check engine light MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 358 of 1146

17-14 EMISSION CONTROL -Exhaust Gas Recirculation (EGR) System / Catalytic Converter

6EM01871

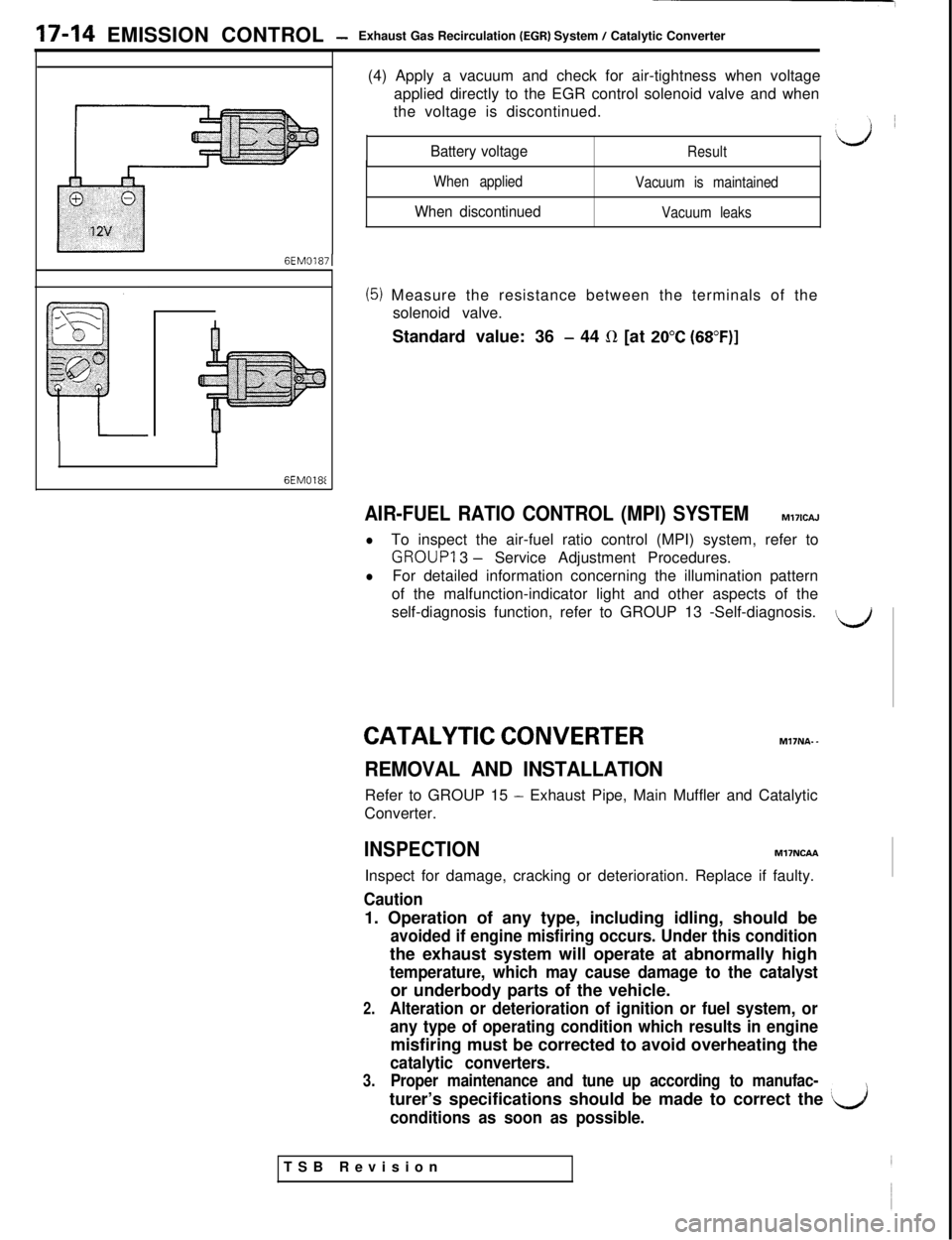

6EM0181(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR control solenoid valve and when

the voltage is discontinued.

Battery voltageResult

When applied

When discontinued

Vacuum is maintained

Vacuum leaks

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36

- 44 R [at 20°C (68”F)]

AIR-FUEL RATIO CONTROL (MPI) SYSTEMM17ICAJ

lTo inspect the air-fuel ratio control (MPI) system, refer to

GROUP1 3 - Service Adjustment Procedures.

lFor detailed information concerning the illumination pattern

of the malfunction-indicator light and other aspects of the

self-diagnosis function, refer to GROUP 13 -Self-diagnosis.

\.J

CATALYTIC CONVERTERMl7N& -

REMOVAL AND INSTALLATIONRefer to GROUP 15

- Exhaust Pipe, Main Muffler and Catalytic

Converter.

INSPECTIONMl7NCAA

Inspect for damage, cracking or deterioration. Replace if faulty.

Caution1. Operation of any type, including idling, should be

avoided if engine misfiring occurs. Under this conditionthe exhaust system will operate at abnormally high

temperature, which may cause damage to the catalystor underbody parts of the vehicle.

2.Alteration or deterioration of ignition or fuel system, or

any type of operating condition which results in enginemisfiring must be corrected to avoid overheating the

catalytic converters.

