engine coolant MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 126 of 1146

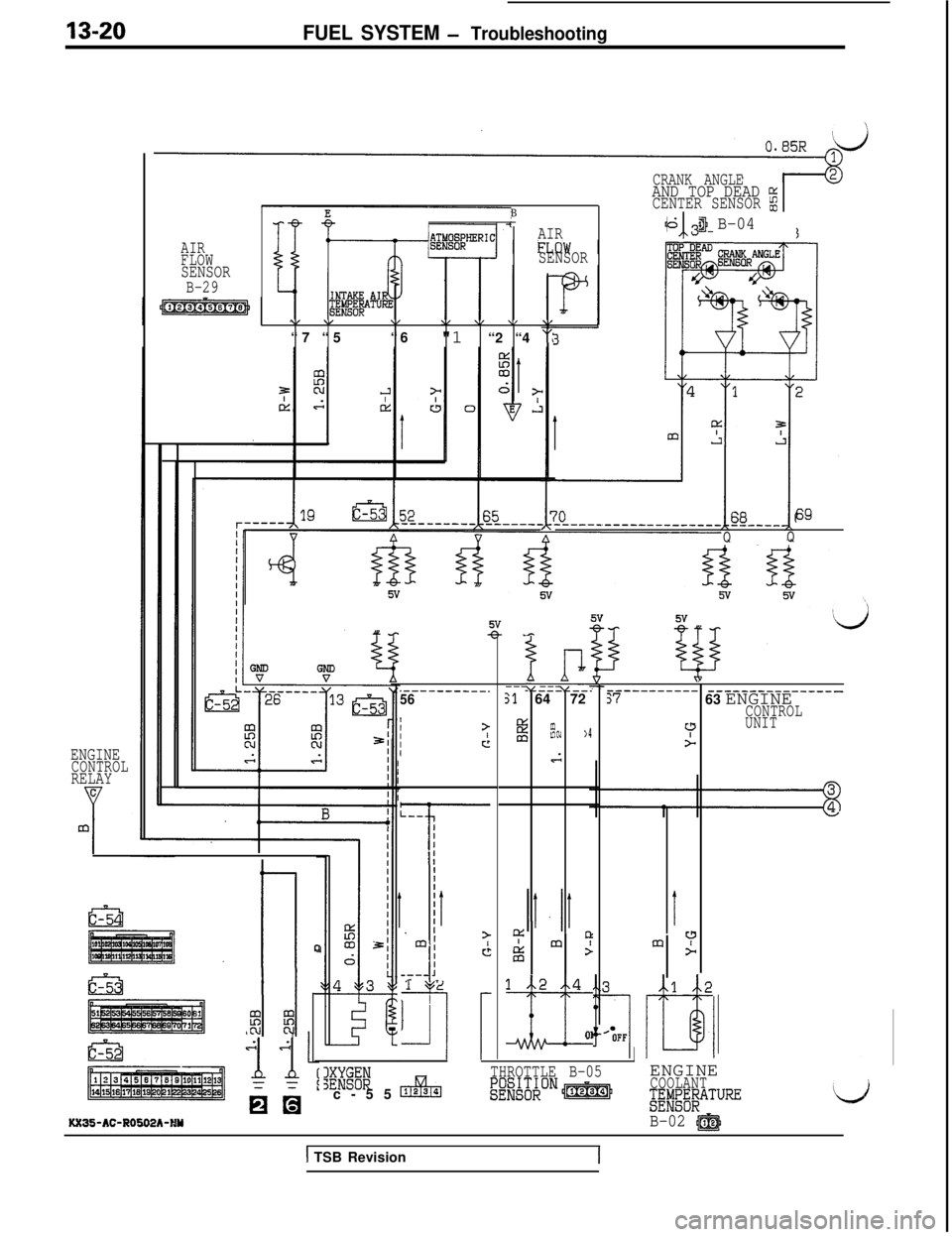

13-20FUEL SYSTEM - Troubleshooting

CRANK ANGLEAND TOP DEAD z

BCENTER SENSOR $j

AIR4-j B-04613

SENSOR

\/ v\/\, \I \/\I“7 “5“6

"1 “2 “4 “l

AIR

FLOW

SENSORB-29

69

QQ

ip--------.Sl6472

4:g$w cu> 4

d

m95

”----------- __---------_____:763 ENGINECONTROL?UNIT>

I

m?>

.----------.56

III?IcIENGINECONTROLRELAYc

Y

mL--I

1;

