jump start MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 63 of 1146

ENGINE - Service Adiustment ProceduresII-13

I_ ianltion tlminaI!H Connector for Igdpstment 6rown)

4tll II -7FUO9371IGNITION TIMING ADJUSTMENTMllFLAF

(1) The vehicle should be prepared as follows before the

inspection and adjustment.

lEngine coolant temperature: 80 - 95°C (176 - 205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: neutral

(P for A/T)l Steering wheel: neutral position

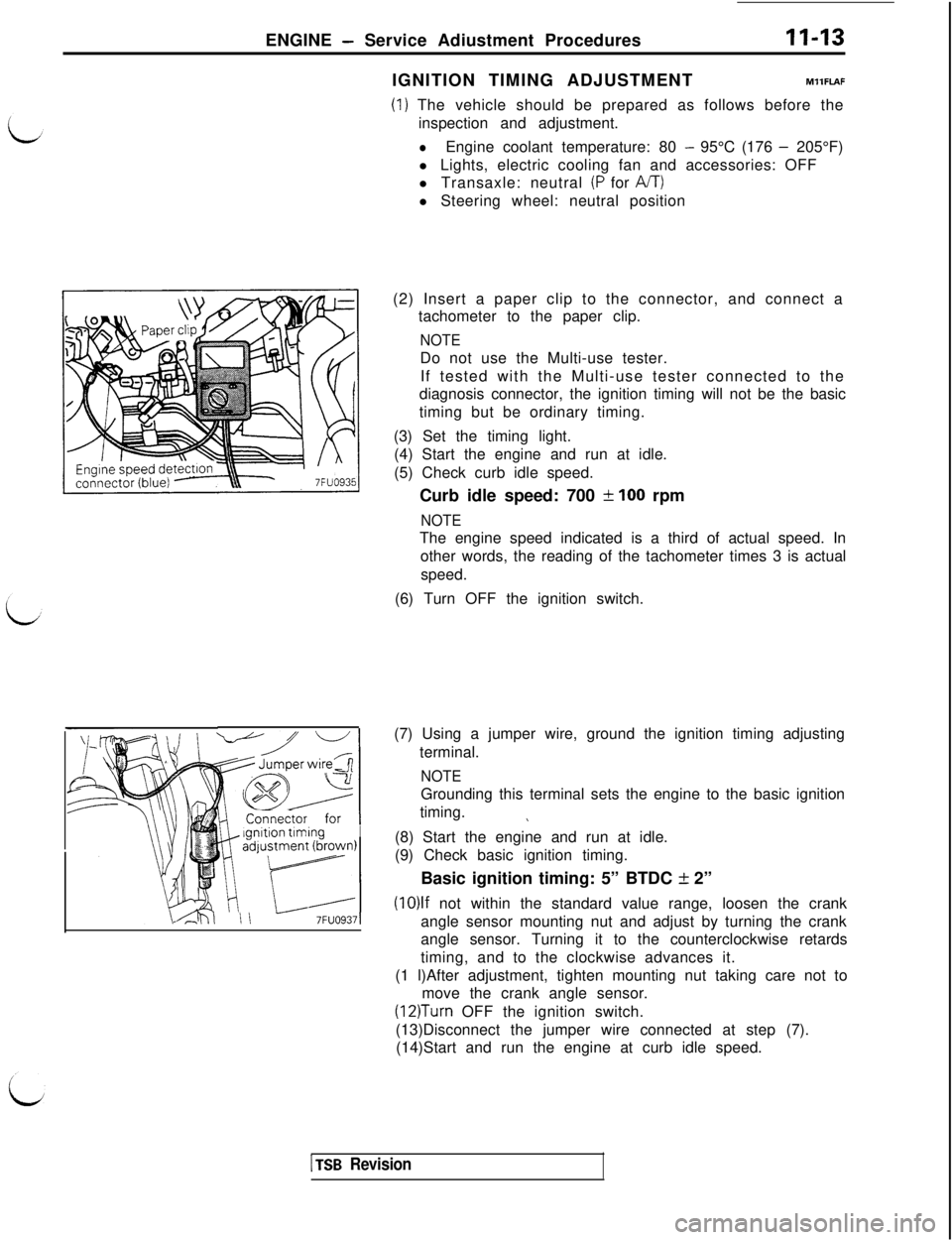

(2) Insert a paper clip to the connector, and connect a

tachometer to the paper clip.

NOTEDo not use the Multi-use tester.

If tested with the Multi-use tester connected to the

diagnosis connector, the ignition timing will not be the basic

timing but be ordinary timing.

(3) Set the timing light.

(4) Start the engine and run at idle.

(5) Check curb idle speed.

