boot MITSUBISHI 3000GT 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 726 of 1146

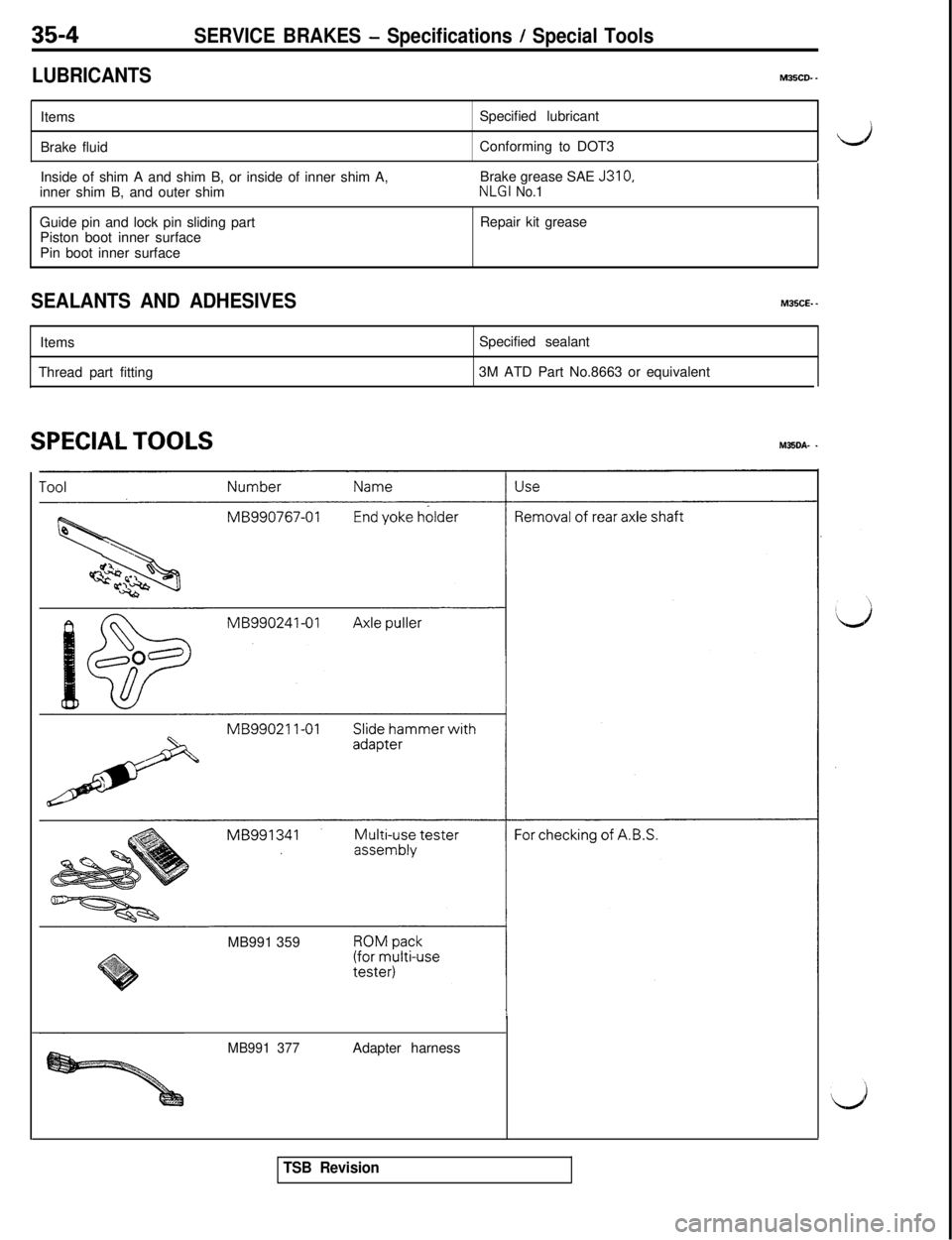

35-4LUBRICANTSItems

Brake fluid

SERVICE BRAKES - Specifications / Special ToolsSpecified lubricant

Conforming to DOT3

M3!3xh~

dInside of shim A and shim B, or inside of inner shim A,

inner shim B, and outer shimBrake grease SAE J310,

NLGI No.1Guide pin and lock pin sliding part

Piston boot inner surface

Pin boot inner surfaceRepair kit grease

SEALANTS AND ADHESIVESM3S.X..