3.Proper maintenance and tune up according to manufac-turer’s specifications should be made to correct the

‘bi

conditions as soon as possible.TSB Revision

Page 364 of 1146

21-6CLUTCH - Service Adjustment Procedures

08YO4Z

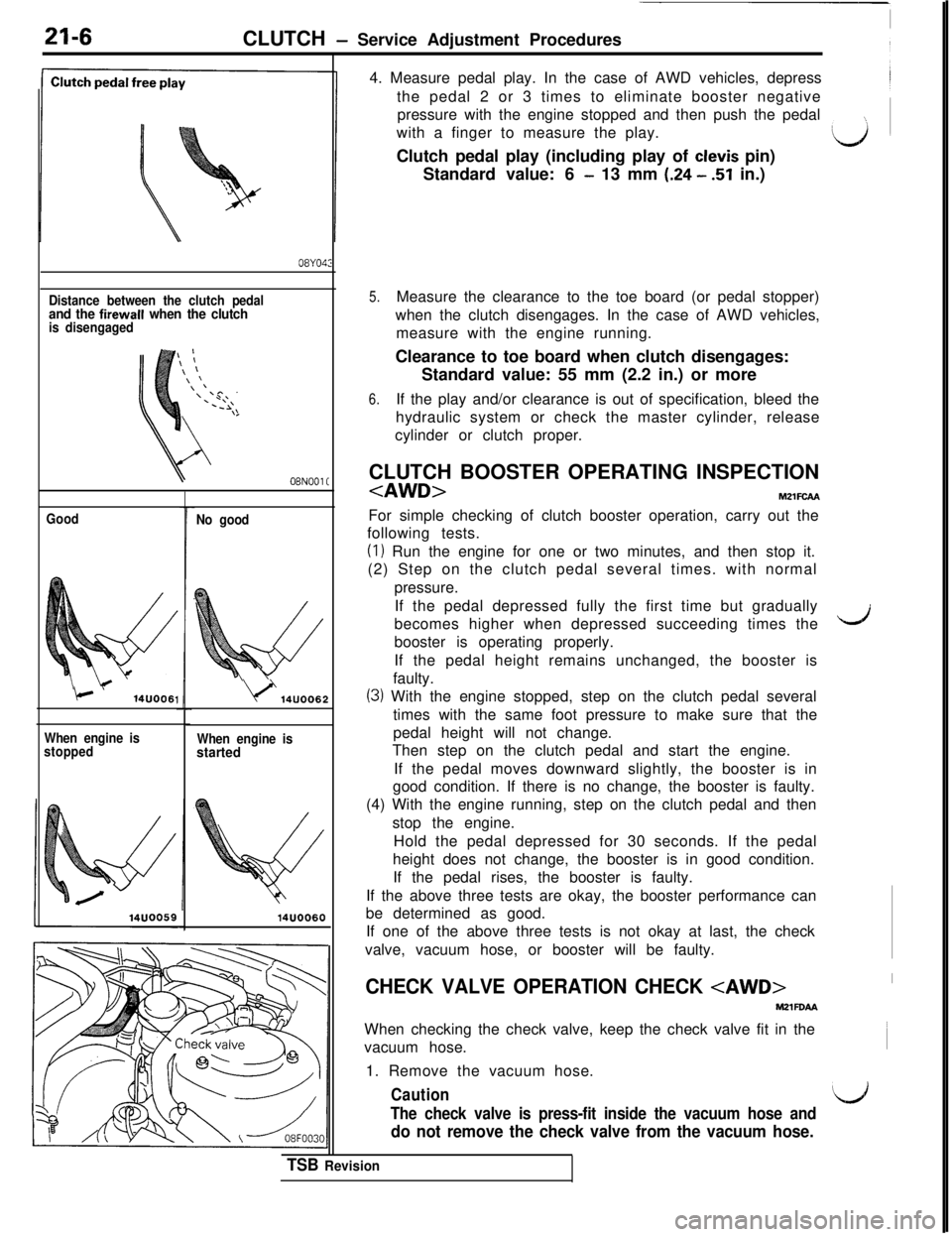

Distance between the clutch pedaland the firewall when the clutchis disengaged

08NOOl C

Good

c1‘14UOO61

When engine is

stoppedNo good

\)‘14UOO6:

When engine isstarted

14UOO604. Measure pedal play. In the case of AWD vehicles, depress~

the pedal 2 or 3 times to eliminate booster negative

pressure with the engine stopped and then push the pedal

with a finger to measure the play.

LJClutch pedal play (including play of clevis pin)

Standard value: 6

- 13 mm (.24 - 51 in.)

2

CHECK VALVE OPERATION CHECK

MZlFOAAWhen checking the check valve, keep the check valve fit in the

vacuum hose.

1. Remove the vacuum hose.

CautionL’The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.

5.Measure the clearance to the toe board (or pedal stopper)

when the clutch disengages. In the case of AWD vehicles,

measure with the engine running.

Clearance to toe board when clutch disengages:

Standard value: 55 mm (2.2 in.) or more

6.If the play and/or clearance is out of specification, bleed the

hydraulic system or check the master cylinder, release

cylinder or clutch proper.

CLUTCH BOOSTER OPERATING INSPECTION

following tests.

(I) Run the engine for one or two minutes, and then stop it.

(2) Step on the clutch pedal several times. with normal

pressure.

