rims MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 343 of 1146

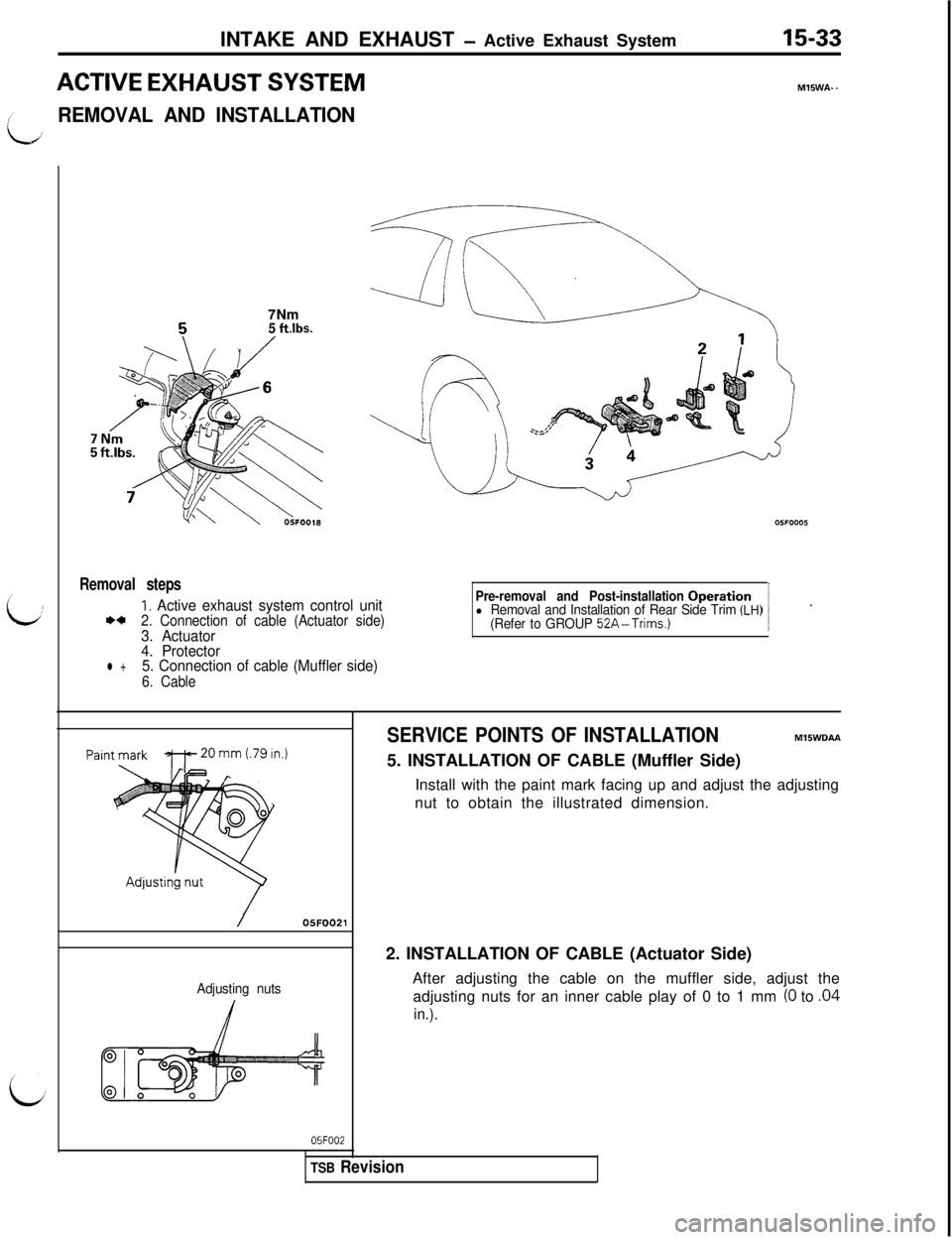

INTAKE AND EXHAUST - Active Exhaust System

ACTIVE EXHAUST SYSTEM

REMOVAL AND INSTALLATION

15-33

M15WA- -7Nm

5 ft.lbs.

Removal steps

I. Active exhaust system control unitI)+2. Connection of cable (Actuator side)3. Actuator

4. Protector

l +5. Connection of cable (Muffler side)

6. CablePre-removal and Post-installation

l Removal and Installation of Rear Side Trim (LH)(Refer to GROUP 52A-Trims.)

/DSFDO21

Adjusting nuts

05FOO2

SERVICE POINTS OF INSTALLATIONMISWDAA

5. INSTALLATION OF CABLE (Muffler Side)

Install with the paint mark facing up and adjust the adjusting

nut to obtain the illustrated dimension.

2. INSTALLATION OF CABLE (Actuator Side)

After adjusting the cable on the muffler side, adjust the

adjusting nuts for an inner cable play of 0 to 1 mm

(0 to .04

in.).

