MITSUBISHI 3000GT 1992 2.G Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 461 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-15

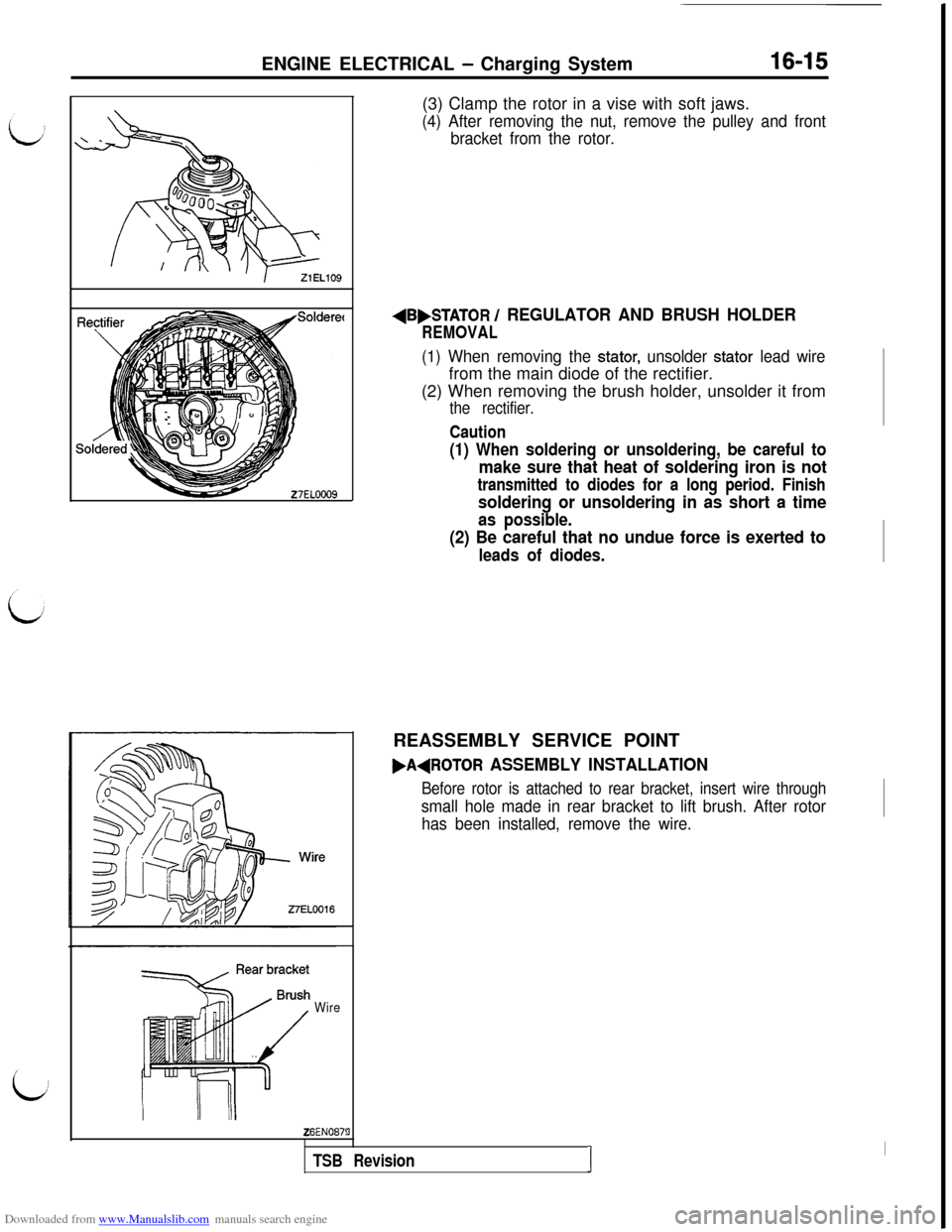

WireZ6EN087!(3) Clamp the rotor in a vise with soft jaws.

(4) After removing the nut, remove the pulley and front

bracket from the rotor.

AB,STATOR / REGULATOR AND BRUSH HOLDER

REMOVAL

(1) When removing the stator, unsolder stator lead wirefrom the main diode of the rectifier.

(2) When removing the brush holder, unsolder it from

the rectifier.

Caution

(1) When soldering or unsoldering, be careful to

make sure that heat of soldering iron is not

transmitted to diodes for a long period. Finish

soldering or unsoldering in as short a time

as possible.

(2) Be careful that no undue force is exerted to

leads of diodes.REASSEMBLY SERVICE POINT

FAdROTOR ASSEMBLY INSTALLATION

Before rotor is attached to rear bracket, insert wire through

small hole made in rear bracket to lift brush. After rotor

has been installed, remove the wire.