III

jr

I>ml

-II

d

--- 11 2

I

~~

12 4

~01

Ii%ml

c-55

c&m

THROTTLE B-05ENGINE

~~~Q~~oNp&q+COOLANT$E!E$BATURELj

B-02 @J

.h

0

I I

$I I$KX35-AC-R0502h-HY

1 TSB Revision

Page 128 of 1146

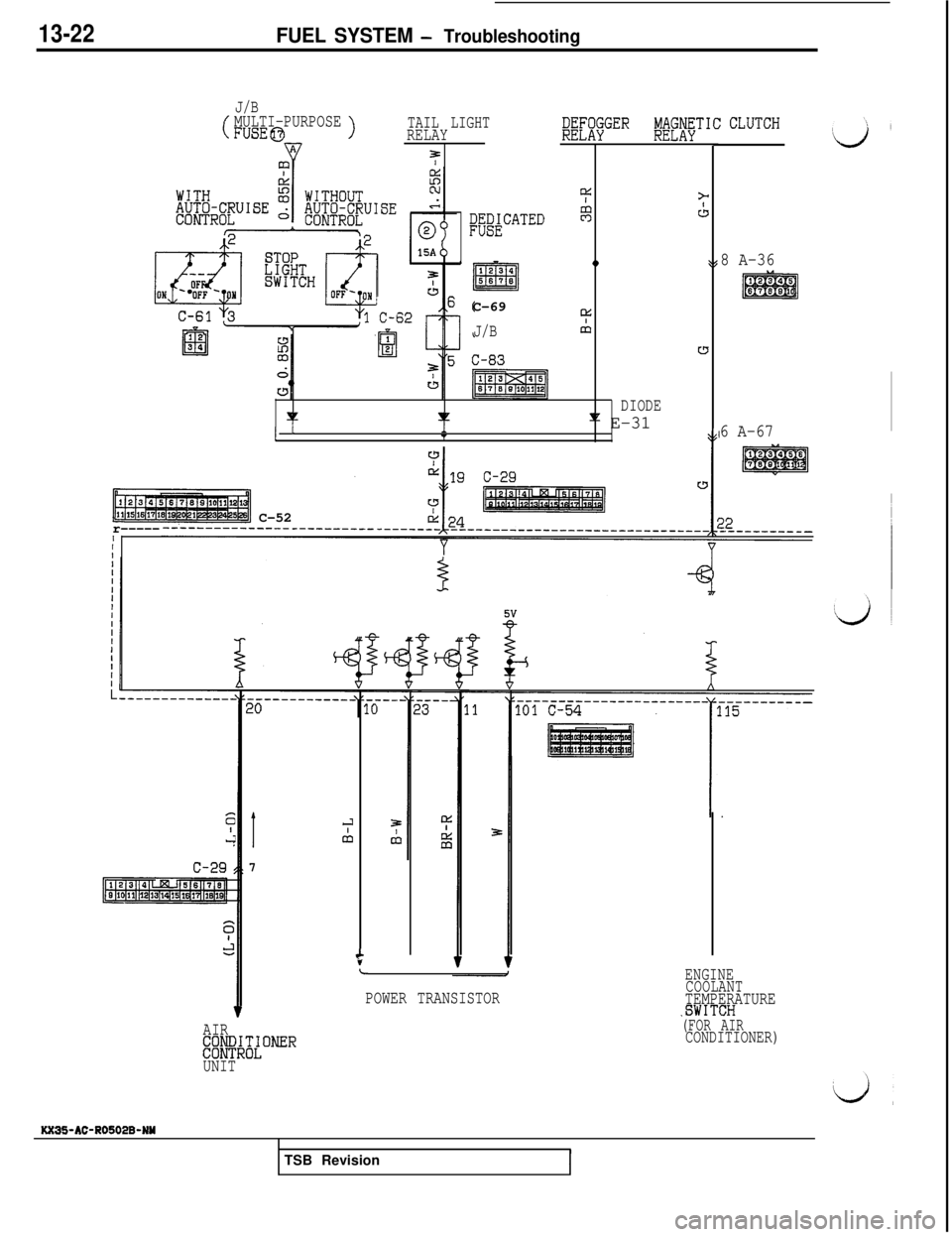

13-22FUEL SYSTEM - Troubleshooting

J/B

(MULTI-PURPOSEFUSE@>TAIL LIGHTRELAYiE;;FGER ikli$IC

5I7

>

;;iZ;CATED gJ

0\IC-69

[1:

J/B&I

w

8 A-36

7

DIODE*Ire E-31I ’1IT6 A-67C-52

r-----IY

6I1

J

CA

7

.i

tc

POWER TRANSISTOR

ENGINE

COOLANT

TEMPERATURE.SWITCH

(FOR AIR

CONDITIONER)AIR~X$Il$T~ONER

UNITKX35-AC-R05025-NY

TSB Revision

Page 135 of 1146

![MITSUBISHI 3000GT 1991 Owners Manual FUEL SYSTEM - Troubleshooting13-29

ENGINE

CONTROL

RELAYF

1 7=2

c----IIIIIIII2,(2Io FUEL

) SE

PRESSURE

SOLENOID

VALVE

IfII

I

I

I

I

J

]i#&B,D i

A-20

1

WASTE

GATE

SOLENOIDVALVE

/

7 EGRi ~XE~~OID

I

; A-21 MITSUBISHI 3000GT 1991 Owners Manual FUEL SYSTEM - Troubleshooting13-29

ENGINE

CONTROL

RELAYF

1 7=2

c----IIIIIIII2,(2Io FUEL

) SE

PRESSURE

SOLENOID

VALVE

IfII

I

I

I

I

J

]i#&B,D i

A-20

1

WASTE

GATE

SOLENOIDVALVE

/

7 EGRi ~XE~~OID

I

; A-21](/img/19/57085/w960_57085-134.png)

FUEL SYSTEM - Troubleshooting13-29

ENGINE

CONTROL

RELAYF

1 7=2

c----IIIIIIII2,(2Io FUEL

) SE

PRESSURE

SOLENOID

VALVE

IfII

I

I

I

I

J

]i#&B,D i

A-20

1

WASTE

GATE

SOLENOIDVALVE

