ECU MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1044 of 1146

526-34 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

CONTINUED FROM PREVIOUS PAGE

c

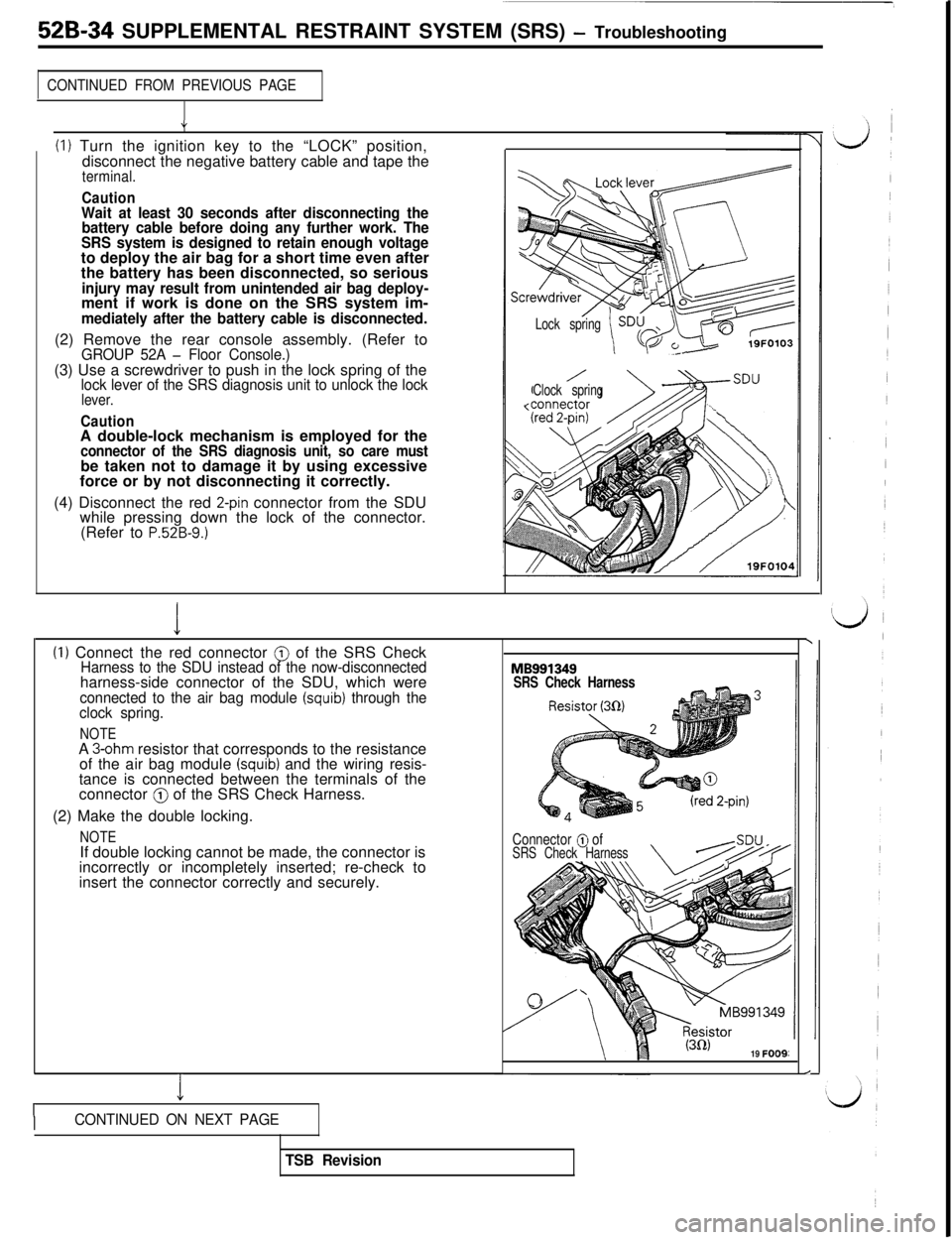

(1) Turn the ignition key to the “LOCK” position,

disconnect the negative battery cable and tape the

terminal.

CautionWait at least 30 seconds after disconnecting the

battery cable before doing any further work. The

SRS system is designed to retain enough voltageto deploy the air bag for a short time even after

the battery has been disconnected, so serious

injury may result from unintended air bag deploy-ment if work is done on the SRS system im-

mediately after the battery cable is disconnected.(2) Remove the rear console assembly. (Refer to

GROUP 52A - Floor Console.)(3) Use a screwdriver to push in the lock spring of the

lock lever of the SRS diagnosis unit to unlock the locklever.

CautionA double-lock mechanism is employed for the

connector of the SRS diagnosis unit, so care mustbe taken not to damage it by using excessive

force or by not disconnecting it correctly.

