SPEED MITSUBISHI 380 2005 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1319 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-40

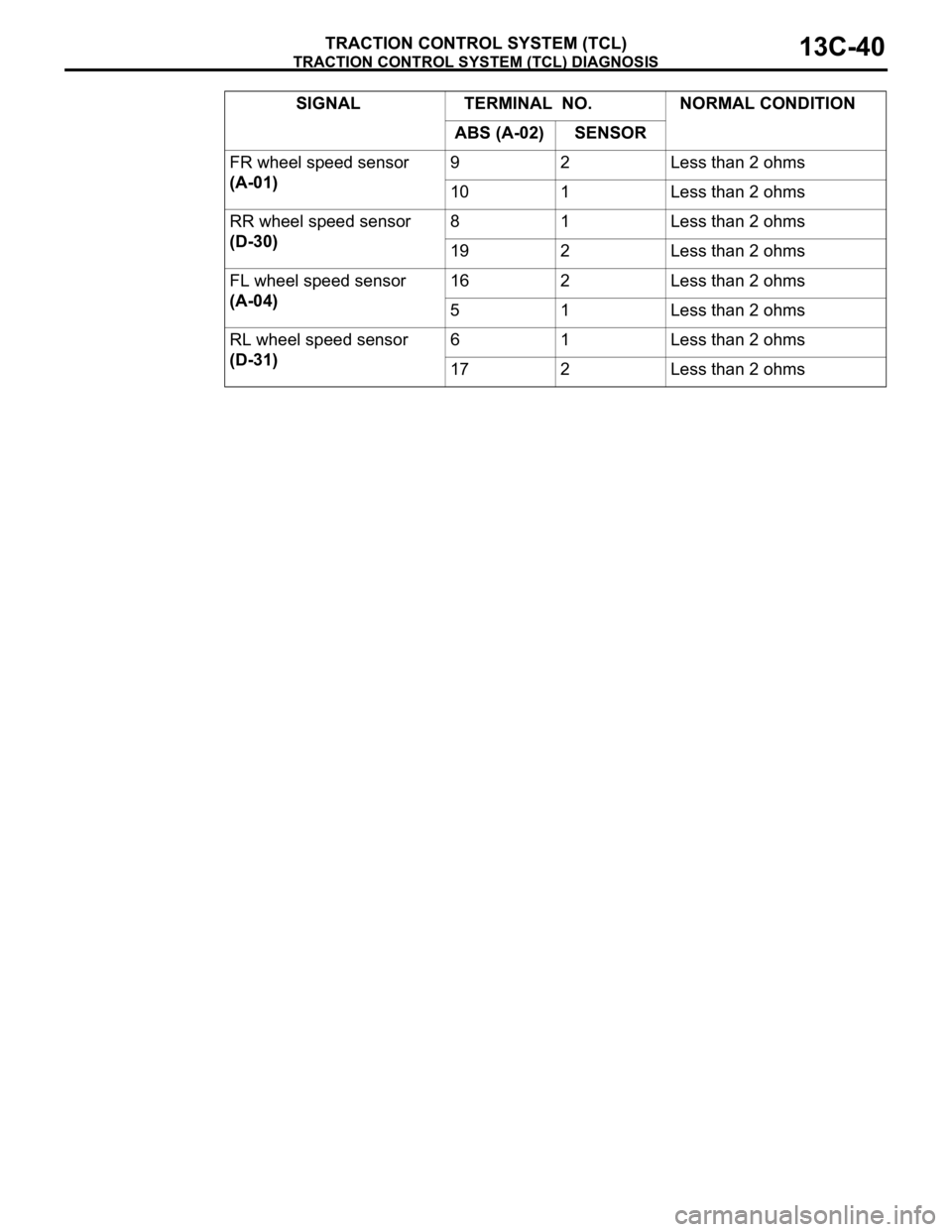

SIGNAL TERMINAL NO. NORMAL CONDITION

ABS (A-02) SENSOR

FR wheel speed sensor

(A-01)9 2 Less than 2 ohms

10 1 Less than 2 ohms

RR wheel speed sensor

(D-30)8 1 Less than 2 ohms

19 2 Less than 2 ohms

FL wheel speed sensor

(A-04)16 2 Less than 2 ohms

5 1 Less than 2 ohms

RL wheel speed sensor

(D-31)6 1 Less than 2 ohms

17 2 Less than 2 ohms

Page 1320 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-41

VOLTAGE AND SIGNAL CHECK AT ABS-ECU

(A-02) USING OSCILLOSCOPE

NOTE: If the ABS-8 ECU or the active wheel speed

sensor are disconnected, or if the wiring is an open/

short circuit, the ABS 8 ECU will shut off power sup-

ply to the respective wheel speed sensor. All other

wheel speed sensors will operate normally. To

restore the power supply, the ignition switch must be

turned to the "OFF" position then to the "ON" position

again..

WHEEL SPEED SENSOR AIR GAP:

Sensor air gap: (0.2mm - 0.85mm).

.