Items

Thread part fittingSpecified sealant

3M ATD Part No.8663 or equivalent

SPECIAL TOOLSM35DA- _MB991 359

MB991 377Adapter harness

TSB Revision

Page 772 of 1146

35-50SERVICE BRAKES - Service Adjustment Procedures

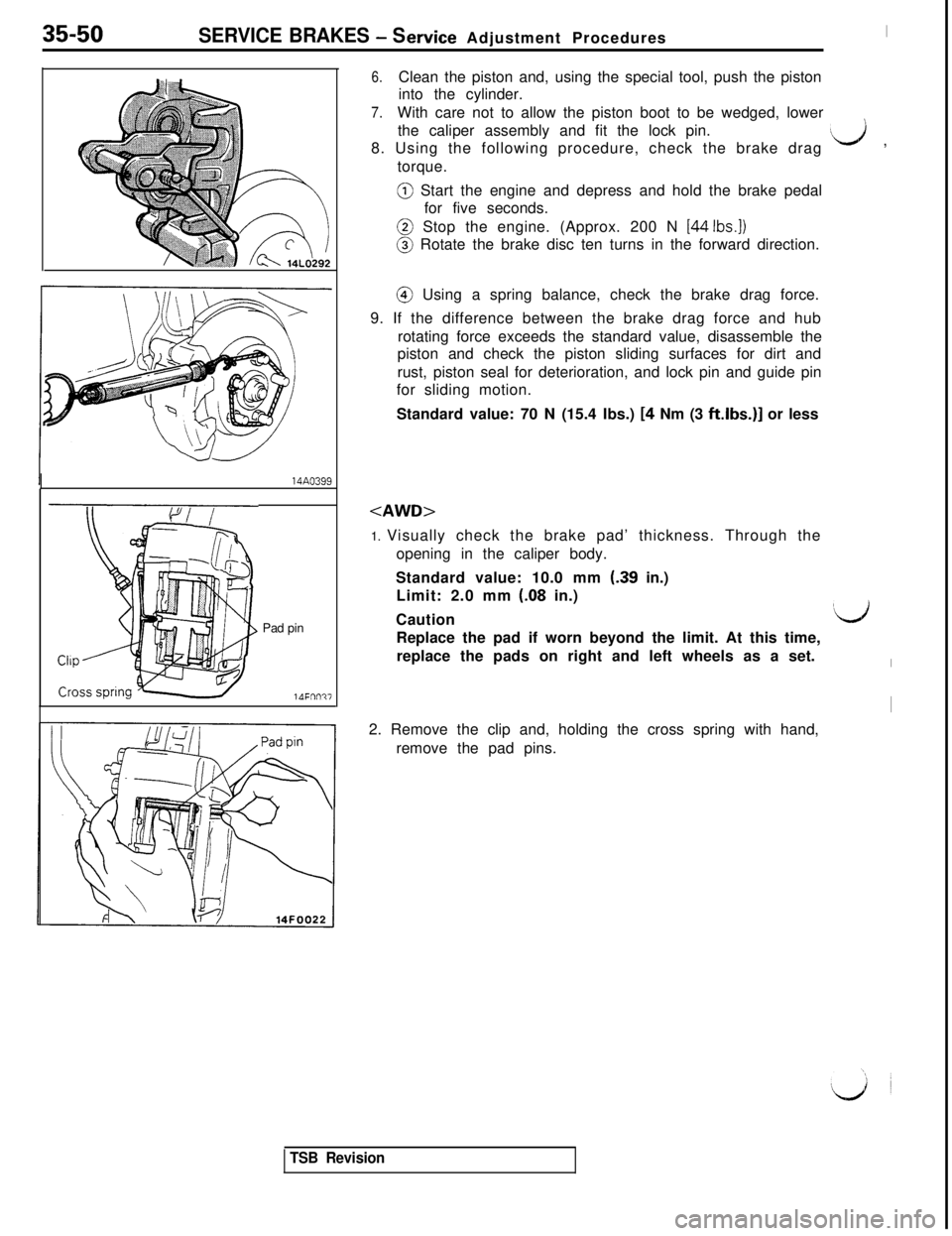

Pad pin

1 AFnn97

6.Clean the piston and, using the special tool, push the piston

into the cylinder.

7.With care not to allow the piston boot to be wedged, lower

the caliper assembly and fit the lock pin.

8. Using the following procedure, check the brake drag

‘d ,

torque.@ Start the engine and depress and hold the brake pedal

for five seconds.@ Stop the engine. (Approx. 200 N

[44 Ibs.])@ Rotate the brake disc ten turns in the forward direction.@ Using a spring balance, check the brake drag force.

9. If the difference between the brake drag force and hub

rotating force exceeds the standard value, disassemble the

piston and check the piston sliding surfaces for dirt and

rust, piston seal for deterioration, and lock pin and guide pin

for sliding motion.

Standard value: 70 N (15.4 Ibs.)

[4 Nm (3 ftlbs.)] or less

opening in the caliper body.

Standard value: 10.0 mm

(-39 in.)

Limit: 2.0 mm

(.08 in.)

Caution

‘L&iReplace the pad if worn beyond the limit. At this time,

replace the pads on right and left wheels as a set.

I2. Remove the clip and, holding the cross spring with hand,

remove the pad pins.

