automatic transmission MERCEDES-BENZ SPRINTER 2019 MY19 with 7” screen

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2019Pages: 354, PDF Size: 6.15 MB

Page 275 of 354

Preparing

theve hicle for a wheel change Re

quirements:

R The tire-change tool kit is available.

R The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Appl yth e parking brake. #

Movethe front wheels tothest ra ight-ahead

position. #

Vehicles with automatic transmission:

shift the transmission toposition 005D. #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

Take theve hicle tool kit from thefo ot we ll on

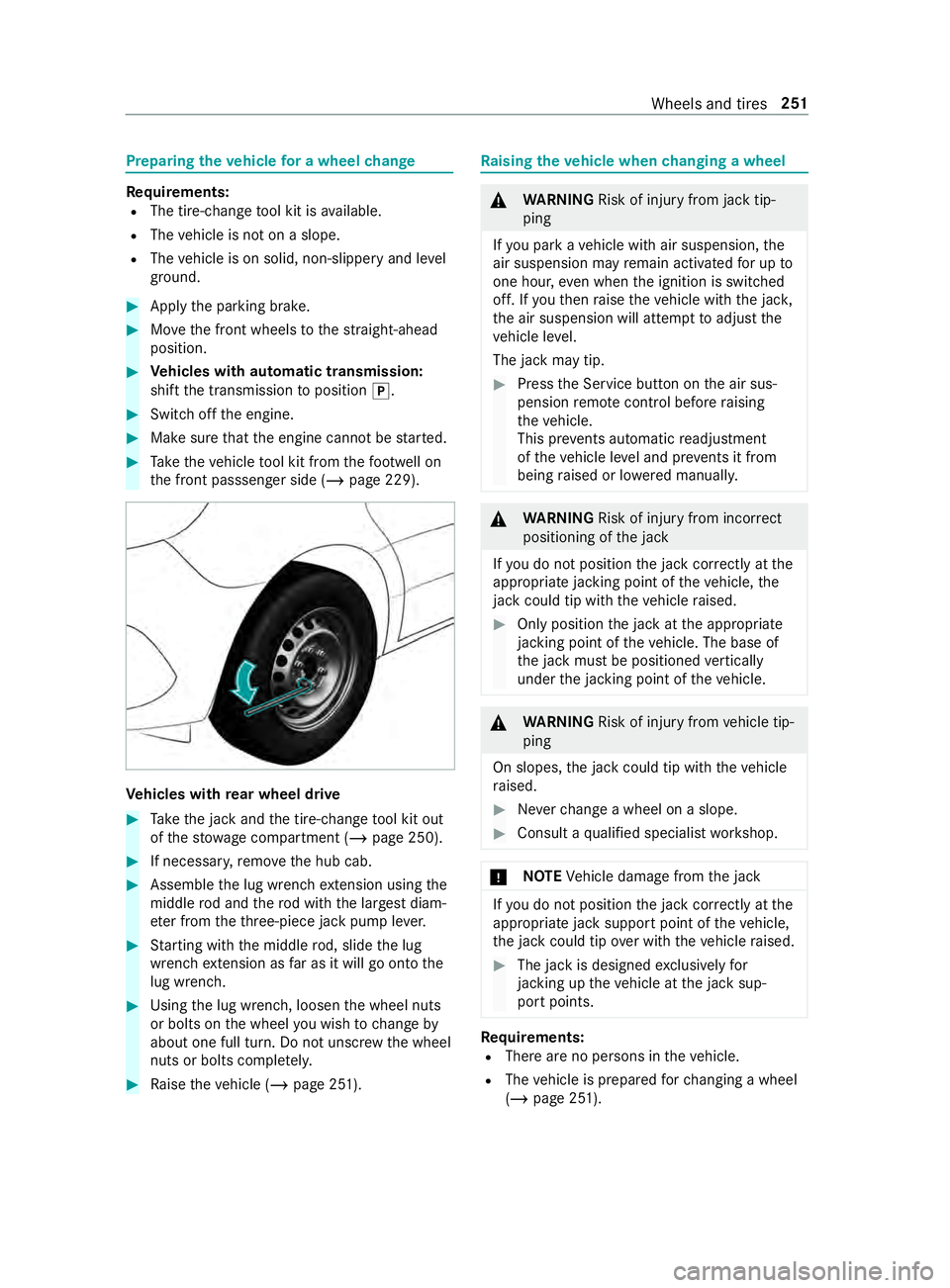

th e front passsenger side (/ page 229).Ve

hicles with rear wheel drive #

Take the jack and the tire-change tool kit out

of thestow age compartment (/ page 250).#

If necessar y,remo vethe hub cab. #

Assemble the lug wrench extension using the

middle rod and thero d with the lar gest diam‐

et er from theth re e-piece jack pump le ver. #

Starting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench. #

Using the lug wrench, loosen the wheel nuts

or bolts on the wheel you wish tochange by

about one full turn. Do not unscr ewthe wheel

nuts or bolts comple tely. #

Raise theve hicle (/ page 251). Ra

ising theve hicle when changing a wheel &

WARNING Risk of inju ryfrom jack tip‐

ping

If yo u park a vehicle with air suspension, the

air suspension may remain activated for up to

one hour, even when the ignition is switched

off. If youth en raise theve hicle with the jac k,

th e air suspension will attem pttoadjust the

ve hicle le vel.

The jack may tip. #

Press the Service button on the air sus‐

pension remo tecontrol before raising

th eve hicle.

This pr events au tomatic readjustment

of theve hicle le vel and pr events it from

being raised or lo wered manually. &

WARNING Risk of inju ryfrom incor rect

positioning of the jack

If yo u do not position the jack cor rectly at the

appropriate jacking point of theve hicle, the

jack could tip wi th theve hicle raised. #

Only position the jack at the appropriate

jacking point of theve hicle. The base of

th e jack must be positioned vertically

under the jacking point of theve hicle. &

WARNING Risk of inju ryfrom vehicle tip‐

ping

On slopes, the jack could tip with theve hicle