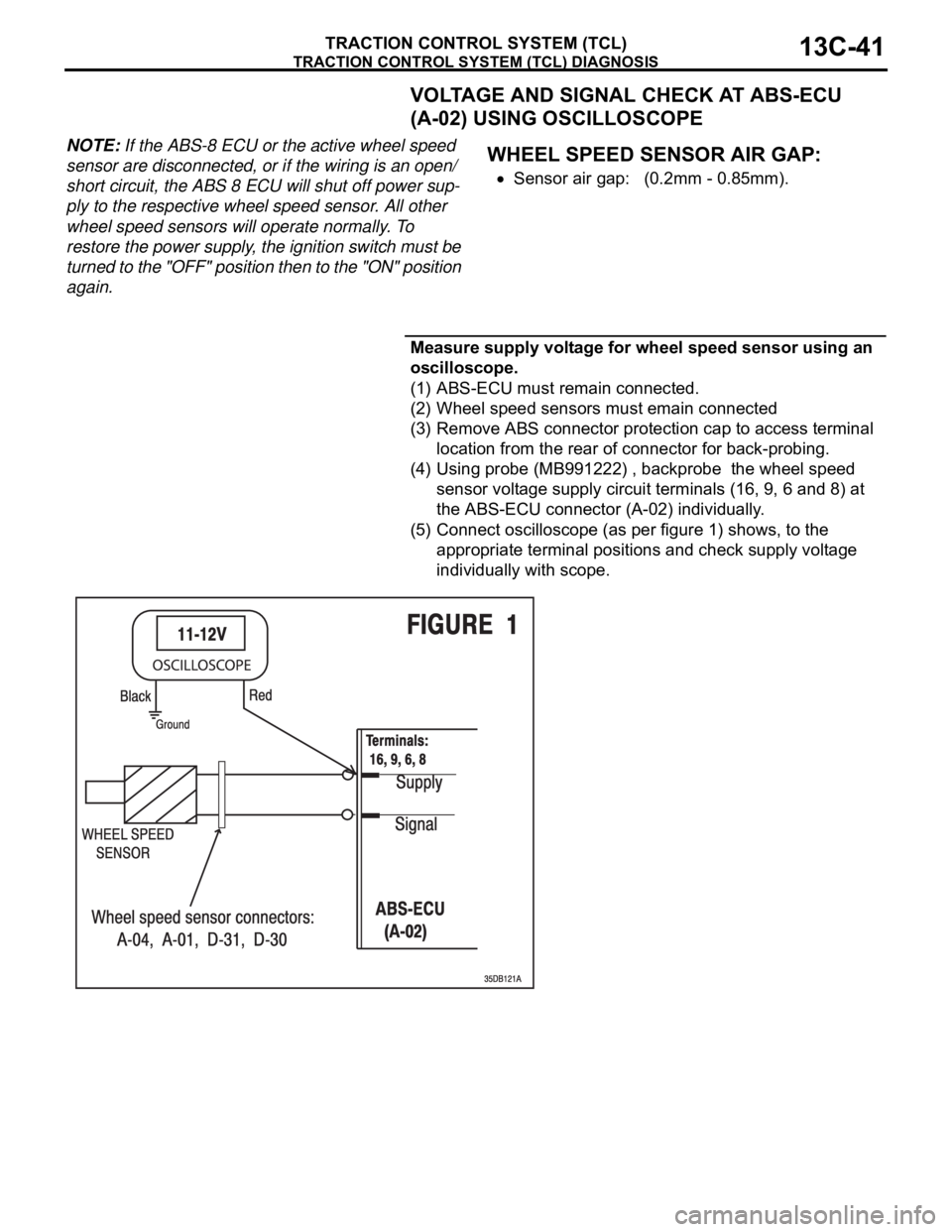

Measure supply voltage for wheel speed sensor using an

oscilloscope.

(1) ABS-ECU must remain connected.

(2) Wheel speed sensors must emain connected

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222) , backprobe the wheel speed

sensor voltage supply circuit terminals (16, 9, 6 and 8) at

the ABS-ECU connector (A-02) individually.

(5) Connect oscilloscope (as per figure 1) shows, to the

appropriate terminal positions and check supply voltage

individually with scope.

Page 1322 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-43

(7) The recommended Supply Voltage at terminals 16, 9, 6,

and 8 are:

Set value: 10.0Volts - 14.5Volts

Q: Is the supply voltage within the set value?

YES : Check wheel speed sensor signal at ABS-ECU using

an oscillopscope

NO :