/

7 EGRi ~XE~~OID

I

; A-21

L

1 A-70

j A-72

f ENGINEj jXICI$ROL

I

-------13s

3.------

s

10

/\1

>

J

c

”-_-

1 A-18

3P

~;~E&DIAGNOSIS #Fjhl;;ON

CONNECTORADJUSTMENT

EFfq&@gCONNECTOR

d

Efpggggg]

I B-OS

ENGINE

COOLANT

Q&;EEATURE ,,'I/\FOR AIR)/@ICONDITIONEROFF --xOlJ

POWER STEERING;tK;BESSURETSB Revision

Page 137 of 1146

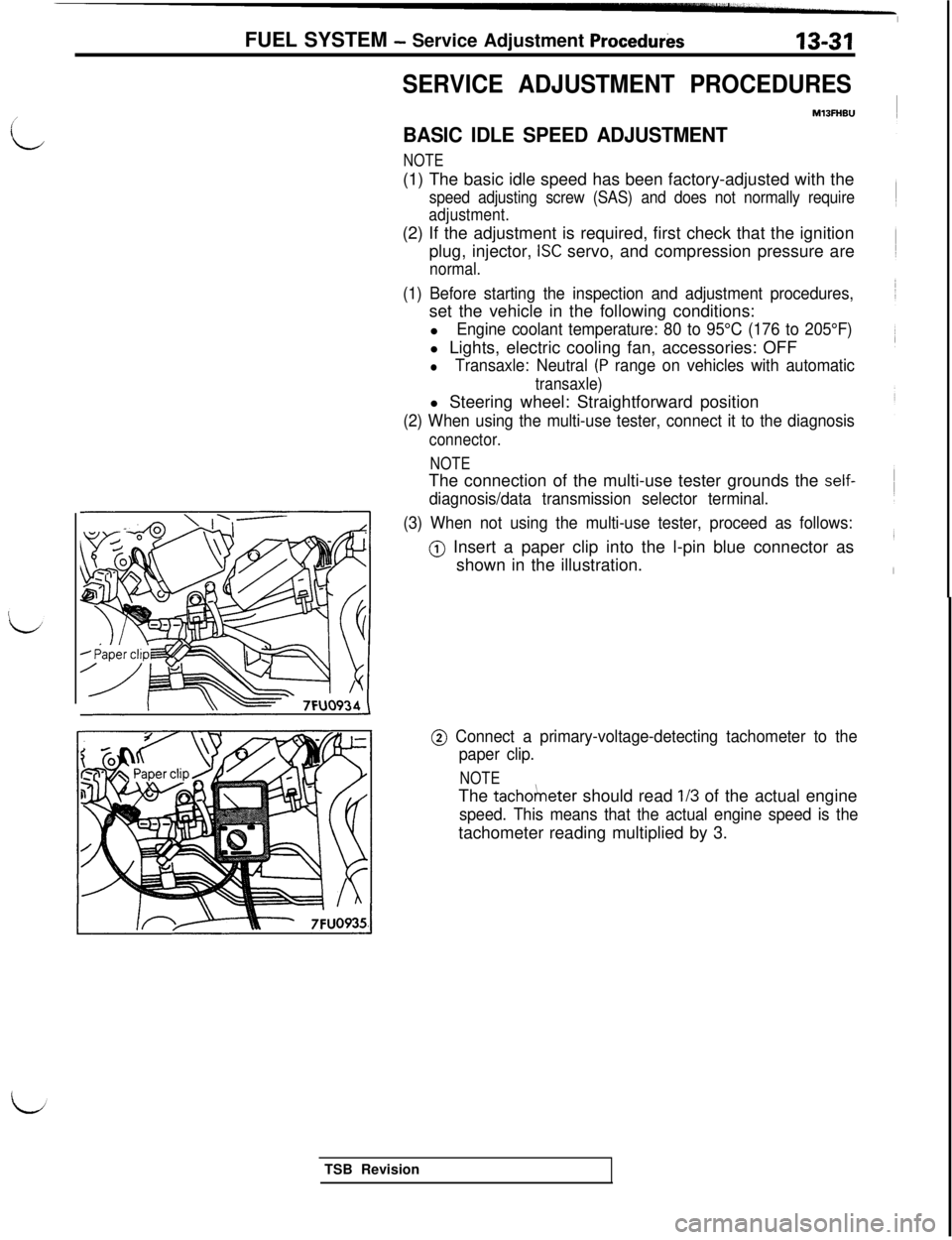

SERVICE ADJUSTMENT PROCEDURES

MlBFHSU

BASIC IDLE SPEED ADJUSTMENT

NOTE(1) The basic idle speed has been factory-adjusted with the

speed adjusting screw (SAS) and does not normally require

adjustment.(2) If the adjustment is required, first check that the ignition

plug, injector,

ISC servo, and compression pressure are

normal.

(1) Before starting the inspection and adjustment procedures,set the vehicle in the following conditions:

l

Engine coolant temperature: 80 to 95°C (176 to 205°F)l Lights, electric cooling fan, accessories: OFF

lTransaxle: Neutral (P range on vehicles with automatic

transaxle)l Steering wheel: Straightforward position

(2) When using the multi-use tester, connect it to the diagnosis

connector.

NOTEThe connection of the multi-use tester grounds the

self-

diagnosis/data transmission selector terminal.

(3) When not using the multi-use tester, proceed as follows:

@) Insert a paper clip into the l-pin blue connector as

