ignition MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 4 of 1146

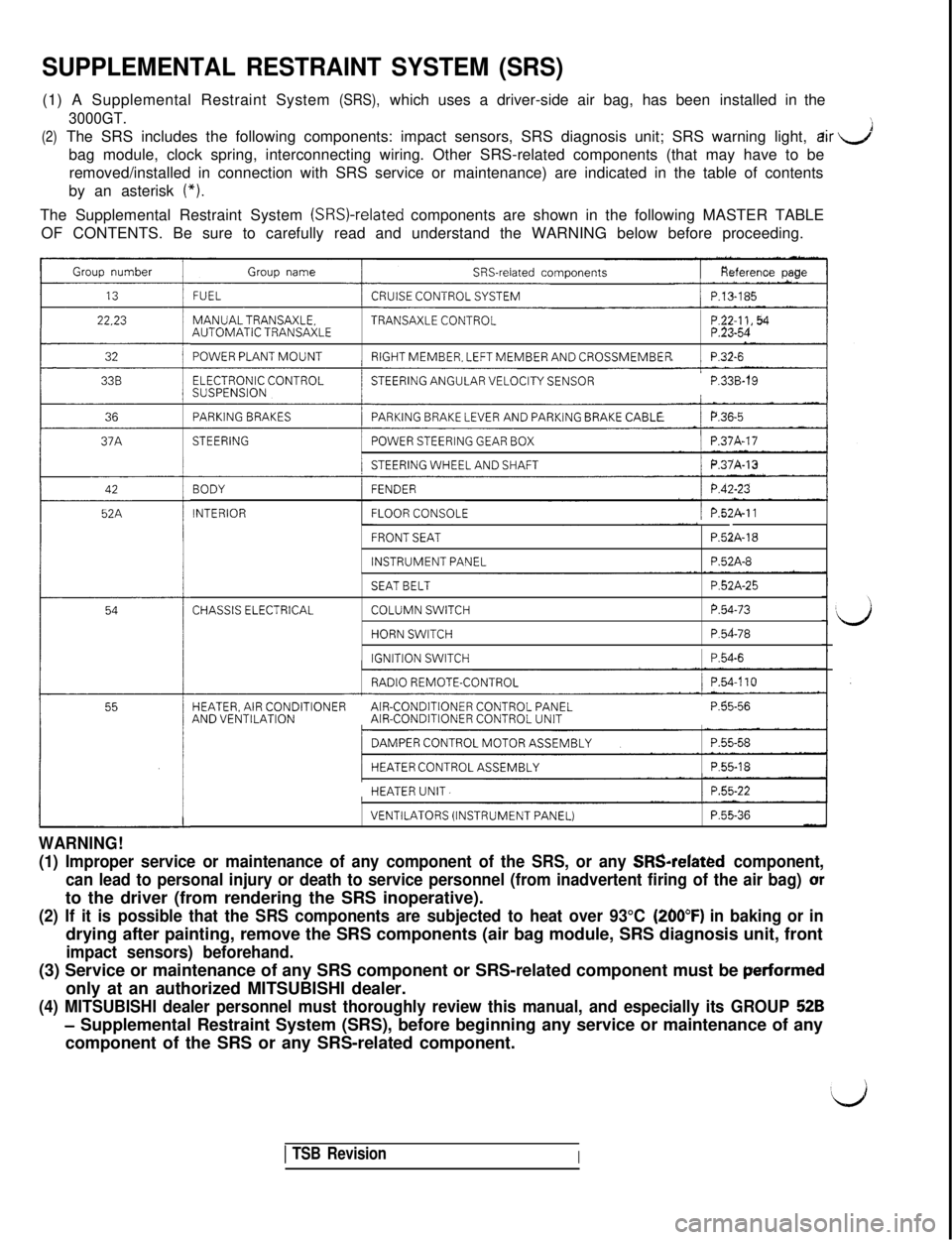

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

dir J

bag module, clock spring, interconnecting wiring. Other SRS-related comp\

onents (that may have to be

(*).

The Supplemental Restraint System (SRSI-related components are shown in the following MASTER TABLE

OF CONTENTS. Be sure to carefully read and understand the WARNING below \

before proceeding.

