display MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 424 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-424

STEP 1. Use diagnostic tool MB991958 to select "ECU

COMM Check" on the SWS monitor display.

Check the column-ECU.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958. Connect special tool MB991910 before con-

necting special tool MB991812. Be sure to connect special

tool MB991806 after turning on special tool MB991824.

(1) Connect the special tool. Refer to "How to connect SWS

monitor P.54B-13."

(2) Turn the ignition switch to the "ON" position.

(3) Operate the diagnostic tool according to the procedure

below to display "ECU COMM Check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "SWS MONITOR."

e. Select "ECU COMM Check."

(4) Diagnostic tool (MUT-III) should show "OK" on the "ECU

COMM Check" menu for the "COLUMN ECU" menu.

Q: Is "OK" displayed for the "COLUMN ECU" menu?

YES : Go to Step 2.

NO : Refer to Inspection Procedure A-2 "Communication

with the column switch (column-ECU) is not possible

P.54B-68."

Page 441 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-441

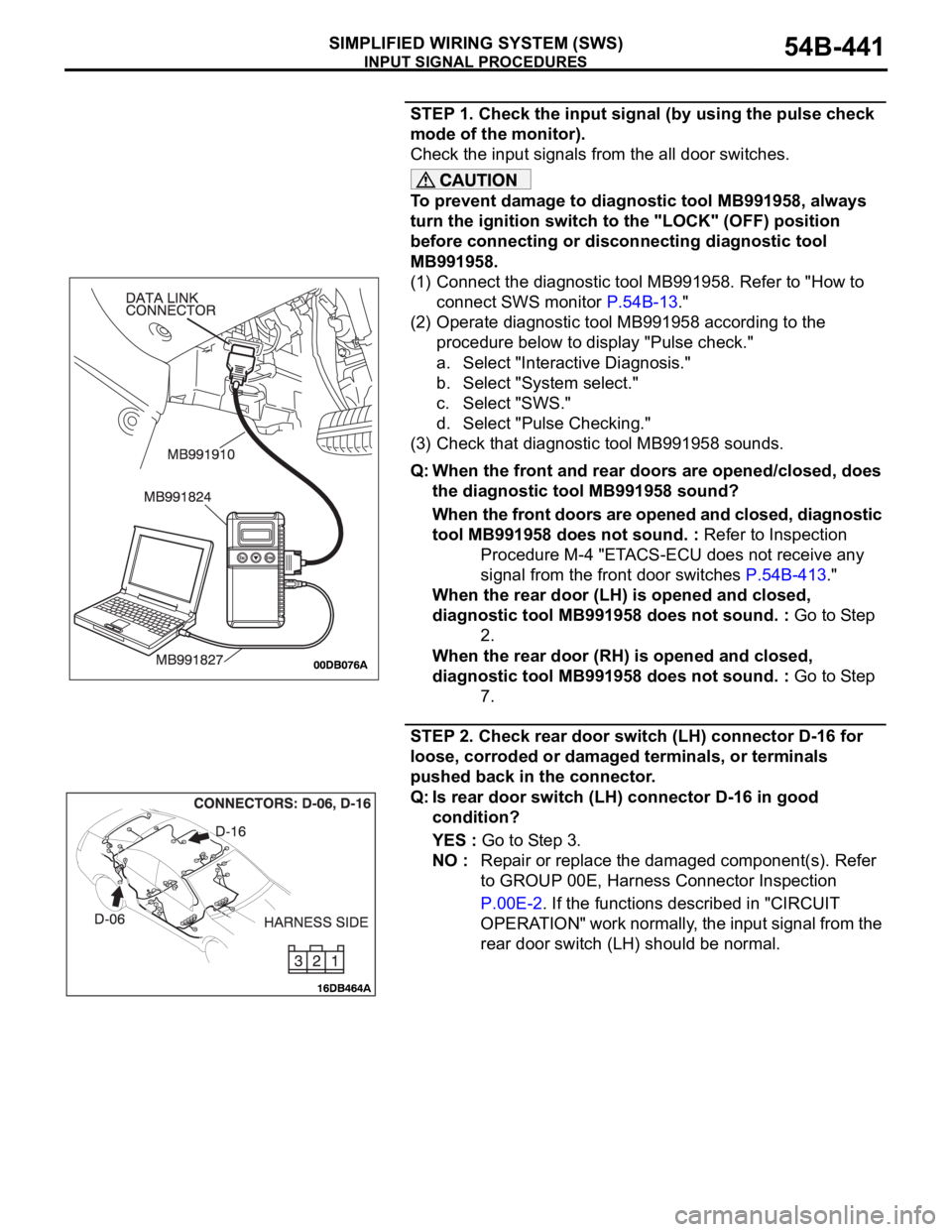

STEP 1. Check the input signal (by using the pulse check

mode of the monitor).