(4) Disconnect the red

2-pin connector from the SDU

while pressing down the lock of the connector.

(Refer to

P.52B-9.)

/Lock spring

/Clock spring

I\(I) Connect the red connector @ of the SRS CheckHarness to the SDU instead of the now-disconnectedharness-side connector of the SDU, which were

connected to the air bag module (squib) through the

clock spring.

NOTE

SRS Check HarnessA

3-ohm resistor that corresponds to the resistance

of the air bag module (squib) and the wiring resis-

tance is connected between the terminals of the

connector

@ of the SRS Check Harness.

(2) Make the double locking.

NOTEIf double locking cannot be made, the connector is

incorrectly or incompletely inserted; re-check to

insert the connector correctly and securely.Connector @ ofSRS Check Harness

(3R)19 FOO9:

1

/

ICONTINUED ON NEXT PAGE

TSB Revision

Page 1050 of 1146

52B-40 SUPPLEMENTAL ,RESTRAINT SYSTEM (SRS) - Troubleshooting

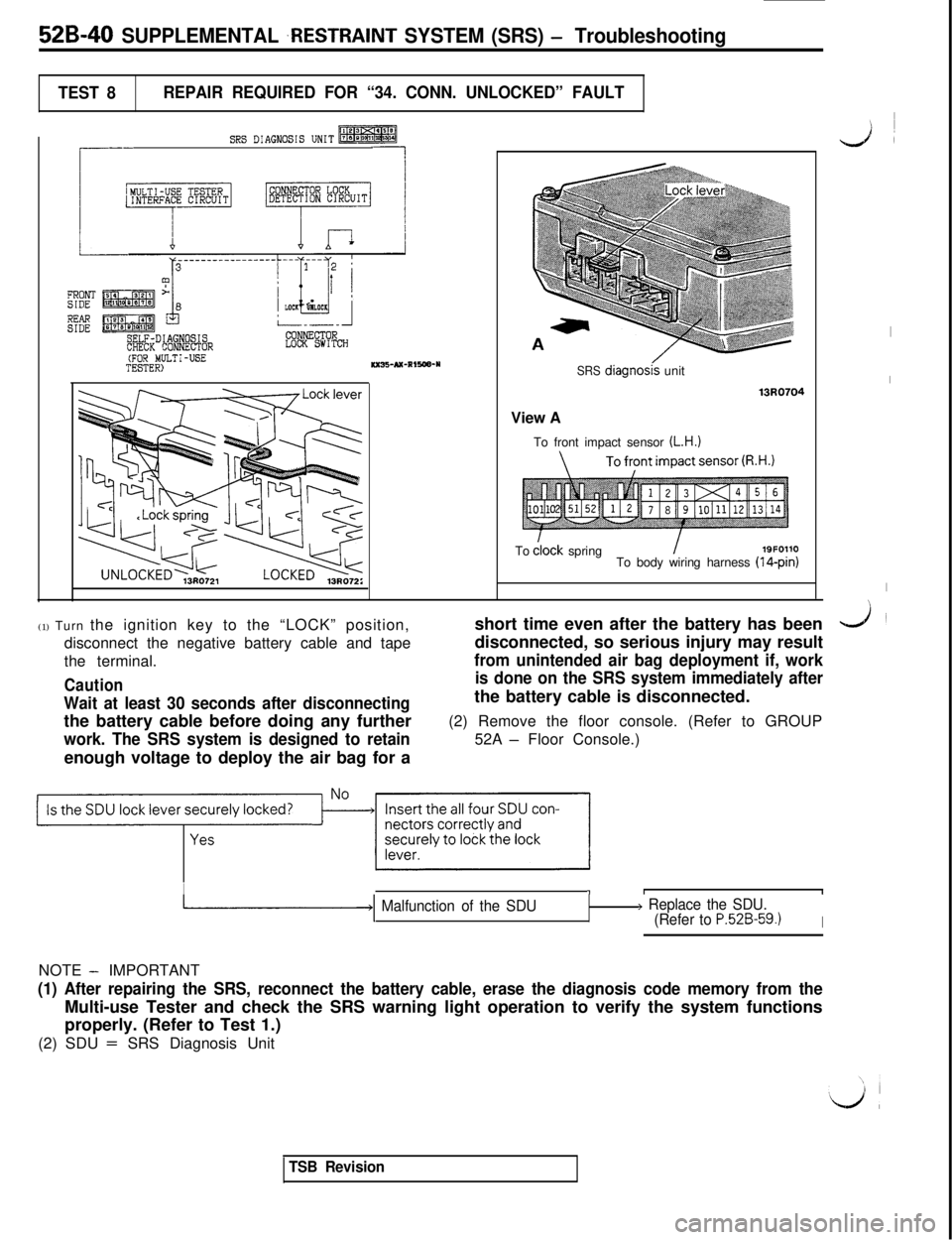

TEST 8REPAIR REQUIRED FOR “34. CONN. UNLOCKED” FAULT

SRS DIAGNOSIS UNIT-

r

--

L

FRONTSIDE

EESELF-DIAGNOSISCHECK CONNECTORLOCK SWITCH(FOR MULTI-USETESTER)KXB-AX-RIRW-YSRS diagnoskunit

13RQ7Q4View A

To front impact sensor

(L.H.)Todlock spring

I19F0110

To body wiring harness (14-pin)