Curb idle speed: 700

f 100 rpm

NOTEThe engine speed indicated is a third of actual speed. In

other words, the reading of the tachometer times 3 is actual

speed.

(6) Turn OFF the ignition switch.

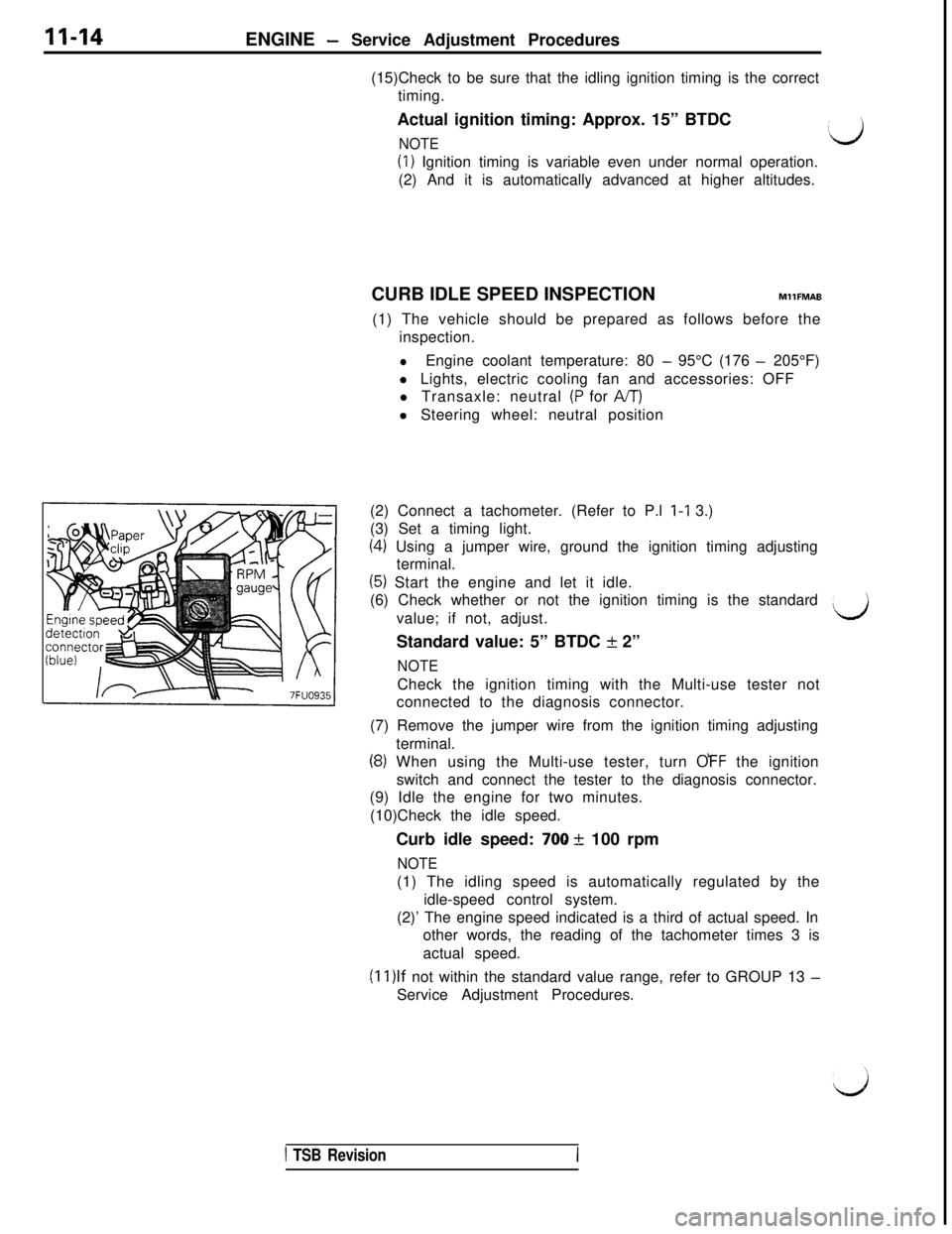

(7) Using a jumper wire, ground the ignition timing adjusting

terminal.

NOTEGrounding this terminal sets the engine to the basic ignition

timing.

\(8) Start the engine and run at idle.

(9) Check basic ignition timing.

Basic ignition timing: 5” BTDC

k 2”

(10)lf not within the standard value range, loosen the crank

angle sensor mounting nut and adjust by turning the crank

angle sensor. Turning it to the counterclockwise retards

timing, and to the clockwise advances it.

(1 l)After adjustment, tighten mounting nut taking care not to

move the crank angle sensor.

(12)Turn OFF the ignition switch.

(13)Disconnect the jumper wire connected at step (7).

(14)Start and run the engine at curb idle speed.

