boot MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 570 of 1146

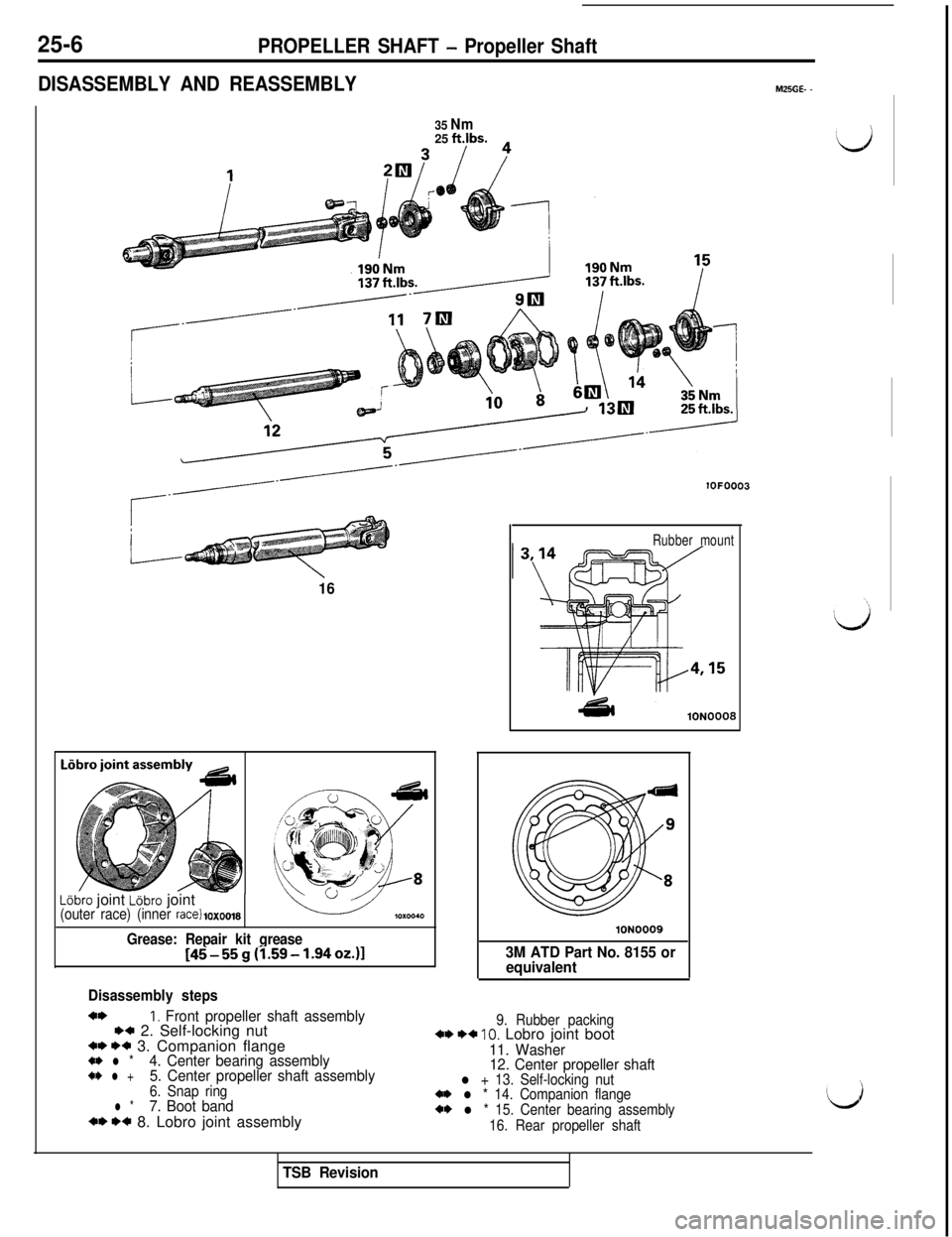

25-6PROPELLER SHAFT - Propeller Shaft

DISASSEMBLY AND REASSEMBLY

M25GE- -

35 Nm25 ft.lbs.

16

.(? yo

4%

ia

1,

0 A;;. i ‘24

\

*

frLijbro joint Ltjbro joint(outer race) (inner race)loxools- ,0x00.0

Grease: Repair kit grease[45-55g(1.59-1.9402.)1lOFOOO3

Rubber mount

Disassembly steps

*I)I, Front propeller shaft assemblyI)+ 2. Self-locking nut** *+ 3. Companion flangea* l *4. Center bearing assembly*I) l +5. Center propeller shaft assembly6. Snap ringl *7. Boot band

+* I)* 8. Lobro joint assembly

9. Rubber packing+* ** IO. Lobro joint boot

11. Washer

12. Center propeller shaft

l + 13. Self-locking nut** l * 14. Companion flange41) l * 15. Center bearing assembly

16. Rear propeller shaft

lON0009

3M ATD Part No. 8155 or

equivalent

TSB Revision

Page 571 of 1146

PROPELLER SHAFT - Propeller Shaft25-7Mating marks

1ONOOOL

1 ON0003Mating marks

(commercially available)

