Manual transaxle MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 413 of 1146

MANUAL TRANSAXLE

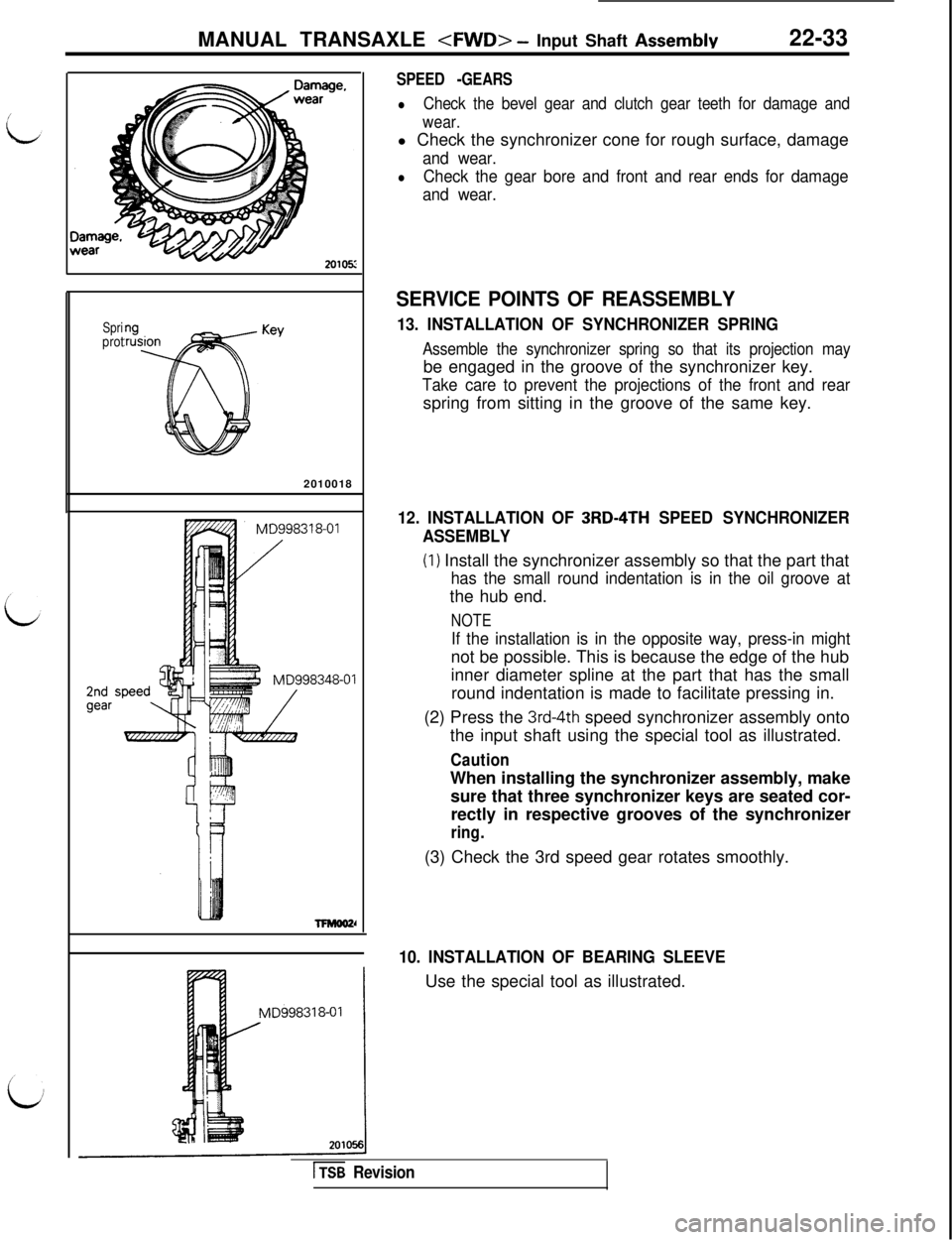

SpriprotKey2010018

MD998348-01

SPEED -GEARS

lCheck the bevel gear and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough surface, damage

and wear.

lCheck the gear bore and front and rear ends for damage

and wear.

SERVICE POINTS OF REASSEMBLY

13. INSTALLATION OF SYNCHRONIZER SPRING

Assemble the synchronizer spring so that its projection maybe engaged in the groove of the synchronizer key.

Take care to prevent the projections of the front and rearspring from sitting in the groove of the same key.

12. INSTALLATION OF 3RD-4TH SPEED SYNCHRONIZER

ASSEMBLY

(I) Install the synchronizer assembly so that the part that

has the small round indentation is in the oil groove atthe hub end.

NOTE

If the installation is in the opposite way, press-in mightnot be possible. This is because the edge of the hub

inner diameter spline at the part that has the small

round indentation is made to facilitate pressing in.

(2) Press the

3rd-4th speed synchronizer assembly onto

the input shaft using the special tool as illustrated.

CautionWhen installing the synchronizer assembly, make

sure that three synchronizer keys are seated cor-

rectly in respective grooves of the synchronizer

ring.(3) Check the 3rd speed gear rotates smoothly.