ra ised. #

Neverch ange a wheel on a slope. #

Consult a qualified specialist workshop. *

NO

TEVehicle damage from the jack If

yo u do not position the jack cor rectly at the

appropriate jack support point of theve hicle,

th e jack could tip over with theve hicle raised. #

The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points. Re

quirements:

R There are no persons in theve hicle.

R The vehicle is prepared forch anging a wheel

(/ page 251). Wheels and tires

251

Page 302 of 354

Display messages

Possible causes/consequences and 0050 0050Solutions

De tection of a restra int sy stem malfunction:

R The 0075 restra int sy stem warning lamp does not light up when

th e ignition is switched on.

R The 0075 restra int sy stem warning lamp lights up continuously

or repeatedly during a journe y. #

Visit a qualified specialist workshop immediately.

0075 SRS Malfunction Service

Required *T

herestra int sy stem is malfunctioning . &

WARNING Risk of inju rydue tomalfunctions in there stra int

sy stem

If th ere stra int sy stem is malfunctioning, restra int sy stem com‐

ponents may be triggered unintentionally or may not deploy as

intended during an accident. This may af fect the Emer gency Ten‐

sioning Devices or airbags, forex ample. #

Have there stra int sy stem checked and repaired immedi‐

ately at a qualified specialist workshop. De

tection of a restra int sy stem malfunction:

R The 0075 restra int sy stem warning lamp does not light up when

th e ignition is switched on.

R The 0075 restra int sy stem warning lamp lights up continuously

or repeatedly during a journe y. #

Visit a qualified specialist workshop immediately.

0024 Parking Brake Inopera-

tive *A

malfunction has occur red in the sy stem, the parking brake is inop‐

erative. &

WARNING Risk of an accident due toa brake sy stem mal‐

function

If th e brake sy stem is malfunctioning, braking characteristics

may be impaired. #

Drive on carefull y. #

Have the brake sy stem checked immediately at a qualified

specialist workshop. #

Park theve hicle on a le vel sur face only and secu reit against

ro lling away. #

Vehicles with automatic transmission: shiftthe transmission

to position 005D. #

Have the brake sy stem checked at a qualified specialist work‐

shop immediatel y.