TSB Revision

Page 693 of 1146

REAR SUSPENSION

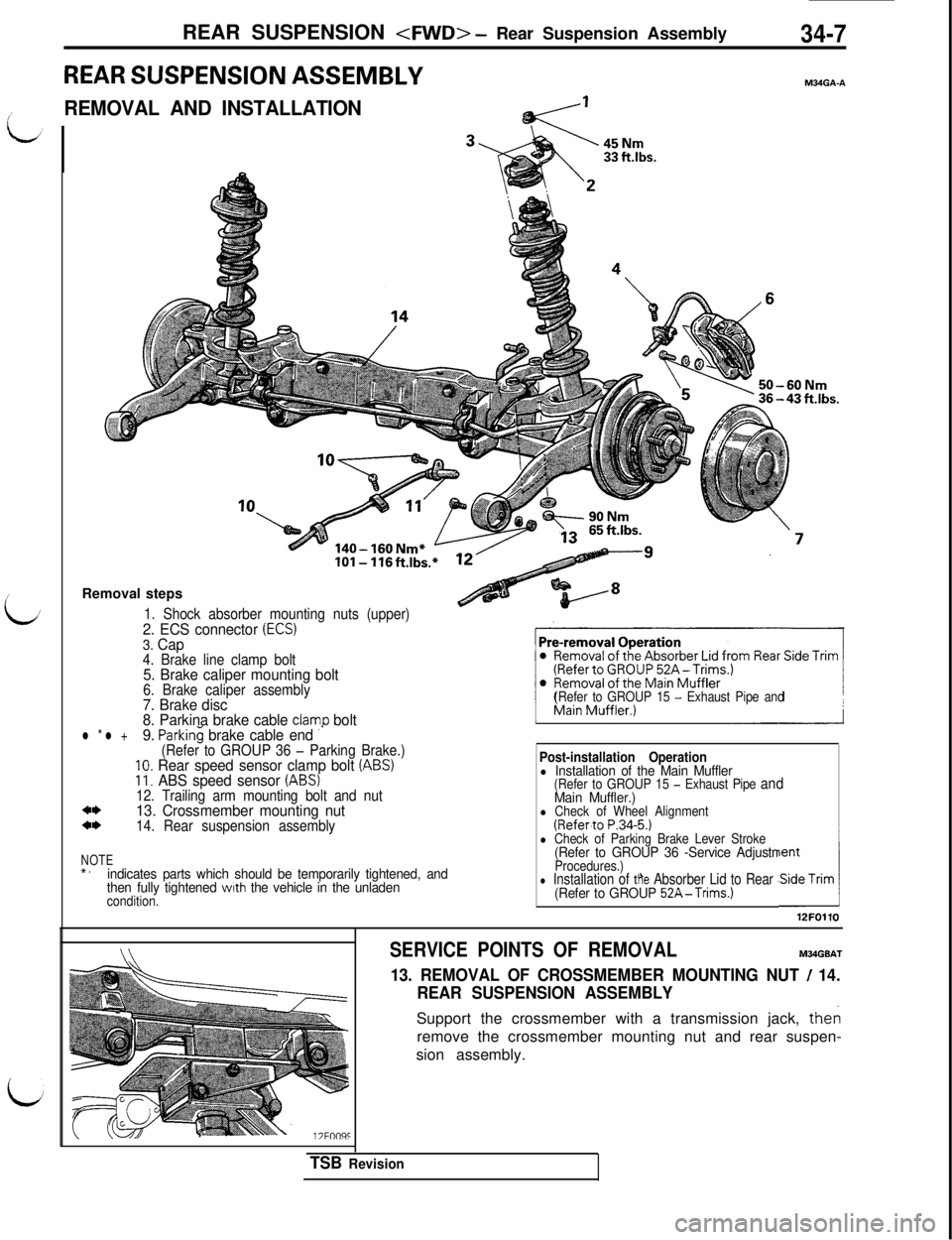

REAR SUSPENSION ASSEMBLYM34GA-A

L/

REMOVAL AND INSTALLATION

140- 160 Nm*IOI- 116ftlbs.

Removal steps

1. Shock absorber mounting nuts (upper)2. ECS connector (ECS)3. Cap4. Brake line clamp bolt5. Brake caliper mounting bolt6. Brake caliper assembly7. Brake disc

8. Parkina brake cable clamo bolt

(Refer to GROUP 15 - Exhaust Pipe and

l * l +9. ParkinG brake cable end ”(Refer to GROUP 36 - Parking Brake.)10. Rear speed sensor clamp bolt (ABS)11. ABS speed sensor (ABS)12. Trailing arm mounting bolt and nut*I)13. Crossmember mounting nut*I)14. Rear suspension assembly

NOTE*.indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladencondition.

Post-installation Operationl Installation of the Main Muffler(Refer to GROUP 15 - Exhaust Pipe andMain Muffler.)l Check of Wheel Alignment(Refer.to P.34-5.)l Check of Parking Brake Lever Stroke(Refer to GROUP 36 -Service AdjustmentProcedures.)l Installation of the Absorber Lid to Rear Side Trim(Refer to GROUP 52A-Trims.)A12FOllO

SERVICE POINTS OF REMOVALM34GBAT

13. REMOVAL OF CROSSMEMBER MOUNTING NUT / 14.

REAR SUSPENSION ASSEMBLYSupport the crossmember with a transmission jack, then

remove the crossmember mounting nut and rear suspen-

sion assembly.