10. INSTALLATION OF BEARING SLEEVEUse the special tool as illustrated.

rTSB Revision

Page 414 of 1146

22-34

MANUAL TRANSAXLE

2nd speedi

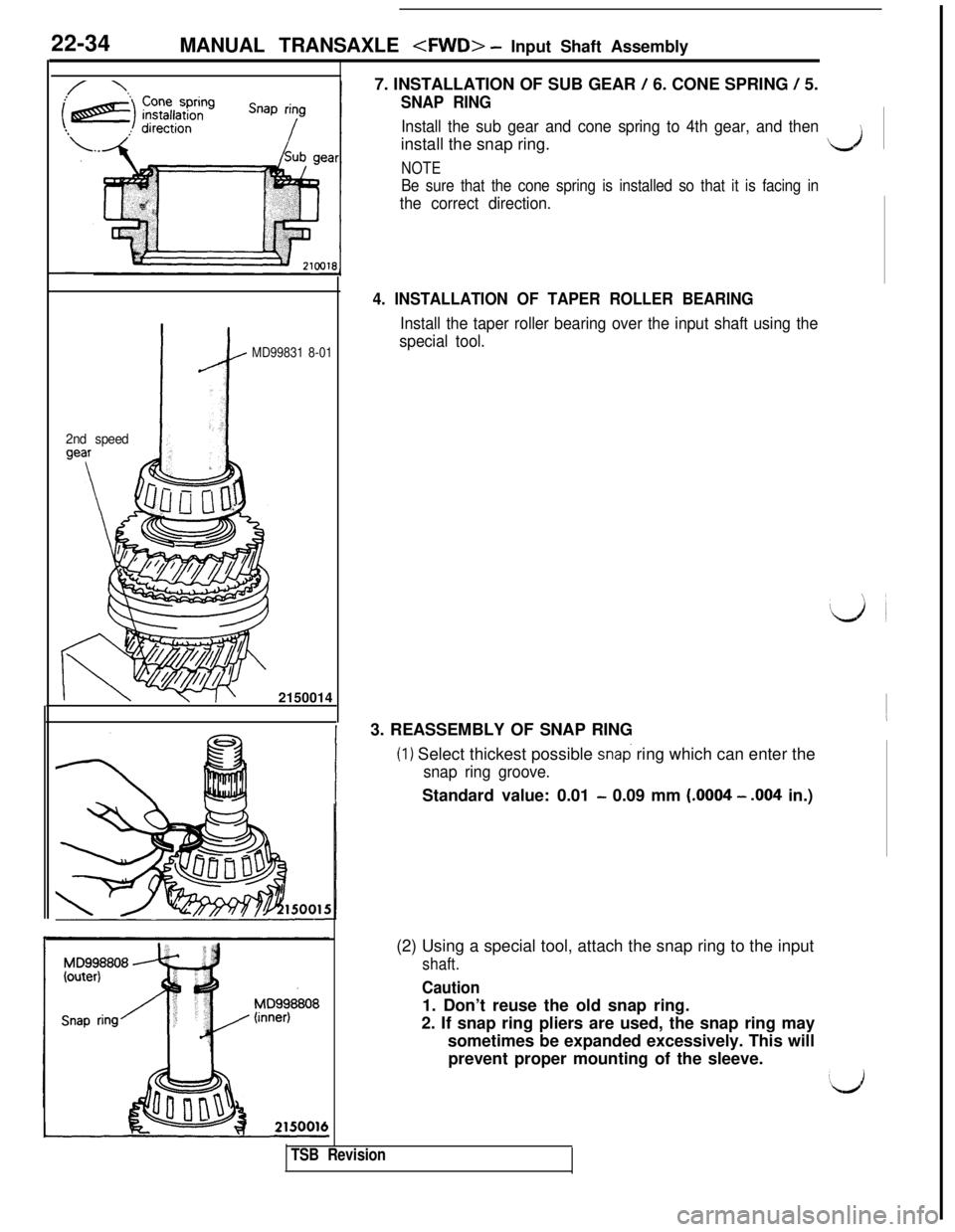

MD99831 8-0121500147. INSTALLATION OF SUB GEAR

/ 6. CONE SPRING / 5.

SNAP RING

Install the sub gear and cone spring to 4th gear, and theninstall the snap ring.

Be sure that the cone spring is installed so that it is facing in

the correct direction.

4. INSTALLATION OF TAPER ROLLER BEARING

Install the taper roller bearing over the input shaft using the

special tool.3. REASSEMBLY OF SNAP RING

(1) Select thickest possible snap ring which can enter the

snap ring groove.Standard value: 0.01

- 0.09 mm (.0004 - .004 in.)

(2) Using a special tool, attach the snap ring to the input

shaft.

Caution1. Don’t reuse the old snap ring.

2. If snap ring pliers are used, the snap ring may

sometimes be expanded excessively. This will

prevent proper mounting of the sleeve.