(1) Turn the ignition key to the “LOCK” position,

disconnect the negative battery cable and tape

the terminal.

Caution

Wait at least 30 seconds after disconnectingthe battery cable before doing any further

work. The SRS system is designed to retainenough voltage to deploy the air bag for ashort time even after the battery has been

disconnected, so serious injury may result

from unintended air bag deployment if, work

is done on the SRS system immediately afterthe battery cable is disconnected.

(2) Remove the floor console. (Refer to GROUP

52A

- Floor Console.)

Is the SDU lock lever securely locked?~JII’~~

I11I

-1 Malfunction of the SDU> Replace the SDU.

(Refer to P.52B-59.1INOTE

- IMPORTANT

(1) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to Test 1.)

(2) SDU

= SRS Diagnosis Unit

I

LA

I

I

I

J

TSB Revision

Page 1068 of 1146

52B-58SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Front Impact Sensors

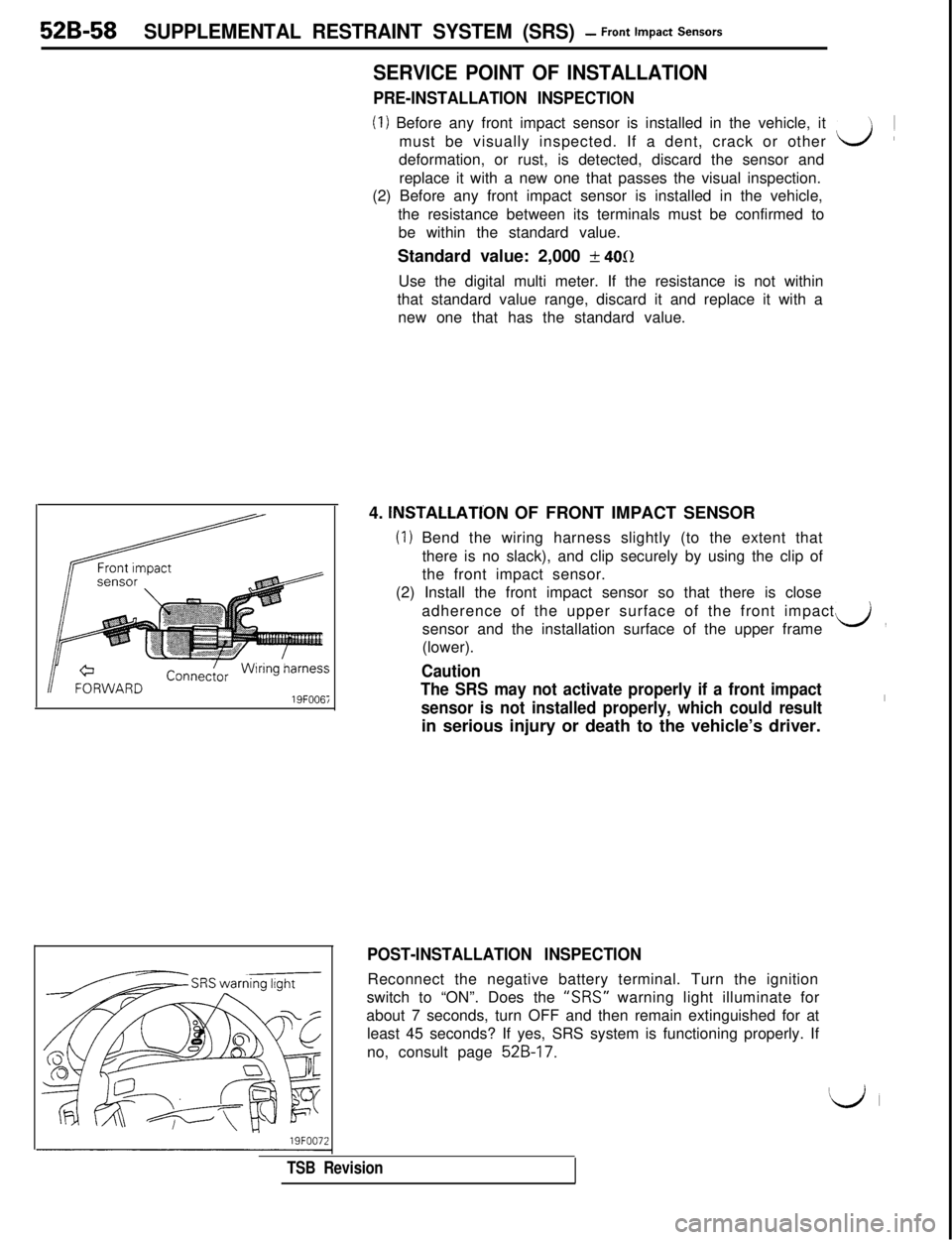

SERVICE POINT OF INSTALLATION

PRE-INSTALLATION INSPECTION

(1) Before any front impact sensor is installed in the vehicle, it

must be visually inspected. If a dent, crack or other

LAdeformation, or rust, is detected, discard the sensor and

replace it with a new one that passes the visual inspection.

(2) Before any front impact sensor is installed in the vehicle,

the resistance between its terminals must be confirmed to

be within the standard value.

Standard value: 2,000

-t 400

Use the digital multi meter. If the resistance is not within

that standard value range, discard it and replace it with a

new one that has the standard value.

19FOO6i4.

INSTALLATI’ON OF FRONT IMPACT SENSOR

(1) Bend the wiring harness slightly (to the extent that

there is no slack), and clip securely by using the clip of

the front impact sensor.

(2) Install the front impact sensor so that there is close

adherence of the upper surface of the front impact

sensor and the installation surface of the upper frame

d’(lower).

Caution

The SRS may not activate properly if a front impact

sensor is not installed properly, which could result

Iin serious injury or death to the vehicle’s driver.

POST-INSTALLATION INSPECTIONReconnect the negative battery terminal. Turn the ignition

switch to “ON”. Does the

“SW” warning light illuminate for

about 7 seconds, turn OFF and then remain extinguished for at

least 45 seconds? If yes, SRS system is functioning properly. If

no, consult page 52B-17.

19FOO72

TSB Revision

Page 1071 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) -SRS Diagnosis Unit (SDU) 52B-611330721

