check engine light MITSUBISHI 3000GT 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 767 of 1146

SERVICE BRAKES - Set-vice Adiustment Procedures35-45lUF51F

Pedal

7\ \!4FOO7.

F14511

F14519

TSB Revision-_.1

SERVICE ADJUSTMENT PROCEDURES

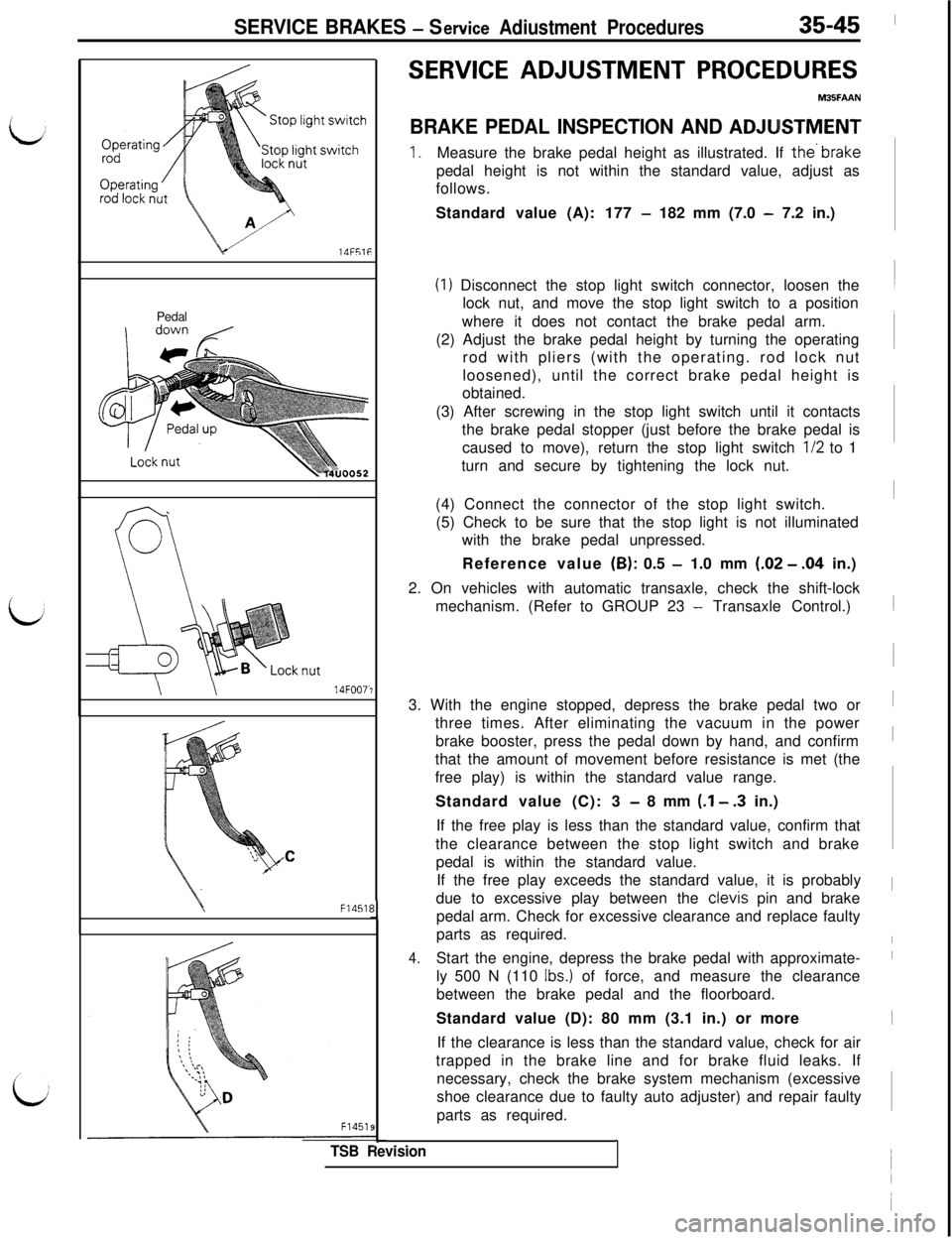

BRAKE PEDAL INSPECTION AND ADJUSTMENT

1.Measure the brake pedal height as illustrated. If the’brakepedal height is not within the standard value, adjust as

follows.

Standard value (A): 177

- 182 mm (7.0 - 7.2 in.)

(I) Disconnect the stop light switch connector, loosen the

lock nut, and move the stop light switch to a position

where it does not contact the brake pedal arm.

(2) Adjust the brake pedal height by turning the operating

rod with pliers (with the operating. rod lock nut

loosened), until the correct brake pedal height is

obtained.

(3) After screwing in the stop light switch until it contacts

the brake pedal stopper (just before the brake pedal is

caused to move), return the stop light switch

l/2 to 1

turn and secure by tightening the lock nut.

(4) Connect the connector of the stop light switch.

(5) Check to be sure that the stop light is not illuminated

with the brake pedal unpressed.

Reference value (6): 0.5

- 1.0 mm (.02 - .04 in.)

2. On vehicles with automatic transaxle, check the shift-lock

mechanism. (Refer to GROUP 23

- Transaxle Control.)

3. With the engine stopped, depress the brake pedal two or

three times. After eliminating the vacuum in the power

brake booster, press the pedal down by hand, and confirm

that the amount of movement before resistance is met (the

free play) is within the standard value range.

Standard value (C): 3

- 8 mm (.I - .3 in.)

If the free play is less than the standard value, confirm that

the clearance between the stop light switch and brake

pedal is within the standard value.

If the free play exceeds the standard value, it is probably

due to excessive play between the clevis pin and brake

pedal arm. Check for excessive clearance and replace faulty

parts as required.