Refer to Power supply systemP.35B-63

Refer to Motor supply systemP.35B-48

Refer to Valve relay systemP.35B-56

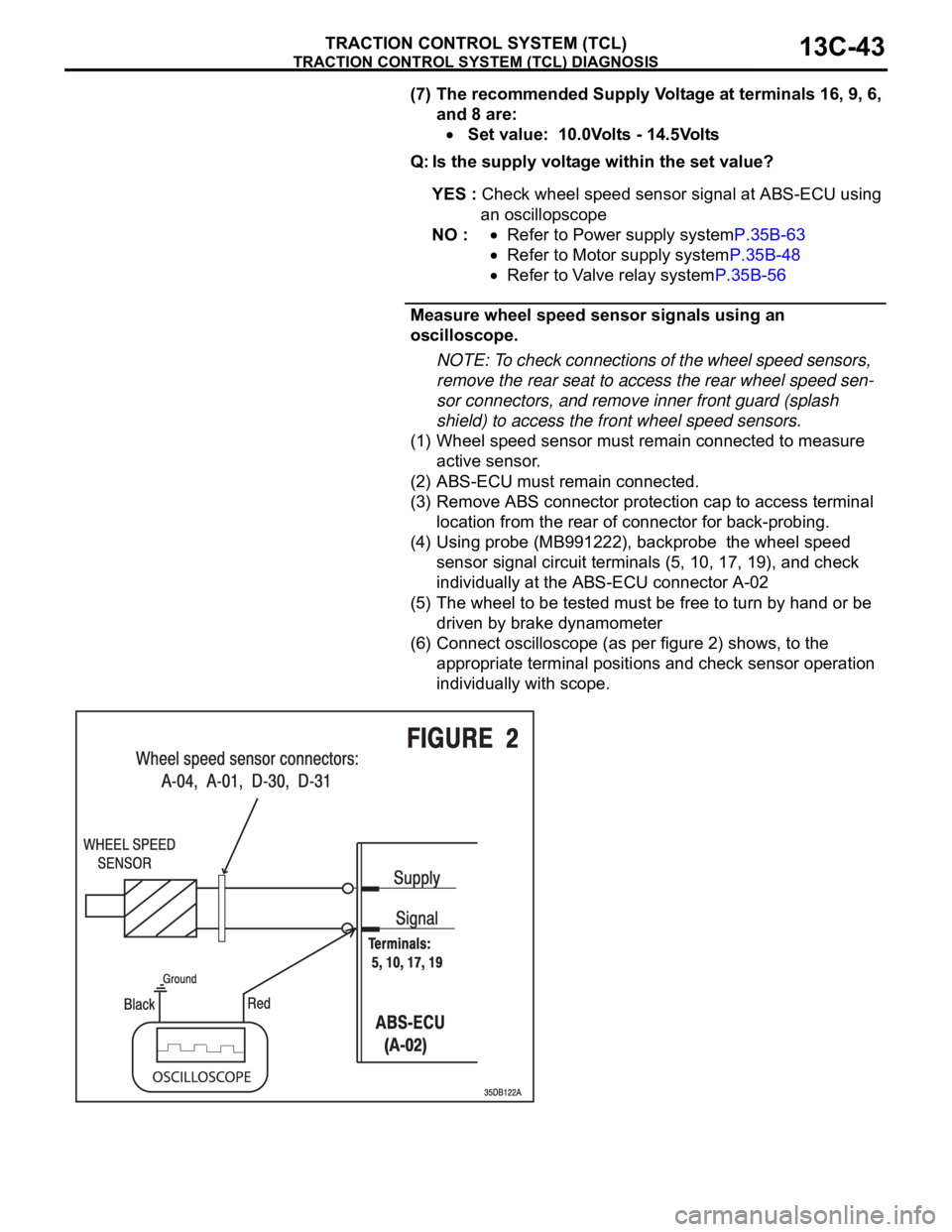

Measure wheel speed sensor signals using an

oscilloscope.

NOTE: To check connections of the wheel speed sensors,

remove the rear seat to access the rear wheel speed sen-

sor connectors, and remove inner front guard (splash

shield) to access the front wheel speed sensors.

(1) Wheel speed sensor must remain connected to measure

active sensor.

(2) ABS-ECU must remain connected.

(3) Remove ABS connector protection cap to access terminal

location from the rear of connector for back-probing.

(4) Using probe (MB991222), backprobe the wheel speed

sensor signal circuit terminals (5, 10, 17, 19), and check

individually at the ABS-ECU connector A-02

(5) The wheel to be tested must be free to turn by hand or be

driven by brake dynamometer

(6) Connect oscilloscope (as per figure 2) shows, to the

appropriate terminal positions and check sensor operation

individually with scope.

Page 1323 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-44

Connect oscilloscope to FL sensor signal terminal (5) at

ABS-ECU (A-02)

Connect oscilloscope to FR sensor signal terminal (10)

at ABS-ECU (A-02)

Connect oscilloscope to RL sensor signal terminal (17)

at ABS-ECU (A-02)

Connect oscilloscope to RR sensor signal terminal (19)

at ABS-ECU (A-02)