TSB Revision

Page 776 of 1146

SERVICE BRAKES - Service Adjustment Procedures

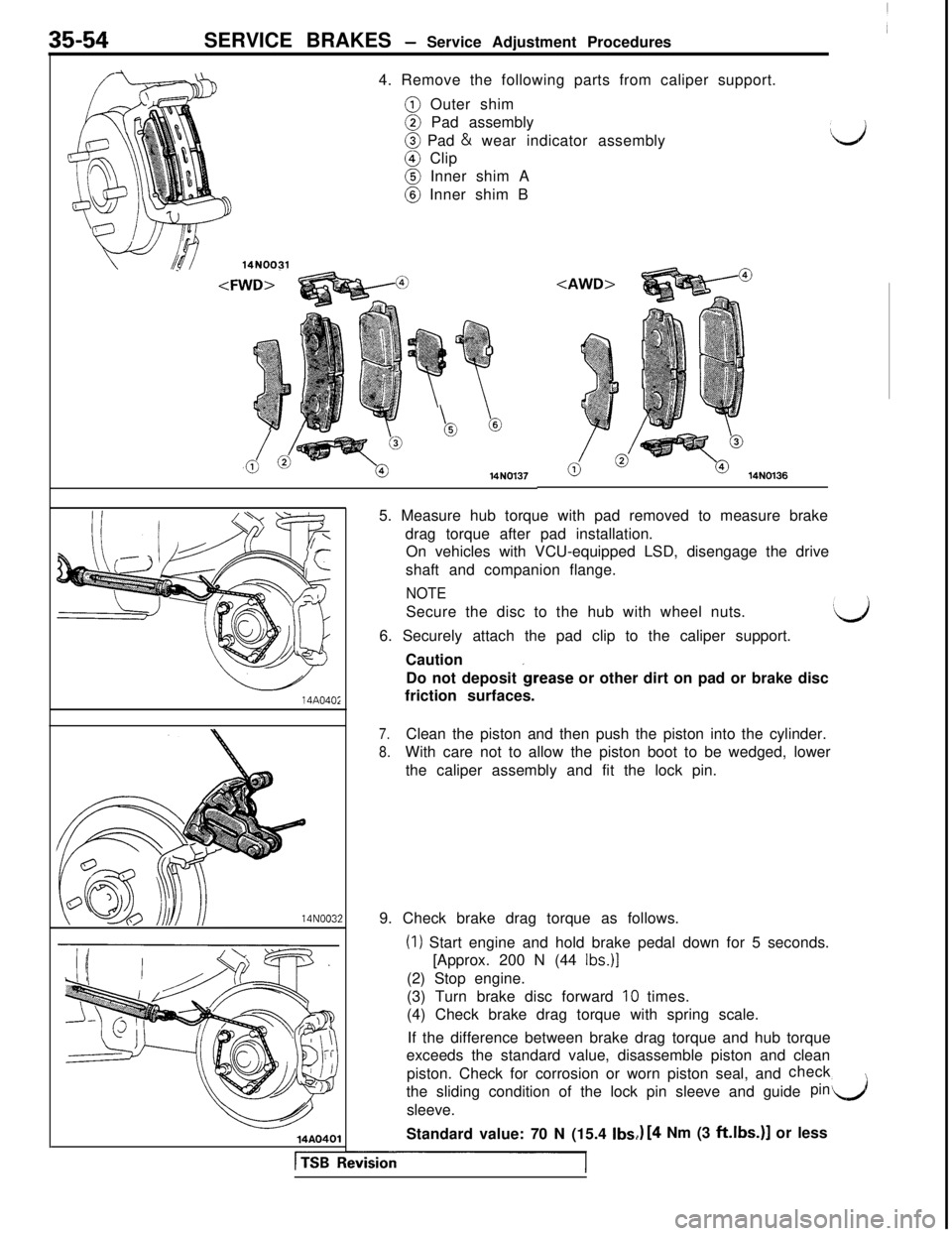

4. Remove the following parts from caliper support.@ Outer shim@ Pad assembly@ Pad & wear indicator assembly@ Clip@ Inner shim A@ Inner shim B

d

14N0031

/0014N013714A040;14N003:

14AO401

l%FLision

14N01365. Measure hub torque with pad removed to measure brake

drag torque after pad installation.

On vehicles with VCU-equipped LSD, disengage the drive

shaft and companion flange.

NOTESecure the disc to the hub with wheel nuts.

6. Securely attach the pad clip to the caliper support.

Caution

Do not deposit

&ease or other dirt on pad or brake disc

friction surfaces.

7.Clean the piston and then push the piston into the cylinder.

8.With care not to allow the piston boot to be wedged, lower

the caliper assembly and fit the lock pin.

9. Check brake drag torque as follows.

(I) Start engine and hold brake pedal down for 5 seconds.

[Approx. 200 N (44

Ibs.)](2) Stop engine.

(3) Turn brake disc forward

10 times.

(4) Check brake drag torque with spring scale.

If the difference between brake drag torque and hub torque

exceeds the standard value, disassemble piston and clean

piston. Check for corrosion or worn piston seal, andcheck

the sliding condition of the lock pin sleeve and guide

pinl/jsleeve.

