engine coolant MITSUBISHI 3000GT 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1086 of 1146

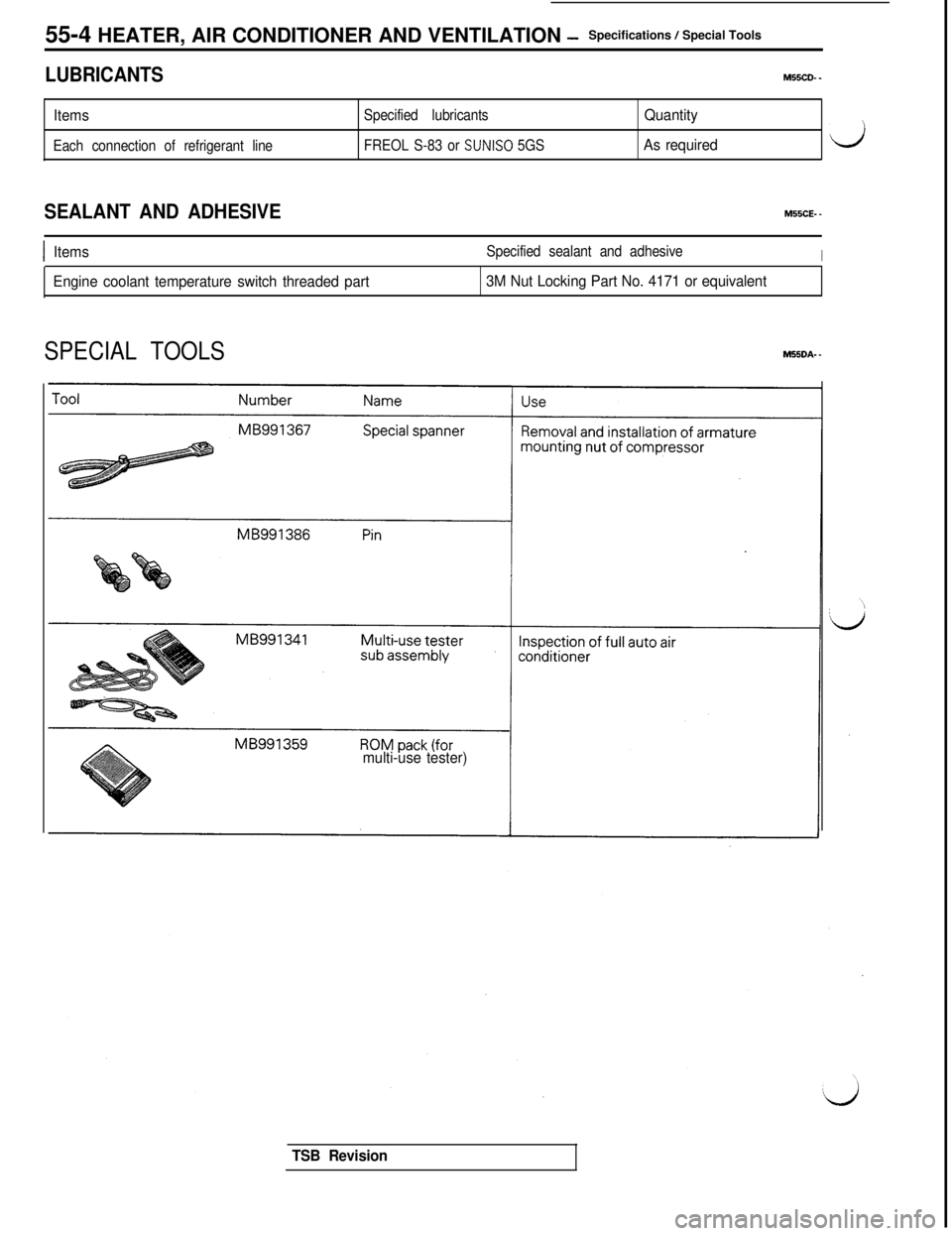

55-4 HEATER, AIR CONDITIONER AND VENTILATION -Specifications / Special Tools

LUBRICANTSM55CD. _

ItemsSpecified lubricants

Each connection of refrigerant lineFREOL S-83 or

SUNISO 5GS

Quantity

As required

SEALANT AND ADHESIVEM55CE- -

IItemsSpecified sealant and adhesiveI

Engine coolant temperature switch threaded part3M Nut Locking Part No. 4171 or equivalent