4.Start the engine, depress the brake pedal with approximate-

ly 500 N (110

Ibs.) of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value (D): 80 mm (3.1 in.) or more

If the clearance is less than the standard value, check for air

trapped in the brake line and for brake fluid leaks. If

necessary, check the brake system mechanism (excessive

shoe clearance due to faulty auto adjuster) and repair faulty

parts as required.~1~1

I

I

I

I

I

Page 768 of 1146

35-46SERVICE BRAKES - Service Adjustment Procedures

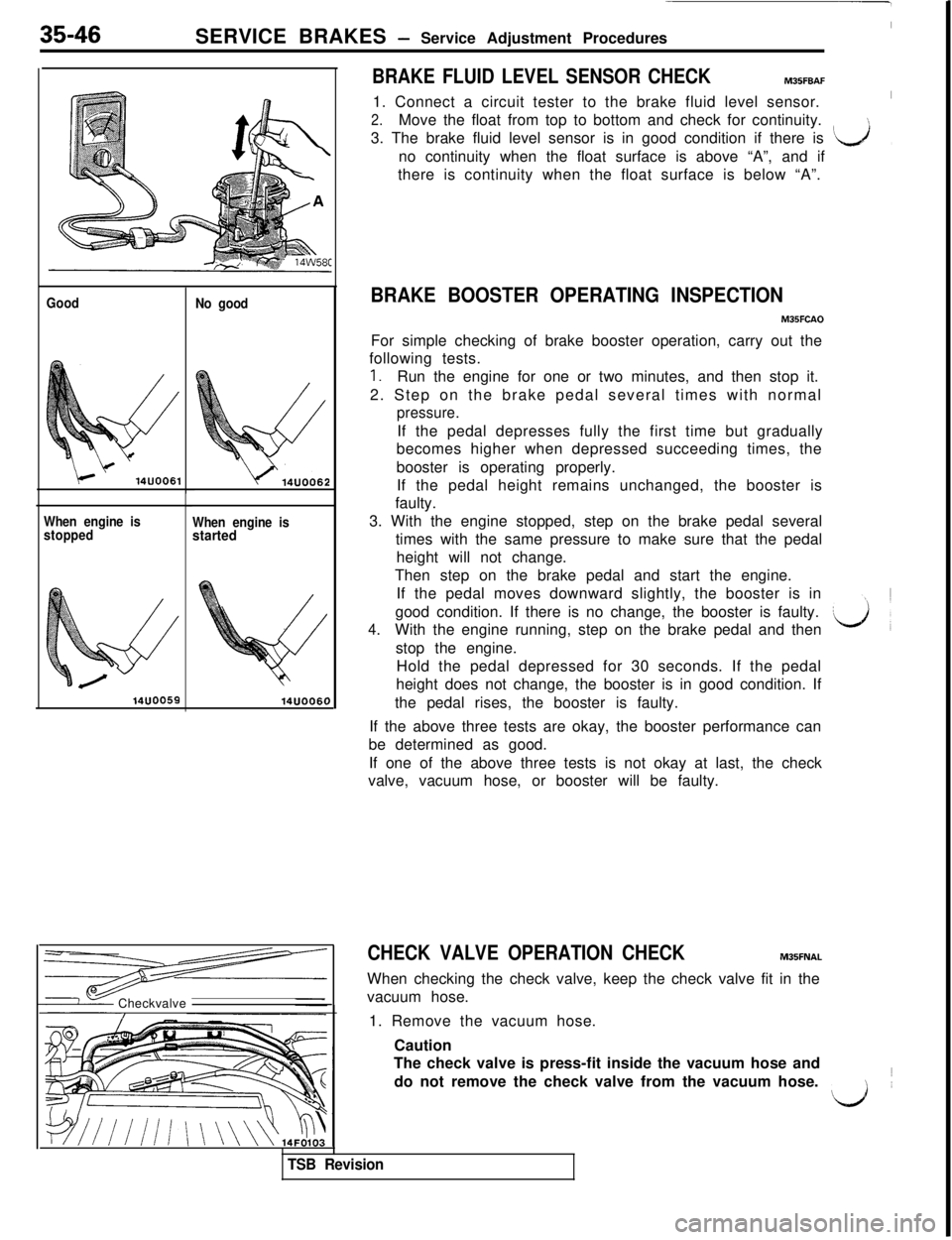

BRAKE FLUID LEVEL SENSOR CHECK

I

MBSFBAF

Good

k‘14UOO61

When engine is

stoppedNo good

When engine isstarted

14UOO6C)Checkvalve/1. Connect a circuit tester to the brake fluid level sensor.

I

2.Move the float from top to bottom and check for continuity.

3. The brake fluid level sensor is in good condition if there is

‘k&Jno continuity when the float surface is above “A”, and if,there is continuity when the float surface is below “A”.

BRAKE BOOSTER OPERATING INSPECTION

M35FCAOFor simple checking of brake booster operation, carry out the

following tests.

1.Run the engine for one or two minutes, and then stop it.

2. Step on the brake pedal several times with normal

pressure.If the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

3. With the engine stopped, step on the brake pedal several

times with the same pressure to make sure that the pedal

height will not change.

Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

4.With the engine running, step on the brake pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition. If

the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance can

be determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

CHECK VALVE OPERATION CHECKM35FNALWhen checking the check valve, keep the check valve fit in the

vacuum hose.