Group number

22.23

32

36

42

52A

Group nameSRS-related components

FUELCRUISE CONTROL SYSTEM/ P.13-185

MANUALTRANSAXLE.TRANSAXLE CONTROLAUTOMATIC TRANSAXLE

POWER PLANT MOUNTRIGHT MEMBER, LEFT MEMBER AND CROSSMEMBERP.32-6

ELECTRONIC CONTROLSUSPENSION’STEERING ANGULAR VELOCITY SENSORP.33B-19

PARKING BRAKESPARKING BRAKE LEVER AND PARKiNG BRAKE CABLE/ P.36~5I

STEERING/POWER STEERING GEAR BOX/ P.37A-17

/STEERING WHEEL AND SHAFTj P.37A-13

BODY

INTERIOR

FENDER

FLOOR CONSOLE/ P.52A-11

FRONT SEAT

INSTRUMENT PANEL

P52A-18

P.52A-8

CHASSIS ELECTRICAL

SEAT BELT

COLUMN SWITCH

HORN SWITCH

IGNITION SWITCH

P.52A-25

P.54-73

P.54-78

1 P.54-6

RADIO REMOTE-CONTROL/ P.54.110

HEATER, AIR CONDITIONERAIR-CONDITIONER CONTROL PANELAND VENTILATIONAIR-CONDITIONER CONTROL UNITP.55-56

/DAMPER CONTROL MOTOR ASSEMBLYI

/HEATER CONTROL ASSEMBLY1 P.55-18I

HEATER UNIT.1 P.55-22

WARNING!

VENTILATORS (INSTRUMENT PANEL)P.55-36

(1) Improper service or maintenance of any component of the SRS, or an\

y SRSrelated component,

can lead to personal injury or death to service personnel (from inadver\

tent firing of the air bag) or

to the driver (from rendering the SRS inoperative).

(260°F) in baking or in

drying after painting, remove the SRS components (air bag module, SRS d\

iagnosis unit, front

perfarmed

only at an authorized MITSUBISHI dealer.

52B

- Supplemental Restraint System (SRS), before beginning any service or m\

aintenance of any

component of the SRS or any SRS-related component.

