engine MITSUBISHI 3000GT 1992 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1992, Model line: 3000GT, Model: MITSUBISHI 3000GT 1992 2.GPages: 738, PDF Size: 35.06 MB

Page 521 of 738

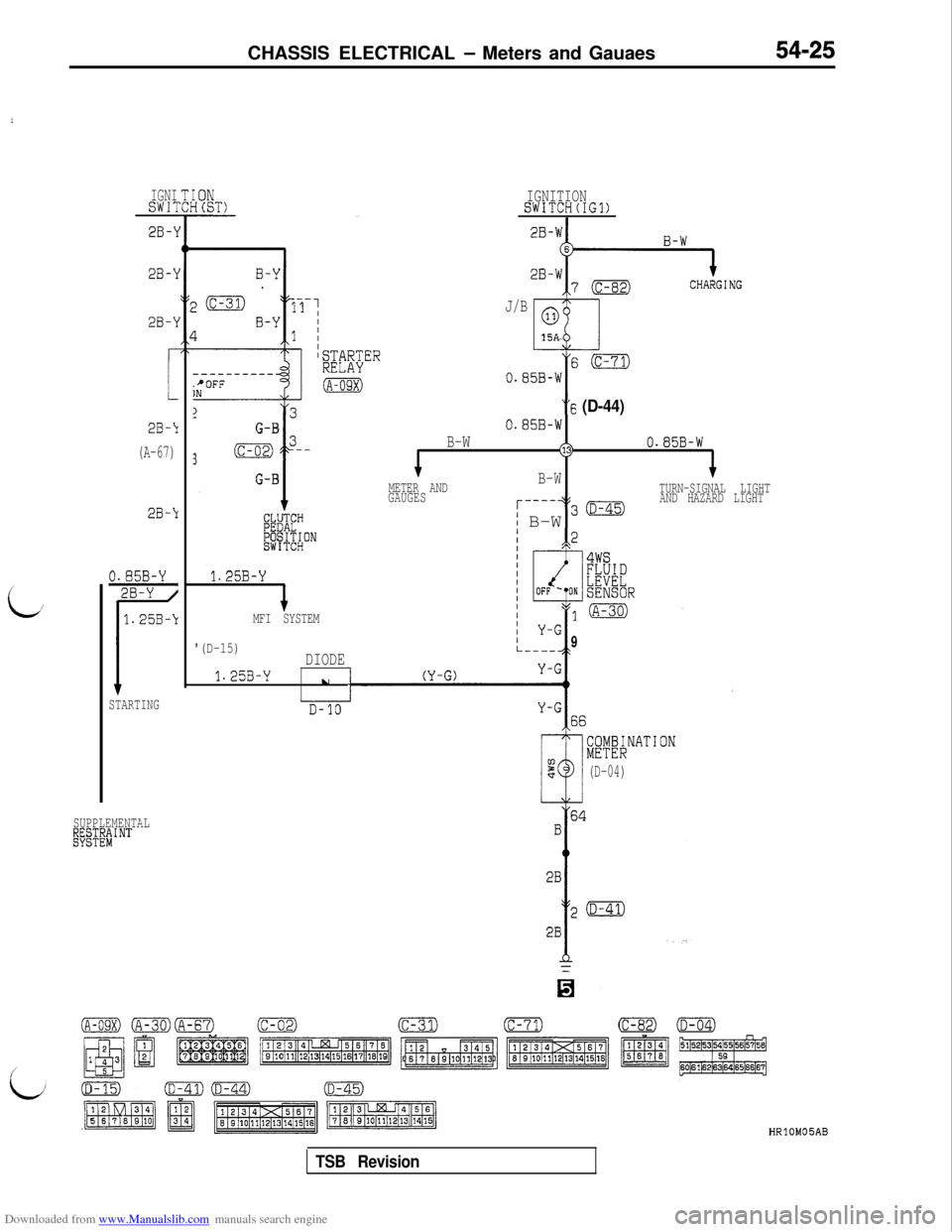

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauaes

i

L/

IGNISW17

2B-\1

28-l

2B-\I

2B-‘1

(A-67)

2B-Y

STARTING

SUPPLEMENTAL

~E~&~J$NT

----------.+OFFIN

13

i

G-B

3(c-02) 3--

G-B

1.25B-Y

+MFI SYSTEM

'(D-15)DIODE

1.25B-Yu

I

IGNITIONSWITCH(IG1)

J/B

ml

0

15A“6

(D-44)

0.85B-W

B-W(130.85B-W

METER AND

GAUGESB-WTURN-SIGNAL LIGHT

r----+$30AND HAZARD LIGHT

i B-W

9

i;yEKNATION

(D-04)

HRlOM05AB

TSB Revision

Page 522 of 738

Downloaded from www.Manualslib.com manuals search engine 54-26CHASSIS ELECTRICAL - Meters and Gauges