3

TSB RevisionI

I

Page 462 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System

h\Z3ELOlO

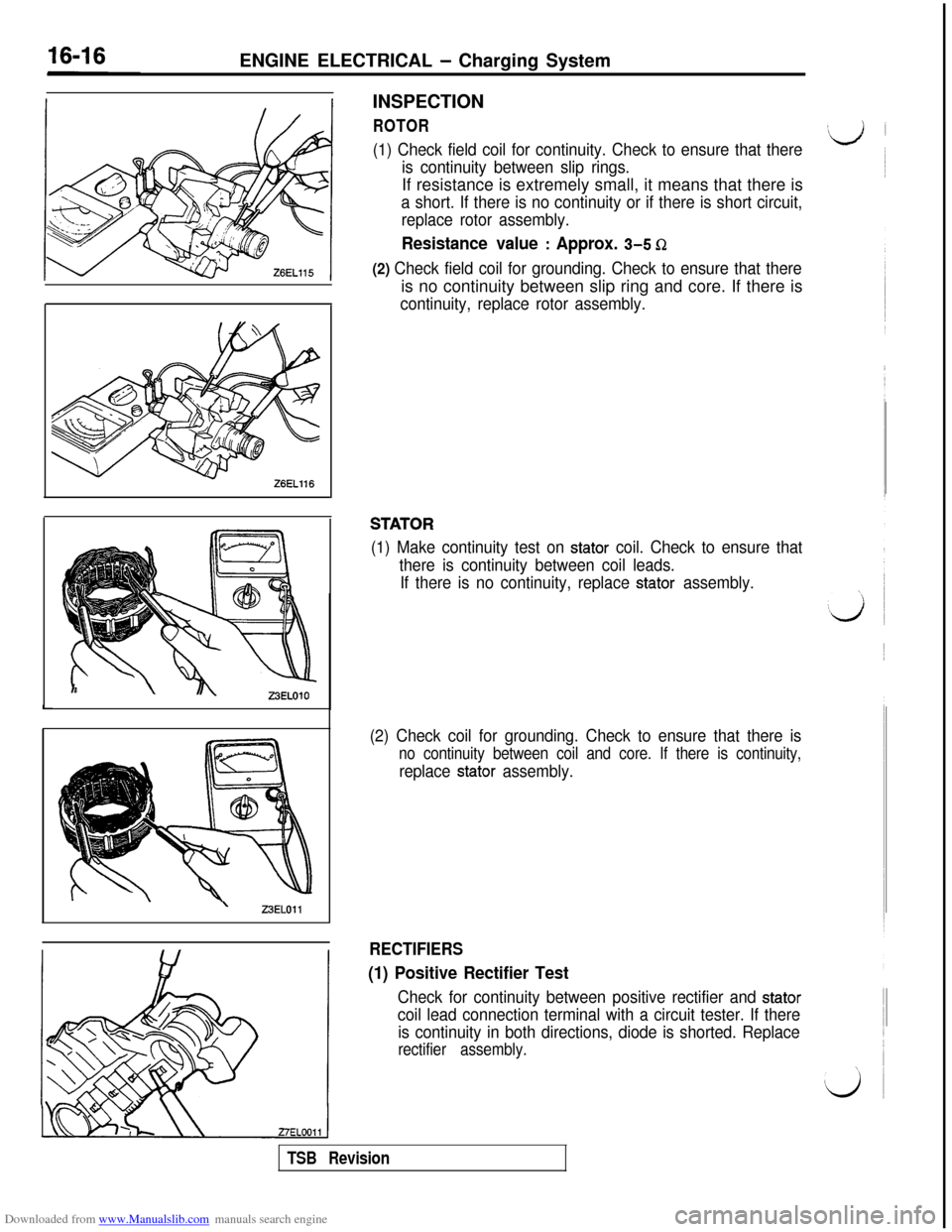

\23ELOllINSPECTION

ROTOR

(1) Check field coil for continuity. Check to ensure that there

is continuity between slip rings.If resistance is extremely small, it means that there is

a short. If there is no continuity or if there is short circuit,

replace rotor assembly.

Resistance value : Approx. 3-5 Q

(2) Check field coil for grounding. Check to ensure that thereis no continuity between slip ring and core. If there is

continuity, replace rotor assembly.

STATOR

(1) Make continuity test on stator coil. Check to ensure that

there is continuity between coil leads.

If there is no continuity, replace

stator assembly.

(2) Check coil for grounding. Check to ensure that there is

no continuity between coil and core. If there is continuity,

replace stator assembly.

RECTIFIERS

(1) Positive Rectifier Test

Check for continuity between positive rectifier and stator

coil lead connection terminal with a circuit tester. If there

is continuity in both directions, diode is shorted. Replace

rectifier assembly.

TSB Revision

Page 463 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Charging System16-17