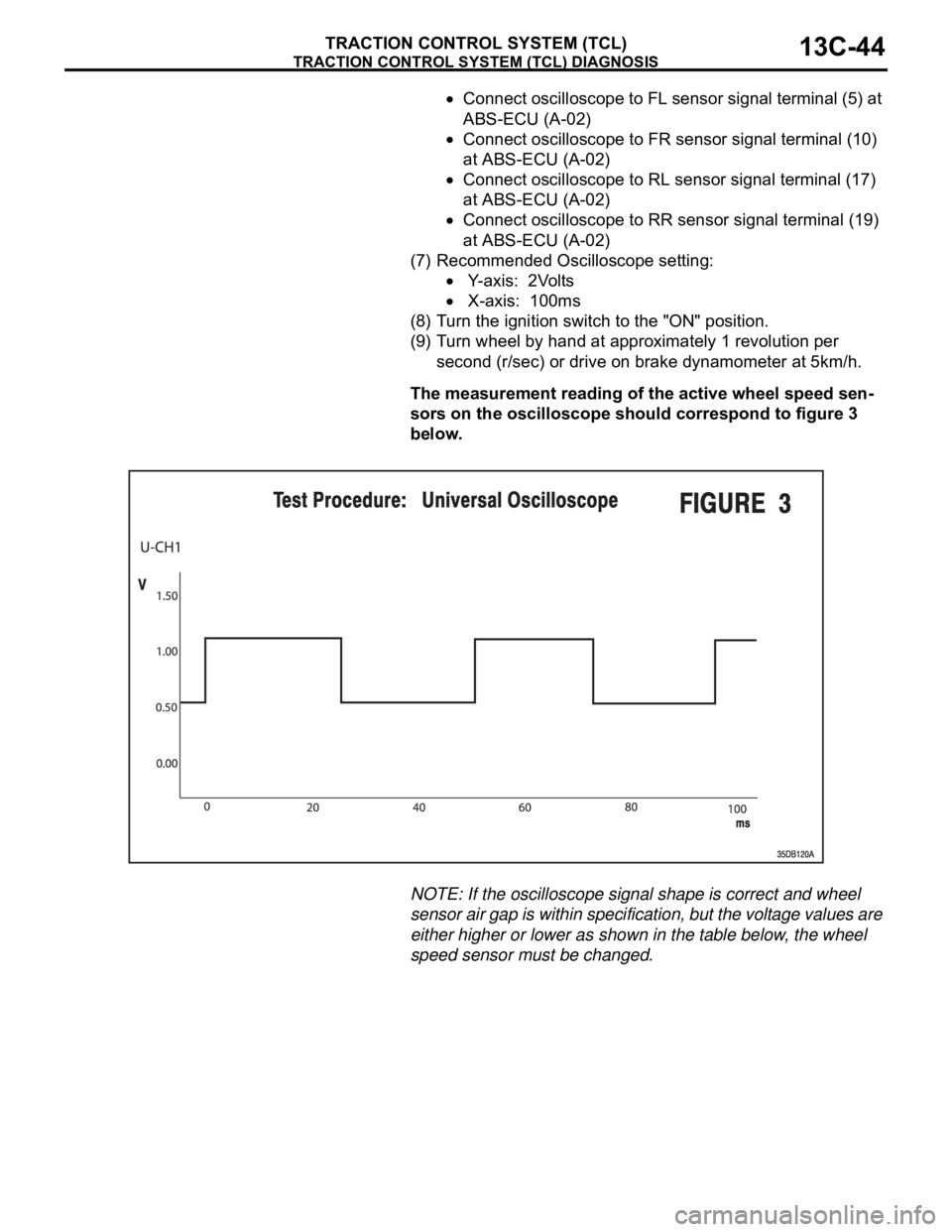

(7) Recommended Oscilloscope setting:

Y-axis: 2Volts

X-axis: 100ms

(8) Turn the ignition switch to the "ON" position.

(9) Turn wheel by hand at approximately 1 revolution per

second (r/sec) or drive on brake dynamometer at 5km/h.

The measurement reading of the active wheel speed sen-

sors on the oscilloscope should correspond to figure 3

below.

NOTE: If the oscilloscope signal shape is correct and wheel

sensor air gap is within specification, but the voltage values are

either higher or lower as shown in the table below, the wheel

speed sensor must be changed.