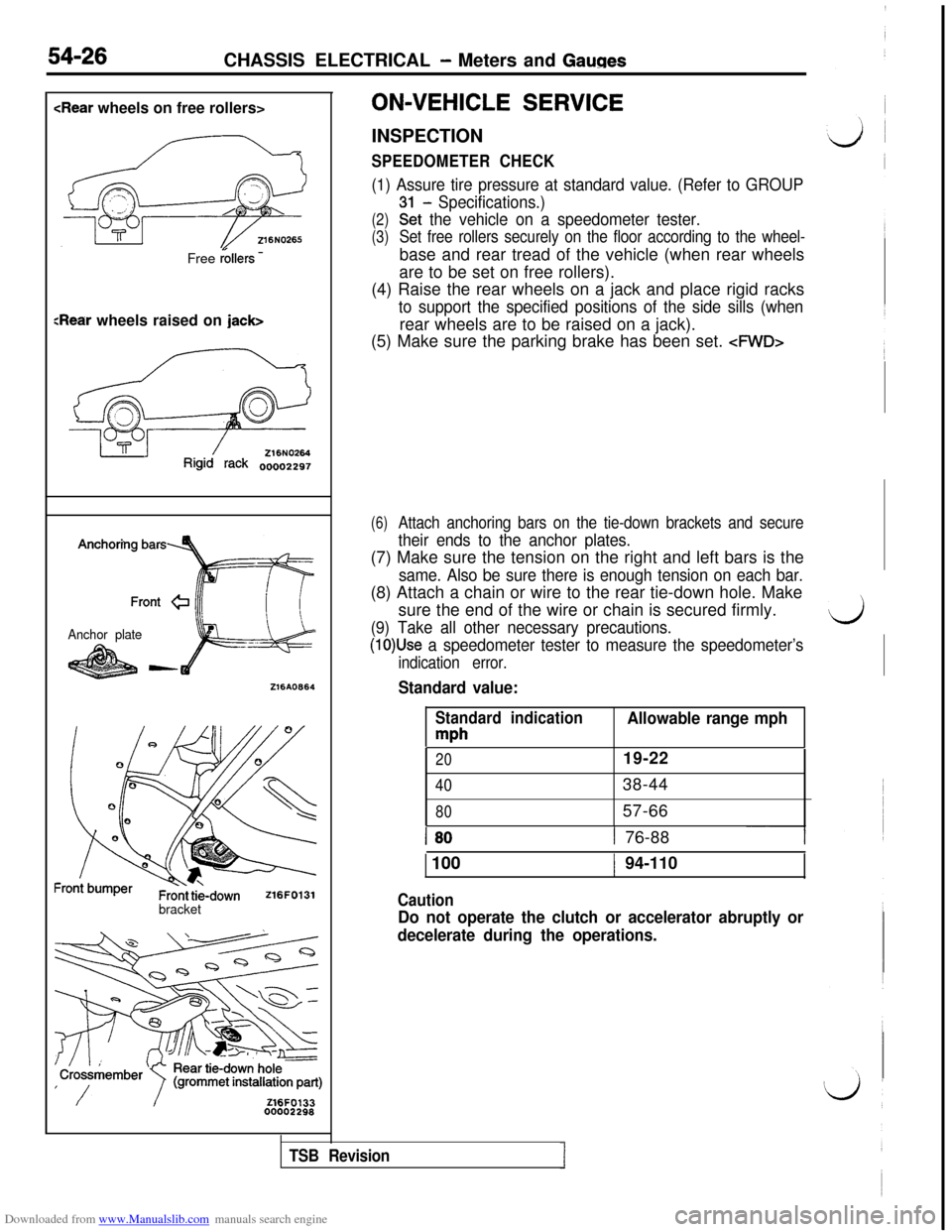

Free

r&Hers -

Sear wheels raised on jack>

?qi&%!g

Rigid rack oooo2297

Anchor plate

-w216AO864

bracket

/IZ16FO13300002298ON-VEHICLE

SERVICEINSPECTION

SPEEDOMETER CHECK

(1) Assure tire pressure at standard value. (Refer to GROUP

- Specifications.)

(2)Gt the vehicle on a speedometer tester.

(3)Set free rollers securely on the floor according to the wheel-base and rear tread of the vehicle (when rear wheels

are to be set on free rollers).

(4) Raise the rear wheels on a jack and place rigid racks

to support the specified positions of the side sills (whenrear wheels are to be raised on a jack).

(5) Make sure the parking brake has been set.

cPWD>

(6)Attach anchoring bars on the tie-down brackets and secure

their ends to the anchor plates.(7) Make sure the tension on the right and left bars is the

same. Also be sure there is enough tension on each bar.(8) Attach a chain or wire to the rear tie-down hole. Make

sure the end of the wire or chain is secured firmly.

(9) Take all other necessary precautions.

(1O)Use a speedometer tester to measure the speedometer’s

indication error.

Standard value:

Standard indication

mph

Allowable range mph

2019-22

4038-44

8057-66

1 801 76-88--I

1 100

Caution

1 94-110

Do not operate the clutch or accelerator abruptly or

decelerate during the operations.