1 TSB RevisionI

Page 19 of 1146

GENERAL - Precautions before Service0045

c

mm (in.)so005

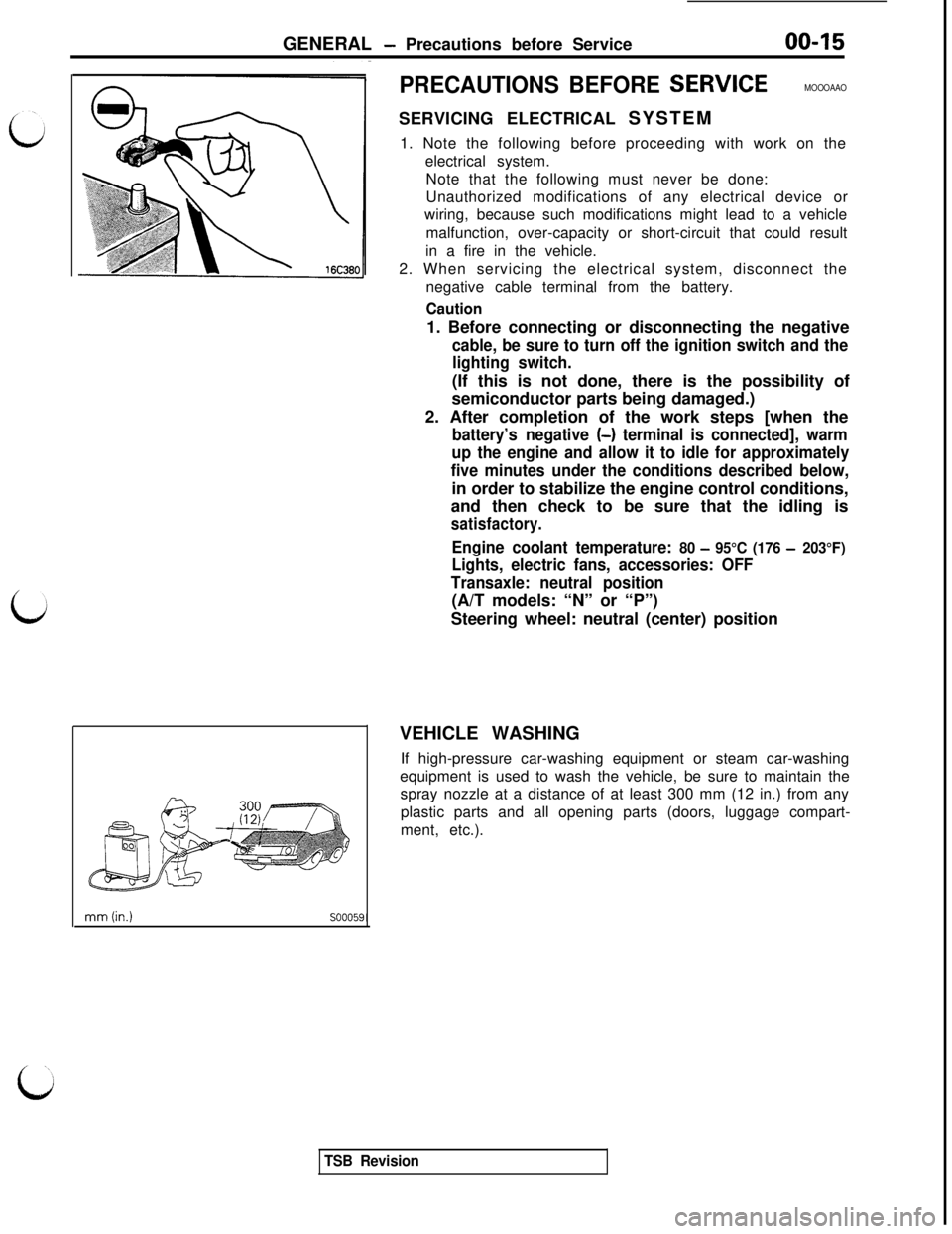

PRECAUTIONS BEFORE SERWCEMOOOAAOSERVICING ELECTRICAL SYSTEM

1. Note the following before proceeding with work on the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result

in a fire in the vehicle.

2. When servicing the electrical system, disconnect the

negative cable terminal from the battery.

Caution1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and the

lighting switch.(If this is not done, there is the possibility of

semiconductor parts being damaged.)

2. After completion of the work steps [when the

battery’s negative (-) terminal is connected], warm

up the engine and allow it to idle for approximately

five minutes under the conditions described below,in order to stabilize the engine control conditions,

and then check to be sure that the idling is

satisfactory.

Engine coolant temperature: 80 - 95°C (176 - 203°F)

Lights, electric fans, accessories: OFF

Transaxle: neutral position(A/T models: “N” or “P”)

Steering wheel: neutral (center) position

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (12 in.) from any

plastic parts and all opening parts (doors, luggage compart-

ment, etc.).

c

TSB Revision

Page 28 of 1146

00-24GENERAL - Master Troubleshooting

MASTER TROUBLESHOOTING

MOOWWENGINE OVERHEATS

Symptom

Engine overheatsProbable cause

Cooling system

faulty

, incorrect ignition timing

Reference page

14-3

11-13

v’.ENGINE WILL NOT CRANK OR CRANKS SLOWLY

Symptom

Engine will not crankor cranks slowly

Probable cause

Starting system faulty

Reference page

16-15ENGINE WILL NOT START OR HARD TO START (CRANKS OK)

1 Symptom

Engine will not start or hard to

start (Cranks OK)Probable causeNo fuel supply to injector

injection system problems

Ignition system problems

Vacuum leaksl Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

Reference page

-

-

16-25

17-3

Compression too low

11-15

d

1 TSB Revision1

Page 29 of 1146

GENERAL - Master Troubleshooting

ROUGH IDLE OR ENGINE STALLS

LProbable causeReference page or remedy

Symptom

Rough idle or engine stallsVacuum leaks

l Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

Ignition system problems16-25

Idle speed set too lowCheck idle speed controlsystem

Idle mixture too lean or too rich-

Fuel injection system problems-

Exhaust gas recirculation (EGR) systemproblems17-11

Engine overheats

114-3

Compression too lowIll-15

ENGINE HESITATES OR POOR ACCELERATION

L

Reference pageSymptomProbable cause

Ignition system problem

Vacuum leaksl Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low11-13

Engine hesitates or poor

acceleration

17-3

15-9

-

17-11

14-3

TSB Revision

Page 30 of 1146

00-26GENERAL - Master Troubleshooting

ENGINE DIESELING

Symptom

Engine dieseling (runs afterignition switch is turned off)

Probable cause

Incorrect ignition timing

Reference page

11-13EXCESSIVE OIL CONSUMPTION

ISymptomProbable cause( Reference page or remedy(

Excessive oil consumptionOil leakRepair as necessary

Positive crankcase ventilation line clogged

Valve stem seal worn or damaged

17-5

11-34

I----Valve stem worn11-34I

IPiston ring worn or damaged11-44IPOOR FUEL MILEAGE

NOISE

SymptomProbable causeReference page or remedy

NoiseLoose bolts and nutsRetighten as necessary

Engine noise

il-10

) TSB Revision

Page 51 of 1146

11-I

ENGINECONTENTS

IMllAA--

CAMSHAFT OIL SEALS....................................