Limit line

WELO

,Soldered

27EL0014

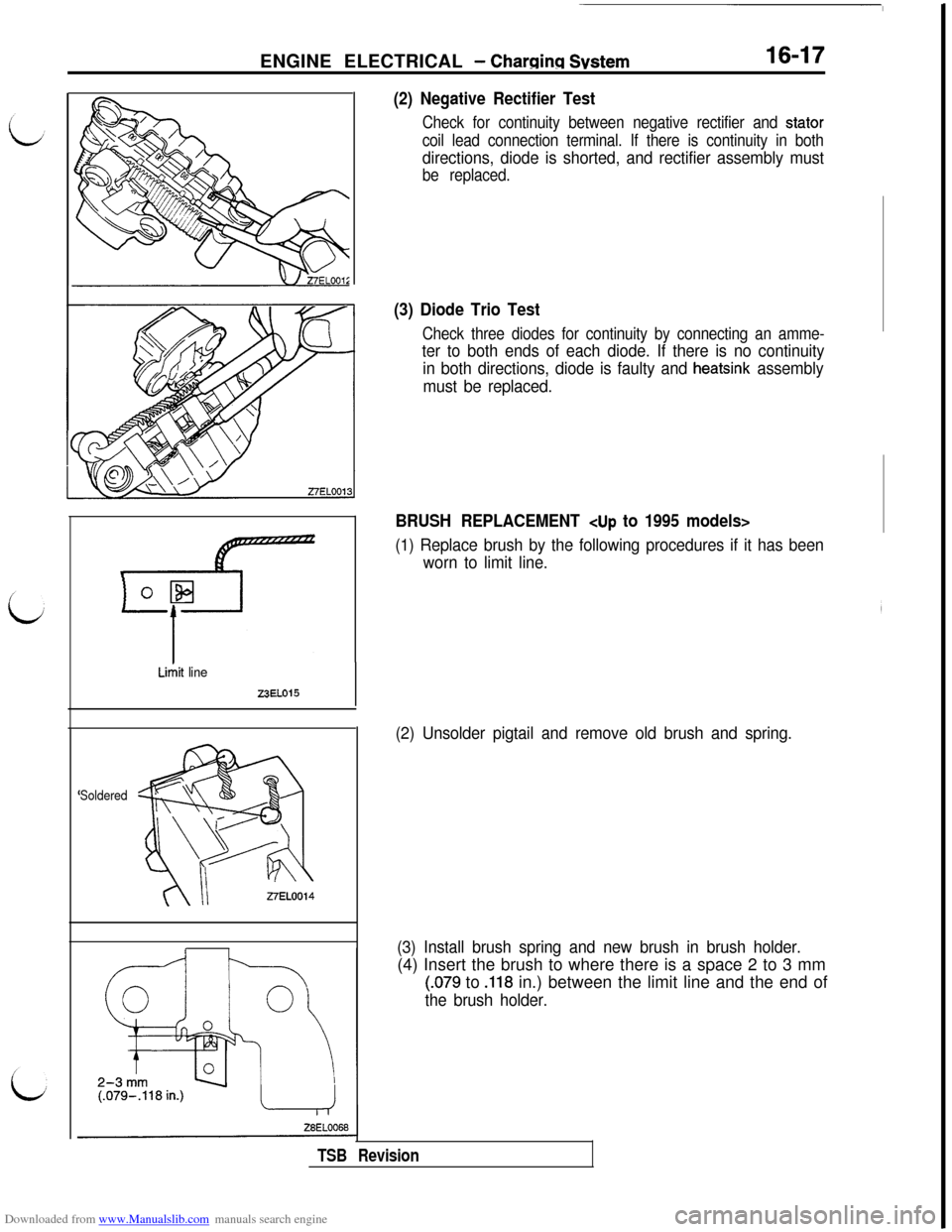

(2) Negative Rectifier Test

Check for continuity between negative rectifier and stator

coil lead connection terminal. If there is continuity in both

directions, diode is shorted, and rectifier assembly must

be replaced.

(3) Diode Trio Test

Check three diodes for continuity by connecting an amme-

ter to both ends of each diode. If there is no continuity

in both directions, diode is faulty and

heatsink assembly

must be replaced.

BRUSH REPLACEMENT

(1) Replace brush by the following procedures if it has been

worn to limit line.

(2) Unsolder pigtail and remove old brush and spring.

(3) Install brush spring and new brush in brush holder.(4) Insert the brush to where there is a space 2 to 3 mm

(.079 to .118 in.) between the limit line and the end of

the brush holder.

TSB Revision

Page 464 of 738

Downloaded from www.Manualslib.com manuals search engine 16-18ENGINE ELECTRICAL - Charging System

Soldered

Limit line

&

mm

o L%4

-if

T

9EN0192

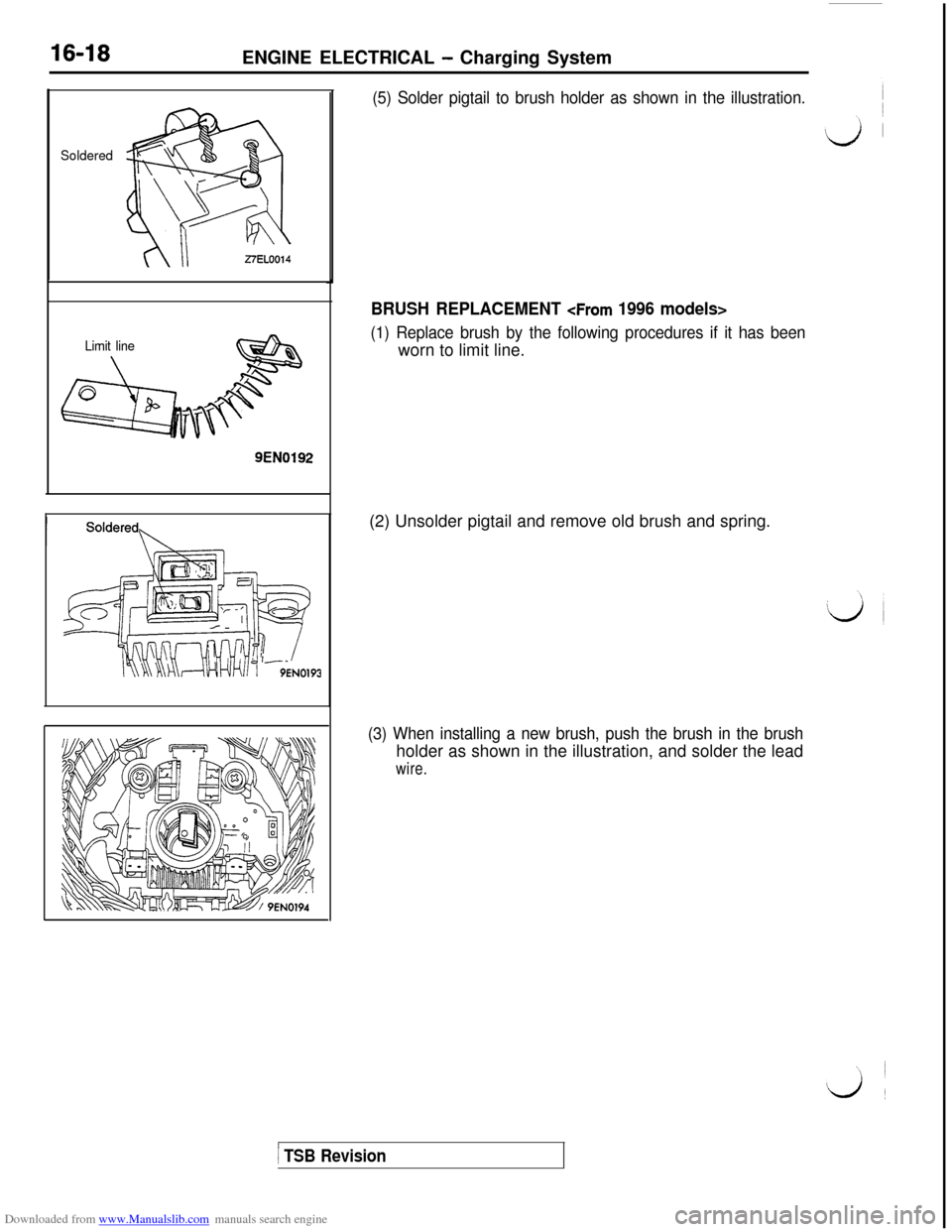

(5) Solder pigtail to brush holder as shown in the illustration.

BRUSH REPLACEMENT

(1) Replace brush by the following procedures if it has beenworn to limit line.

(2) Unsolder pigtail and remove old brush and spring.

(3) When installing a new brush, push the brush in the brushholder as shown in the illustration, and solder the lead

wire.

