MINI Clubman 2011 Owner's Manual (Mini Connected)

Manufacturer: MINI, Model Year: 2011, Model line: Clubman, Model: MINI Clubman 2011Pages: 256, PDF Size: 3.75 MB

Page 211 of 256

Replacing componentsMOBILITY

209

4.Unhook the wiper blade toward the wind-

shield.

5. Pull the wiper blade past the wiper arm

toward the top.

6. Insert the new wiper blade.

7. Press into position until you hear it engage.

8. Fold down the wiper arm.

To avoid damage, make sure that the

wiper arms are against the windshield

before you open the hood. <

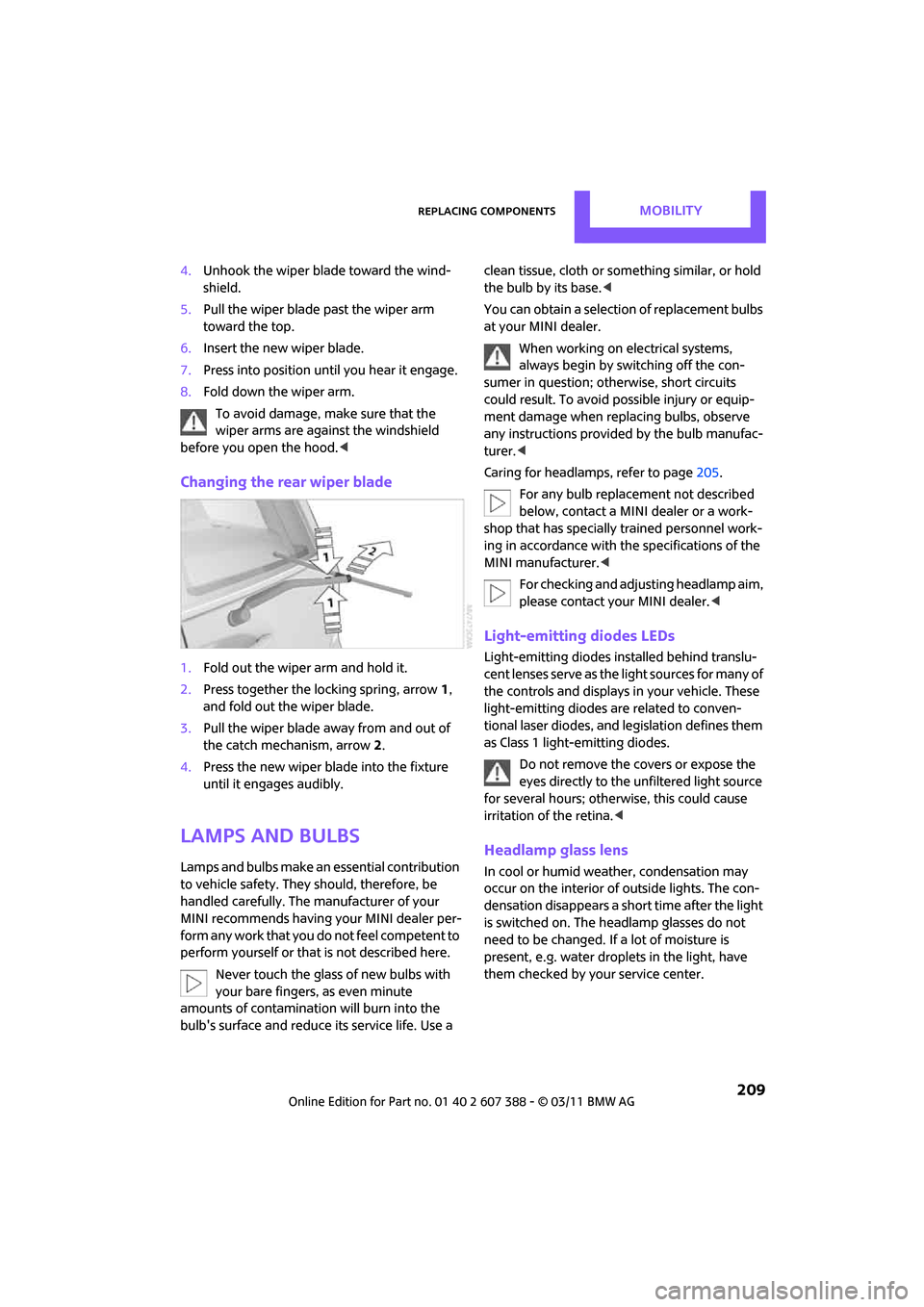

Changing the rear wiper blade

1.Fold out the wiper arm and hold it.

2. Press together the locking spring, arrow 1,

and fold out the wiper blade.

3. Pull the wiper blade away from and out of

the catch mechanism, arrow 2.

4. Press the new wiper blade into the fixture

until it engages audibly.

Lamps and bulbs

Lamps and bulbs make an essential contribution

to vehicle safety. They should, therefore, be

handled carefully. The manufacturer of your

MINI recommends having your MINI dealer per-

form any work that you do not feel competent to

perform yourself or that is not described here.

Never touch the glass of new bulbs with

your bare fingers, as even minute

amounts of contaminatio n will burn into the

bulb's surface and reduce its service life. Use a clean tissue, cloth or some

thing similar, or hold

the bulb by its base.<

You can obtain a selectio n of replacement bulbs

at your MINI dealer.

When working on electrical systems,

always begin by switching off the con-

sumer in question; otherwise, short circuits

could result. To avoid possible injury or equip-

ment damage when replacing bulbs, observe

any instructions provided by the bulb manufac-

turer. <

Caring for headlamps, refer to page 205.

For any bulb replacement not described

below, contact a MINI dealer or a work-

shop that has specially trained personnel work-

ing in accordance with th e specifications of the

MINI manufacturer. <

For checking and adjusting headlamp aim,

please contact your MINI dealer. <

Light-emitting diodes LEDs

Light-emitting diodes installed behind translu-

cent lenses serve as the light sources for many of

the controls and displays in your vehicle. These

light-emitting diodes are related to conven-

tional laser diodes, and legislation defines them

as Class 1 light-emitting diodes.