Standard value: 70 N (15.4

Ibs,,) [4 Nm (3 ft.lbs.)] or less

Page 797 of 1146

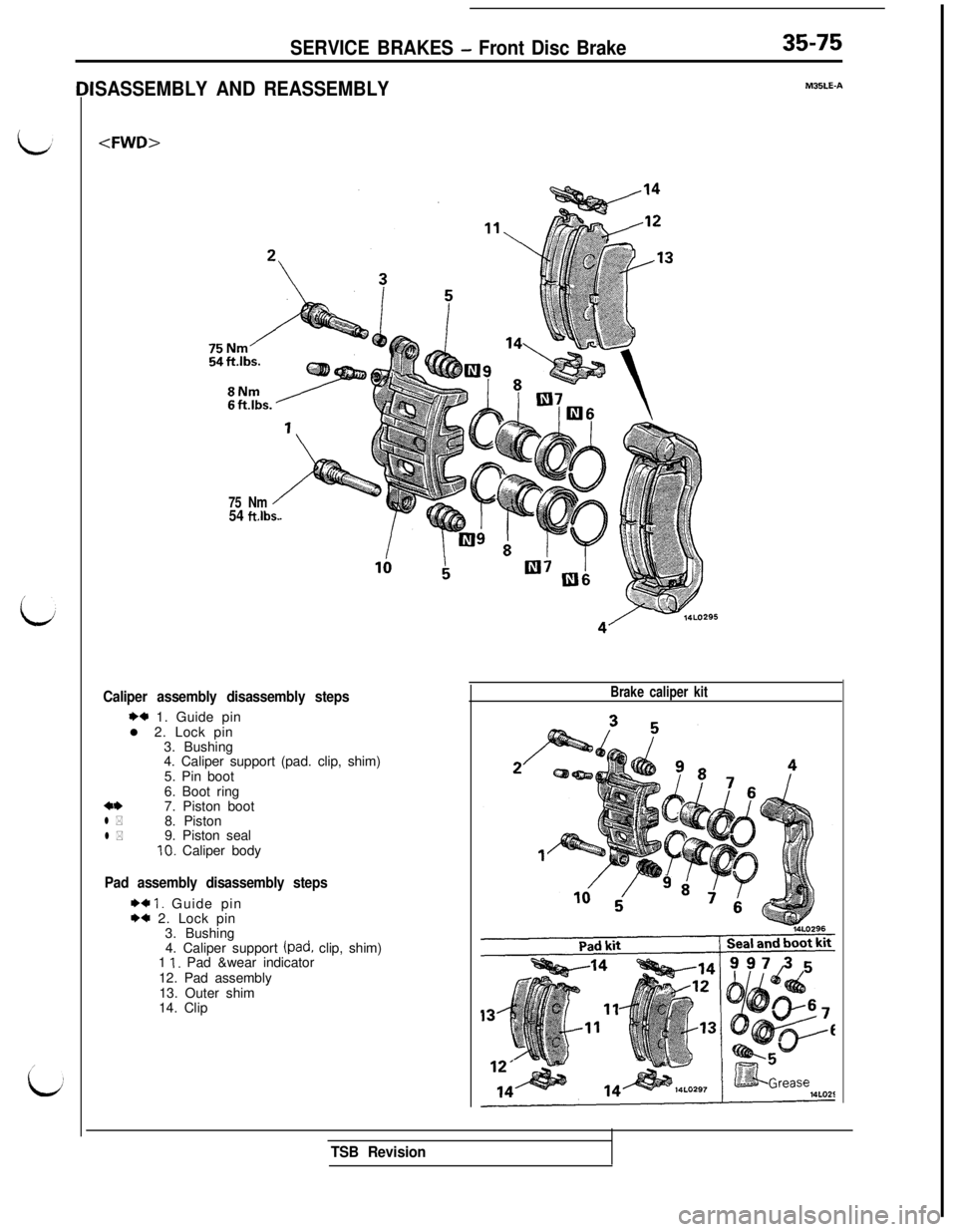

SERVICE BRAKES - Front Disc Brake35-75

SASSEMBLY AND REASSEMBLYM35LE-A

Caliper assembly disassembly steps

1)* 1. Guide pin

l 2. Lock pin

3. Bushing

4. Caliper support (pad. clip, shim)

5. Pin boot

6. Boot ring

7. Piston boot

8. Piston

9. Piston sealIO. Caliper body

a*l *

l *

Pad assembly disassembly steps

I)+ I. Guide pinw 2. Lock pin

3. Bushing

4. Caliper support

(pad, clip, shim)

1 I. Pad &wear indicator

12. Pad assembly

13. Outer shim

14. Clip

75 Nm54 ftlbs.

Brake caliper kit

TSB Revision

Page 799 of 1146

SERVICE BRAKES - Front Disc Brake35-77

14AO553

14AO55114uoo7i

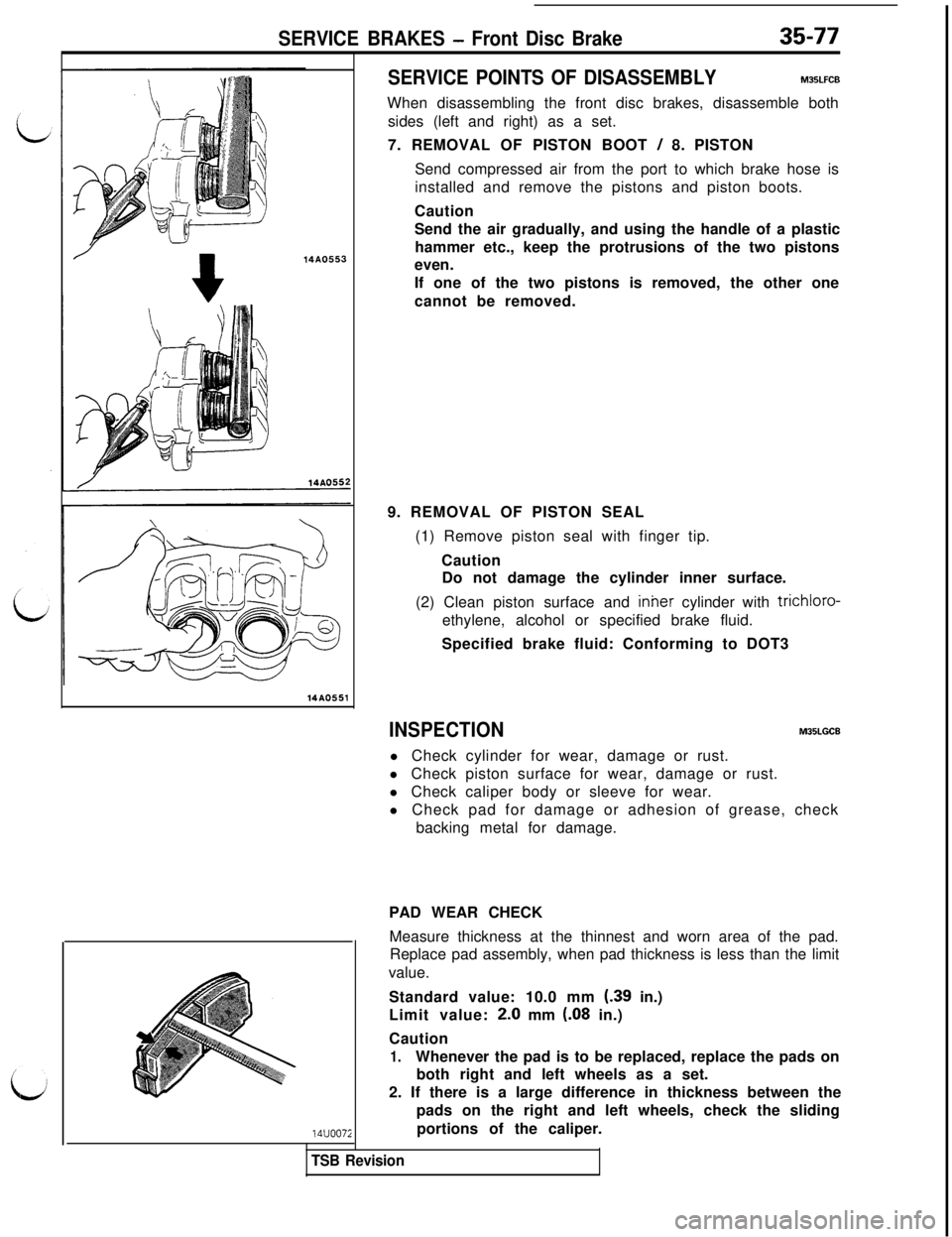

SERVICE POINTS OF DISASSEMBLYM35LFCB

When disassembling the front disc brakes, disassemble both

sides (left and right) as a set.

7. REMOVAL OF PISTON BOOT

/ 8. PISTON

Send compressed air from the port to which brake hose is

installed and remove the pistons and piston boots.

Caution

Send the air gradually, and using the handle of a plastic

hammer etc., keep the protrusions of the two pistons

even.

If one of the two pistons is removed, the other one

cannot be removed.

9. REMOVAL OF PISTON SEAL

(1) Remove piston seal with finger tip.

Caution

Do not damage the cylinder inner surface.

(2) Clean piston surface and inher cylinder with trichloro-

ethylene, alcohol or specified brake fluid.

Specified brake fluid: Conforming to DOT3

INSPECTIONMOBLGCBl Check cylinder for wear, damage or rust.

l Check piston surface for wear, damage or rust.

l Check caliper body or sleeve for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly, when pad thickness is less than the limit

value.

