boot MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 843 of 1146

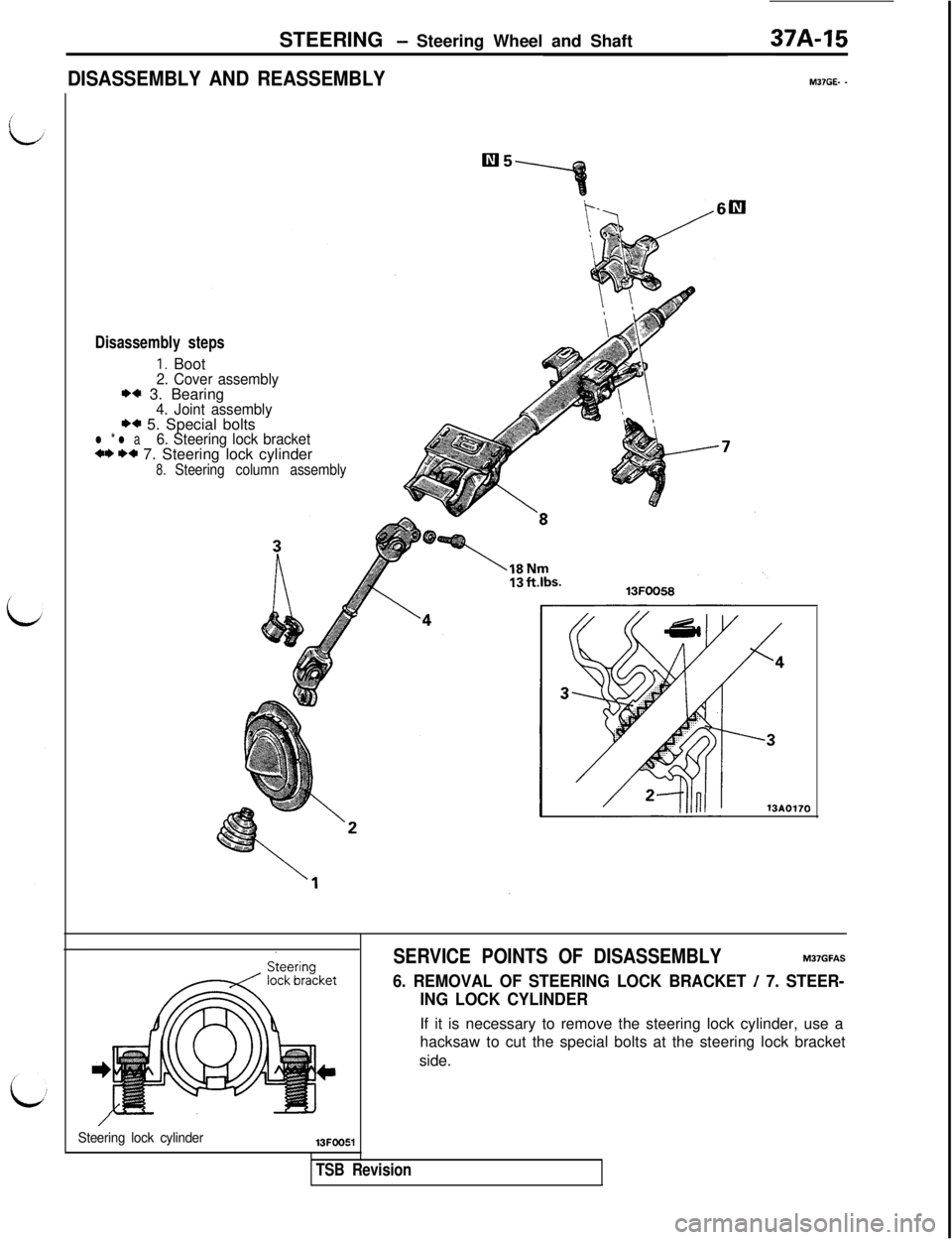

STEERING - Steering Wheel and Shaft

DISASSEMBLY AND REASSEMBLYM37GE- -

Disassembly steps

1. Boot2. Cover assemblyI)* 3. Bearing4. Joint assembly*+ 5. Special boltsl * l a6. Steering lock bracket+* I)* 7. Steering lock cylinder8.Steering column assembly

13A0170

Steering lock cylinder13FOO51

SERVICE POINTS OF DISASSEMBLYM37GFAS

6. REMOVAL OF STEERING LOCK BRACKET / 7. STEER-

ING LOCK CYLINDERIf it is necessary to remove the steering lock cylinder, use a

hacksaw to cut the special bolts at the steering lock bracket

side.