TSB Revision

Page 415 of 1146

MANUAL TRANSAXLE

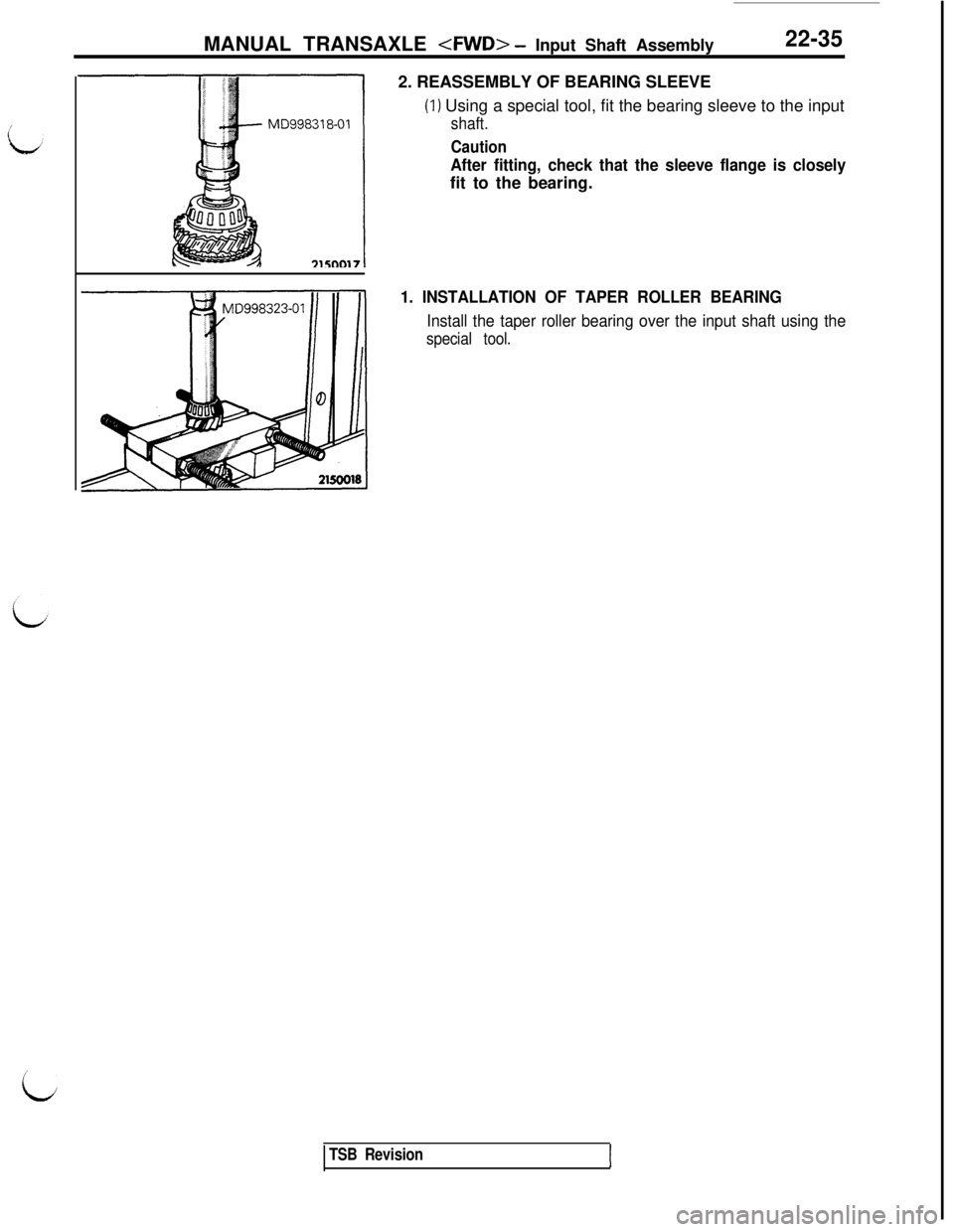

i2. REASSEMBLY OF BEARING SLEEVE

(1) Using a special tool, fit the bearing sleeve to the input

shaft.

Caution

After fitting, check that the sleeve flange is closelyfit to the bearing.

1. INSTALLATION OF TAPER ROLLER BEARING

Install the taper roller bearing over the input shaft using the

special tool.

TSB Revision

Page 416 of 1146

22-36MANUAL TRANSAXLE

INTERMEDIATE GEAR ASSEMBLY

IMZZMJAS

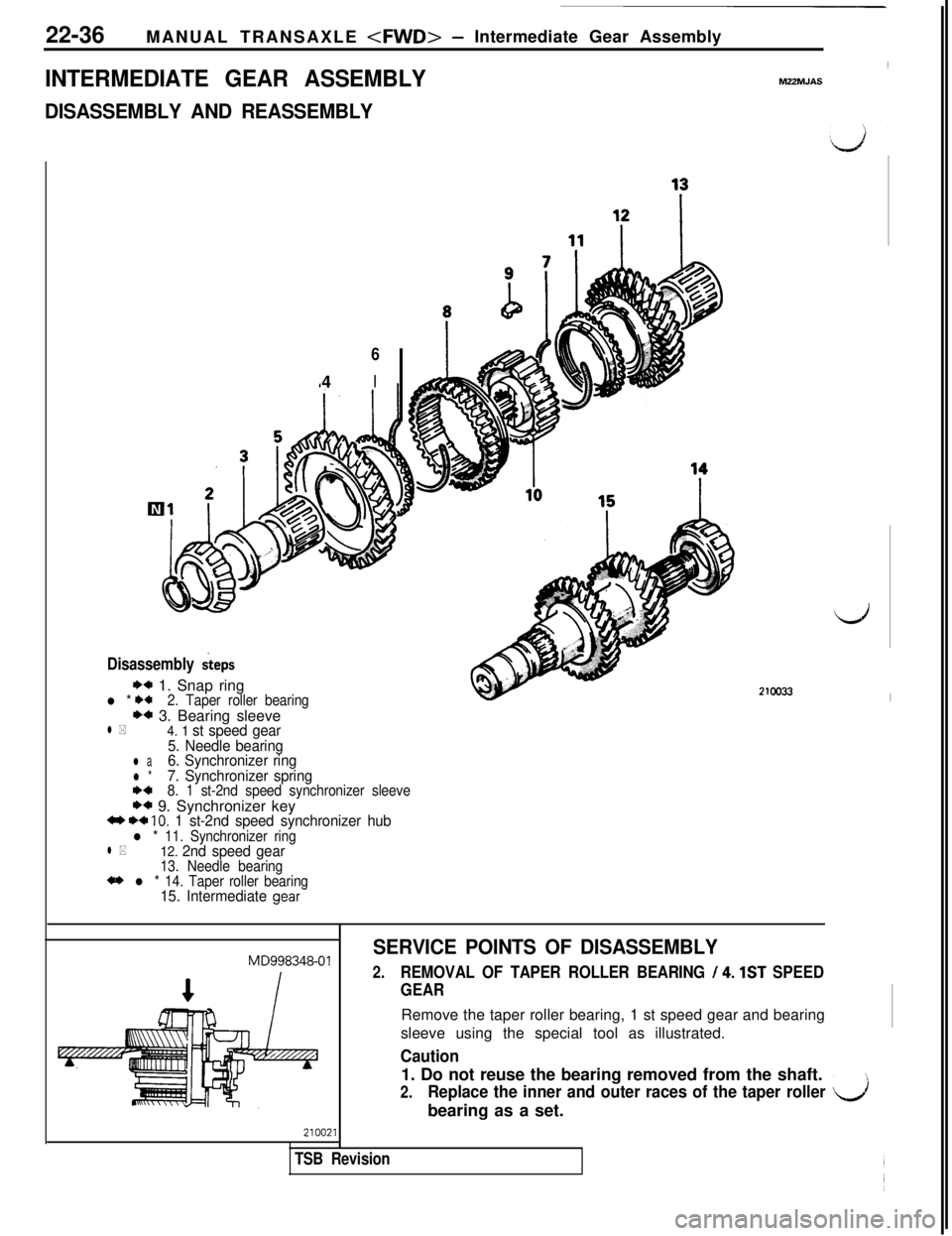

DISASSEMBLY AND REASSEMBLY

64

I

Disassembly steps

I)* 1. Snap ringl * **2. Taper roller bearing

** 3. Bearing sleevel *4. 1 st speed gear

5. Needle bearing

l a6. Synchronizer ring

l **C7. Synchronizer spring8. 1 st-2nd speed synchronizer sleeve

I)* 9. Synchronizer key*I) I)+ IO. 1 st-2nd speed synchronizer hubl * 11. Synchronizer ringl *12. 2nd speed gear13. Needle bearing** l * 14. Taper roller bearing

