SPEED MITSUBISHI 380 2005 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1135 of 1500

KEYLESS ENTRY SYSTEM

BODY42-68

If none of the doors is opened or the ignition key

is not inserted in the ignition switch within 30 sec-

onds after the doors are unlocked using the

transmitter, the ETACS-ECU will relock the doors

automatically. This is called "Timer lock function."

This timer lock function prevents accidental

unlocking of doors. The adjustment function

allows you to change the timer lock period from 30 seconds (default setting) to 60, 120 or 180

seconds. For further details on using the

multi-center display (middle grade type) to adjust

the timer lock period, refer to GROUP 54B,

On-vehicle Service P.54B-486.

NOTE: The timer lock period begins when the doors

are unlocked, and ends when the doors is relocked

automatically.

KEYLESS ENTRY SYSTEM DIAGNOSISBGBCJGAI

The keyless entry system is controlled by the Simpli-

fied Wiring System (SWS). Refer to GROUP 54B,

SWS Diagnosis P.54B-57.

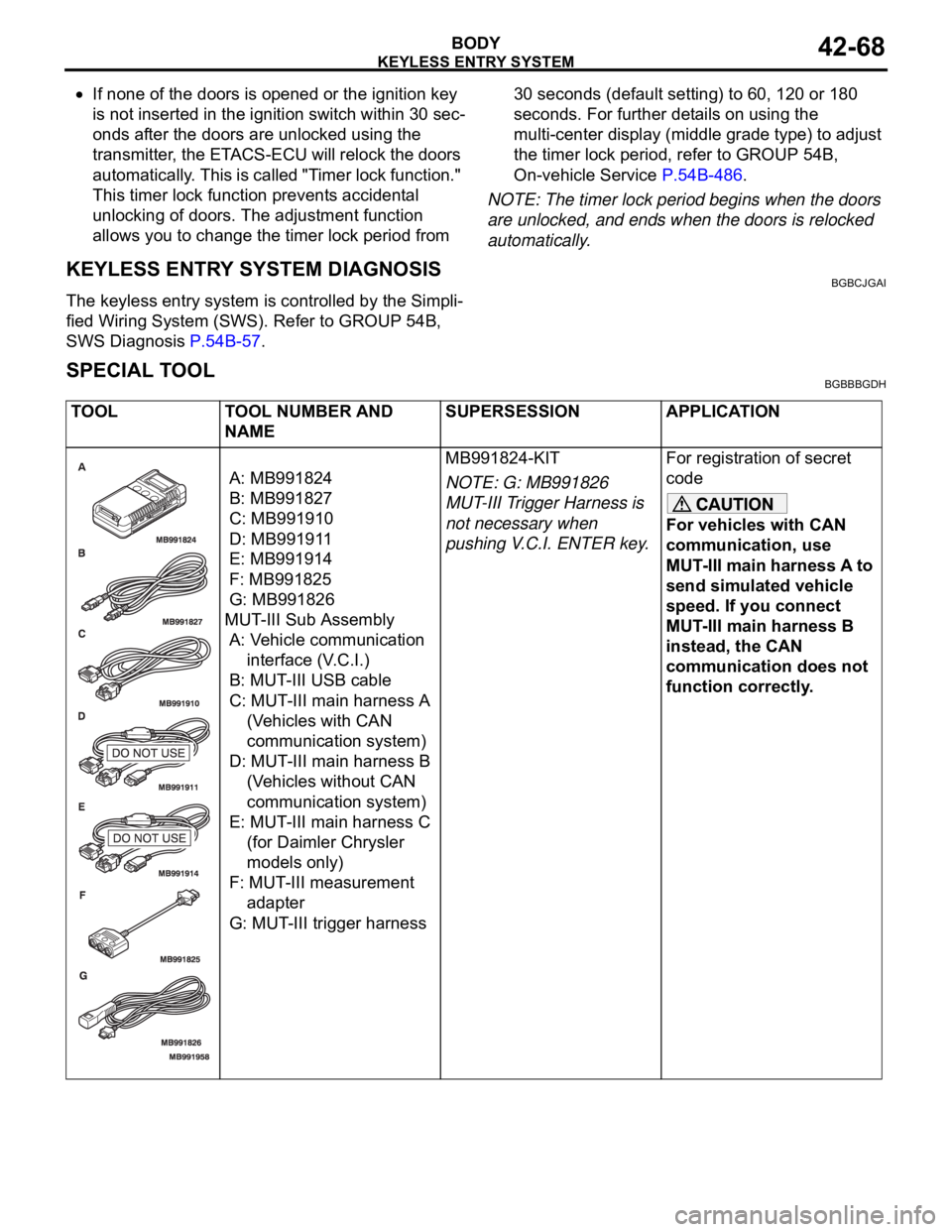

SPECIAL TOOLBGBBBGDH

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III Sub Assembly

A: Vehicle communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness A

(Vehicles with CAN

communication system)

D: MUT-III main harness B

(Vehicles without CAN

communication system)

E: MUT-III main harness C

(for Daimler Chrysler

models only)

F: MUT-III measurement

adapter

G: MUT-III trigger harnessMB991824-KIT

NOTE: G: MB991826

MUT-III Trigger Harness is

not necessary when

pushing V.C.I. ENTER key.For registration of secret

code

For vehicles with CAN

communication, use

MUT-III main harness A to

send simulated vehicle

speed. If you connect

MUT-III main harness B

instead, the CAN

communication does not

function correctly.