Standard value: 10.0 mm (.39 in.)

Limit value: 2.0 mm

(08 in.)

Caution

1.Whenever the pad is to be replaced, replace the pads on

both right and left wheels as a set.

2. If there is a large difference in thickness between the

pads on the right and left wheels, check the sliding

portions of the caliper.

TSB Revision

Page 801 of 1146

SERVICE BRAKES - Front Disc Brake

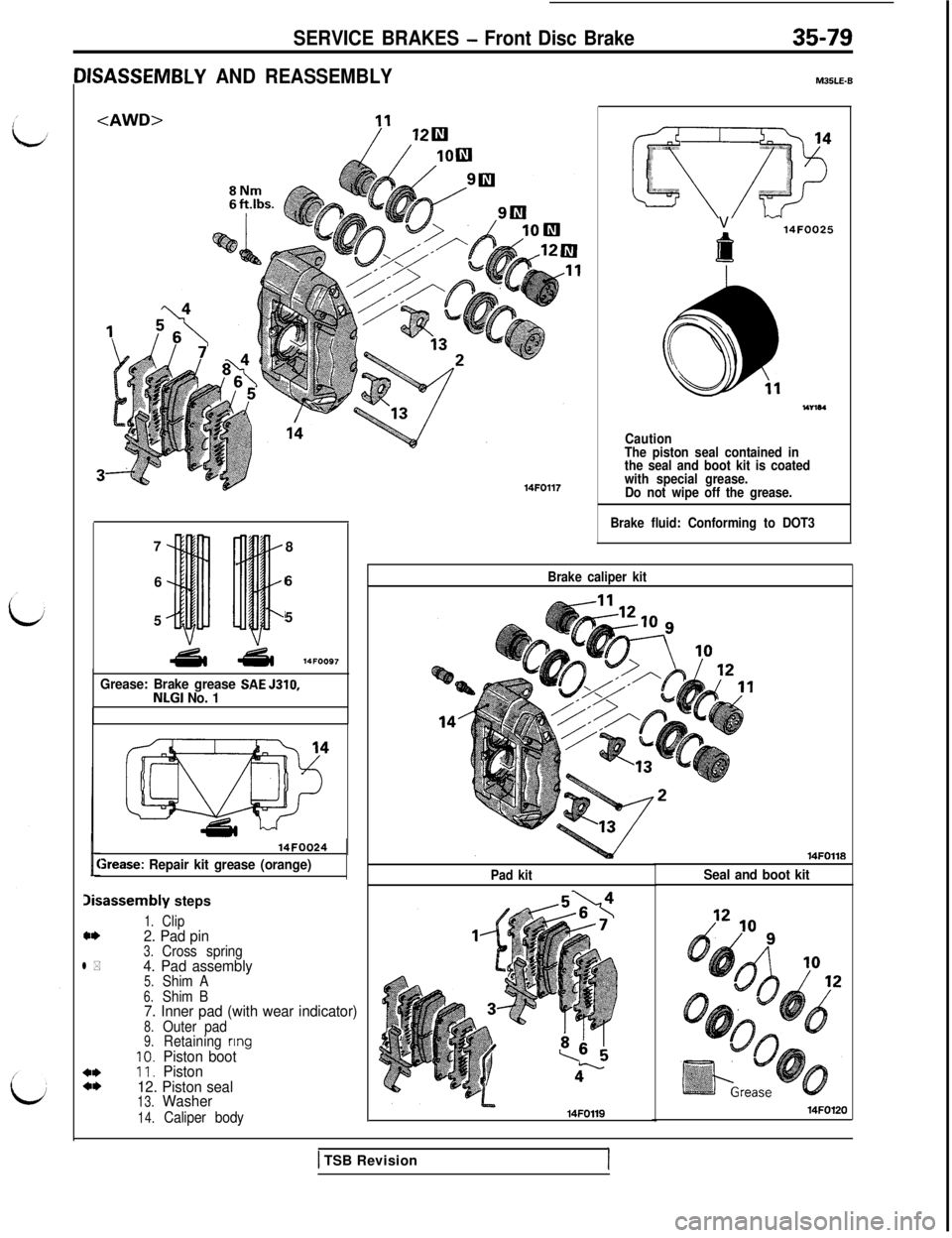

IISASSEMBLY AND REASSEMBLY

8

66

55

Grease: Brake grease SAE 5310,NLGI No. 1

14FOQ24

St-ease: Repair kit grease (orange)

Xsassembly steps

1.Clip*I)2. Pad pin3.Cross springl *4. Pad assembly5.Shim A6.Shim B7. Inner pad (with wear indicator)8.Outer pad9.Retainingnng

10.Piston boot*I)11.Piston*I)12. Piston seal13.Washer

14.Caliper body

14FO117

MJSLE-8V

f

14FOO25

Caution

The piston seal contained in

the seal and boot kit is coated

with special grease.

Do not wipe off the grease.

