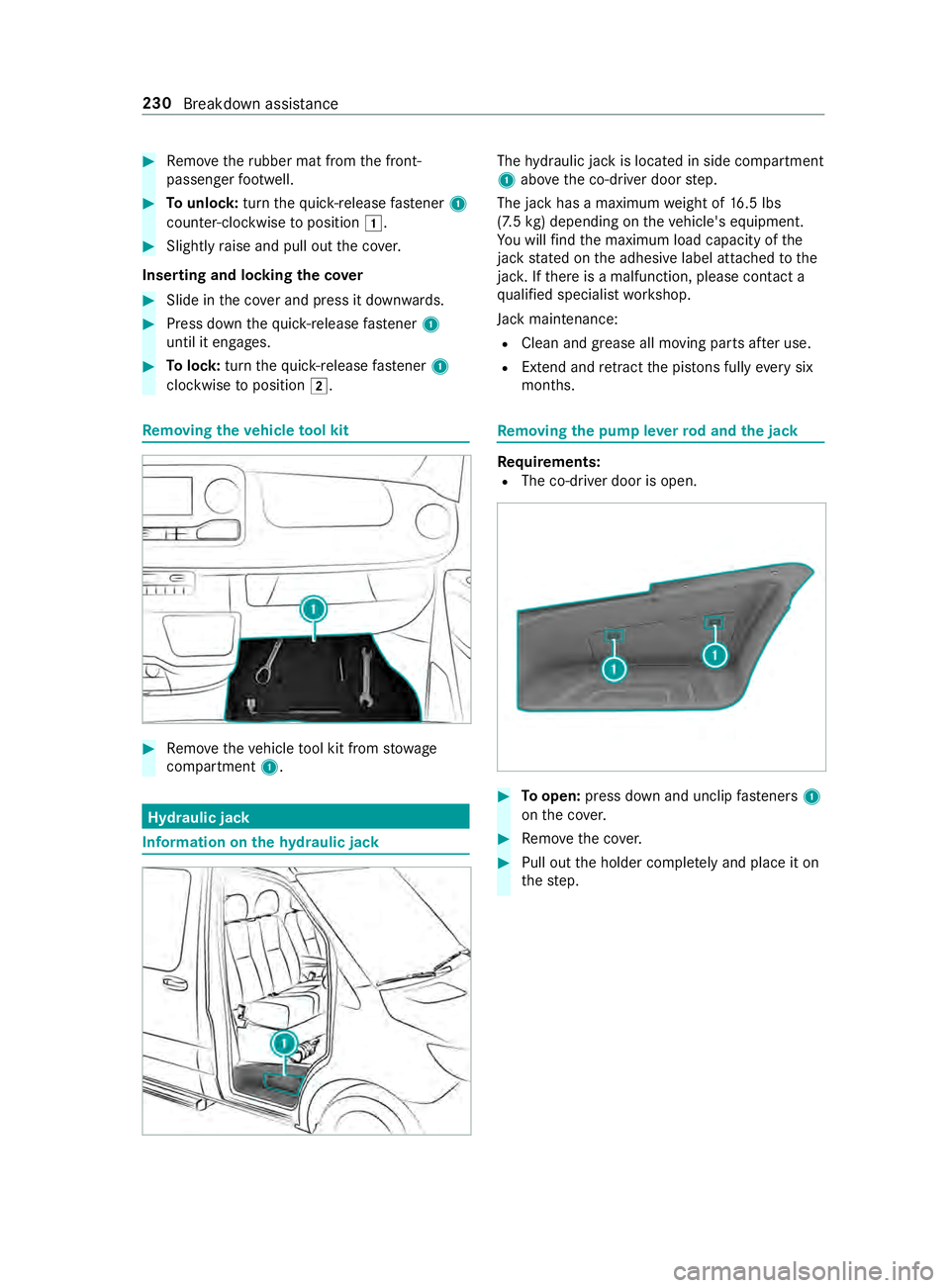

moving the vehicle tool kit #

Remo vetheve hicle tool kit from stowage

compartment 1. Hyd

raulic jack Information on

thehy draulic jack The

hydraulic jack is located in side compartment

1 abo vethe co-driver door step.

The jack has a maximum weight of 16.5 lbs

(7.5 kg) depe nding on theve hicle's equipment.

Yo u will find the maximum load capacity of the

jack stated on the adhesive label attached tothe

jac k.Ifth ere is a malfunction, please contact a

qu alified specialist workshop.

Jack maintenance:

R Clean and grease all moving parts af ter use.