Page 1212 of 1500

ON-VEHICLE SERVICE

PARKING BRAKES36-5

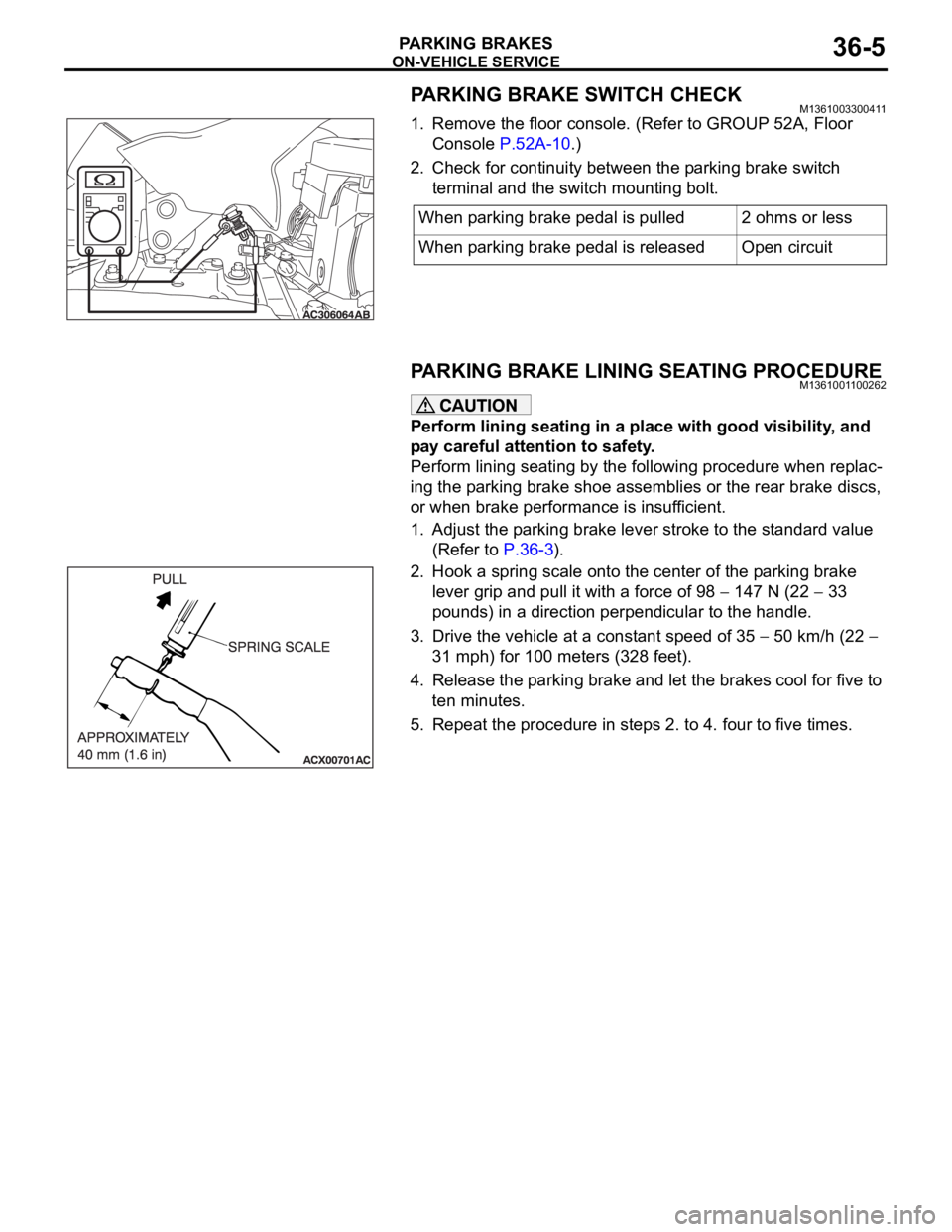

PARKING BRAKE SWITCH CHECKM1361003300411

1. Remove the floor console. (Refer to GROUP 52A, Floor

Console P.52A-10.)

2. Check for continuity between the parking brake switch

terminal and the switch mounting bolt.

PARKING BRAKE LINING SEATING PROCEDUREM1361001100262

Perform lining seating in a place with good visibility, and

pay careful attention to safety.

Perform lining seating by the following procedure when replac-

ing the parking brake shoe assemblies or the rear brake discs,

or when brake performance is insufficient.

1. Adjust the parking brake lever stroke to the standard value

(Refer to P.36-3).

2. Hook a spring scale onto the center of the parking brake

lever grip and pull it with a force of 98

147 N (22 33

pounds) in a direction perpendicular to the handle.

3. Drive the vehicle at a constant speed of 35

50 km/h (22

31 mph) for 100 meters (328 feet).

4. Release the parking brake and let the brakes cool for five to

ten minutes.