shown in the illustration. FUEL SYSTEM

- Service Adjustment Procedurks13-31

i

@ Connect a primary-voltage-detecting tachometer to the

paper clip.

NOTEThe

tacho/neter should read l/3 of the actual engine

speed. This means that the actual engine speed is thetachometer reading multiplied by 3.

TSB Revision

Page 139 of 1146

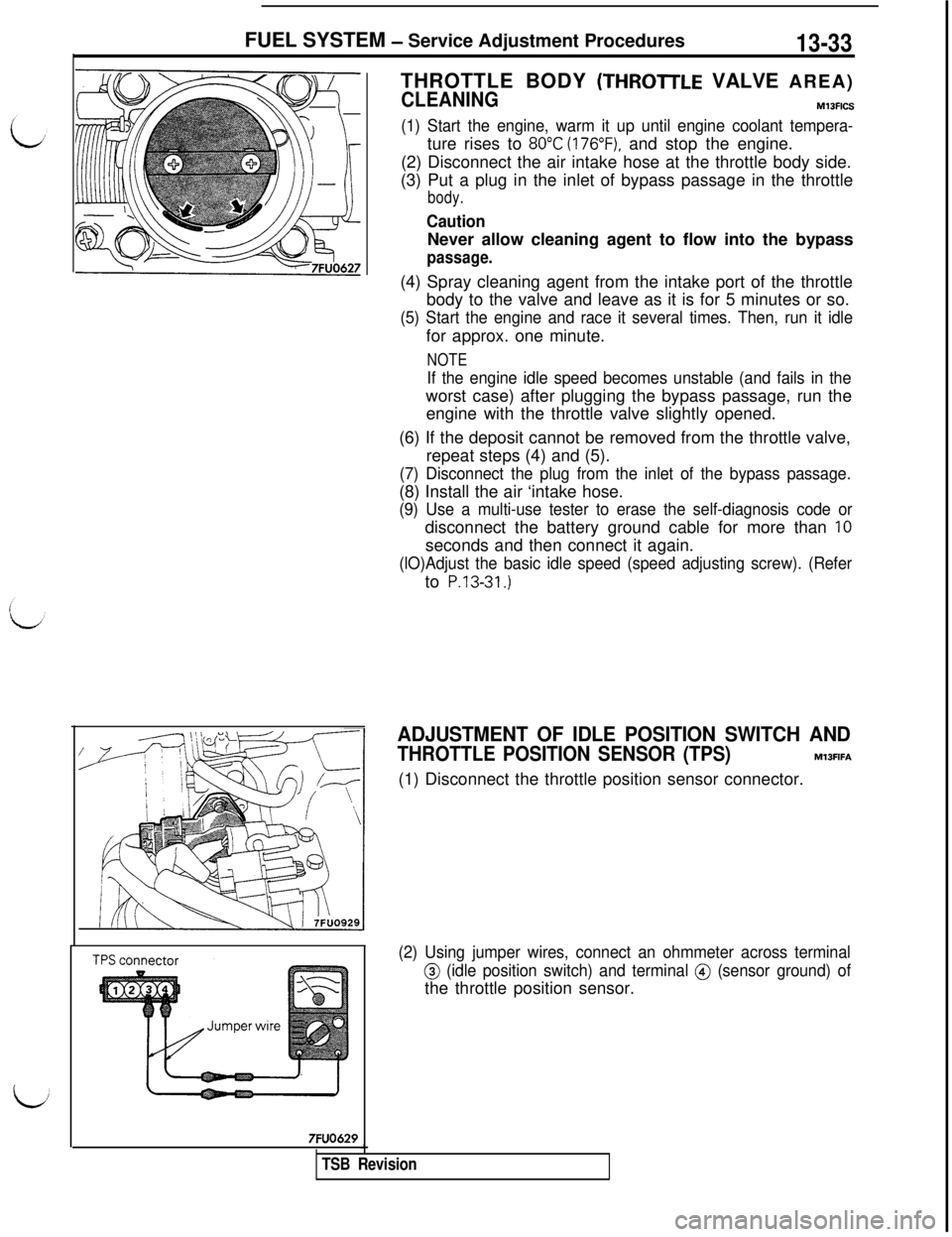

FUEL SYSTEM - Service Adjustment Procedures13-33THROTTLE BODY

(THROTrLE VALVE AREA)

CLEANINGM13FICS

(1) Start the engine, warm it up until engine coolant tempera-ture rises to

80°C (176”F), and stop the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Put a plug in the inlet of bypass passage in the throttle

body.

CautionNever allow cleaning agent to flow into the bypass

passage.(4) Spray cleaning agent from the intake port of the throttle

body to the valve and leave as it is for 5 minutes or so.

(5) Start the engine and race it several times. Then, run it idlefor approx. one minute.

NOTE

If the engine idle speed becomes unstable (and fails in theworst case) after plugging the bypass passage, run the

engine with the throttle valve slightly opened.

(6) If the deposit cannot be removed from the throttle valve,

repeat steps (4) and (5).

(7) Disconnect the plug from the inlet of the bypass passage.(8) Install the air ‘intake hose.