d

I

15. Intermediate gear-

MD998348-01

TSB Revision

SERVICE POINTS OF DISASSEMBLY

2.REMOVAL OF TAPER ROLLER BEARING / 4.1ST SPEED

GEARRemove the taper roller bearing, 1 st speed gear and bearing

sleeve using the special tool as illustrated.

Caution1. Do not reuse the bearing removed from the shaft.

2.Replace the inner and outer races of the taper rollerbearing as a set.d

Page 417 of 1146

MANUAL TRANSAXLE

22-37

210022Spine

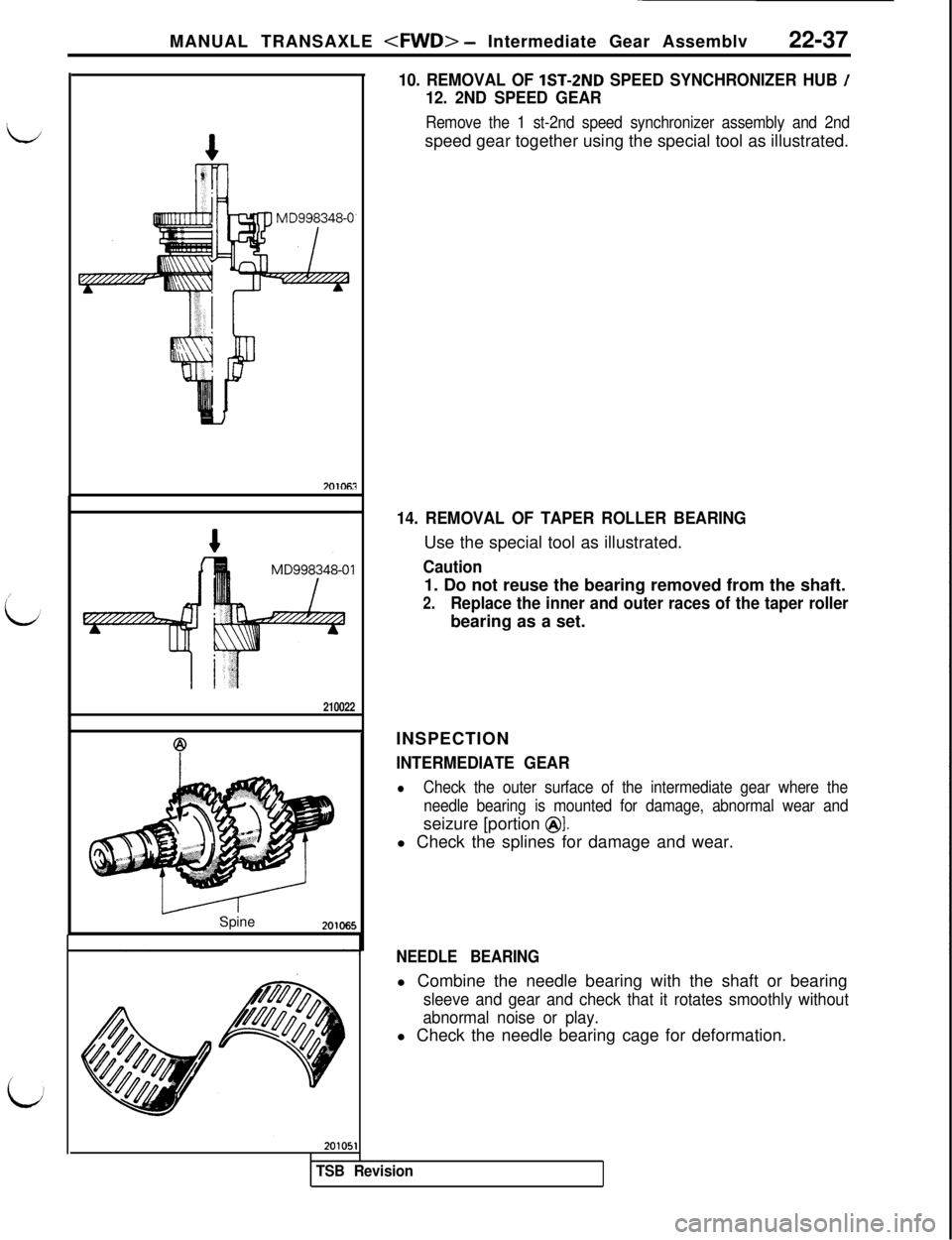

10. REMOVAL OF lST-ZND SPEED SYNCHRONIZER HUB /

12. 2ND SPEED GEAR

Remove the 1 st-2nd speed synchronizer assembly and 2ndspeed gear together using the special tool as illustrated.

14. REMOVAL OF TAPER ROLLER BEARINGUse the special tool as illustrated.

Caution1. Do not reuse the bearing removed from the shaft.

2.Replace the inner and outer races of the taper rollerbearing as a set.

INSPECTION

INTERMEDIATE GEAR

lCheck the outer surface of the intermediate gear where the

needle bearing is mounted for damage, abnormal wear andseizure [portion

@I.l Check the splines for damage and wear.

NEEDLE BEARINGl Combine the needle bearing with the shaft or bearing

sleeve and gear and check that it rotates smoothly without

abnormal noise or play.l Check the needle bearing cage for deformation.