5. Repeat the procedure in steps 2. to 4. four to five times.When parking brake pedal is pulled 2 ohms or less

When parking brake pedal is released Open circuit

Page 1216 of 1500

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-9

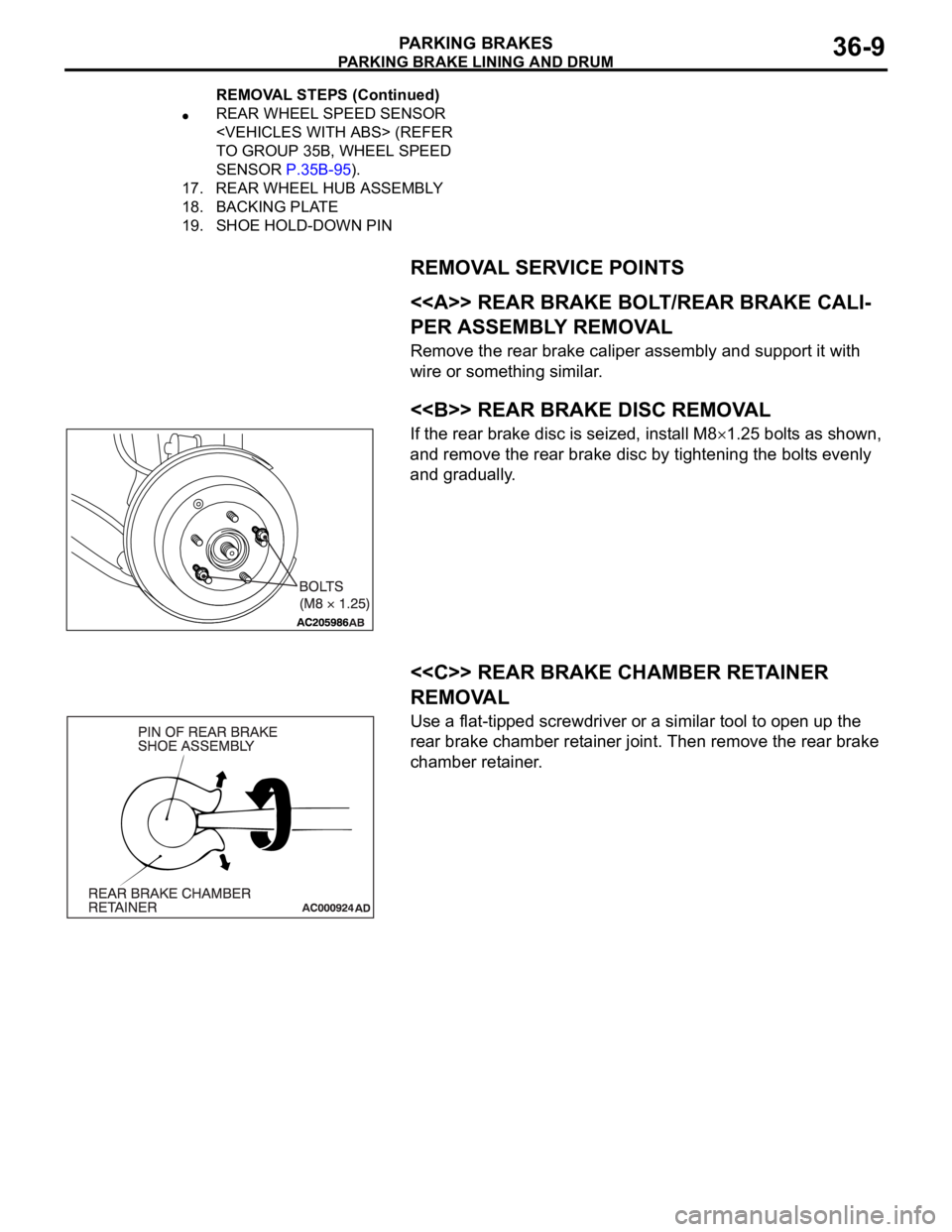

REMOVAL SERVICE POINTS

.

<> REAR BRAKE BOLT/REAR BRAKE CALI-

PER ASSEMBLY REMOVAL

Remove the rear brake caliper assembly and support it with

wire or something similar.

.

<> REAR BRAKE DISC REMOVAL

If the rear brake disc is seized, install M81.25 bolts as shown,

and remove the rear brake disc by tightening the bolts evenly

and gradually.

.

<

REMOVAL

Use a flat-tipped screwdriver or a similar tool to open up the

rear brake chamber retainer joint. Then remove the rear brake

chamber retainer.

REAR WHEEL SPEED SENSOR

TO GROUP 35B, WHEEL SPEED

SENSOR P.35B-95).

17. REAR WHEEL HUB ASSEMBLY

18. BACKING PLATE

19. SHOE HOLD-DOWN PIN

REMOVAL STEPS (Continued)