0024 Incline Too Steep See

Operator's Manual *T

he on-board electrical sy stem voltage is low or a malfunction has

occur red in the sy stem; the holding forc e may not be suf ficient for

th e incline. 278

Displaymessa ges and warning and indicator lamps

Page 303 of 354

Display messages

Possible causes/consequences and 0050 0050Solutions &

WARNING Risk of accident if the electrical parking brake

has insuf ficient holding force

If th e electrical parking brake does not ha vesuf ficient holding

fo rc e on a steep incline, theve hicle may rollaw ay. #

Park theve hicle on a le vel sur face only and secu reit

against rolling away. #

Shift the automatic transmission toposition 005D. Obser

vethe no tes on parking theve hicle (/ page132).

0024

Parking Brake See Oper-

ator's Manual *T

he on-board voltage is low or a malfunction has occur red in the

sy stem; the closing forc e may not be suf ficient forth e incline. &

WARNING Risk of an accident due toa brake sy stem mal‐

function

If th e brake sy stem is malfunctioning, braking characteristics

may be impaired. #

Drive on carefull y. #

Have the brake sy stem checked immediately at a qualified

specialist workshop. #

Park theve hicle on a le vel sur face only and secu reit against

ro lling away. #

Vehicles with automatic transmission: shiftthe transmission

to position 005D. #

Have the brake sy stem checked at a qualified specialist work‐

shop immediatel y.

Check Brake Pads See

Operator's Manual *T

he brake pads ha vereached their wear limit. &

WARNING Risk of accident due torestricted braking po wer

When the brake pads ha vereached their wear limit, the braking

po we r may be restricted. #

Drive on carefully. #

Have the brake sy stem checked immediately at a qualified

specialist workshop. #

Visit a qualified specialist workshop.

004D

Check Brake Fluid Level *T

here is not enough brake fluid in the brake fluid reser voir. &

WARNING Risk of an accident due tolow brake fluid le vel

If th e brake fluid le vel is too lo w,the braking ef fect and the brak‐

ing characteristics may be impaired. #

Pull over and stop theve hicle safely as soon as possible,

paying attention toroad and traf fic conditions. Do not con‐

tinue driving under any circums tances. #

Consult a qualified specialist workshop. #

Do not add brake fluid. Display messages and

warning and indicator lamps 279

Page 318 of 354

Display messages

Possible causes/consequences and 0050 0050Solutions

To Engage Transmiss.

Position R First Depress

the Brake #

Shift the transmission toposition 005E.

Air Conditioning Malfunc-

tion See Operator's Man-

ual *T

he climate contro l system is functional, subject totemp orary

re strictions. The air quantity and fresh air supply are controlled

automaticall y. #

Have the climate cont rol sy stem checked at a qualified specialist

wo rkshop.

Auxiliary Battery Mal-

function *T

he bac kup battery forth e transmission is not being charge d. #

Visit a qualified specialist workshop. #

Until then, alw ays shift the transmission toposition 005Dmanually

before you swit choff the engine. #

Before leaving theve hicle, apply the parking brake.

Reversing Not Possible

Service Required *T

he transmission is malfunctioning. It is no longer possible toshift

to reve rsege ar. #

Visit a qualified specialist workshop.

Transmission Malfunc-

tion Stop *T

he transmission is malfunctioning. The transmission automatically

shifts toposition 005C. #

Stop in a safe location immediately. #

Shift the transmission toposition 005D. #

Consult a qualified specialist workshop.

0072

Vehicle Operational

Switch the Ignition Off

Before Exiting *Y

ou are about toexitth eve hicle while it is ready tostart. #

When youex itth eve hicle, switch off the ignition and take the

ke y with you. #

Ifyo u do not exitth eve hicle, switch off the electrical consum‐

ers, e.g. the seat heating. Otherwise, the12 ‑Volt‑battery may

discha rge and theve hicle can only be star ted using a boos ter

battery (jump start).