TSB Revision

Page 710 of 1146

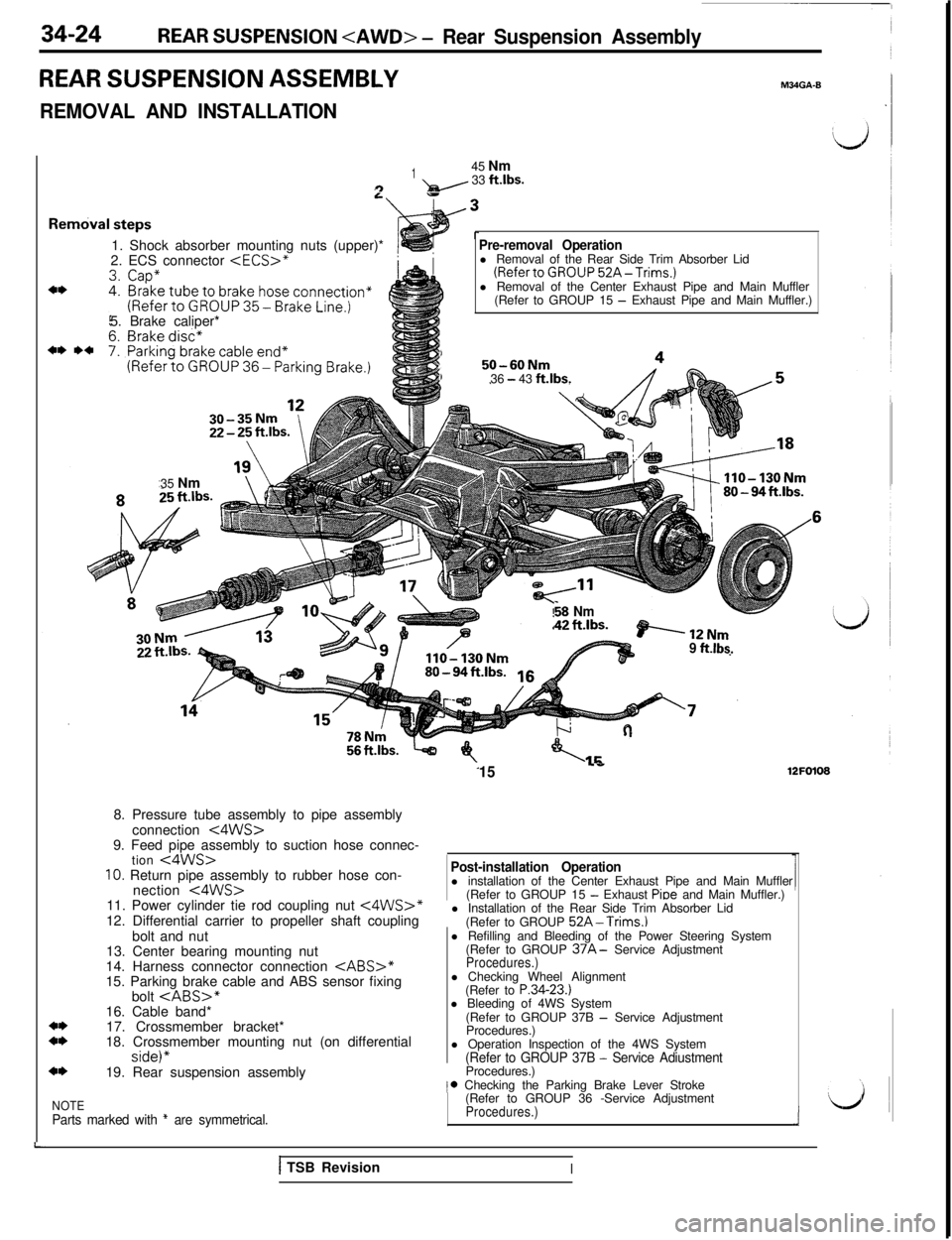

34-24REAR SUSPENSION

REAR SUSPENSION ASSEMBLY

REMOVAL AND INSTALLATION

M34GA-B

L

Rel

145 Nm9- 33 ftlbs.

1. Shock absorber mounting nuts (upper)*

2. ECS connector

(RefertoGROUP52A-Trims.)l Removal of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pipe and Main Muffler.)

5. Brake caliper*

1,50-60NmI36 - 43 ft.lbs.35 Nm

$8 Nm“?C,ILc. ashwez I,..“=.BP’----12Nm9 ftlbs.

15..e12FO1088. Pressure tube assembly to pipe assembly

connection

<4WS>9. Feed pipe assembly to suction hose connec-

tion

<4WS>10. Return pipe assembly to rubber hose con-

nection t4WS>11. Power cylinder tie rod coupling nut <4WS>*12. Differential carrier to propeller shaft coupling

bolt and nut

Post-installation Operationl installation of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pioe and Main Muffler.)

l Installation of the Rear Side Trim Absorber Lid

(Refer to GROUP

52A-Trims.)13. Center bearing mounting nut

14. Harness connector connection

CABS>*15. Parking brake cable and ABS sensor fixingl Refilling and Bleeding of the Power Steering System

(Refer to GROUP

37A- Service AdjustmentProcedures.)bolt

17. Crossmember bracket*

18. Crossmember mounting nut (on differential

side)”19. Rear suspension assemblyl Checking Wheel Alignment

(Refer to P.34-23.)

l Bleeding of 4WS System

(Refer to GROUP 37B

- Service Adjustment

Procedures.)

l Operation Inspection of the 4WS System

(Refer to GROUP 37B - Service AdiustmentProcedures.)

NOTEParts marked with * are symmetrical.