Brake fluid: Conforming to DOT3

Brake caliper kit

14FO118

Pad kitSeal and boot kit14FOll9

14FO120

,1 TSB Revision

Page 804 of 1146

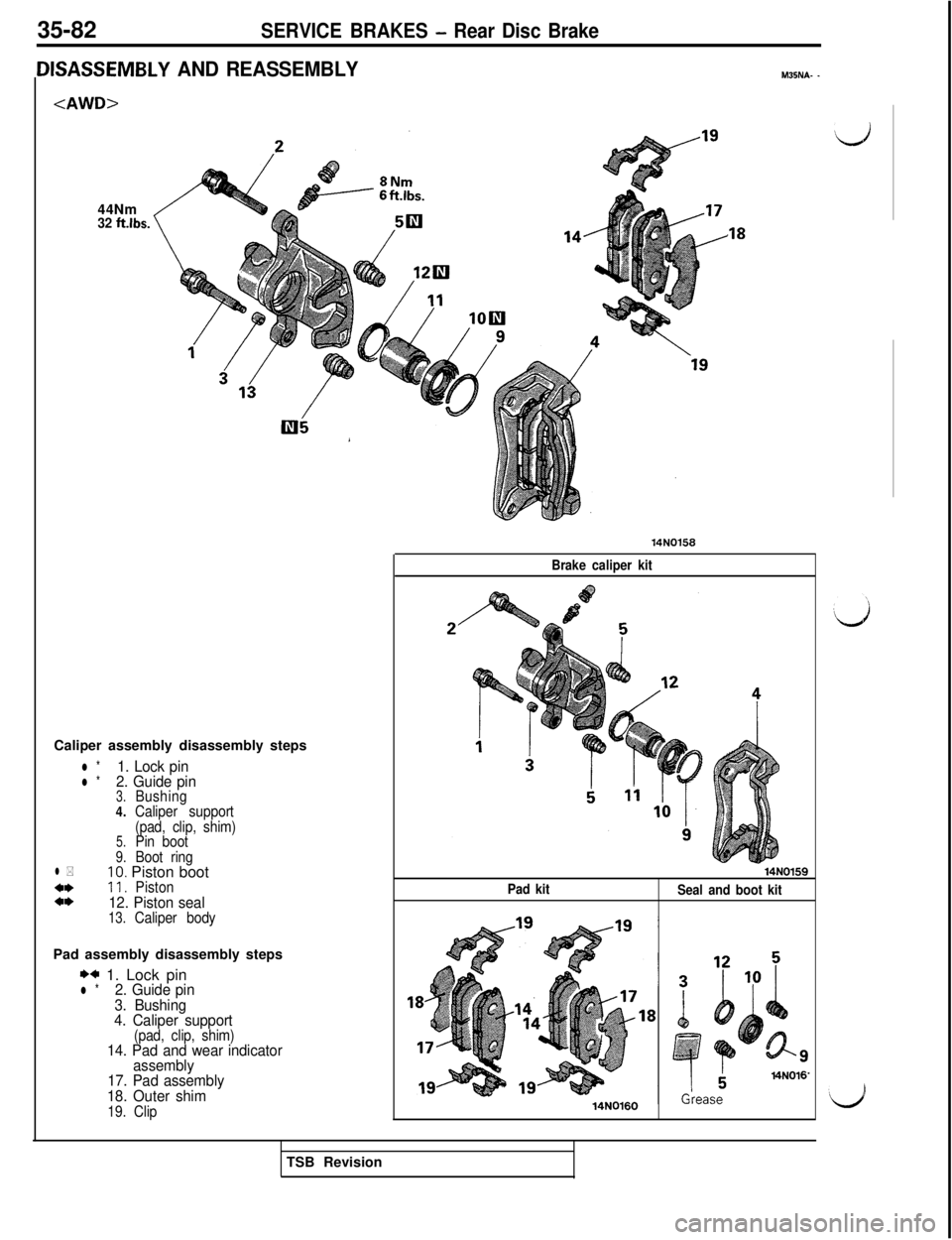

35-82SERVICE BRAKES - Rear Disc Brake

USASSEMBLY AND REASSEMBLYM35NA- -

32 ft.lbs.Caliper assembly disassembly steps

l *1. Lock pinl *2. Guide pin3.Bushing

4.Caliper support

(pad, clip, shim)

5.Pin boot9.Boot ringl *10. Piston boot4*11.Pistona*12. Piston seal13.Caliper bodyPad assembly disassembly steps