Check the input signals from the all door switches.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect the diagnostic tool MB991958. Refer to "How to

connect SWS monitor P.54B-13."

(2) Operate diagnostic tool MB991958 according to the

procedure below to display "Pulse check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "Pulse Checking."

(3) Check that diagnostic tool MB991958 sounds.

Q: When the front and rear doors are opened/closed, does

the diagnostic tool MB991958 sound?

When the front doors are opened and closed, diagnostic

tool MB991958 does not sound. : Refer to Inspection

Procedure M-4 "ETACS-ECU does not receive any

signal from the front door switches P.54B-413."

When the rear door (LH) is opened and closed,

diagnostic tool MB991958 does not sound. : Go to Step

2.

When the rear door (RH) is opened and closed,

diagnostic tool MB991958 does not sound. : Go to Step

7.

STEP 2. Check rear door switch (LH) connector D-16 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is rear door switch (LH) connector D-16 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the functions described in "CIRCUIT

OPERATION" work normally, the input signal from the

rear door switch (LH) should be normal.

Page 452 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-452

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

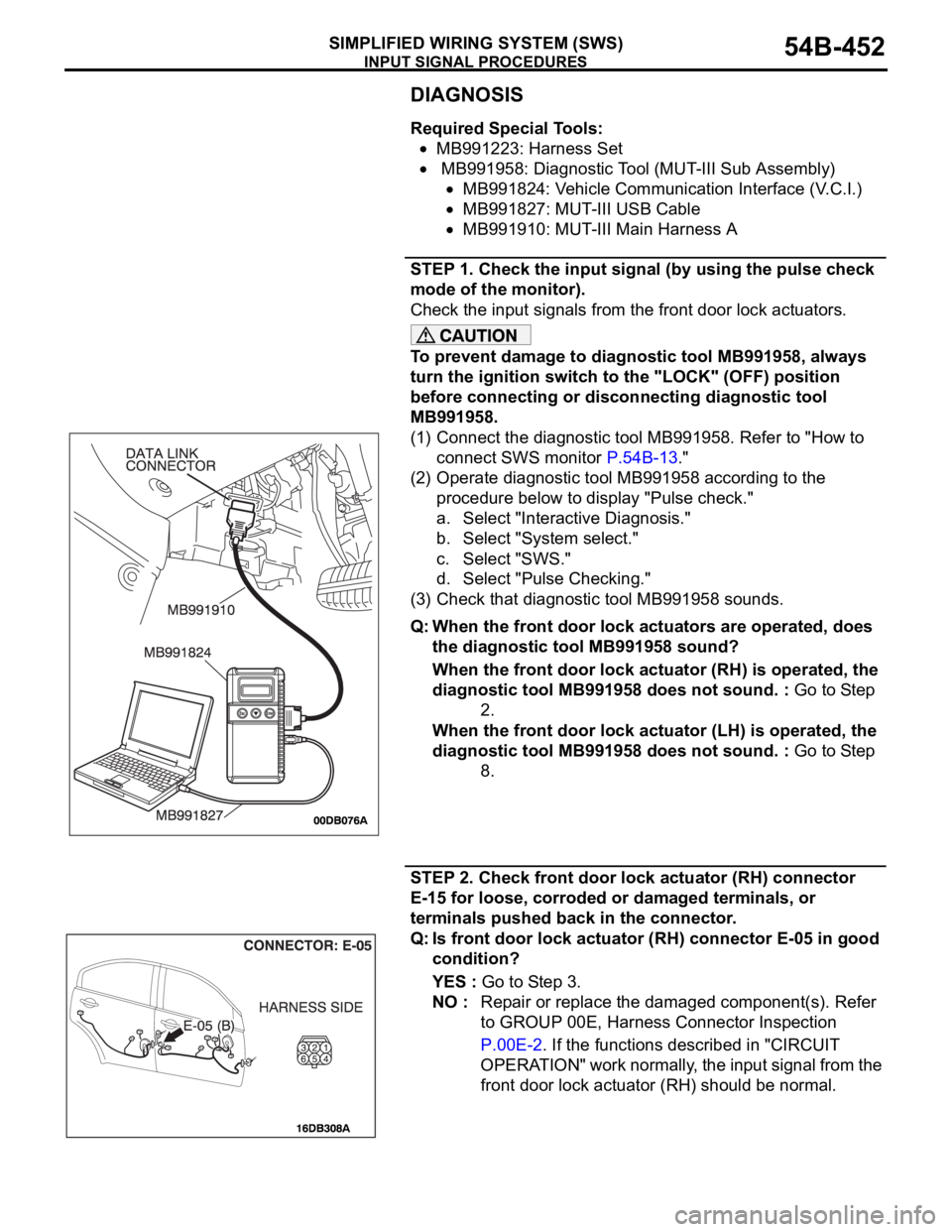

STEP 1. Check the input signal (by using the pulse check

mode of the monitor).