d

TSB Revision

Page 523 of 738

Downloaded from www.Manualslib.com manuals search engine I,;CHASSIS ELECTRICAL

- Meters and Gauges54-27

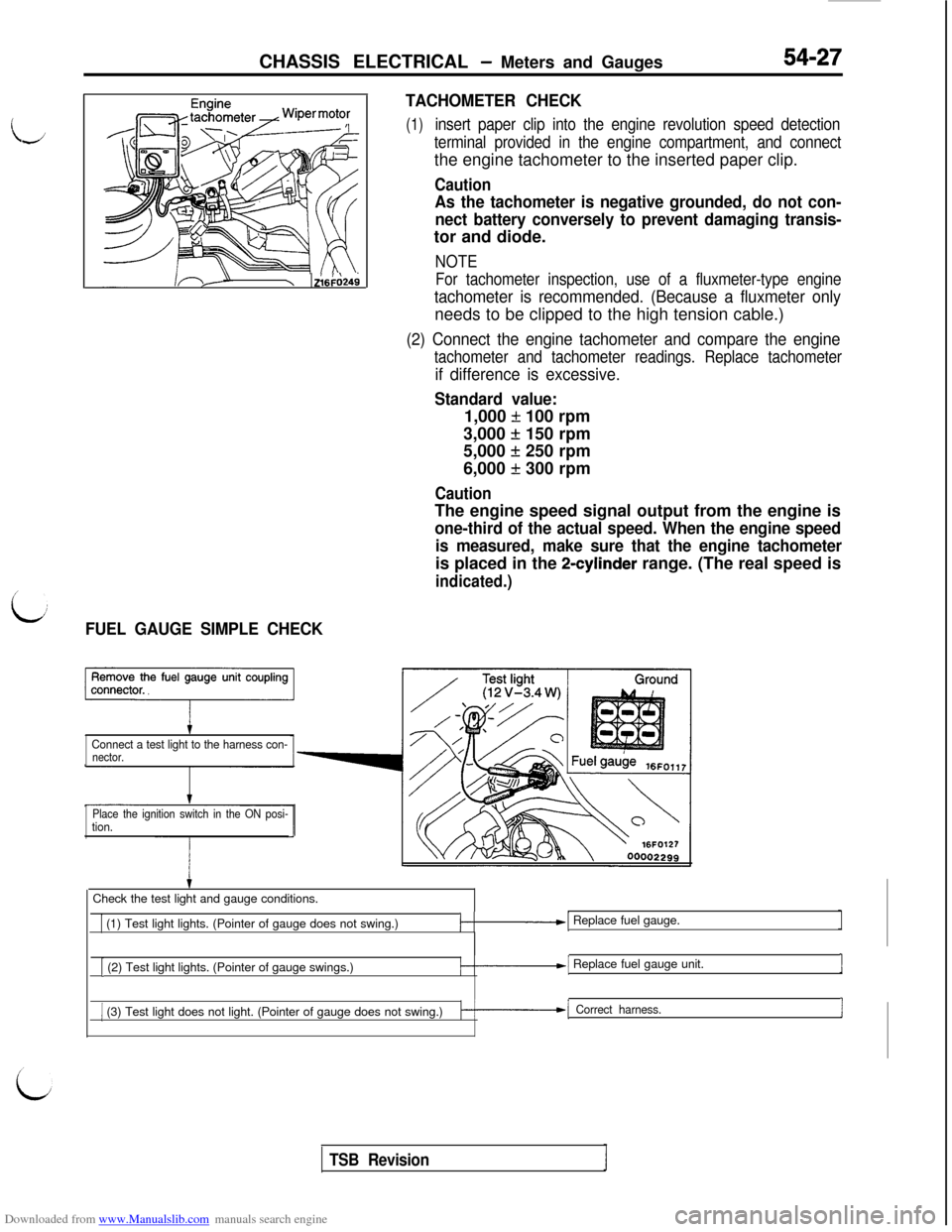

c I\\ zl6F024;

L:FUEL GAUGE SIMPLE CHECKTACHOMETER CHECK

(1)insert paper clip into the engine revolution speed detection

terminal provided in the engine compartment, and connectthe engine tachometer to the inserted paper clip.

Caution

As the tachometer is negative grounded, do not con-

nect battery conversely to prevent damaging transis-tor and diode.

NOTE

For tachometer inspection, use of a fluxmeter-type engine

tachometer is recommended. (Because a fluxmeter onlyneeds to be clipped to the high tension cable.)

(2) Connect the engine tachometer and compare the engine

tachometer and tachometer readings. Replace tachometer

if difference is excessive.

Standard value:1,000

f 100 rpm

3,000

+ 150 rpm

5,000

f 250 rpm

6,000

f 300 rpm

CautionThe engine speed signal output from the engine is

one-third of the actual speed. When the engine speed

is measured, make sure that the engine tachometeris placed in the

2-cylinder range. (The real speed is

indicated.)

Connect a test light to the harness con-nector.

Place the ignition switch in the ON posi-

tion.Check the test light and gauge conditions.

1 (1) Test light lights. (Pointer of gauge does not swing.)/-.-I Replace fuel gauge.

[ (2) Test light lights. (Pointer of gauge swings.)/-.--I Replace fuel gauge unit.1

1 (3) Test light does not light. (Pointer of gauge does not swing.)k-1 Correct harness.I

TSB Revision

Page 524 of 738

Downloaded from www.Manualslib.com manuals search engine 54-28CHASSIS ELECTRICAL - Meters and Gauges