SPECIAL TOOLSMSSDA- -

multi-use tester)

TSB Revision

Page 1099 of 1146

HEATERS AND MANUAL AIR CbNDlTlONER -Service Adjustment Procedures 55 17

ADJUSTMENT PROCEDURES(1) Select a quiet area for testing. Duplicate conditions as much

as possible. Switch compressor on and off several times to

clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure),

restrict air flow through condenser. Install manifold gauge

set to make sure discharge pressure doesn’t exceed 2,070

kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting

bolt, and compressor drive belt. Check to assure clutch coil

is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can

cause unusual noises.

(4) Check refrigerant charge. (See “Charging System”.)

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and

retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

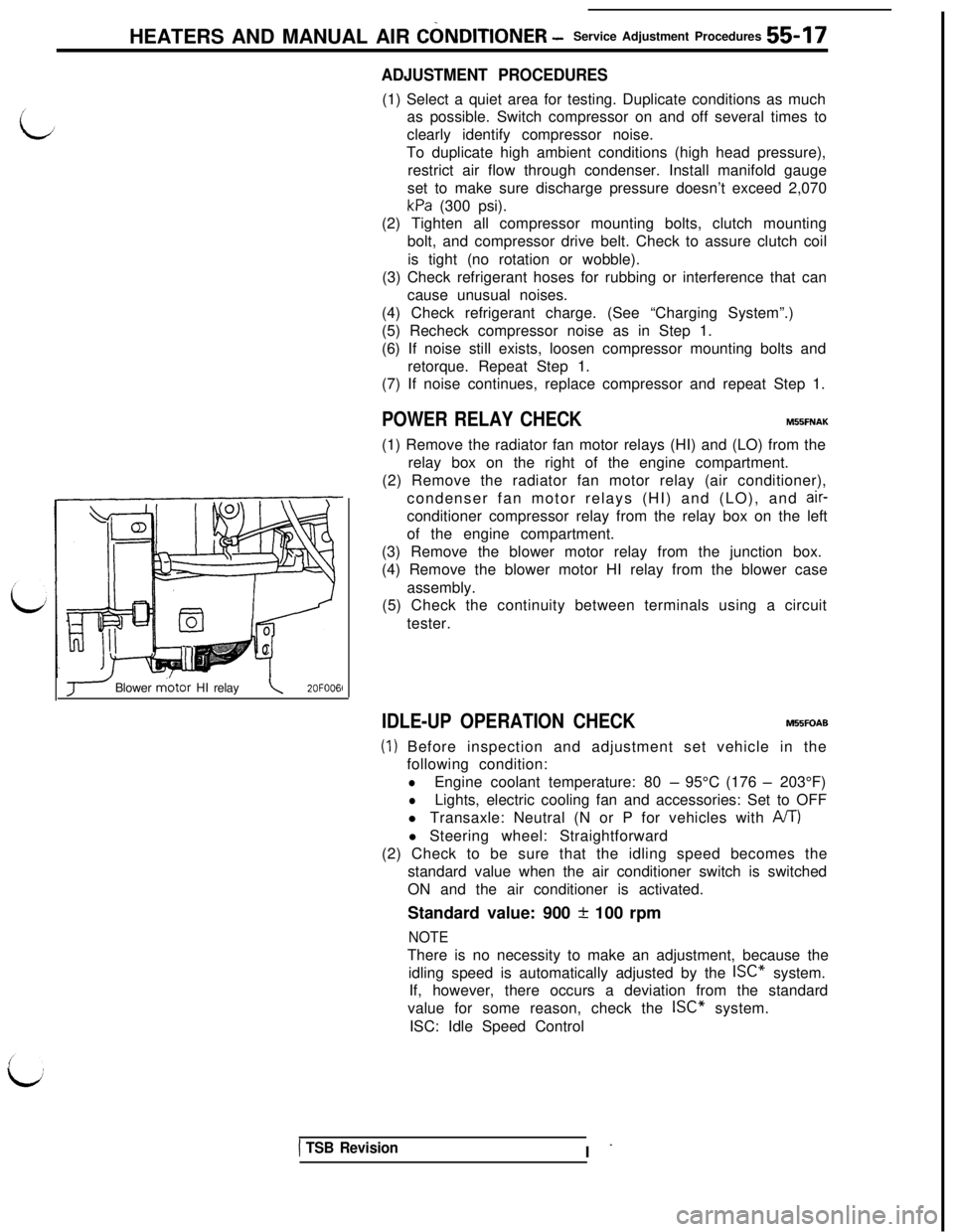

POWER RELAY CHECKMBBFNAK(1) Remove the radiator fan motor relays (HI) and (LO) from the

relay box on the right of the engine compartment.