Check the input signals from the front door lock actuators.

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect the diagnostic tool MB991958. Refer to "How to

connect SWS monitor P.54B-13."

(2) Operate diagnostic tool MB991958 according to the

procedure below to display "Pulse check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "Pulse Checking."

(3) Check that diagnostic tool MB991958 sounds.

Q: When the front door lock actuators are operated, does

the diagnostic tool MB991958 sound?

When the front door lock actuator (RH) is operated, the

diagnostic tool MB991958 does not sound. : Go to Step

2.

When the front door lock actuator (LH) is operated, the

diagnostic tool MB991958 does not sound. : Go to Step

8.

STEP 2. Check front door lock actuator (RH) connector

E-15 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is front door lock actuator (RH) connector E-05 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the functions described in "CIRCUIT

OPERATION" work normally, the input signal from the

front door lock actuator (RH) should be normal.

Page 461 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-461

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

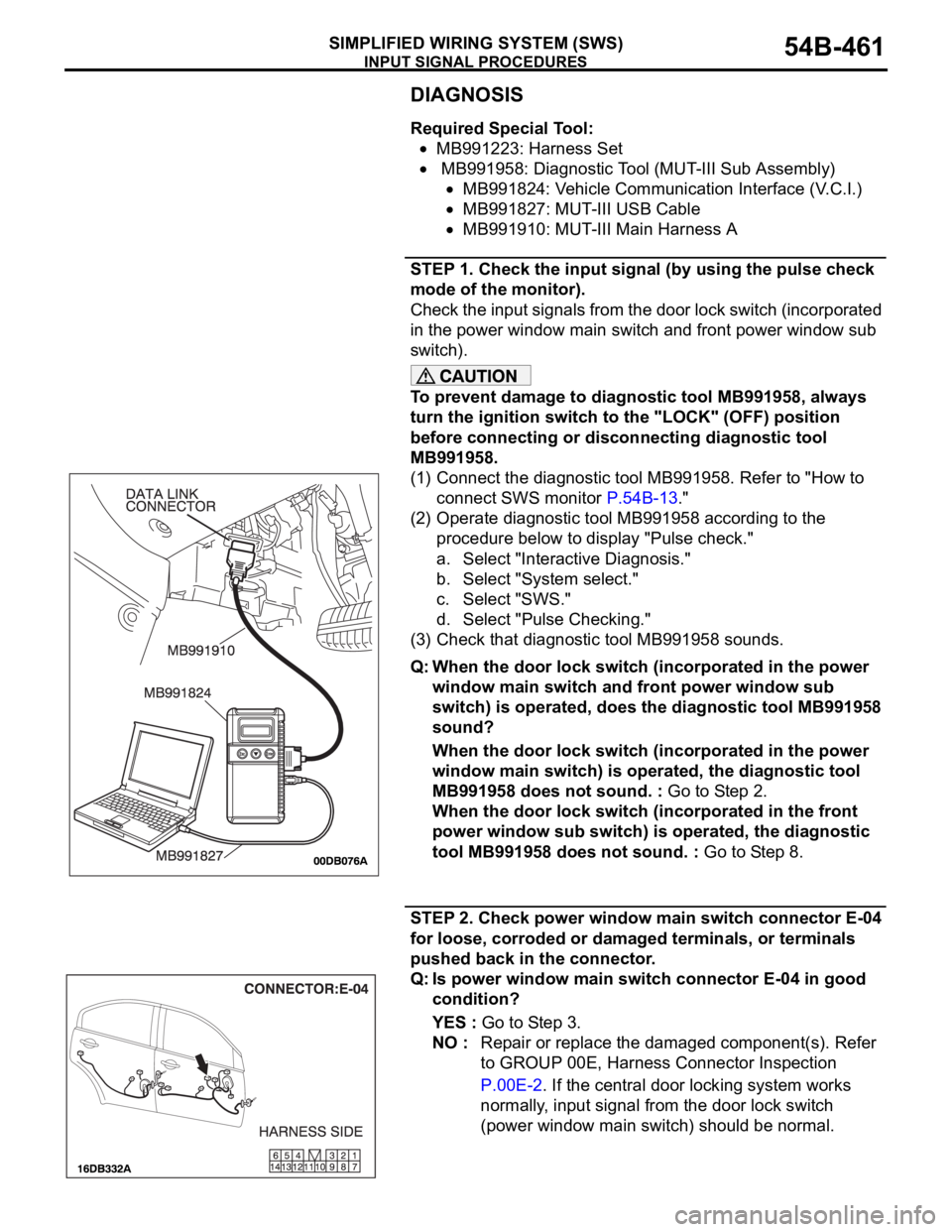

STEP 1. Check the input signal (by using the pulse check

mode of the monitor).