1 TSB Revision

Page 64 of 1146

11-14ENGINE - Service Adjustment Procedures

(15)Check to be sure that the idling ignition timing is the correct

timing.

Actual ignition timing: Approx. 15” BTDC

NOTE:d

(1) Ignition timing is variable even under normal operation.

(2) And it is automatically advanced at higher altitudes.

CURB IDLE SPEED INSPECTIONMllFMAB

(1) The vehicle should be prepared as follows before the

inspection.

lEngine coolant temperature: 80 - 95°C (176 - 205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: neutral

(P for A/T)l Steering wheel: neutral position

(2) Connect a tachometer. (Refer to P.l l-1 3.)

(3) Set a timing light.

(4) Using a jumper wire, ground the ignition timing adjusting

terminal.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value: 5” BTDC + 2”

NOTECheck the ignition timing with the Multi-use tester not

connected to the diagnosis connector.

(7) Remove the jumper wire from the ignition timing adjusting

terminal.

(8) When using the Multi-use tester, turn OFF the ignition

switch and connect the tester to the diagnosis connector.

(9) Idle the engine for two minutes.

(10)Check the idle speed.

Curb idle speed:

700 + 100 rpm

NOTE(1) The idling speed is automatically regulated by the

idle-speed control system.

(2)’ The engine speed indicated is a third of actual speed. In

other words, the reading of the tachometer times 3 is

actual speed.

(1l)lf not within the standard value range, refer to GROUP 13 -Service Adjustment Procedures.