TSB Revision

Page 846 of 1146

37A-18

STEERING - Power Steering Gear Box

MB991 006-01\l\

13R017

8 Mounting clamp13R0077

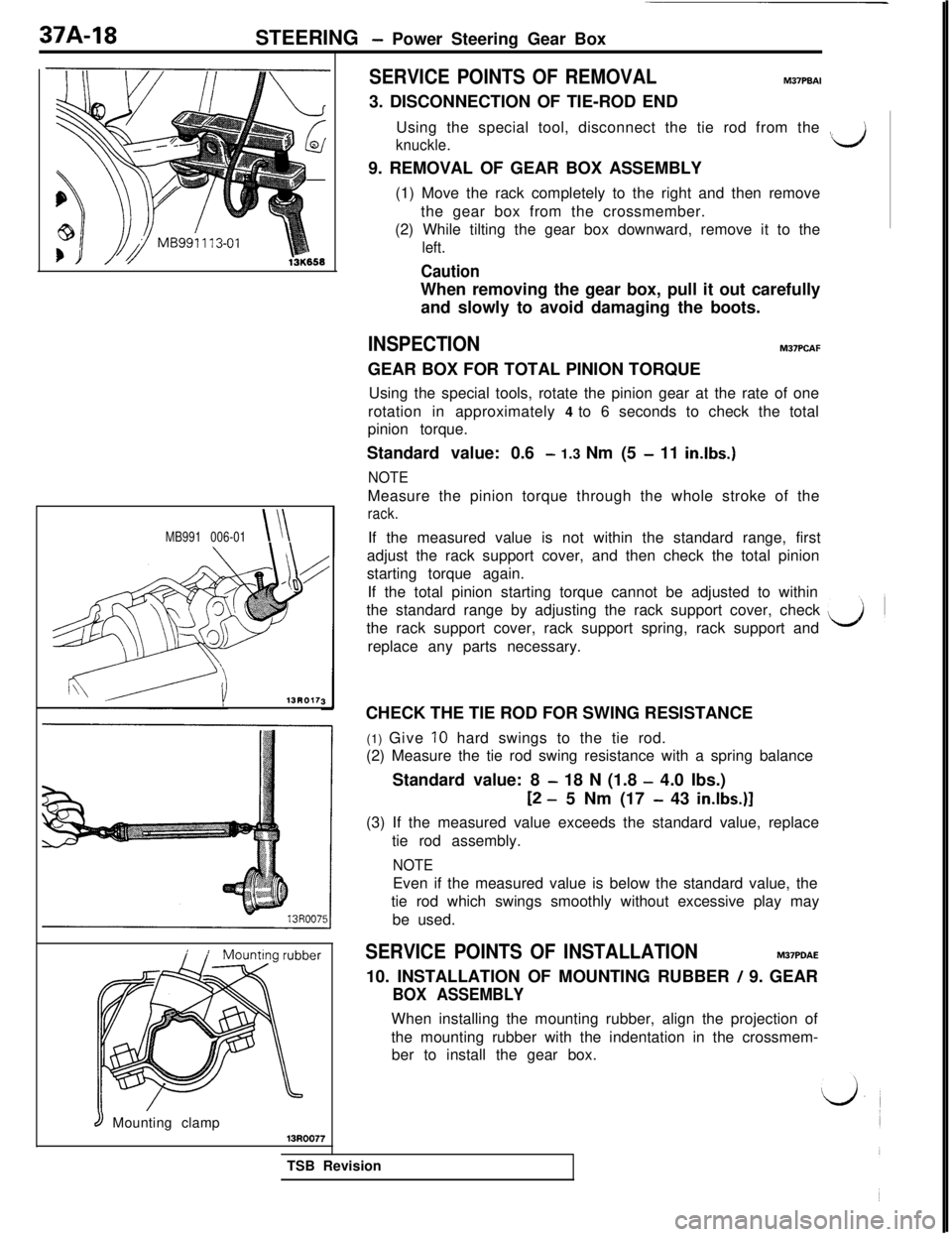

SERVICE POINTS OF REMOVALM37PBAI3. DISCONNECTION OF TIE-ROD END

Using the special tool, disconnect the tie rod from the

,,

knuckle.LJ9. REMOVAL OF GEAR BOX ASSEMBLY

(1) Move the rack completely to the right and then remove

the gear box from the crossmember.

(2) While tilting the gear box downward, remove it to the

left.

CautionWhen removing the gear box, pull it out carefully

and slowly to avoid damaging the boots.

INSPECTIONM37PCAFGEAR BOX FOR TOTAL PINION TORQUE

Using the special tools, rotate the pinion gear at the rate of one

rotation in approximately 4 to 6 seconds to check the total

pinion torque.

Standard value: 0.6

- 1.3 Nm (5 - 11 in.lbs.)

NOTEMeasure the pinion torque through the whole stroke of the

rack.If the measured value is not within the standard range, first

adjust the rack support cover, and then check the total pinion

starting torque again.

If the total pinion starting torque cannot be adjusted to within

the standard range by adjusting the rack support cover, check

the rack support cover, rack support spring, rack support and

replace any parts necessary.

CHECK THE TIE ROD FOR SWING RESISTANCE

(1) Give

10 hard swings to the tie rod.

(2) Measure the tie rod swing resistance with a spring balance

Standard value: 8

- 18 N (1.8 - 4.0 Ibs.)

[2 - 5 Nm (17 - 43 in.lbs.)](3) If the measured value exceeds the standard value, replace

tie rod assembly.

NOTEEven if the measured value is below the standard value, the

tie rod which swings smoothly without excessive play may

be used.

SERVICE POINTS OF INSTALLATIONM37PDAE10. INSTALLATION OF MOUNTING RUBBER

/ 9. GEAR

BOX ASSEMBLYWhen installing the mounting rubber, align the projection of

the mounting rubber with the indentation in the crossmem-

ber to install the gear box.