\lOS520 'lOY507

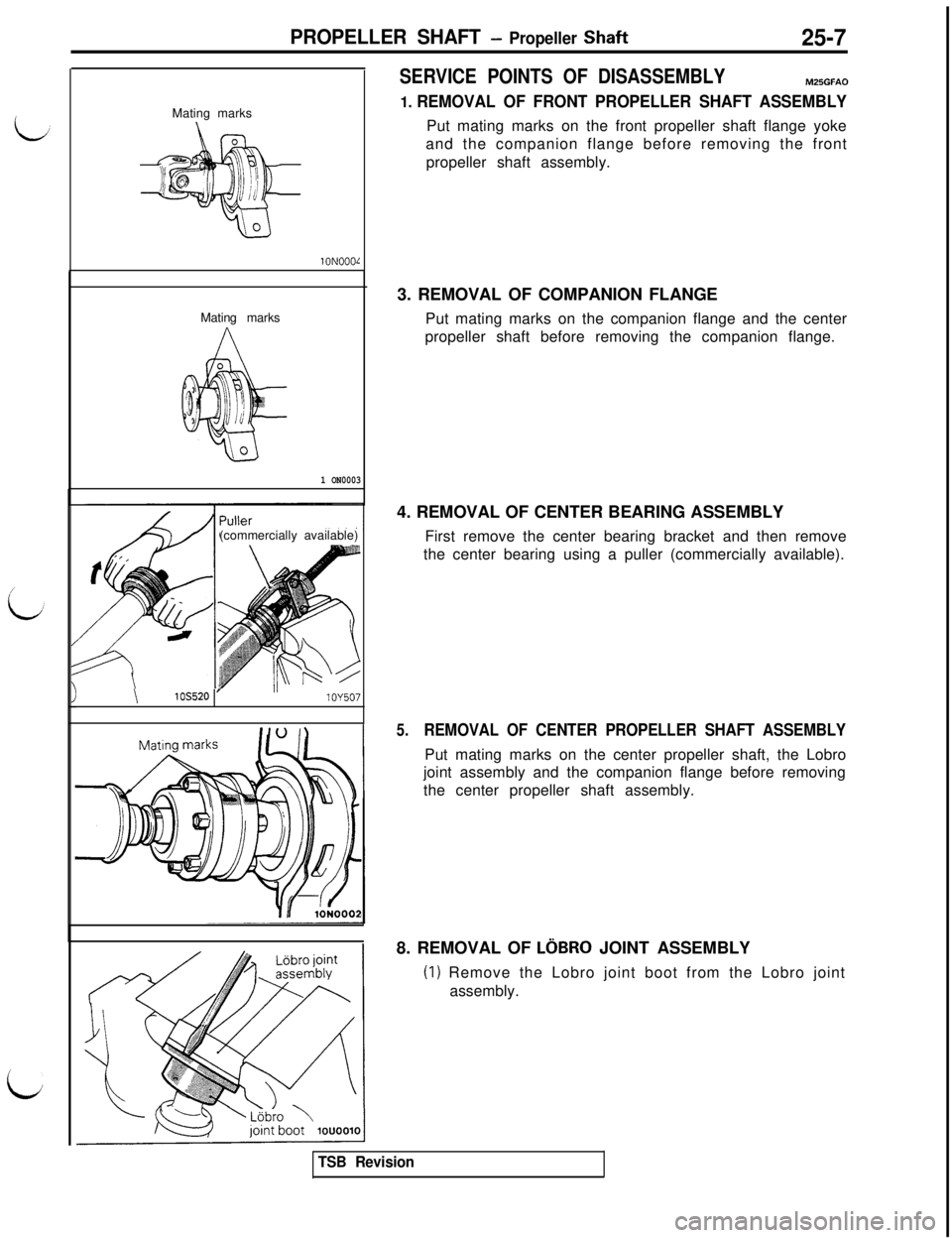

SERVICE POINTS OF DISASSEMBLYM25GFAO

1. REMOVAL OF FRONT PROPELLER SHAFT ASSEMBLYPut mating marks on the front propeller shaft flange yoke

and the companion flange before removing the front

propeller shaft assembly.

3. REMOVAL OF COMPANION FLANGE

Put mating marks on the companion flange and the center

propeller shaft before removing the companion flange.

4. REMOVAL OF CENTER BEARING ASSEMBLY

First remove the center bearing bracket and then remove

the center bearing using a puller (commercially available).

5.REMOVAL OF CENTER PROPELLER SHAFT ASSEMBLYPut mating marks on the center propeller shaft, the Lobro

joint assembly and the companion flange before removing

the center propeller shaft assembly.

8. REMOVAL OF

LOBRO JOINT ASSEMBLY

(1) Remove the Lobro joint boot from the Lobro joint

assembly.