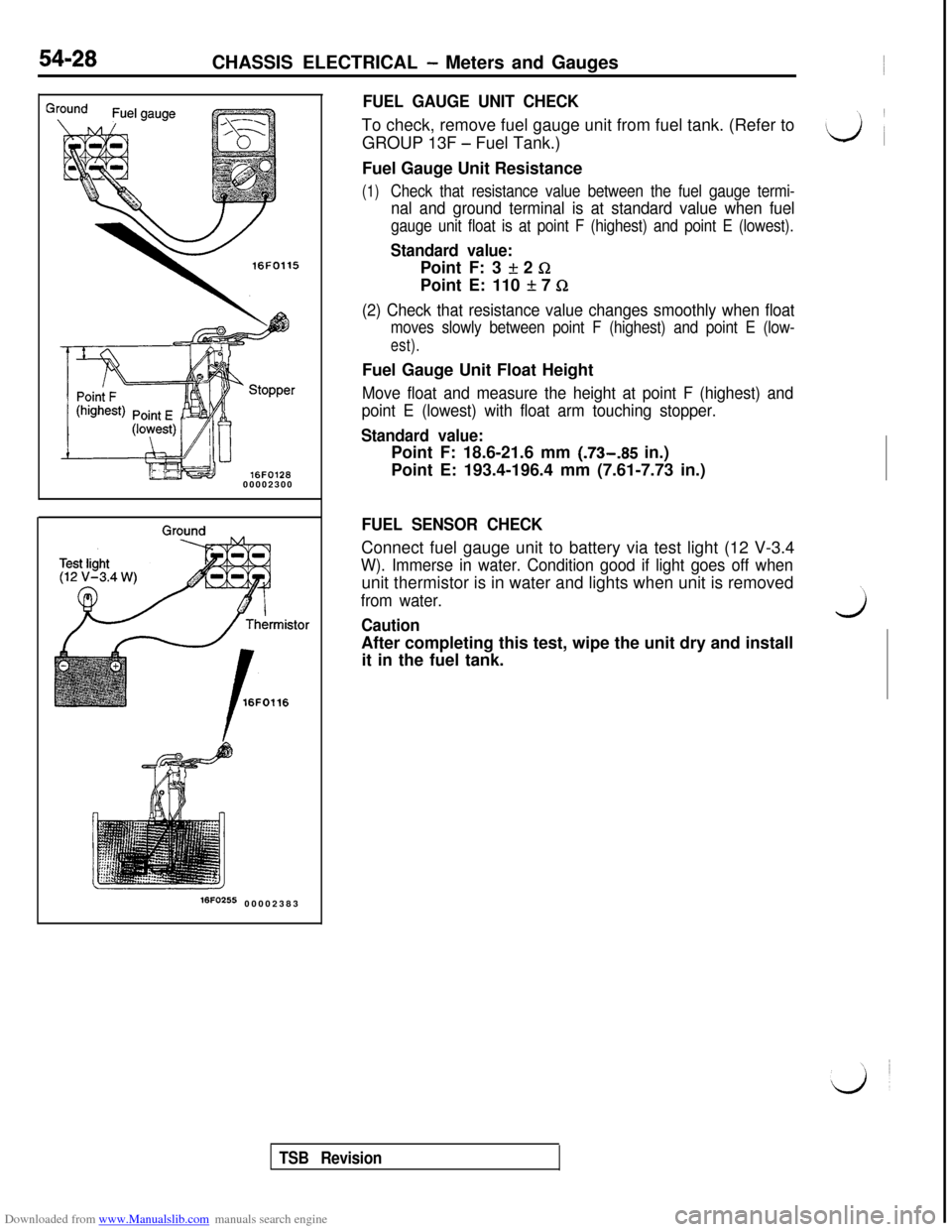

16FO11500002300

16Fo255 00002383

FUEL GAUGE UNIT CHECKTo check, remove fuel gauge unit from fuel tank. (Refer to

GROUP 13F

- Fuel Tank.)

Fuel Gauge Unit Resistance

(1)Check that resistance value between the fuel gauge termi-

nal and ground terminal is at standard value when fuel

gauge unit float is at point F (highest) and point E (lowest).

Standard value:Point F: 3

If: 2 GPoint E: 110

It 7 Q

(2) Check that resistance value changes smoothly when float

moves slowly between point F (highest) and point E (low-

est).Fuel Gauge Unit Float Height

Move float and measure the height at point F (highest) and

point E (lowest) with float arm touching stopper.

Standard value:Point F: 18.6-21.6 mm (.73-.85 in.)

Point E: 193.4-196.4 mm (7.61-7.73 in.)

FUEL SENSOR CHECKConnect fuel gauge unit to battery via test light (12 V-3.4

W). Immerse in water. Condition good if light goes off whenunit thermistor is in water and lights when unit is removed

from water.

CautionwAfter completing this test, wipe the unit dry and install

it in the fuel tank.

TSB Revision

Page 525 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauaes

i

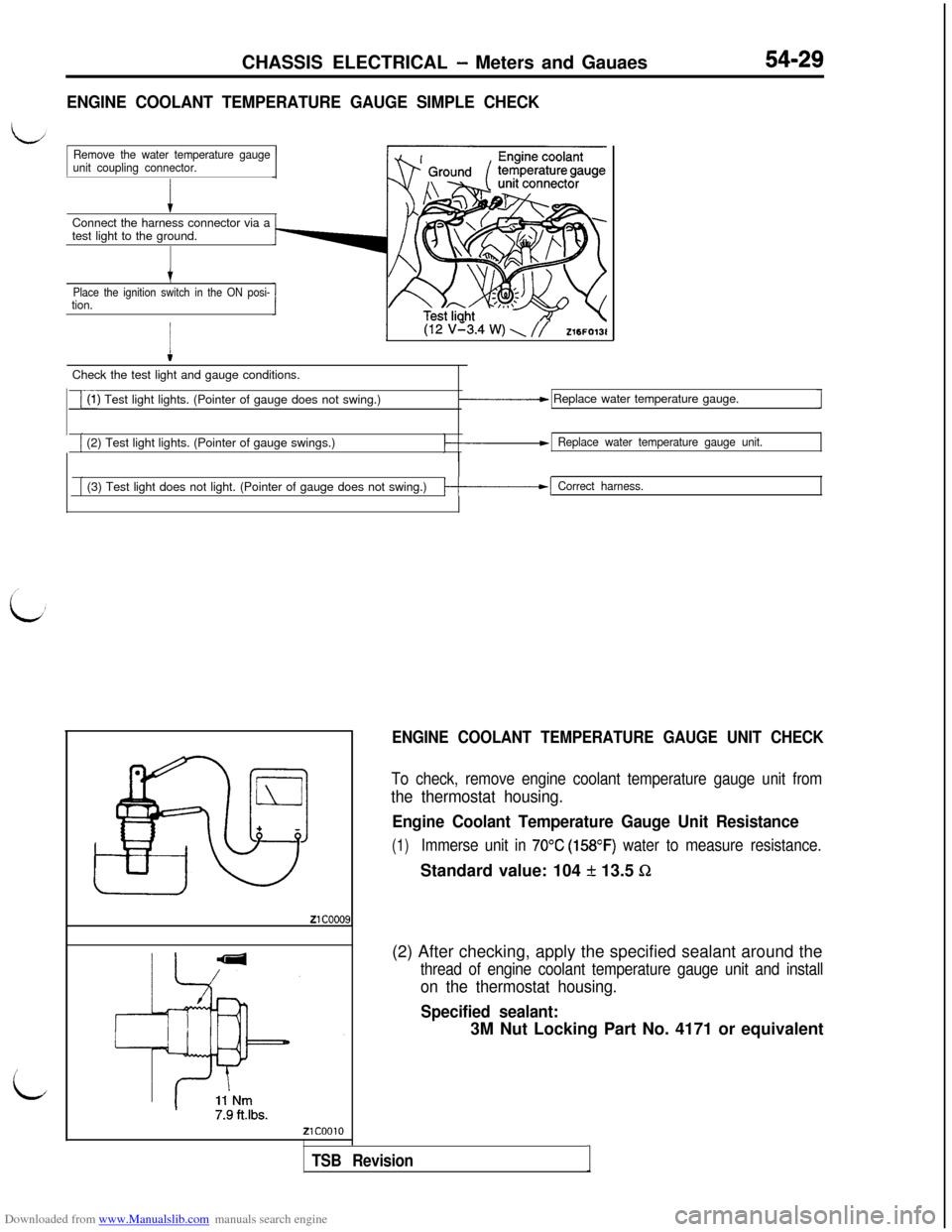

ENGINE COOLANT TEMPERATURE GAUGE SIMPLE CHECKConnect the harness connector via a

test light to the ground.

Remove the water temperature gauge

unit coupling connector.

t

Place the ignition switch in the ON posi-tion.