Do not remove the covers or expose the

eyes directly to the unfiltered light source

for several hours; otherwise, this could cause

irritation of the retina. <

Headlamp glass lens

In cool or humid weather, condensation may

occur on the interior of outside lights. The con-

densation disappears a short time after the light

is switched on. The headlamp glasses do not

need to be changed. If a lot of moisture is

present, e.g. water droplets in the light, have

them checked by your service center.

Page 212 of 256

MOBILITYReplacing components

210

Xenon lamps*

The service life of these bulbs is very long and

the probability of failure very low, provided that

they are not switched on and off an excessive

number of times. If a xenon lamp fails neverthe-

less, switch on the fog lamps and continue the

journey with great care, provided that local leg-

islation does not prohibit this.

Have any work on the xenon lamp system,

including bulb replacement, carried out

only by a MINI dealer or a workshop that has

specially trained personnel working in accor-

dance with the specifications of the MINI manu-

facturer. Due to high voltage, there is a risk of

fatal injury if work on the xenon lamps is carried

out improperly.<

Halogen low beams and high beams

H13 bulb, 60/55 watts

The H13 bulb is pressurized. Therefore,

wear safety glasses and protective gloves.

Otherwise, there is a risk of injury if the bulb is

damaged. <

Be careful when insta lling the cover; oth-

erwise, leaks could occur and cause dam-

age to the headlamp system. <

Accessing the lamp from the engine

compartment

The low-beam/high-beam bulb can be changed

from the engine compartment.

Removing the cover: 1.

Press the tab.

2. Flip open the cover and take it out of the

holder.

Follow the same steps in reverse order to reat-

tach the cover. Be careful when insta lling the cover; oth-

erwise, leaks could occur and cause dam-

age to the headlamp system. <

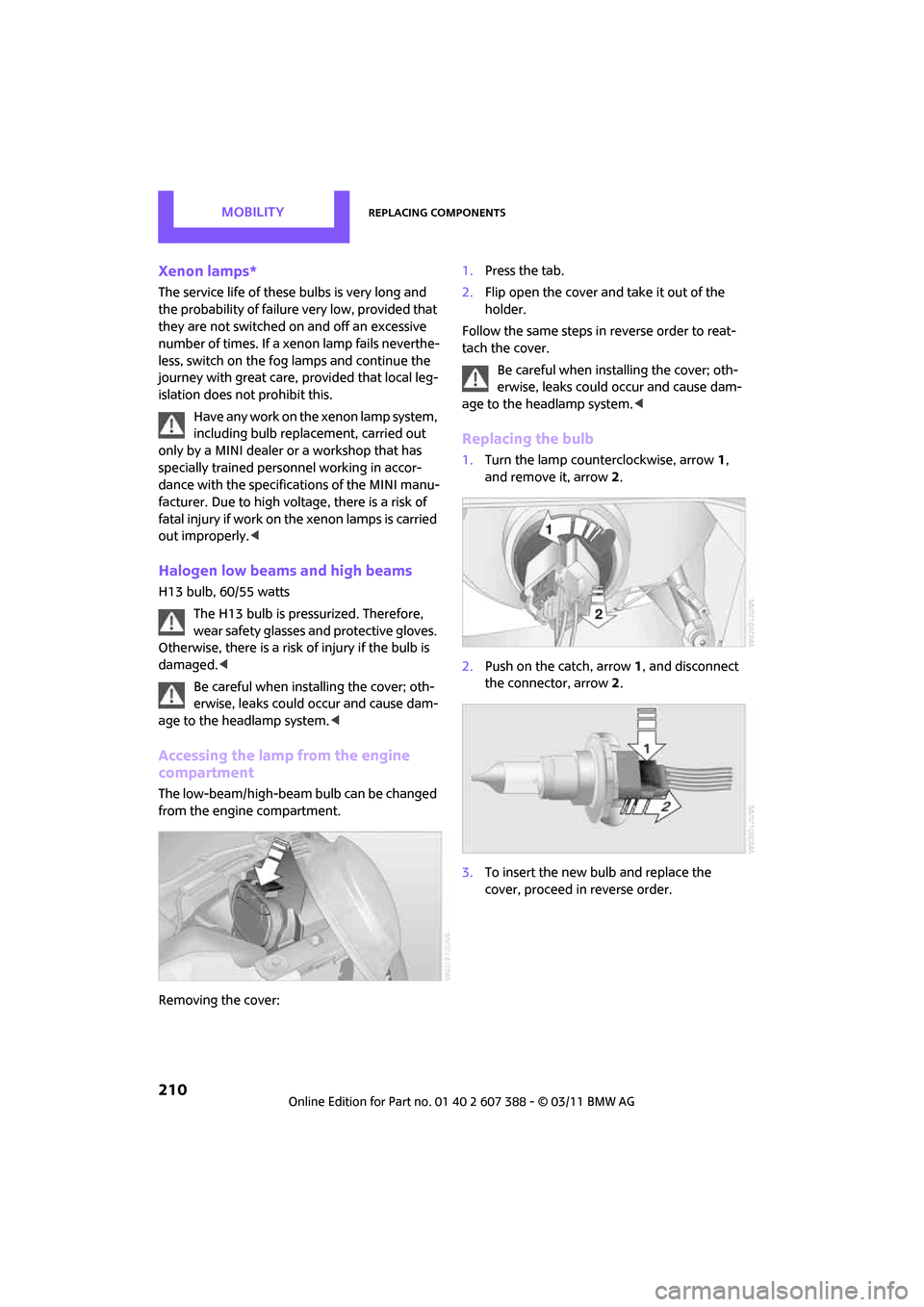

Replacing the bulb

1.Turn the lamp counterclockwise, arrow 1,

and remove it, arrow 2.

2. Push on the catch, arrow 1, and disconnect

the connector, arrow 2.