1. Remove the vacuum hose.

Caution

The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.1

d~

TSB Revision

Page 780 of 1146

35-58SERVICE BRAKES - Service Adjustment Procedures

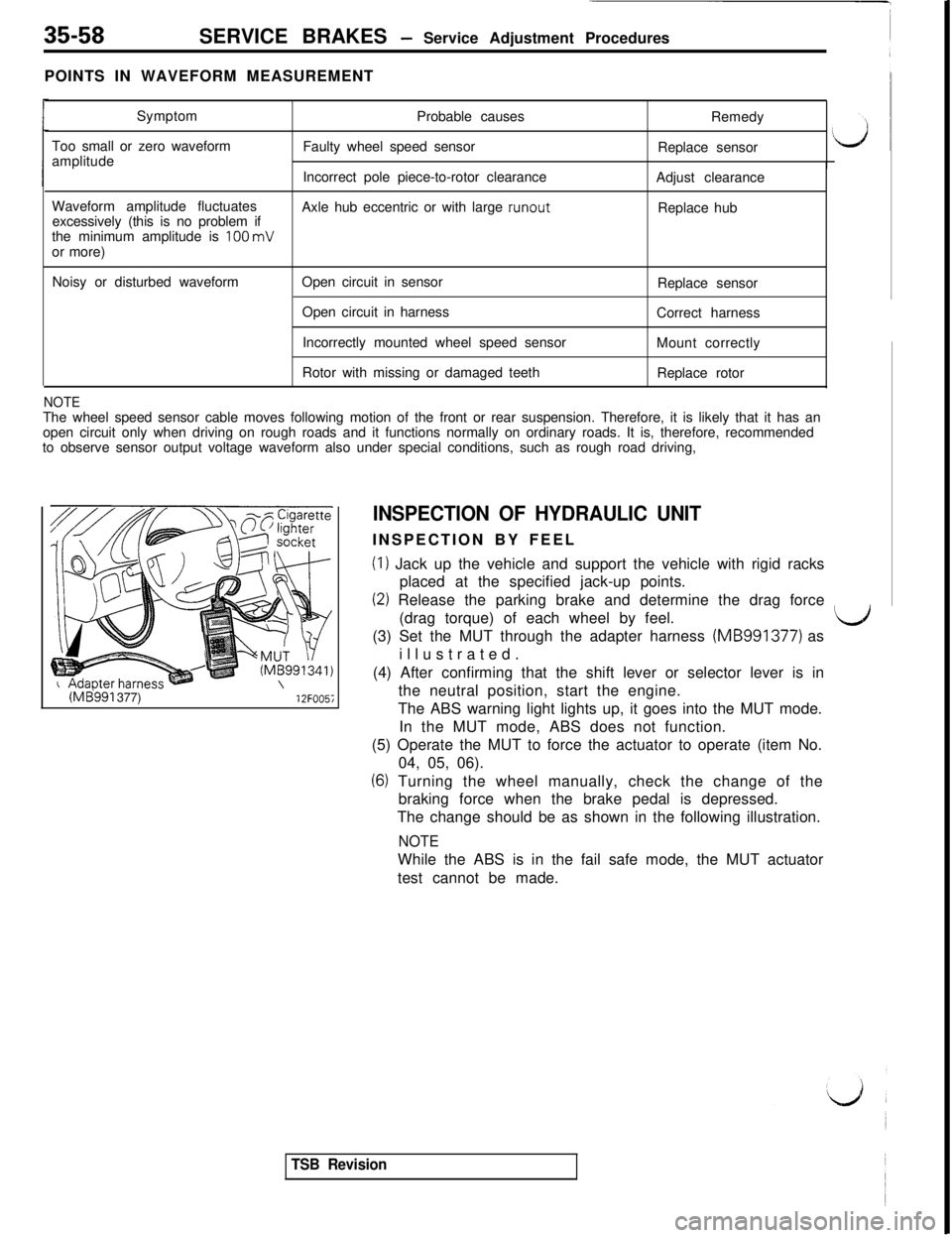

POINTS IN WAVEFORM MEASUREMENT

Symptom

Too small or zero waveform

amplitudeProbable causes

Faulty wheel speed sensorRemedy

Replace sensor

Incorrect pole piece-to-rotor clearance

Adjust clearance

Waveform amplitude fluctuates

excessively (this is no problem ifAxle hub eccentric or with large runout

Replace hub

the minimum amplitude is

100 mV

or more)

Noisy or disturbed waveformOpen circuit in sensor

Open circuit in harness

Incorrectly mounted wheel speed sensor

Rotor with missing or damaged teethReplace sensor

Correct harness

Mount correctly

Replace rotor

NOTEThe wheel speed sensor cable moves following motion of the front or rear suspension. Therefore, it is likely that it has an

open circuit only when driving on rough roads and it functions normally on ordinary roads. It is, therefore, recommended

to observe sensor output voltage waveform also under special conditions, such as rough road driving,

(ME!991 377)12FOO5i

INSPECTION OF HYDRAULIC UNITINSPECTION BY FEEL

(I) Jack up the vehicle and support the vehicle with rigid racks

placed at the specified jack-up points.

(2) Release the parking brake and determine the drag force

(drag torque) of each wheel by feel.

LJ(3) Set the MUT through the adapter harness (MB991377) as

illustrated.

(4) After confirming that the shift lever or selector lever is in

the neutral position, start the engine.

The ABS warning light lights up, it goes into the MUT mode.

In the MUT mode, ABS does not function.

(5) Operate the MUT to force the actuator to operate (item No.

04, 05, 06).

(6) Turning the wheel manually, check the change of the

braking force when the brake pedal is depressed.

The change should be as shown in the following illustration.

NOTEWhile the ABS is in the fail safe mode, the MUT actuator

test cannot be made.

