SPEED MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1384 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-53

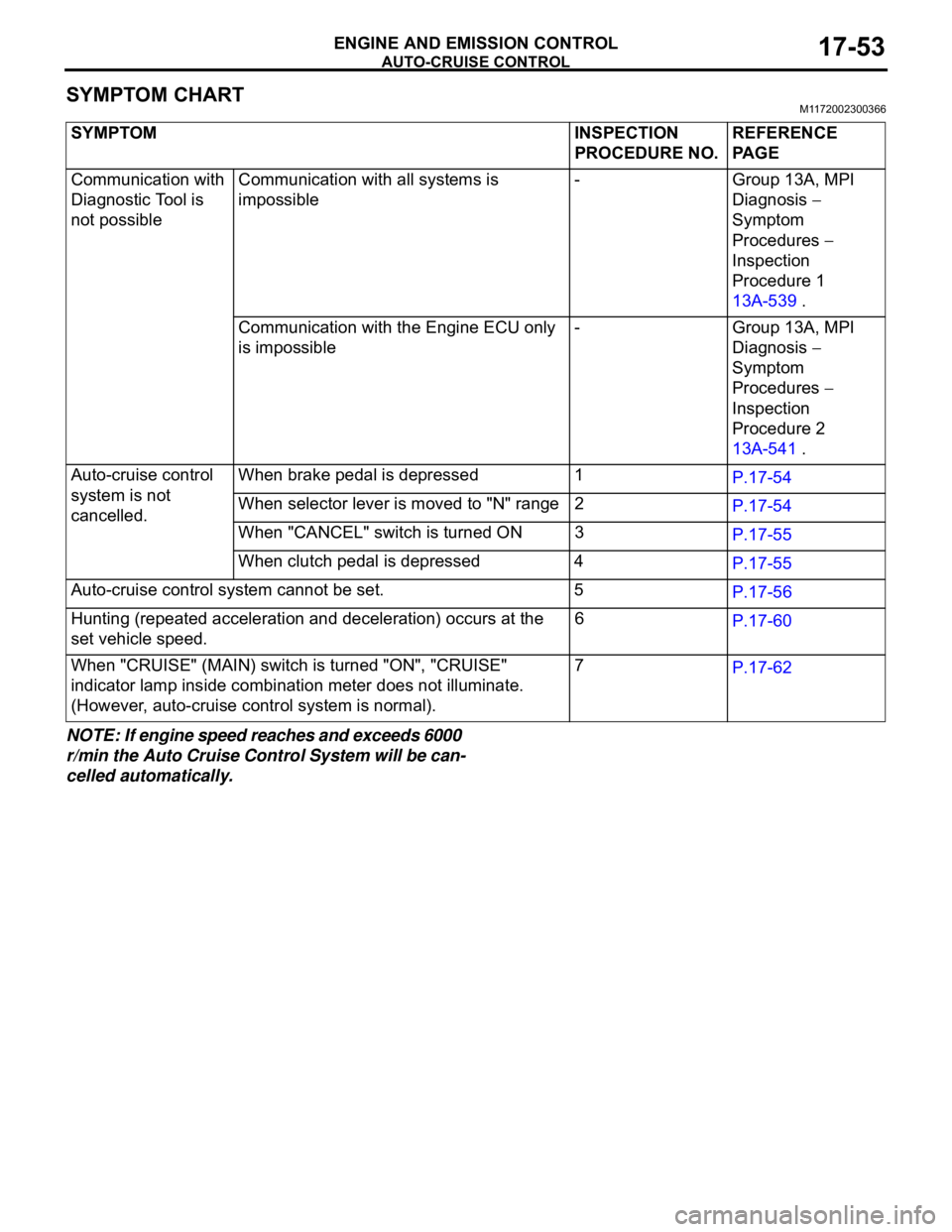

SYMPTOM CHARTM1172002300366

NOTE: If engine speed reaches and exceeds 6000

r/min the Auto Cruise Control System will be can-

celled automatically.SYMPTOM INSPECTION

PROCEDURE NO.REFERENCE

PA G E

Communication with

Diagnostic Tool is

not possibleCommunication with all systems is

impossible- Group 13A, MPI

Diagnosis

Symptom

Procedures

Inspection

Procedure 1

13A-539 .

Communication with the Engine ECU only

is impossible- Group 13A, MPI

Diagnosis

Symptom

Procedures

Inspection

Procedure 2

13A-541 .

Auto-cruise control

system is not

cancelled.When brake pedal is depressed 1

P.17-54

When selector lever is moved to "N" range 2

P.17-54

When "CANCEL" switch is turned ON 3

P.17-55

When clutch pedal is depressed 4

P.17-55

Auto-cruise control system cannot be set. 5

P.17-56

Hunting (repeated acceleration and deceleration) occurs at the

set vehicle speed.6

P.17-60

When "CRUISE" (MAIN) switch is turned "ON", "CRUISE"

indicator lamp inside combination meter does not illuminate.

(However, auto-cruise control system is normal).7

P.17-62

Page 1391 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-60

INSPECTION PROCEDURE 6: Hunting (Repeated Acceleration and Deceleration) Occurs at the Set

Vehicle Speed.

.

COMMENT

The output shaft speed sensor signal or the throttle

body is suspected.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CASE:)

Malfunction of the output shaft speed sensor.

Malfunction of the throttle body.

Malfunction of the Engine ECU.