Page 1239 of 1500

VEHICLE IDENTIFICATION

GENERAL00-18

VEHICLE IDENTIFICATION

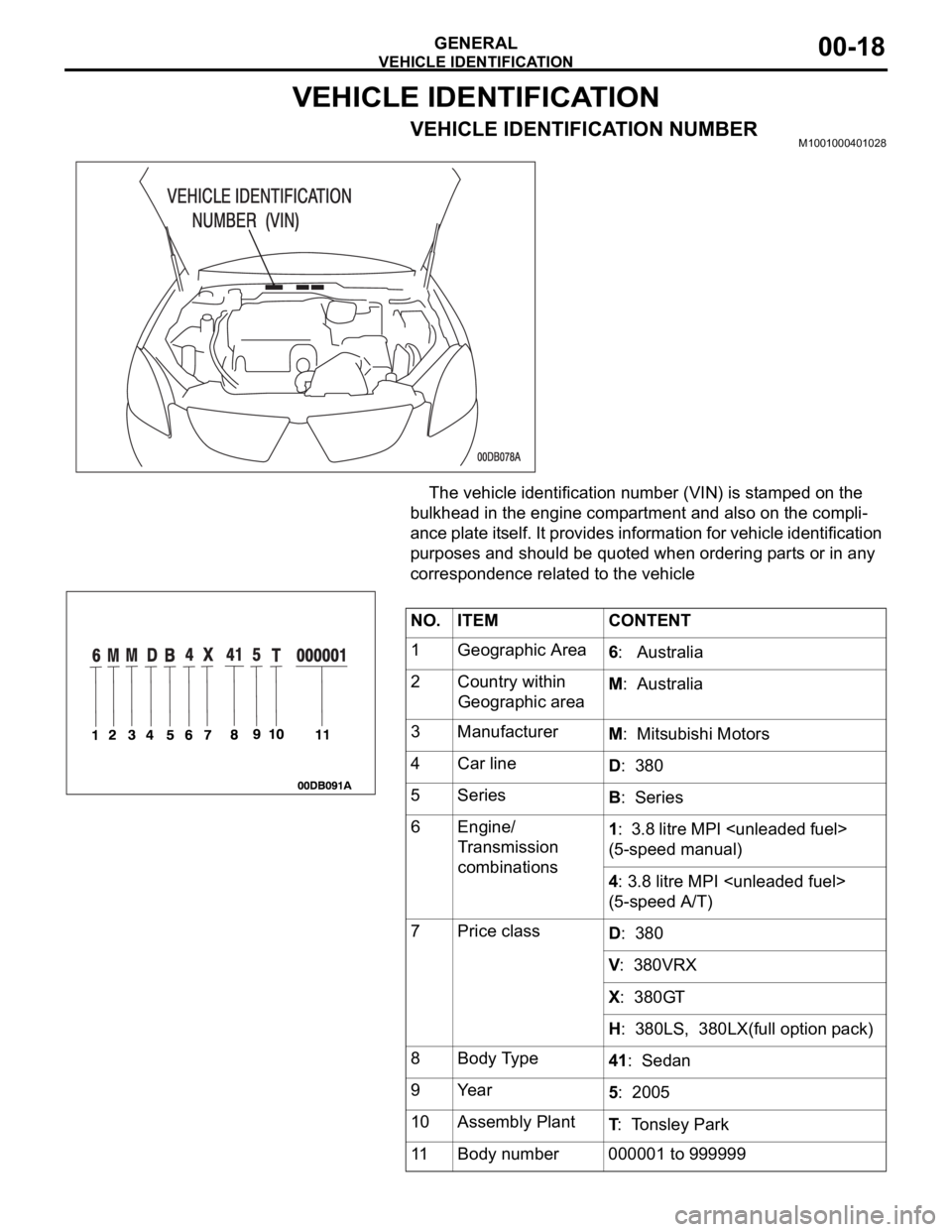

VEHICLE IDENTIFICATION NUMBERM1001000401028

The vehicle identification number (VIN) is stamped on the

bulkhead in the engine compartment and also on the compli-

ance plate itself. It provides information for vehicle identification

purposes and should be quoted when ordering parts or in any

correspondence related to the vehicle

NO. ITEM CONTENT

1 Geographic Area

6: Australia

2 Country within

Geographic areaM: Australia

3 Manufacturer

M: Mitsubishi Motors

4 Car line

D: 380

5Series

B: Series

6 Engine/

Transmission

combinations1: 3.8 litre MPI

(5-speed manual)

4: 3.8 litre MPI

(5-speed A/T)

7Price class

D: 380

V: 380VRX

X: 380GT

H: 380LS, 380LX(full option pack)

8 Body Type

41: Sedan

9Year

5: 2005

10 Assembly Plant

T: Tonsley Park

11 Body number 000001 to 999999

Page 1247 of 1500

TOWING AND HOISTING

GENERAL00-26

TOWING AND HOISTINGM1001000800380

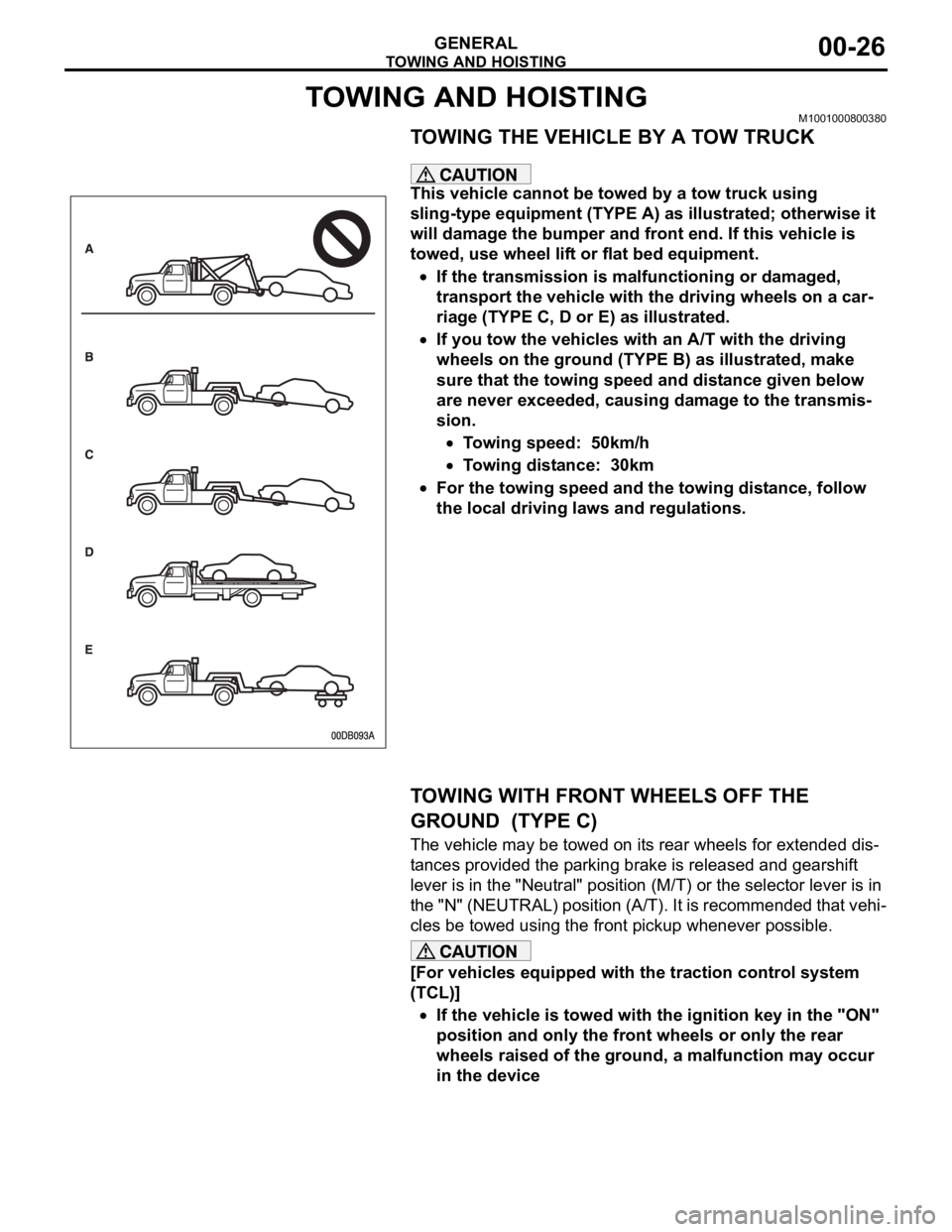

TOWING THE VEHICLE BY A TOW TRUCK

.