TSB Revision

Page 784 of 1146

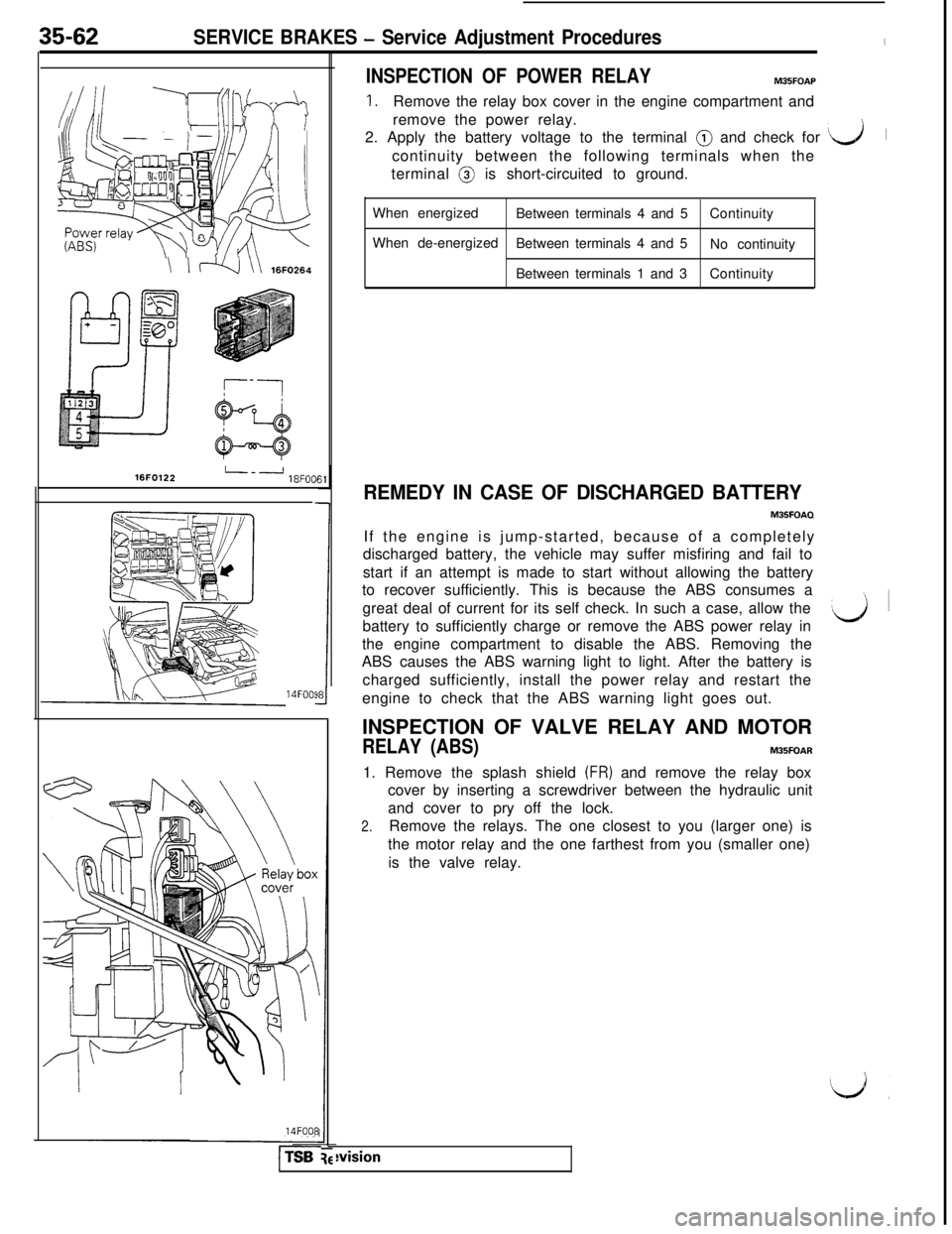

When energized

Between terminals 4 and 5Continuity

When de-energized

Between terminals 4 and 5\i fl \\ 16FO264No continuity

Between terminals 1 and 3Continuity

16FO122L--J18FOCII

SERVICE BRAKES - Service Adjustment ProceduresI

INSPECTION OF POWER RELAYM35FOAP

7

1.Remove the relay box cover in the engine compartment and

remove the power relay.

2. Apply the battery voltage to the terminal @ and check for

‘L-J1

continuity between the following terminals when the

terminal @ is short-circuited to ground.

35-62

14FOOS14FOO8

l-TSB

1

REMEDY IN CASE OF DISCHARGED BATTERY

M35FOAQIf the engine is jump-started, because of a completely

discharged battery, the vehicle may suffer misfiring and fail to

start if an attempt is made to start without allowing the battery

to recover sufficiently. This is because the ABS consumes a

great deal of current for its self check. In such a case, allow the

battery to sufficiently charge or remove the ABS power relay in

the engine compartment to disable the ABS. Removing the

ABS causes the ABS warning light to light. After the battery is

charged sufficiently, install the power relay and restart the

engine to check that the ABS warning light goes out.

INSPECTION OF VALVE RELAY AND MOTOR

RELAY (ABS)M35FOAR1. Remove the splash shield

(FR) and remove the relay box

cover by inserting a screwdriver between the hydraulic unit

and cover to pry off the lock.

2.Remove the relays. The one closest to you (larger one) is

the motor relay and the one farthest from you (smaller one)

is the valve relay.