Malfunction of the A/T ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

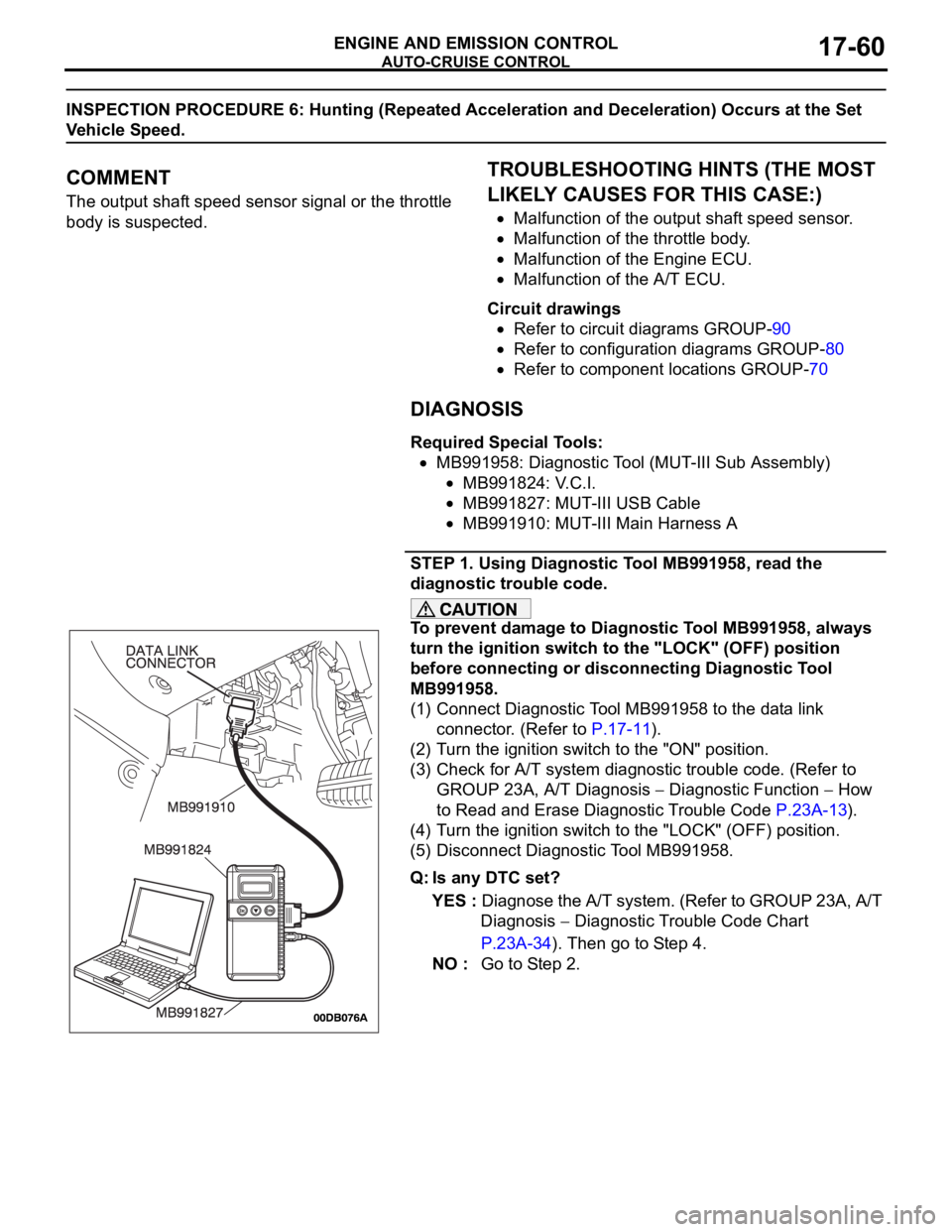

DIAGNOSIS

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

STEP 1. Using Diagnostic Tool MB991958, read the

diagnostic trouble code.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Check for A/T system diagnostic trouble code. (Refer to

GROUP 23A, A/T Diagnosis

Diagnostic Function How

to Read and Erase Diagnostic Trouble Code P.23A-13).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is any DTC set?

YES : Diagnose the A/T system. (Refer to GROUP 23A, A/T

Diagnosis

Diagnostic Trouble Code Chart

P.23A-34). Then go to Step 4.

NO : Go to Step 2.