Check the input signals from the door lock switch (incorporated

in the power window main switch and front power window sub

switch).

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect the diagnostic tool MB991958. Refer to "How to

connect SWS monitor P.54B-13."

(2) Operate diagnostic tool MB991958 according to the

procedure below to display "Pulse check."

a. Select "Interactive Diagnosis."

b. Select "System select."

c. Select "SWS."

d. Select "Pulse Checking."

(3) Check that diagnostic tool MB991958 sounds.

Q: When the door lock switch (incorporated in the power

window main switch and front power window sub

switch) is operated, does the diagnostic tool MB991958

sound?

When the door lock switch (incorporated in the power

window main switch) is operated, the diagnostic tool

MB991958 does not sound. : Go to Step 2.

When the door lock switch (incorporated in the front

power window sub switch) is operated, the diagnostic

tool MB991958 does not sound. : Go to Step 8.

STEP 2. Check power window main switch connector E-04

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is power window main switch connector E-04 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. If the central door locking system works

normally, input signal from the door lock switch

(power window main switch) should be normal.

Page 486 of 1500

ON-VEHICLE SERVICE

SIMPLIFIED WIRING SYSTEM (SWS)54B-486

ON-VEHICLE SERVICE

CONFIGURATION FUNCTIONM1549002500861

ADJUSTMENT BY OPERATING THE

MULTI CENTER DISPLAY

The following function and system customizations

are possible by using the multi center display.