,* Checking the Parking Brake Lever Stroke

(Refer to GROUP 36 -Service Adjustment

Procedures.)i

1 TSB RevisionI

Page 719 of 1146

L

REAR SUSPENSION

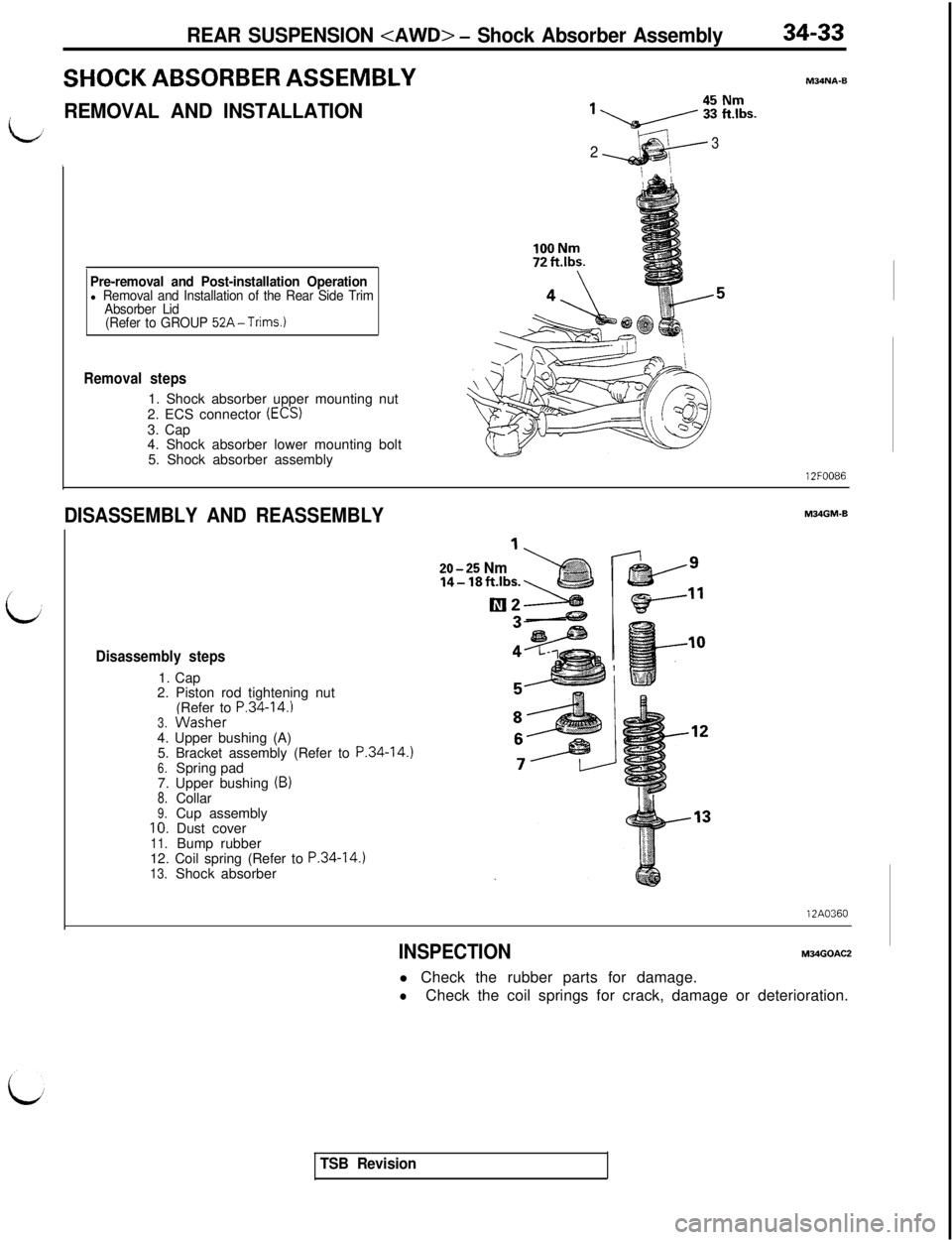

SHOCK ABSORBER ASSEMBLY

REMOVAL AND INSTALLATION1 v i5 KS

23

,

Pre-removal and Post-installation Operation

l Removal and Installation of the Rear Side Trim

Absorber Lid

(Refer to GROUP 52A-Trims.)

Removal steps1. Shock absorber upper mounting nut

2. ECS connector

(ECS)3. Cap

4. Shock absorber lower mounting bolt

5. Shock absorber assembly

M34NA-612FOO86

M34GM-BDISASSEMBLY AND REASSEMBLY

20-25 Nm14- 18ft.lbs.

Disassembly steps1. Cap

2. Piston rod tightening nut

(Refer to

P.34-14.)3.hasher4. Upper bushing (A)

5. Bracket assembly (Refer to

P.34-14.)6.Spring pad

7. Upper bushing (B)8.Collar9.Cup assembly10.Dust cover11.Bump rubber

12. Coil spring (Refer to P.34-14.)13.Shock absorber

12A0360

INSPECTIONM34GOAC2l Check the rubber parts for damage.

lCheck the coil springs for crack, damage or deterioration.

TSB Revision

Page 892 of 1146

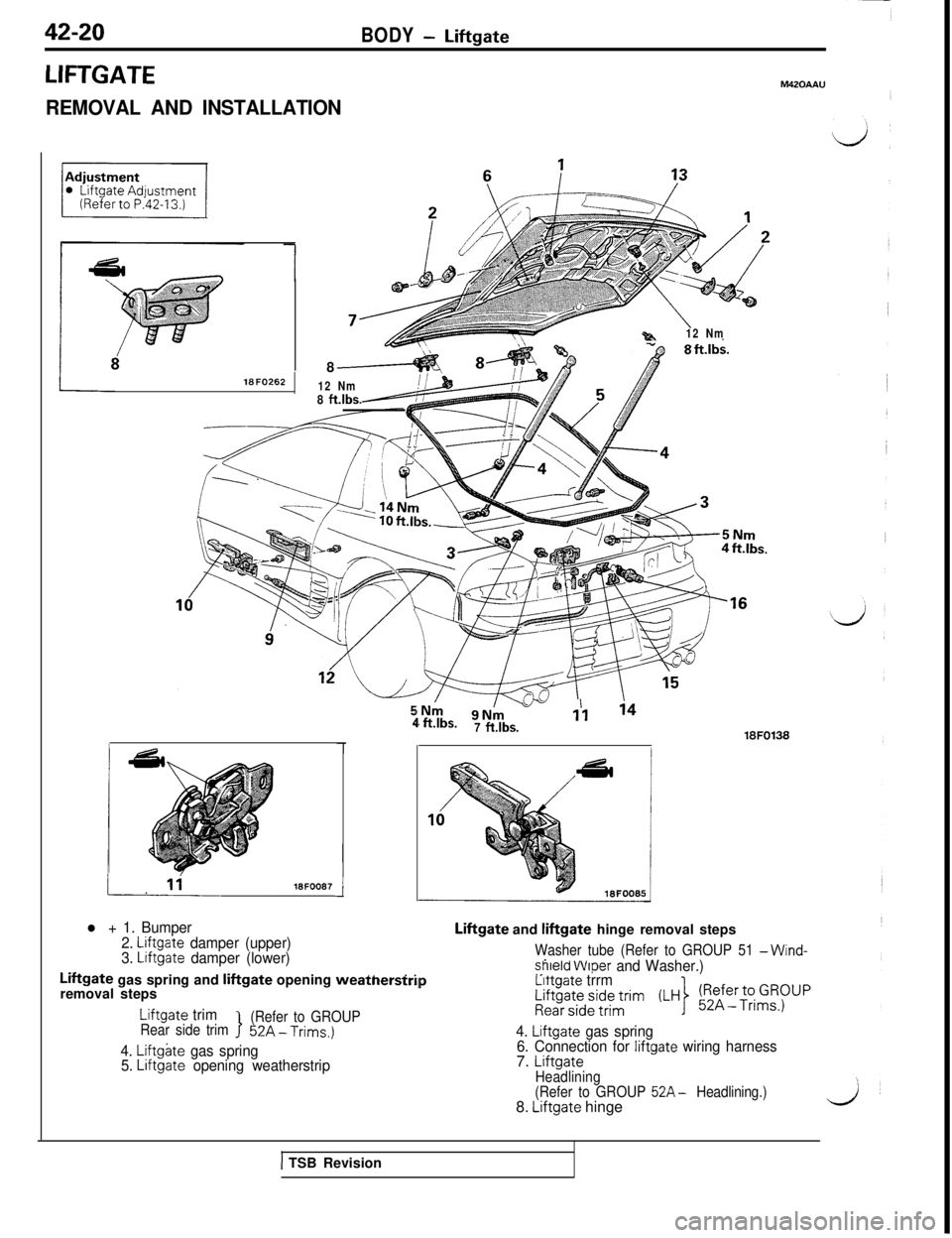

42-20BODY- Liftgate

LIFTGATEM420AAU

REMOVAL AND INSTALLATION8lSFO262

12 Nm8 ft.lbs.

%a12 Nm

18FOO87

l + 1. Bumper

2. Liftgate damper (upper)

3. Liftgate damper (lower)

1

4, ft.‘bs.1’1 ‘47 ftlbs.18FO138Liftgate and

liftgate hinge removal steps

Washer tube (Refer to GROUP 51 -Wind-

.