I

(12 v’3.4 w) \ //Z16FO13lCheck the test light and gauge conditions.

i(1) Test light lights. (Pointer of gauge does not swing.)_____c Replace water temperature gauge.

[ (2) Test light lights. (Pointer of gauge swings.)Replace water temperature gauge unit.

[ (3) Test light does not light. (Pointer of gauge does not swing.)/-------I Correct harness.

ENGINE COOLANT TEMPERATURE GAUGE UNIT CHECK

To check, remove engine coolant temperature gauge unit from

the thermostat housing.

Engine Coolant Temperature Gauge Unit Resistance

(1)Immerse unit in 70°C (158OF) water to measure resistance.Standard value: 104

f 13.5 Sz(2) After checking, apply the specified sealant around the

thread of engine coolant temperature gauge unit and install

on the thermostat housing.

Specified sealant:3M Nut Locking Part No. 4171 or equivalent

TSB RevisionI

Page 526 of 738

Downloaded from www.Manualslib.com manuals search engine 54-30CHASSIS ELECTRICAL - Meters and Gauges

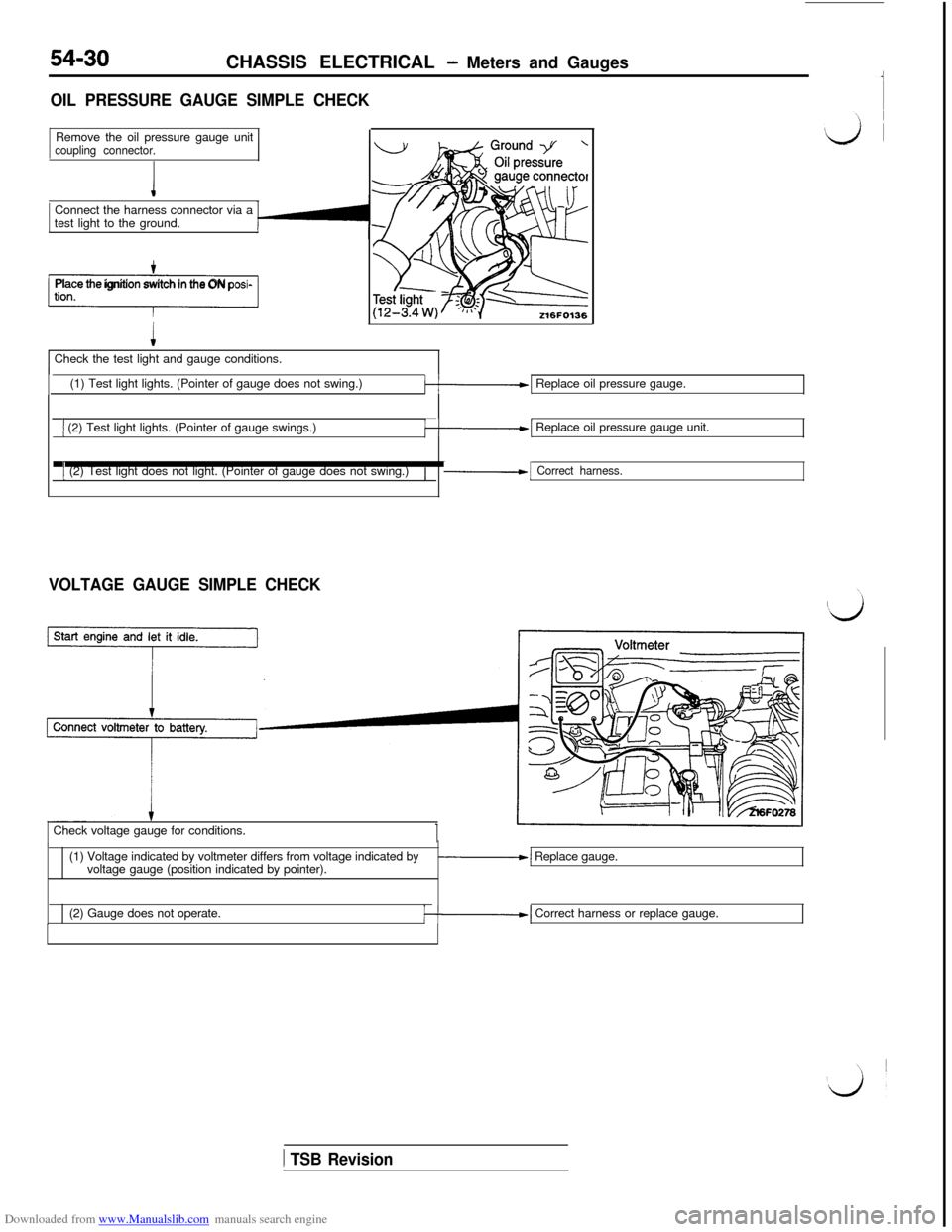

OIL PRESSURE GAUGE SIMPLE CHECKRemove the oil pressure gauge unit

coupling connector.Connect the harness connector via a

test light to the ground.

-1Place the ignition switch in the ON posi-Check the test light and gauge conditions.

(1) Test light lights. (Pointer of gauge does not swing.)

k-1 Replace oil pressure gauge.

1 (2) Test light lights. (Pointer of gauge swings.)k-1 Replace oil pressure gauge unit.

1 (2) Test light does not light. (Pointer of gauge does not swing.)/-1 Correct harness.

VOLTAGE GAUGE SIMPLE CHECKCheck voltage gauge for conditions.

(1) Voltage indicated by voltmeter differs from voltage indicated by

voltage gauge (position indicated by pointer).

-1 Replace gauge.

(2) Gauge does not operate.

/--I Correct harness or replace gauge.