CRANKSHAFT, FLYWHEEL AND

DRIVEPLATE........................................................

CYLINDER BLOCK................................................

CYLINDER HEAD AND VALVE........................

CYLINDER HEAD GASKET................................

ENGINE ASSEMBLY............................................

ENGINE OIL COOLER........................................

GENERAL INFORMATION................................

lbLubricationSystem............................................SectionalView

....................................................

OIL PAN AND OIL PUMP....................................

OIL PAN AND OIL SCREEN................................20

49

5334

23

17

552

3

240

22

PISTON AND CONNECTING ROD....................

ROCKER ARM AND CAMSHAFT....................

SERVICE ADJUSTMENT PROCEDURES........Compression Pressure Check

........................Curb Idle Speed Inspection

............................Drive Belts Tension Adjustment

....................Ignition Timing Adjustment

............................

LashAdjusters

Check........................................Manifold Vacuum

Inspection

.............................

SPECIAL TOOLS....................................................

SPECIFICATIONS................................................General Specifications

....................................

Sealants

.......................................

.....................Service Specifications

....................................

TIMING BELT........................................................

TROUBLESHOOTING........................................44

31

11

15

14

11

13

16

16

84

4

84

26

10

Page 63 of 1146

ENGINE - Service Adiustment ProceduresII-13

I_ ianltion tlminaI!H Connector for Igdpstment 6rown)