1 TSB Revision

Page 465 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-19

L/J

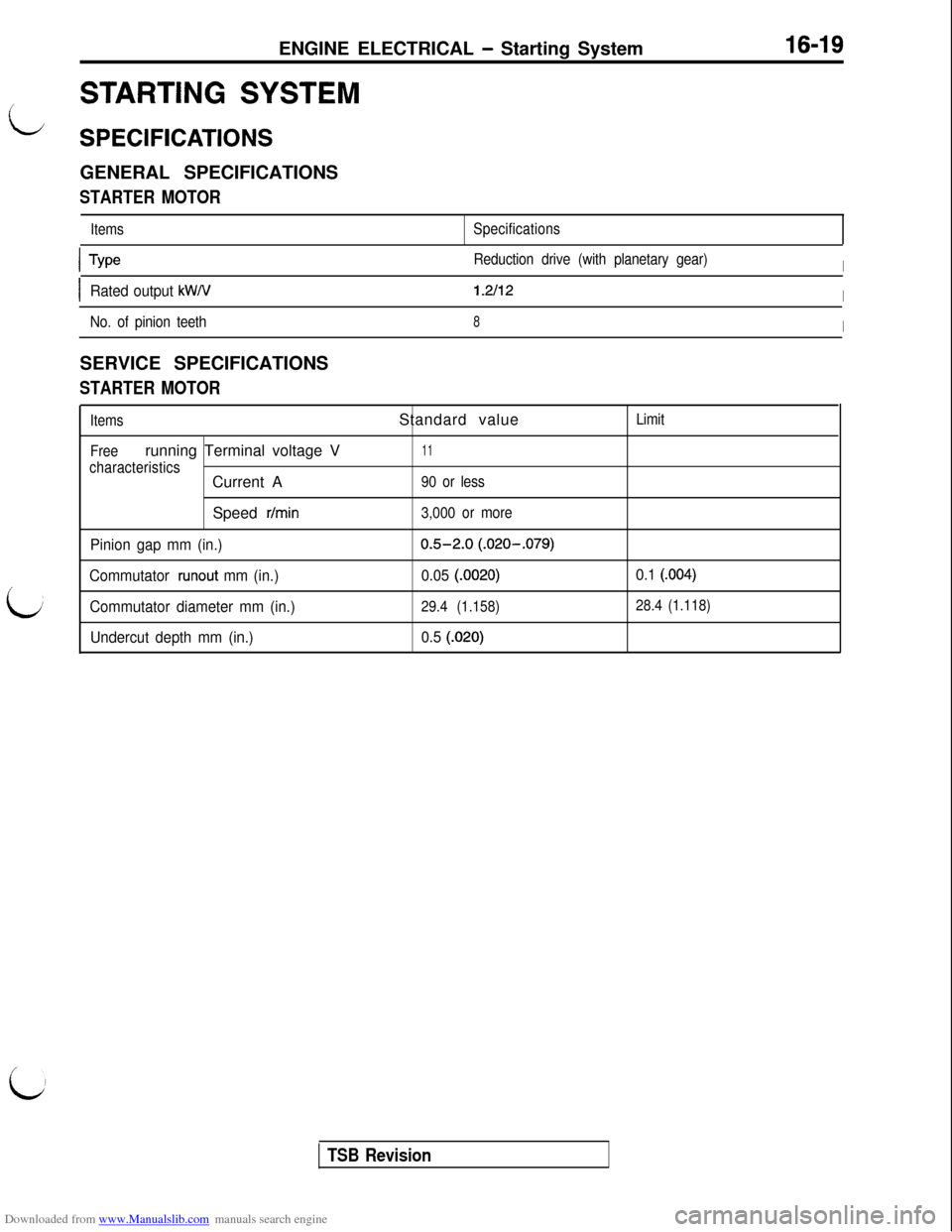

STARTING SYSTEM

SPECIFICATIONSGENERAL SPECIFICATIONS

STARTER MOTOR

ItemsSpecifications

L

ITypeReduction drive (with planetary gear)I

IRated output kW/V1.2112I

No. of pinion teeth8ISERVICE SPECIFICATIONS

STARTER MOTOR

Items

Freerunning Terminal voltage V

characteristicsCurrent A

Speed

r/min

Pinion gap mm (in.)

Commutator

runout mm (in.)

Commutator diameter mm (in.)

Undercut depth mm (in.)Standard value

11

90 or less

3,000 or more

0.5-2.0 (.020-.079)

0.05

(.0020)

29.4 (1.158)

0.5 (.020)Limit

0.1 (.004)

28.4 (1.118)