1 TSB Revision

Page 527 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges54-31

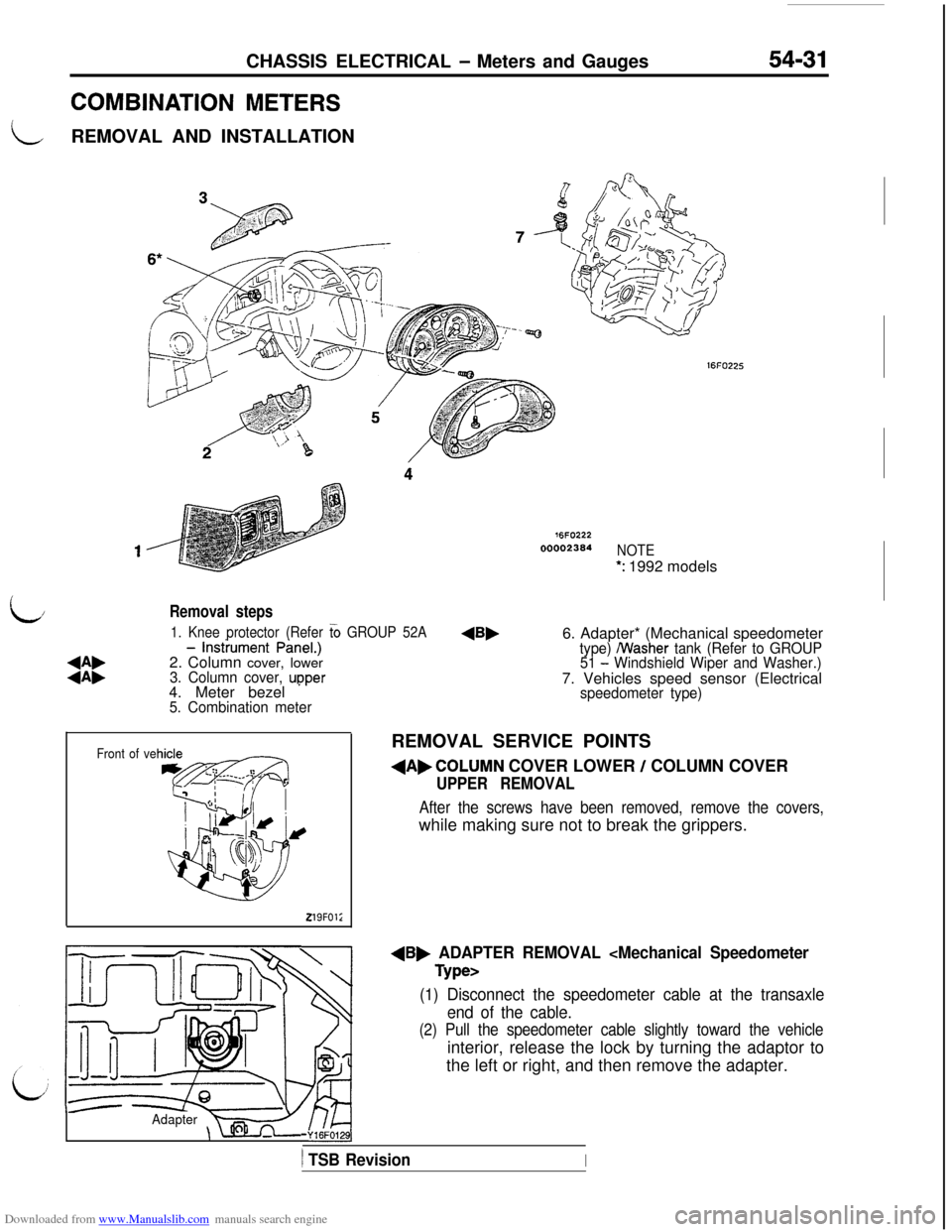

COMBINATION METERS

LREMOVAL AND INSTALLATION

76FO22200002364

NOTE

*: 1992 models

L/

:i:

- lnstiument PineI.)

2. Column cover, lower

3. Column cover, upper 1. Knee protector (Refer

G GROUP 52A4. Meter bezel

* ’5. Combination meter

Removal steps6. Adapter* (Mechanical speedometer

type) /Washer tank (Refer to GROUP

51 - Windshield Wiper and Washer.)7. Vehicles speed sensor (Electrical

Front of ve

219FOl;

speedometer type)REMOVAL SERVICE POINTS

dAbCOLUMN COVER LOWER / COLUMN COVER

UPPER REMOVAL

After the screws have been removed, remove the covers,while making sure not to break the grippers.

dB, ADAPTER REMOVAL

(1) Disconnect the speedometer cable at the transaxle

end of the cable.

(2) Pull the speedometer cable slightly toward the vehicleinterior, release the lock by turning the adaptor to

the left or right, and then remove the adapter.

Adapter-Y16FO129],

) TSB RevisionI

Page 528 of 738

Downloaded from www.Manualslib.com manuals search engine 54-32CHASSIS ELECTRICAL - Meters and Gauges