13R072i

ht-----

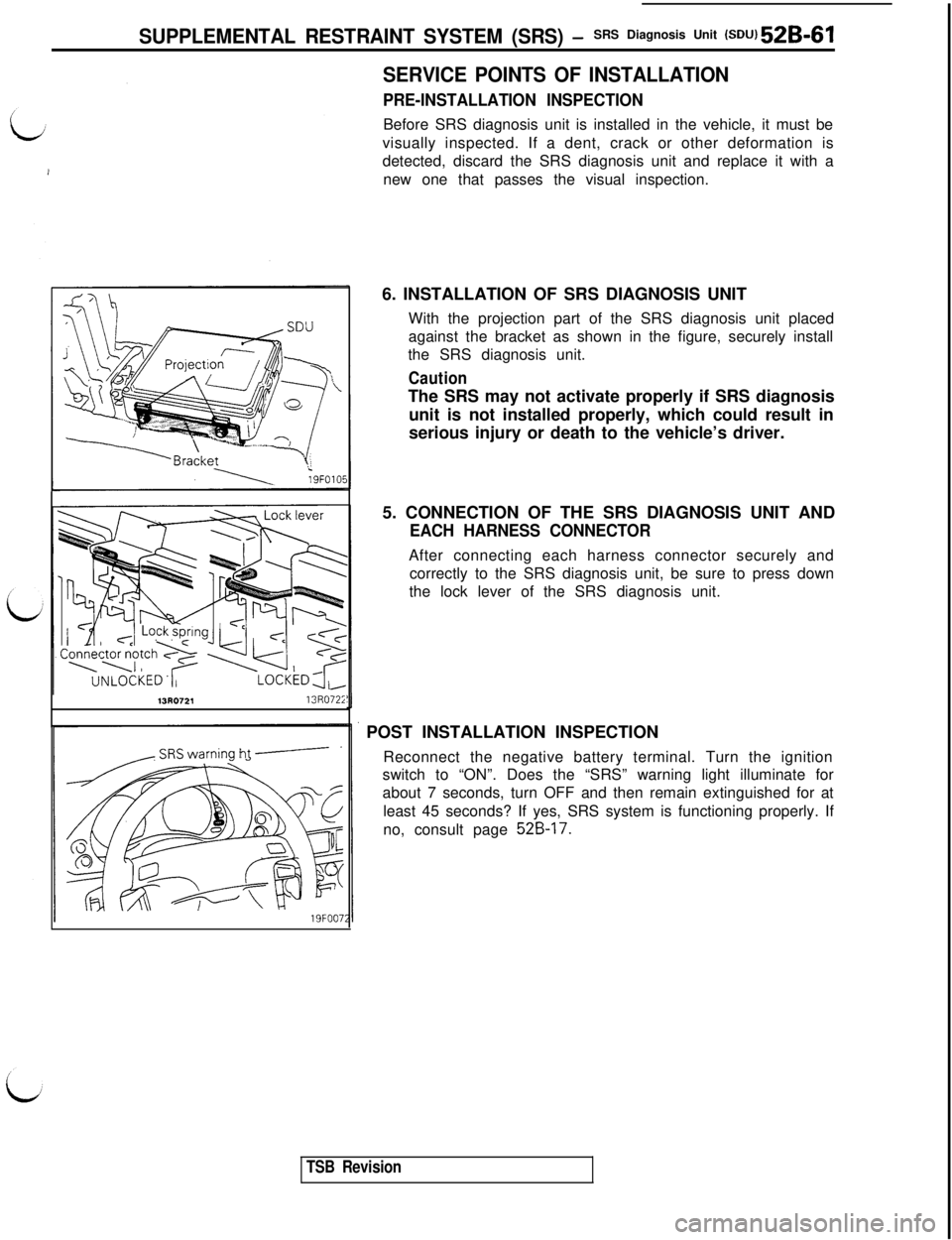

SERVICE POINTS OF INSTALLATION

PRE-INSTALLATION INSPECTIONBefore SRS diagnosis unit is installed in the vehicle, it must be

visually inspected. If a dent, crack or other deformation is

detected, discard the SRS diagnosis unit and replace it with a

new one that passes the visual inspection.

6. INSTALLATION OF SRS DIAGNOSIS UNIT

With the projection part of the SRS diagnosis unit placed

against the bracket as shown in the figure, securely install

the SRS diagnosis unit.

CautionThe SRS may not activate properly if SRS diagnosis

unit is not installed properly, which could result in

serious injury or death to the vehicle’s driver.

5. CONNECTION OF THE SRS DIAGNOSIS UNIT AND

EACH HARNESS CONNECTORAfter connecting each harness connector securely and

correctly to the SRS diagnosis unit, be sure to press down

the lock lever of the SRS diagnosis unit.

POST INSTALLATION INSPECTION

Reconnect the negative battery terminal. Turn the ignition

switch to “ON”. Does the “SRS” warning light illuminate for

about 7 seconds, turn OFF and then remain extinguished for at

least 45 seconds? If yes, SRS system is functioning properly. If

no, consult page

52B-17.