TSB Revision

Page 418 of 1146

22-38

MANUAL TRANSAXLE

Damage and breakage

TFMOllE

Syndhronizer ringGAarTFMOll:201045

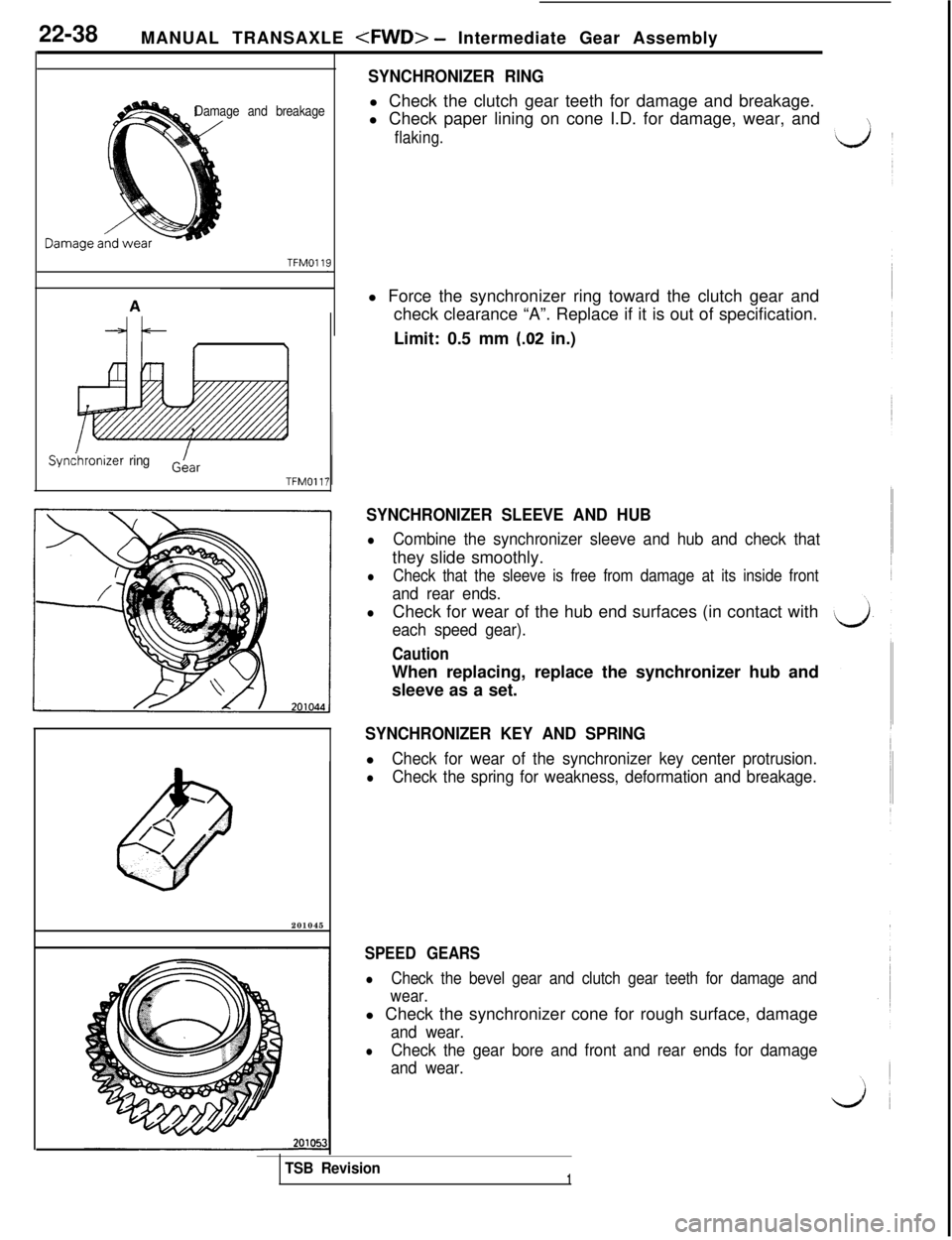

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check paper lining on cone I.D. for damage, wear, and

flaking.l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if it is out of specification.

Limit: 0.5 mm

(.02 in.)

SYNCHRONIZER SLEEVE AND HUB

lCombine the synchronizer sleeve and hub and check thatthey slide smoothly.

lCheck that the sleeve is free from damage at its inside front

and rear ends.

lCheck for wear of the hub end surfaces (in contact with

each speed gear).

CautionWhen replacing, replace the synchronizer hub and

sleeve as a set.

SYNCHRONIZER KEY AND SPRINGl

Check for wear of the synchronizer key center protrusion.

lCheck the spring for weakness, deformation and breakage.

SPEED GEARS

lCheck the bevel gear and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough surface, damage

and wear.

lCheck the gear bore and front and rear ends for damage

and wear.