TSB Revision

Page 849 of 1146

STEERING - Power Steering Gear Box37A-21 ~'13K588

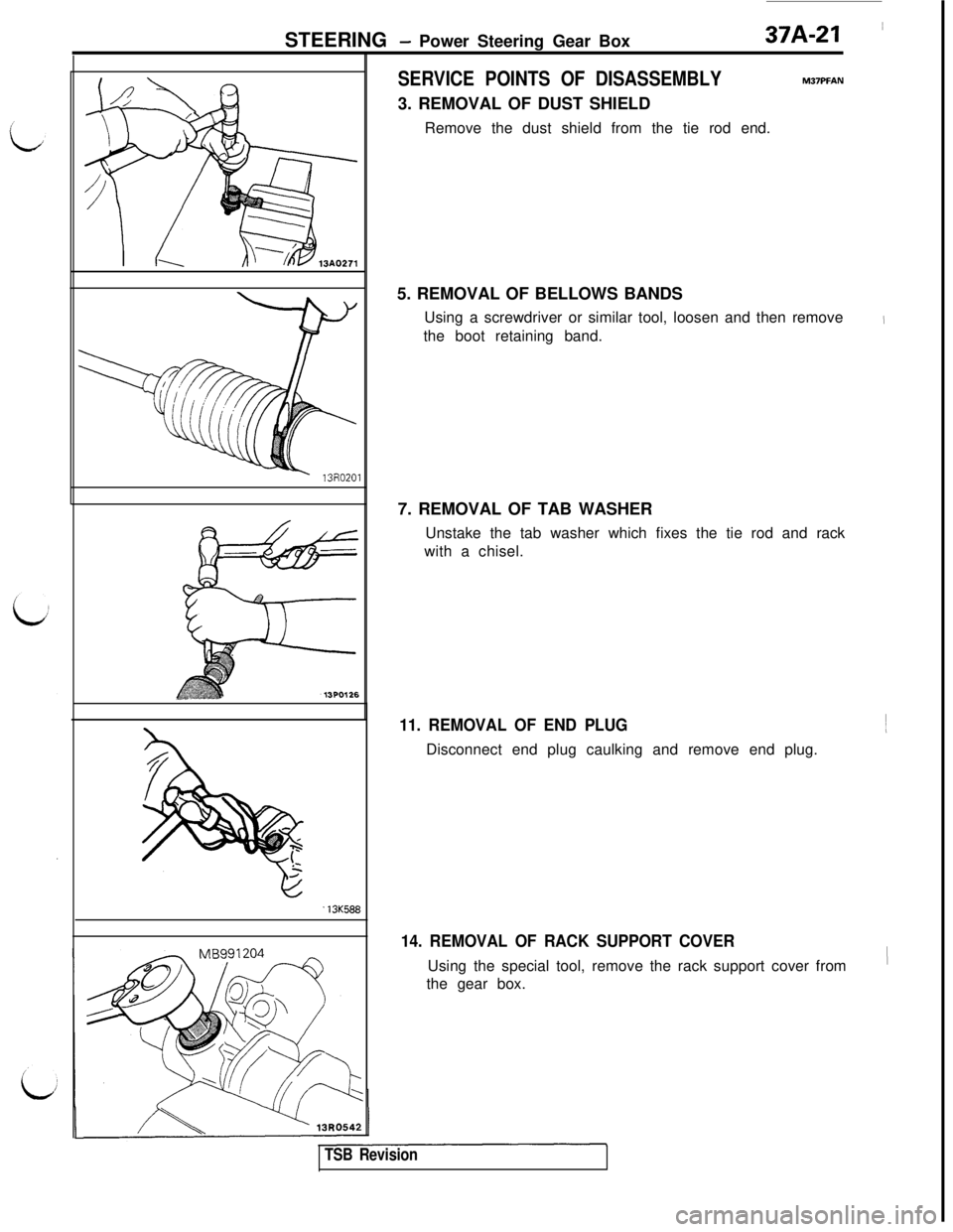

SERVICE POINTS OF DISASSEMBLYM37PFAN3. REMOVAL OF DUST SHIELD

Remove the dust shield from the tie rod end.

5. REMOVAL OF BELLOWS BANDS

Using a screwdriver or similar tool, loosen and then remove

Ithe boot retaining band.

7. REMOVAL OF TAB WASHER

Unstake the tab washer which fixes the tie rod and rack

with a chisel.

11. REMOVAL OF END PLUGDisconnect end plug caulking and remove end plug.

14. REMOVAL OF RACK SUPPORT COVERUsing the special tool, remove the rack support cover from

Ithe gear box.