TSB Revision

Page 1077 of 1146

Air Bag Module

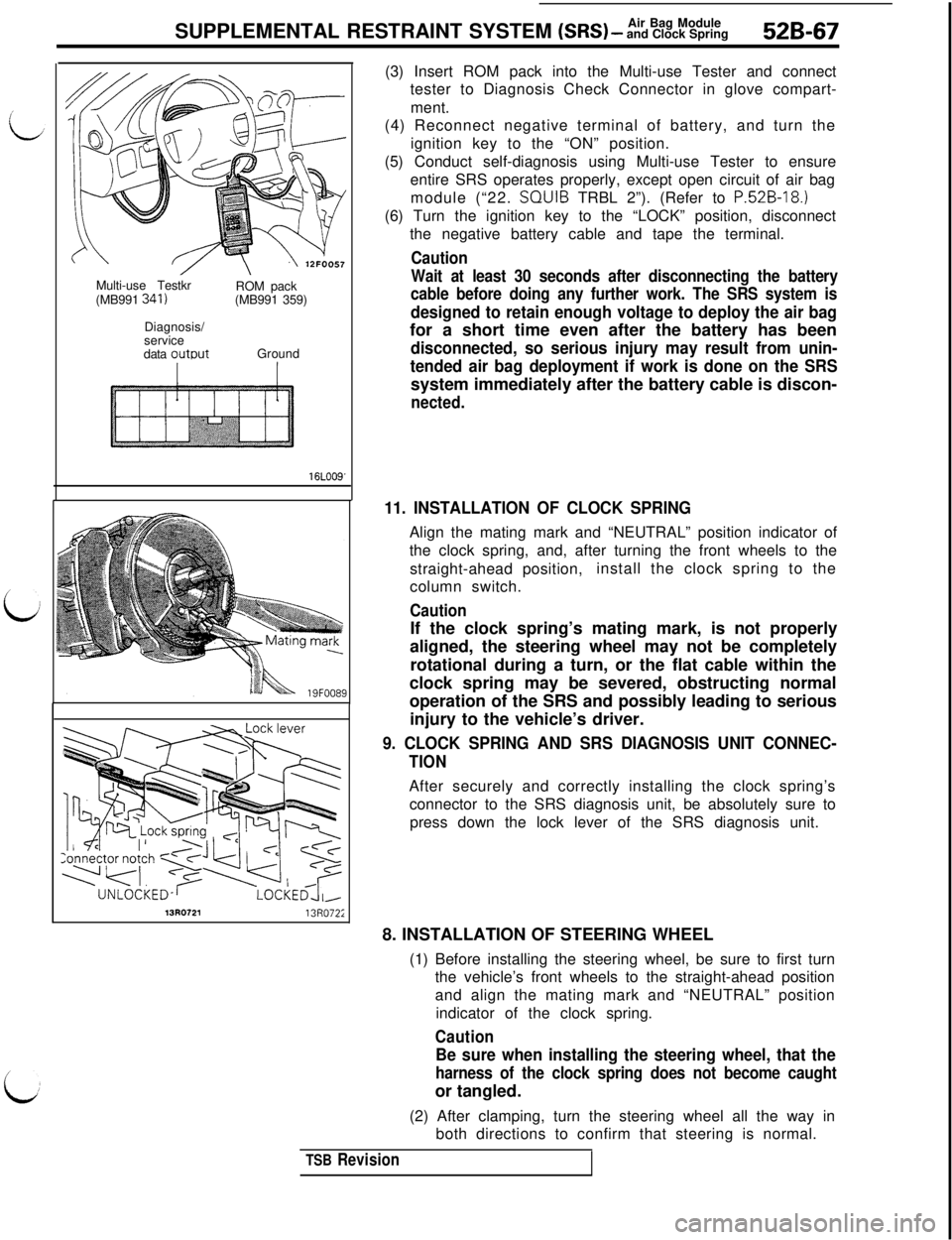

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock Spring52B-67Multi-use Testkr

ROM pack

(MB991 341)(MB991 359)

Diagnosis/

service

data

oumutGround

16LOO9'(3) Insert ROM pack into the Multi-use Tester and connect

tester to Diagnosis Check Connector in glove compart-

ment.

(4) Reconnect negative terminal of battery, and turn the

ignition key to the “ON” position.

(5) Conduct self-diagnosis using Multi-use Tester to ensure

entire SRS operates properly, except open circuit of air bag

module (“22. SQUIB TRBL 2”). (Refer to

P.52B-18.)(6) Turn the ignition key to the “LOCK” position, disconnect

the negative battery cable and tape the terminal.

Caution

Wait at least 30 seconds after disconnecting the battery

cable before doing any further work. The SRS system is

designed to retain enough voltage to deploy the air bagfor a short time even after the battery has been

disconnected, so serious injury may result from unin-

tended air bag deployment if work is done on the SRSsystem immediately after the battery cable is discon-

nected.

11. INSTALLATION OF CLOCK SPRINGAlign the mating mark and “NEUTRAL” position indicator of

the clock spring, and, after turning the front wheels to the

straight-ahead position,install the clock spring to the

column switch.

CautionIf the clock spring’s mating mark, is not properly

aligned, the steering wheel may not be completely

rotational during a turn, or the flat cable within the

clock spring may be severed, obstructing normal

operation of the SRS and possibly leading to serious

injury to the vehicle’s driver.

9. CLOCK SPRING AND SRS DIAGNOSIS UNIT CONNEC-

TIONAfter securely and correctly installing the clock spring’s

connector to the SRS diagnosis unit, be absolutely sure to

press down the lock lever of the SRS diagnosis unit.

13R072113R072;8. INSTALLATION OF STEERING WHEEL

(1) Before installing the steering wheel, be sure to first turn

the vehicle’s front wheels to the straight-ahead position

and align the mating mark and “NEUTRAL” position

indicator of the clock spring.

Caution

Be sure when installing the steering wheel, that the

harness of the clock spring does not become caughtor tangled.

(2) After clamping, turn the steering wheel all the way in

both directions to confirm that steering is normal.

TSB Revision

Page 1101 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Heater cmrol *=mW55-19