3. To insert the new bulb and replace the

cover, proceed in reverse order.

Page 213 of 256

Replacing componentsMOBILITY

211

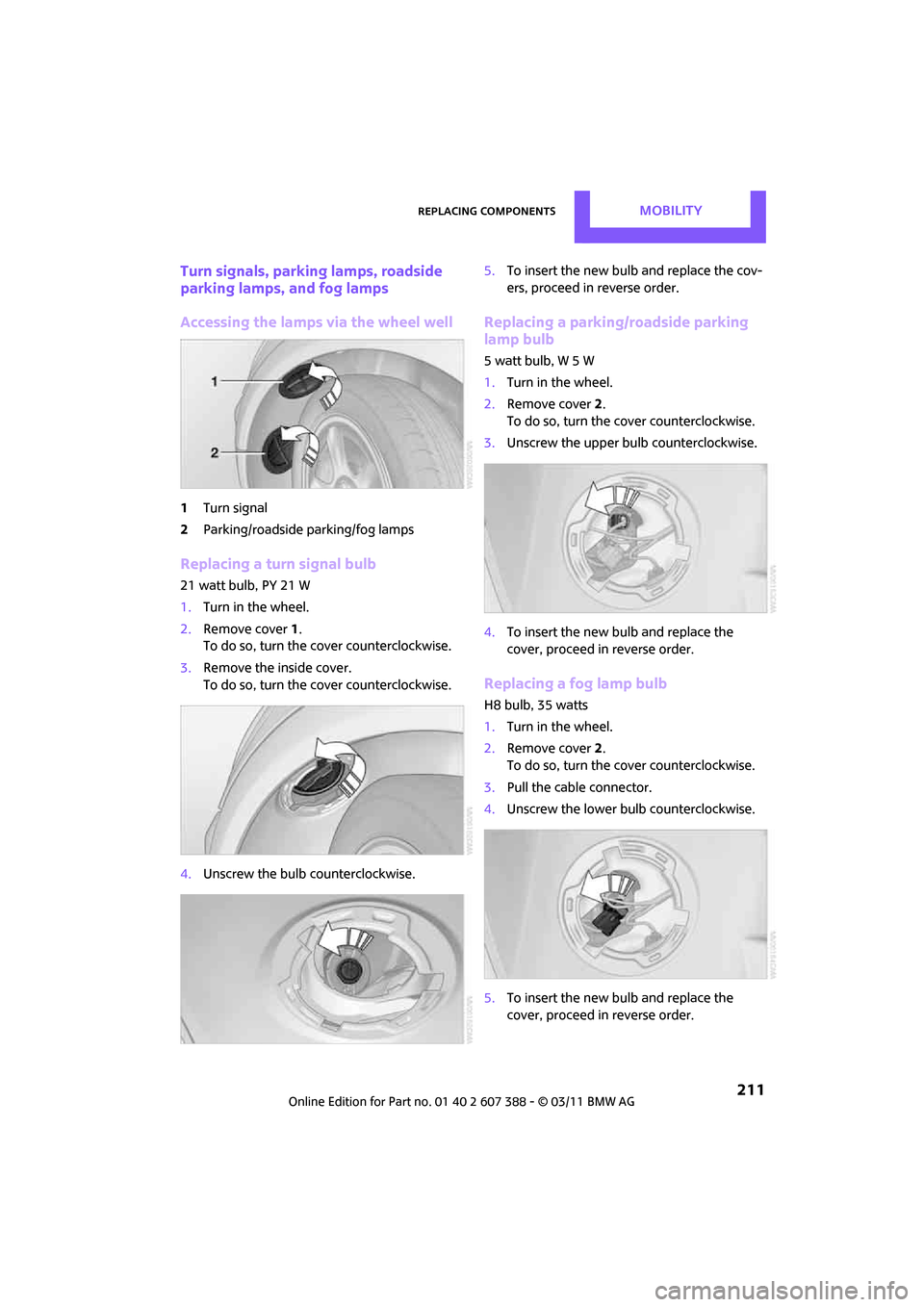

Turn signals, parking lamps, roadside

parking lamps, and fog lamps

Accessing the lamps via the wheel well

1Turn signal

2 Parking/roadside parking/fog lamps

Replacing a turn signal bulb

21 watt bulb, PY 21 W

1.Turn in the wheel.

2. Remove cover 1.

To do so, turn the cover counterclockwise.

3. Remove the inside cover.

To do so, turn the cover counterclockwise.

4. Unscrew the bulb counterclockwise. 5.

To insert the new bulb and replace the cov-

ers, proceed in reverse order.

Replacing a parking/roadside parking

lamp bulb

5watt bulb, W5W

1.Turn in the wheel.

2. Remove cover 2.

To do so, turn the cover counterclockwise.

3. Unscrew the upper bulb counterclockwise.

4. To insert the new bulb and replace the

cover, proceed in reverse order.

Replacing a fog lamp bulb

H8 bulb, 35 watts

1.Turn in the wheel.

2. Remove cover 2.

To do so, turn the cover counterclockwise.

3. Pull the cable connector.

4. Unscrew the lower bulb counterclockwise.

5. To insert the new bulb and replace the

cover, proceed in reverse order.

Page 214 of 256

MOBILITYReplacing components

212

Side turn signals

5 watt bulb, W 5 W

1.Push the lamp with the ventilation grate for-

ward and remove.

2. Unscrew the bulb holder counterclockwise.

3. Pull out and replace the bulb.

4. To insert the new bulb and replace the

cover, proceed in reverse order.