Page 1324 of 1500

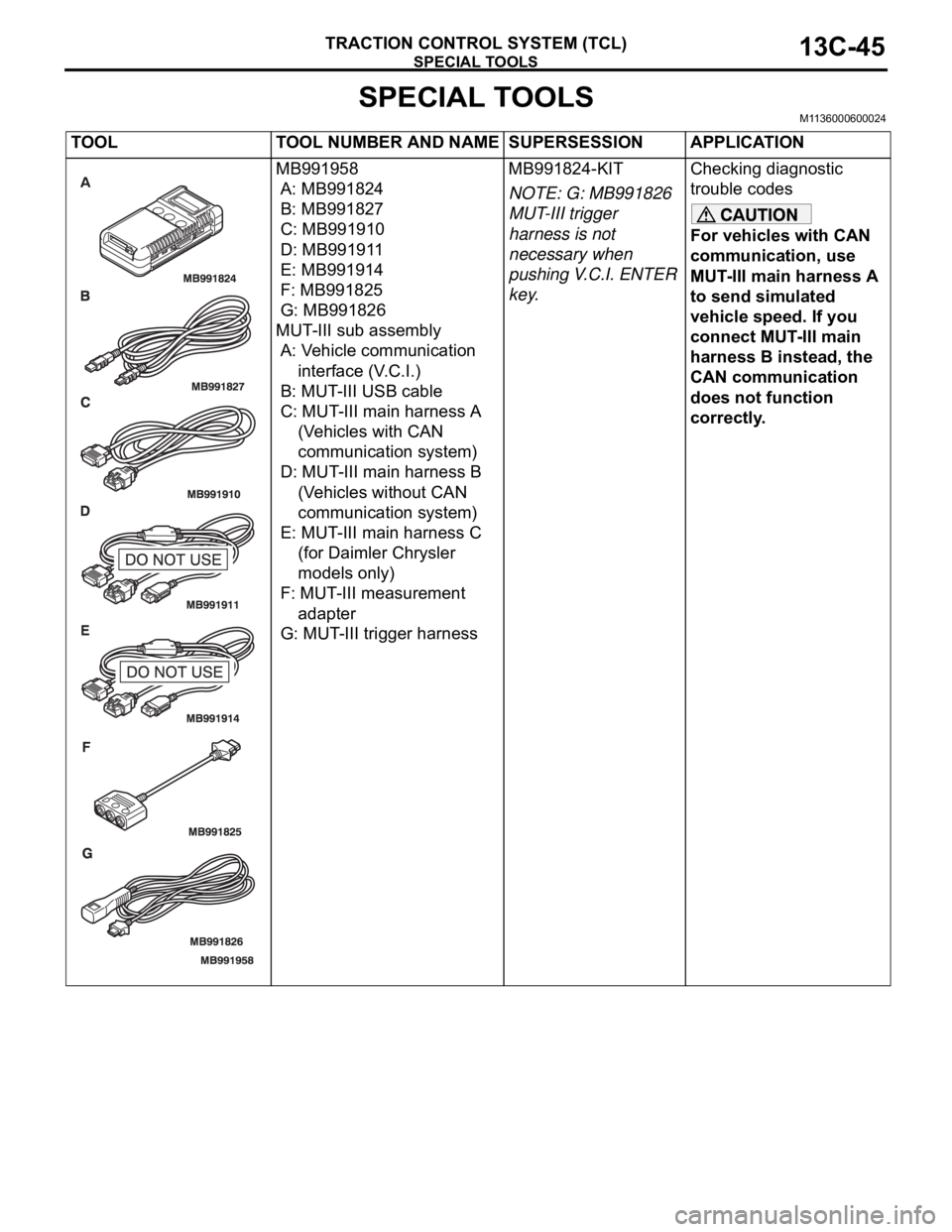

SPECIAL TOOLS

TRACTION CONTROL SYSTEM (TCL)13C-45

SPECIAL TOOLSM1136000600024

TOOL TOOL NUMBER AND NAME SUPERSESSION APPLICATION

MB991958

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III sub assembly

A: Vehicle communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness A

(Vehicles with CAN

communication system)

D: MUT-III main harness B

(Vehicles without CAN

communication system)

E: MUT-III main harness C

(for Daimler Chrysler

models only)

F: MUT-III measurement

adapter

G: MUT-III trigger harnessMB991824-KIT

NOTE: G: MB991826

MUT-III trigger

harness is not

necessary when

pushing V.C.I. ENTER

key.Checking diagnostic

trouble codes

For vehicles with CAN

communication, use

MUT-III main harness A

to send simulated

vehicle speed. If you

connect MUT-III main

harness B instead, the

CAN communication

does not function

correctly.

Page 1327 of 1500

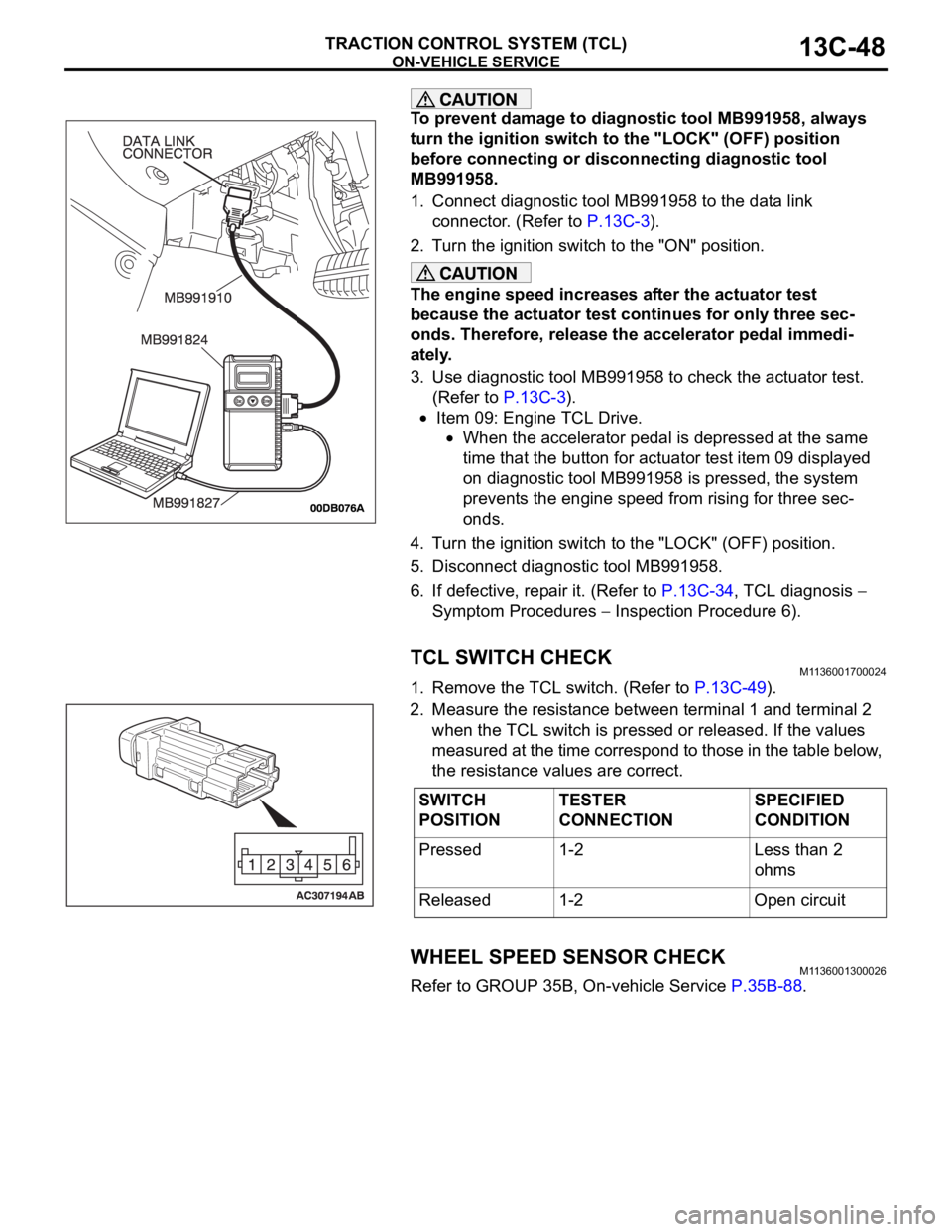

ON-VEHICLE SERVICE

TRACTION CONTROL SYSTEM (TCL)13C-48

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Connect diagnostic tool MB991958 to the data link

connector. (Refer to P.13C-3).

2. Turn the ignition switch to the "ON" position.

The engine speed increases after the actuator test

because the actuator test continues for only three sec-

onds. Therefore, release the accelerator pedal immedi-

ately.