‘d~ i

wision

Page 833 of 1146

STEERING 2 Service Adjustment Procedures37A-5

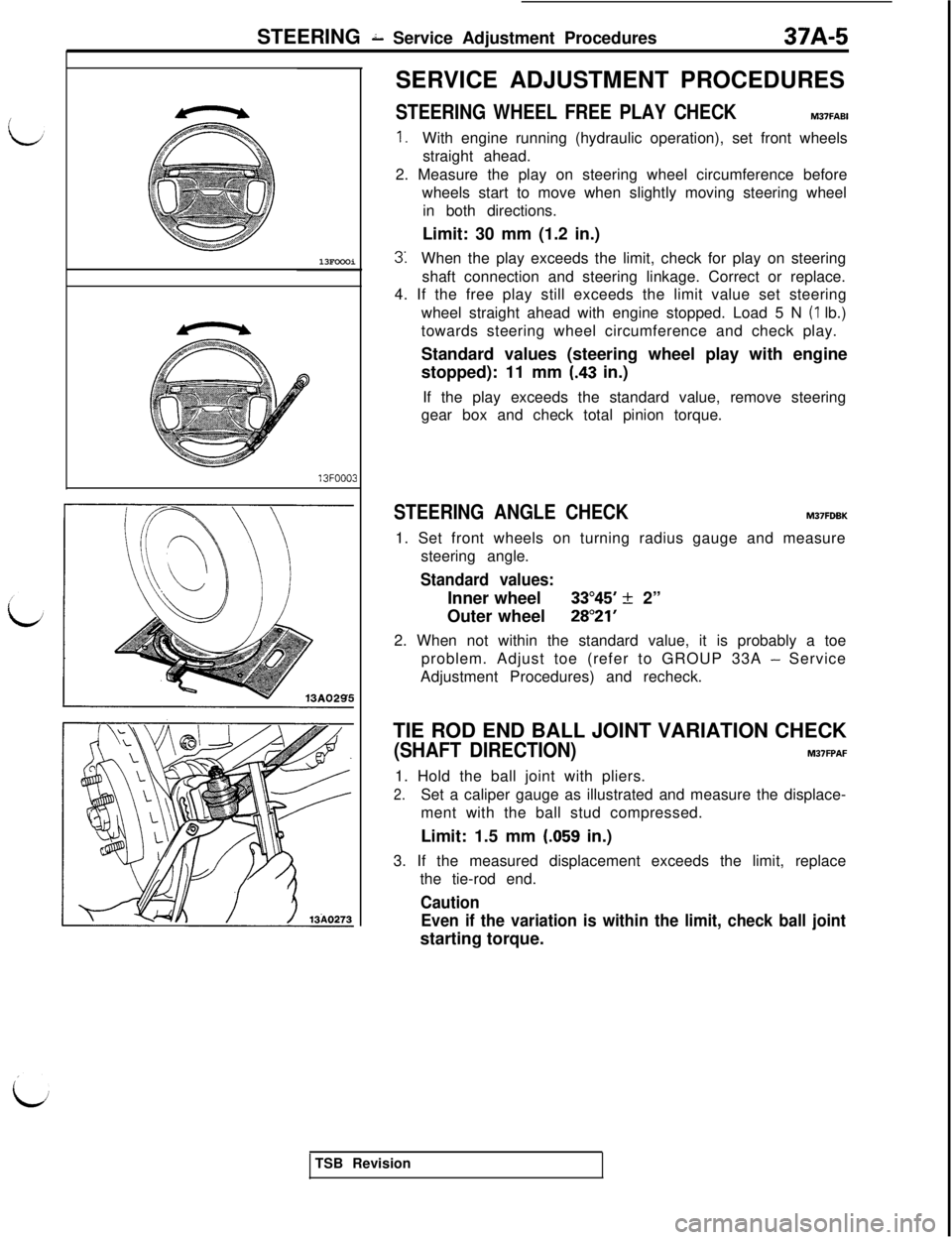

13FOOOi13FOOO3SERVICE ADJUSTMENT PROCEDURES

STEERING WHEEL FREE PLAY CHECKM37FABI

1.With engine running (hydraulic operation), set front wheels

straight ahead.

2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm (1.2 in.)

3:When the play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4. If the free play still exceeds the limit value set steering

wheel straight ahead with engine stopped. Load 5 N

(1 lb.)

towards steering wheel circumference and check play.

Standard values (steering wheel play with engine

stopped): 11 mm

(.43 in.)

If the play exceeds the standard value, remove steering

gear box and check total pinion torque.

STEERING ANGLE CHECKM37FDBK1. Set front wheels on turning radius gauge and measure

steering angle.

Standard values:Inner wheel

33”45’ k 2”

Outer wheel

28”21’2. When not within the standard value, it is probably a toe

problem. Adjust toe (refer to GROUP 33A

- Service

Adjustment Procedures) and recheck.

TIE ROD END BALL JOINT VARIATION CHECK

(SHAFT DIRECTION)M37FPAF1. Hold the ball joint with pliers.

2.Set a caliper gauge as illustrated and measure the displace-

ment with the ball stud compressed.

Limit: 1.5 mm

(.059 in.)

3. If the measured displacement exceeds the limit, replace

the tie-rod end.

Caution

Even if the variation is within the limit, check ball jointstarting torque.

TSB Revision

Page 873 of 1146

42-1

BODY

CONTENTSM42AA- -

CENTER PILLAR GLASS........................................................32

CENTRAL DOOR LOCKING SYSTEM

................................55

DOOR ASSEMBLY....................................................................40

DOOR GLASS AND REGULATOR

........................................42

DOOR HANDLE AND LATCH

................................................54

DOOR TRIM AND WATERPROOF FILM

............................41

DRIP LINE WEATHERSTRIP....................................................65

ENGINE HOOD........................................................................18

FENDER*....................................................................................23

FUEL TANK FILLER DOOR

....................................................22

LIFTGATE....................................................................................20

LIFTGATE GLASS....................................................................37

LOOSE PANEL

........................................................................24

POWER WINDOW

....................................................................43

QUARTER WINDOW GLASS

................................................33SERVICE ADJUSTMENT PROCEDURES

............................

Door Adjustment................................................................Door inside Handle Play Check............................................Door Window Glass Adjustment........................................Floor Pan inspection............................................................Fuel Filler Door Adjustment................................................Hood Adjustment................................................................Liftgate Adjustment............................................................

SPECIAL TOOLS........................................................................

SPECIFICATIONS....................................................................

General Specifications........................................................Sealants and Adhesives........................................................

ServiceSpecifications........................................................

TROUBLESHOOTING............................................................

WINDOW GLASS....................................................................

WINDSHIELD............................................................................

13

14

16

14

17

14

13

13

4

2

2

3

3

5

25

28

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of the

SRS or any SRS-related component.