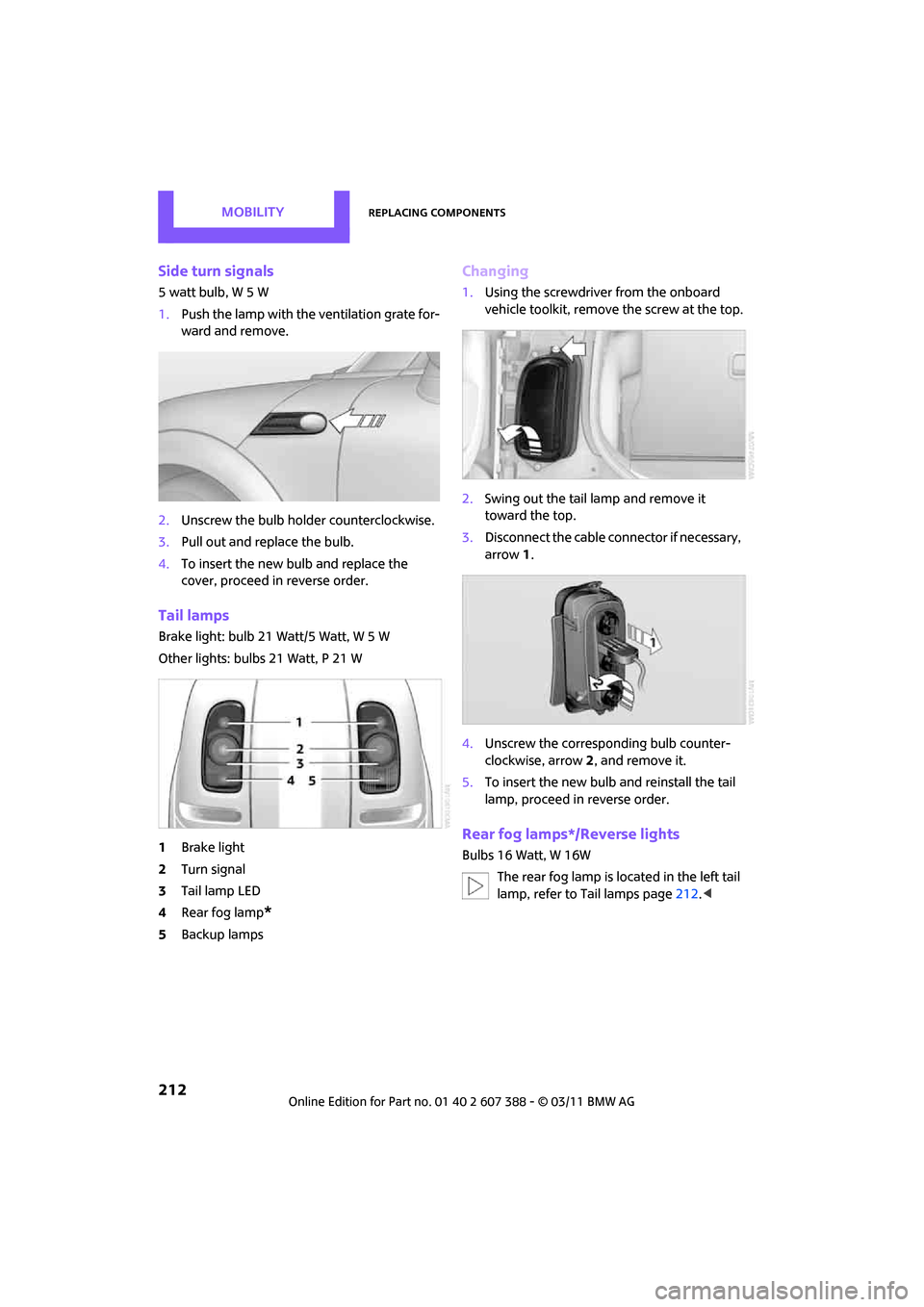

Tail lamps

Brake light: bulb 21 Watt/5 Watt, W 5 W

Other lights: bulbs 21 Watt, P 21 W

1Brake light

2 Turn signal

3 Tail lamp LED

4 Rear fog lamp

*

5Backup lamps

Changing

1.Using the screwdriver from the onboard

vehicle toolkit, remove the screw at the top.

2. Swing out the tail lamp and remove it

toward the top.

3. Disconnect the cable co nnector if necessary,

arrow 1.

4. Unscrew the corresponding bulb counter-

clockwise, arrow 2, and remove it.

5. To insert the new bulb and reinstall the tail

lamp, proceed in reverse order.