Page 1397 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-66

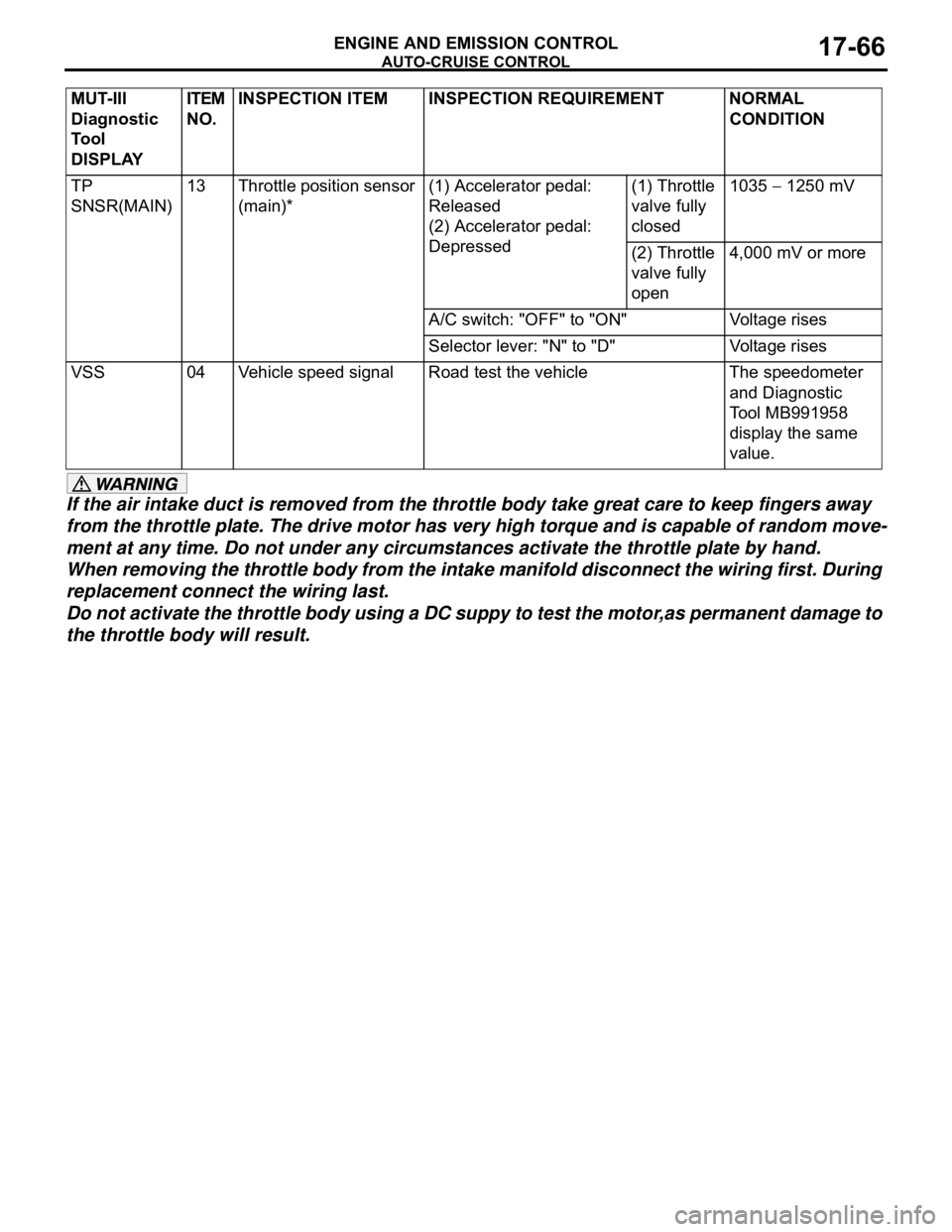

If the air intake duct is removed from the throttle body take great care to keep fingers away

from the throttle plate. The drive motor has very high torque and is capable of random move-

ment at any time. Do not under any circumstances activate the throttle plate by hand.

When removing the throttle body from the intake manifold disconnect the wiring first. During

replacement connect the wiring last.

Do not activate the throttle body using a DC suppy to test the motor,as permanent damage to

the throttle body will result.

TP

SNSR(MAIN)13 Throttle position sensor

(main)*(1) Accelerator pedal:

Released

(2) Accelerator pedal:

Depressed(1) Throttle

valve fully

closed1035 1250 mV

(2) Throttle

valve fully

open4,000 mV or more

A/C switch: "OFF" to "ON" Voltage rises

Selector lever: "N" to "D" Voltage rises

VSS 04 Vehicle speed signal Road test the vehicle The speedometer

and Diagnostic

Tool MB991958

display the same

value. MUT-III

Diagnostic

To o l

DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL

CONDITION

Page 1400 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-69

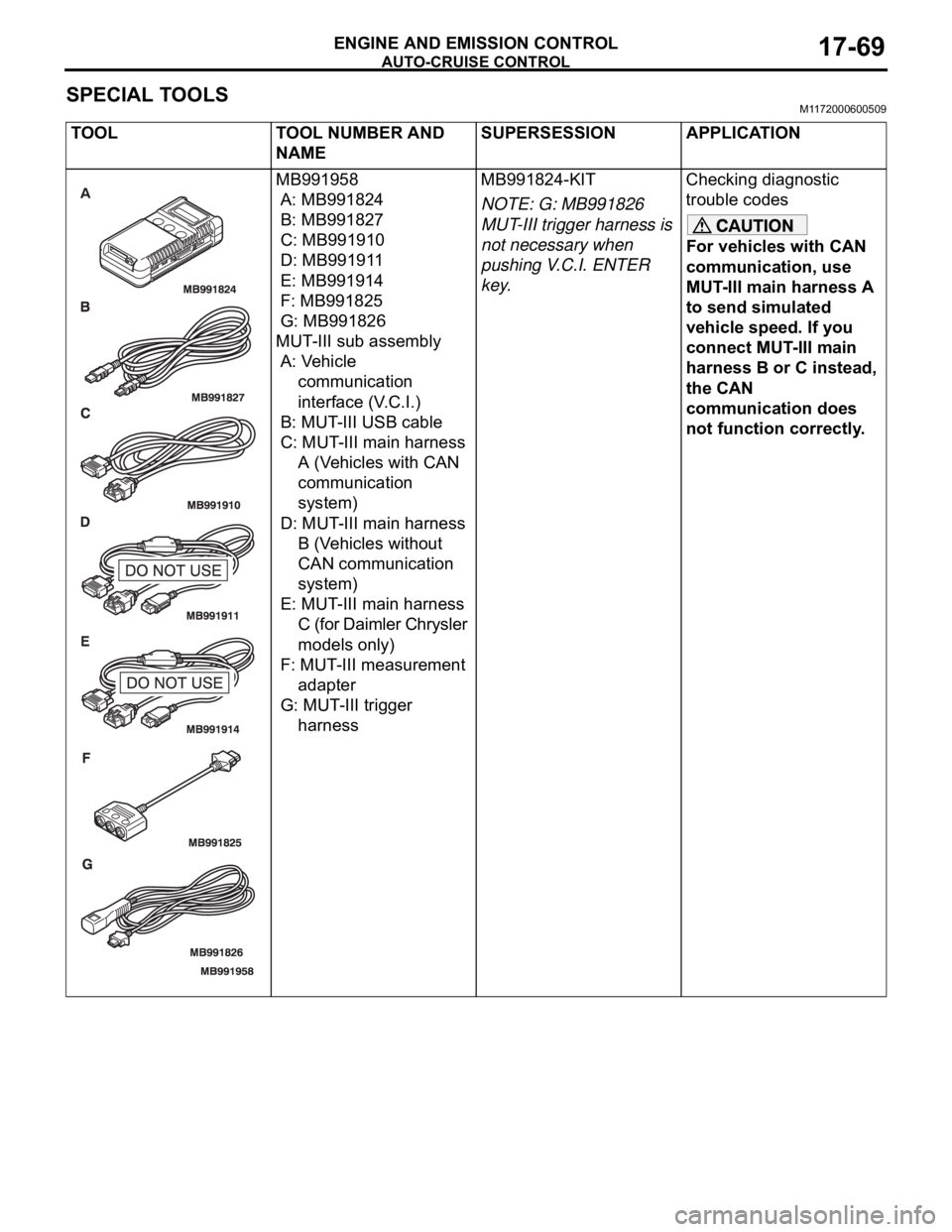

SPECIAL TOOLSM1172000600509

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB991958

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III sub assembly

A: Vehicle

communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness

A (Vehicles with CAN

communication

system)

D: MUT-III main harness

B (Vehicles without

CAN communication

system)

E: MUT-III main harness

C (for Daimler Chrysler

models only)

F: MUT-III measurement

adapter

G: MUT-III trigger

harnessMB991824-KIT

NOTE: G: MB991826

MUT-III trigger harness is

not necessary when

pushing V.C.I. ENTER

key.Checking diagnostic

trouble codes

For vehicles with CAN

communication, use

MUT-III main harness A

to send simulated

vehicle speed. If you

connect MUT-III main

harness B or C instead,

the CAN

communication does

not function correctly.