Page 891 of 1146

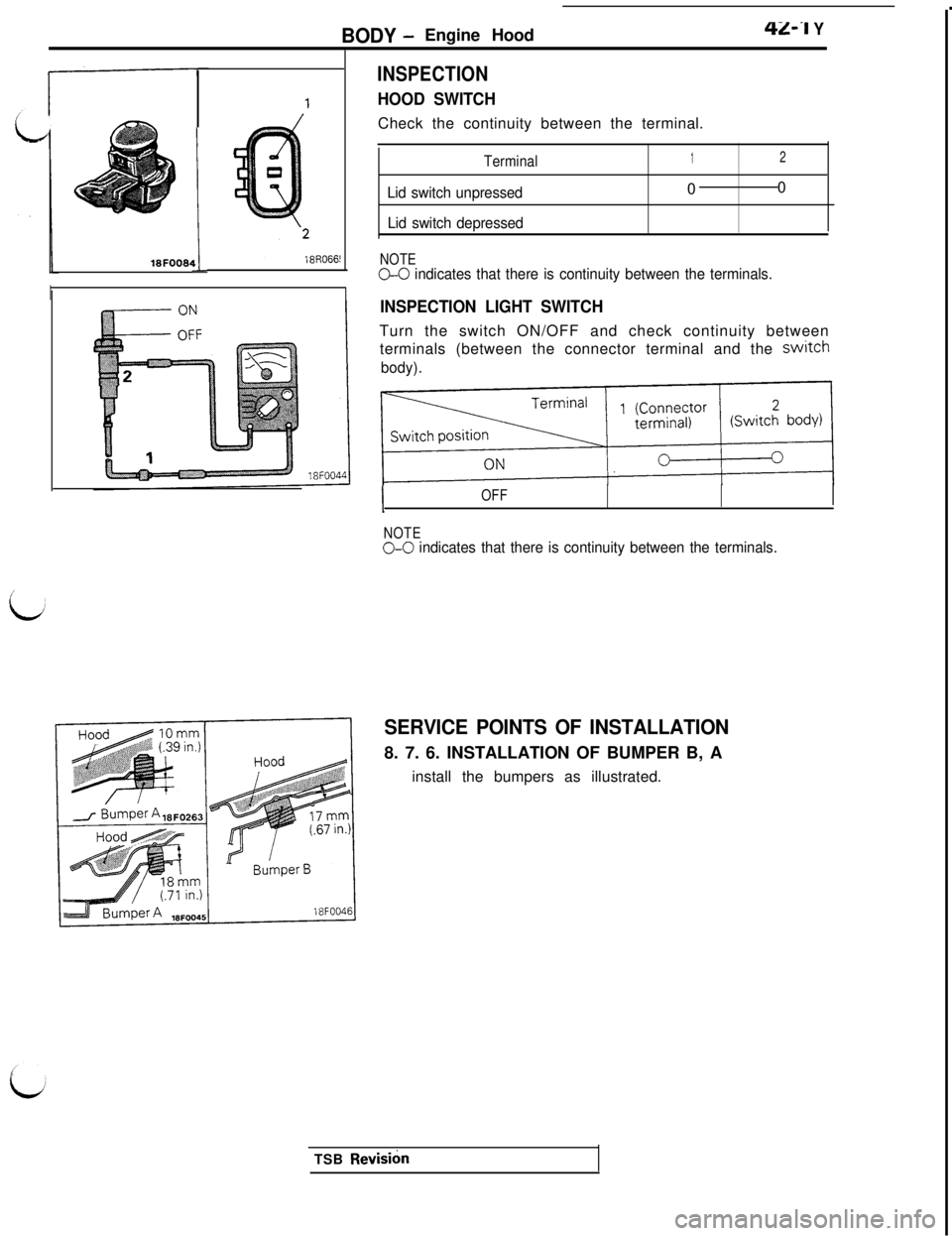

BODY -Engine Hood42-I Y18FOOW

!I

II

INSPECTION

HOOD SWITCHCheck the continuity between the terminal.

Terminal

Lid switch unpressed

Lid switch depressed

1200

NOTEG-0 indicates that there is continuity between the terminals.

INSPECTION LIGHT SWITCHTurn the switch ON/OFF and check continuity between

terminals (between the connector terminal and the

switch

body).

IOFF

NOTE

O-0 indicates that there is continuity between the terminals.

t

SERVICE POINTS OF INSTALLATION8. 7. 6. INSTALLATION OF BUMPER B, A

install the bumpers as illustrated.

TSB

Revish

Page 1027 of 1146

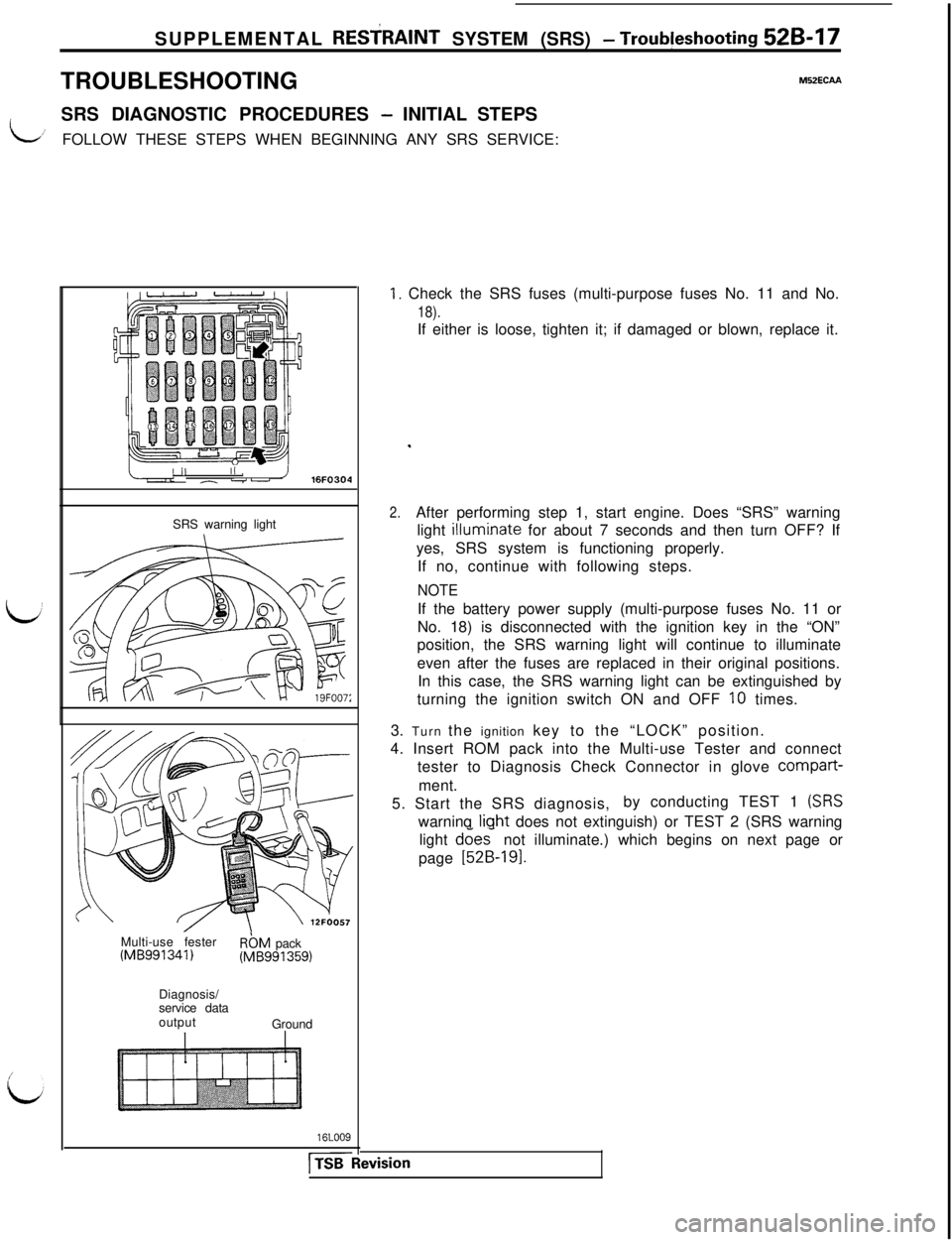

SUPPLEMENTAL RESfRAlNT SYSTEM (SRS) - Troub!eshooting 52B-17TROUBLESHOOTING

M52ECAA

idSRS DIAGNOSTIC PROCEDURES

- INITIAL STEPS’FOLLOW THESE STEPS WHEN BEGINNING ANY SRS SERVICE:

/II/ ,- -u’ 16FO304

SRS warning light

Multi-use fester

(MB991341)RbM pack(MB991359)

Diagnosis/

service data

output

Ground

16LOO9

[TSB

1. Check the SRS fuses (multi-purpose fuses No. 11 and No.

18).If either is loose, tighten it; if damaged or blown, replace it.