Page 488 of 1500

ON-VEHICLE SERVICE

SIMPLIFIED WIRING SYSTEM (SWS)54B-488

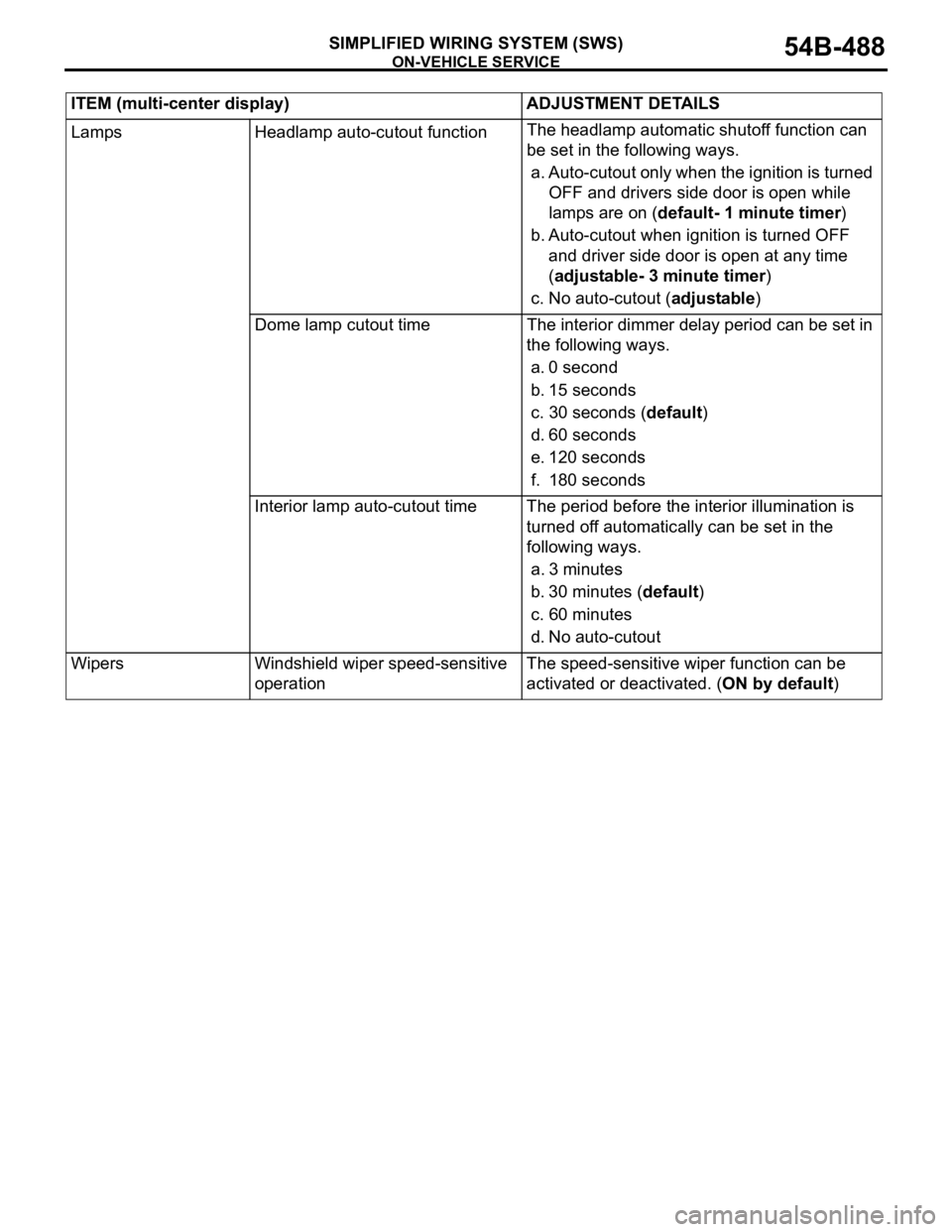

ITEM (multi-center display) ADJUSTMENT DETAILS

Lamps Headlamp auto-cutout functionThe headlamp automatic shutoff function can

be set in the following ways.

a. Auto-cutout only when the ignition is turned

OFF and drivers side door is open while

lamps are on (default- 1 minute timer)

b. Auto-cutout when ignition is turned OFF

and driver side door is open at any time

(adjustable- 3 minute timer)

c. No auto-cutout (adjustable)

Dome lamp cutout time The interior dimmer delay period can be set in

the following ways.

a. 0 second

b. 15 seconds

c. 30 seconds (default)

d. 60 seconds

e. 120 seconds

f. 180 seconds

Interior lamp auto-cutout time The period before the interior illumination is

turned off automatically can be set in the

following ways.

a. 3 minutes

b. 30 minutes (default)

c. 60 minutes

d. No auto-cutout

Wipers Windshield wiper speed-sensitive

operationThe speed-sensitive wiper function can be

activated or deactivated. (ON by default)