i

TSB Revision

Page 466 of 738

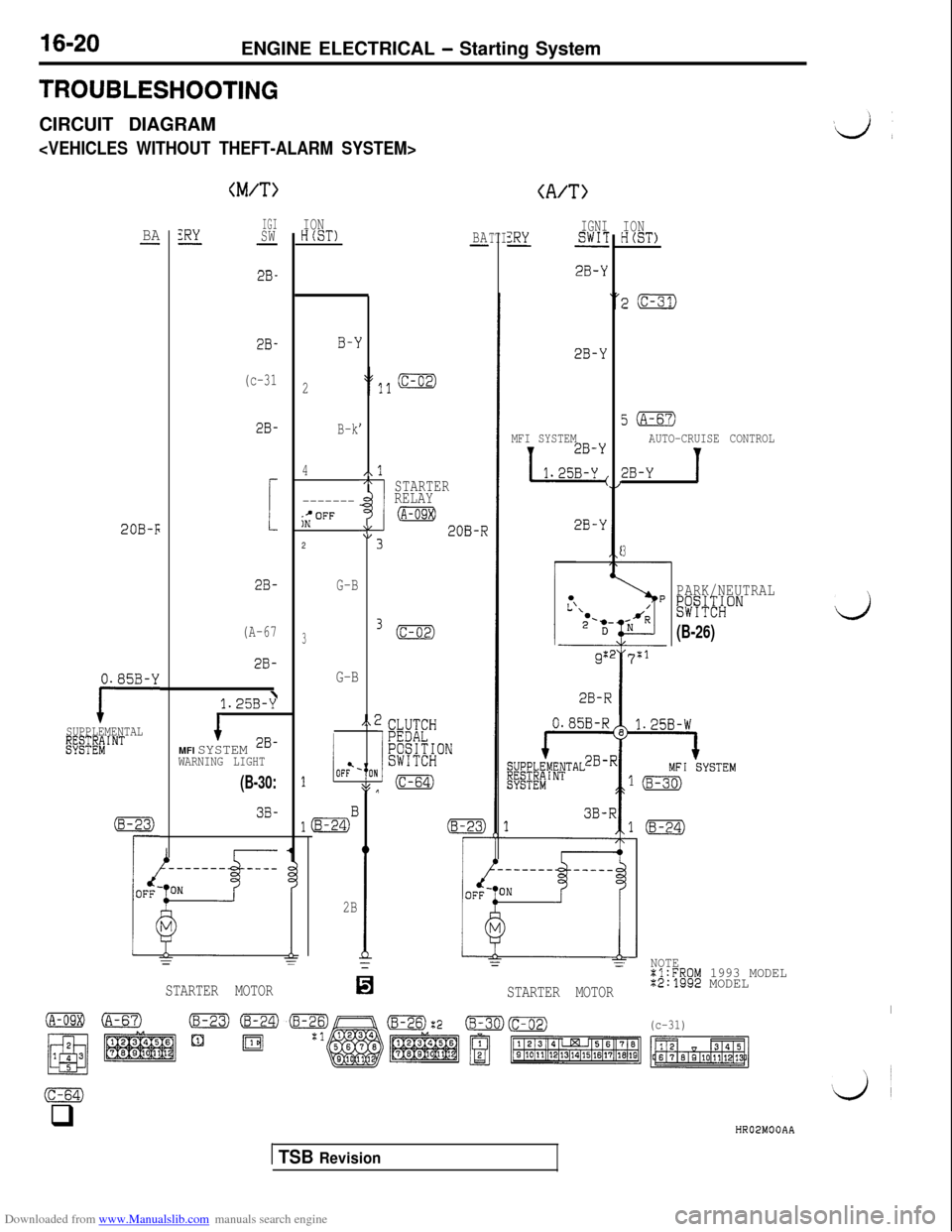

Downloaded from www.Manualslib.com manuals search engine 16-20ENGINE ELECTRICAL - Starting SystemTROUBLESHOOTING

CIRCUIT DIAGRAM

(M/T>(A/T>

IGISW-

2B-

2B-

(c-31

2B-

!

2B-

(A-67

2B-ION

HCST)IGNIZRYSWIT-

2B-Y

IONHCST)BAZRY--BA-TTI

B-1

2

B-k

4

-------;;OFF2

G-B

3

G-B

I

I

/\17rSTARTERRELAY

(A-09X)AL\I;20B-R

3.

,.;

,

8$J (c-64)

0I

2B-Y

5(A-67)

AUTO-CRUISE CONTROL

2B-Y 1

MFI SYSTEM

1 1.25y

2B-Y20B-F

3

PARK/NEUTRAL&~#ONij

(B-26)

g:27:1

i28-R

0.85B-Y

ISUPPLEMENTALgf;EEiINT

1.25B-y\

1MFI SYSTEM 2B-WARNING LIGHT

1iOF?-

lmB

2B

(B-30:

3B-(8-23)

rii------- ____

d

0

==

STARTER MOTOR

NOTE%l:FROM 1993 MODEL%2:1992 MODEL

I(c-31)