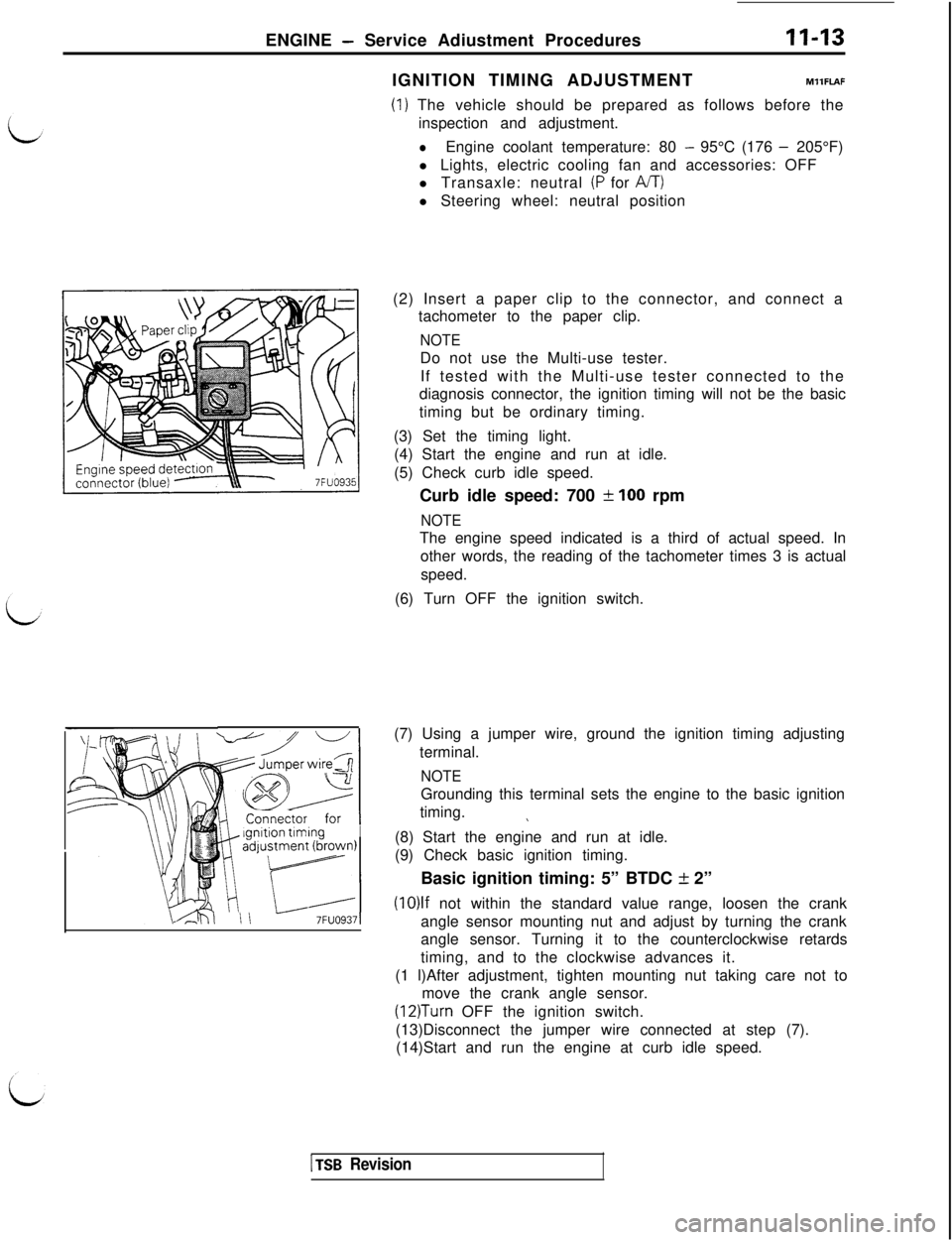

4tll II -7FUO9371IGNITION TIMING ADJUSTMENTMllFLAF

(1) The vehicle should be prepared as follows before the

inspection and adjustment.

lEngine coolant temperature: 80 - 95°C (176 - 205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: neutral

(P for A/T)l Steering wheel: neutral position

(2) Insert a paper clip to the connector, and connect a

tachometer to the paper clip.

NOTEDo not use the Multi-use tester.

If tested with the Multi-use tester connected to the

diagnosis connector, the ignition timing will not be the basic

timing but be ordinary timing.

(3) Set the timing light.

(4) Start the engine and run at idle.

(5) Check curb idle speed.

Curb idle speed: 700

f 100 rpm

NOTEThe engine speed indicated is a third of actual speed. In

other words, the reading of the tachometer times 3 is actual

speed.

(6) Turn OFF the ignition switch.

(7) Using a jumper wire, ground the ignition timing adjusting

terminal.

NOTEGrounding this terminal sets the engine to the basic ignition

timing.

\(8) Start the engine and run at idle.

(9) Check basic ignition timing.

Basic ignition timing: 5” BTDC

k 2”

(10)lf not within the standard value range, loosen the crank

angle sensor mounting nut and adjust by turning the crank

angle sensor. Turning it to the counterclockwise retards

timing, and to the clockwise advances it.

(1 l)After adjustment, tighten mounting nut taking care not to

move the crank angle sensor.

(12)Turn OFF the ignition switch.

(13)Disconnect the jumper wire connected at step (7).

(14)Start and run the engine at curb idle speed.

1 TSB Revision

Page 64 of 1146

11-14ENGINE - Service Adjustment Procedures

(15)Check to be sure that the idling ignition timing is the correct

timing.

Actual ignition timing: Approx. 15” BTDC

NOTE:d

(1) Ignition timing is variable even under normal operation.

(2) And it is automatically advanced at higher altitudes.