Rear fog lamps*/Reverse lights

Bulbs 16 Watt, W 16W

The rear fog lamp is located in the left tail

lamp, refer to Tail lamps page 212.<

Page 215 of 256

Replacing componentsMOBILITY

213

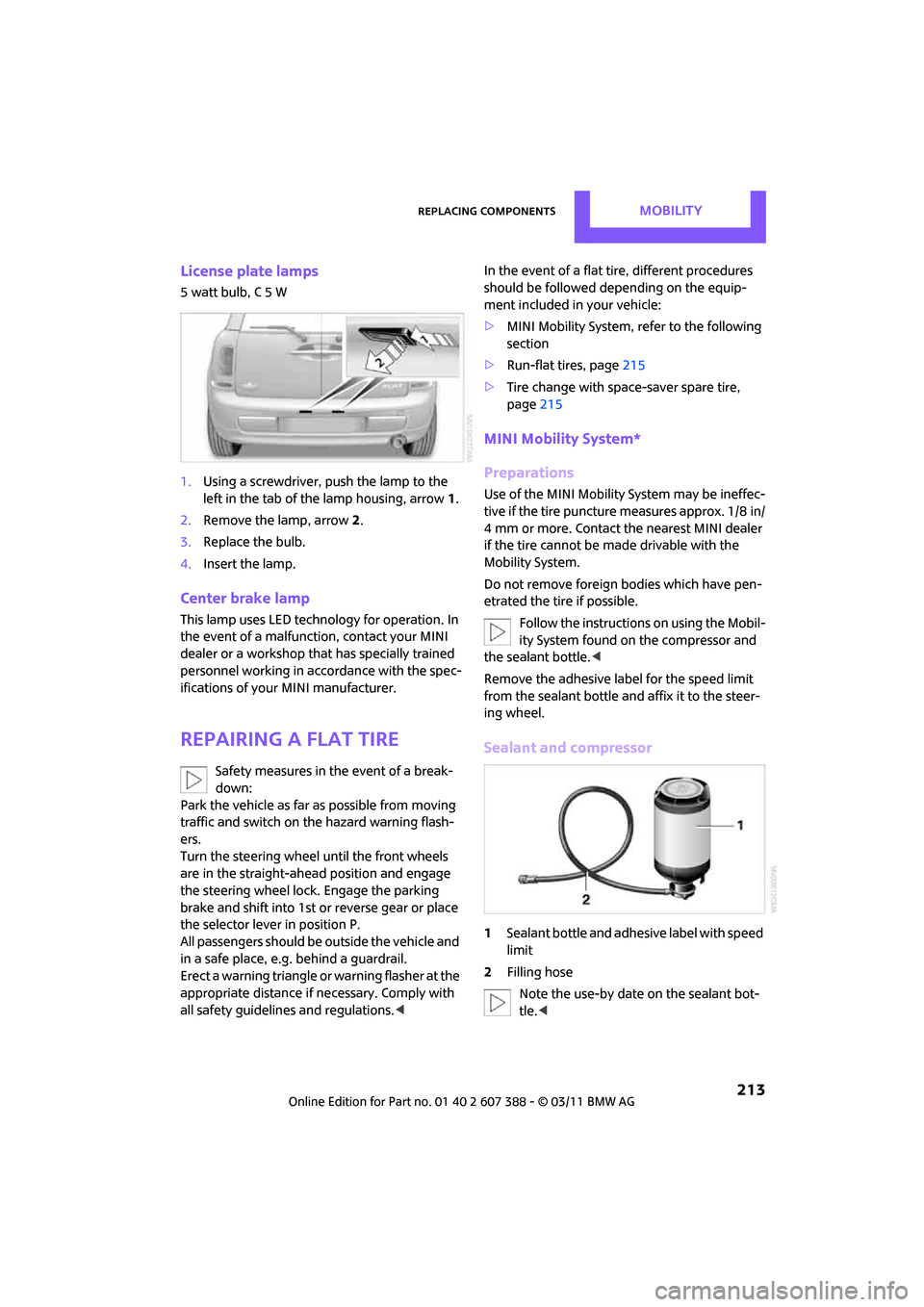

License plate lamps

5watt bulb, C5W

1.Using a screwdriver, push the lamp to the

left in the tab of the lamp housing, arrow 1.

2. Remove the lamp, arrow 2 .

3. Replace the bulb.

4. Insert the lamp.

Center brake lamp

This lamp uses LED technology for operation. In

the event of a malfunction, contact your MINI

dealer or a workshop that has specially trained

personnel working in acco rdance with the spec-

ifications of your MINI manufacturer.

Repairing a flat tire

Safety measures in the event of a break-

down:

Park the vehicle as far as possible from moving

traffic and switch on th e hazard warning flash-

ers.

Turn the steering wheel until the front wheels

are in the straight-ahead position and engage

the steering wheel lock. Engage the parking

brake and shift into 1st or reverse gear or place

the selector lever in position P.

All passengers should be outside the vehicle and

in a safe place, e.g. behind a guardrail.

Erect a warning triangle or warning flasher at the

appropriate distance if necessary. Comply with

all safety guidelines and regulations.

ment included in your vehicle:

>

MINI Mobility System, refer to the following

section

> Run-flat tires, page 215

> Tire change with space-saver spare tire,

page 215

MINI Mobility System*

Preparations

Use of the MINI Mobility System may be ineffec-

tive if the tire puncture measures approx. 1/8 in/

4 mm or more. Contact the nearest MINI dealer

if the tire cannot be made drivable with the

Mobility System.

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Follow the instructions on using the Mobil-

ity System found on the compressor and

the sealant bottle. <

Remove the adhesive label for the speed limit

from the sealant bottle and affix it to the steer-

ing wheel.