TSB Revision

Page 572 of 1146

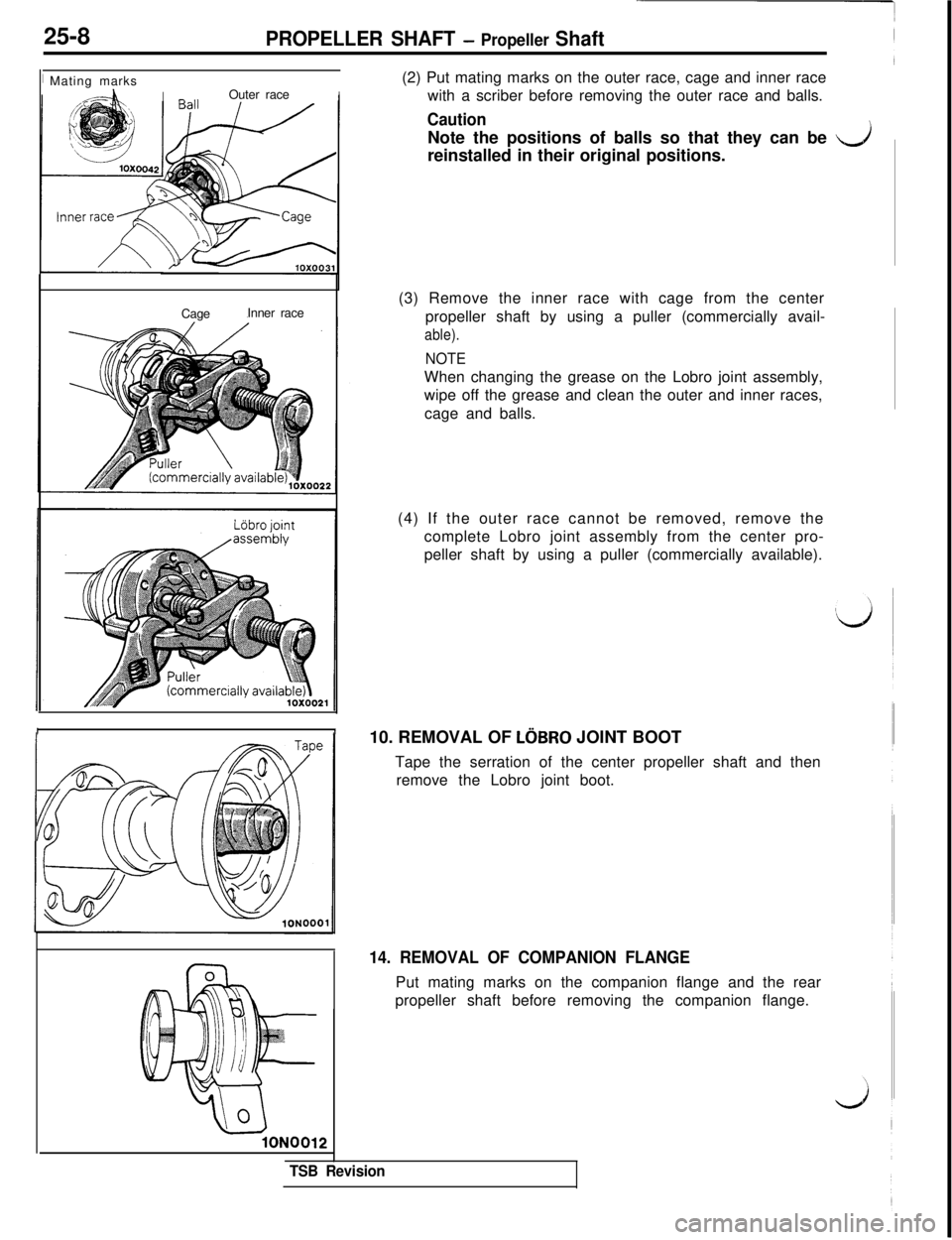

25-8PROPELLER SHAFT - Propeller Shaft1 Mating marks

I,A ^.IOuter raceICageInner race

IIlON0012(2) Put mating marks on the outer race, cage and inner race

with a scriber before removing the outer race and balls.

CautionNote the positions of balls so that they can be

dreinstalled in their original positions.

(3) Remove the inner race with cage from the center

propeller shaft by using a puller (commercially avail-

able).

NOTEWhen changing the grease on the Lobro joint assembly,

wipe off the grease and clean the outer and inner races,

cage and balls.

(4) If the outer race cannot be removed, remove the

complete Lobro joint assembly from the center pro-

peller shaft by using a puller (commercially available).

10. REMOVAL OF

LOBRO JOINT BOOT

Tape the serration of the center propeller shaft and then

remove the Lobro joint boot.

14. REMOVAL OF COMPANION FLANGEPut mating marks on the companion flange and the rear

propeller shaft before removing the companion flange.

TSB Revision

Page 573 of 1146

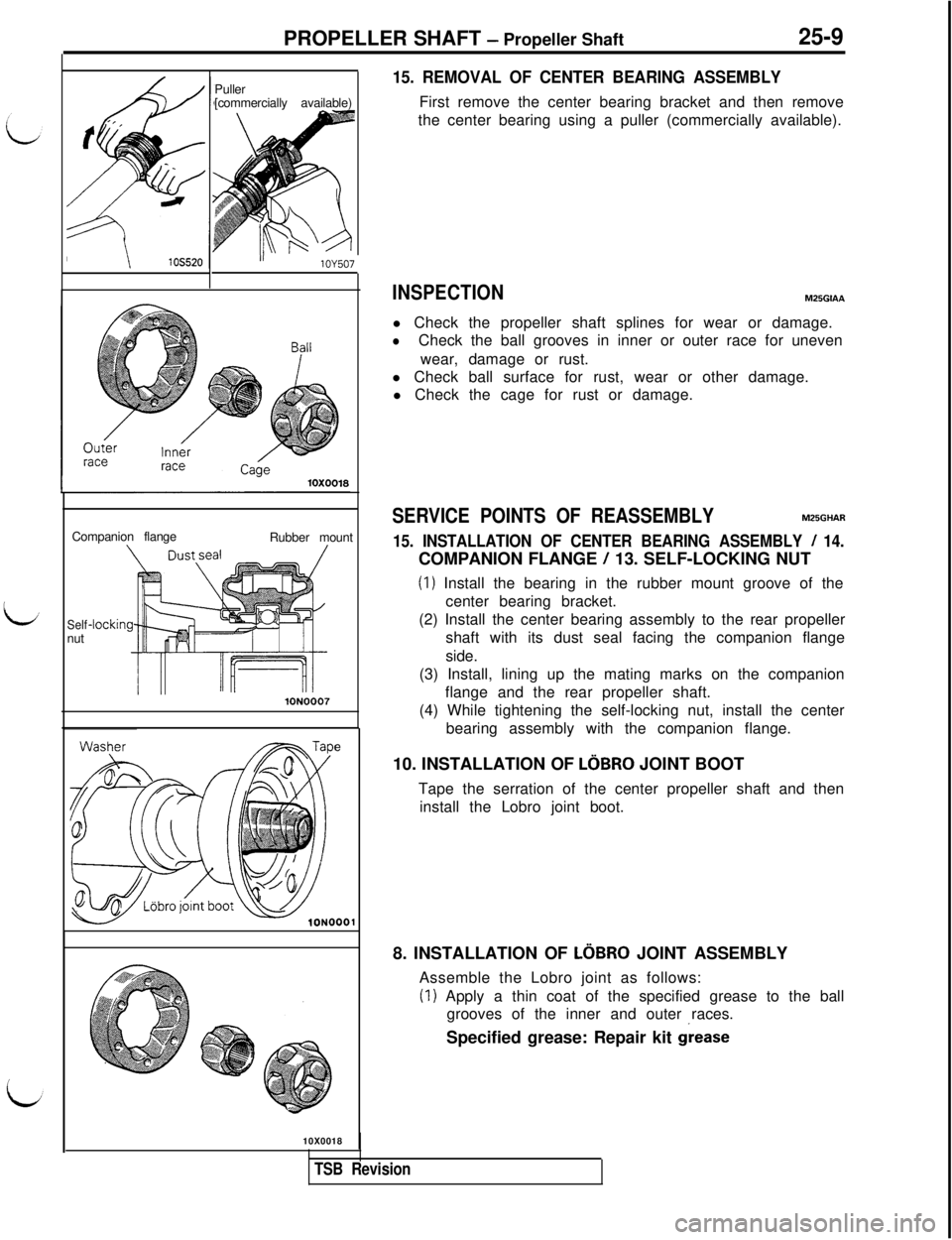

PROPELLER SHAFT - Propeller Shaft25-9

L;Puller

[commercially available)

Companion flange

Rubber mountSelfnut-lockir

lON0007

e

lONO10X0018

15. REMOVAL OF CENTER BEARING ASSEMBLYFirst remove the center bearing bracket and then remove

the center bearing using a puller (commercially available).