*+ 1. Lock pinl *2. Guide pin

3. Bushing

4. Caliper support

(pad, clip, shim)14. Pad and wear indicator

assembly

17. Pad assembly

18. Outer shim

19. Clip

,1814NOl58

Brake caliper kit

Pad kit

Seal and boot kit14N0160

TSB Revision

Page 805 of 1146

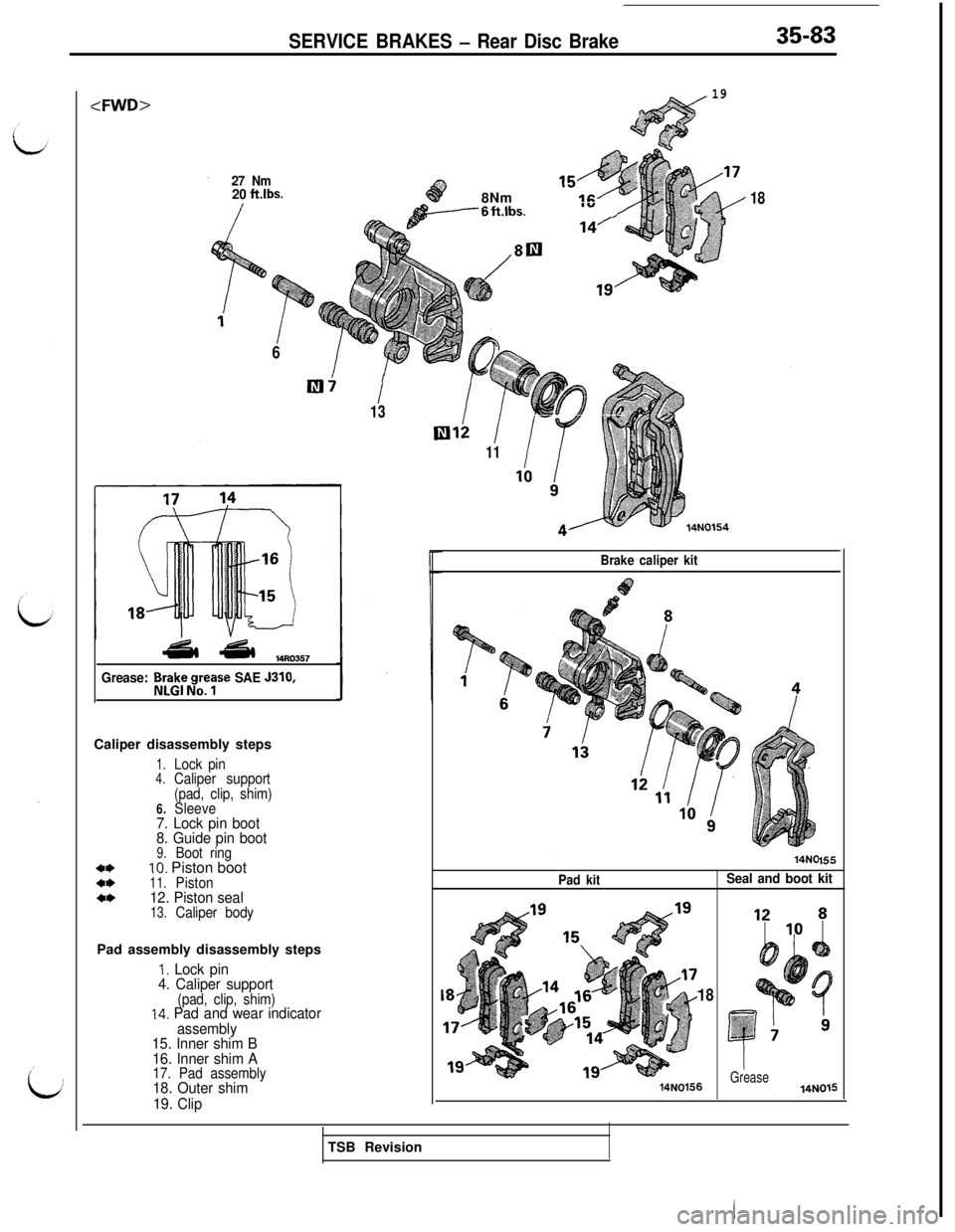

SERVICE BRAKES - Rear Disc Brake35-83

:FWD>

27 Nm20 ft.lbs.

6

Illi ’I13

-

11"?"L

pi,

d $A,, :;y,

44 4% w403.57

Grease: Br3rt;ty SAE J310,Caliper disassembly steps

1.Lock pin4.Caliper support

(pad, clip, shim)

6.Sleeve7. Lock pin boot

8. Guide pin boot

9.Boot ring*I)10. Piston boot*I)11.Piston*+12. Piston seal13.Caliper bodyPad assembly disassembly steps

1. Lock pin

4. Caliper support

(pad, clip, shim)14. Pad and wear indicator

assembly

15. Inner shim B

16. Inner shim A

17. Pad assembly18. Outer shim

19. Clip

w

19".*:a;*4~. ,/'.*"+:-r

48Nm&&----6ft.lbs.18I”,

Brake caliper kit

Pad kit

155

Seal and boot kit

18

14N0156Grease14N015TSB Revision

Page 806 of 1146

35-84SERVICE BRAKES - Rear Disc Brake

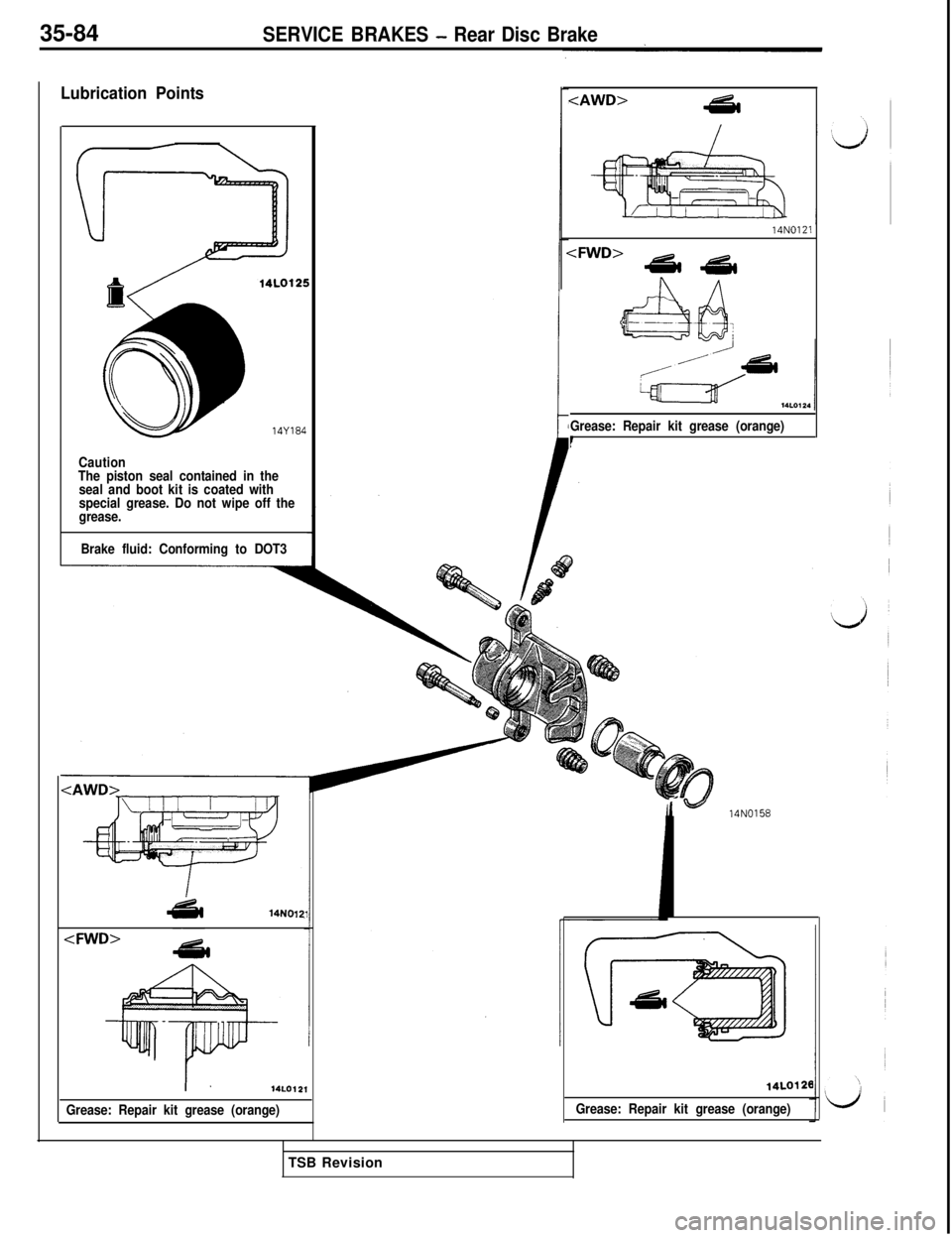

Lubrication Points14Y184

Caution

The piston seal contained in the

seal and boot kit is coated with

special grease. Do not wipe off the

grease.