(9) Use a multi-use tester to erase the self-diagnosis code ordisconnect the battery ground cable for more than

IOseconds and then connect it again.

(lO)Adjust the basic idle speed (speed adjusting screw). (Referto

P.13-31.)

7FUO629

ADJUSTMENT OF IDLE POSITION SWITCH AND

THROTTLE POSITION SENSOR (TPS)M13FIFA(1) Disconnect the throttle position sensor connector.

(2) Using jumper wires, connect an ohmmeter across terminal

@ (idle position switch) and terminal @ (sensor ground) ofthe throttle position sensor.

TSB Revision

Page 142 of 1146

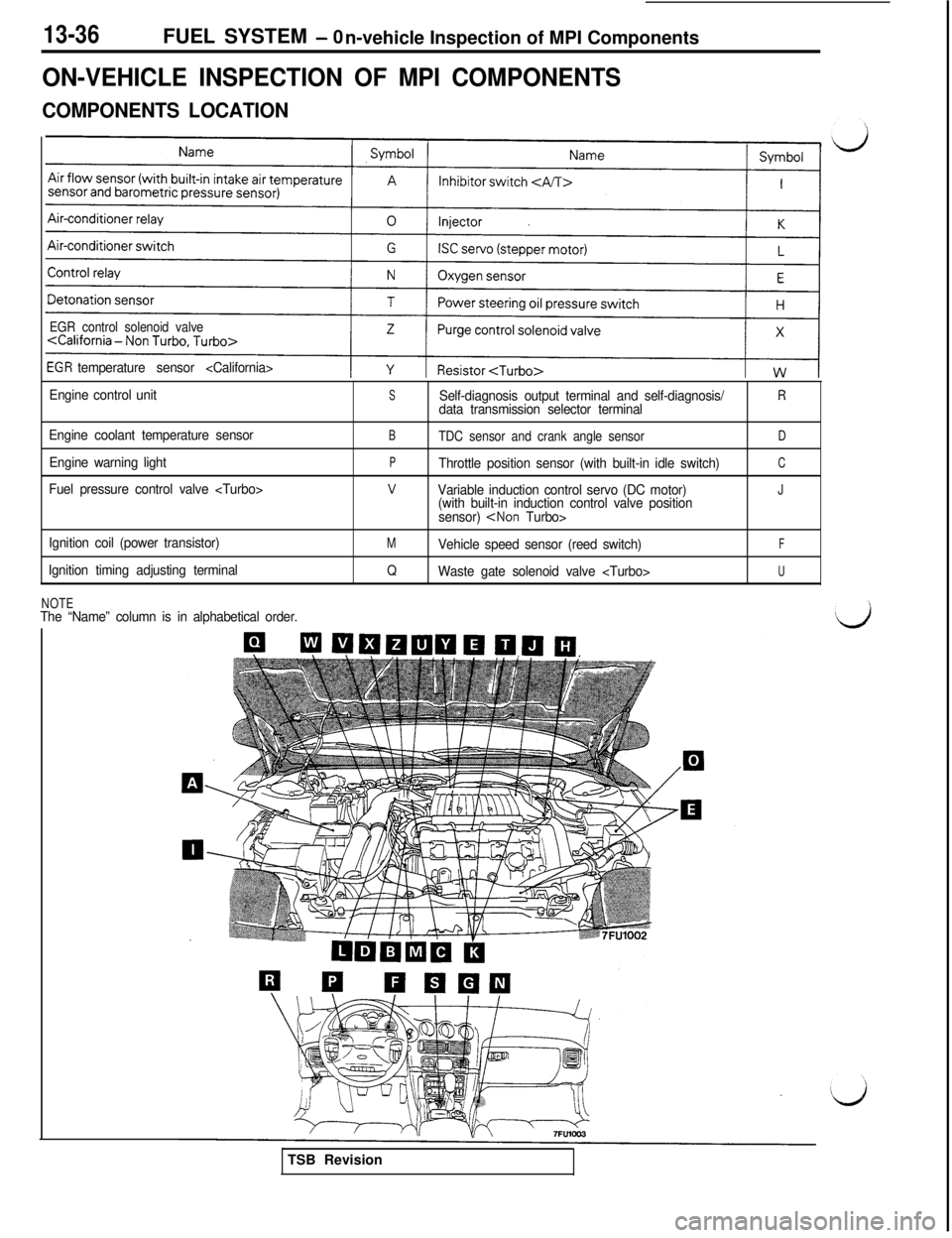

13-36FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

ON-VEHICLE INSPECTION OF MPI COMPONENTS

COMPONENTS LOCATION

EGR control solenoid valve

temperature sensor

Engine control unit

Engine coolant temperature sensor

Engine warning light

Fuel pressure control valve

Ignition coil (power transistor)

Ignition timing adjusting terminal

SSelf-diagnosis output terminal and self-diagnosis/Rdata transmission selector terminal

BTDC sensor and crank angle sensorD

PThrottle position sensor (with built-in idle switch)C

vVariable induction control servo (DC motor)J(with built-in induction control valve position

sensor)

MVehicle speed sensor (reed switch)F

QWaste gate solenoid valve

NOTEThe “Name” column is in alphabetical order.TSB Revision

Page 161 of 1146

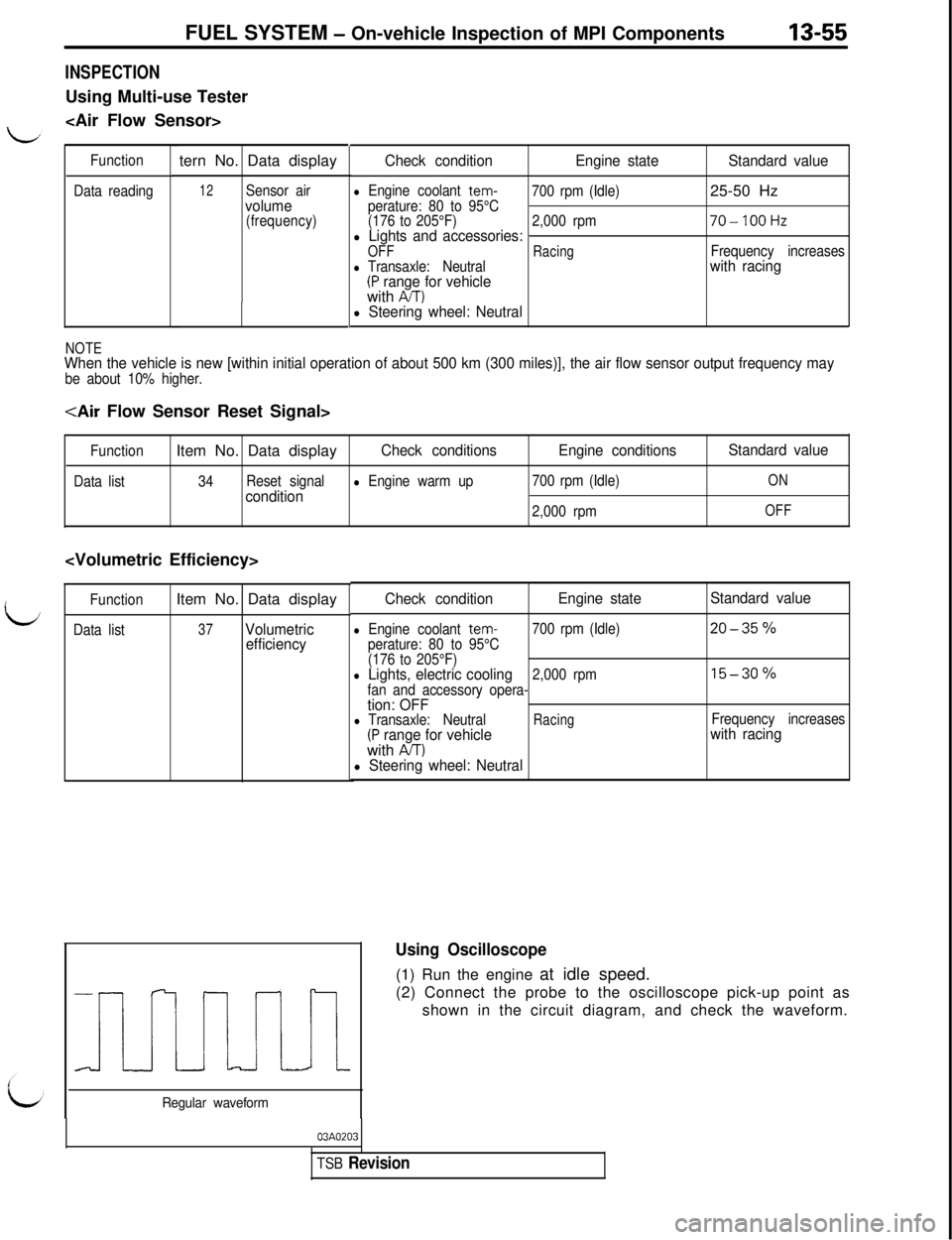