Page 1402 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-71

ON-VEHICLE SERVICE

AUTO-CRUISE CONTROL SWITCH CHECKM1172001200054

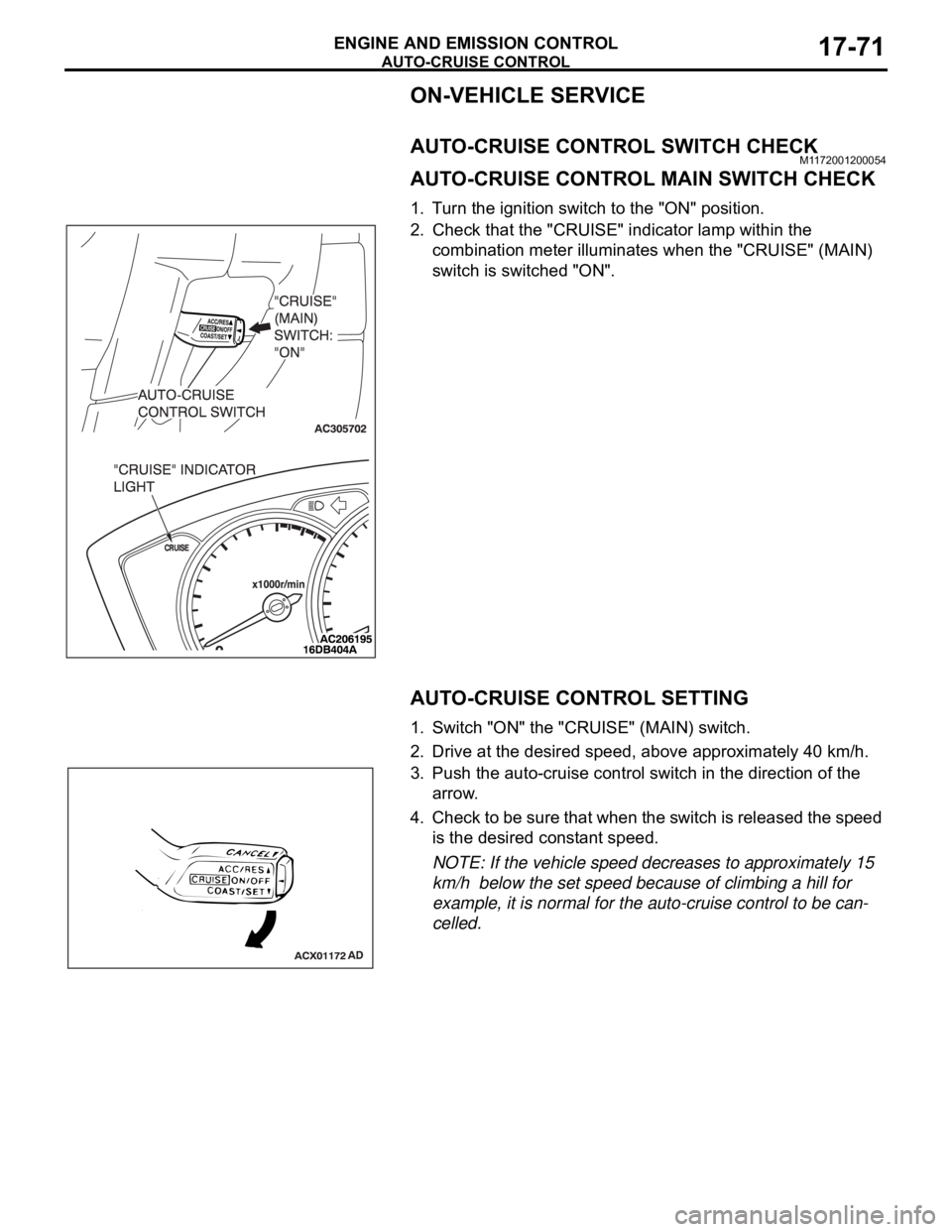

AUTO-CRUISE CONTROL MAIN SWITCH CHECK

1. Turn the ignition switch to the "ON" position.

2. Check that the "CRUISE" indicator lamp within the

combination meter illuminates when the "CRUISE" (MAIN)

switch is switched "ON".