Brake fluid: Conforming to DOT3

Grease: Repair kit grease (orange)

t14N0121

14LO12,

Grease: Repair kit grease (orange)

I-14NO158

Grease: Repair kit grease (orange)14LO128

TSB Revision

Page 807 of 1146

SERVICE BRAKES - Rear Disc Brake35-85

i

id14N0131

i

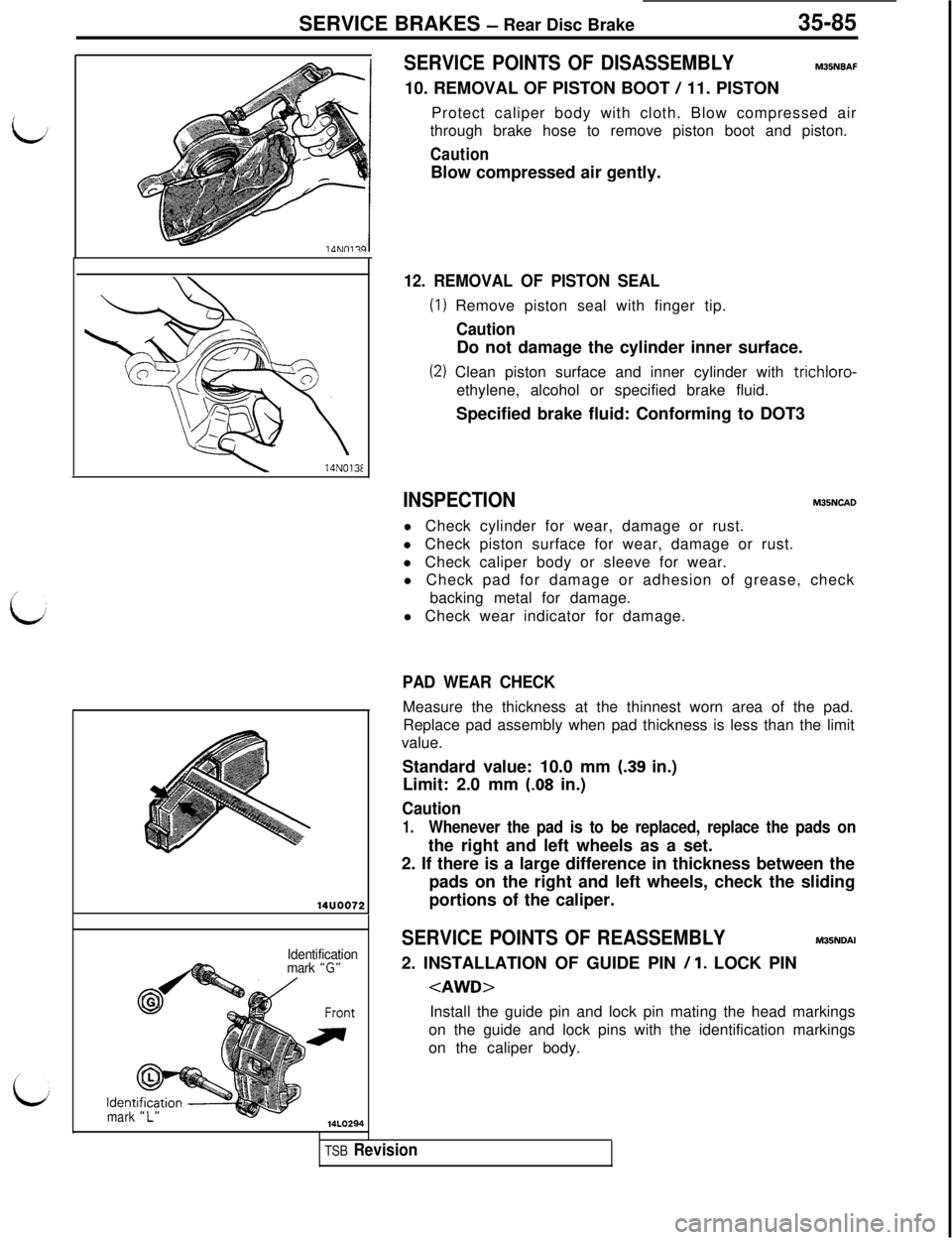

SERVICE POINTS OF DISASSEMBLYM35NBAF10. REMOVAL OF PISTON BOOT

/ 11. PISTON

Protect caliper body with cloth. Blow compressed air

through brake hose to remove piston boot and piston.

CautionBlow compressed air gently.

12. REMOVAL OF PISTON SEAL

(I) Remove piston seal with finger tip.

CautionDo not damage the cylinder inner surface.

(2) Clean piston surface and inner cylinder with trichloro-

ethylene, alcohol or specified brake fluid.

Specified brake fluid: Conforming to DOT3

INSPECTIONM35NCAOl Check cylinder for wear, damage or rust.

l Check piston surface for wear, damage or rust.

l Check caliper body or sleeve for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

l Check wear indicator for damage.

PAD WEAR CHECKMeasure the thickness at the thinnest worn area of the pad.

Replace pad assembly when pad thickness is less than the limit

value.

Standard value: 10.0 mm

(39 in.)

Limit: 2.0 mm

(.08 in.)

Caution

1.Whenever the pad is to be replaced, replace the pads onthe right and left wheels as a set.

2. If there is a large difference in thickness between the

pads on the right and left wheels, check the sliding

portions of the caliper.

Identification

mark “G”

ldentmark

SERVICE POINTS OF REASSEMBLYM35NOAI2. INSTALLATION OF GUIDE PIN

/ 1. LOCK PIN

on the guide and lock pins with the identification markings

on the caliper body.

TSB Revision