d

1 TSB RevisionI

Page 138 of 1146

13-32FUEL SYSTEM - Service Adjustment Procedures

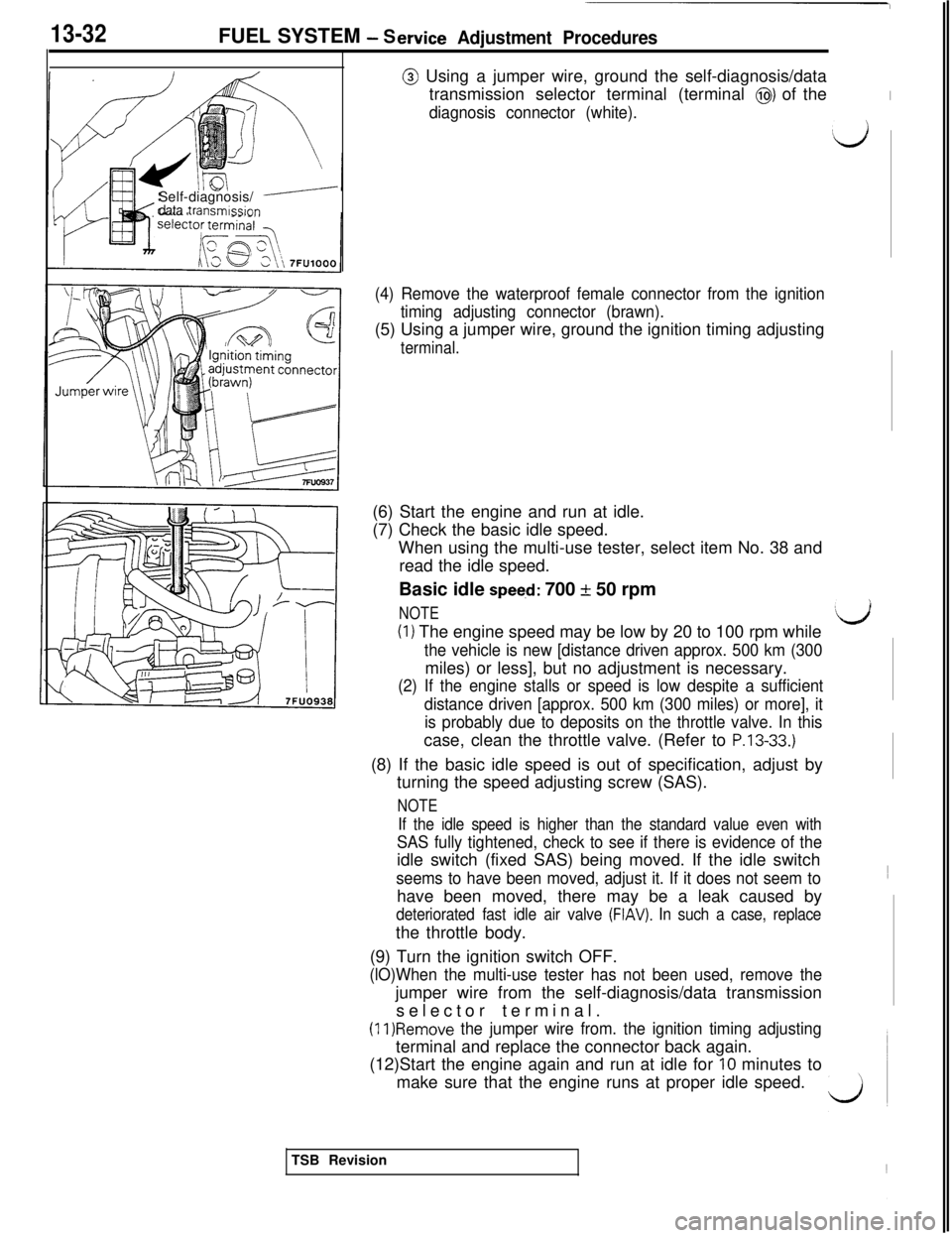

@ Using a jumper wire, ground the self-diagnosis/data

transmission selector terminal (terminal

@) of theI

diagnosis connector (white).

dSelf-diagnosis/

ydata transmission

(4) Remove the waterproof female connector from the ignition

timing adjusting connector (brawn).(5) Using a jumper wire, ground the ignition timing adjusting

terminal.(6) Start the engine and run at idle.

(7) Check the basic idle speed.

When using the multi-use tester, select item No. 38 and

read the idle speed.

Basic idle

speeci: 700 + 50 rpm

NOTE(I) The engine speed may be low by 20 to 100 rpm while

the vehicle is new [distance driven approx. 500 km (300miles) or less], but no adjustment is necessary.

(2) If the engine stalls or speed is low despite a sufficient

distance driven [approx. 500 km (300 miles) or more], it

is probably due to deposits on the throttle valve. In thiscase, clean the throttle valve. (Refer to

P.13-33.)(8) If the basic idle speed is out of specification, adjust by

turning the speed adjusting screw (SAS).

NOTE

If the idle speed is higher than the standard value even with

SAS fully tightened, check to see if there is evidence of theidle switch (fixed SAS) being moved. If the idle switch

seems to have been moved, adjust it. If it does not seem tohave been moved, there may be a leak caused by

deteriorated fast idle air valve (FIAV). In such a case, replacethe throttle body.

(9) Turn the ignition switch OFF.

(lO)When the multi-use tester has not been used, remove thejumper wire from the self-diagnosis/data transmission

selector terminal.

(11)Remove the jumper wire from. the ignition timing adjustingterminal and replace the connector back again.

(12)Start the engine again and run at idle for

10 minutes to

make sure that the engine runs at proper idle speed.