Page 489 of 1500

ON-VEHICLE SERVICE

SIMPLIFIED WIRING SYSTEM (SWS)54B-489

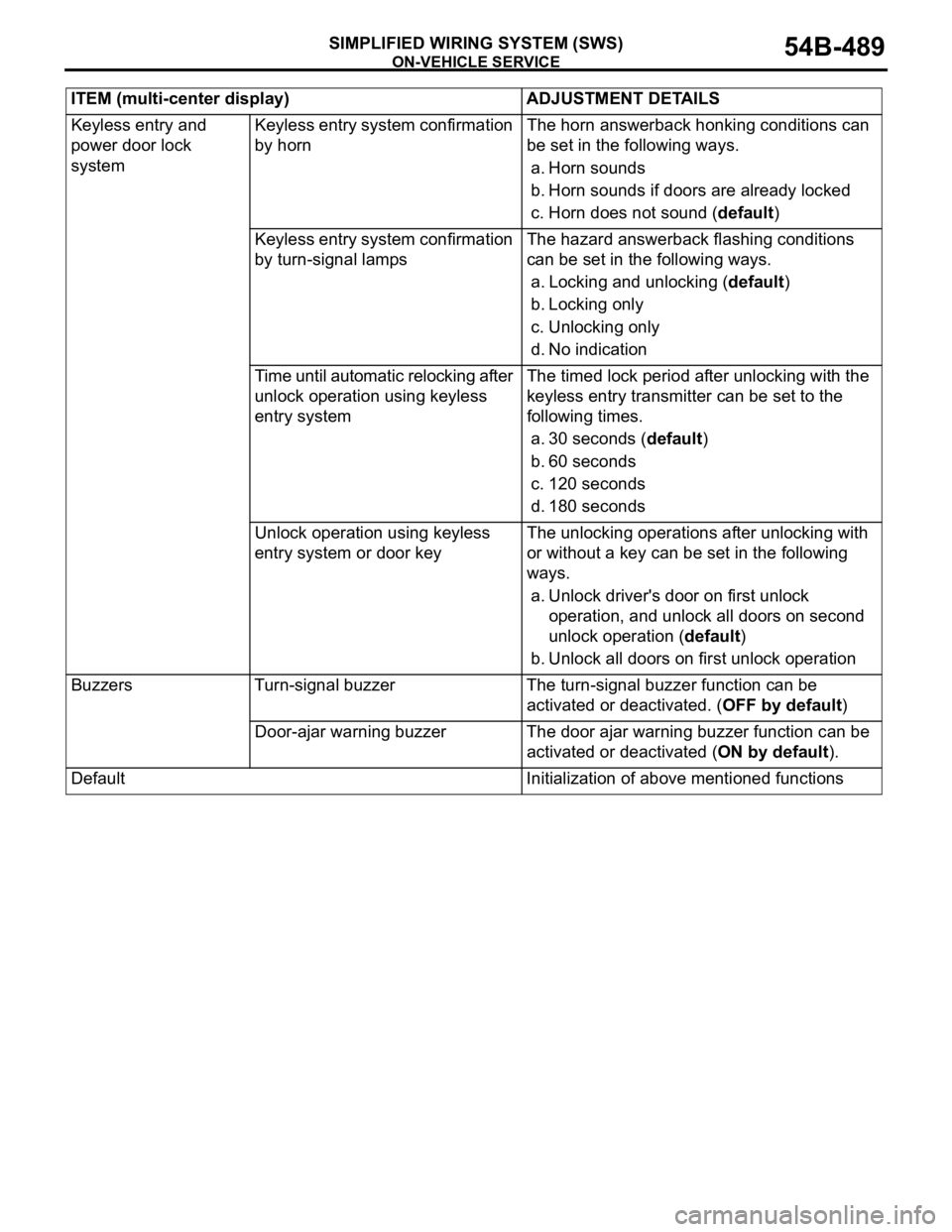

Keyless entry and

power door lock

systemKeyless entry system confirmation

by hornThe horn answerback honking conditions can

be set in the following ways.

a. Horn sounds

b. Horn sounds if doors are already locked

c. Horn does not sound (default)

Keyless entry system confirmation

by turn-signal lampsThe hazard answerback flashing conditions

can be set in the following ways.

a. Locking and unlocking (default)

b. Locking only

c. Unlocking only

d. No indication

Time until automatic relocking after

unlock operation using keyless

entry systemThe timed lock period after unlocking with the

keyless entry transmitter can be set to the

following times.

a. 30 seconds (default)

b. 60 seconds

c. 120 seconds

d. 180 seconds

Unlock operation using keyless

entry system or door keyThe unlocking operations after unlocking with

or without a key can be set in the following

ways.

a. Unlock driver's door on first unlock

operation, and unlock all doors on second

unlock operation (default)

b. Unlock all doors on first unlock operation

Buzzers Turn-signal buzzer The turn-signal buzzer function can be

activated or deactivated. (OFF by default)

Door-ajar warning buzzer The door ajar warning buzzer function can be

activated or deactivated (ON by default).

Default Initialization of above mentioned functions ITEM (multi-center display) ADJUSTMENT DETAILS

Page 495 of 1500

INSTRUMENT PANEL ASSEMBLY

INTERIOR52A-6

6. RADIO AND CD PLAYER,

ASSEMBLY

7. RADIO, CD PLAYER AND CD

CHANGER ASSEMBLY

8. CONSOLE METER HOOD

11. MULTI-CENTER DISPLAY

ASSEMBLY

12. INSTRUMENT DIGITAL CLOCK

ASSEMBLY

13. CENTER CONSOLE ASSEMBLY

14. INSTURMENT PANEL GARNISH

15. COMBINATION METER

ASSEMBLY

FRONT PILLAR TRIM (REFER TO

P.52A-11.)

16. FRONT SPEAKER GARNISH

17. TWEETER

18. INSTRUMENT PANEL SIDE

COVER

19. INSTRUMETN PANEL SIDE AIR

OUTLET

AIR BAG MODULE ASSEMBLY

(DRIVER’S SIDE) (REFER TO

GROUP 52B, AIR BAG MODULE

AND CLOCK SPRING P.52B-237.)

STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37,

STEERING WHEEL P.37-23.)

20. STEERING COLUMN COVERREMOVAL STEPS (Continued)

<>CLOCK SPRING CONNECTOR

<>COLUMN SWITHC CONNECTOR

CLOCK SPRING AND COLUMN

SWITCH ASSEMBLY (REFER TO

GROUP 37, STEERING SHAFT

P.37-25.)

21. INTERIOR TEMPERATURE

SENSOR (GROUP 55B,

SENSORS 55-160.)

22. INSTRUMENT PANEL FRONT

END GARNISH

23. PHOTO SENSOR (GROUP 55B,

SENSORS 55-160.) AND

SECURITY LED.

FLOOR CONSOLE ASSEMBLY

(REFER TO P.52A-10.)

COWL SIDE TRIM (REFER TO

P.52A-11.)

<>AIR BAG MODULE CONNECTOR

(PASSENGER’S SIDE) (REFER

TO GROUP 52B, AIR BAG

MODULE AND CLOCK SPRING

P.52B-237.)