INSPECTIONM25GIAAl Check the propeller shaft splines for wear or damage.

lCheck the ball grooves in inner or outer race for uneven

wear, damage or rust.

l Check ball surface for rust, wear or other damage.

l Check the cage for rust or damage.

SERVICE POINTS OF REASSEMBLYM25GHA.R

15. INSTALLATION OF CENTER BEARING ASSEMBLY

/ 14.COMPANION FLANGE

/ 13. SELF-LOCKING NUT

(1) Install the bearing in the rubber mount groove of the

center bearing bracket.

(2) Install the center bearing assembly to the rear propeller

shaft with its dust seal facing the companion flange

side.

(3) Install, lining up the mating marks on the companion

flange and the rear propeller shaft.

(4) While tightening the self-locking nut, install the center

bearing assembly with the companion flange.

10. INSTALLATION OF

LOBRO JOINT BOOT

Tape the serration of the center propeller shaft and then

install the Lobro joint boot.

8. INSTALLATION OF

LOBRO JOINT ASSEMBLY

Assemble the Lobro joint as follows:

(I) Apply a thin coat of the specified grease to the ball

grooves of the inner and outer races.

Specified grease: Repair kit

giease

TSB Revision

Page 575 of 1146

PROPELLER SHAFT - Propeller Shaft25-11

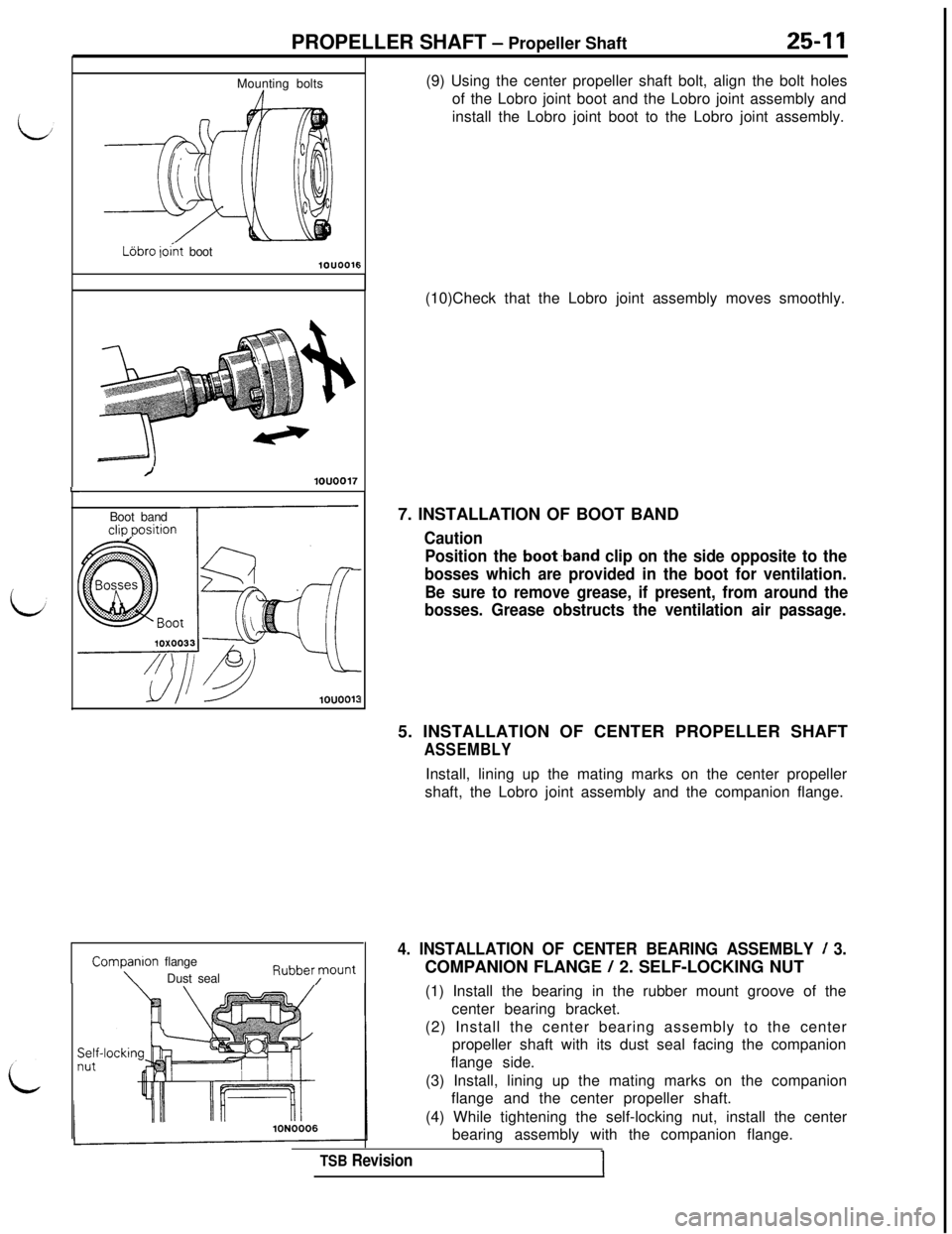

LMounting boltsL6bro

ioht boot1ouooll

/1ouoo17

5(9) Using the center propeller shaft bolt, align the bolt holes

of the Lobro joint boot and the Lobro joint assembly and

install the Lobro joint boot to the Lobro joint assembly.

(10)Check that the Lobro joint assembly moves smoothly.clio Dosition

7Boot band

1ouoo13

Companion flange

\Dust sealRubber/mount

I7. INSTALLATION OF BOOT BAND

Caution

Position the

boot,band clip on the side opposite to the

bosses which are provided in the boot for ventilation.

Be sure to remove grease, if present, from around the

bosses. Grease obstructs the ventilation air passage.5. INSTALLATION OF CENTER PROPELLER SHAFT

ASSEMBLYInstall, lining up the mating marks on the center propeller

shaft, the Lobro joint assembly and the companion flange.

4. INSTALLATION OF CENTER BEARING ASSEMBLY / 3.COMPANION FLANGE

/ 2. SELF-LOCKING NUT

(1) Install the bearing in the rubber mount groove of the

center bearing bracket.

(2) Install the center bearing assembly to the center

propeller shaft with its dust seal facing the companion

flange side.

(3) Install, lining up the mating marks on the companion

flange and the center propeller shaft.