‘dTSB Revision

Page 139 of 1146

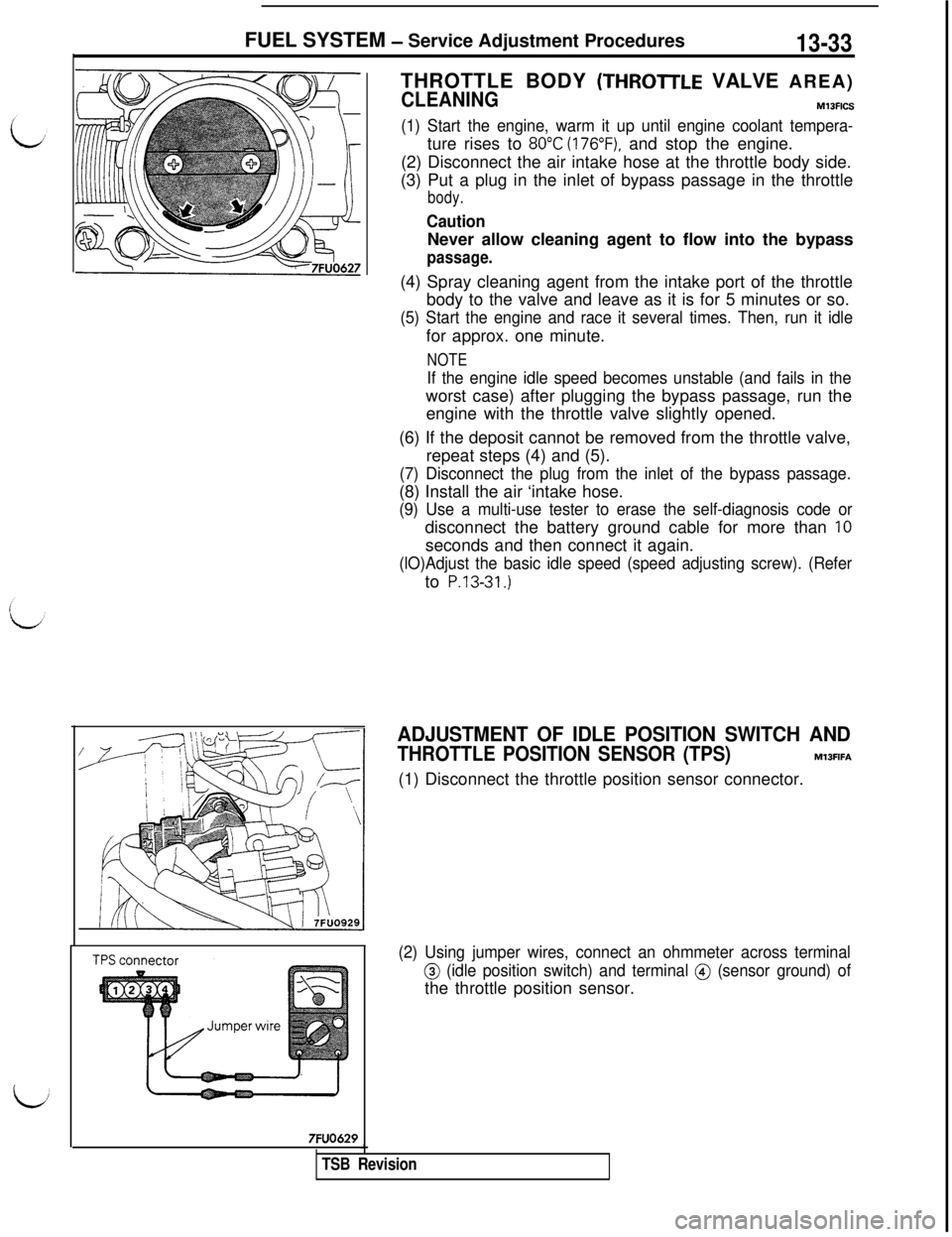

FUEL SYSTEM - Service Adjustment Procedures13-33THROTTLE BODY

(THROTrLE VALVE AREA)

CLEANINGM13FICS

(1) Start the engine, warm it up until engine coolant tempera-ture rises to

80°C (176”F), and stop the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Put a plug in the inlet of bypass passage in the throttle

body.

CautionNever allow cleaning agent to flow into the bypass

passage.(4) Spray cleaning agent from the intake port of the throttle

body to the valve and leave as it is for 5 minutes or so.

(5) Start the engine and race it several times. Then, run it idlefor approx. one minute.

NOTE

If the engine idle speed becomes unstable (and fails in theworst case) after plugging the bypass passage, run the

engine with the throttle valve slightly opened.

(6) If the deposit cannot be removed from the throttle valve,

repeat steps (4) and (5).

(7) Disconnect the plug from the inlet of the bypass passage.(8) Install the air ‘intake hose.

(9) Use a multi-use tester to erase the self-diagnosis code ordisconnect the battery ground cable for more than

IOseconds and then connect it again.

(lO)Adjust the basic idle speed (speed adjusting screw). (Referto

P.13-31.)

7FUO629

ADJUSTMENT OF IDLE POSITION SWITCH AND

THROTTLE POSITION SENSOR (TPS)M13FIFA(1) Disconnect the throttle position sensor connector.

(2) Using jumper wires, connect an ohmmeter across terminal

@ (idle position switch) and terminal @ (sensor ground) ofthe throttle position sensor.