. .shield Wtper and Washer.). .._Liftgate gas spring and liftgate opening weatnerstrllp

removal steps

Liftgate trimRear side trim>

(Refer to GROUP52A-Trims.)

4. Liftgate gas spring

5. Liftgate opening weatherstrip

Lrttgate trrmi$ftft;e$d;nm (LH) !!-!-~~~G$)upi

4. Liftgate gas spring

6. Connection for liftgate wiring harness7. LiftgateHeadlining

(Refer to GROUP 52A- Headlining.)8. Liftgate hinge

1 TSB Revision

Page 893 of 1146

BODY - Liftgate42-21

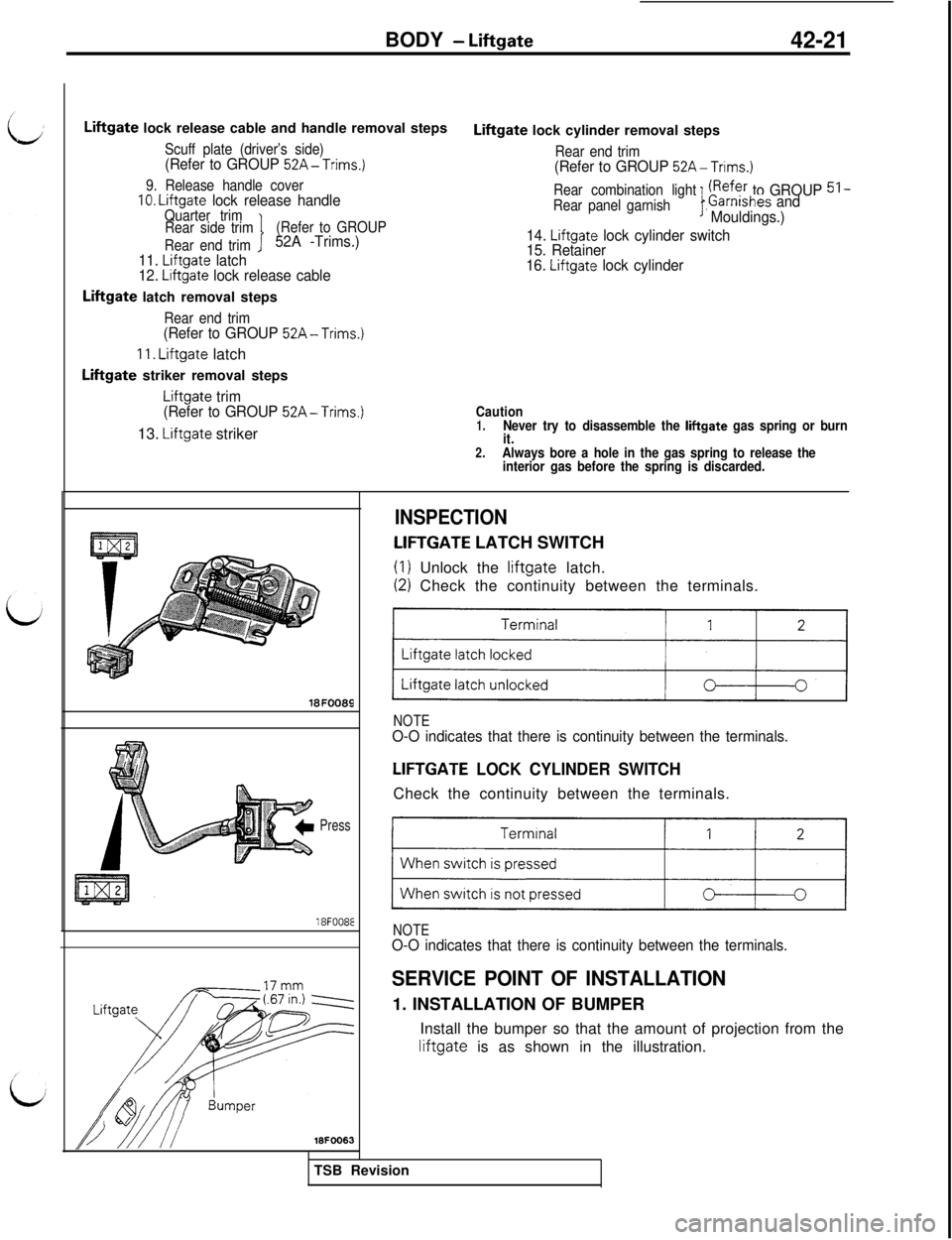

Liftgate lock release cable and handle removal steps

Scuff plate (driver’s side)(Refer to GROUP 52A-Trims.)

9. Release handle cover10. Liftgate lock release handleQuarter trim

Rear side trim(Refer to GROUP

Rear end trim

I52A -Trims.)

11.

Liftgate latch

12. Liftgate lock release cable

Liftgate latch removal steps

Rear end trim(Refer to GROUP 52A-Trims.)

11. Liftgate latch

Liftgate striker removal steps

Liftgate trim

(Refer to GROUP 52A-Trims.)13.

Liftgate strikerLiftgate lock cylinder removal steps

Rear end trim(Refer to GROUP 52A-Trims.)

Rear combination light

I

fRefer to GROUP 51 -Rear panel garnish,Garnishes and

Mouldings.)

14.

Liftgate lock cylinder switch

15. Retainer

16.

Liftgate lock cylinder

Caution1.Never try to disassemble the liftgate gas spring or burn

it.

2.Always bore a hole in the gas spring to release the

interior gas before the spring is discarded.

18FOO89

Press

18F008E

18FOO63

INSPECTION

LIFTGATE LATCH SWITCH

(I) Unlock the liftgate latch.

(2) Check the continuity between the terminals.

)I

NOTEO-O indicates that there is continuity between the terminals.