STARTER MOTOR

(c-64)q

HR02MOOAA

1 TSB Revision

Page 467 of 738

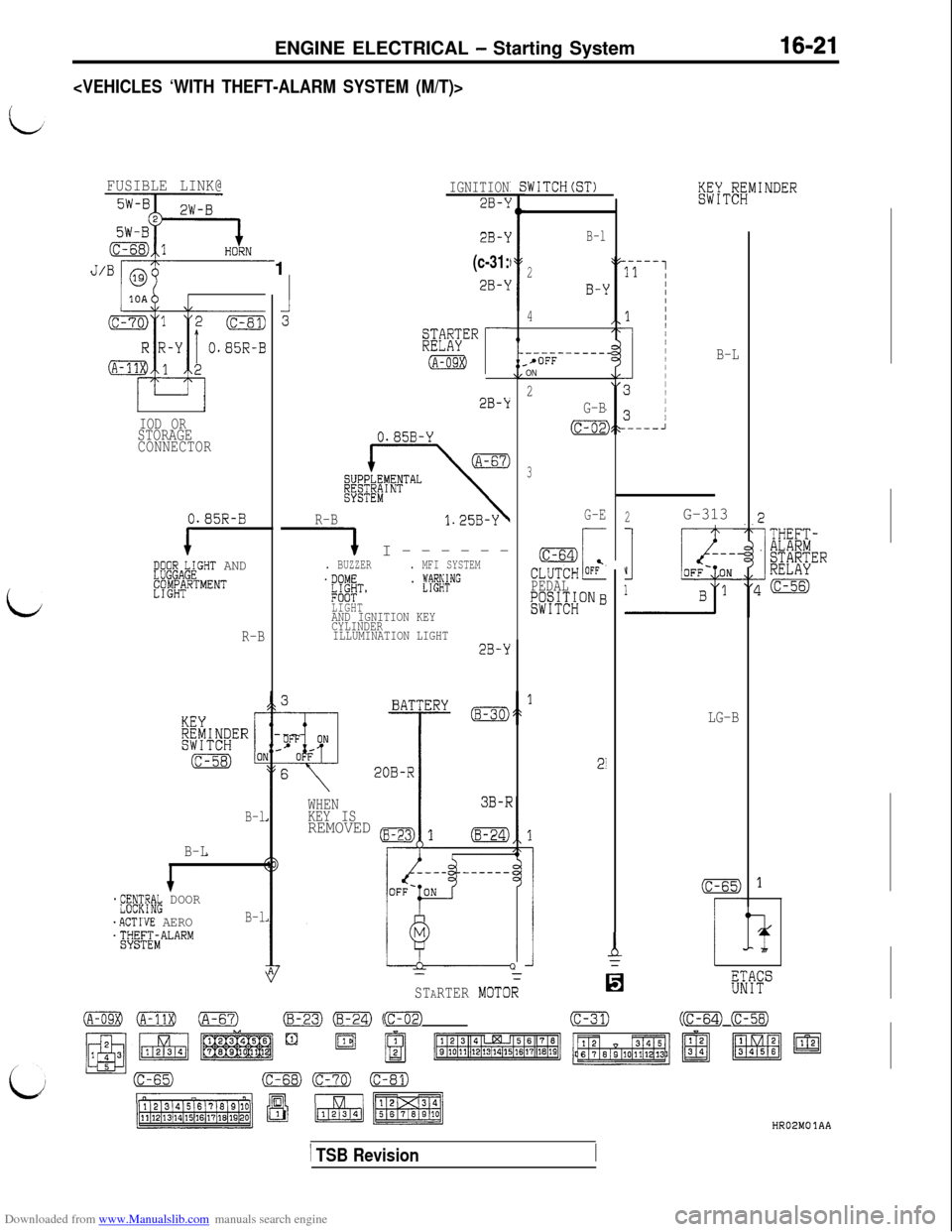

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-21

FUSIBLE LINK@

zJ==%~,

IGNITION

2B-k

iWITCH

B-L

B-l

2

B-j

4

2B-k1

(c-31:

2B-kJ/Br

rwER

(A-OSXII-

----------SrOFFON

2

G-B

(c-02

3

G-E

PEDAL&~#,;~ONB

28-k

IOD ORSTORAGE

CONNECTOR0.85B-Y

R-B

1 I------. BUZZER. MFI SYSTEM.DOME#T,. fl@+NG

LIGHT

AND IGNITION KEY

CYLINDER

ILLUMINATION LIGHT

2G-3130.85R-B

1E;$gAb;GHT AND

EW';RTMENT

i

R-B2B-Y

3B-F

20B-R

WHEN

KEY IS

REMOVED (B-23:

r-

'TE

!

LG-B

21Q

MOTOR

B-l

B-L-

*;~F$K& DOOR

.ACTWE AEROB-l

4EHE;iALARM

(c-65)

r

d

6

I

ms

(c-31)(c-56) (c-58)(c-64)

STARTER

mf3t7)(c-02)

HR02MOlAA

1 TSB Revision

Page 468 of 738

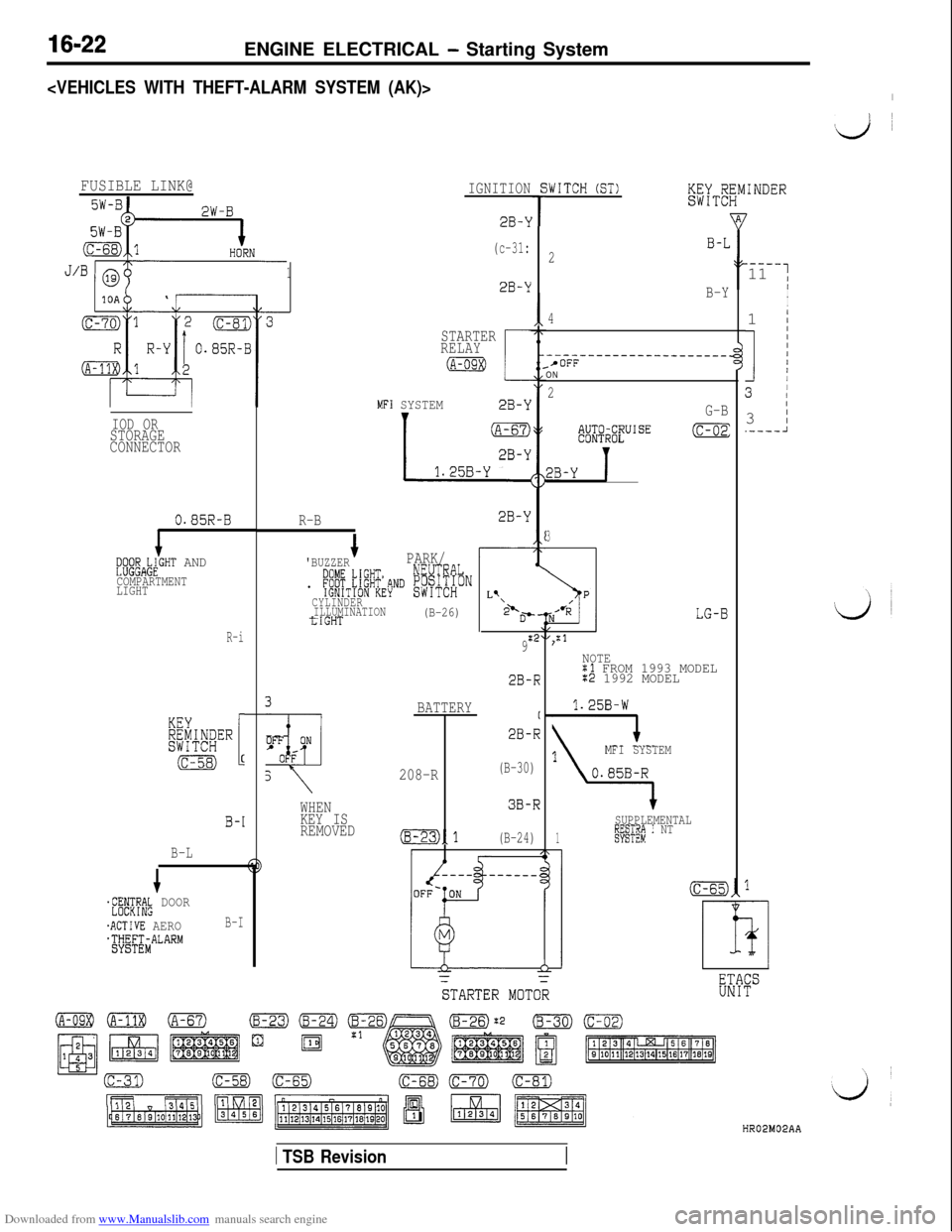

Downloaded from www.Manualslib.com manuals search engine 16-22ENGINE ELECTRICAL - Starting System

#d ~

FUSIBLE LINK@IGNITIONf

T2B-k

(c-31:

1

iWITCH (ST)