If the pedal depressed fully the first time but gradually

becomes higher when depressed succeeding times the

dbooster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

(3) With the engine stopped, step on the clutch pedal several

times with the same foot pressure to make sure that the

pedal height will not change.

Then step on the clutch pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

(4) With the engine running, step on the clutch pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance can

be determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

TSB Revision

Page 647 of 1146

POWER PLANT MOUNT - Engine Roll Stopper

ENGINE ROLL STOPPER

REMOVAL ANDINSTALLATION

32-5

MJZGF- .

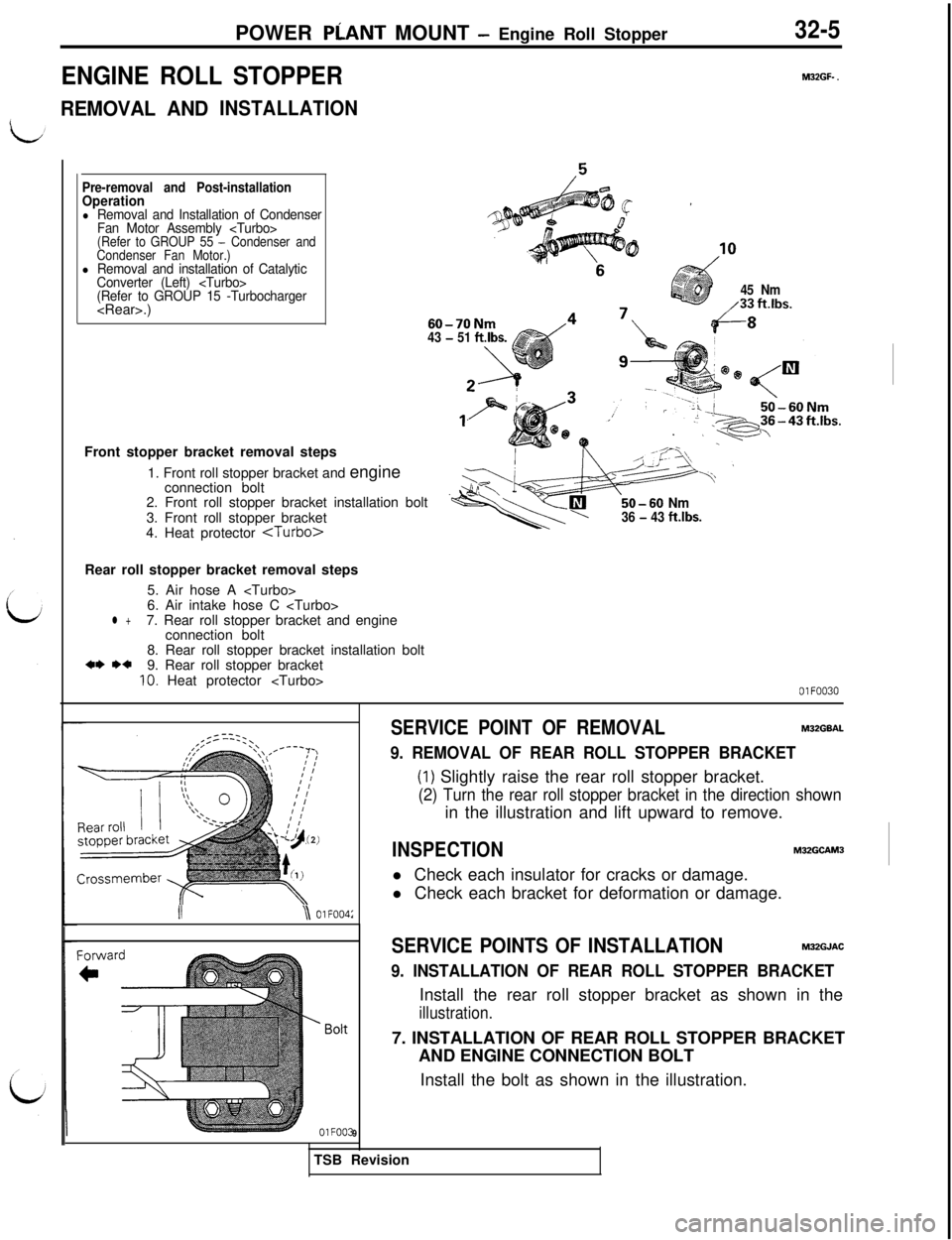

Pre-removal and Post-installationOperationl Removal and Installation of Condenser

Fan Motor Assembly

(Refer to GROUP 55 - Condenser and

Condenser Fan Motor.)

l Removal and installation of Catalytic

Converter (Left)

(Refer to GROUP 15 -Turbocharger

45 Nm/33 ft.lbs.

43

- 51 ftlbs.Front stopper bracket removal steps

1. Front roll stopper bracket and engine

connection bolt

2. Front roll stopper bracket installation bolt

3. Front roll stopper bracket

4. Heat protector

50-60 Nm36 - 43 ft.lbs.Rear roll stopper bracket removal steps

5. Air hose A

6. Air intake hose C

l +7. Rear roll stopper bracket and engine

connection bolt

8. Rear roll stopper bracket installation bolt

+* *+9. Rear roll stopper bracketIO. Heat protector

II\ OlFOO4:

SERVICE POINT OF REMOVALM32GEAL

9. REMOVAL OF REAR ROLL STOPPER BRACKET

(1) Slightly raise the rear roll stopper bracket.