This vehicle cannot be towed by a tow truck using

sling-type equipment (TYPE A) as illustrated; otherwise it

will damage the bumper and front end. If this vehicle is

towed, use wheel lift or flat bed equipment.

If the transmission is malfunctioning or damaged,

transport the vehicle with the driving wheels on a car-

riage (TYPE C, D or E) as illustrated.

If you tow the vehicles with an A/T with the driving

wheels on the ground (TYPE B) as illustrated, make

sure that the towing speed and distance given below

are never exceeded, causing damage to the transmis-

sion.

Towing speed: 50km/h

Towing distance: 30km

For the towing speed and the towing distance, follow

the local driving laws and regulations.

.

TOWING WITH FRONT WHEELS OFF THE

GROUND (TYPE C)

The vehicle may be towed on its rear wheels for extended dis-

tances provided the parking brake is released and gearshift

lever is in the "Neutral" position (M/T) or the selector lever is in

the "N" (NEUTRAL) position (A/T). It is recommended that vehi-

cles be towed using the front pickup whenever possible.

[For vehicles equipped with the traction control system

(TCL)]

If the vehicle is towed with the ignition key in the "ON"

position and only the front wheels or only the rear

wheels raised of the ground, a malfunction may occur

in the device

.

Page 1253 of 1500

TIGHTENING TORQUE

GENERAL00-32

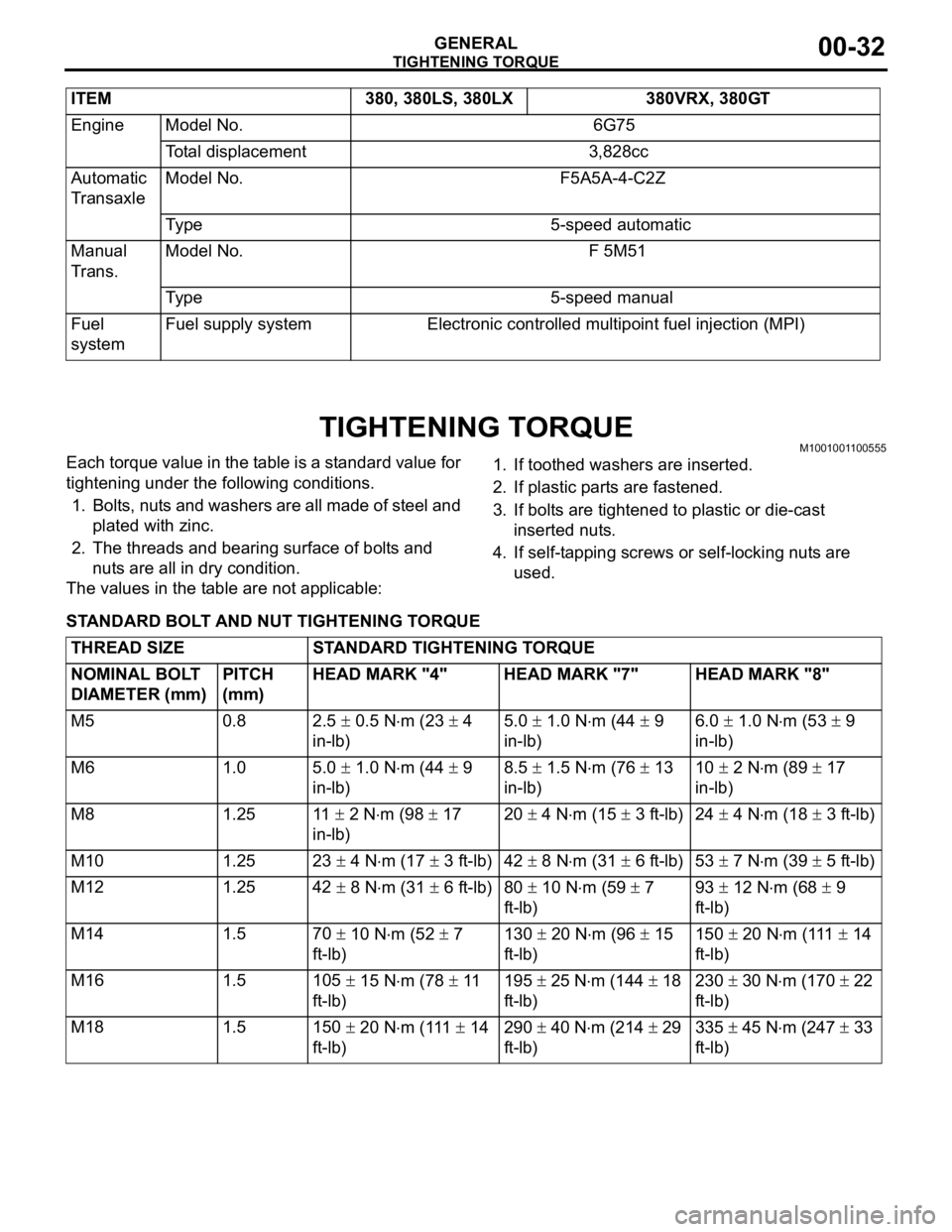

TIGHTENING TORQUEM1001001100555

Each torque value in the table is a standard value for

tightening under the following conditions.