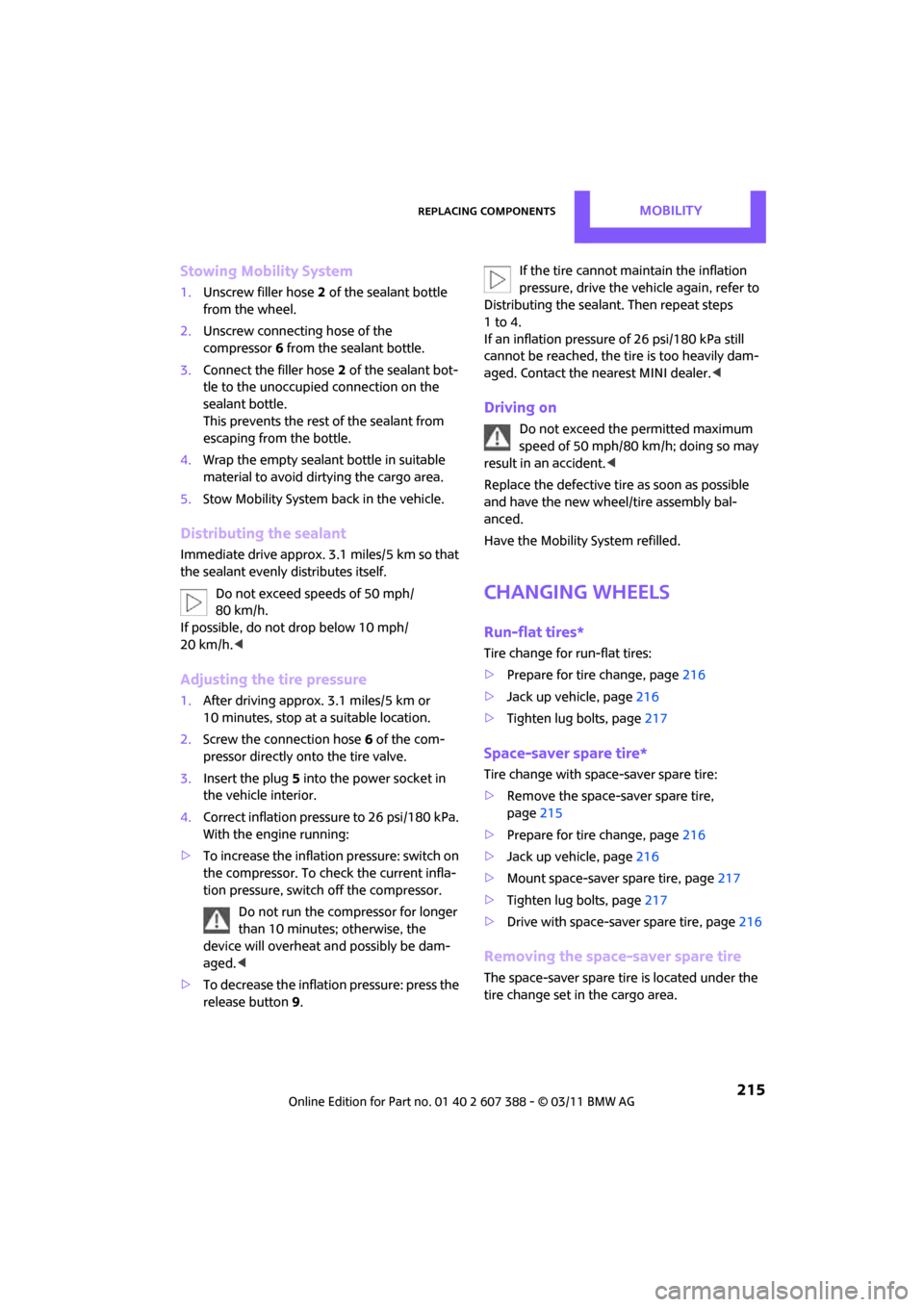

Sealant and compressor

1 Sealant bottle and adhesi ve label with speed

limit

2 Filling hose

Note the use-by date on the sealant bot-

tle. <

Page 216 of 256

MOBILITYReplacing components

214

3Holder for the sealant bottle

4 Compressor

5 Plug and cable for the socket in the vehicle

interior, page 94

6 Connection hose to connect the compressor

and sealant bottle or the compressor and

wheel

7 On/off switch

8 Pressure gauge for indi cating the tire infla-

tion pressure

9 Release button for reduci ng the tire inflation

pressure

Connector, cable and connection hose are

stored in the compressor housing.

Using the Mobility System

To repair a tire puncture with the Mobility Sys-

tem, proceed as follows:

> Filling the tire with sealant

> Distributing the sealant

> Correct the tire inflation pressure

Filling the tire with sealant

Proceed in the specified order; otherwise,

sealant may emerge under high pres-

sure. <

1. Shake the sealant bottle.

2. Pull the connecting hose 6 completely out of

the compressor housing and screw it onto

the connector of the sealant bottle. Make

sure that the hose is not kinked.

3. Insert the sealant bo ttle on the compressor

housing in an upright position. 4.

Unscrew the dust cap from the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.

5. Ensure that the compre ssor is switched off.

6. Insert the plug 5 into the lighter socket/

power socket in the vehicle interior,

page 94.

7. With the engine running:

Switch on the compressor and let is run for

approx. 3 to 8 minutes to fill the tire with

sealant and achieve a ti re inflation pressure

of approx. 26 psi/180 kPa.

When filling the tire with sealant, the

inflation pressure can briefly rise to

approx. 73 psi/500 kPa. Do not switch off

the compressor during this phase. <

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be dam-

aged.<

8. Switch off the compressor.

If an air pressure of 26 psi/180 kPa is not

reached:

1. Unscrew the filling hose 2 from the wheel

and drive the vehicle forward and backward

approx. 33 ft/10 m to distribute the liquid

sealant in the tire evenly.

2. Inflate the tire again with the compressor.

If an inflation pressure of 26 psi/180 kPa

still cannot be reached, the tire is too

heavily damaged. Please contact the nearest

MINI dealer. <

Page 217 of 256

Replacing componentsMOBILITY

215

Stowing Mobility System

1.Unscrew filler hose 2 of the sealant bottle

from the wheel.

2. Unscrew connecting hose of the

compressor 6 from the sealant bottle.

3. Connect the filler hose 2 of the sealant bot-

tle to the unoccupied connection on the

sealant bottle.

This prevents the rest of the sealant from

escaping from the bottle.

4. Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.

5. Stow Mobility System back in the vehicle.

Distributing the sealant

Immediate drive approx. 3.1 miles/5 km so that

the sealant evenly distributes itself.

Do not exceed speeds of 50 mph/

80 km/h.

If possible, do not drop below 10 mph/

20 km/h.<

Adjusting the tire pressure

1. After driving approx. 3.1 miles/5 km or

10 minutes, stop at a suitable location.

2. Screw the connection hose 6 of the com-

pressor directly onto the tire valve.

3. Insert the plug 5 into the power socket in

the vehicle interior.

4. Correct inflation pressu re to 26 psi/180 kPa.

With the engine running:

> To increase the inflatio n pressure: switch on

the compressor. To check the current infla-

tion pressure, switch off the compressor.

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be dam-

aged. <

> To decrease the inflation pressure: press the

release button 9. If the tire cannot ma

intain the inflation

pressure, drive the vehicle again, refer to

Distributing the sealan t. Then repeat steps

1to4.

If an inflation pressure of 26 psi/180 kPa still

cannot be reached, the tire is too heavily dam-

aged. Contact the nearest MINI dealer. <

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident.<

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.

Have the Mobility System refilled.