(2) Turn the rear roll stopper bracket in the direction shownin the illustration and lift upward to remove.

INSPECTIONM32GCAM3l Check each insulator for cracks or damage.

l Check each bracket for deformation or damage.

9TSB Revision

SERVICE POINTS OF INSTALLATIONM32GJAC

9. INSTALLATION OF REAR ROLL STOPPER BRACKETInstall the rear roll stopper bracket as shown in the

illustration.7. INSTALLATION OF REAR ROLL STOPPER BRACKET

AND ENGINE CONNECTION BOLT

Install the bolt as shown in the illustration.

Page 666 of 1146

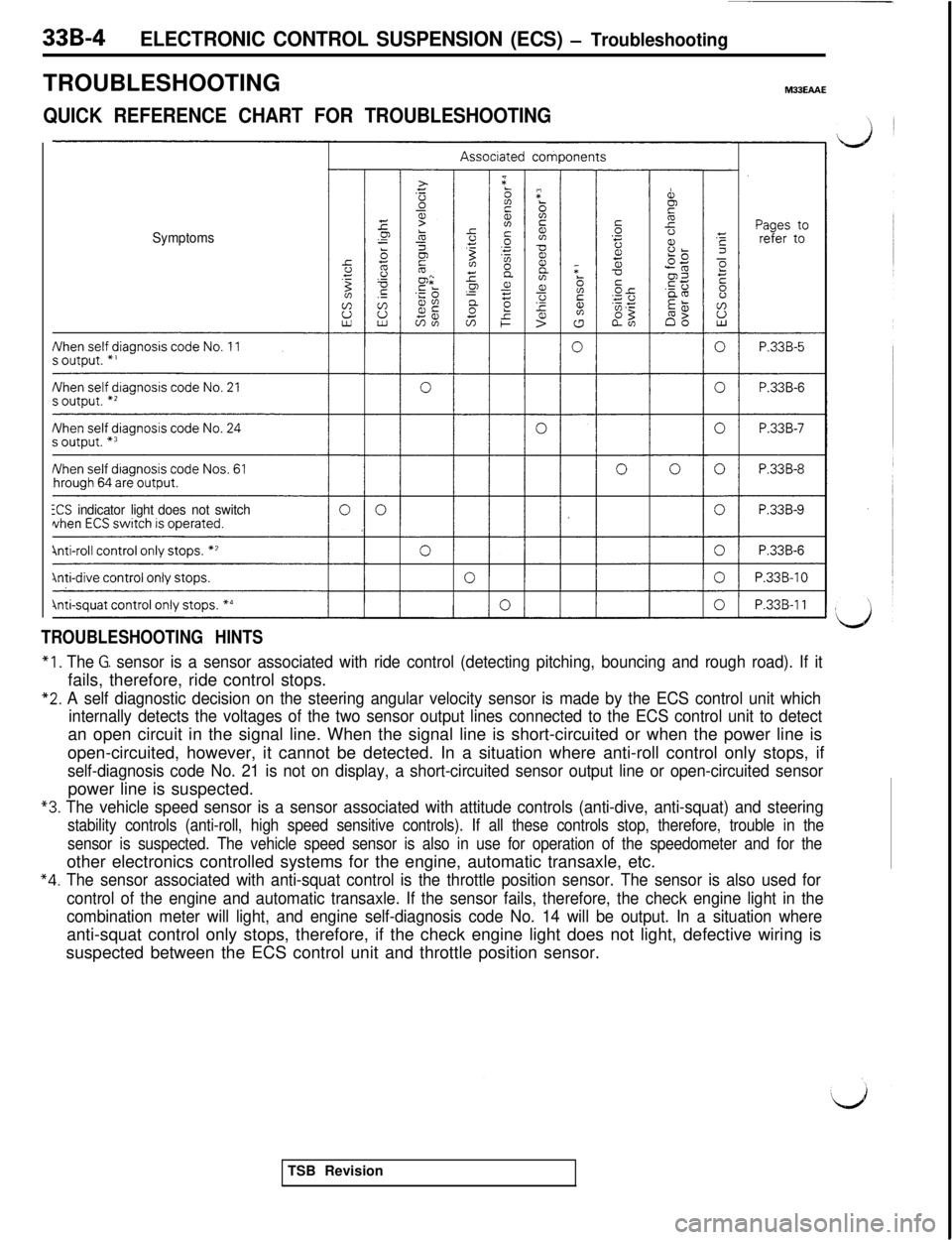

33B-4ELECTRONIC CONTROL SUSPENSION (ECS) - TroubleshootingTROUBLESHOOTING

M33EAAE

QUICK REFERENCE CHART FOR TROUBLESHOOTING

SymptomsXS

indicator lightdoes not switch

TROUBLESHOOTING HINTS

“1. The G. sensor is a sensor associated with ride control (detecting pitching, bouncing and rough road). If itfails, therefore, ride control stops.

“2. A self diagnostic decision on the steering angular velocity sensor is made by the ECS control unit which

internally detects the voltages of the two sensor output lines connected to the ECS control unit to detectan open circuit in the signal line. When the signal line is short-circuited or when the power line is

open-circuited, however, it cannot be detected. In a situation where anti-roll control only stops, if

self-diagnosis code No. 21 is not on display, a short-circuited sensor output line or open-circuited sensorpower line is suspected.