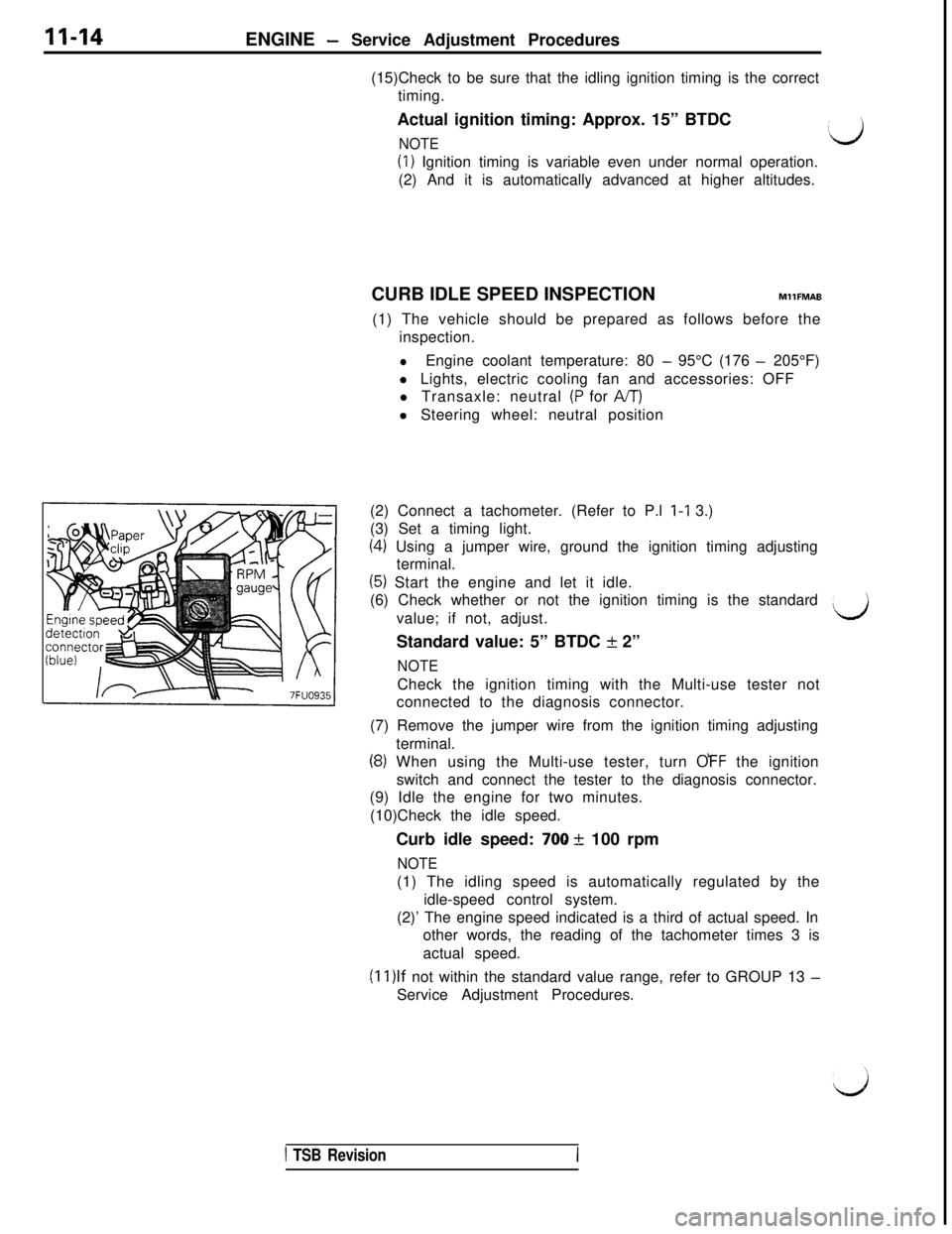

CURB IDLE SPEED INSPECTIONMllFMAB

(1) The vehicle should be prepared as follows before the

inspection.

lEngine coolant temperature: 80 - 95°C (176 - 205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: neutral

(P for A/T)l Steering wheel: neutral position

(2) Connect a tachometer. (Refer to P.l l-1 3.)

(3) Set a timing light.

(4) Using a jumper wire, ground the ignition timing adjusting

terminal.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value: 5” BTDC + 2”

NOTECheck the ignition timing with the Multi-use tester not

connected to the diagnosis connector.

(7) Remove the jumper wire from the ignition timing adjusting

terminal.

(8) When using the Multi-use tester, turn OFF the ignition

switch and connect the tester to the diagnosis connector.

(9) Idle the engine for two minutes.

(10)Check the idle speed.

Curb idle speed:

700 + 100 rpm

NOTE(1) The idling speed is automatically regulated by the

idle-speed control system.

(2)’ The engine speed indicated is a third of actual speed. In

other words, the reading of the tachometer times 3 is

actual speed.

(1l)lf not within the standard value range, refer to GROUP 13 -Service Adjustment Procedures.