TSB Revision

1

Page 419 of 1146

MANUAL TRANSAXLE

22-39

/

MD998350-01

Identificationmark

Front +

Identi-

fication

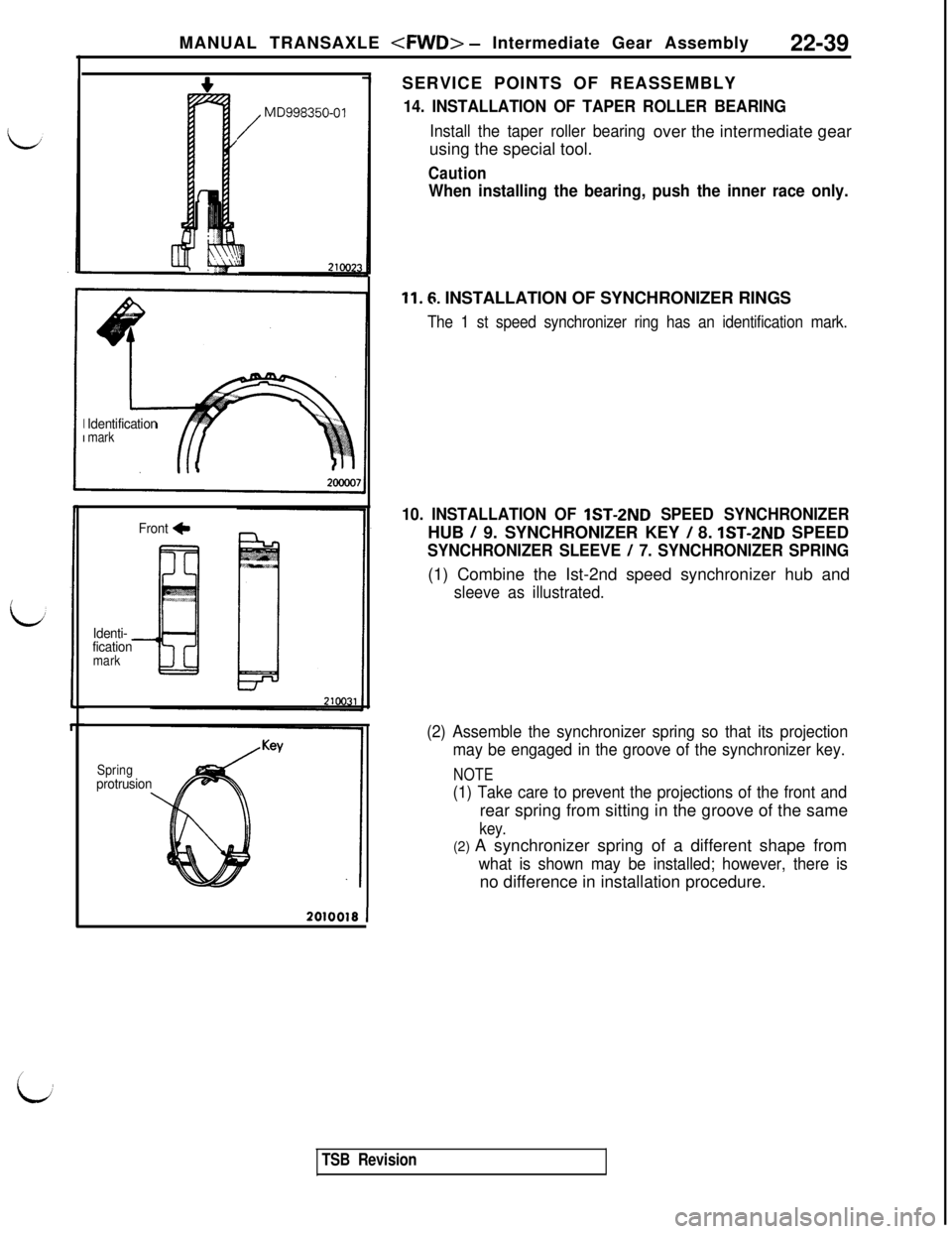

markSERVICE POINTS OF REASSEMBLY

14. INSTALLATION OF TAPER ROLLER BEARING

Install the taper roller bearingusing the special tool.over the intermediate gear

Caution

When installing the bearing, push the inner race only.

Springprotrusion11.8. INSTALLATION OF SYNCHRONIZER RINGS

The 1 st speed synchronizer ring has an identification mark.

10. INSTALLATION OF lST-2ND SPEED SYNCHRONIZERHUB

/ 9. SYNCHRONIZER KEY / 8. lST-2ND SPEED

SYNCHRONIZER SLEEVE / 7. SYNCHRONIZER SPRING(1) Combine the Ist-2nd speed synchronizer hub and

sleeve as illustrated.

(2) Assemble the synchronizer spring so that its projection

may be engaged in the groove of the synchronizer key.

NOTE

(1) Take care to prevent the projections of the front andrear spring from sitting in the groove of the same

key.(2) A synchronizer spring of a different shape from

what is shown may be installed; however, there isno difference in installation procedure.