1. Bolts, nuts and washers are all made of steel and

plated with zinc.

2. The threads and bearing surface of bolts and

nuts are all in dry condition.

The values in the table are not applicable:1. If toothed washers are inserted.

2. If plastic parts are fastened.

3. If bolts are tightened to plastic or die-cast

inserted nuts.

4. If self-tapping screws or self-locking nuts are

used.

STANDARD BOLT AND NUT TIGHTENING TORQUE Engine Model No. 6G75

Total displacement 3,828cc

Automatic

TransaxleModel No. F5A5A-4-C2Z

Type 5-speed automatic

Manual

Trans.Model No. F 5M51

Type 5-speed manual

Fuel

systemFuel supply system Electronic controlled multipoint fuel injection (MPI) ITEM 380, 380LS, 380LX 380VRX, 380GT

THREAD SIZE STANDARD TIGHTENING TORQUE

NOMINAL BOLT

DIAMETER (mm)PITCH

(mm)HEAD MARK "4" HEAD MARK "7" HEAD MARK "8"

M5 0.8 2.5

0.5 Nm (23 4

in-lb)5.0 1.0 Nm (44 9

in-lb)6.0 1.0 Nm (53 9

in-lb)

M6 1.0 5.0

1.0 Nm (44 9

in-lb)8.5 1.5 Nm (76 13

in-lb)10 2 Nm (89 17

in-lb)

M8 1.25 11

2 Nm (98 17

in-lb)20 4 Nm (15 3 ft-lb) 24 4 Nm (18 3 ft-lb)

M10 1.25 23

4 Nm (17 3 ft-lb) 42 8 Nm (31 6 ft-lb) 53 7 Nm (39 5 ft-lb)

M12 1.25 42

8 Nm (31 6 ft-lb) 80 10 Nm (59 7

ft-lb)93 12 Nm (68 9

ft-lb)

M14 1.5 70

10 Nm (52 7

ft-lb)130 20 Nm (96 15

ft-lb)150 20 Nm ( 111 14

ft-lb)

M16 1.5 105

15 Nm (78 11

ft-lb)195 25 Nm (144 18

ft-lb)230 30 Nm (170 22

ft-lb)

M18 1.5 150

20 Nm ( 111 14

ft-lb)290 40 Nm (214 29

ft-lb)335 45 Nm (247 33

ft-lb)

Page 1280 of 1500

13C-1

GROUP 13C

TRACTION

CONTROL SYSTEM

(TCL)

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .13C-2

TRACTION CONTROL SYSTEM (TCL)

DIAGNOSIS . . . . . . . . . . . . . . . . . . . .13C-3

INTRODUCTION TO TRACTION CONTROL

SYSTEM (TCL) DIAGNOSIS . . . . . . . . . . . 13C-3

TROUBLESHOOTING STRATEGY . . . . . . 13C-3

DIAGNOSIS FUNCTION. . . . . . . . . . . . . . . 13C-3

DIAGNOSTIC TROUBLE CODE CHART . . 13C-8

DIAGNOSTIC TROUBLE CODE

PROCEDURES . . . . . . . . . . . . . . . . . . . . . . 13C-10

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 13C-23

SYMPTOM PROCEDURES . . . . . . . . . . . . 13C-23

DATA LIST REFERENCE TABLE . . . . . . . 13C-36

ACTUATOR TEST REFERENCE TABLE. . 13C-37

CHECK AT ABS/TCL-ECU RESISTANCE

AND TERMINAL VOLTAGE . . . . . . . . . . . . 13C-38RESISTANCE AND CONTINUITY

BETWEEN ABS-ECU AND WHEEL SPEED

SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 13C-39

VOLTAGE AND SIGNAL CHECK AT

ABS-ECU USING AN OSCILLOSCOPE . . . 13C-41

SPECIAL TOOLS . . . . . . . . . . . . . . . .13C-45

ON-VEHICLE SERVICE . . . . . . . . . . .13C-47

TCL INDICATOR LIGHT CHECK . . . . . . . . 13C-47

TCL OPERATION CHECK . . . . . . . . . . . . . 13C-47

TCL SWITCH CHECK . . . . . . . . . . . . . . . . . 13C-48

WHEEL SPEED SENSOR CHECK . . . . . . . 13C-48

TCL SWITCH . . . . . . . . . . . . . . . . . . .13C-49

REMOVAL AND INSTALLATION . . . . . . . . 13C-49

WHEEL SPEED SENSOR . . . . . . . . .13C-49

REMOVAL AND INSTALLATION . . . . . . . . 13C-49

ABS/TCL-ECU . . . . . . . . . . . . . . . . . .13C-49

REMOVAL AND INSTALLATION . . . . . . . . 13C-49

Page 1282 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-3

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

INTRODUCTION TO TRACTION CONTROL SYSTEM (TCL) DIAGNOSISM1136004600026

TCL Diagnostic Trouble Code Detection

Conditions

TCL diagnostic trouble codes (TCL DTCs) are set

under different conditions, depending on the mal-

function detected. Most TCL DTCs will only be set

during vehicle operation. Some TCL DTCs will also

be set during the TCL self-check immediately after

the engine is started. When you check if an TCL DTC will be displayed again after the DTC has been

erased, you should recreate the TCL DTC set condi-

tions. Depending on the detection timing and set

conditions for the specific TCL DTC, you must either

drive the vehicle or turn the engine off and restart it.

To set the proper conditions for that DTC again, refer

to "TCL DTC SET CONDITIONS" for each TCL DTC

that you are trying to reset.

TROUBLESHOOTING STRATEGYM1136003100062

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will check most of the

possible causes of a TCL problem.

1. Gather information from the customer.

2. Verify that the condition described by the

customer exists.