TSB Revision

Page 244 of 1146

13438FUEL SYSTEM - On-vehicle Inspection of MPI ComponentsI/

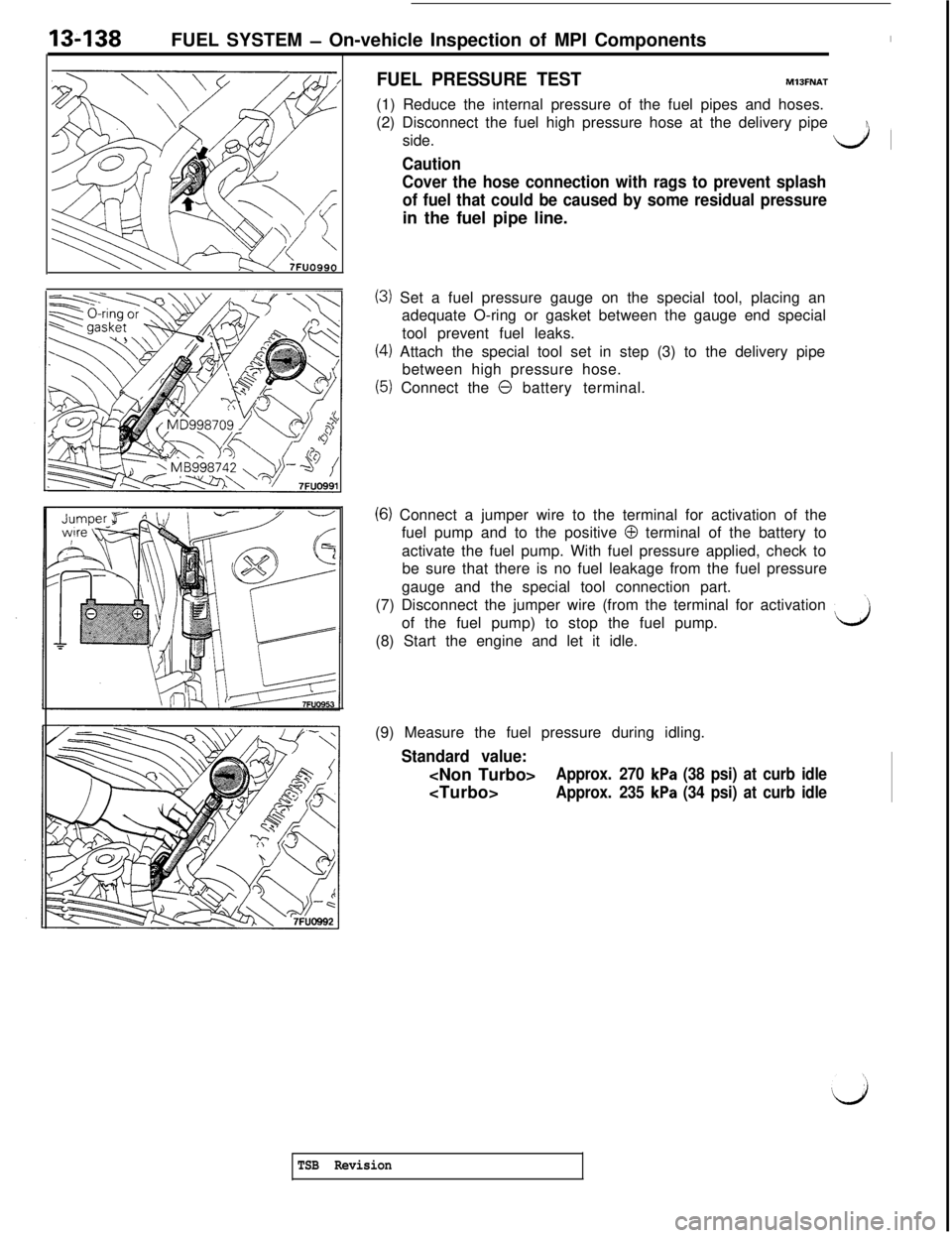

FUEL PRESSURE TESTMlJFNAT(1) Reduce the internal pressure of the fuel pipes and hoses.

(2) Disconnect the fuel high pressure hose at the delivery pipe

side.

dl

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

(3) Set a fuel pressure gauge on the special tool, placing an

adequate O-ring or gasket between the gauge end special

tool prevent fuel leaks.

(4) Attach the special tool set in step (3) to the delivery pipe

between high pressure hose.

(5) Connect the 0 battery terminal.

(6) Connect a jumper wire to the terminal for activation of the

fuel pump and to the positive

0 terminal of the battery to

activate the fuel pump. With fuel pressure applied, check to

be sure that there is no fuel leakage from the fuel pressure

gauge and the special tool connection part.

(7) Disconnect the jumper wire (from the terminal for activation

’of the fuel pump) to stop the fuel pump.

(8) Start the engine and let it idle.

d(9) Measure the fuel pressure during idling.

Standard value:

Approx. 270 kPa (38 psi) at curb idle

Approx. 235 kPa (34 psi) at curb idle

TSB Revision

Page 318 of 1146

INTAKE AND EXHAUST - Service Adiustment Procedures

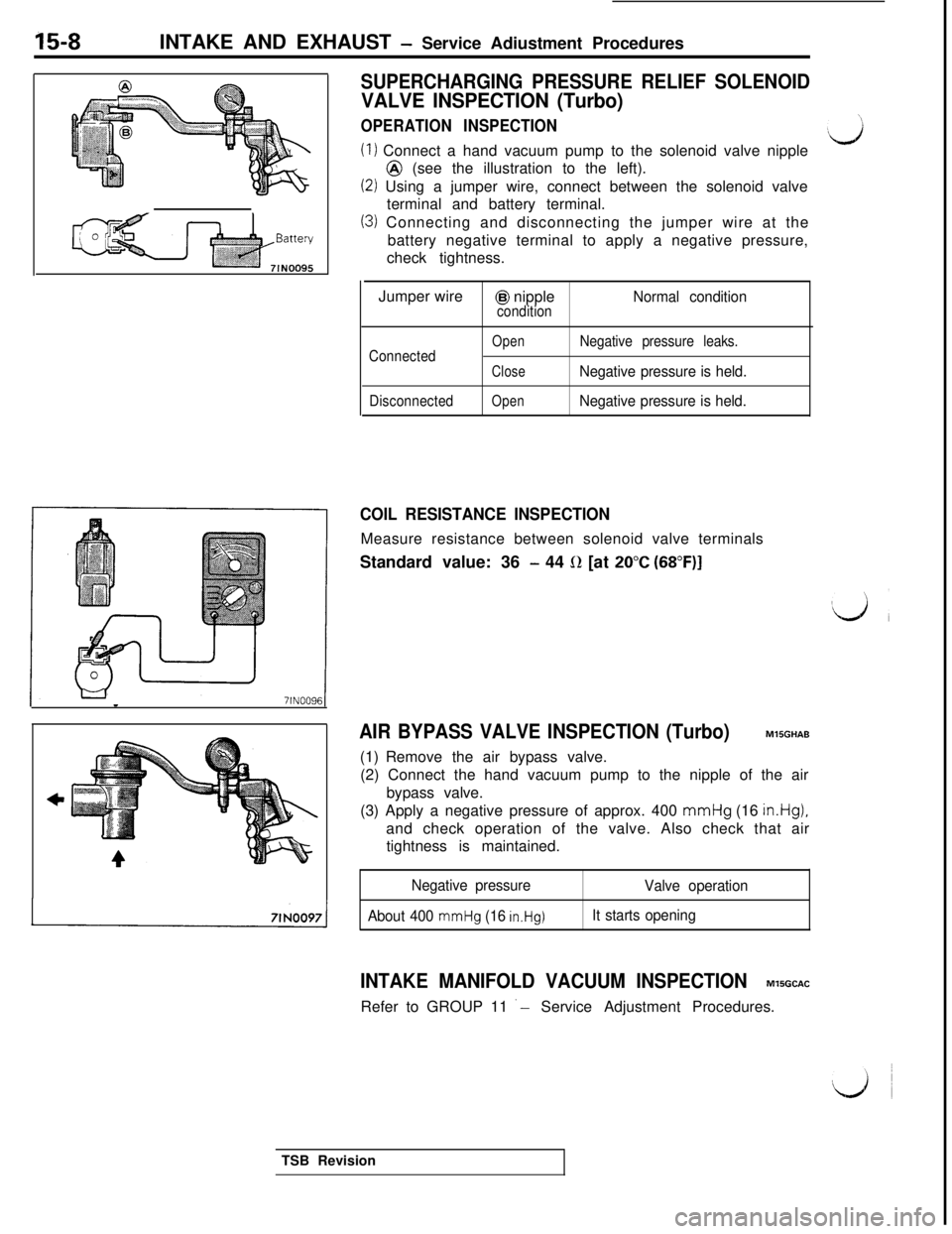

SUPERCHARGING PRESSURE RELIEF SOLENOID

VALVE INSPECTION (Turbo)

OPERATION INSPECTION

(1) Connect a hand vacuum pump to the solenoid valve nipple@ (see the illustration to the left).

(2) Using a jumper wire, connect between the solenoid valve

terminal and battery terminal.

(3) Connecting and disconnecting the jumper wire at the

battery negative terminal to apply a negative pressure,

check tightness.

Jumper wire

@I nippleNormal conditioncondition

Connected

Disconnected

OpenNegative pressure leaks.

CloseNegative pressure is held.

OpenNegative pressure is held.

COIL RESISTANCE INSPECTIONMeasure resistance between solenoid valve terminals

Standard value: 36

- 44 0 [at 20°C (68”F)I

AIR BYPASS VALVE INSPECTION (Turbo)MlSGHAB

(1) Remove the air bypass valve.

(2) Connect the hand vacuum pump to the nipple of the air

bypass valve.

(3) Apply a negative pressure of approx. 400 mmHg (16

in.Hg),and check operation of the valve. Also check that air

tightness is maintained.

Negative pressure

About 400

mmHg (16 in.Hg)

Valve operation

It starts opening

INTAKE MANIFOLD VACUUM INSPECTIONM’ISGCACRefer to GROUP 11

‘- Service Adjustment Procedures.