Changing wheels

Run-flat tires*

Tire change for run-flat tires:

> Prepare for tire change, page 216

> Jack up vehicle, page 216

> Tighten lug bolts, page 217

Space-saver spare tire*

Tire change with space-saver spare tire:

>Remove the space-saver spare tire,

page 215

> Prepare for tire change, page 216

> Jack up vehicle, page 216

> Mount space-saver spare tire, page 217

> Tighten lug bolts, page 217

> Drive with space-saver spare tire, page 216

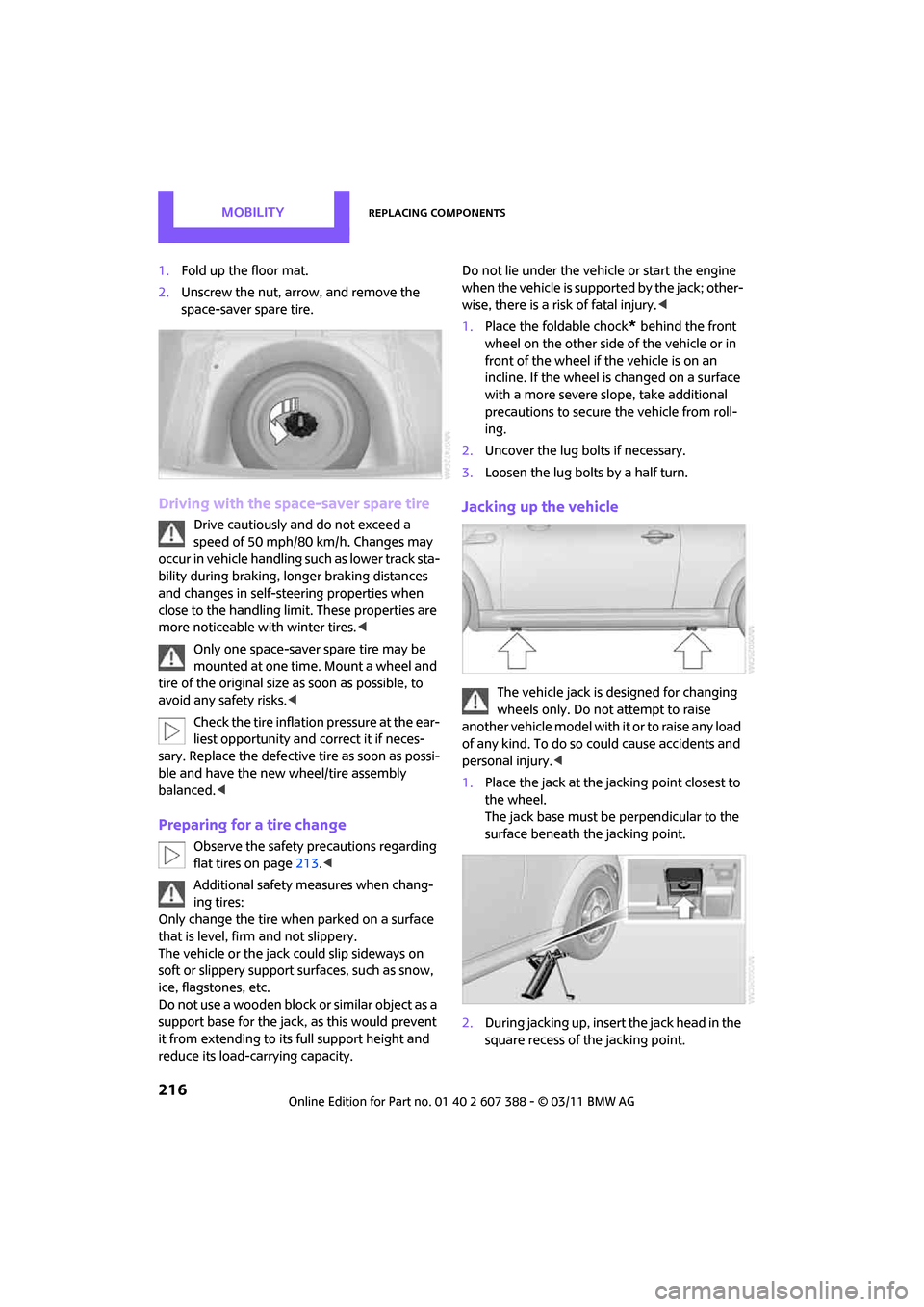

Removing the space-saver spare tire

The space-saver spare tire is located under the

tire change set in the cargo area.

Page 218 of 256

MOBILITYReplacing components

216

1.Fold up the floor mat.

2. Unscrew the nut, arrow, and remove the

space-saver spare tire.

Driving with the space-saver spare tire

Drive cautiously and do not exceed a

speed of 50 mph/80 km/h. Changes may

occur in vehicle handling such as lower track sta-

bility during br aking, longer braking distances

and changes in self-steering properties when

close to the handling limit. These properties are

more noticeable with winter tires. <

Only one space-saver spare tire may be

mounted at one time. Mount a wheel and

tire of the original size as soon as possible, to

avoid any safety risks. <

Check the tire inflation pressure at the ear-

liest opportunity and correct it if neces-

sary. Replace the defective tire as soon as possi-

ble and have the new wheel/tire assembly

balanced. <

Preparing for a tire change

Observe the safety precautions regarding

flat tires on page 213.<

Additional safety measures when chang-

ing tires:

Only change the tire wh en parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity. Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise, there is a risk of fatal injury.

<

1. Place the foldable chock

* behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe sl ope, take additional

precautions to secure the vehicle from roll-

ing.