(4) While tightening the self-locking nut, install the center

bearing assembly with the companion flange.

TSB Revision

Page 578 of 1146

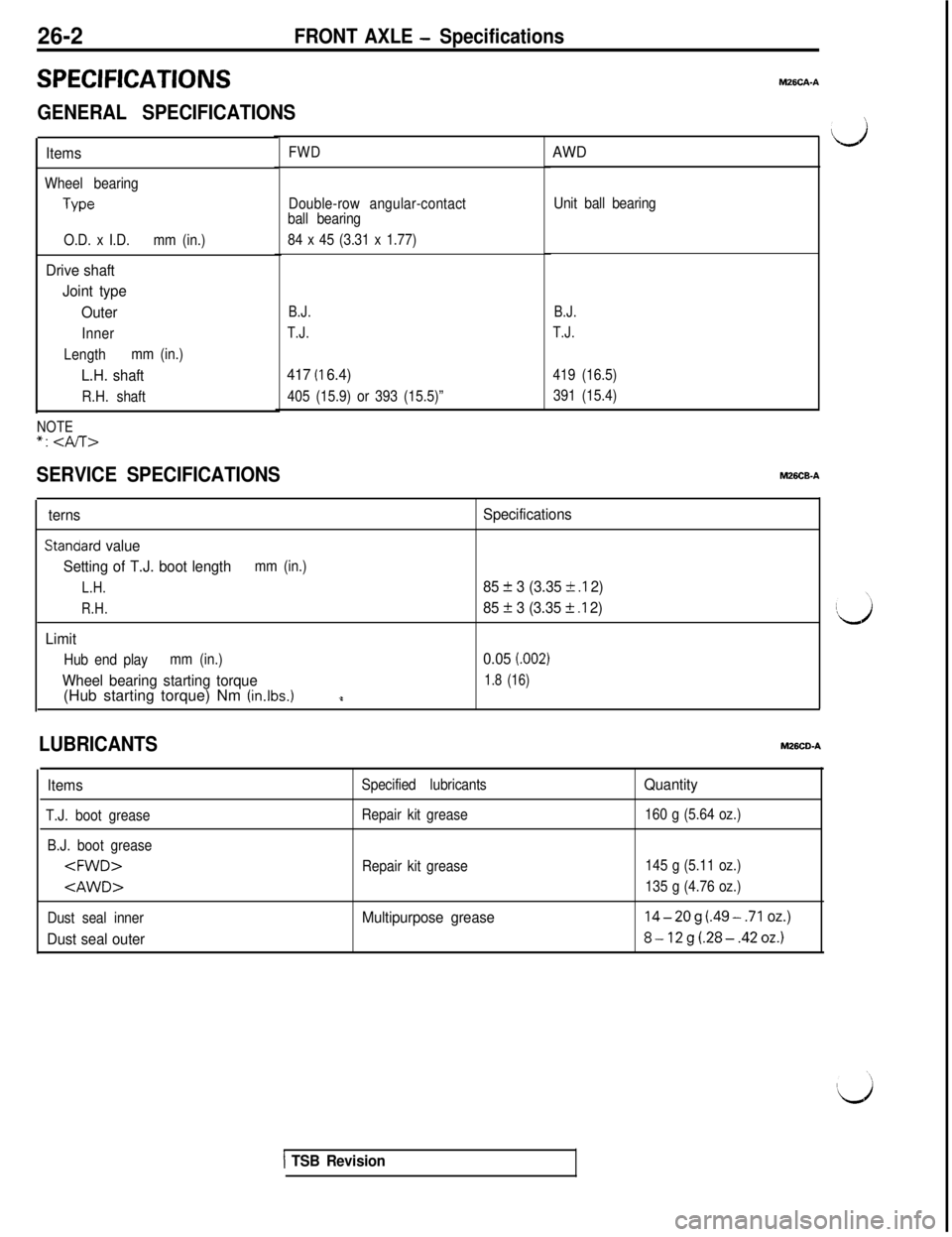

26-2FRONT AXLE - Specifications

SERVICE SPECIFICATIONS

FWD

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items

Wheel bearing

TypeDouble-row angular-contact

ball bearing

O.D. x I.D.mm (in.)

Drive shaft

Joint type

Outer

Inner

Lengthmm (in.)

L.H. shaft

R.H. shaft84 x 45 (3.31 x 1.77)

B.J.

T.J.

417 (I 6.4)

405 (15.9) or 393 (15.5)”

NOTE“1

AWD

Unit ball bearing

B.J.

T.J.

419 (16.5)

391 (15.4)

M26CB-A

terns

standard value

Setting of T.J. boot length

mm (in.)

L.H.

R.H.

Limit

Hub end playmm (in.)

Wheel bearing starting torque(Hub starting torque) Nm (in.lbs.)

Specifications

85

f 3 (3.35 k .I 2)

85

+ 3 (3.35 +- .I 2)

0.05

(.002)

1.8 (16)

LUBRICANTSM26CO-A

Items

T.J. boot grease

B.J. boot grease

Dust seal inner

Dust seal outer

Specified lubricants

Repair kit grease

Repair kit grease

Multipurpose greaseQuantity

160 g (5.64 oz.)

145 g (5.11 oz.)

135 g (4.76 oz.)

14-2og (.49-.71 oz.)

8-12g(.28-.42oz.)