i

TSB Revision

Page 420 of 1146

22-40

MANUAL TRANSAXLE

MD998350-01

/

1 st-2ndspeedsynchronizer

assembly

MD998348-012100022

MD998350-01

1st speed

gear

20106

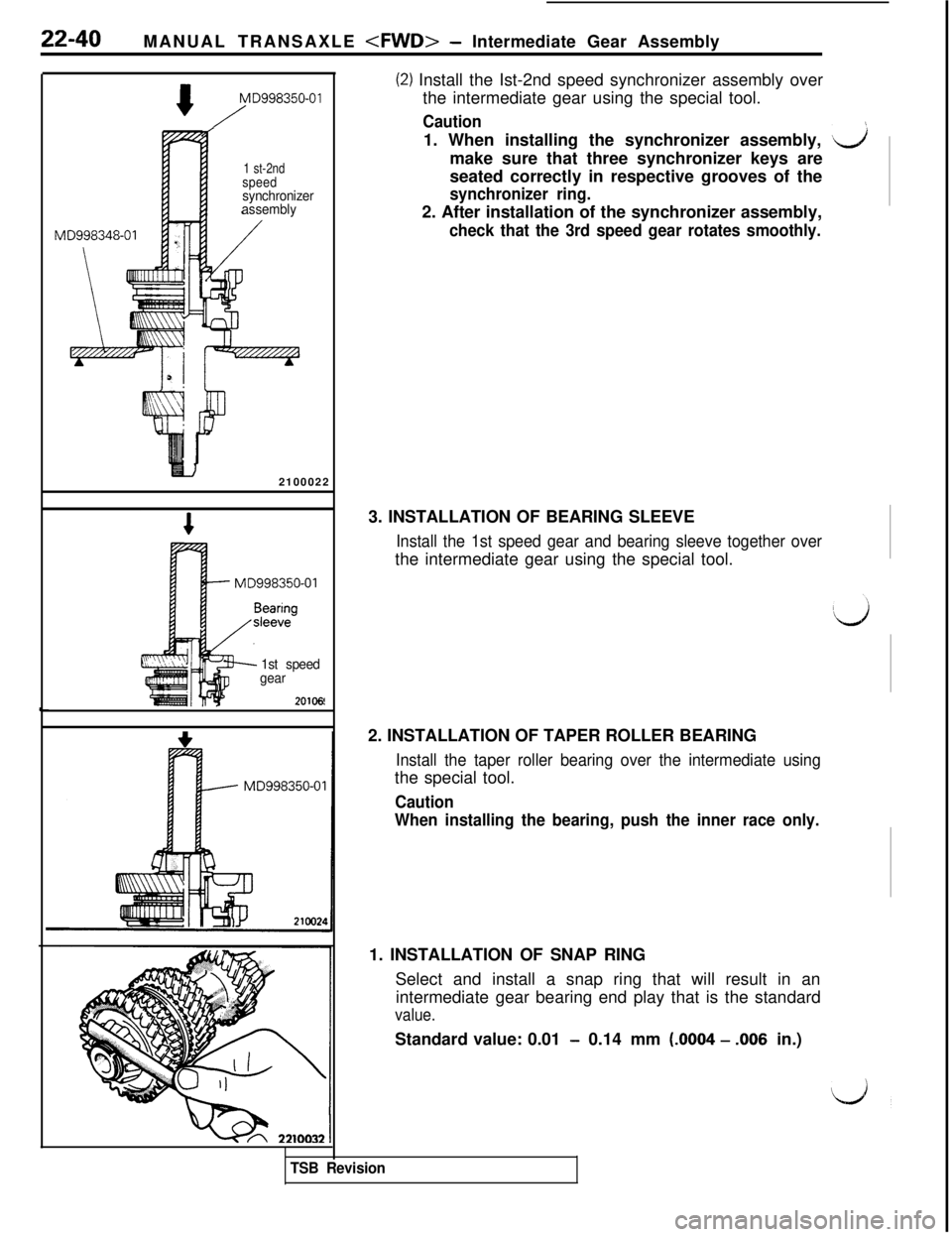

(2) Install the Ist-2nd speed synchronizer assembly over

the intermediate gear using the special tool.

Caution1. When installing the synchronizer assembly,

L/:make sure that three synchronizer keys are

seated correctly in respective grooves of the

synchronizer ring.2. After installation of the synchronizer assembly,

check that the 3rd speed gear rotates smoothly.3. INSTALLATION OF BEARING SLEEVE

Install the 1st speed gear and bearing sleeve together overthe intermediate gear using the special tool.

2. INSTALLATION OF TAPER ROLLER BEARING

Install the taper roller bearing over the intermediate usingthe special tool.

Caution

When installing the bearing, push the inner race only.1. INSTALLATION OF SNAP RING

Select and install a snap ring that will result in an

intermediate gear bearing end play that is the standard

value.Standard value: 0.01

- 0.14 mm (.0004 - .006 in.)