.----11 1II

I1

I

1 1

3 /3

I.----A 2

2B-Y

B-Y

4ISTARTER

RELAY

@liB

MFI SYSTEM2B-Y

--____----------------.-*OFFON

2

G-B

IOD OR

STORAGE

CONNECTOR32B~yg$!y”IsE (c-02:

O.a5R-BR-B2B-Y

eQsCIAk;GHT AND

COMPARTMENT

LIGHT

3

'BUZZERPARK/

. f~[f,\6[!?.+~~ [#~f#hI

CYLINDER

ILLUMINATION

tIGHT(B-26)

L’\2'D-'

9:2

r’”

,:1R-i

NOTEXl FROM 1993 MODEL:2 1992 MODEL

'l.25B-W

MFI SYSTEM

2B-R

BATTERY(

2B-R

208-R(B-30)

3B-R

(B-23)1(B-24)

SUPPLEMENTAL

1gEyL&E"i I NT

h

STARTER ~0~0: WHEN

KEY IS

REMOVED

B-1

B-L

$FRIW& DOOR

.ACTIVE AEROB-I

*TWF;~ALARM

HR02M02AA

1 TSB Revision

Page 469 of 738

Downloaded from www.Manualslib.com manuals search engine ENGINE ELECTRICAL - Starting System16-23

OPERATION

L

0For models equipped with the M/T, the clutch

pedal position switch contact is switched OFF

when the clutch pedal is depressed; when the

ignition switch is then switched to the “ST’ posi-tion, electricity flows to the starter relay and

the starter motor, the contact (magnetic switch)of the starter is switched ON and the starter

motor is activated.

NOTEIf the ignition switch is switched to the “ST

position without the clutch pedal being de-

pressed, electricity flows to the starter relay

(coil), the clutch pedal position switch (contacts)

and to ground, with the result that the contacts

of the starter relay are switched OFF, and, be-

cause the power to the starter motor is thereby

interrupted, the starter motor is not activated.lFor models equipped with the

AIT, when the

ignition switch is switched to the “ST’ position

while the selector lever is at the “P” or “N” posi-

tion, the contact (magnetic switch) of the starter

is switched ON and the starter motor is activated.

TROUBLESHOOTING HINTSThe starter motor does not operate at all.

l Check the starter (coil).

lCheck for poor contact at the battery terminals

and starter.l Check Park/Neutral position switch.

l Check clutch pedal position switch.

l Check starter relay.

l Check theft-alarm starter relay.

l Check key reminder switch.

i

/’

L&J

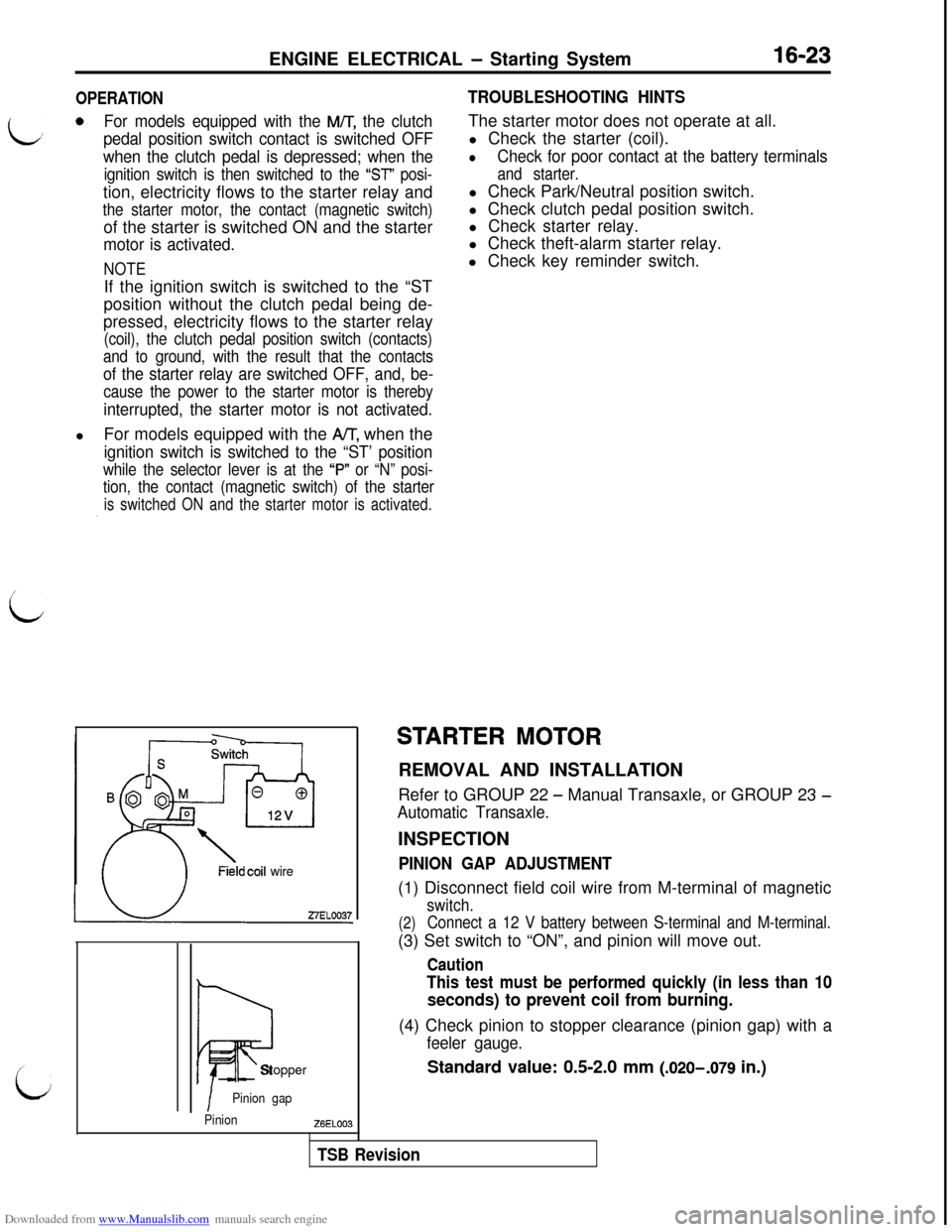

Fieldcoil wire

Iii?Stopper

IPinion gap

PinionZ6EL003

STARTER MOTORREMOVAL AND INSTALLATION

Refer to GROUP 22

- Manual Transaxle, or GROUP 23 -

Automatic Transaxle.INSPECTION

PINION GAP ADJUSTMENT(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)Connect a 12 V battery between S-terminal and M-terminal.(3) Set switch to “ON”, and pinion will move out.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(4) Check pinion to stopper clearance (pinion gap) with a

feeler gauge.