“3. The vehicle speed sensor is a sensor associated with attitude controls (anti-dive, anti-squat) and steering

stability controls (anti-roll, high speed sensitive controls). If all these controls stop, therefore, trouble in the

sensor is suspected. The vehicle speed sensor is also in use for operation of the speedometer and for theother electronics controlled systems for the engine, automatic transaxle, etc.

“4. The sensor associated with anti-squat control is the throttle position sensor. The sensor is also used for

control of the engine and automatic transaxle. If the sensor fails, therefore, the check engine light in the

combination meter will light, and engine self-diagnosis code No. 14 will be output. In a situation whereanti-squat control only stops, therefore, if the check engine light does not light, defective wiring is

suspected between the ECS control unit and throttle position sensor.

TSB Revision

Page 673 of 1146

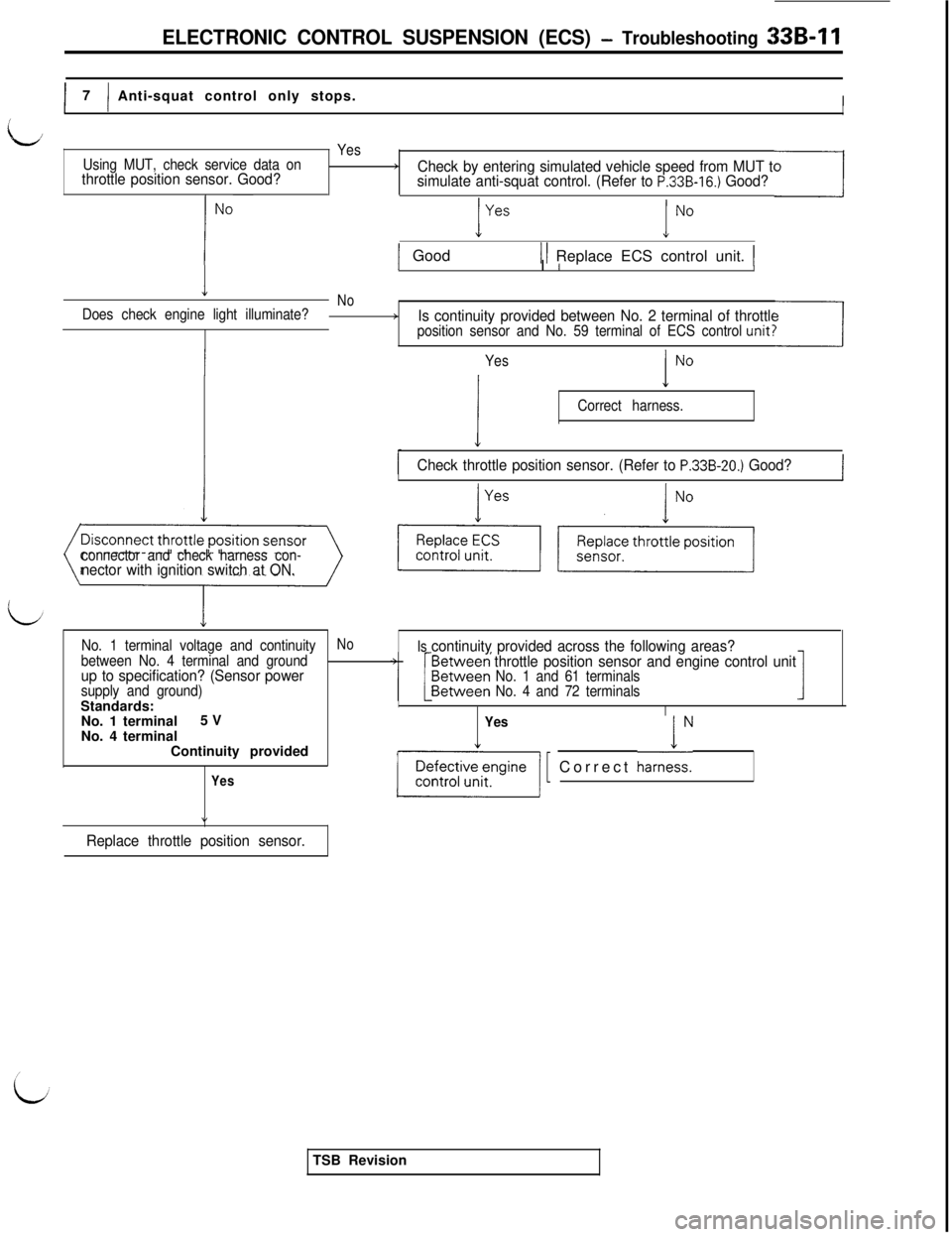

ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting 33B-11

I I7

Anti-squat control only stops.III

L,

I

Using MUT, check service data onthrottle position sensor. Good?

Yes

rCheck by entering simulated vehicle speed from MUT to

simulate anti-squat control. (Refer to P.33B-16.) Good?!

1 Good1 ) Replace ECS control unit. 1

I

1I II

NoDoes check engine light illuminate?>Is continuity provided between No. 2 terminal of throttleposition sensor and No. 59 terminal of ECS controlunityII

Yes

i

Correct harness.

1Check throttle position sensor. (Refer to P.33B-20.) Good?III1

connector and check harness con-nector with ignition switch at ON.