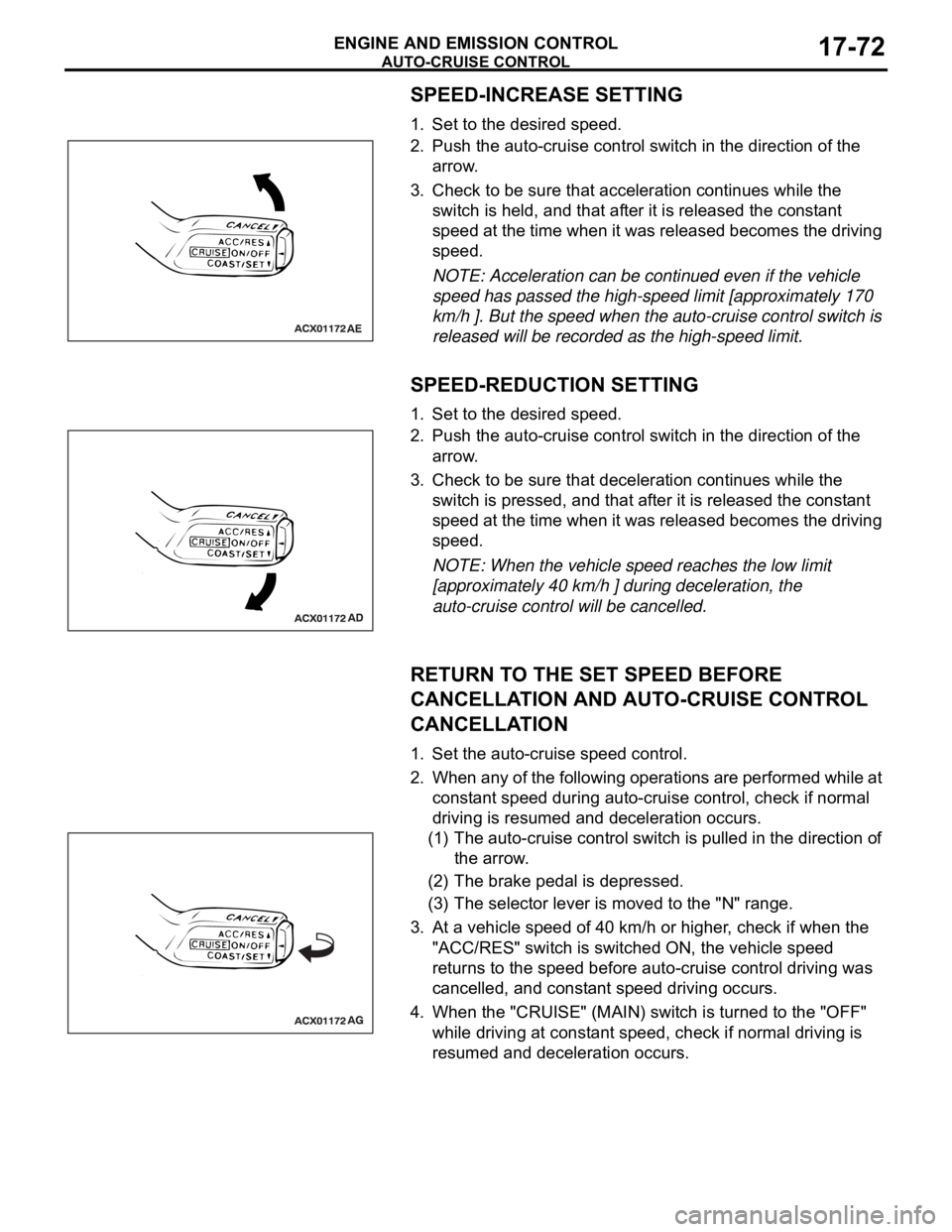

AUTO-CRUISE CONTROL SETTING

1. Switch "ON" the "CRUISE" (MAIN) switch.

2. Drive at the desired speed, above approximately 40 km/h.

3. Push the auto-cruise control switch in the direction of the

arrow.

4. Check to be sure that when the switch is released the speed

is the desired constant speed.

NOTE: If the vehicle speed decreases to approximately 15

km/h below the set speed because of climbing a hill for

example, it is normal for the auto-cruise control to be can-

celled.

Page 1403 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-72

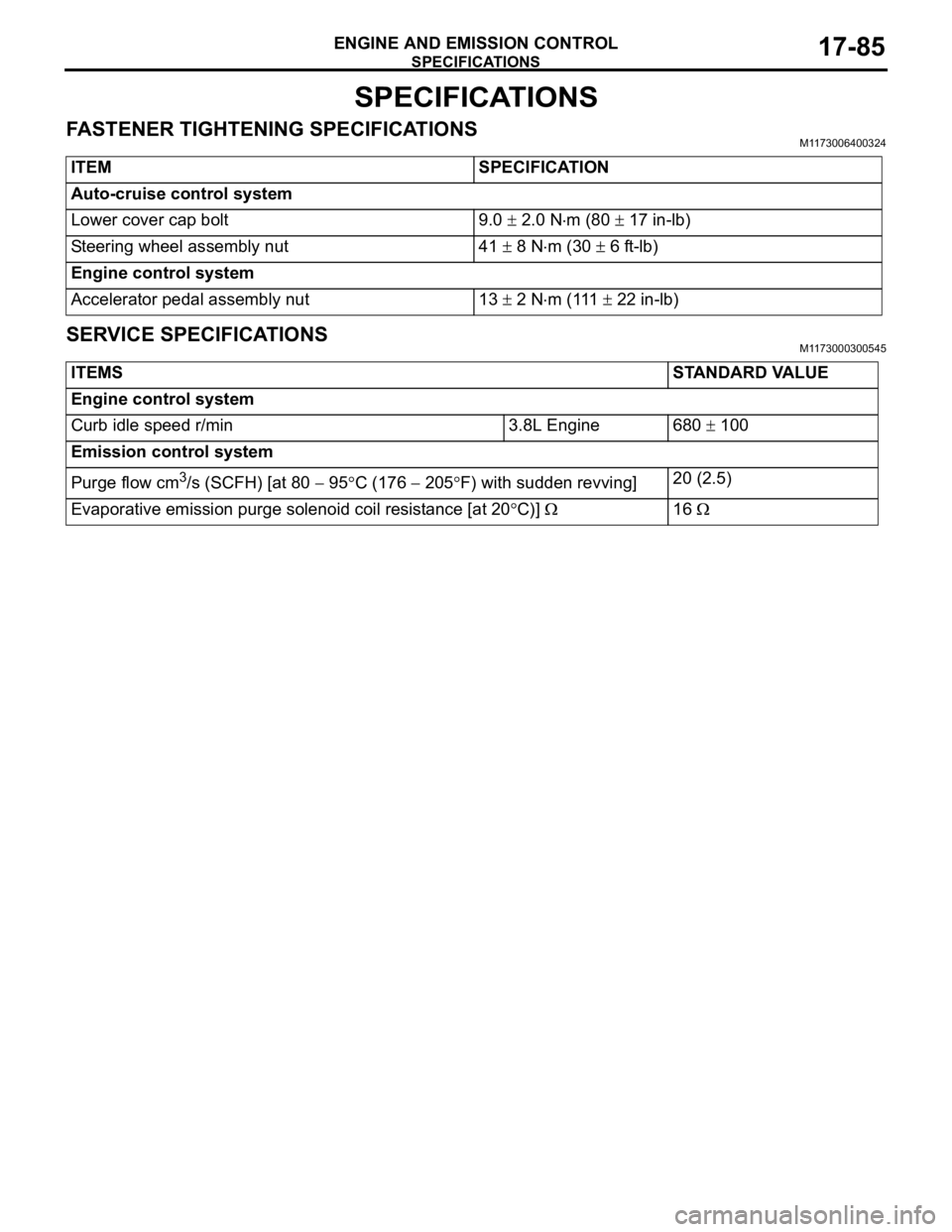

SPEED-INCREASE SETTING

1. Set to the desired speed.

2. Push the auto-cruise control switch in the direction of the

arrow.