3. Use diagnostic tool MB991958 to check the actuator test.

(Refer to P.13C-3).

Item 09: Engine TCL Drive.

When the accelerator pedal is depressed at the same

time that the button for actuator test item 09 displayed

on diagnostic tool MB991958 is pressed, the system

prevents the engine speed from rising for three sec-

onds.

4. Turn the ignition switch to the "LOCK" (OFF) position.

5. Disconnect diagnostic tool MB991958.

6. If defective, repair it. (Refer to P.13C-34, TCL diagnosis

Symptom Procedures

Inspection Procedure 6).

TCL SWITCH CHECKM1136001700024

1. Remove the TCL switch. (Refer to P.13C-49).

2. Measure the resistance between terminal 1 and terminal 2

when the TCL switch is pressed or released. If the values

measured at the time correspond to those in the table below,

the resistance values are correct.

WHEEL SPEED SENSOR CHECKM1136001300026

Refer to GROUP 35B, On-vehicle Service P.35B-88.

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

Pressed 1-2 Less than 2

ohms

Released 1-2 Open circuit

Page 1328 of 1500

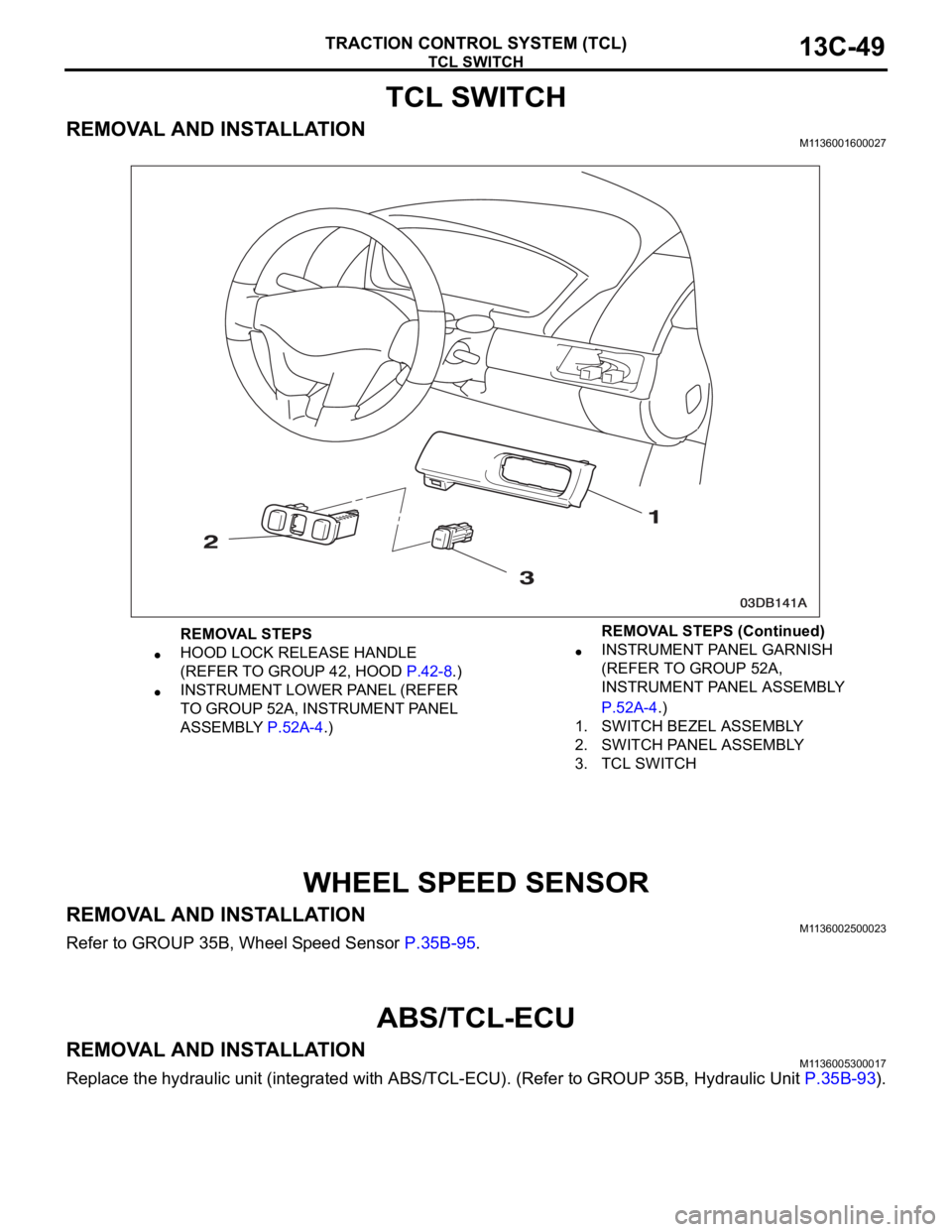

TCL SWITCH

TRACTION CONTROL SYSTEM (TCL)13C-49

TCL SWITCH

REMOVAL AND INSTALLATIONM1136001600027

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATIONM1136002500023

Refer to GROUP 35B, Wheel Speed Sensor P.35B-95.

ABS/TCL-ECU

REMOVAL AND INSTALLATIONM1136005300017

Replace the hydraulic unit (integrated with ABS/TCL-ECU). (Refer to GROUP 35B, Hydraulic Unit P.35B-93).

REMOVAL STEPS

HOOD LOCK RELEASE HANDLE

(REFER TO GROUP 42, HOOD P.42-8.)