No. 1 terminal voltage and continuityNo

Is

between No. 4 terminal and groundcontinuity provided across the following areas?

up to specification? (Sensor powerthrottle position sensor and engine control unit

No. 1 and 61 terminals

supply and ground)

No. 4 and 72 terminalsStandards:

INo. 1 terminal5 V

YesNo. 4 terminal

Continuity provided

Yes-1 1 Correct harnei:

”

Replace throttle position sensor.TSB Revision

Page 729 of 1146

SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-7

ANTI-LOCK BRAKING SYSTEM TROUBLESHOOTlilGPARTICULAR PHENOMENA OF THE

LANTI-LOCK BRAKING SYSTEMModels equipped with the anti-lock braking system

(ABS) may exhibit one or more of the following

phenomena from time to time, but none of these

are abnormal.

(1) A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.

.9ctually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.(2) When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), a

whining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place, but this noise is simply the result

of a self-check being made of the anti-lock

braking system operation.

TROUBLESHOOTING METHODSProblems related to the anti-lock braking system

(ABS) can be classified into two general categories:

problems in the electrical system and those in the

Lhydraulic system.For problems in the electrical system, the

self-diagnosis function is built into the electronic control

unit (E.C.U.) causing the ABS warning light to

illuminate as a warning to the driver. In this instance,

checks can be made by using the multi-use tester

and oscilloscope.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check to

determine whether the problem is related to ordin-

ary brake components or to the components related

to the ABS. To make this check, use the multi-use

tester.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART(1) Using the flow chart, check the ABS warning

light light-up sequence. Read the diagnosis

codes and check the condition of braking opera-

tion.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Explana-

tion] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTEECU: Electronic control unit

HU: Hydraulic unit

MUT: Multi-use tester

1 TSB Revision

Page 730 of 1146

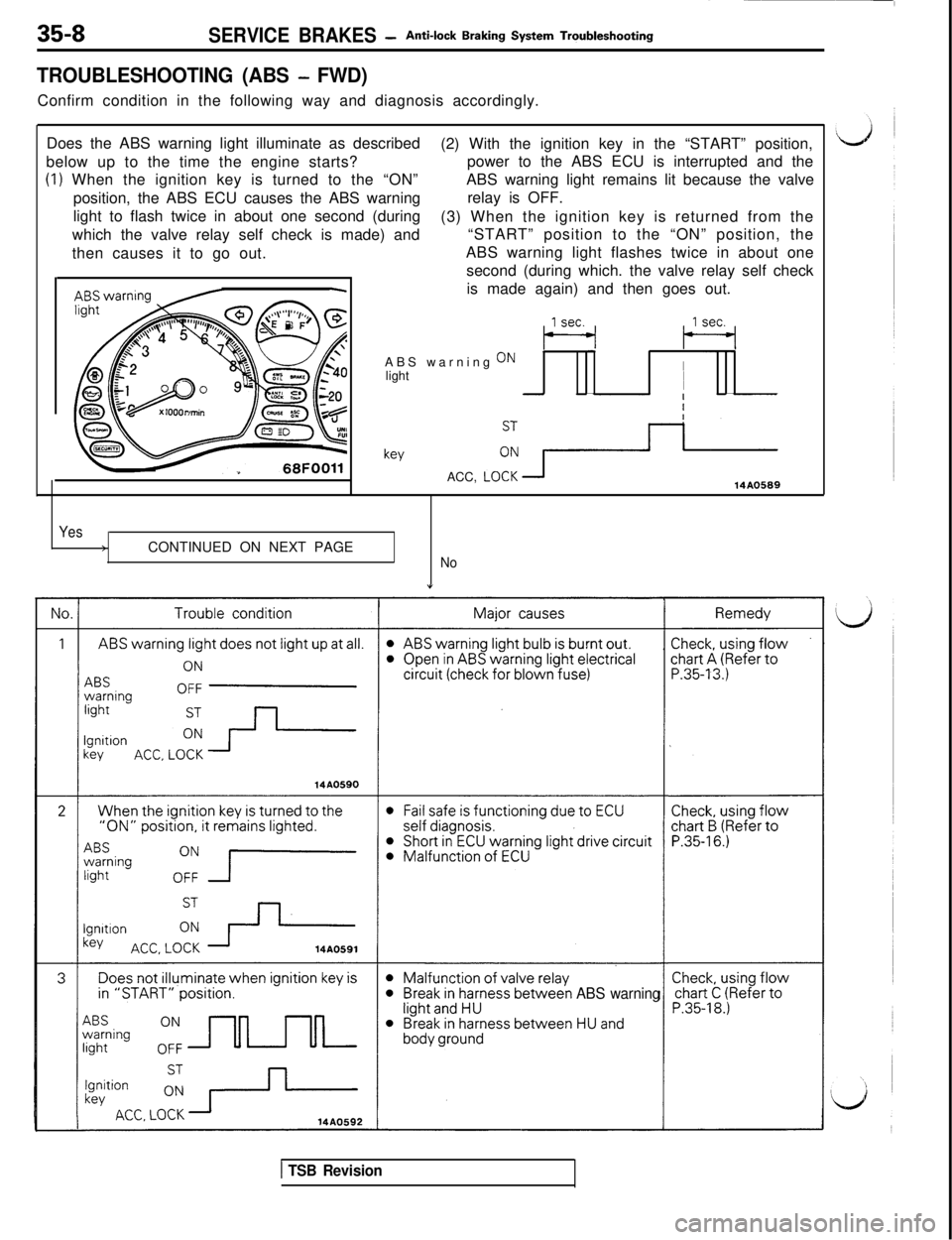

35-8SERVICE BRAKES -Anti-lock Braking System Troubleshooting

TROUBLESHOOTING (ABS - FWD)Confirm condition in the following way and diagnosis accordingly.