3. Check to be sure that acceleration continues while the

switch is held, and that after it is released the constant

speed at the time when it was released becomes the driving

speed.

NOTE: Acceleration can be continued even if the vehicle

speed has passed the high-speed limit [approximately 170

km/h ]. But the speed when the auto-cruise control switch is

released will be recorded as the high-speed limit.

SPEED-REDUCTION SETTING

1. Set to the desired speed.

2. Push the auto-cruise control switch in the direction of the

arrow.

3. Check to be sure that deceleration continues while the

switch is pressed, and that after it is released the constant

speed at the time when it was released becomes the driving

speed.

NOTE: When the vehicle speed reaches the low limit

[approximately 40 km/h ] during deceleration, the

auto-cruise control will be cancelled.

RETURN TO THE SET SPEED BEFORE

CANCELLATION AND AUTO-CRUISE CONTROL

CANCELLATION

1. Set the auto-cruise speed control.

2. When any of the following operations are performed while at

constant speed during auto-cruise control, check if normal

driving is resumed and deceleration occurs.

(1) The auto-cruise control switch is pulled in the direction of

the arrow.

(2) The brake pedal is depressed.

(3) The selector lever is moved to the "N" range.

3. At a vehicle speed of 40 km/h or higher, check if when the

"ACC/RES" switch is switched ON, the vehicle speed

returns to the speed before auto-cruise control driving was

cancelled, and constant speed driving occurs.

4. When the "CRUISE" (MAIN) switch is turned to the "OFF"

while driving at constant speed, check if normal driving is

resumed and deceleration occurs.

Page 1416 of 1500

SPECIFICATIONS

ENGINE AND EMISSION CONTROL17-85

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1173006400324

SERVICE SPECIFICATIONSM1173000300545

ITEM SPECIFICATION

Auto-cruise control system

Lower cover cap bolt 9.0

2.0 Nm (80 17 in-lb)

Steering wheel assembly nut 41

8 Nm (30 6 ft-lb)

Engine control system

Accelerator pedal assembly nut 13

2 Nm ( 111 22 in-lb)

ITEMSSTANDARD VALUE

Engine control system

Curb idle speed r/min 3.8L Engine 680

100

Emission control system

Purge flow cm

3/s (SCFH) [at 80 95C (176 205F) with sudden revving]20 (2.5)

Evaporative emission purge solenoid coil resistance [at 20

C)] 16

Page 1419 of 1500

GENERAL DESCRIPTION

FRONT AXLE26-2

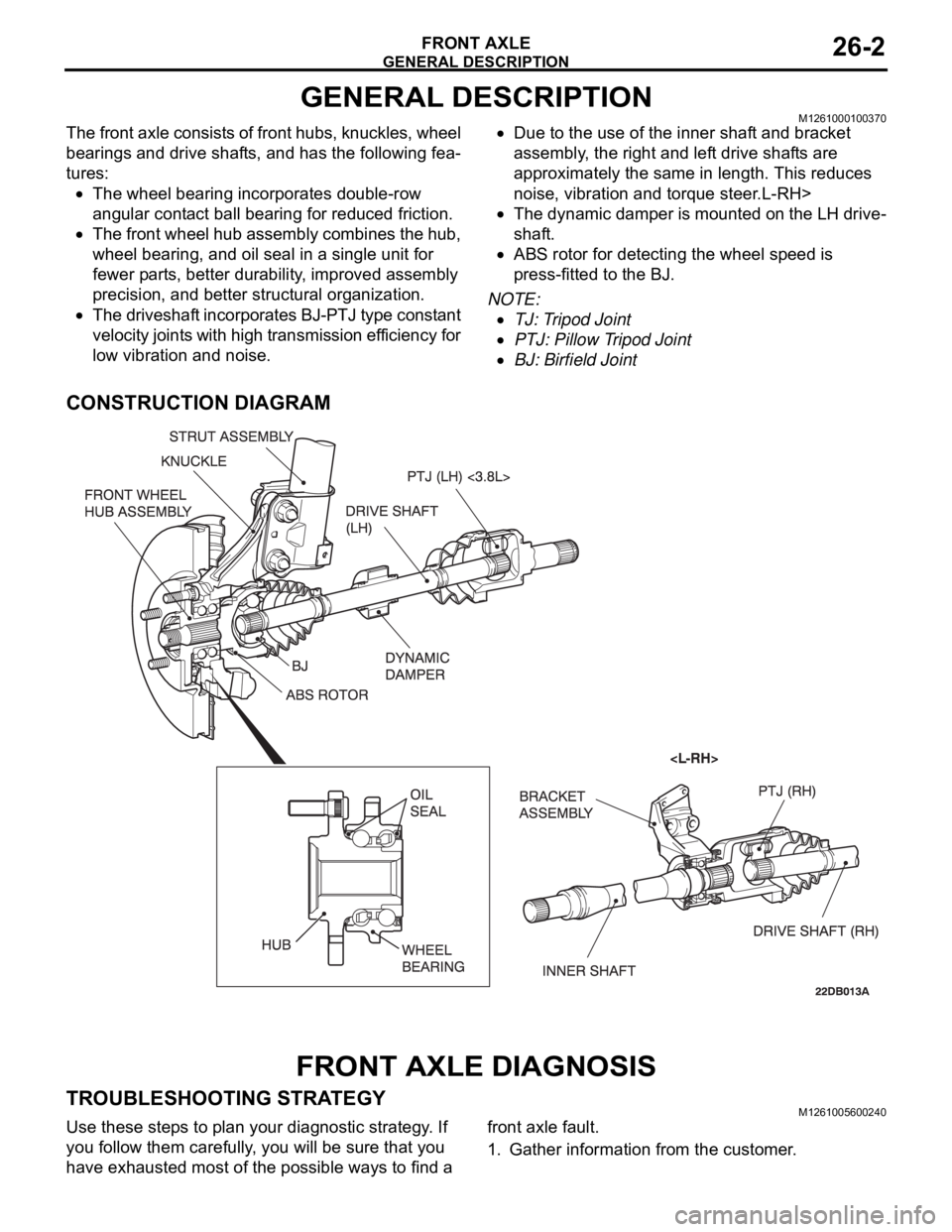

GENERAL DESCRIPTIONM1261000100370

The front axle consists of front hubs, knuckles, wheel

bearings and drive shafts, and has the following fea-

tures:

The wheel bearing incorporates double-row

angular contact ball bearing for reduced friction.