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-55

INSPECTIONUsing Multi-use Tester

Function

Data readingtern No. Data display

12Sensor airvolume(frequency)

Check conditionEngine stateStandard value

l Engine coolant tem-

700 rpm (Idle)25-50 Hzperature: 80 to 95°C

(176 to 205°F)2,000 rpm70-IOOHzl Lights and accessories:OFFRacingFrequency increasesl Transaxle: Neutralwith racing(P range for vehiclewith AIT)l Steering wheel: Neutral

NOTEWhen the vehicle is new [within initial operation of about 500 km (300 miles)], the air flow sensor output frequency maybe about 10% higher.

Function

Data listItem No. Data displayCheck conditionsEngine conditionsStandard value

34Reset signall Engine warm up700 rpm (Idle)ON

condition2,000 rpmOFF

L;

FunctionItem No. Data display

Data list37Volumetric

efficiencyCheck conditionEngine stateStandard valuel Engine coolant tem-700 rpm (Idle)20-35%

perature: 80 to 95°C

(176 to 205°F)

l Lights, electric cooling2,000 rpm15-30%

fan and accessory opera-tion: OFFl Transaxle: NeutralRacingFrequency increases

(P range for vehiclewith racingwith &T)

l Steering wheel: Neutral

Using Oscilloscope(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

Regular waveform

03A0203

TSB Revision

Page 168 of 1146

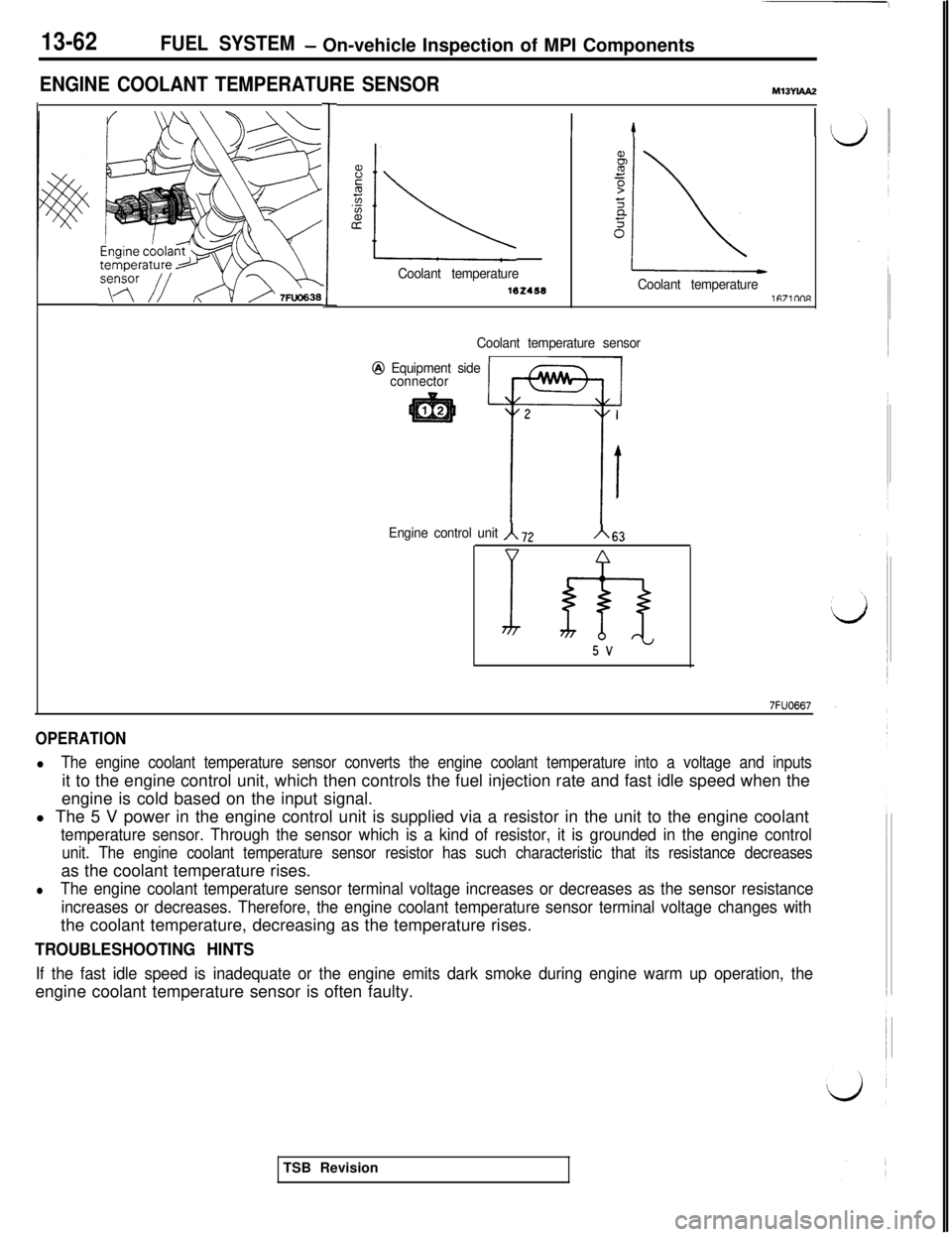

13-62FUEL SYSTEM- On-vehicle Inspection of MPI Components