Service Required Do Not

Shift Gears Visit Dealer *T

he transmission is malfunctioning. The transmission position can

no longer be changed. #

Ifth e transmission is in position 005B, visit aqualified specialist

wo rkshop, without changing the transmission position. #

For all other transmission positions, park theve hicle in a safe

location. #

Inform a qualified specialist workshop or the breakdown service.

Only Shift to 'P' when

Vehicle is Stationary *

The transmission can only be brought into position 005Difth eve hicle

is at a standstill.

N Permanently Active

Risk of Rolling Away *W

hile theve hicle is rolling or driving, the transmission was shif ted

to position 005C. #

Tostop, press the brake pedal and, when theve hicle is at a

st andstill, shift the transmission toposition 005D. #

Tocontinue driving, shi ftthe transmission toposition 005Bor005E. 294

Display messages and warning and indicator lamps

Page 338 of 354

Emer

gency

Assis tance overview .......................... .16

Fir st-aid kit (so ftsided) ..................... 216

Saf etyve st ........................................ 216

Wa rning lamp .................................... 216

Emer gency braking

Elect ric pa rking brake ...................... .136

Manual parking brake ....................... 13 4

Emer gency call sy stem

Au tomatic emergency call ............... .217

Information ....................................... 216

Manual emer gency call ..................... 217

Overview ...........................................2 16

Emer gency engine start ..................... .228

Emer gency operation mode

St arting theve hicle .......................... 104

Emer gency Tensioning Devices

Ac tivation ........................................... 29

En gaging drive position (automatic

transmission) ........................................ 11 7

Engaging neut ral (automatic trans‐

mission) ................................................ .116

Engaging reve rsege ar .......................... 11 6

Engaging/disengaging LOW RANGE ...11 9

Engine Engine number ................................ .261

Jump-s tarting .................................... 219

Pa rking (s tart/s top button) .............. 13 2

Problems .......................................... 127

St arting (in emer gency operation

mode) ............................................... 104

St arting (s tart/s top button) .............1 04

Engine data Showing ............................................ 181

Engine electronics (no tes) ...................2 60

Engine number ...................................... 261

Engine oil .............................................. 205

Ad ditive ............................................ 267

Checking the oil le vel (on-board

computer) ........................................ 205

Checking the oil le vel with a dip‐

st ick ................................................ .204

Filling capacity ................................. 268

To pping up .......................................2 05

Engine output Notes on changes .............................. .23

ENR (electronic le vel control) ..............121

Fu nction ............................................ 121

Lo we ring theve hicle .........................1 23

Manually inflating air bello ws............ 124 Problems ..........................................

12 5

Ra ising theve hicle ............................1 23

Entering characters

Fu nction/no tes ................................ 178

Setting theke yboard ........................ 17 9

Using the media display ...................1 79

Environmental pr otection

No tes .................................................. 18

ESC (Electronic Stability Control)

see ESP ®

(Electronic Stability Prog ram)

ESP ®

Crosswind Assist .............................. 13 8

Tr ailer stabilization .......................... .139

ESP ®

(Electronic Stability Prog ram) ...13 8

Ac tivating/deactivating .................... 13 8

Fu nction/no tes ................................ 13 8

Exhaust emission moni toring .............1 07

Exterior lighting Care .................................................. 212

Exterior lighting see Lights F

Fa tigue de tection

see ATTENTION ASSIST

Favo rites

Ad ding .............................................. 17 7

Calling up ........................................ .177

Del eting ............................................ 178

Moving ..............................................1 78

Overview .......................................... 17 7

Re naming ......................................... 178

Firs t-aid kit (soft sided) ........................216

Flat tire .................................................. 218

Changing a wheel ............................ .251

No tes ................................................ 218

Floor co vering

Ins talling/ removing (s tarter bat‐

te ry ) .................................................. 221

Floor mat .................................................78

Fore ign trip

Instructions ...................................... 107

symmetrical low beam ....................... 79

Fr ee software ........................................ .27

Fr equencies

Mobile phone .................................. .260

Tw o-w ayradio .................................. 260

Fr ont airbag (driver, front passenger) .. 32314

Index