LIFTGATE LOCK CYLINDER SWITCHCheck the continuity between the terminals.

11

NOTEO-O indicates that there is continuity between the terminals.

SERVICE POINT OF INSTALLATION1. INSTALLATION OF BUMPER

Install the bumper so that the amount of projection from theliftgate is as shown in the illustration.

TSB Revision

Page 894 of 1146

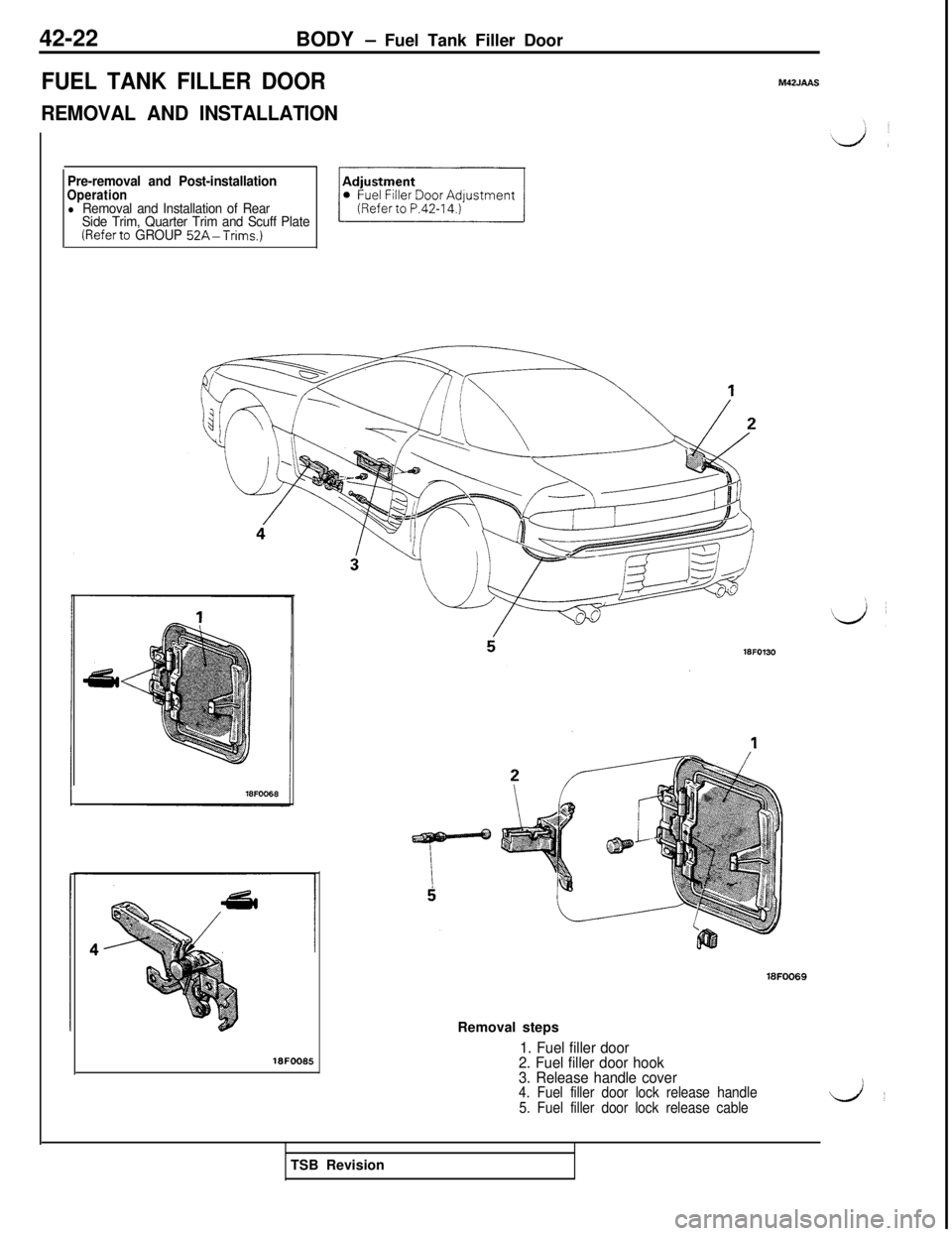

42-22BODY - Fuel Tank Filler Door

FUEL TANK FILLER DOOR

REMOVAL AND INSTALLATION

M42JAAS

Pre-removal and Post-installationOperationl Removal and Installation of Rear

Side Trim, Quarter Trim and Scuff Plate

(Referto GROUP 52A-Trims.)