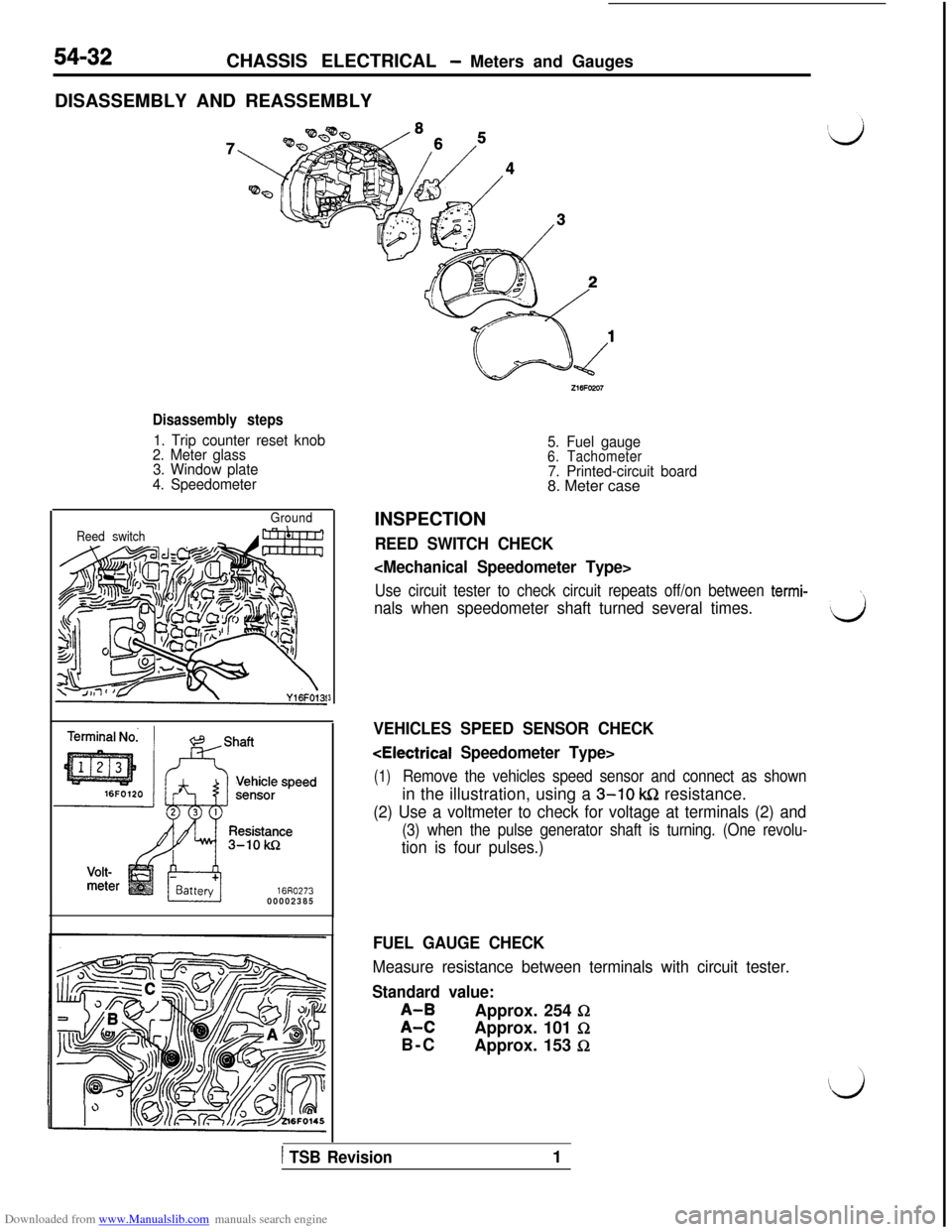

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1. Trip counter reset knob

2. Meter glass

3. Window plate

4. Speedometer

Ground

Reed switch

16R027300002385

3

5. Fuel gauge6. Tachometer7. Printed-circuit board8. Meter case

INSPECTION

REED SWITCH CHECK

Use circuit tester to check circuit repeats off/on between termi-\

nals when speedometer shaft turned several times.d

VEHICLES SPEED SENSOR CHECK

(1)Remove the vehicles speed sensor and connect as shownin the illustration, using a

3-10 k&2 resistance.

(2) Use a voltmeter to check for voltage at terminals (2) and

(3) when the pulse generator shaft is turning. (One revolu-

tion is four pulses.)

FUEL GAUGE CHECK

Measure resistance between terminals with circuit tester.

Standard value:

;I;Approx. 254 0Approx. 101

I2B-C

Approx. 153

fi

1 TSB Revision1

Page 529 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Meters and Gauges

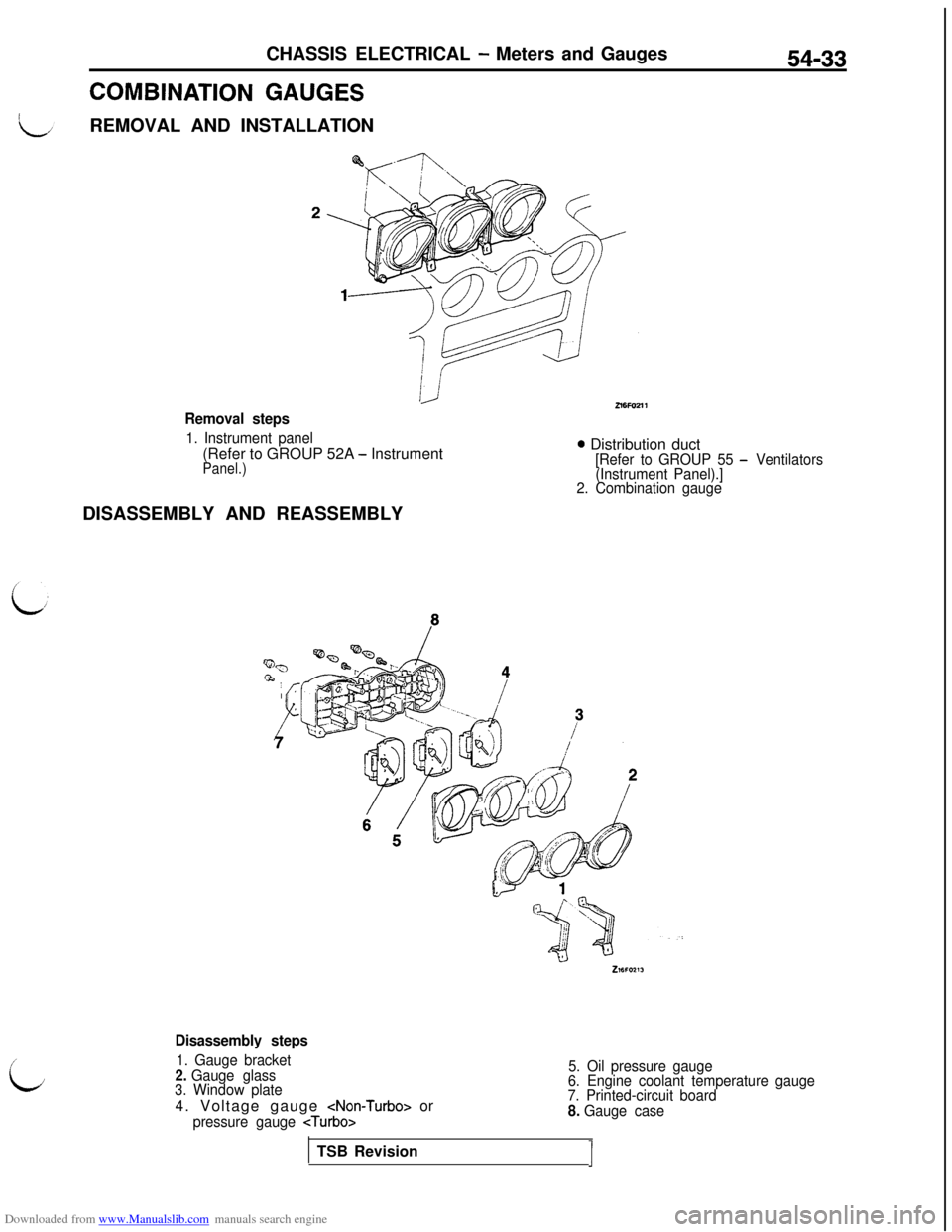

COMBINATION GAUGESREMOVAL AND INSTALLATION

54-33

Removal steps

1. Instrument panel(Refer to GROUP 52A

- InstrumentPanel.)

0 Distribution duct[Refer to GROUP 55 - Ventilators

(Instrument Panel).]

2. Combination gaugeDISASSEMBLY AND REASSEMBLY

i;

Disassembly steps

1. Gauge bracket2. Gauge glass

3. Window plate4. Voltage gauge

pressure gauge

5. Oil pressure gauge

6. Engine coolant temperature gauge

7. Printed-circuit board

8. Gauge caseTSB Revision

J

Page 530 of 738

Downloaded from www.Manualslib.com manuals search engine 54-34CHASSIS ELECTRICAL - Meters and Gauges216FO14C

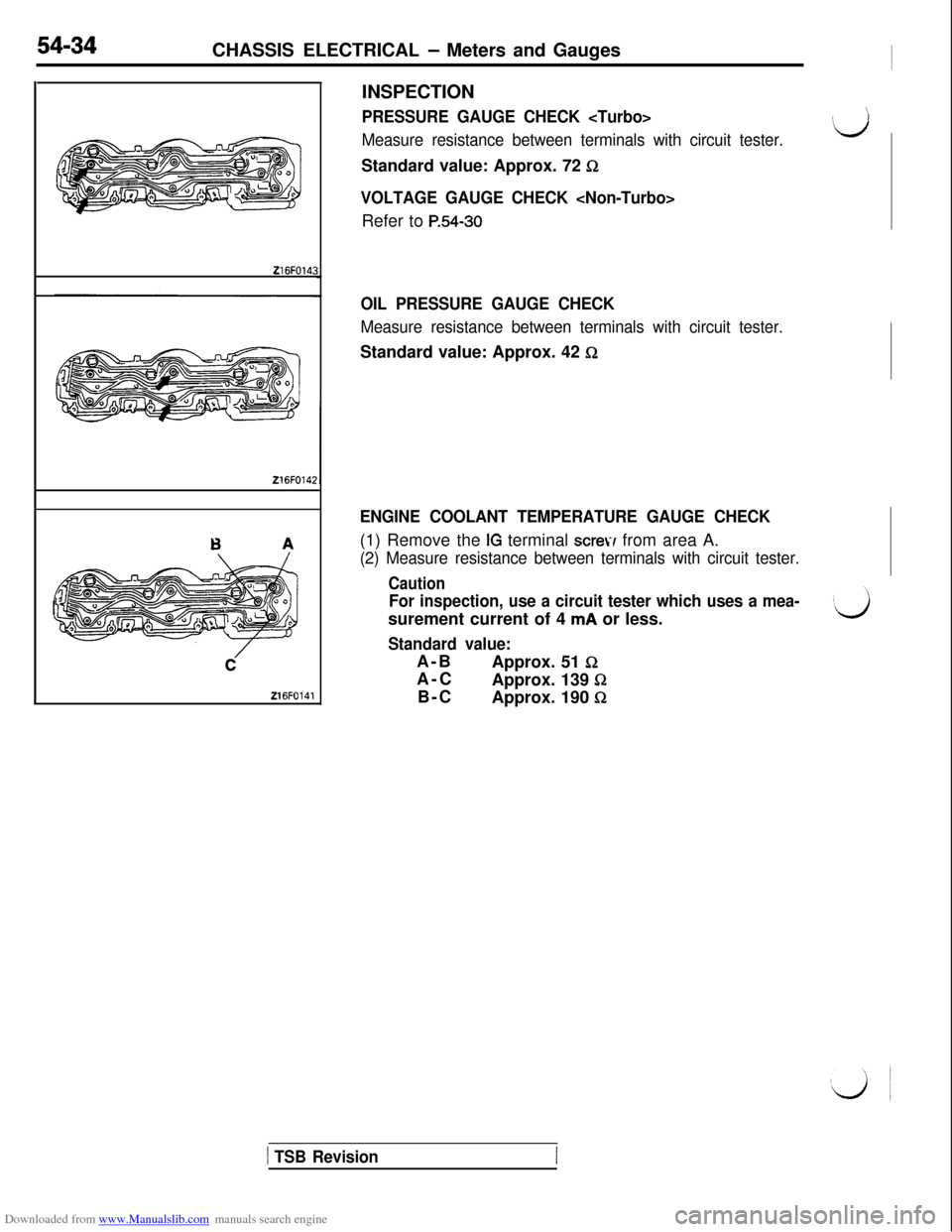

216FO14:216FO141INSPECTION

PRESSURE GAUGE CHECK

Measure resistance between terminals with circuit tester.Standard value: Approx. 72

&2

VOLTAGE GAUGE CHECK

P.54-30

OIL PRESSURE GAUGE CHECK

Measure resistance between terminals with circuit tester.Standard value: Approx. 42

Q

ENGINE COOLANT TEMPERATURE GAUGE CHECK(1) Remove the

IG terminal scre\;/ from area A.

(2) Measure resistance between terminals with circuit tester.

Caution

For inspection, use a circuit tester which uses a mea-surement current of 4

mA or less.

Standard value:A-B

Approx. 51

SzA-C

Approx. 139

QB-C

Approx. 190

R

1 TSB Revision