25. INSTRUMENT PANEL ASSEMBLYREMOVAL STEPS (Continued)

Page 520 of 1500

FRONT SEAT ASSEMBLY

INTERIOR52A-31

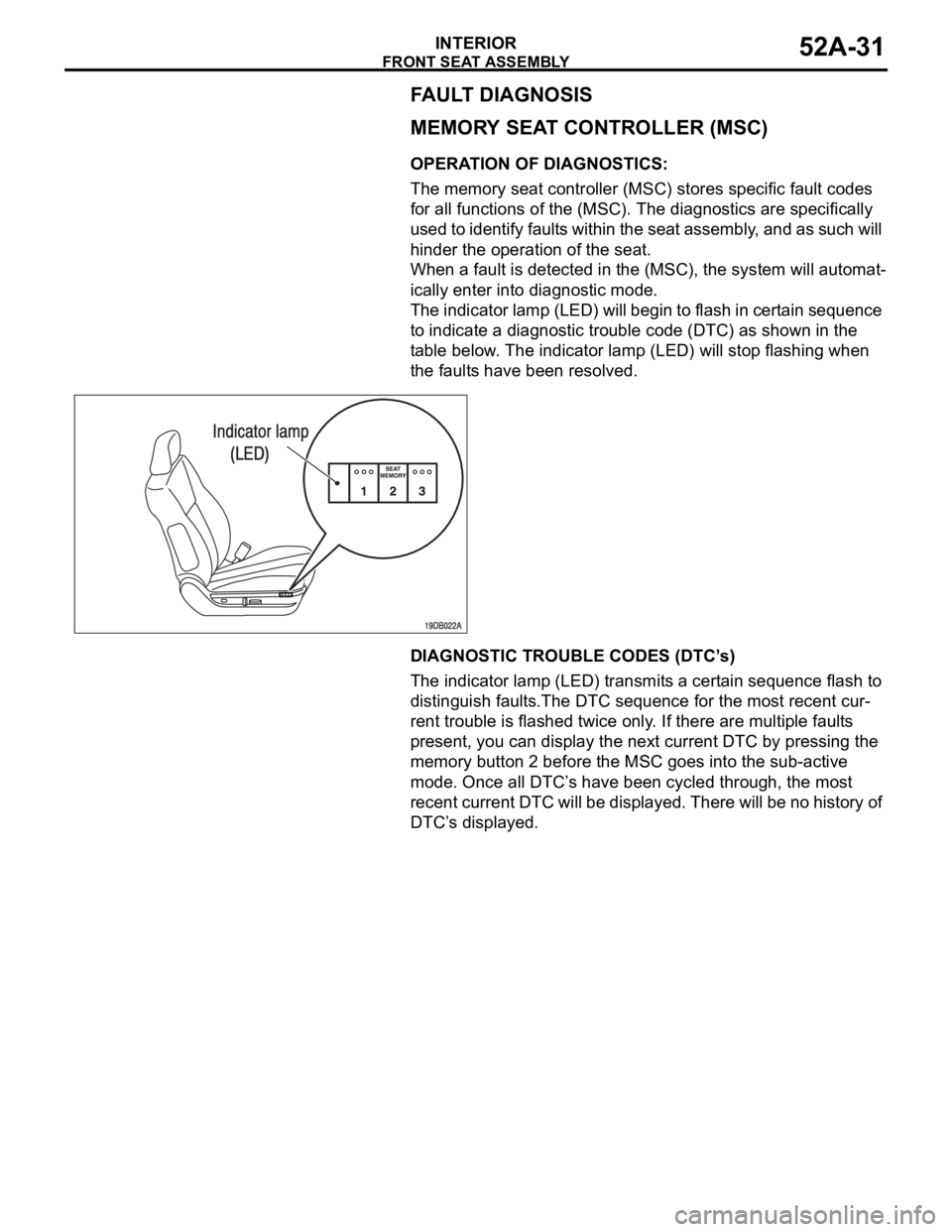

FAULT DIAGNOSIS

MEMORY SEAT CONTROLLER (MSC)

OPERATION OF DIAGNOSTICS:

The memory seat controller (MSC) stores specific fault codes

for all functions of the (MSC). The diagnostics are specifically

used to identify faults within the seat assembly, and as such will

hinder the operation of the seat.

When a fault is detected in the (MSC), the system will automat-

ically enter into diagnostic mode.

The indicator lamp (LED) will begin to flash in certain sequence

to indicate a diagnostic trouble code (DTC) as shown in the

table below. The indicator lamp (LED) will stop flashing when

the faults have been resolved.

DIAGNOSTIC TROUBLE CODES (DTC’s)

The indicator lamp (LED) transmits a certain sequence flash to

distinguish faults.The DTC sequence for the most recent cur-

rent trouble is flashed twice only. If there are multiple faults

present, you can display the next current DTC by pressing the

memory button 2 before the MSC goes into the sub-active

mode. Once all DTC’s have been cycled through, the most

recent current DTC will be displayed. There will be no history of

DTC’s displayed.