(2) Remove the radiator fan motor relay (air conditioner),

condenser fan motor relays (HI) and (LO), and

air-conditioner compressor relay from the relay box on the left

of the engine compartment.

(3) Remove the blower motor relay from the junction box.

(4) Remove the blower motor HI relay from the blower case

assembly.

(5) Check the continuity between terminals using a circuit

tester.

J Blower m.otor HI relay\2OFOO6l

IDLE-UP OPERATION CHECKM55FOAB

(1) Before inspection and adjustment set vehicle in the

following condition:

lEngine coolant temperature: 80 - 95°C (176 - 203°F)

lLights, electric cooling fan and accessories: Set to OFF

l Transaxle: Neutral (N or P for vehicles with

A/T)l Steering wheel: Straightforward

(2) Check to be sure that the idling speed becomes the

standard value when the air conditioner switch is switched

ON and the air conditioner is activated.

Standard value: 900

+ 100 rpm

NOTEThere is no necessity to make an adjustment, because the

idling speed is automatically adjusted by the ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the ISC” system.

ISC: Idle Speed Control

1 TSB RevisionI -

Page 1121 of 1146

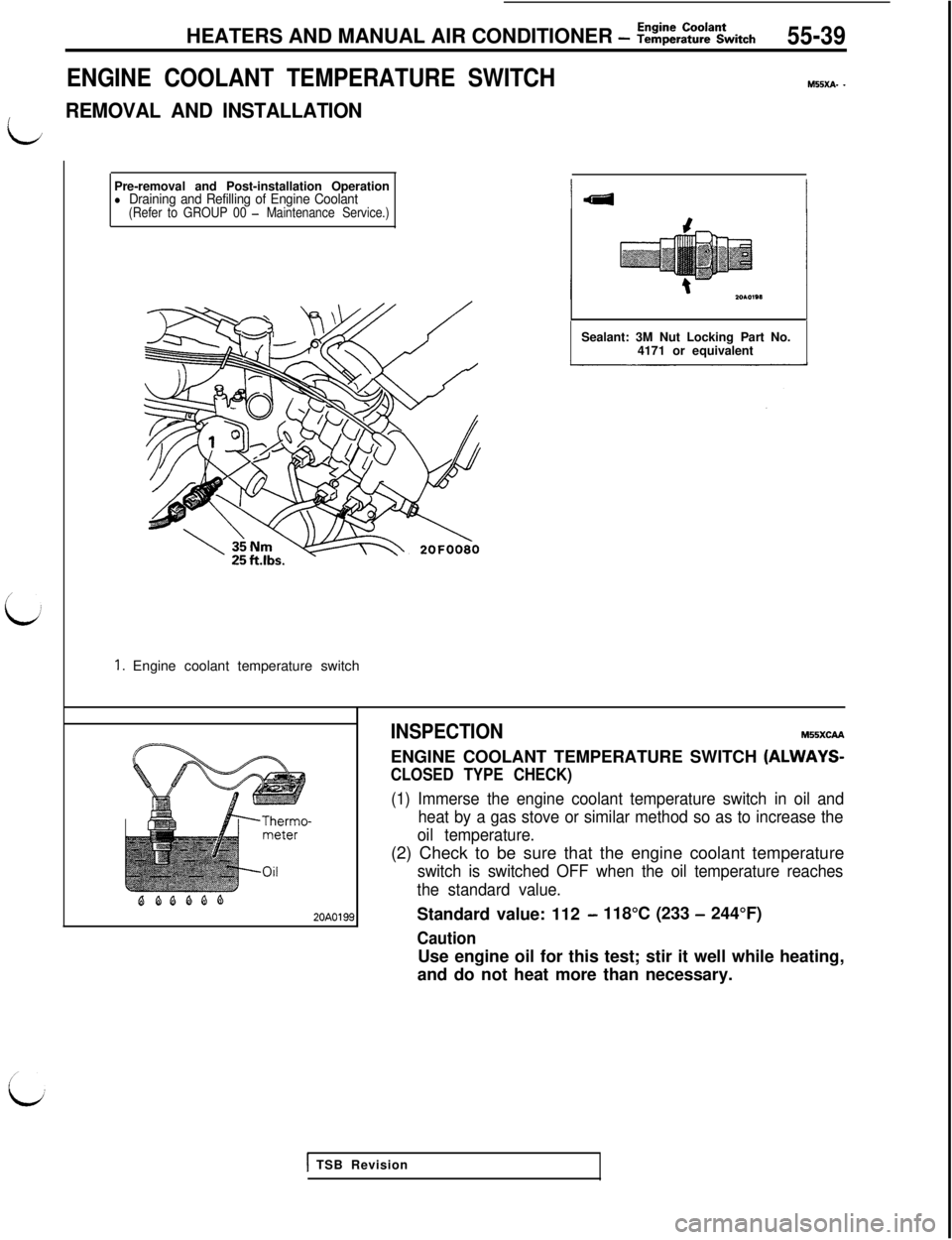

Pre-removal and Post-installation Operationl Draining and Refilling of Engine Coolant(Refer to GROUP 00 - Maintenance Service.)

1. Engine coolant temperature switchHEATERS AND MANUAL AIR CONDITIONER

- Z!&E%Ltch55-39

ENGINE COOLANT TEMPERATURE SWITCH

M55xA- -

L

REMOVAL AND INSTALLATIONSealant: 3M Nut Locking Part No.

4171 or equivalent

BQQQQQ20A0199INSPECTION

MSSXCAAENGINE COOLANT TEMPERATURE SWITCH

(ALWAYS-

CLOSED TYPE CHECK)

(1) Immerse the engine coolant temperature switch in oil and

heat by a gas stove or similar method so as to increase the

oil temperature.(2) Check to be sure that the engine coolant temperature

switch is switched OFF when the oil temperature reaches

the standard value.Standard value: 112

- 118°C (233 - 244°F)

CautionUse engine oil for this test; stir it well while heating,

and do not heat more than necessary.