3. Check the vehicle for any TCL DTC. (Refer to

P.13C-3, Diagnosis Function

How to Read and

Erase Diagnostic Trouble Codes).

4. If you can verify the condition but no TCL DTCs

are set, and the malfunction may be intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How

to Cope with Intermittent Malfunctions P.00-14).

5. If you can verify the condition but there is no TCL

DTCs, or the system cannot communicate with

diagnostic tool MB991958 (MUT-III sub

assembly), and find the fault. (Refer to P.13C-23,

Symptom Chart).6. If there is a TCL DTC, record the number of the

code, then erase the code from vehicle memory

using the diagnostic tool MB991958 (MUT-III sub

assembly). (Refer to P.13C-3, Diagnosis Function

How to Read and Erase Diagnostic Trouble

Codes).

7. Re-create the TCL DTC set conditions to see if

the same TCL DTC will set again. (Refer to

P.13C-3, Diagnosis Function

How to Read and

Erase Diagnostic Trouble Codes).

If the same TCL DTC sets again, perform the

diagnostic procedures for the set code. (Refer to

P.13C-8, Diagnostic Trouble Code Chart).

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wir-

ing is an open/ short circuit, the ABS 8 ECU

will shut off power supply to the respective

wheel speed sensor. All other wheel speed

sensors will operate normally. To restore the

power supply, the ignition switch must be

turned to the "OFF" position then to the "ON"

position again.

DIAGNOSIS FUNCTIONM1136003200025

HOW TO CONNECT THE DIAGNOSTIC TOOL

(MUT-III)

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1287 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-8

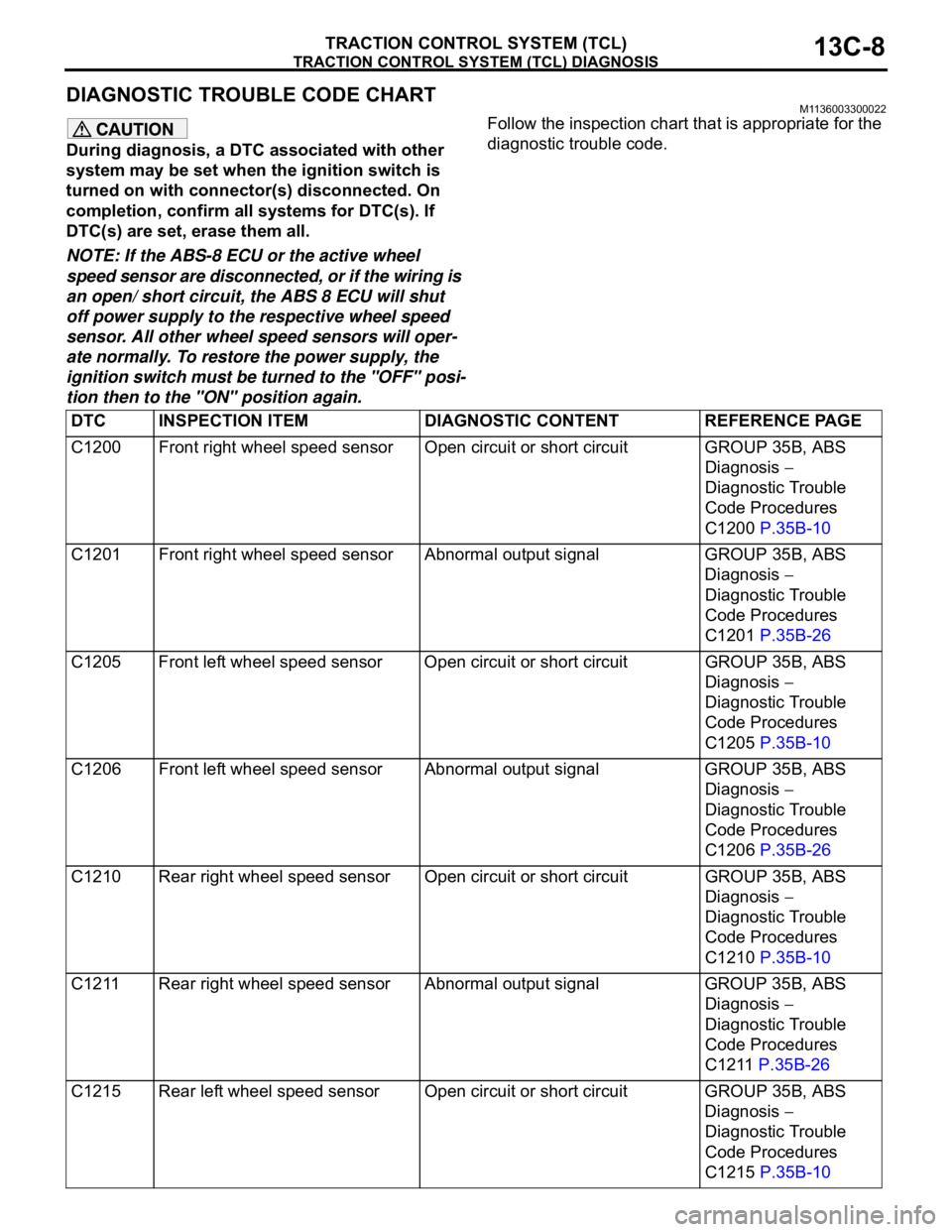

DIAGNOSTIC TROUBLE CODE CHARTM1136003300022

During diagnosis, a DTC associated with other

system may be set when the ignition switch is

turned on with connector(s) disconnected. On

completion, confirm all systems for DTC(s). If

DTC(s) are set, erase them all.

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.Follow the inspection chart that is appropriate for the

diagnostic trouble code.