.

2.After performing step 1, start engine. Does “SRS” warning

light

illumi.nate for about 7 seconds and then turn OFF? If

yes, SRS system is functioning properly.

If no, continue with following steps.

NOTEIf the battery power supply (multi-purpose fuses No. 11 or

No. 18) is disconnected with the ignition key in the “ON”

position, the SRS warning light will continue to illuminate

even after the fuses are replaced in their original positions.

In this case, the SRS warning light can be extinguished by

turning the ignition switch ON and OFF

10 times.

3. Turn the ignition key to the “LOCK” position.

4. Insert ROM pack into the Multi-use Tester and connect

tester to Diagnosis Check Connector in glove compart-

ment.

5. Start the SRS diagnosis,by conducting TEST 1

(SRSwarninq liqht does not extinguish) or TEST 2 (SRS warning

light does- not illuminate.) which begins on next page or

page

[52B-191.

ivision

Page 1028 of 1146

52B-18 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

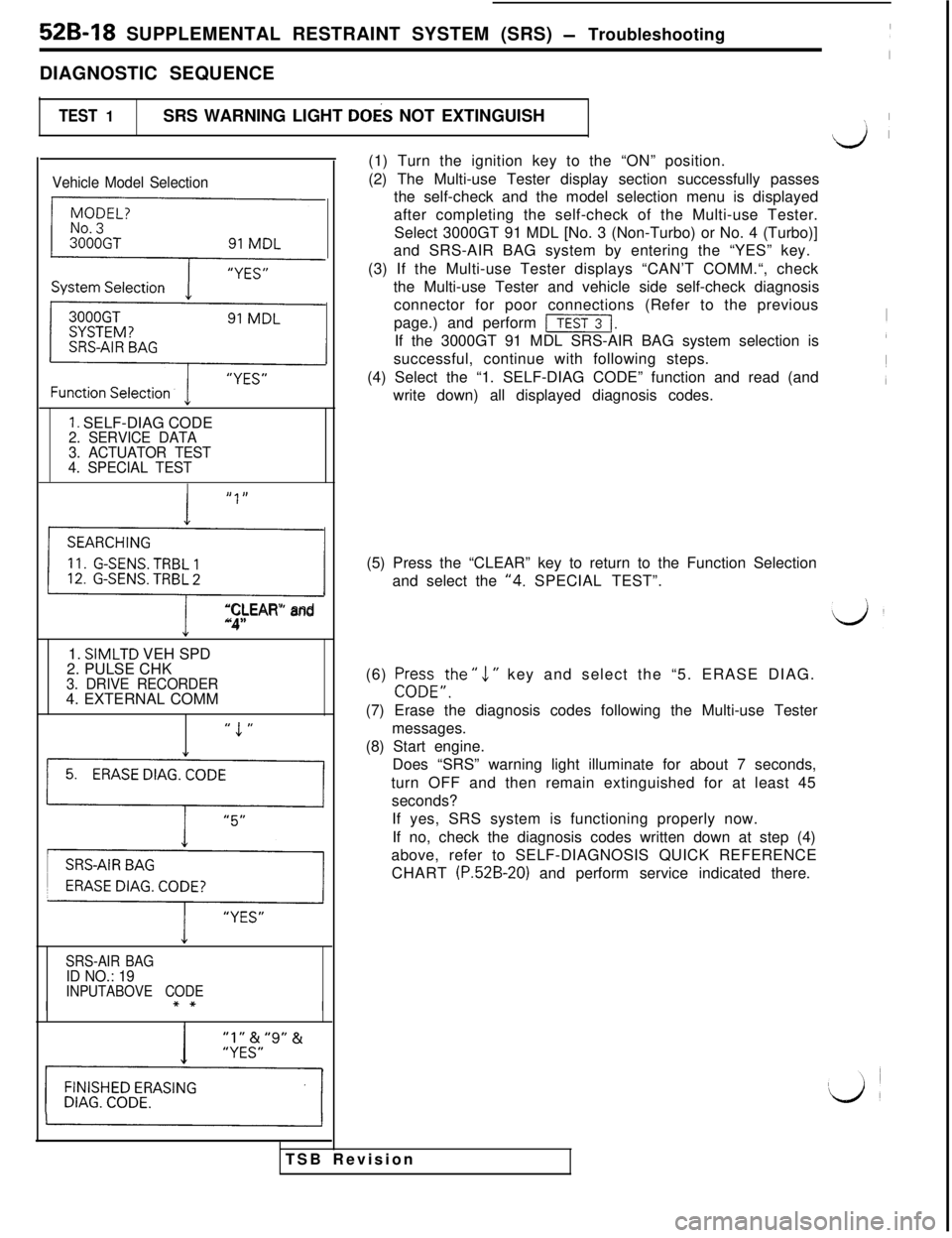

DIAGNOSTIC SEQUENCE

TEST 1SRS WARNING LIGHT DOES NOT EXTINGUISH

\1 I

Vehicle Model Selection

{

F

1. SELF-DIAG CODE2. SERVICE DATA

3. ACTUATOR TEST

4. SPECIAL TEST

,, I,

0

“CLEAR” and“4”1.

SIMLTD VEH SPD

2. PULSE CHK

3. DRIVE RECORDER4. EXTERNAL COMM

” 1 ”

1’1

y,,

SRS-AIR BAGID NO.: 19INPUTABOVE CODE

I(1) Turn the ignition key to the “ON” position.

(2) The Multi-use Tester display section successfully passes

the self-check and the model selection menu is displayed

after completing the self-check of the Multi-use Tester.

Select 3000GT 91 MDL [No. 3 (Non-Turbo) or No. 4 (Turbo)]

and SRS-AIR BAG system by entering the “YES” key.