R Extend and retract the pis tons ful lyeve rysix

months. Re

moving the pump le verro d and the jack Re

quirements:

R The co-driver door is open. #

Toopen: press down and unclip fasteners 1

on the co ver. #

Remo vethe co ver. #

Pull out the holder comple tely and place it on

th estep. 230

Breakdown assis tance

Page 276 of 354

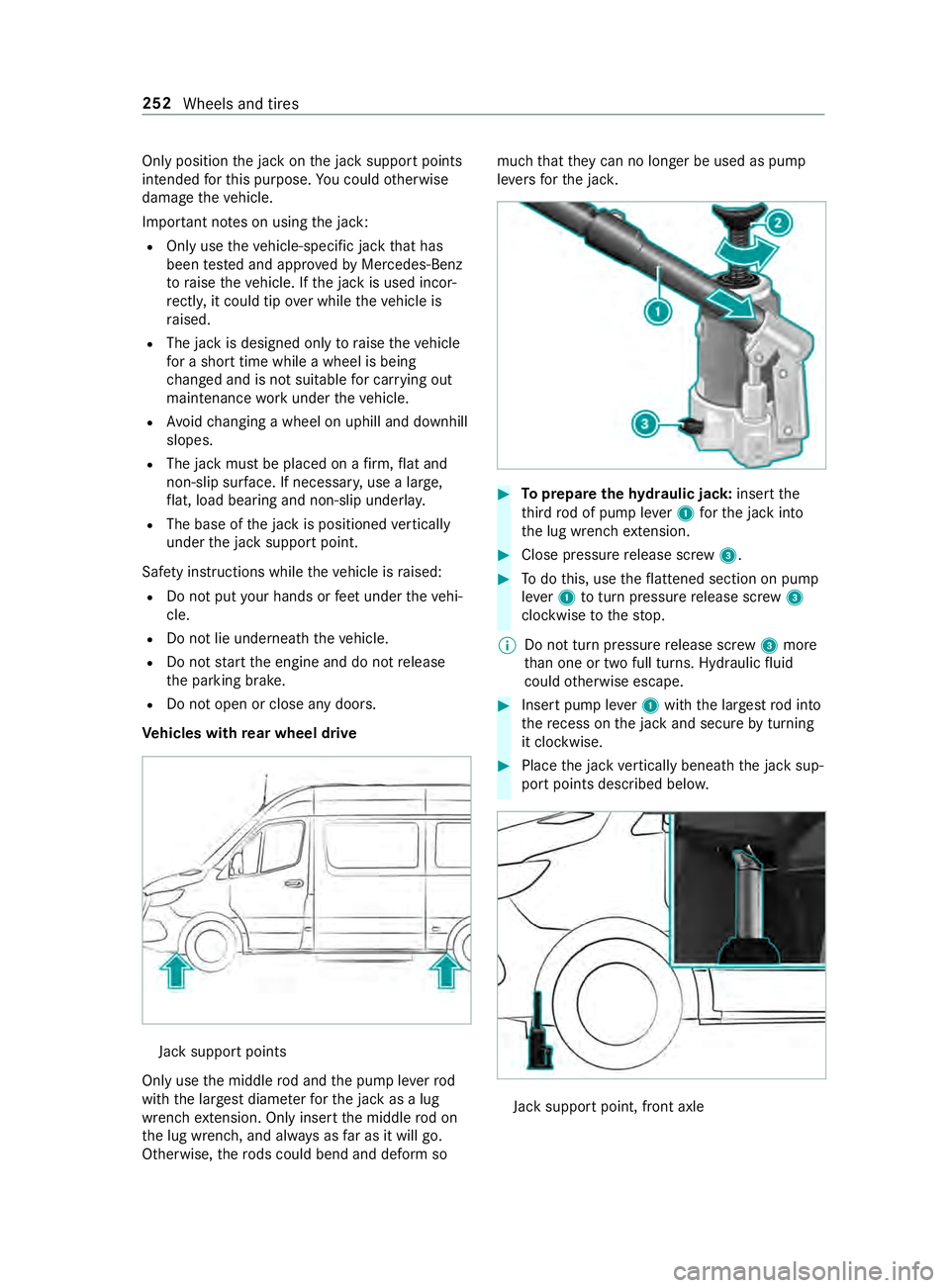

Only position

the jack on the jack support points

intended forth is purpose. You could otherwise

damage theve hicle.

Impor tant no tes on using the jack:

R Only use theve hicle-specific jack that has

been tested and appr ovedby Mercedes-Benz

to raise theve hicle. If the jack is used incor‐

re ctly, it could tip over while theve hicle is

ra ised.