DTC INSPECTION ITEM DIAGNOSTIC CONTENT REFERENCE PAGE

C1200 Front right wheel speed sensor Open circuit or short circuit GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1200 P.35B-10

C1201 Front right wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1201 P.35B-26

C1205 Front left wheel speed sensor Open circuit or short circuitGROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1205 P.35B-10

C1206 Front left wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1206 P.35B-26

C1210 Rear right wheel speed sensor Open circuit or short circuitGROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1210 P.35B-10

C1211 Rear right wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1211 P.35B-26

C1215 Rear left wheel speed sensor Open circuit or short circuit GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1215 P.35B-10

Page 1288 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-9

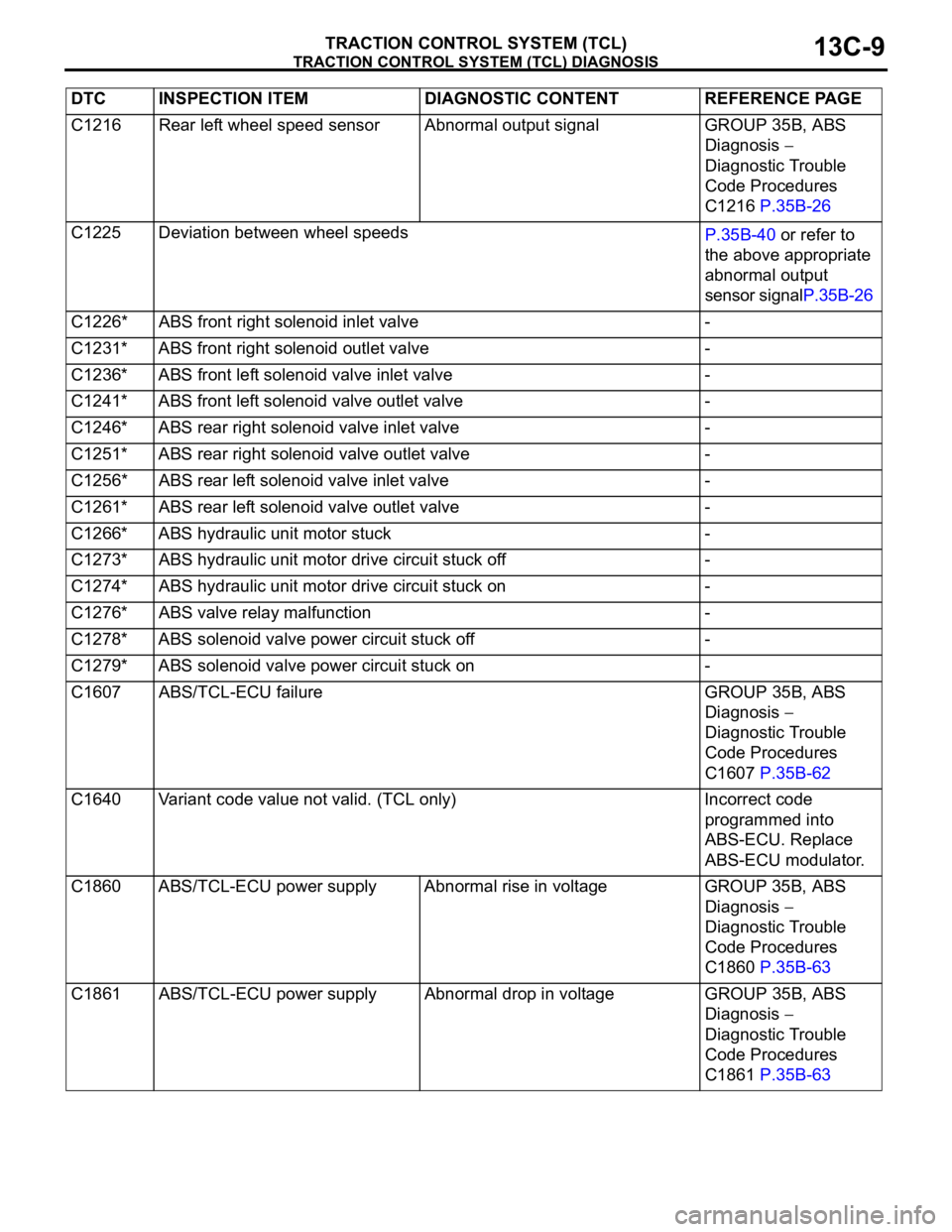

C1216 Rear left wheel speed sensor Abnormal output signal GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1216 P.35B-26

C1225 Deviation between wheel speeds

P.35B-40 or refer to

the above appropriate

abnormal output

sensor signalP.35B-26

C1226* ABS front right solenoid inlet valve -

C1231* ABS front right solenoid outlet valve -

C1236* ABS front left solenoid valve inlet valve -

C1241* ABS front left solenoid valve outlet valve -

C1246* ABS rear right solenoid valve inlet valve -

C1251* ABS rear right solenoid valve outlet valve -

C1256* ABS rear left solenoid valve inlet valve -

C1261* ABS rear left solenoid valve outlet valve -

C1266* ABS hydraulic unit motor stuck -

C1273* ABS hydraulic unit motor drive circuit stuck off -

C1274* ABS hydraulic unit motor drive circuit stuck on -

C1276* ABS valve relay malfunction -

C1278* ABS solenoid valve power circuit stuck off -

C1279* ABS solenoid valve power circuit stuck on -

C1607 ABS/TCL-ECU failure GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1607 P.35B-62

C1640 Variant code value not valid. (TCL only) Incorrect code

programmed into

ABS-ECU. Replace

ABS-ECU modulator.

C1860 ABS/TCL-ECU power supply Abnormal rise in voltage GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1860 P.35B-63

C1861 ABS/TCL-ECU power supply Abnormal drop in voltage GROUP 35B, ABS

Diagnosis

Diagnostic Trouble

Code Procedures

C1861 P.35B-63 DTC INSPECTION ITEM DIAGNOSTIC CONTENT REFERENCE PAGE