Does the ABS warning light illuminate as described

(2) With the ignition key in the “START” position,

below up to the time the engine starts?power to the ABS ECU is interrupted and the

(1) When the ignition key is turned to the “ON”ABS warning light remains lit because the valve

position, the ABS ECU causes the ABS warningrelay is OFF.

light to flash twice in about one second (during

(3) When the ignition key is returned from the

which the valve relay self check is made) and“START” position to the “ON” position, the

then causes it to go out.ABS warning light flashes twice in about one

second (during which. the valve relay self check

-is made again) and then goes out.

ABS warning

ONlightII

-I

keyACC,

LO!: +--14A0589

Yes>CONTINUED ON NEXT PAGE

No

”

weenABS warning

1 TSB Revision

Page 738 of 1146

![MITSUBISHI 3000GT 1991 Owners Manual 35-16SERVICE BRAKES -Anti-lock Braking System Troubleshooting

BABS warning light stays on when the ignition key is in the “ON” position.

[Explanation]

[Hint]

This is the symptom when the ABS ECU d MITSUBISHI 3000GT 1991 Owners Manual 35-16SERVICE BRAKES -Anti-lock Braking System Troubleshooting

BABS warning light stays on when the ignition key is in the “ON” position.

[Explanation]

[Hint]

This is the symptom when the ABS ECU d](/img/19/57085/w960_57085-737.png)

35-16SERVICE BRAKES -Anti-lock Braking System Troubleshooting

BABS warning light stays on when the ignition key is in the “ON” position.

[Explanation]

[Hint]

This is the symptom when the ABS ECU does not

Check the diagnosis output and if there is no output

power up due to broken ECU power circuit, etc.,

voltage or if the MUT and ABS ECU cannot

when the fail safe function operates and isolates thecommunicate, there is a good possibility that power

system or when the warning light drive circuit is

is not flowing to the ECU.

short circuited.

!8IGNIISWIT(-

:Et

J’B @

C151

:

E

COMBINATION

METER

-19

7

------____-_---1

2

610 2

~;@lizEFgIIc,

6227J

r bL-1

IN(IGl)

1

,

ig

)

158

7

r-TSB iCaution

lIf the trouble code is output, the system can

be in the fail safe mode. in such a case, erase

the trouble code and then restart the engine

to check if the system is currently in a fault

condition.

~~~~

~~~~1

I,No ,I

Yes6

Replace ECU.

41,No rIDoes the ABS warning light

remain illuminated even with

the HU connector discon-

nected?

Yes

Short-circuit in harness

between HU or ECU and ABS

warning light

> Repair harness or replace

combination meter.