1 TSB Revision

Page 581 of 1146

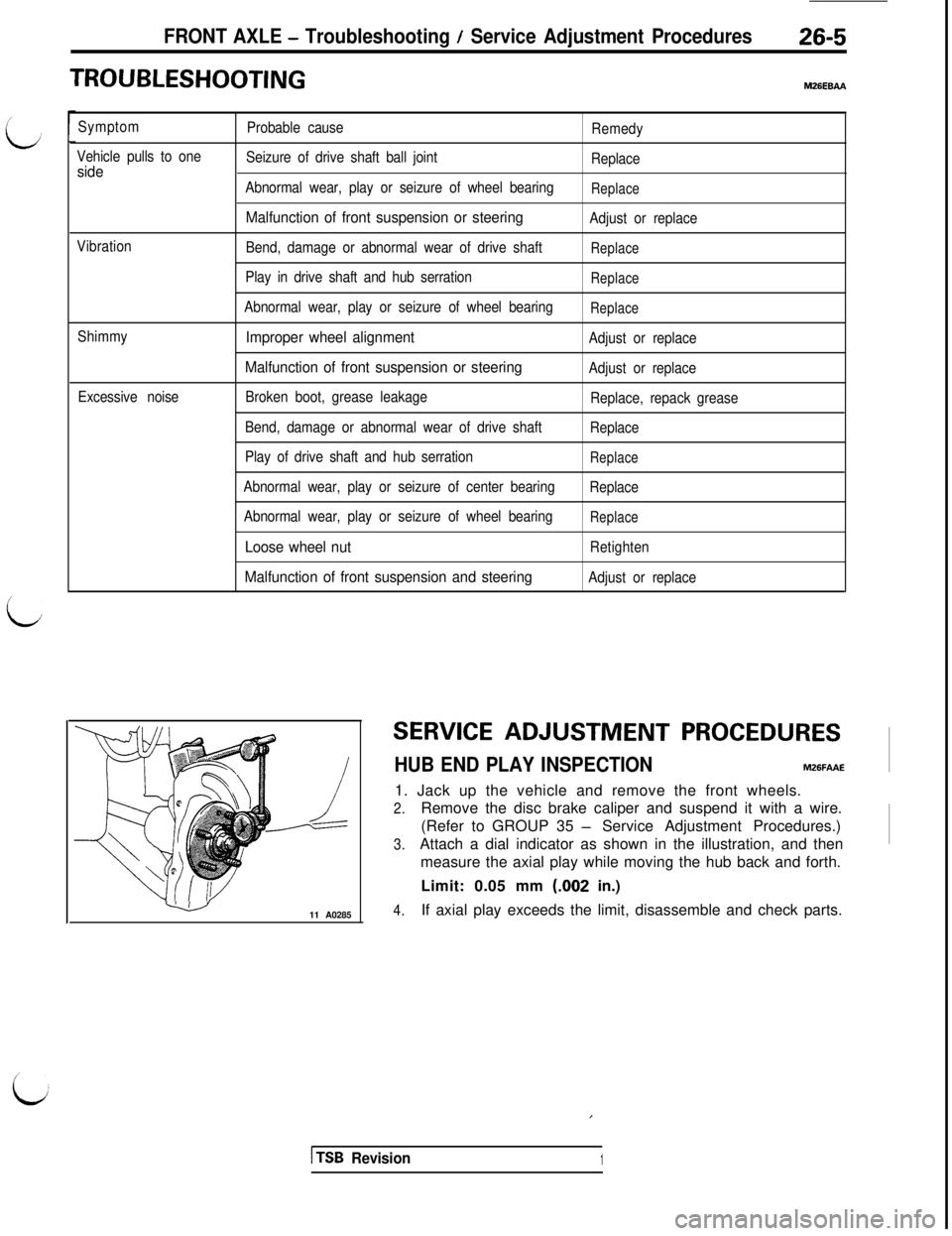

FRONT AXLE - Troubleshooting / Service Adjustment Procedures

TROUBLESHOOTING

26-5

MPBEBAA

i.

Symptom

Vehicle pulls to one

side

Vibration

Shimmy

Excessive noiseProbable cause

Seizure of drive shaft ball joint

Abnormal wear, play or seizure of wheel bearing

Malfunction of front suspension or steering

Bend, damage or abnormal wear of drive shaft

Play in drive shaft and hub serration

Abnormal wear, play or seizure of wheel bearing

Improper wheel alignment

Malfunction of front suspension or steering

Broken boot, grease leakage

Bend, damage or abnormal wear of drive shaft

Play of drive shaft and hub serration

Abnormal wear, play or seizure of center bearing

Abnormal wear, play or seizure of wheel bearing

Loose wheel nut

Malfunction of front suspension and steering

Remedy

Replace

Replace

Adjust or replace

Replace

Replace

Replace

Adjust or replace

Adjust or replace

Replace, repack grease

Replace

Replace

Replace

Replace

Retighten

Adjust or replace

u11 A0285

SERVICE ADJUSTMENT PROCEDURES

HUB END PLAY INSPECTIONM26FAAE1. Jack up the vehicle and remove the front wheels.

2.Remove the disc brake caliper and suspend it with a wire.

(Refer to GROUP 35

- Service Adjustment Procedures.)

3.Attach a dial indicator as shown in the illustration, and then

measure the axial play while moving the hub back and forth.

Limit: 0.05 mm (.002 in.)

4.If axial play exceeds the limit, disassemble and check parts.