Page 559 of 1500

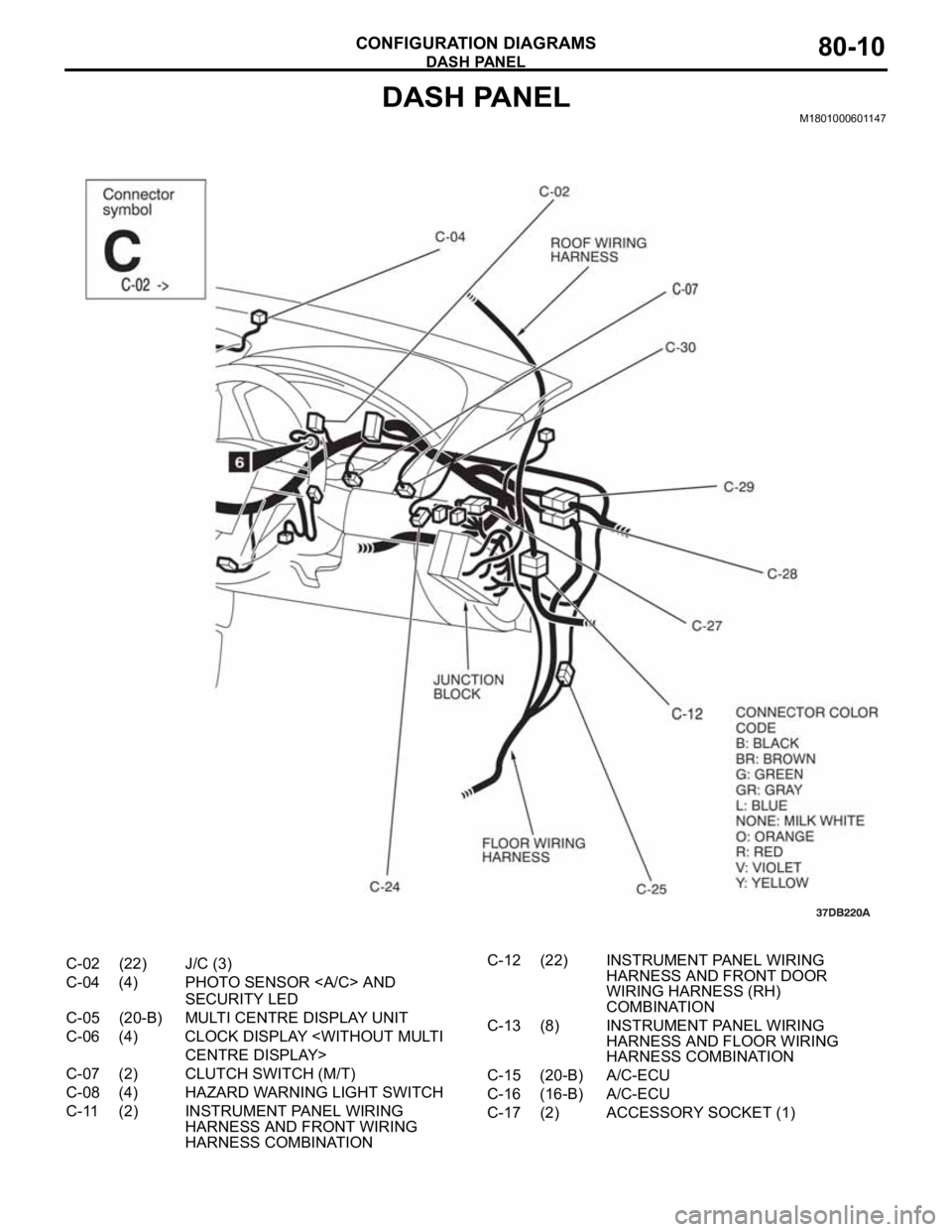

DASH PANEL

CONFIGURATION DIAGRAMS80-10

DASH PANELM1801000601147

C-02 (22) J/C (3)

C-04 (4) PHOTO SENSOR AND

SECURITY LED

C-05 (20-B) MULTI CENTRE DISPLAY UNIT

C-06 (4) CLOCK DISPLAY

C-07 (2) CLUTCH SWITCH (M/T)

C-08 (4) HAZARD WARNING LIGHT SWITCH

C-11 (2) INSTRUMENT PANEL WIRING

HARNESS AND FRONT WIRING

HARNESS COMBINATIONC-12 (22) INSTRUMENT PANEL WIRING

HARNESS AND FRONT DOOR

WIRING HARNESS (RH)

COMBINATION

C-13 (8) INSTRUMENT PANEL WIRING

HARNESS AND FLOOR WIRING

HARNESS COMBINATION

C-15 (20-B) A/C-ECU

C-16 (16-B) A/C-ECU

C-17 (2) ACCESSORY SOCKET (1)