18FOO86

18FOO69Removal steps

1. Fuel filler door

2. Fuel filler door hook

3. Release handle cover

4. Fuel filler door lock release handle

5. Fuel filler door lock release cableLA’TSB Revision

Page 904 of 1146

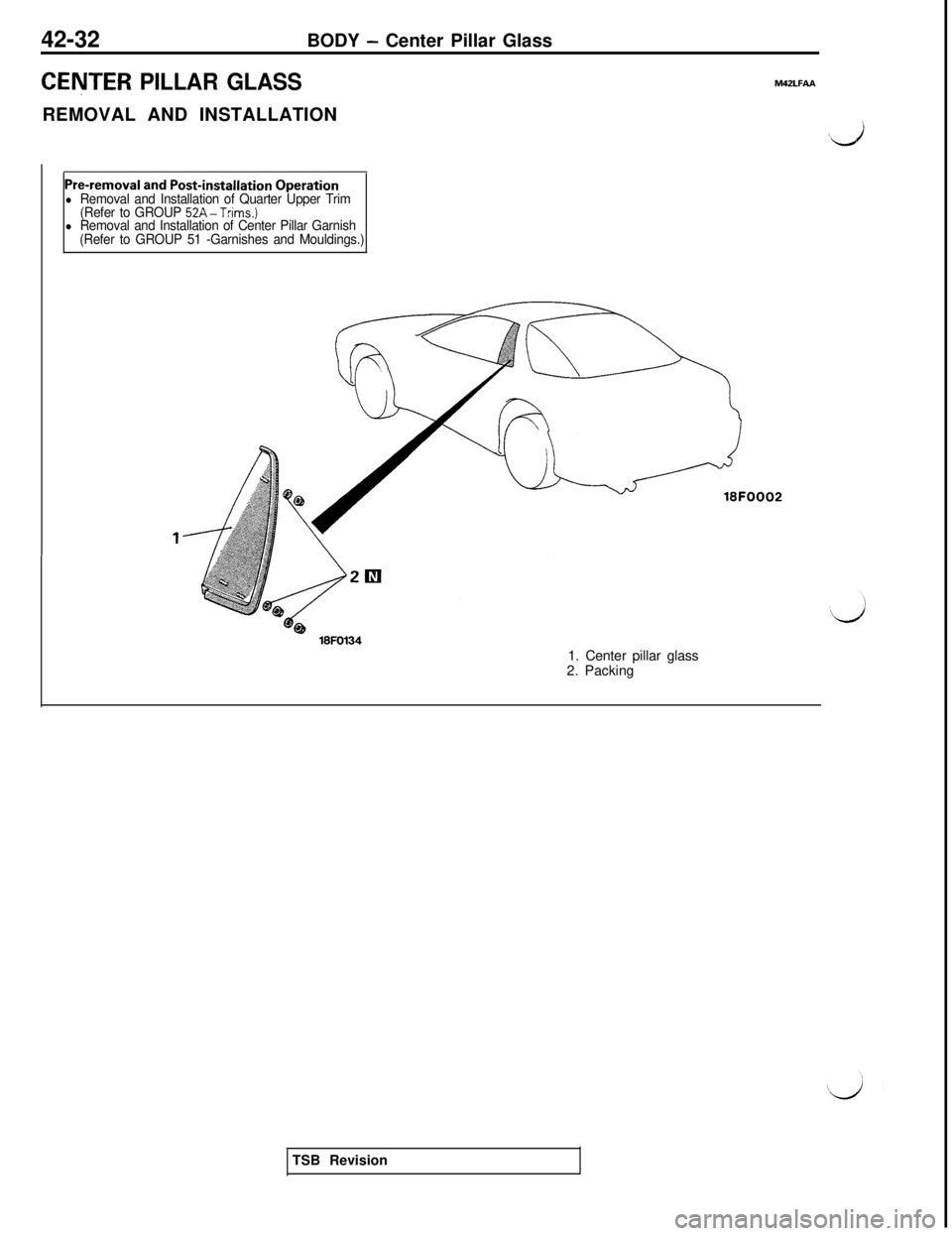

42-32BODY - Center Pillar Glass

CENTER PILLAR GLASSM42LFAAREMOVAL AND INSTALLATION

j‘u

Pre-removal and Post-installation Operationl Removal and Installation of Quarter Upper Trim

(Refer to GROUP 52A-Trims.)l Removal and Installation of Center Pillar Garnish

(Refer to GROUP 51 -Garnishes and Mouldings.)

18FOOO2

18FO1341. Center pillar glass

2. Packing

TSB Revision

Page 905 of 1146

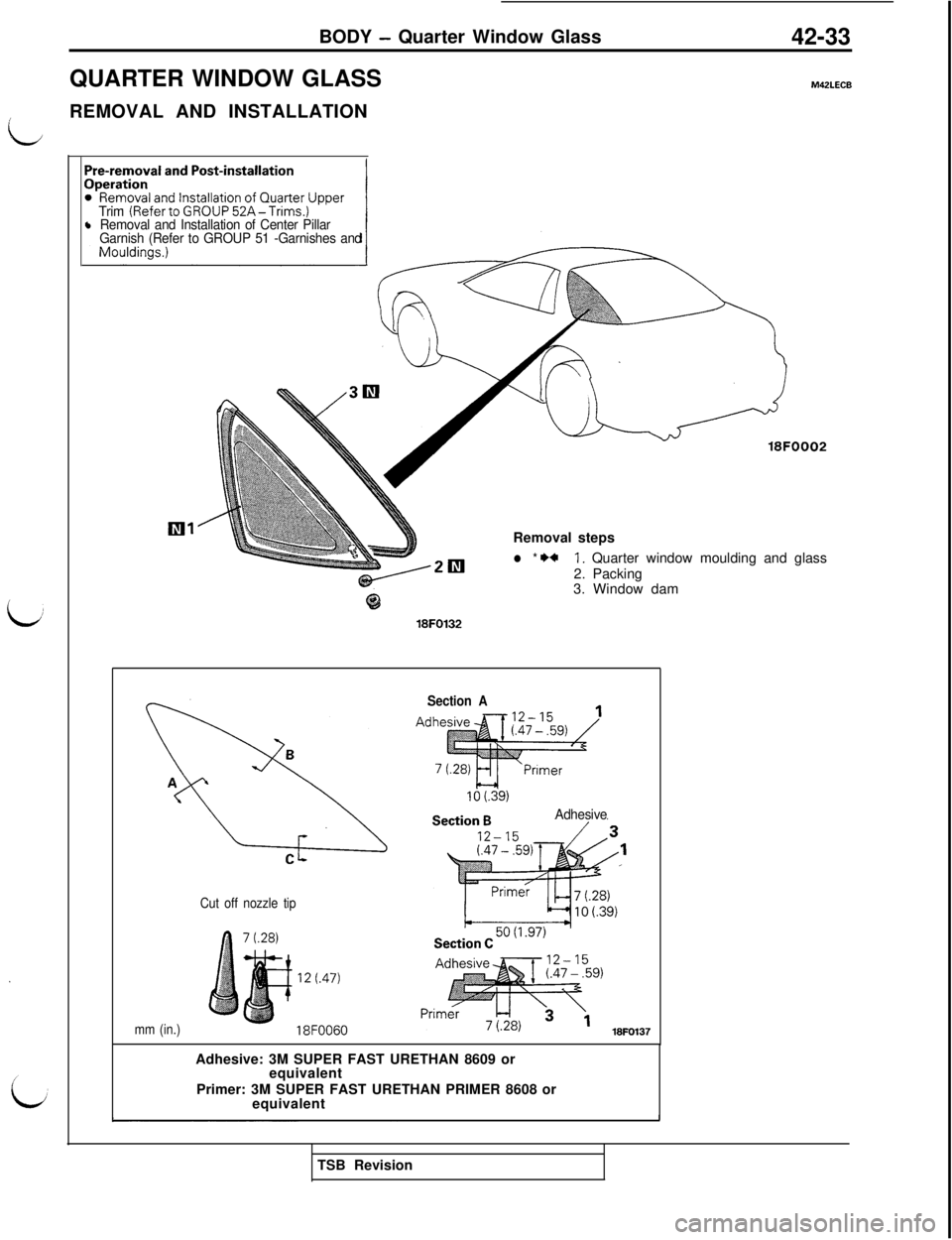

BODY - Quarter Window Glass

42-33

QUARTER WINDOW GLASS

M42LECB

:REMOVAL AND INSTALLATION

Trim (RefertoGROUP52A-Trims.)l Removal and Installation of Center Pillar

Garnish (Refer to GROUP 51 -Garnishes and

18FOOO2

18FO132Removal steps

l * I)*1. Quarter window moulding and glass

2. Packing

3. Window dam

Section A

Adhesive

Cut off nozzle tip

mm (in.)