1 TSB Revision

Page 1130 of 1146

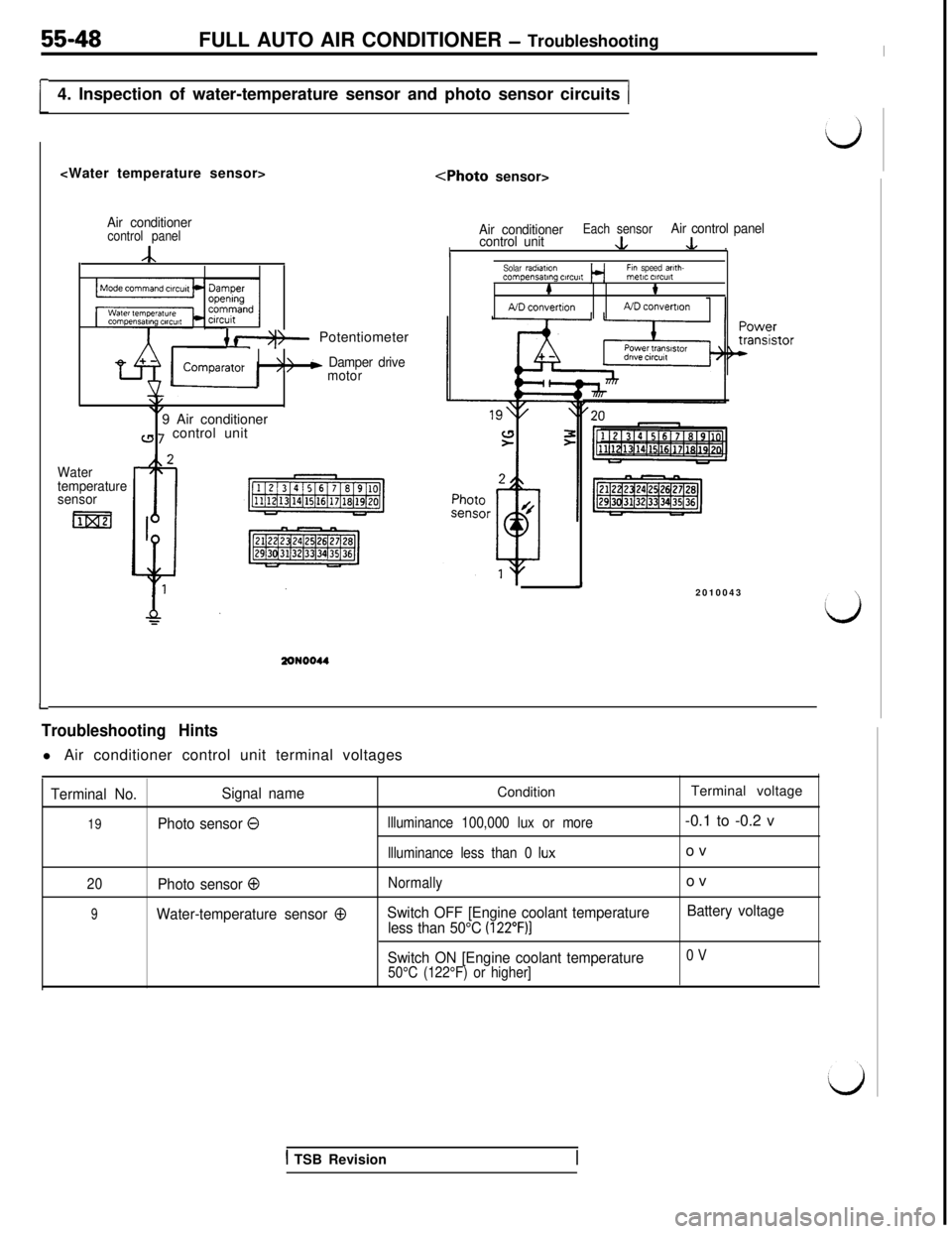

55-48FULL AUTO AIR CONDITIONER - Troubleshooting

[4. Inspection of water-temperature sensor and photo sensor circuits (

Air conditionercontrol panel

A

{ f*)- Potentiometer

‘>/b Damper drive

motor

\/\,9 Air conditioner

a 7 control unit

Water

temperature

sensor

m

Air conditionerEach sensorcontrol unit&

Air control panel

I.L .Solar radmtmnFin speed arlth-compensating ClrC”itmetIC ClrCUlt#t

A/D convertionND convemon

J2010043

I-

Troubleshooting Hintsl Air conditioner control unit terminal voltages

Terminal No.Signal nameConditionTerminal voltage

19Photo sensor 0llluminance 100,000 lux or more-0.1 to -0.2 v

llluminance less than 0 Iuxov

20Photo sensor 0Normallyov

9Water-temperature sensor 0Switch OFF [Engine coolant temperature

less than 50°C (122”F)]

Battery voltage

Switch ON [Engine coolant temperature

0 V

50°C (122°F) or higher]