(3) If the Multi-use Tester displays “CAN’T COMM.“, check

the Multi-use Tester and vehicle side self-check diagnosis

TSB Revisionconnector for poor connections (Refer to the previous

page.) and perform

[I.If the 3000GT 91 MDL SRS-AIR BAG system selection is

successful, continue with following steps.

(4) Select the “1. SELF-DIAG CODE” function and read (and

write down) all displayed diagnosis codes.

(5) Press the “CLEAR” key to return to the Function Selection

and select the

“4. SPECIAL TEST”.

(6) Pr+FE,the ”

1 ” key and select the “5. ERASE DIAG.

(7) Erase the diagnosis codes following the Multi-use Tester

messages.

(8) Start engine.

Does “SRS” warning light illuminate for about 7 seconds,

turn OFF and then remain extinguished for at least 45

seconds?

If yes, SRS system is functioning properly now.

If no, check the diagnosis codes written down at step (4)

above, refer to SELF-DIAGNOSIS QUICK REFERENCE

CHART

(P.52B-20) and perform service indicated there.

Page 1049 of 1146

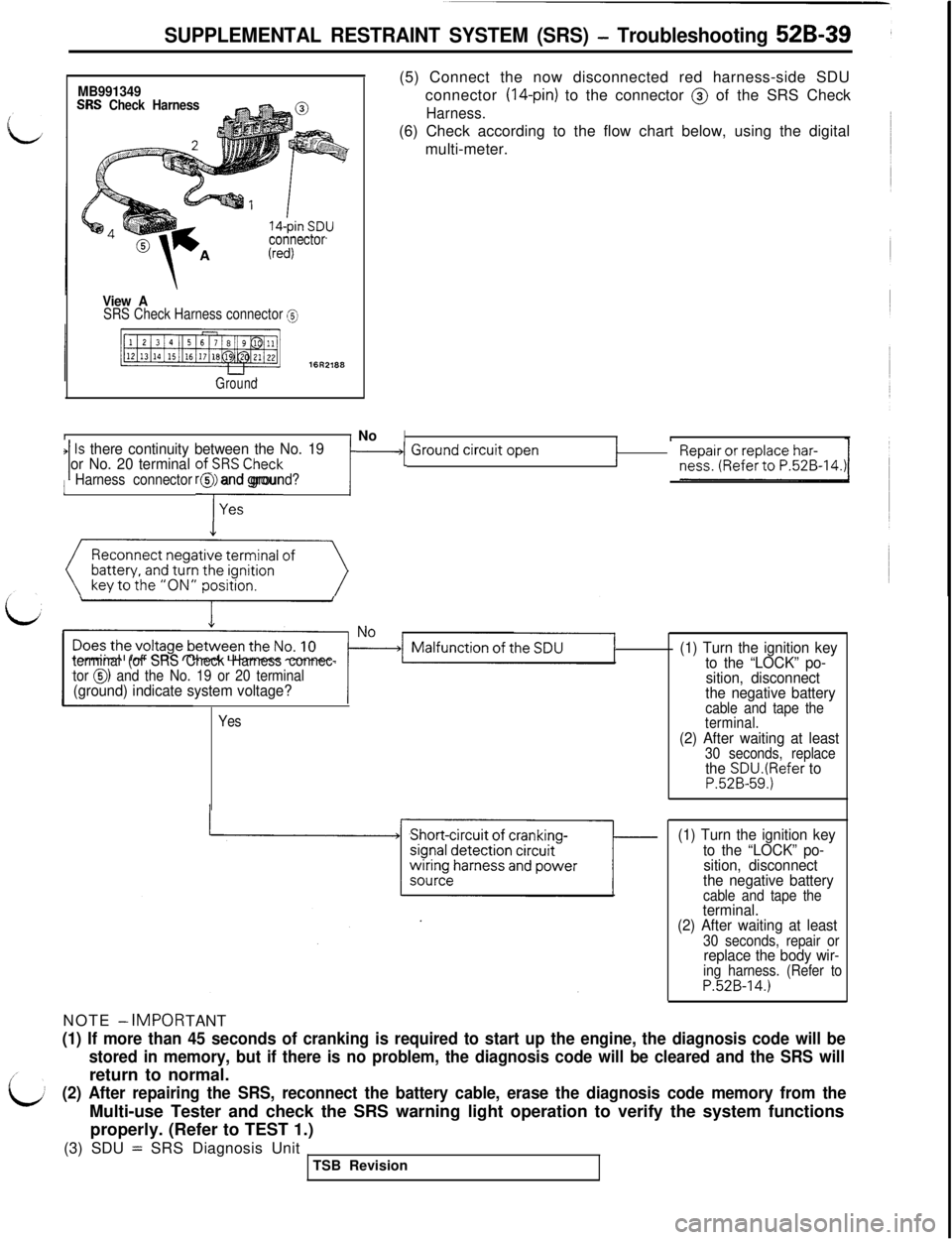

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting 52B-39

MB991349SRS Check Harness

connector

View ASRS Check Harness connector @

Ground

II No(5) Connect the now disconnected red harness-side SDU

connector

(14-pin) to the connector @ of the SRS Check

Harness.(6) Check according to the flow chart below, using the digital

multi-meter.

IIIIs there continuity between the No. 191 or No. 20 terminal ofi;RSCheck‘1 ~~~~~;,0~~~~~~.~~~-14.~r1 Ground ‘jrcuit Open1Harness connector @ and ground?

Reconnect negative terminal of

(()

terminal (of SRS Check Harness connec-

tor 0) and the No. 19 or 20 terminal(ground) indicate system voltage?NOTE

- IMPOR

TANT

Yes

(1) Turn the ignition key

to the “LOCK” po-

sition, disconnect

the negative battery

cable and tape the

terminal.

(2) After waiting at least30 seconds, replacethe SDU.(Refer toP.52B-59.)

(1) Turn the ignition key

to the “LOCK” po-

sition, disconnect

the negative battery

cable and tape theterminal.

(2) After waiting at least

30 seconds, repair orreplace the body wir-ing harness. (Refer toP.52B-14.)

(1) If more than 45 seconds of cranking is required to start up the engine, the diagnosis code will be

stored in memory, but if there is no problem, the diagnosis code will be cleared and the SRS willreturn to normal.

(2) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(3) SDU

= SRS Diagnosis Unit

TSB Revision