The front wheel hub assembly combines the hub,

wheel bearing, and oil seal in a single unit for

fewer parts, better durability, improved assembly

precision, and better structural organization.

The driveshaft incorporates BJ-PTJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.

Due to the use of the inner shaft and bracket

assembly, the right and left drive shafts are

approximately the same in length. This reduces

noise, vibration and torque steer.L-RH>

The dynamic damper is mounted on the LH drive-

shaft.

ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

TJ: Tripod Joint

PTJ: Pillow Tripod Joint

BJ: Birfield Joint

CONSTRUCTION DIAGRAM

FRONT AXLE DIAGNOSIS

TROUBLESHOOTING STRATEGYM1261005600240

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a front axle fault.

1. Gather information from the customer.

Page 1426 of 1500

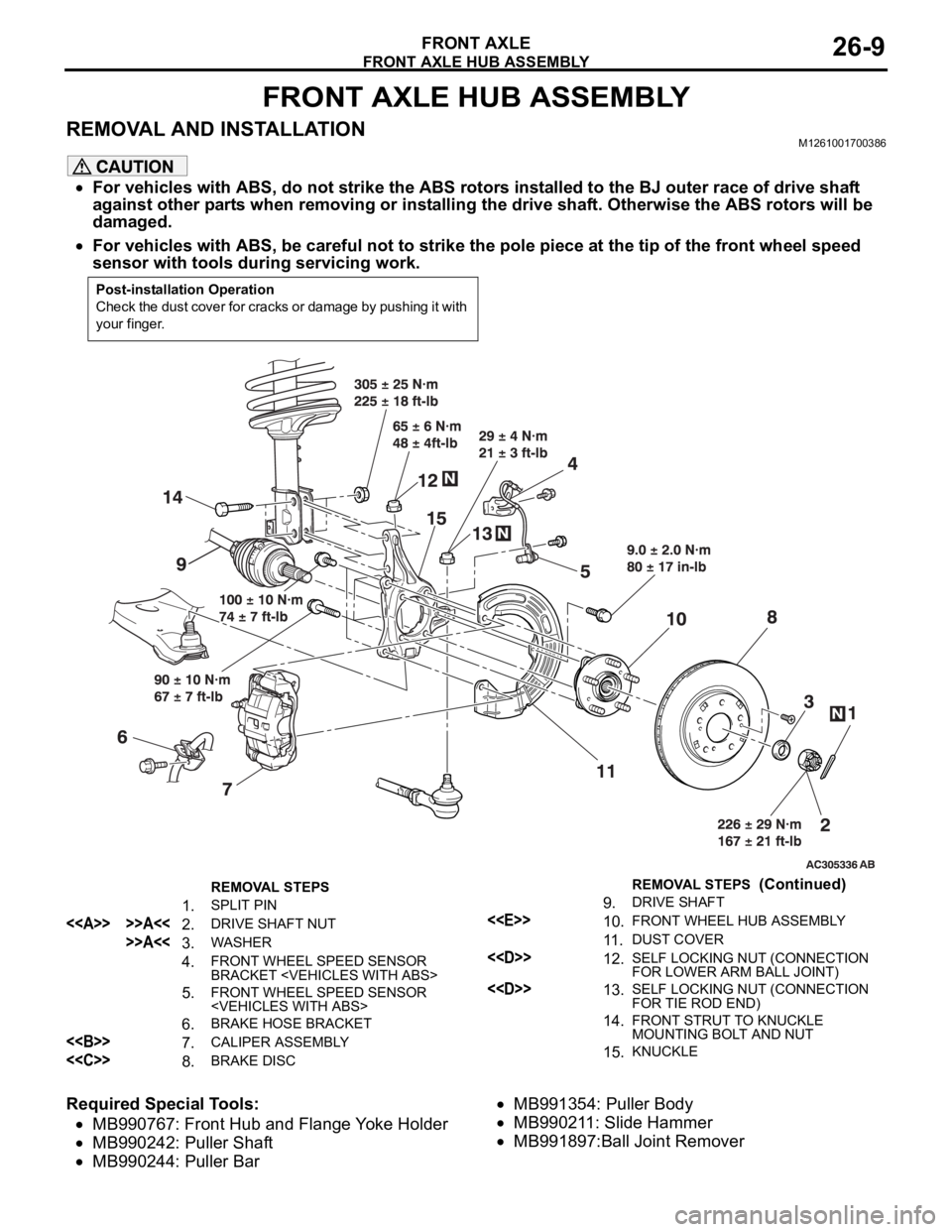

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-9

FRONT AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1261001700386

For vehicles with ABS, do not strike the ABS rotors installed to the BJ outer race of drive shaft

against other parts when removing or installing the drive shaft. Otherwise the ABS rotors will be

damaged.

For vehicles with ABS, be careful not to strike the pole piece at the tip of the front wheel speed

sensor with tools during servicing work.

Required Special Tools:

MB990767: Front Hub and Flange Yoke Holder

MB990242: Puller Shaft

MB990244: Puller Bar

MB991354: Puller Body

MB990211: Slide Hammer

MB991897:Ball Joint Remover

Post-installation Operation

Check the dust cover for cracks or damage by pushing it with

your finger.