2. Uncover the lug bolts if necessary.

3. Loosen the lug bolts by a half turn.

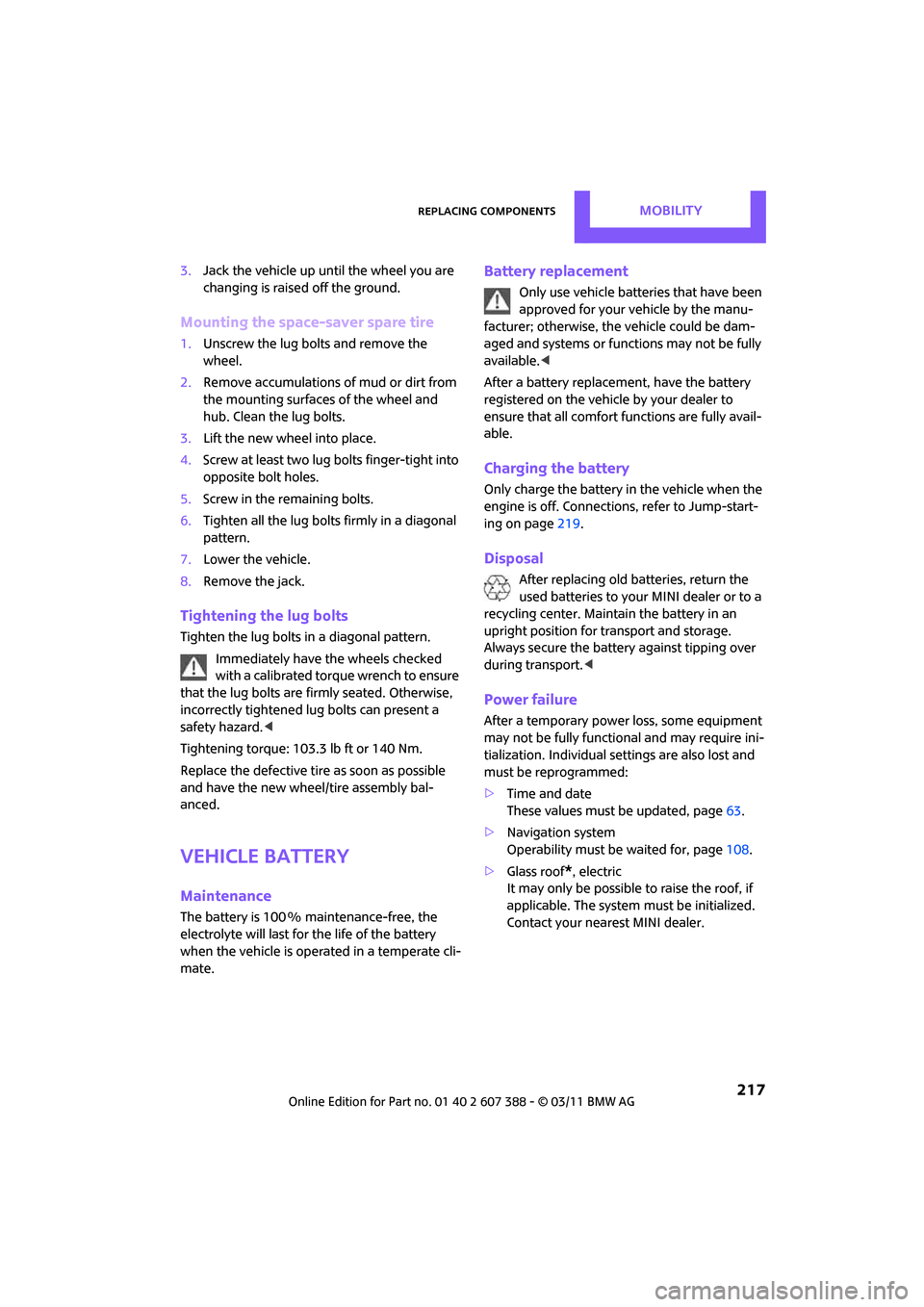

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

of any kind. To do so could cause accidents and

personal injury. <

1. Place the jack at the jacking point closest to

the wheel.

The jack base must be perpendicular to the

surface beneath the jacking point.

2. During jacking up, insert the jack head in the

square recess of the jacking point.

Page 219 of 256

Replacing componentsMOBILITY

217

3.Jack the vehicle up until the wheel you are

changing is raised off the ground.

Mounting the space-saver spare tire

1.Unscrew the lug bolts and remove the

wheel.

2. Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Clean the lug bolts.

3. Lift the new wheel into place.

4. Screw at least two lug bolts finger-tight into

opposite bolt holes.

5. Screw in the remaining bolts.

6. Tighten all the lug bolts firmly in a diagonal

pattern.

7. Lower the vehicle.

8. Remove the jack.

Tightening the lug bolts

Tighten the lug bolts in a diagonal pattern.

Immediately have the wheels checked

with a calibrated torque wrench to ensure

that the lug bolts are firmly seated. Otherwise,

incorrectly tightened lug bolts can present a

safety hazard. <

Tightening torque: 103.3 lb ft or 140 Nm.

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.

Vehicle battery

Maintenance

The battery is 100 % maintenance-free, the

electrolyte will last for the life of the battery

when the vehicle is operated in a temperate cli-

mate.

Battery replacement

Only use vehicle batteries that have been

approved for your vehicle by the manu-

facturer; otherwise, the vehicle could be dam-

aged and systems or func tions may not be fully

available. <

After a battery replacement, have the battery

registered on the vehicle by your dealer to

ensure that all comfort functions are fully avail-

able.

Charging the battery

Only charge the battery in the vehicle when the

engine is off. Connection s, refer to Jump-start-

ing on page 219.

Disposal

After replacing old batteries, return the

used batteries to your MINI dealer or to a

recycling center. Maintain the battery in an

upright position for transport and storage.

Always secure the battery against tipping over

during transport. <

Power failure

After a temporary power loss, some equipment

may not be fully functional and may require ini-

tialization. Individual se ttings are also lost and

must be reprogrammed:

> Time and date

These values must be updated, page 63.

> Navigation system

Operability must be waited for, page 108.

> Glass roof

*, electric

It may only be possible to raise the roof, if

applicable. The system must be initialized.

Contact your nearest MINI dealer.

Page 220 of 256

MOBILITYReplacing components

218

Fuses

Do not attempt to repair a blown fuse or

replace it with a fuse of a different color or

Ampere rating. To do this could cause a fire in

the vehicle resulting from a circuit overload.

Have the fuse changed only by a MINI dealer or

a workshop that has specially trained personnel

working in accordance with the specifications of

the MINI manufacturer. <

A fuse allocation diagram is located on the inside

of the fuse box cover panels.

In the engine compartment

Opening the cover

Press the latch.

In the vehicle interior

On the right side of the footwell.

Opening the cover

Press out at the recess.