INSTRUMENT LOWER PANEL (REFER

TO GROUP 52A, INSTRUMENT PANEL

ASSEMBLY P.52A-4.)

INSTRUMENT PANEL GARNISH

(REFER TO GROUP 52A,

INSTRUMENT PANEL ASSEMBLY

P.52A-4.)

1. SWITCH BEZEL ASSEMBLY

2. SWITCH PANEL ASSEMBLY

3. TCL SWITCH REMOVAL STEPS (Continued)

Page 1339 of 1500

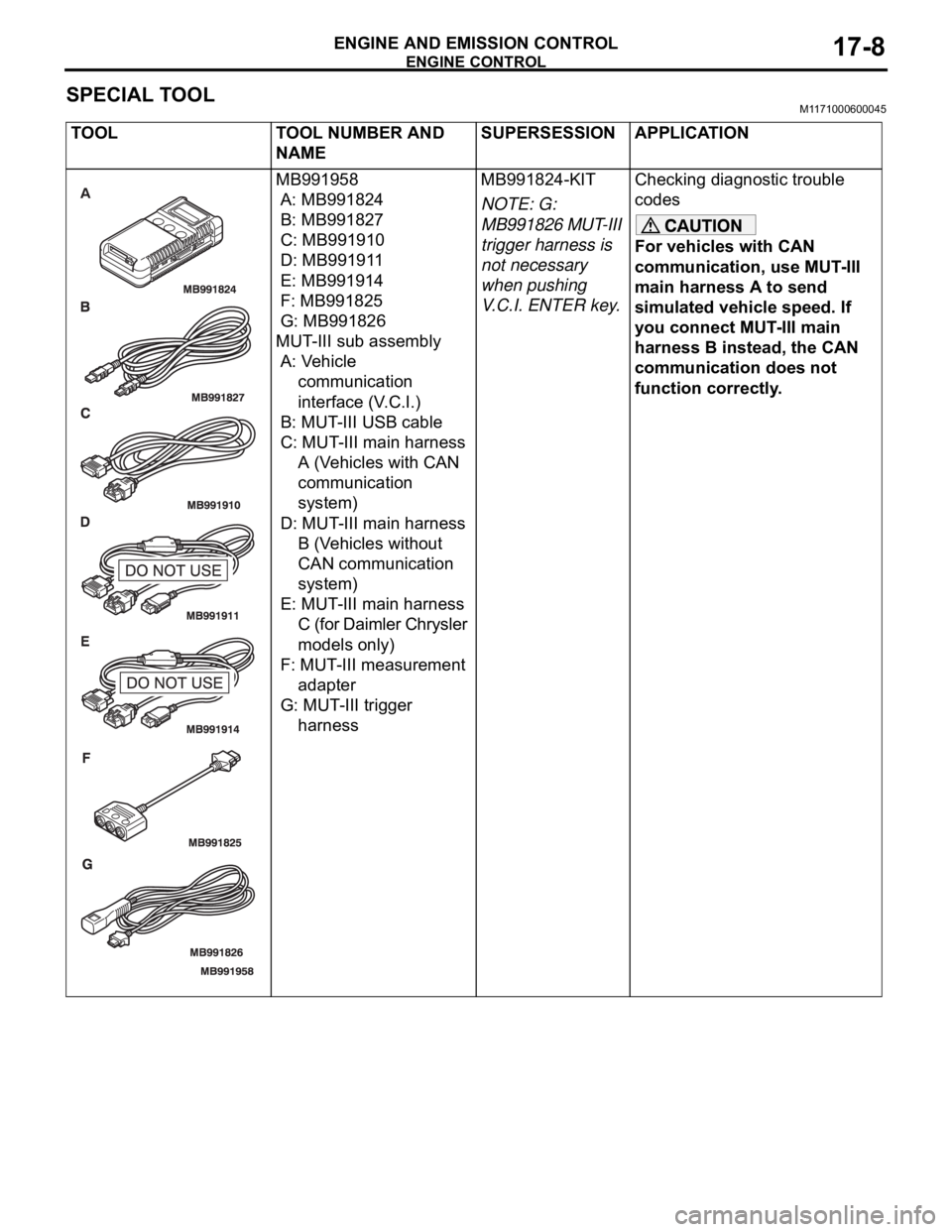

ENGINE CONTROL

ENGINE AND EMISSION CONTROL17-8

SPECIAL TOOLM1171000600045

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB991958

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III sub assembly

A: Vehicle

communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness

A (Vehicles with CAN

communication

system)

D: MUT-III main harness

B (Vehicles without

CAN communication

system)

E: MUT-III main harness

C (for Daimler Chrysler

models only)

F: MUT-III measurement

adapter

G: MUT-III trigger

harnessMB991824-KIT

NOTE: G:

MB991826 MUT-III

trigger harness is

not necessary

when pushing

V.C.I. ENTER key.Checking diagnostic trouble

codes

For vehicles with CAN

communication, use MUT-III

main harness A to send

simulated vehicle speed. If

you connect MUT-III main

harness B instead, the CAN

communication does not

function correctly.