R The jack is designed only toraise theve hicle

fo r a short time while a wheel is being

ch anged and is not suitable for car rying out

maintenance workunder theve hicle.

R Avoid changing a wheel on uphill and downhill

slopes.

R The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

fl at, load bearing and non-slip unde rlay.

R The base of the jack is positioned vertically

under the jack support point.

Saf ety instructions while theve hicle is raised:

R Do not put your hands or feet under theve hi‐

cle.

R Do not lie underneath theve hicle.

R Do not start the engine and do not release

th e parking brake.

R Do not open or close any doors.

Ve hicles with rear wheel drive Jack

support points

Only use the middle rod and the pump le verrod

with the largest diame terfo rth e jack as a lug

wrench extension. Only inse rtthe middle rod on

th e lug wrench, and alw ays as far as it will go.

Otherwise, thero ds could bend and deform so much

that they can no longer be used as pu mp

le ve rs forth e jac k. #

Toprepare the hydraulic jack: insertthe

th ird rod of pump le ver1 forth e jack into

th e lug wrench extension. #

Close pressure release scr ew3. #

Todo this, use theflattened section on pump

le ve r1 toturn pressure release scr ew3

clockwise tothestop.

% Do not turn pressure

release scr ew3 more

th an one or two full turns. Hydraulic fluid

could otherwise escape. #

Insert pump le ver1 with the largest rod into

th ere cess on the jack and secure byturning

it clo ckwise. #

Place the jack vertically beneath the jack sup‐

port points described belo w. Jack support point, front axle252