,

1 TSB Revision1

i

Page 589 of 1146

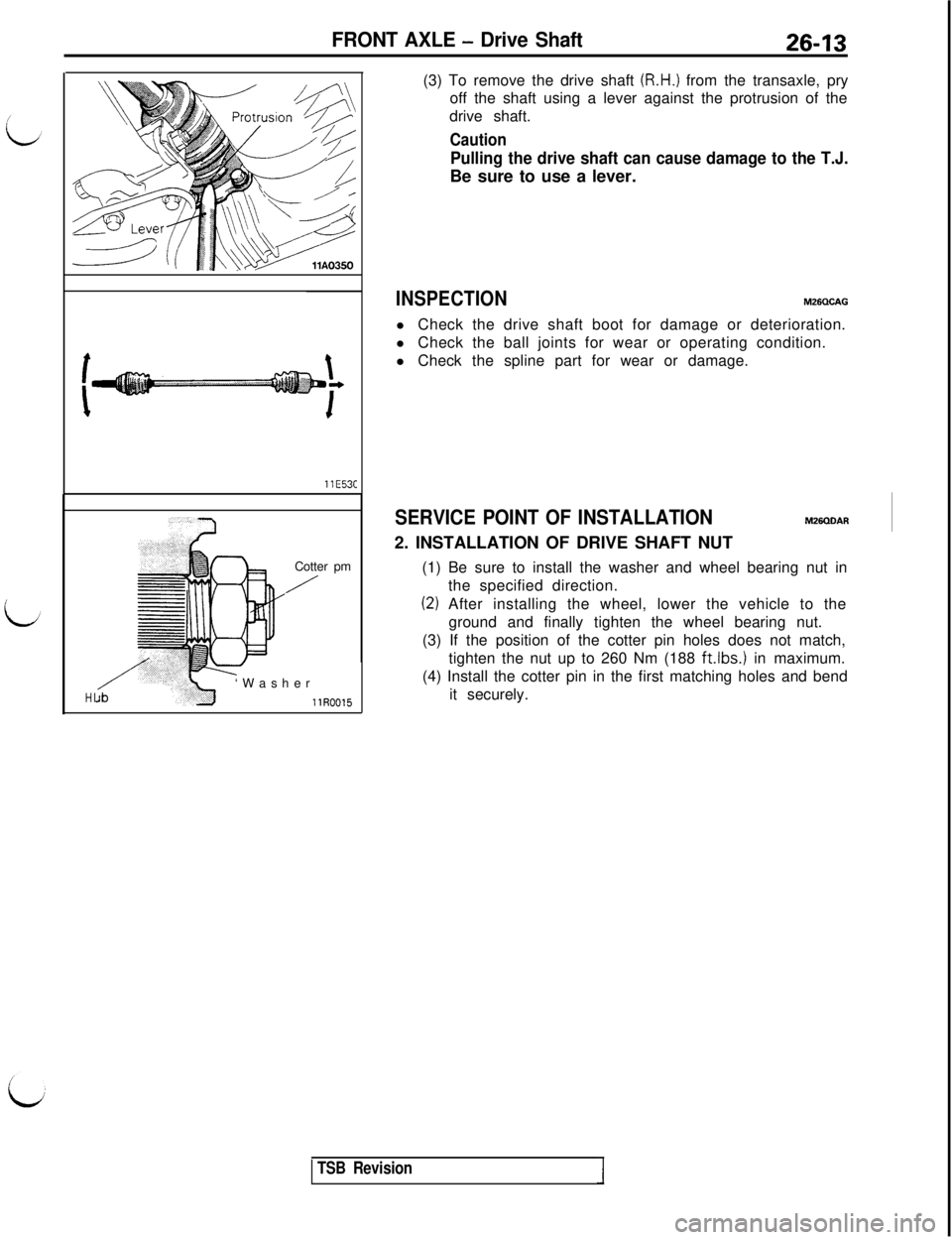

FRONT AXLE - Drive Shaft26-13

llE53C

HI/JbCotter pm

/‘Washer

llR0015(3) To remove the drive shaft

(R.H.) from the transaxle, pry

off the shaft using a lever against the protrusion of the

drive shaft.

Caution

Pulling the drive shaft can cause damage to the T.J.Be sure to use a lever.

INSPECTIONM26QCAGl Check the drive shaft boot for damage or deterioration.

l Check the ball joints for wear or operating condition.

l Check the spline part for wear or damage.

SERVICE POINT OF INSTALLATIONM26QLlAR2. INSTALLATION OF DRIVE SHAFT NUT

(1) Be sure to install the washer and wheel bearing nut in

the specified direction.

(2) After installing the wheel, lower the vehicle to the

ground and finally tighten the wheel bearing nut.

(3) If the position of the cotter pin holes does not match,

tighten the nut up to 260 Nm (188

ft.lbs.1 in maximum.

(4) Install the cotter pin in the first matching holes and bend

it securely.

TSB Revision

Page 590 of 1146

26-14FRONT AXLE - Drive Shaft

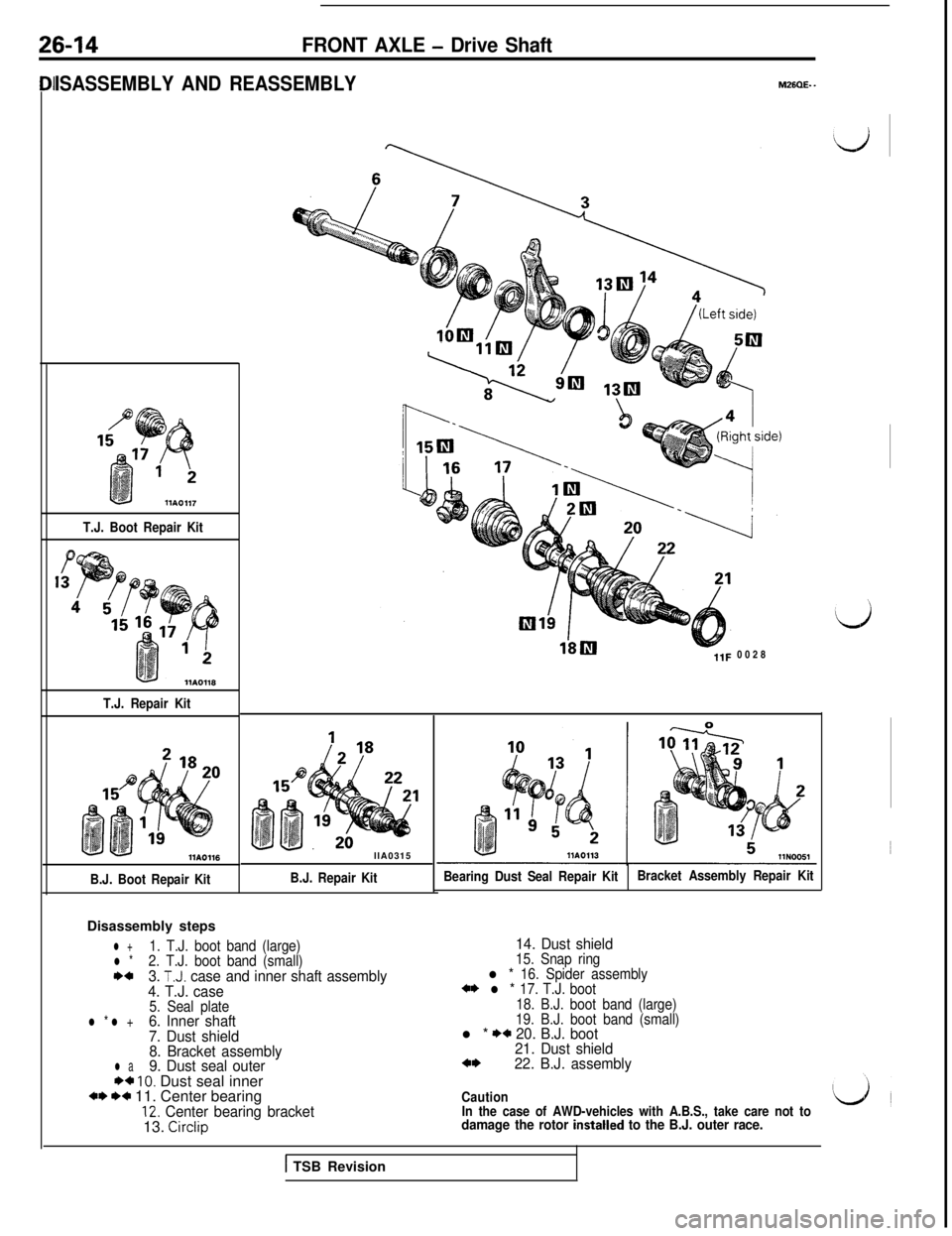

ISASSEMBLY AND REASSEMBLY

T.J. Boot Repair Kit

T.J. Repair KitllA0116

B.J. Boot Repair KitDisassembly stepsllA0315B.J. Repair Kit

l +1. T.J. boot band (large)l *2. T.J. boot band (small)I)+3. T.J. case and inner shaft assembly