d

1 TSB RevisionI

Page 68 of 1146

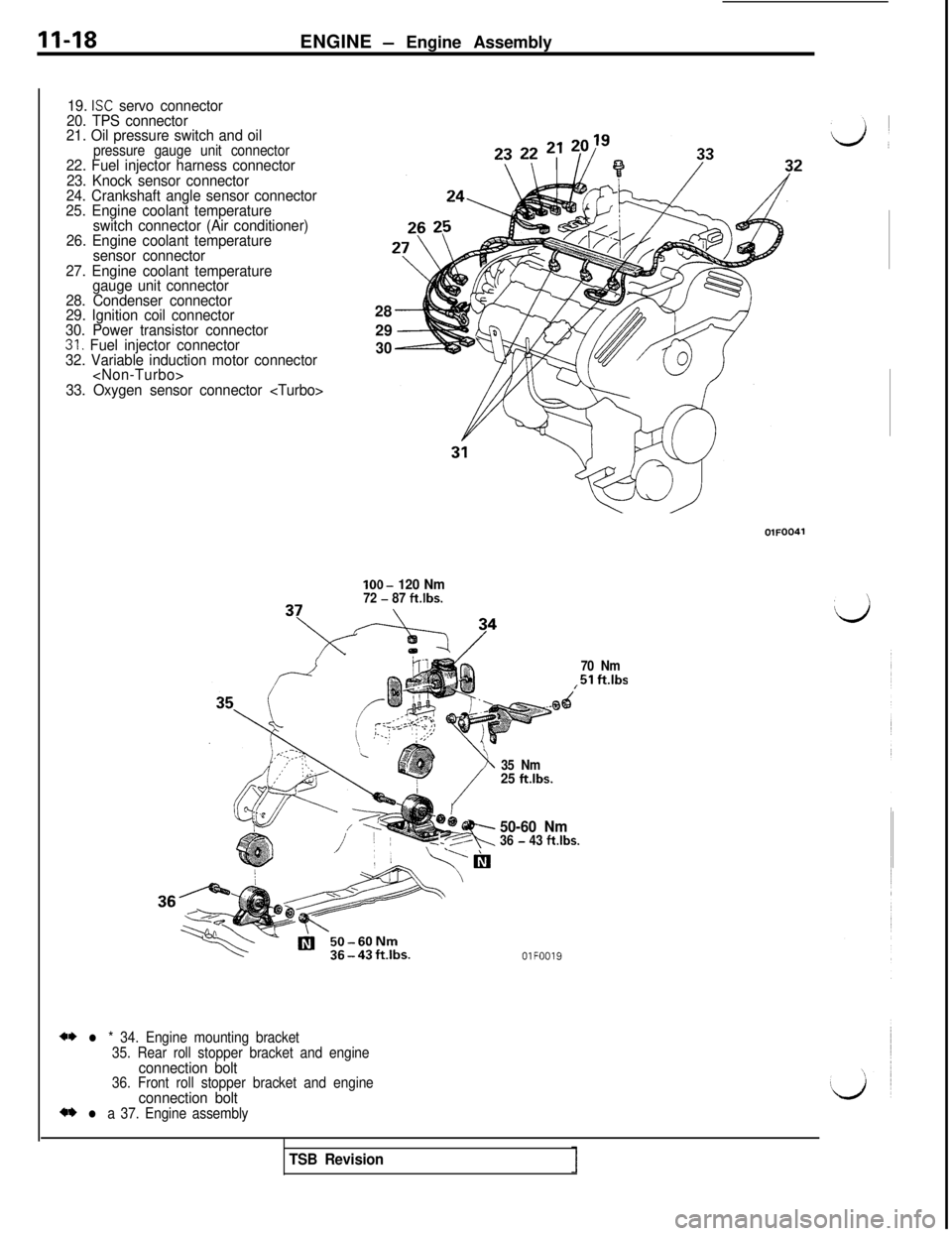

II-18ENGINE - Engine Assembly

19. ISC servo connector

20. TPS connector

21. Oil pressure switch and oil

pressure gauge unit connector22. Fuel injector harness connector

23. Knock sensor connector

24. Crankshaft angle sensor connector

25. Engine coolant temperature

switch connector (Air conditioner)

26. Engine coolant temperature

sensor connector

27. Engine coolant temperature

gauge unit connector

28. Condenser connector

29. Ignition coil connector

30. Power transistor connector

31. Fuel injector connector

32. Variable induction motor connector

33. Oxygen sensor connector

2930lOO-

120 Nm72 - 87 ft.lbs.

70 Nm

,51 ftlbs

** l * 34. Engine mounting bracket

35. Rear roll stopper bracket and engine

connection bolt36. Front roll stopper bracket and engineconnection bolt** l a 37. Engine assembly35 Nm

25 ft.lbs.

?I,---R

50-60 Nm36 - 43 ftlbs.