Wheels and tires

Page 277 of 354

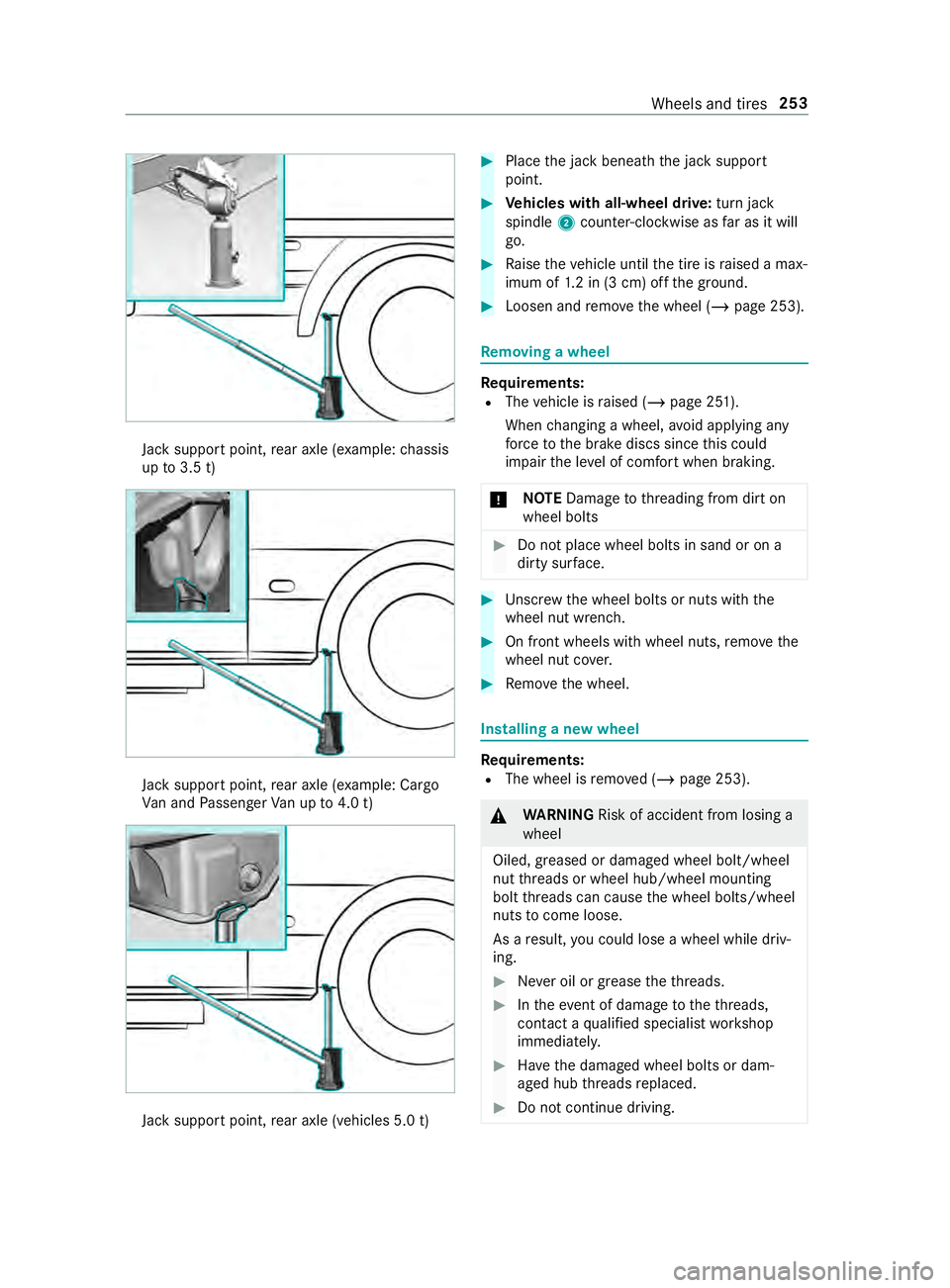

Jack support point,

rear axle (e xamp le:chassis

up to3.5 t) Jack

support point, rear axle (e xamp le: Cargo

Va n and Passenger Van up to4.0 t) Jack

support point, rear axle (vehicles 5.0 t) #

Place the jack beneath the jack support

point. #

Vehicles with all-wheel drive: turn jack

spindle 2counter-clockwise as far as it will

go. #

Raise theve hicle until the tire is raised a max‐

imum of 1.2 in (3 cm) off the ground. #

Loosen and remo vethe wheel (/ page 253). Re

moving a wheel Re

quirements:

R The vehicle is raised (/ page 251).

When changing a wheel, avoid applying any

fo rc eto the brake discs since this could

impair the le vel of com fort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on a

dirty sur face. #

Unscr ewthe wheel bolts or nuts with the

wheel nut wrench. #

On front wheels with wheel nuts, remo vethe

wheel nut co ver. #

Remo vethe wheel. Installing a new wheel

Re

quirements:

R The wheel is remo ved (/ page 253). &

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can cause the wheel bolts/wheel

nuts tocome loose.

As a result, you could lose a wheel while driv‐

ing. #

Never oil or grease theth re ads. #

Intheeve nt of damage totheth re ads,

con tact a qualified specialist workshop

immediatel y. #

Have the damaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do not continue driving. Wheels and tires

253

Page 279 of 354

#

Place the jack toone side. #

Pull thero d with the smallest diame ter off the

pump le ver.