REMOVAL STEPS

1. SPLIT PIN

<> >>A<<2. DRIVE SHAFT NUT

>>A<<3. WASHER

4. FRONT WHEEL SPEED SENSOR

BRACKET

5. FRONT WHEEL SPEED SENSOR

6. BRAKE HOSE BRACKET

<> 7. CALIPER ASSEMBLY

<

9. DRIVE SHAFT

<

11 .DUST COVER

<

FOR LOWER ARM BALL JOINT)

<

FOR TIE ROD END)

14.FRONT STRUT TO KNUCKLE

MOUNTING BOLT AND NUT

15.KNUCKLE

REMOVAL STEPS (Continued)

Page 1430 of 1500

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-13

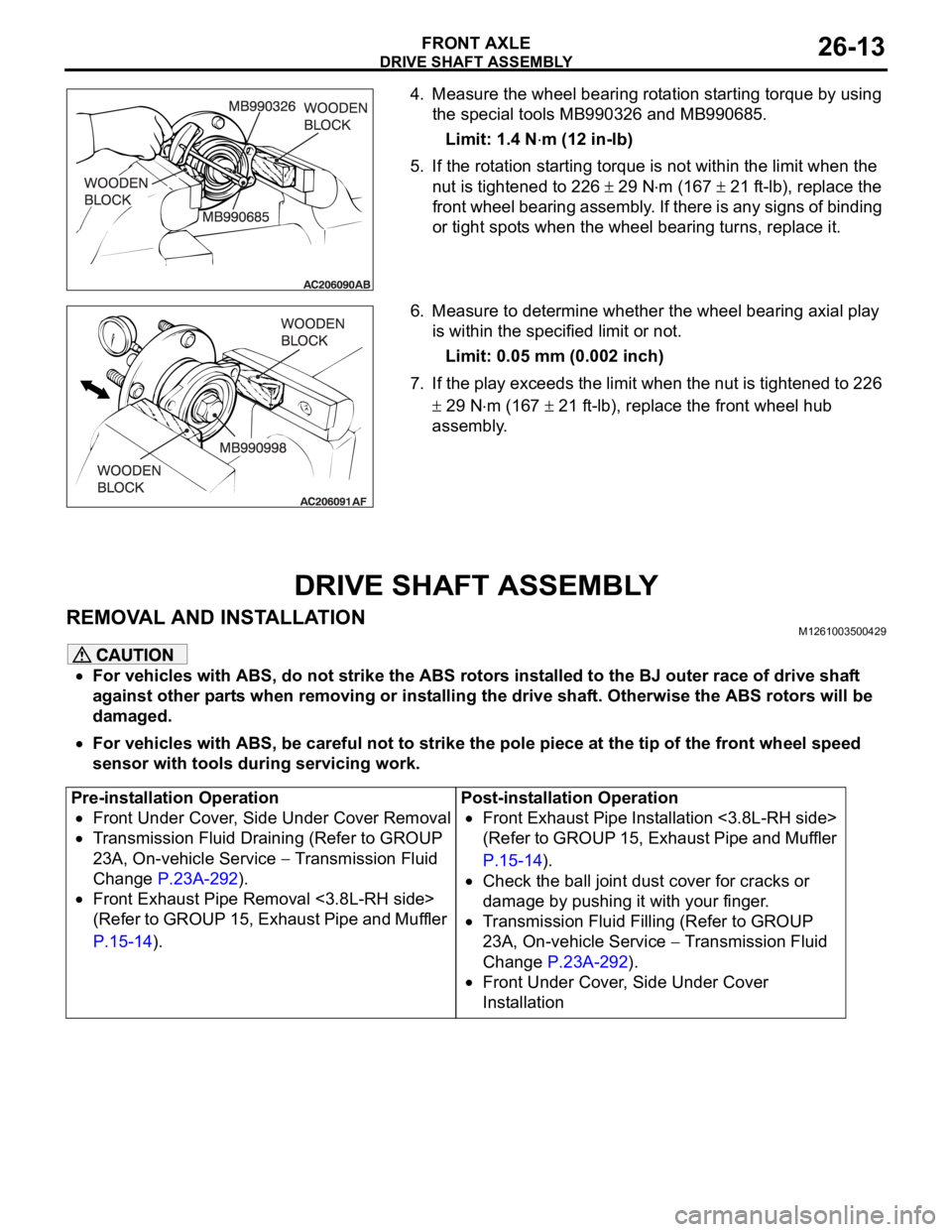

4. Measure the wheel bearing rotation starting torque by using

the special tools MB990326 and MB990685.

Limit: 1.4 N

m (12 in-lb)

5. If the rotation starting torque is not within the limit when the

nut is tightened to 226

29 Nm (167 21 ft-lb), replace the

front wheel bearing assembly. If there is any signs of binding

or tight spots when the wheel bearing turns, replace it.

6. Measure to determine whether the wheel bearing axial play

is within the specified limit or not.

Limit: 0.05 mm (0.002 inch)

7. If the play exceeds the limit when the nut is tightened to 226

29 Nm (167 21 ft-lb), replace the front wheel hub

assembly.

DRIVE SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500429

For vehicles with ABS, do not strike the ABS rotors installed to the BJ outer race of drive shaft

against other parts when removing or installing the drive shaft. Otherwise the ABS rotors will be

damaged.

For vehicles with ABS, be careful not to strike the pole piece at the tip of the front wheel speed

sensor with tools during servicing work.

Pre-installation Operation

Front Under Cover, Side Under Cover Removal

Transmission Fluid Draining (Refer to GROUP

23A, On-vehicle Service

Transmission Fluid

Change P.23A-292).

Front Exhaust Pipe Removal <3.8L-RH side>

(Refer to GROUP 15, Exhaust Pipe and Muffler

P.15-14).Post-installation Operation

Front Exhaust Pipe Installation <3.8L-RH side>

(Refer to GROUP 15, Exhaust Pipe and Muffler

P.15-14).

Check the ball joint dust cover for cracks or

damage by pushing it with your finger.

Transmission Fluid Filling (Refer to GROUP

23A, On-vehicle Service

Transmission Fluid

Change P.23A-292).

Front Under Cover, Side Under Cover

Installation