TSB Revision

Page 421 of 1146

MANUAL TRANSAXLE

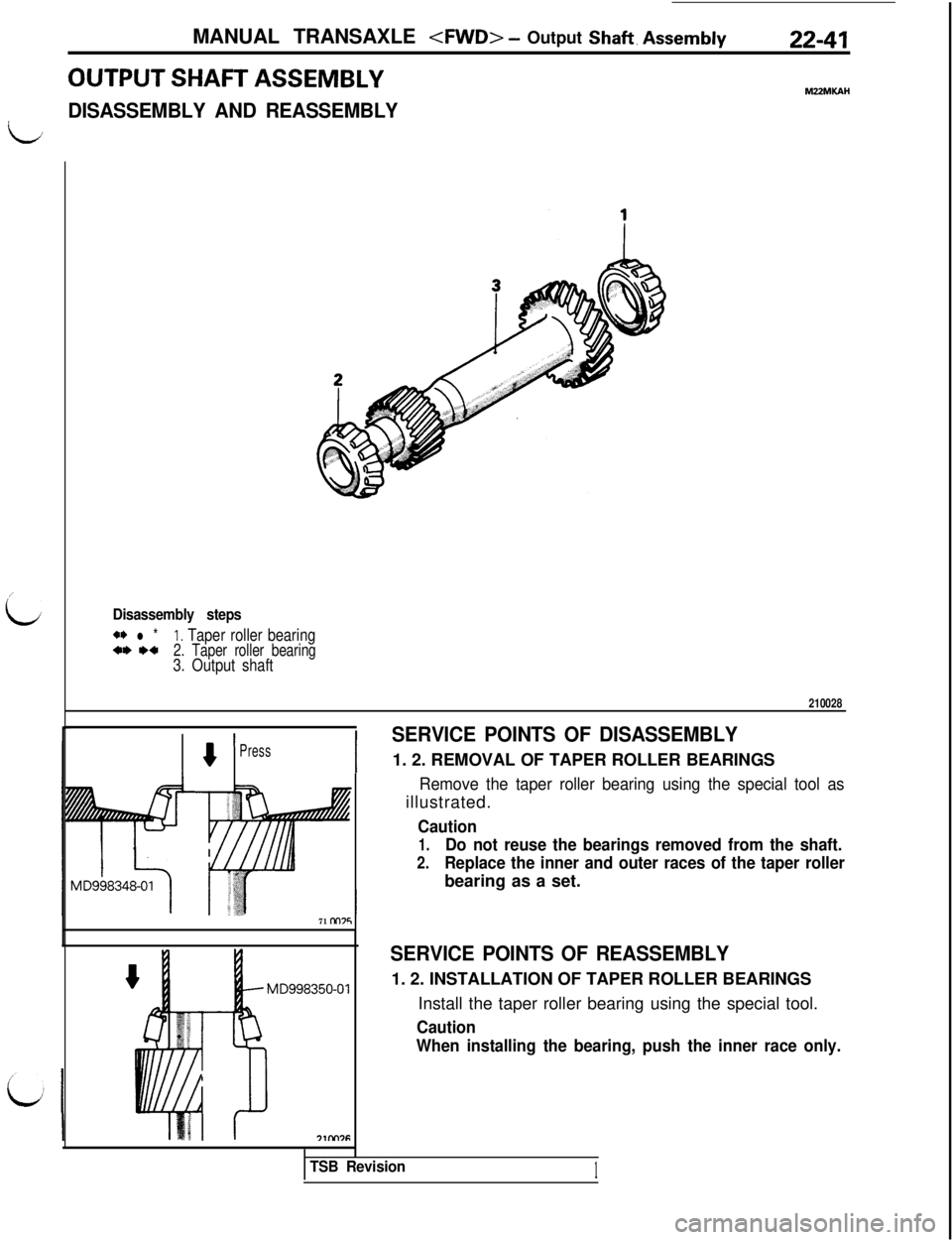

OUTPUT SHAFT ASSEMBLYMZZMKAH

DISASSEMBLY AND REASSEMBLY

L

/

id

I I

SERVICE POINTS OF DISASSEMBLY

8Press1. 2. REMOVAL OF TAPER ROLLER BEARINGS

Remove the taper roller bearing using the special tool asillustrated.

Caution

1.Do not reuse the bearings removed from the shaft.

2.Replace the inner and outer races of the taper rollerbearing as a set.

Disassembly steps**

l *I. Taper roller bearing*I) I)*2. Taper roller bearing3. Output shaft

210028

71 nn75

MD998350-01

SERVICE POINTS OF REASSEMBLY1. 2. INSTALLATION OF TAPER ROLLER BEARINGS

Install the taper roller bearing using the special tool.

Caution

When installing the bearing, push the inner race only.

TSB Revision1

Page 422 of 1146

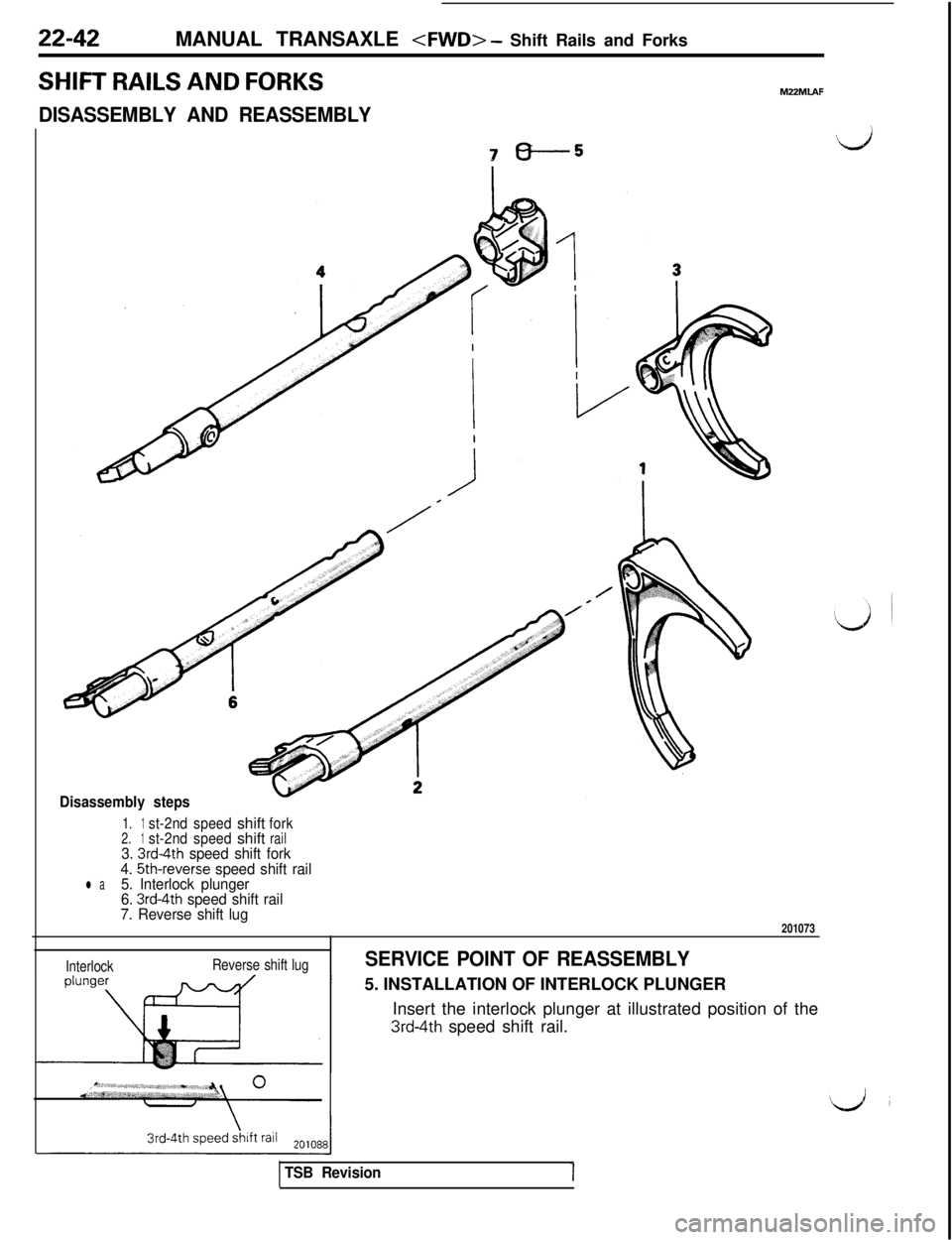

22-42MANUAL TRANSAXLE

SHIFT RAILS AND FORKSMZZMLAF

DISASSEMBLY AND REASSEMBLY

7-5i-s

Disassembly steps

1.1st-2ndspeedshiftfork2.1st-2ndspeedshiftrail3. 3rd4th speed shift fork

4. 5th-reverse speed shift raill a5. Interlock plunger

6. 3rd-4th speed shift rail

7. Reverse shift lug

201073

InterlockReverse shift lugSERVICE POINT OF REASSEMBLY5. INSTALLATION OF INTERLOCK PLUNGER

Insert the interlock plunger at illustrated position of the

3rd-4th speed shift rail.

TSB Revision