Page 1341 of 1500

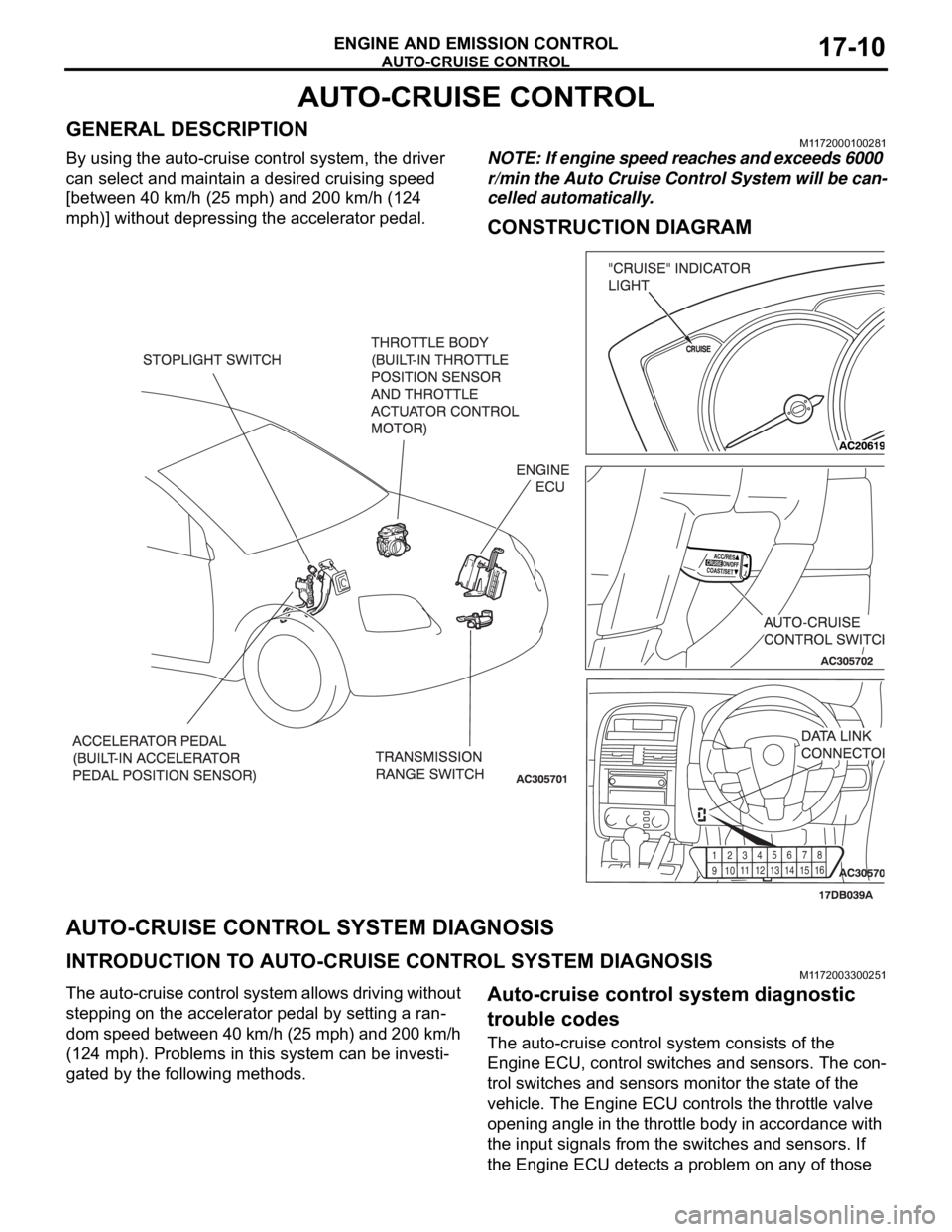

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-10

AUTO-CRUISE CONTROL

GENERAL DESCRIPTIONM1172000100281

By using the auto-cruise control system, the driver

can select and maintain a desired cruising speed

[between 40 km/h (25 mph) and 200 km/h (124

mph)] without depressing the accelerator pedal.NOTE: If engine speed reaches and exceeds 6000

r/min the Auto Cruise Control System will be can-

celled automatically.

CONSTRUCTION DIAGRAM

AUTO-CRUISE CONTROL SYSTEM DIAGNOSIS

INTRODUCTION TO AUTO-CRUISE CONTROL SYSTEM DIAGNOSISM1172003300251

The auto-cruise control system allows driving without

stepping on the accelerator pedal by setting a ran-

dom speed between 40 km/h (25 mph) and 200 km/h

(124 mph). Problems in this system can be investi-

gated by the following methods.Auto-cruise control system diagnostic

trouble codes

The auto-cruise control system consists of the

Engine ECU, control switches and sensors. The con-

trol switches and sensors monitor the state of the

vehicle. The Engine ECU controls the throttle valve

opening angle in the throttle body in accordance with

the input signals from the switches and sensors. If

the Engine ECU detects a problem on any of those

91

01

1

12

1

31

41

5

16 123

456

78

Page 1346 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-15

DIAGNOSTIC TROUBLE CODE PROCEDURES

DTC P0830: Clutch Switch (5M/T Only)

.

CIRCUIT OPERATION

A 5 Volt power supply is applied to the clutch

switch output terminal (terminal No. 1) from the

ENGINE-ECU(terminal No. B-21 pin 41) when

the clutch pedal is applied the power supply is

switched to earth.

.

TECHNICAL DESCRIPTION

The ENGINE-ECU uses the clutch switch earth-

ing as a signal that clutch pedal has been

applied.

.

DTC SET CONDITIONS

Check Conditions

Vehicle speed is above 50 km/h.Judgement Criteria

Gear shift is above 5 times.

Clutch control is below 2 times.

No MIL.

No Limp home.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are:)

Clutch switch failed

Harness damage in clutch switch circuit, or con-

nector damage.

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tools:

: Diagnostic tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: USB Cable

MB991910: Main Harness A