Standard value: 0.5-2.0 mm (.020-,079 in.)

TSB Revision

Page 470 of 738

Downloaded from www.Manualslib.com manuals search engine 16-24ENGINE ELECTRICAL - Starting System

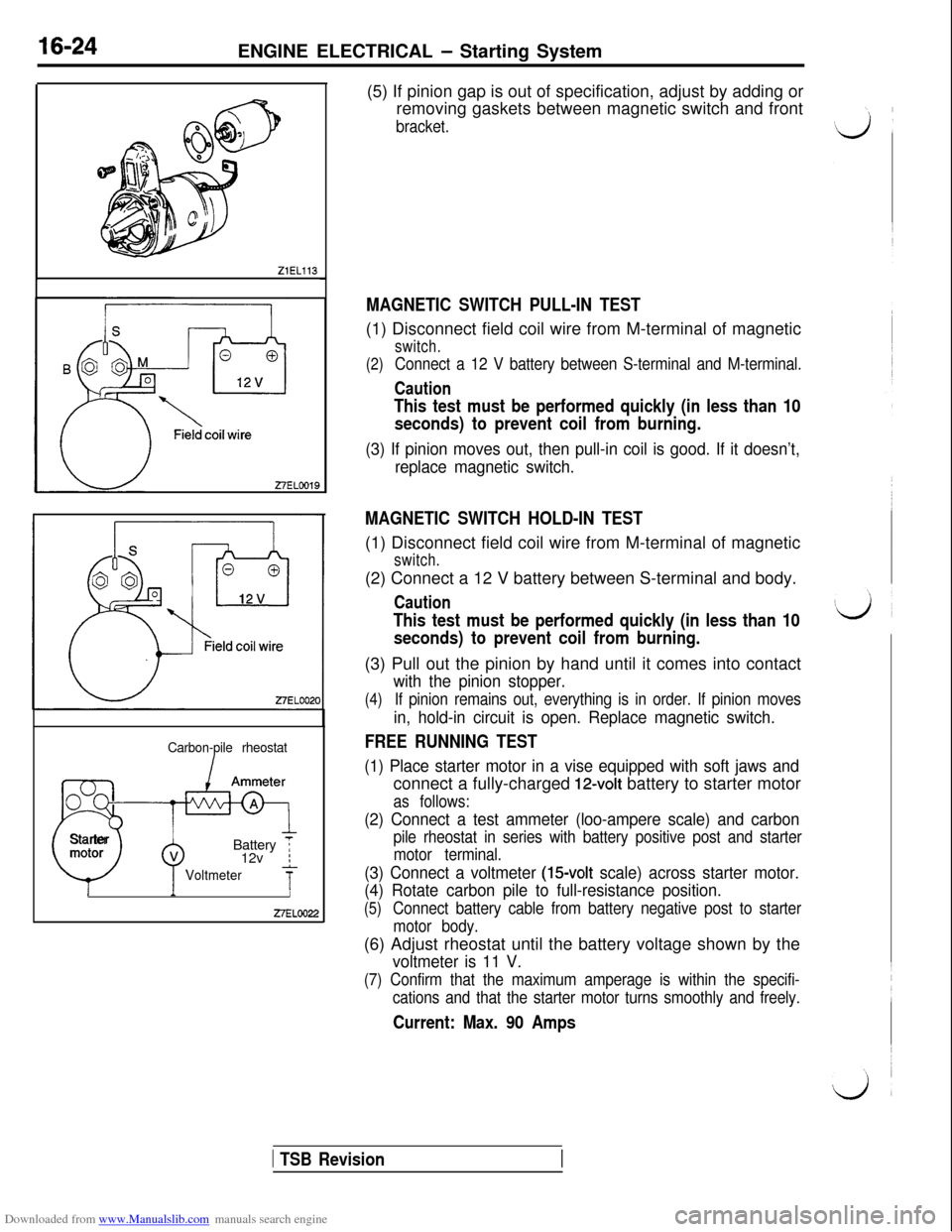

ZlEL11327ELOOlQ

0

5

Startermotor

Carbon-pile rheostat

-I-Battery

i12v I

Voltmeter7-II27ELOO22(5) If pinion gap is out of specification, adjust by adding or

removing gaskets between magnetic switch and front

bracket.

MAGNETIC SWITCH PULL-IN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.

(2)

Connect a 12 V battery between S-terminal and M-terminal.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.

(3) If pinion moves out, then pull-in coil is good. If it doesn’t,

replace magnetic switch.

MAGNETIC SWITCH HOLD-IN TEST(1) Disconnect field coil wire from M-terminal of magnetic

switch.(2) Connect a 12 V battery between S-terminal and body.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning.(3) Pull out the pinion by hand until it comes into contact

with the pinion stopper.

(4)If pinion remains out, everything is in order. If pinion moves

in, hold-in circuit is open. Replace magnetic switch.

FREE RUNNING TEST

(1) Place starter motor in a vise equipped with soft jaws andconnect a fully-charged

12-volt battery to starter motor

as follows:

(2) Connect a test ammeter (loo-ampere scale) and carbon

pile rheostat in series with battery positive post and starter

motor terminal.

(3) Connect a voltmeter (15volt scale) across starter motor.

(4) Rotate carbon pile to full-resistance position.

(5)Connect battery cable from battery negative post to starter

motor body.(6) Adjust rheostat until the battery voltage shown by the

voltmeter is 11 V.

(7) Confirm that the maximum amperage is within the specifi-

cations and that the starter motor turns smoothly and freely.

Current: Max. 90 Amps

1 TSB Revision