TSB Revision

Page 784 of 1146

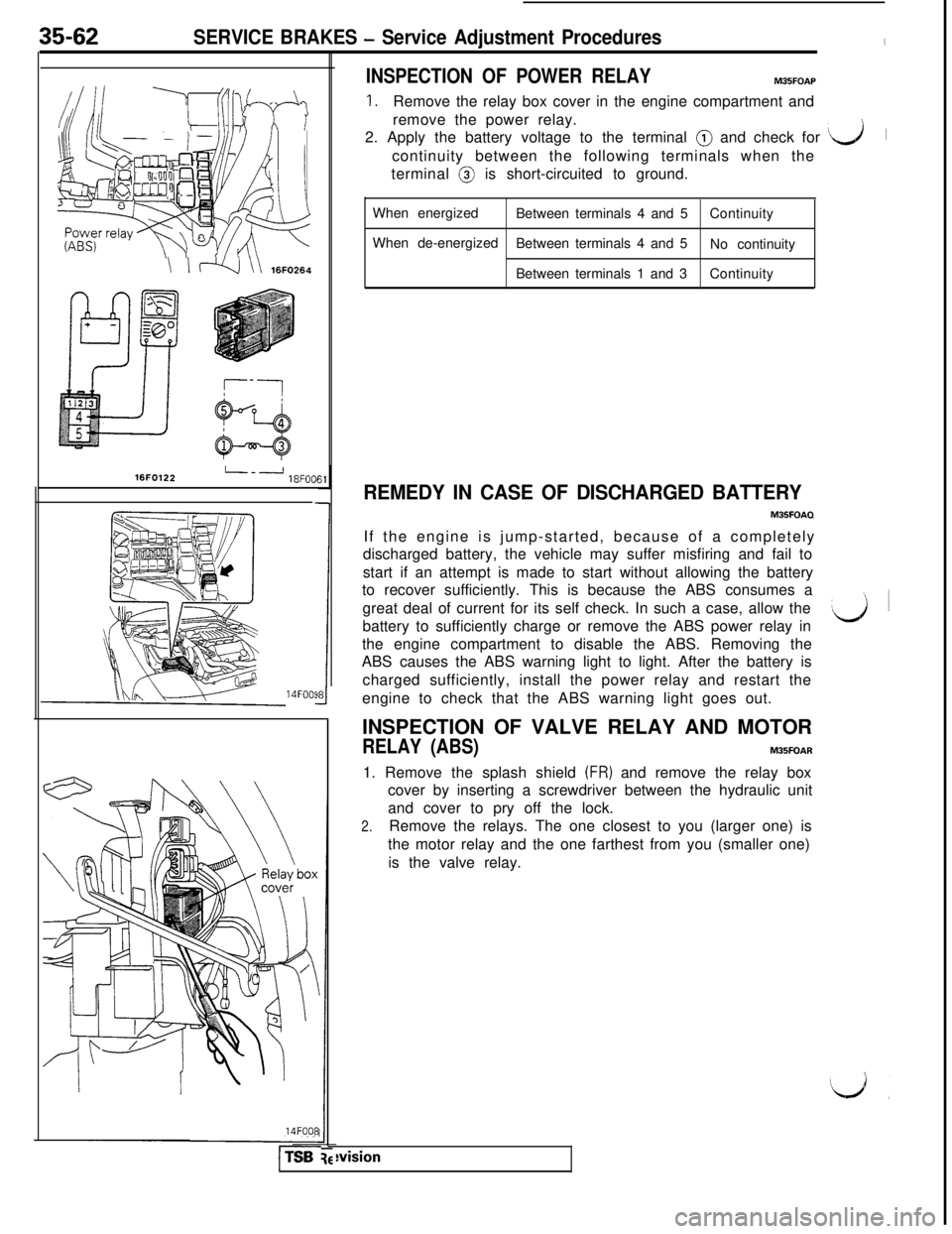

When energized

Between terminals 4 and 5Continuity

When de-energized

Between terminals 4 and 5\i fl \\ 16FO264No continuity

Between terminals 1 and 3Continuity

16FO122L--J18FOCII

SERVICE BRAKES - Service Adjustment ProceduresI

INSPECTION OF POWER RELAYM35FOAP

7

1.Remove the relay box cover in the engine compartment and

remove the power relay.

2. Apply the battery voltage to the terminal @ and check for

‘L-J1

continuity between the following terminals when the

terminal @ is short-circuited to ground.

35-62

14FOOS14FOO8

l-TSB

1

REMEDY IN CASE OF DISCHARGED BATTERY

M35FOAQIf the engine is jump-started, because of a completely

discharged battery, the vehicle may suffer misfiring and fail to

start if an attempt is made to start without allowing the battery

to recover sufficiently. This is because the ABS consumes a

great deal of current for its self check. In such a case, allow the

battery to sufficiently charge or remove the ABS power relay in

the engine compartment to disable the ABS. Removing the

ABS causes the ABS warning light to light. After the battery is

charged sufficiently, install the power relay and restart the

engine to check that the ABS warning light goes out.

INSPECTION OF VALVE RELAY AND MOTOR

RELAY (ABS)M35FOAR1. Remove the splash shield

(FR) and remove the relay box

cover by inserting a screwdriver between the hydraulic unit

and cover to pry off the lock.

2.Remove the relays. The one closest to you (larger one) is

the motor relay and the one farthest from you (smaller one)

is the valve relay.

‘d~ i

wision