ENGINE COOLANT TEMPERATURE SENSORM13Ybu2

1

If

il\__ ;I\*

Coolant temperature

162458Coolant temperaturei67im-m

Coolant temperature sensor

@ Equipment side

connector

2

fi

I

Engine control unit ), 72A63

1 ff35V

7FUO667

OPERATION

lThe engine coolant temperature sensor converts the engine coolant temperature into a voltage and inputsit to the engine control unit, which then controls the fuel injection rate and fast idle speed when the

engine is cold based on the input signal.

l The 5 V power in the engine control unit is supplied via a resistor in the unit to the engine coolant

temperature sensor. Through the sensor which is a kind of resistor, it is grounded in the engine control

unit. The engine coolant temperature sensor resistor has such characteristic that its resistance decreasesas the coolant temperature rises.

lThe engine coolant temperature sensor terminal voltage increases or decreases as the sensor resistance

increases or decreases. Therefore, the engine coolant temperature sensor terminal voltage changes withthe coolant temperature, decreasing as the temperature rises.

TROUBLESHOOTING HINTS

If the fast idle speed is inadequate or the engine emits dark smoke during engine warm up operation, theengine coolant temperature sensor is often faulty.

TSB Revision

Page 169 of 1146

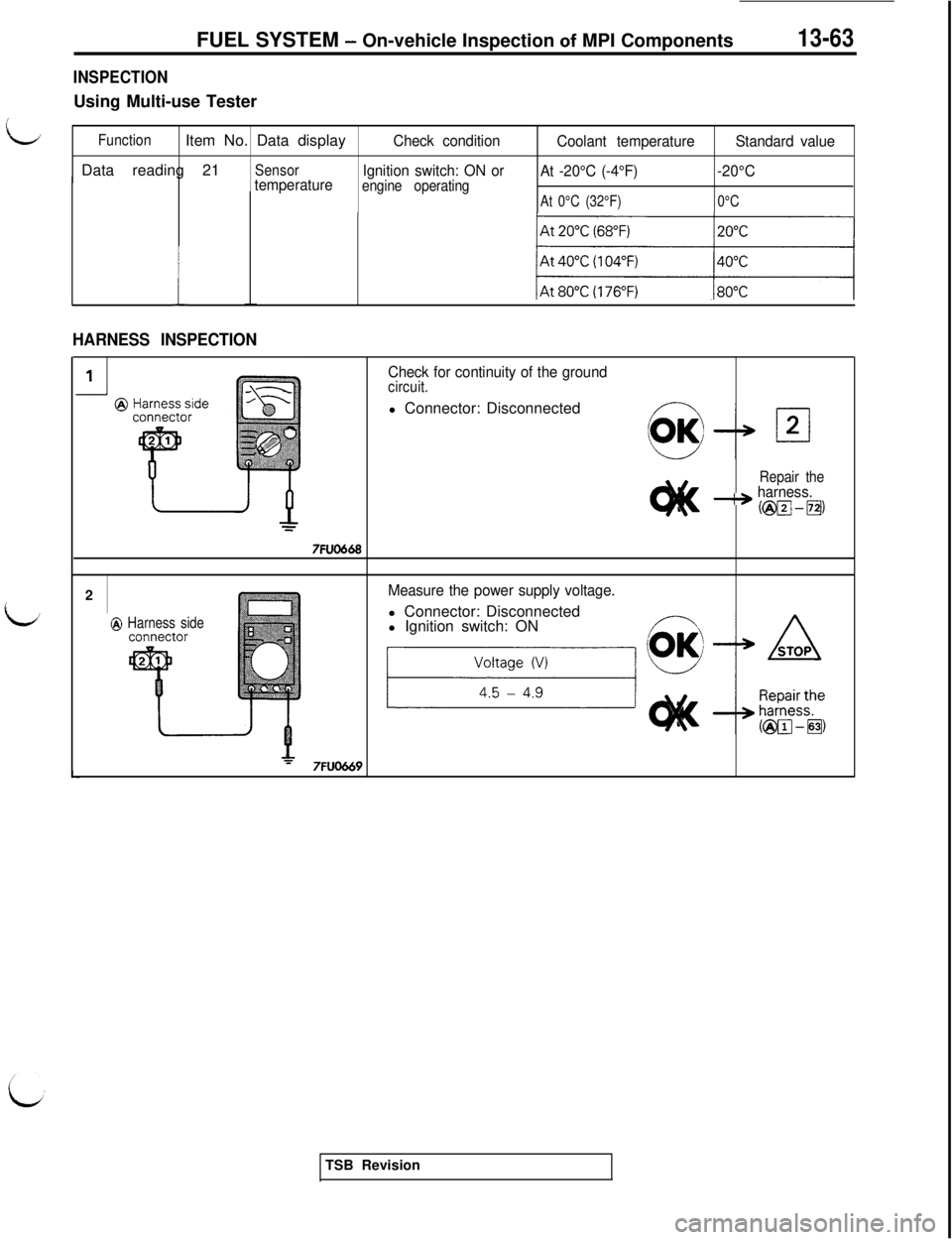