OlFOO19

TSB Revision

Page 73 of 1146

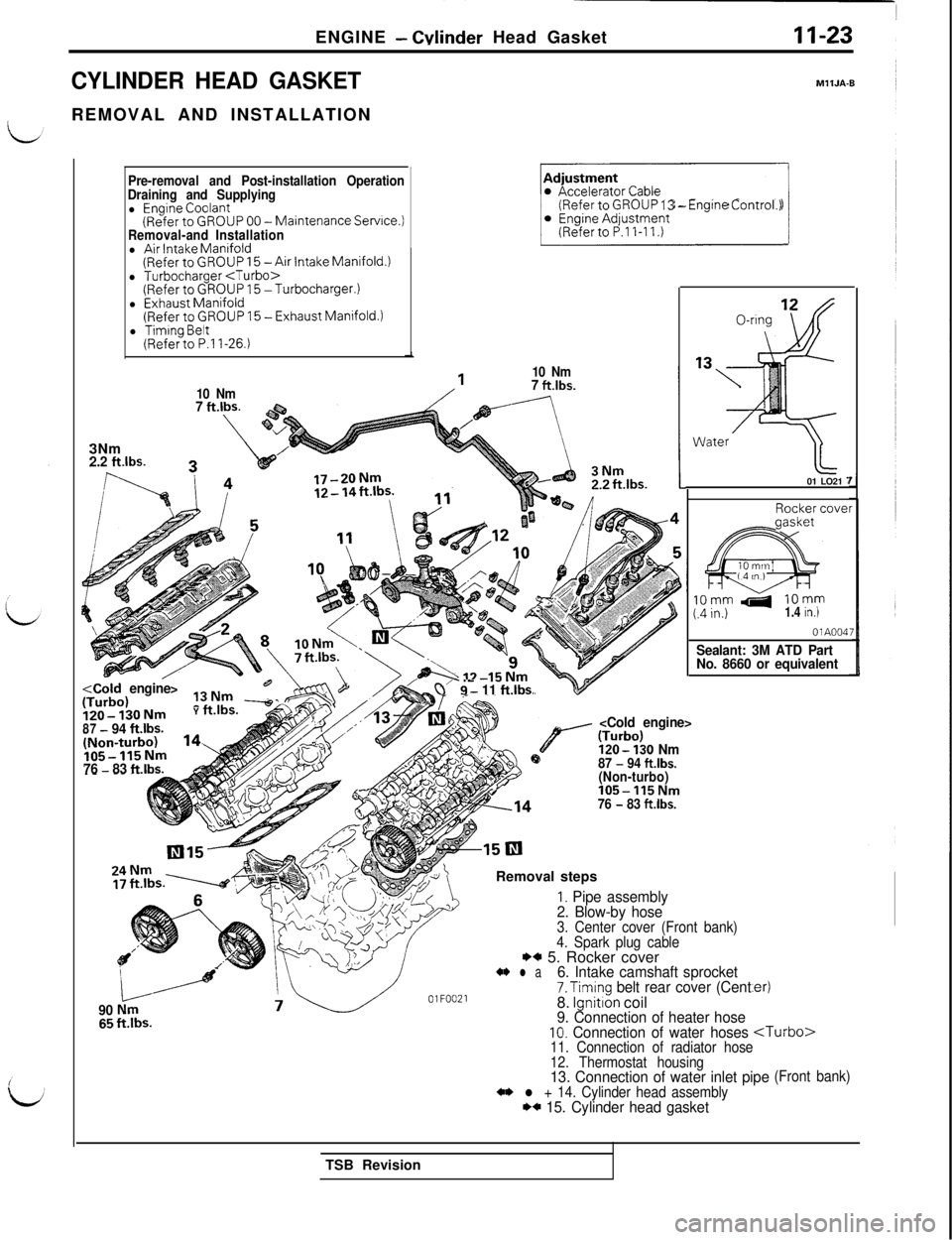

ENGINE - Winder Head Gasket11-23

CYLINDER HEAD GASKETREMOVAL AND INSTALLATION

MllJA-6

Pre-removal and Post-installation Operation

Draining and Supplying

l Engine Coolant(Refer to GROUP 00 -Maintenance Service.)Removal-and Installationl Air Intake Manifold(Refer to GROUP 15 -Air intake Manifold.)l Turbocharger

10 Nm3Nm

2.2 klbs.P

~~(Refer to GROUP 13 - Engrne Control.)

10 Nm7 ft.lbs.

7 ft.lbs.\

120-nng

‘3, ;

%

;;

Water01 LO21

7

i2o-IjONmY rt.lDS.

87

- 94 ft.lbs.

76 - 83 ft.lbs.d

I. Pipe assembly

2. Blow-by hose

90

Nm3. Center cover (Front bank)

4. Spark plug cable

HI 5. Rocker cover4* l a

I

6. Intake camshaft sprocket7. Timing belt rear cover (Cent

7.----A//OlFOO218. Ignition coil9. Connection of heater hose10. Connection of water hoses

Rocker coverIOmm

410mm(.4 in.)1.4 in.)

OlA004;

Sealant: 3M ATD Part

No. 8660 or equivalent

.er)

tl-urbo>11. Connection of radiator hose

12. Thermostat housing

13. Connection of water inlet pipe** l + 14. Cylinder head assembly** 15. Cylinder head gasket

(Front bank)TSB Revision