bvision

Page 748 of 1146

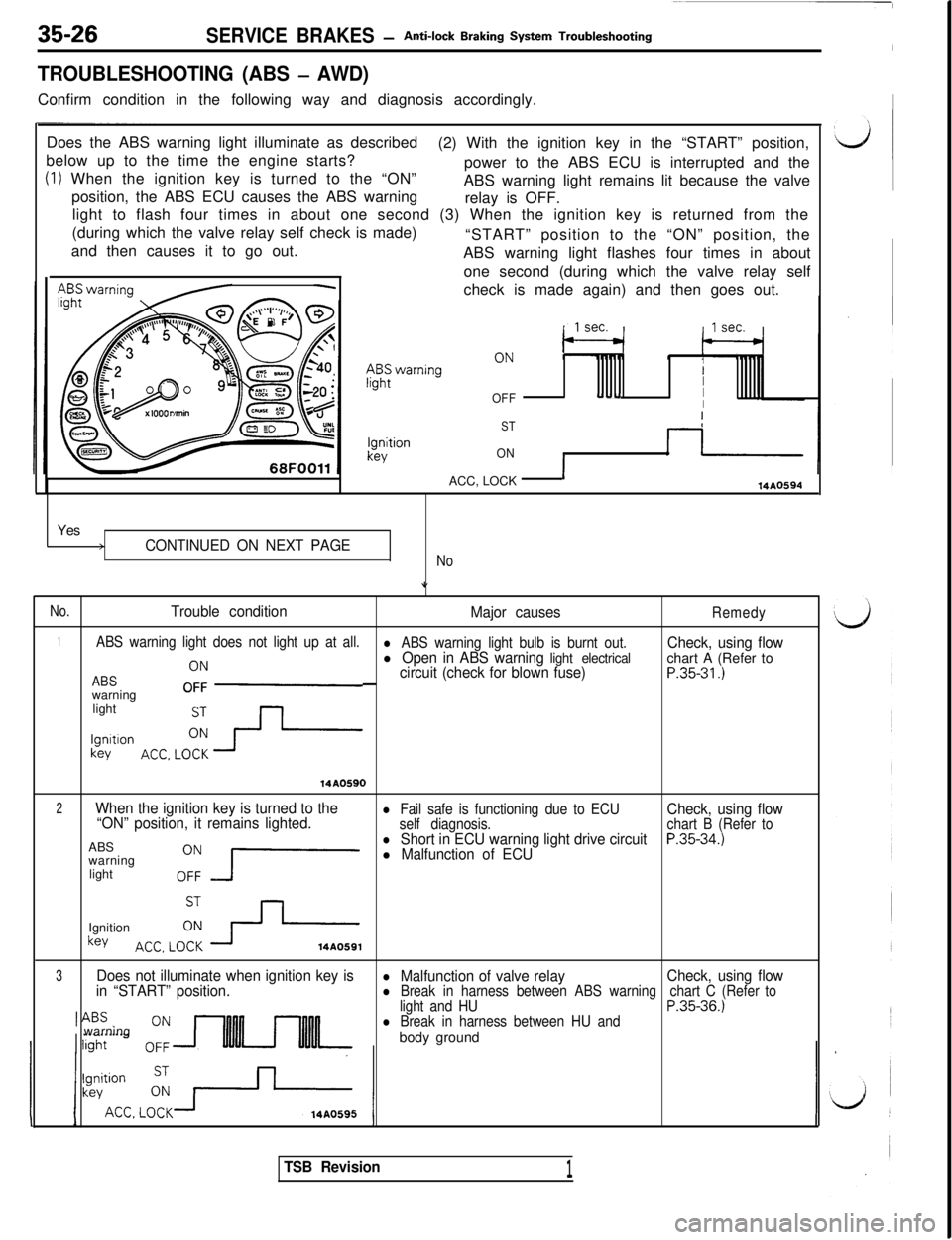

35-26SERVICE BRAKES -Anti-lock Braking System TroubleshootingI

TROUBLESHOOTING (ABS - AWD)Confirm condition in the following way and diagnosis accordingly.

Does the ABS warning light illuminate as described

below up to the time the engine starts?(2) With the ignition key in the “START” position,

(1) When the ignition key is turned to the “ON”power to the ABS ECU is interrupted and the

position, the ABS ECU causes the ABS warningABS warning light remains lit because the valve

relay is OFF.

light to flash four times in about one second (3) When the ignition key is returned from the

(during which the valve relay self check is made)

and then causes it to go out.“START” position to the “ON” position, the

ABS warning light flashes four times in about

one second (during which the valve relay self

-check is made again) and then goes out.

III

OFFu--I-II

ST

ONACC, LOCK

114A0594Yes

>CONTINUED ON NEXT PAGE

No

No.

Trouble condition

Major causesRemedy

1ABS warning light does not light up at all.l ABS warning light bulb is burnt out.

ACC,LOb--

l Open in ABS warning light electricalCheck, using flowchart A (Refer to

ABScircuit (check for blown fuse)P.35-31.)warningOFFlight

lgmtlon

key

14AO590

2When the ignition key is turned to the

“ON” position, it remains lighted.l Fail safe is functioning due to ECU

self diagnosis.Check, using flowchart B (Refer toABS,“,F

J-l Short in ECU warning light drive circuitP.35-34.)warningl Malfunction of ECUlight

Ignition

key.;i,LOi h

3Does not illuminate when ignition key is

in “START” position.l Malfunction of valve relayl Break in harness between ABS warningCheck, using flowchart C (Refer to

light and HUP.35-36.)l Break in harness between HU andwarning

body ground

TSB Revision1

Page 756 of 1146

![MITSUBISHI 3000GT 1991 Owners Manual 35-34SERVICE BRAKES -Anti-lock Braking System Troubleshooting

II1

1 B 1 ABS warning light stays on when the ignition key is in the “ON” position.1II\[Explanation]

[Hint]

k.JThis is the symptom whe MITSUBISHI 3000GT 1991 Owners Manual 35-34SERVICE BRAKES -Anti-lock Braking System Troubleshooting

II1

1 B 1 ABS warning light stays on when the ignition key is in the “ON” position.1II\[Explanation]

[Hint]

k.JThis is the symptom whe](/img/19/57085/w960_57085-755.png)

35-34SERVICE BRAKES -Anti-lock Braking System Troubleshooting

II1

1 B 1 ABS warning light stays on when the ignition key is in the “ON” position.1II\[Explanation]

[Hint]

k.JThis is the symptom when the ABS ECU does not

power up due to broken ECU power circuit, etc.,Check the diagnosis output and if there is no output

when the fail safe function operates and isolates thevoltage or if the MUT and ABS ECU cannot

system or when the warning light drive circuit iscommunicate, there is a good possibility that power

short circuited.is not flowing to the ECU.

IGNITIONSWITCH(IG1)Caution

lIf the trouble code is output, the system can

be in the fail safe mode. In such a case, erase

the trouble code and then restart the engine

to check if the system is currently in a fault

condition.

f

j @

?

j 0

:ml-

I2a-----11 g:I aI7

:I1

-_307a

-

I-=_-. -----------1

P

Y

4 a:&

I25ABS

ECU

iz- 11213 ia1516j7j819~10~11~12~13~14~15~16~17~1819l20l21C2C3Ca~25~~7~3~29~0~1~32~3~35

:95-AK-R9502

4

Replace ECU.

I YesI.

Replace HU or replace

valve relay.

I

_

ai.. .

ITSB hevIsIon