id

LFUEL SYSTEM

- On-vehicle Inspection of MPI Components13-63

INSPECTIONUsing Multi-use Tester

LFunctionItem No. Data displayCheck condition

Coolant temperatureStandard valueData reading 21

SensorIgnition switch: ON or

At -20°C (-4°F)-20°C

temperatureengine operatingAt 0°C (32°F)0°C

HARNESS INSPECTION

Check for continuity of the groundcircuit.l Connector: Disconnected

Repair the---+ harness.

7FUO6682

Measure the power supply voltage.l Connector: Disconnected

@ Harness sidel Ignition switch: ON

7FUO669TSB Revision

Page 170 of 1146

13-64FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

7FUO670

Apply sealant

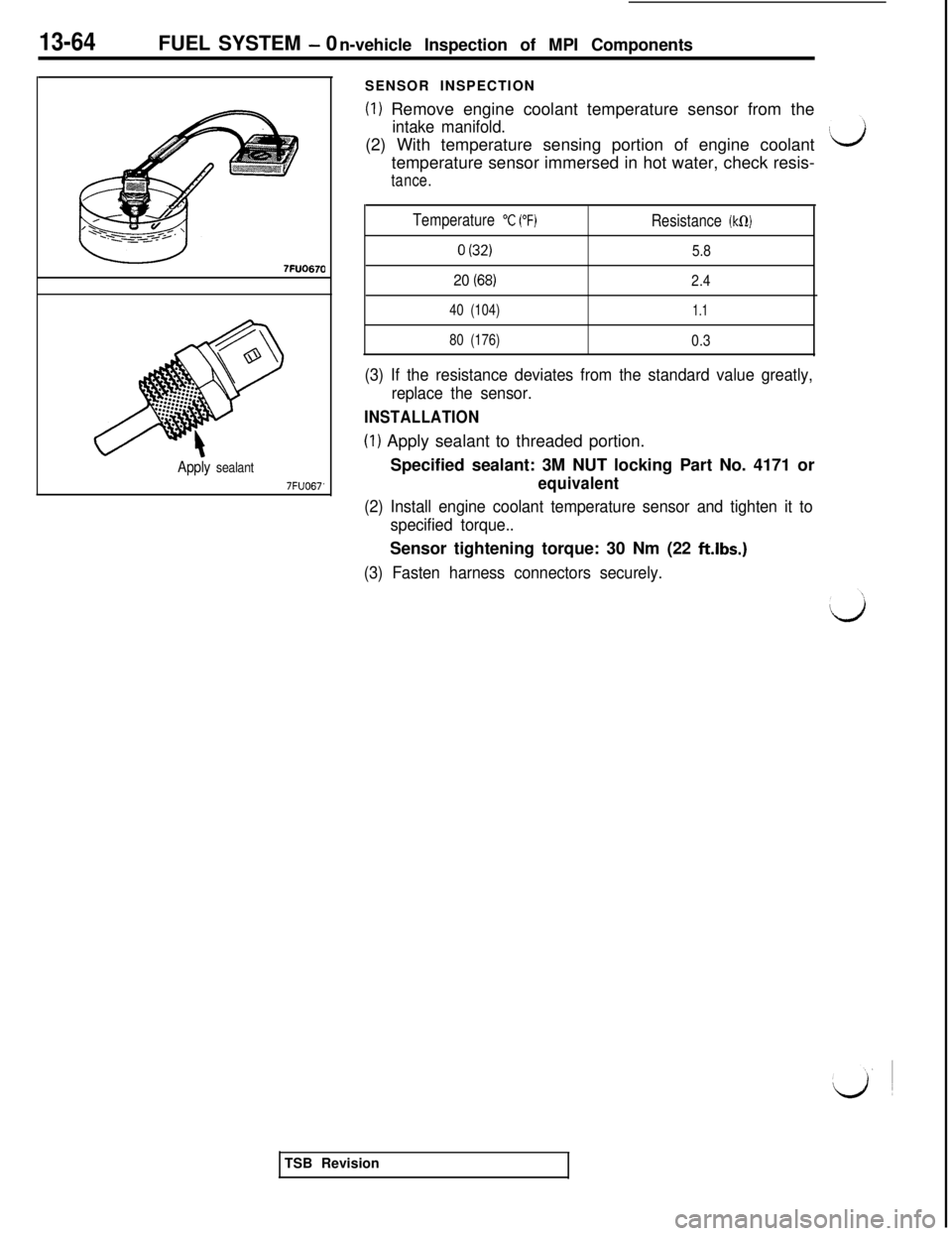

7FUO67’SENSOR INSPECTION

(1) Remove engine coolant temperature sensor from the

intake manifold.(2) With temperature sensing portion of engine coolant

temperature sensor immersed in hot water, check resis-

tance.

Temperature

“C (“F)Resistance (kCI)

0 (32)5.8

20 (68)2.4

40 (104)1.1

80 (176)0.3

(3) If the resistance deviates from the standard value greatly,

replace the sensor.

INSTALLATION

(1) Apply sealant to threaded portion.

Specified sealant: 3M NUT locking Part No. 4171 or

equivalent

(2) Install engine coolant temperature sensor and tighten it to

specified torque..Sensor tightening torque: 30 Nm (22

ft.lbs.)

(3) Fasten harness connectors securely.TSB Revision