TSB Revision

Page 851 of 1146

i

LSTEERING

- Power Steering Gear Box37A-23

13R054f

_ Needlebearing

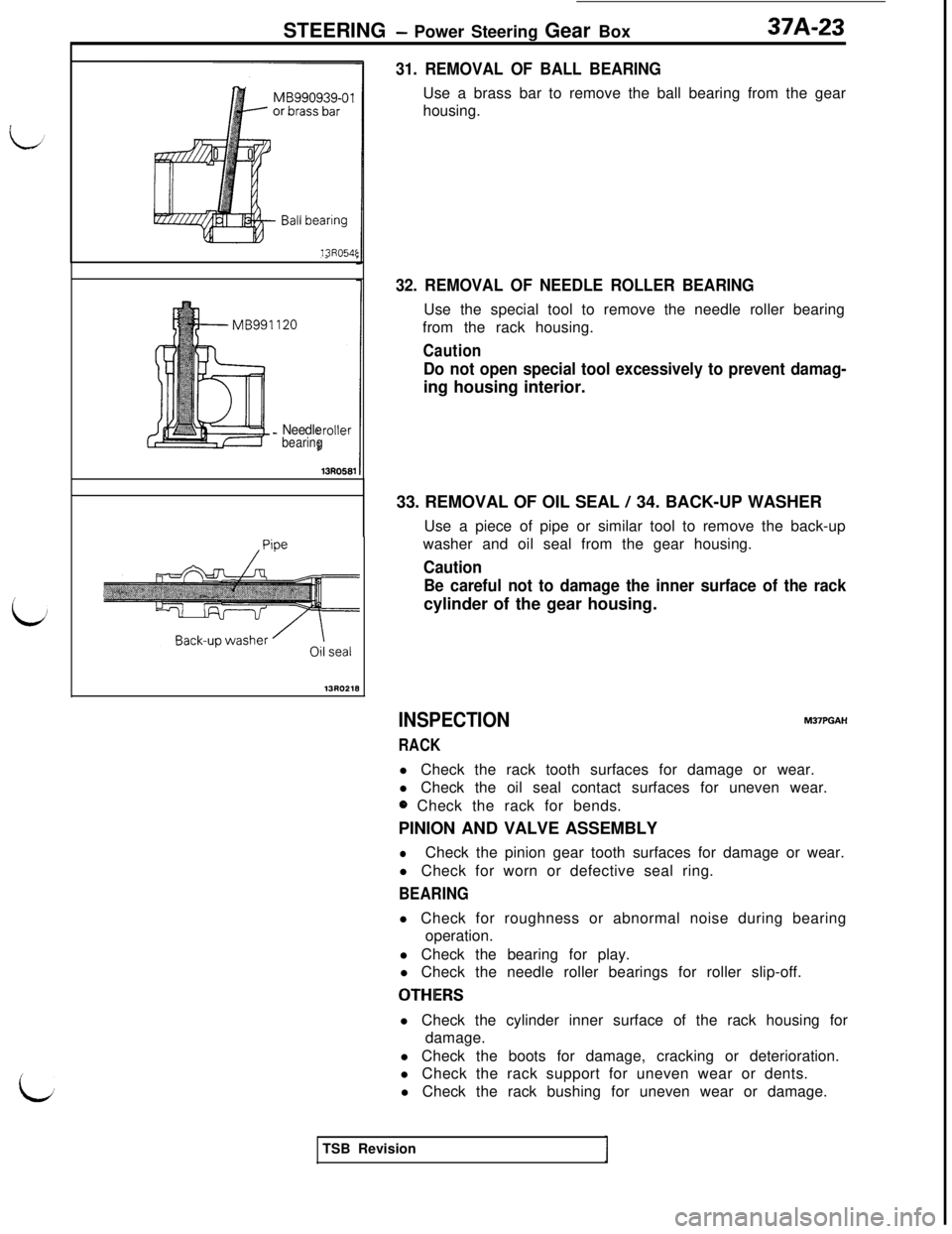

31. REMOVAL OF BALL BEARINGUse a brass bar to remove the ball bearing from the gear

housing.

32. REMOVAL OF NEEDLE ROLLER BEARINGUse the special tool to remove the needle roller bearing

from the rack housing.

Caution

Do not open special tool excessively to prevent damag-ing housing interior.

33. REMOVAL OF OIL SEAL

/ 34. BACK-UP WASHER

Use a piece of pipe or similar tool to remove the back-up

washer and oil seal from the gear housing.

Caution

Be careful not to damage the inner surface of the rackcylinder of the gear housing.

INSPECTION

RACK

M37PGAHl Check the rack tooth surfaces for damage or wear.

l Check the oil seal contact surfaces for uneven wear.

0 Check the rack for bends.

PINION AND VALVE ASSEMBLY

lCheck the pinion gear tooth surfaces for damage or wear.

l Check for worn or defective seal ring.

BEARINGl Check for roughness or abnormal noise during bearing

operation.

l Check the bearing for play.

l Check the needle roller bearings for roller slip-off.

OTHIERSl Check the cylinder inner surface of the rack housing for

damage.

l Check the boots for damage, cracking or deterioration.

l Check the rack support for uneven wear or dents.

l Check the rack bushing for uneven wear or damage.

TSB Revision