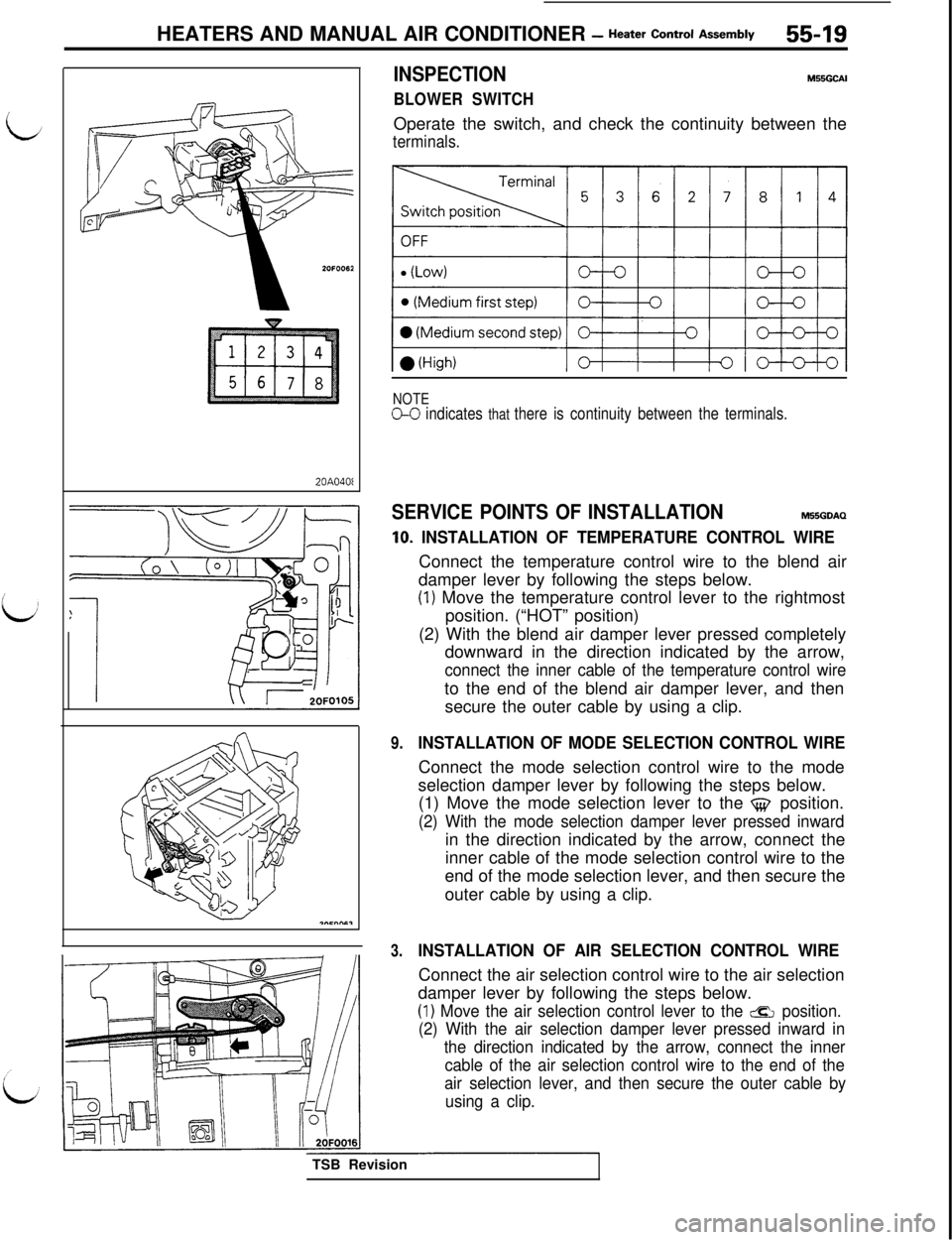

20A040fINSPECTION

BLOWER SWITCH

M55GCAIOperate the switch, and check the continuity between the

terminals.

NOTEo-0 indicates that there is continuity between the terminals.

SERVICE POINTS OF INSTALLATIONM55GDAQ

10. INSTALLATION OF TEMPERATURE CONTROL WIREConnect the temperature control wire to the blend air

damper lever by following the steps below.

(1) Move the temperature control lever to the rightmost

position. (“HOT” position)

(2) With the blend air damper lever pressed completely

downward in the direction indicated by the arrow,

connect the inner cable of the temperature control wireto the end of the blend air damper lever, and then

secure the outer cable by using a clip.

9.INSTALLATION OF MODE SELECTION CONTROL WIREConnect the mode selection control wire to the mode

selection damper lever by following the steps below.

(1) Move the mode selection lever to the

$$ position.

(2) With the mode selection damper lever pressed inwardin the direction indicated by the arrow, connect the

inner cable of the mode selection control wire to the

end of the mode selection lever, and then secure the

outer cable by using a clip.

3.INSTALLATION OF AIR SELECTION CONTROL WIREConnect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the &ZI position.