The shor tened pu mpleve r ser ves as a lug

wrench extension. #

Starting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench. #

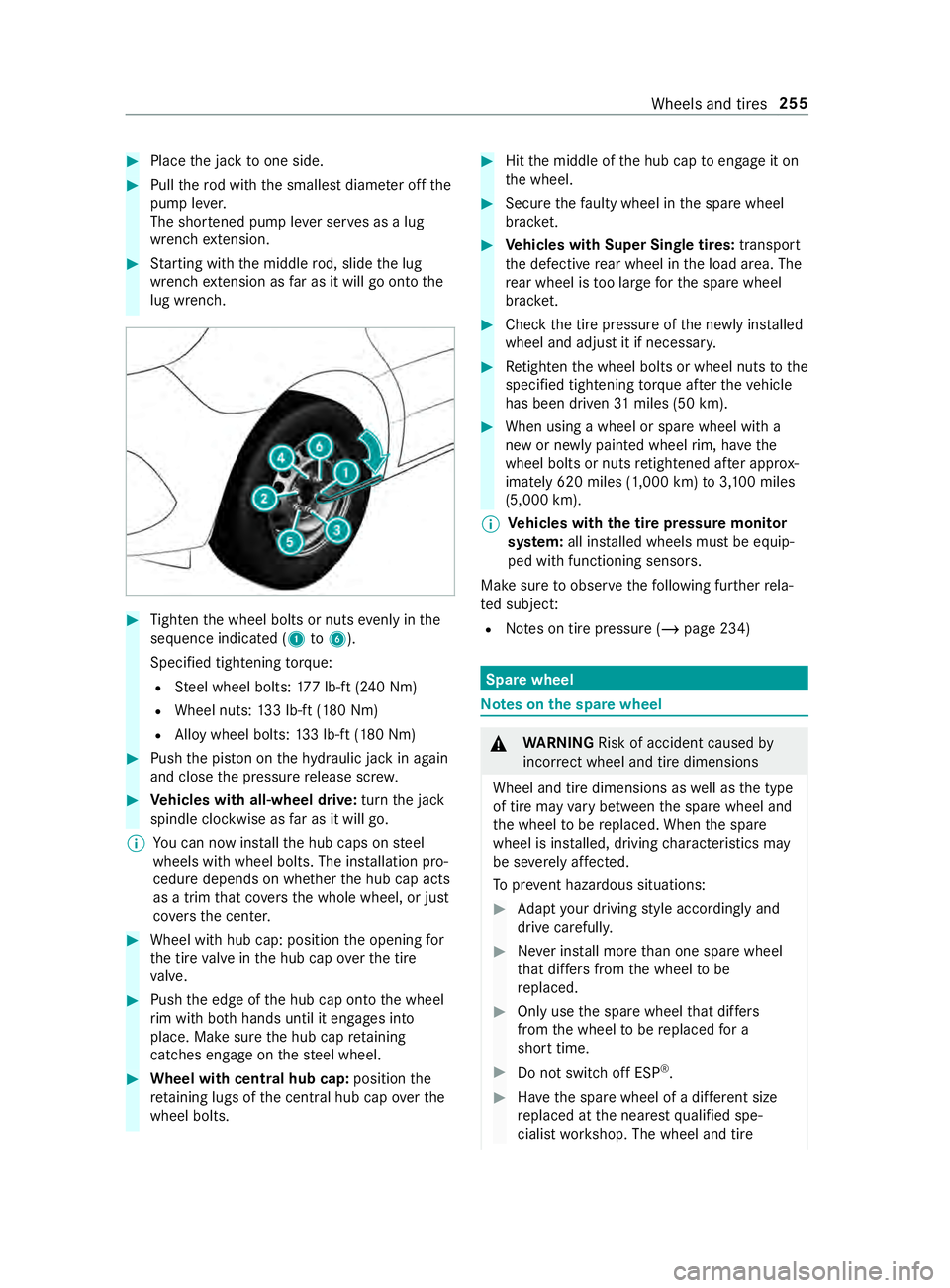

Tighten the wheel bolts or nuts evenly in the

sequence indicated (1 to6 ).

Specified tightening torque:

R Steel wheel bolts: 177 lb-ft (240 Nm)

R Wheel nuts: 133 lb-f t(180 Nm)

R Alloy wheel bolts: 133 lb-f t(180 Nm) #

Push the pis ton on thehy draulic jack in again

and close the pressure release scr ew. #

Vehicles with all-wheel drive: turnthe jack

spindle clockwise as far as it will go.

% Yo

u can now ins tallth e hub caps on steel

wheels with wheel bolts. The ins tallation pro‐

cedure depends on whe ther the hub cap acts

as a trim that co vers the whole wheel, or just

co vers the center. #

Wheel with hub cap: position the opening for

th e tire valve in the hub cap overth e tire

va lve. #

Push the edge of the hub cap onto the wheel

ri m with bo thhands until it engages into

place. Make sure the hub cap retaining

cat ches engage on thesteel wheel. #

Wheel with central hub cap: positionthe

re taining lugs of the cent ral hub cap overthe

wheel bolts. #

Hitthe middle of the hub cap toengage it on

th e wheel. #

Secure thefa ulty wheel in the spare wheel

brac ket. #

Vehicles with Super Single tires: transport

th e defective rear wheel in the load area. The

re ar wheel is too lar geforth e spare wheel

brac ket. #

Check the tire pressure of the newly ins talled

wheel and adjust it if necessar y. #

Retighten the wheel bolts or wheel nuts tothe

specified tightening torque af terth eve hicle

has been driven 31miles (50 km). #

When using a wheel or spare wheel with a

new or newly painted wheel rim, ha vethe

wheel bolts or nuts retightened af ter appro x‐

ima tely 620 miles (1,000 km) to3,10 0 miles

(5,000 km).

% Ve

hicles with the tire pressure monitor

sy stem: all ins talled wheels must be equip‐

ped with functioning sensors.

Make sure toobser vethefo llowing fur ther rela‐

te d subject:

R Notes on tire pressure (/ page 234) Spare wheel

Note

s onthe spa rewheel &

WARNING Risk of accident caused by

incor rect wheel and tire dimensions

Wheel and tire dimensions as well as the type

of tire may vary between the spare wheel and

th e wheel tobe replaced. When the spare

wheel is ins talled, driving characteristics may

be se verely af fected.

To prev ent hazardous situations: #

Adapt your driving style according lyand

drive carefull y. #

Never ins tall more than one spare wheel

th at dif fers from the wheel tobe

re placed. #

Only use the spare wheel that dif fers

from the wheel tobe replaced for a

short time. #

Do not switch off ESP ®

. #

Have the spare wheel of a dif fere nt size

re placed at the nearest qualified spe‐

cialist workshop. The wheel and tire Wheels and tires

255