1 TSB Revision

Page 1144 of 1146

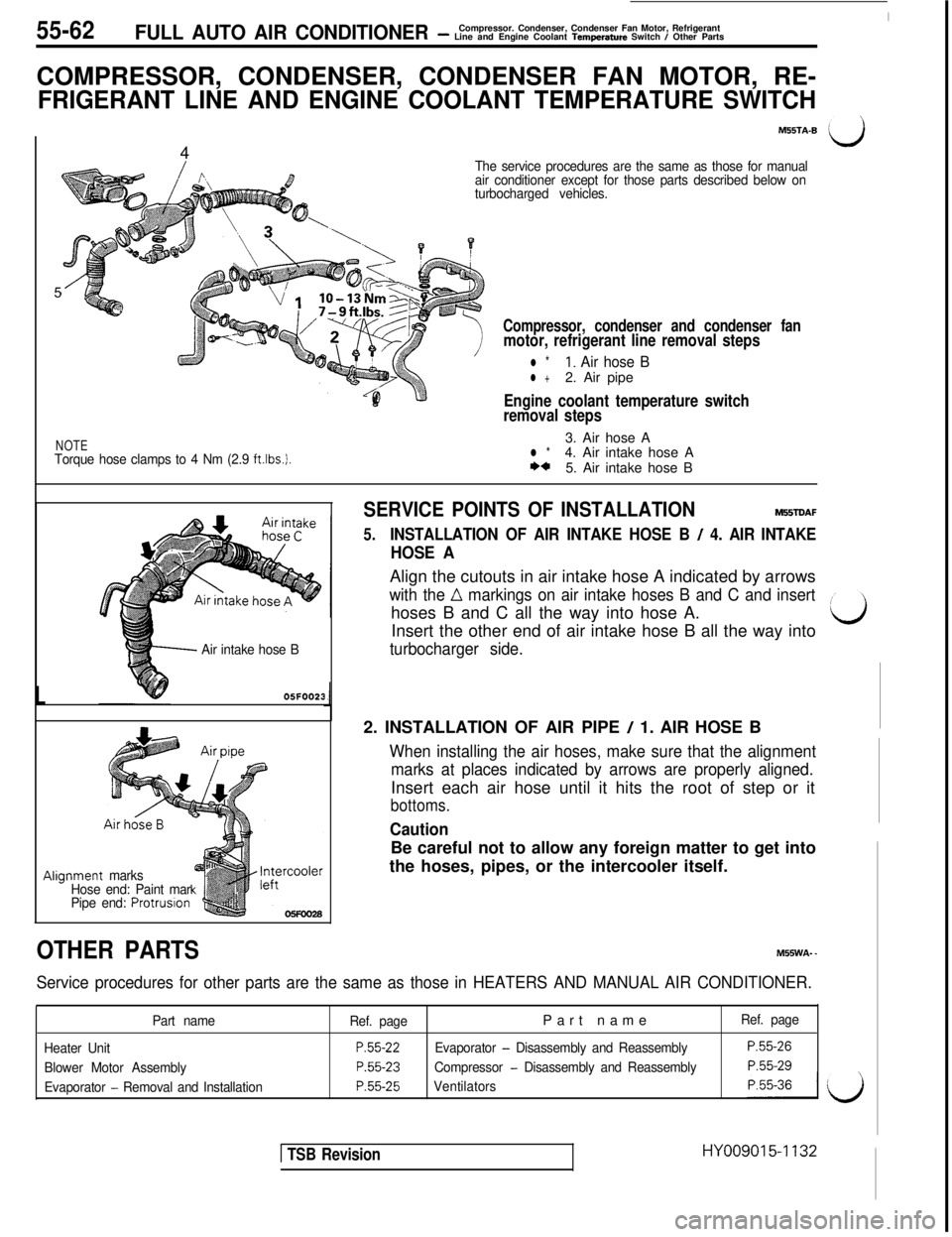

55-62FULL AUTO AIR CONDITIONER

ICompressor. Condenser, Condenser Fan Motor, Refrigerant

- Line and Engine Coolant Temperature Switch / Other Parts

COMPRESSOR, CONDENSER, CONDENSER FAN MOTOR, RE-

FRIGERANT LINE AND ENGINE COOLANT TEMPERATURE SWITCH

M55TA-B4

The service procedures are the same as those for manual

air conditioner except for those parts described below on

turbocharged vehicles.5

Compressor, condenser and condenser fanmotor, refrigerant line removal steps

l *I. Air hose Bl +2. Air pipe

ii

Engine coolant temperature switch

removal steps

NOTETorque hose clamps to 4 Nm (2.9 ftlbs.).3. Air hose Al *4. Air intake hose A*a5. Air intake hose B

L

Air intake hose B

OSFOO23

Align7ment marks

Hose end: Paint mar

Pipe end:

Protrusron

OTHER PARTS

SERVICE POINTS OF INSTALLATIONM55iDAF

5.INSTALLATION OF AIR INTAKE HOSE B / 4. AIR INTAKE

HOSE AAlign the cutouts in air intake hose A indicated by arrows

with the n markings on air intake hoses B and C and inserthoses B and C all the way into hose A.

Insert the other end of air intake hose B all the way into

turbocharger side.2. INSTALLATION OF AIR PIPE

/ 1. AIR HOSE B

When installing the air hoses, make sure that the alignment

marks at places indicated by arrows are properly aligned.Insert each air hose until it hits the root of step or it

bottoms.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.M55WA-

-

Service procedures for other parts are the same as those in HEATERS AND MANUAL AIR CONDITIONER.

Part name

Ref. page

Heater Unit

P.55-22

Blower Motor AssemblyP.55-23

Evaporator - Removal and InstallationP.55-25Part name

Evaporator - Disassembly and Reassembly

Compressor

- Disassembly and Reassembly

VentilatorsRef. page

P.55-26

P.55-29

1 TSB RevisionHY009015-1132