4. T.J. case

5. Seal platel * l +6. Inner shaft

7. Dust shield

8. Bracket assembly

l a9. Dust seal outer** 10. Dust seal innerw W+ 11. Center bearing12. Center bearing bracket13. Circlip

M26QE- -0028

Bearing Dust Seal Repair KitBracket Assembly Repair Kit

14. Dust shield15. Snap ringl * 16. Spider assembly*I) l * 17. T.J. boot

18. B.J. boot band (large)

19. B.J. boot band (small)

l * I)* 20. B.J. boot

21. Dust shield

a*22. B.J. assembly

Caution

In the case of AWD-vehicles with A.B.S., take care not to

damage the rotor instatted to the B.J. outer race.

1 TSB Revision

Page 591 of 1146

FRONT AXLE - Drive Shaft26-15

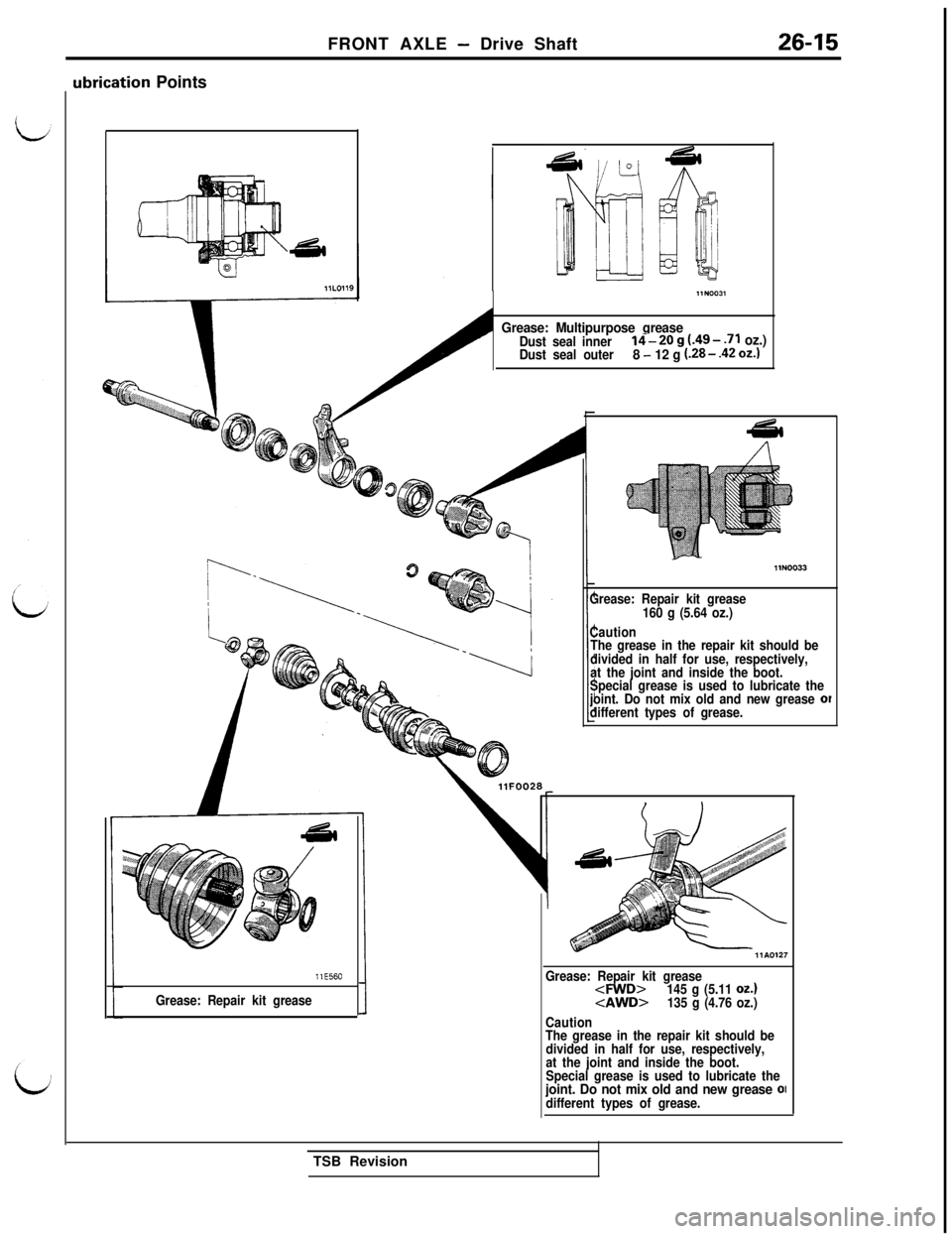

ubrication Points

Grease: Multipurpose greaseDust seal inner14-2Og(.49-.71 oz.)Dust seal outer8 - 12 g (.28- .42 oz.)

llE560

Grease: Repair kit greaseGrease: Repair kit grease

160 g (5.64 oz.)

Caution

The grease in the repair kit should be

divided in half for use, respectively,

at the joint and inside the boot.

Special grease is used to lubricate the

joint. Do not mix old and new grease

ofdifferent types of grease.

Grease: Repair kit grease

145 g (5.11 oz.)

Caution

The grease in the repair kit should be

divided in half for use, respectively,

at the joint and inside the boot.

Special grease is used to lubricate the

joint. Do not mix old and new grease OIdifferent types of grease.TSB Revision