18FOO6018FO137

Adhesive: 3M SUPER FAST URETHAN 8609 or

equivalent

Primer: 3M SUPER FAST URETHAN PRIMER 8608 or

equivalent

TSB Revision

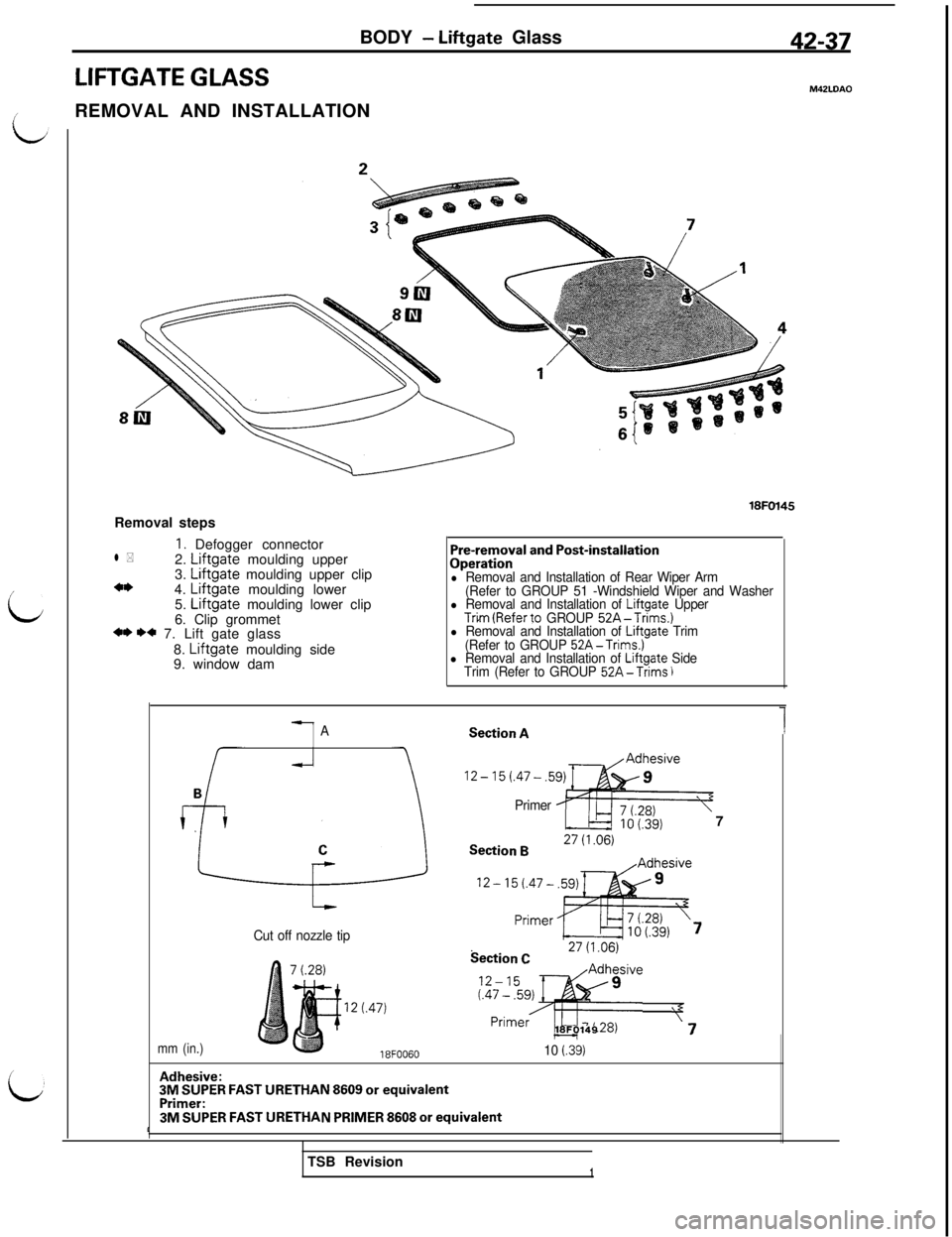

Page 909 of 1146

BODY - Liftgate Glass

LIFTGATE GLASSREMOVAL AND INSTALLATION

42-37

M42LDAO

i

LRemoval steps

I. Defogger connectorl *2. Liftgate moulding upper

3. Liftgate moulding upper clipa*4. Liftgate moulding lower

5. Liftgate moulding lower clip

6. Clip grommet

+* *+ 7. Lift gate glass

8.

Liftgate moulding side

9. window dam

18FO145

Pre-removal and Post-installationOperationl Removal and Installation of Rear Wiper Arm

(Refer to GROUP 51 -Windshield Wiper and Washer

l Removal and Installation of Liftgate UpperTrim (Referto GROUP 52A-Trims.)l Removal and Installation of Liftgate Trim

(Refer to GROUP 52A-Trims.)

l Removal and Installation of Liftgate Side

Trim (Refer to GROUP 52A-Trims )

-ASection A

12-15(.47-.59)

Primer7

Section B27 (1.06)

Cut off nozzle tip

1

,

Adhesive:3M SUPER FAST URETHAN 8609 or equivalentPrimer:3M SUPER FAST URETHAN PRIMER 8608 or equivalent

12 (.47)E!;~;qiffy,8Fo,48,f 7

mm (in.)18FOO6010 t.391TSB Revision

1