(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection lever, and then secure the outer cable by

using a clip.TSB Revision

Page 1106 of 1146

55-24

IHEATERS AND MANUAL AIR CONDITIONER

- Blower Assembly

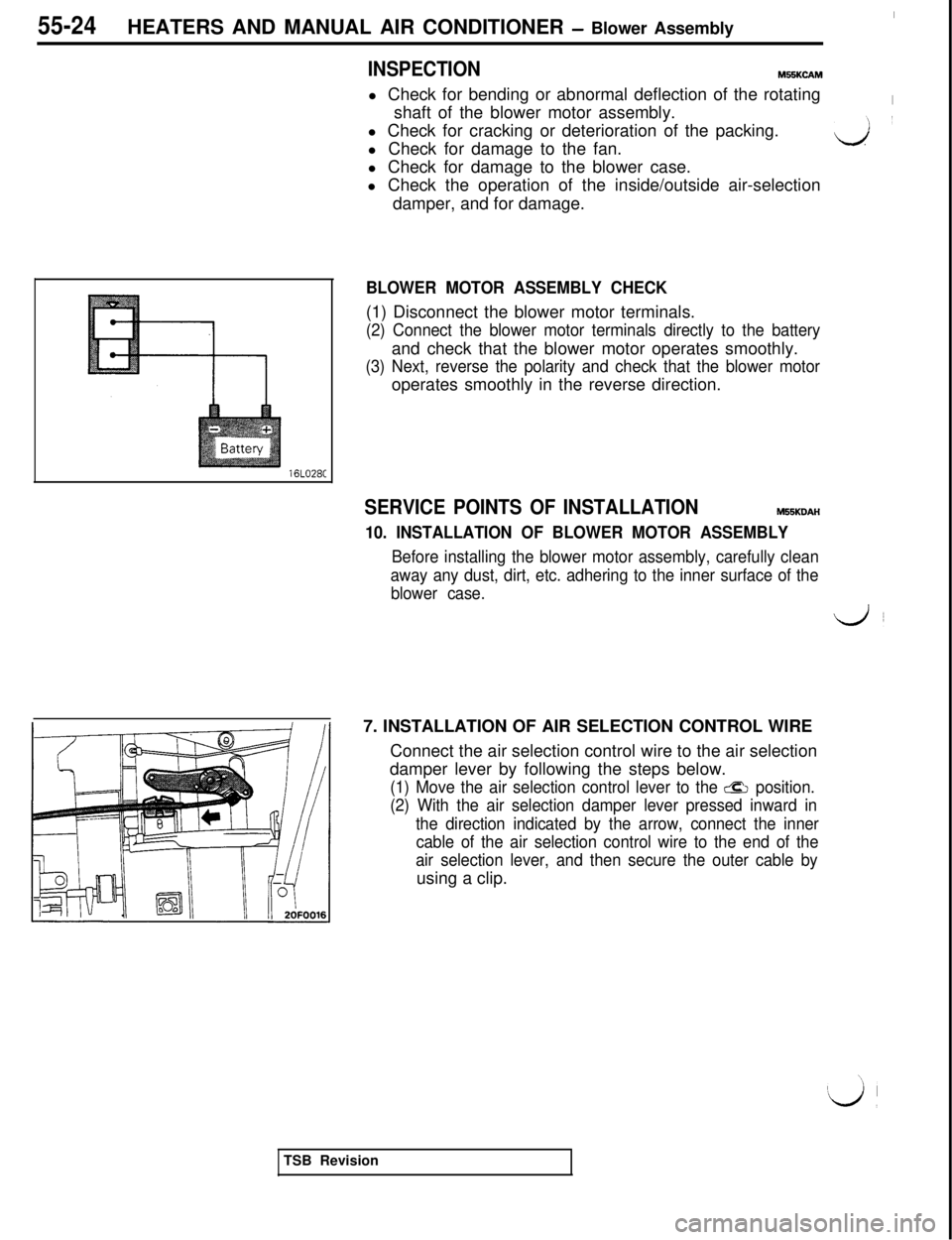

INSPECTIONM55KCAMl Check for bending or abnormal deflection of the rotating

Ishaft of the blower motor assembly.

l Check for cracking or deterioration of the packing.

l Check for damage to the fan.

d’l Check for damage to the blower case.

l Check the operation of the inside/outside air-selection

damper, and for damage.

16LO28C

BLOWER MOTOR ASSEMBLY CHECK(1) Disconnect the blower motor terminals.

(2) Connect the blower motor terminals directly to the batteryand check that the blower motor operates smoothly.

(3) Next, reverse the polarity and check that the blower motoroperates smoothly in the reverse direction.

SERVICE POINTS OF INSTALLATIONM55KDAH

10. INSTALLATION OF BLOWER MOTOR ASSEMBLY

Before installing the blower motor assembly, carefully clean

away any dust, dirt, etc. adhering to the inner surface of the

blower case.7. INSTALLATION OF AIR SELECTION CONTROL WIRE

Connect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the CQ position.

(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection lever, and then secure the outer cable byusing a clip.

TSB Revision