Exhaust MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 967 of 1500

Page 968 of 1500

INTAKE MANIFOLD

INTAKE AND EXHAUST15-9

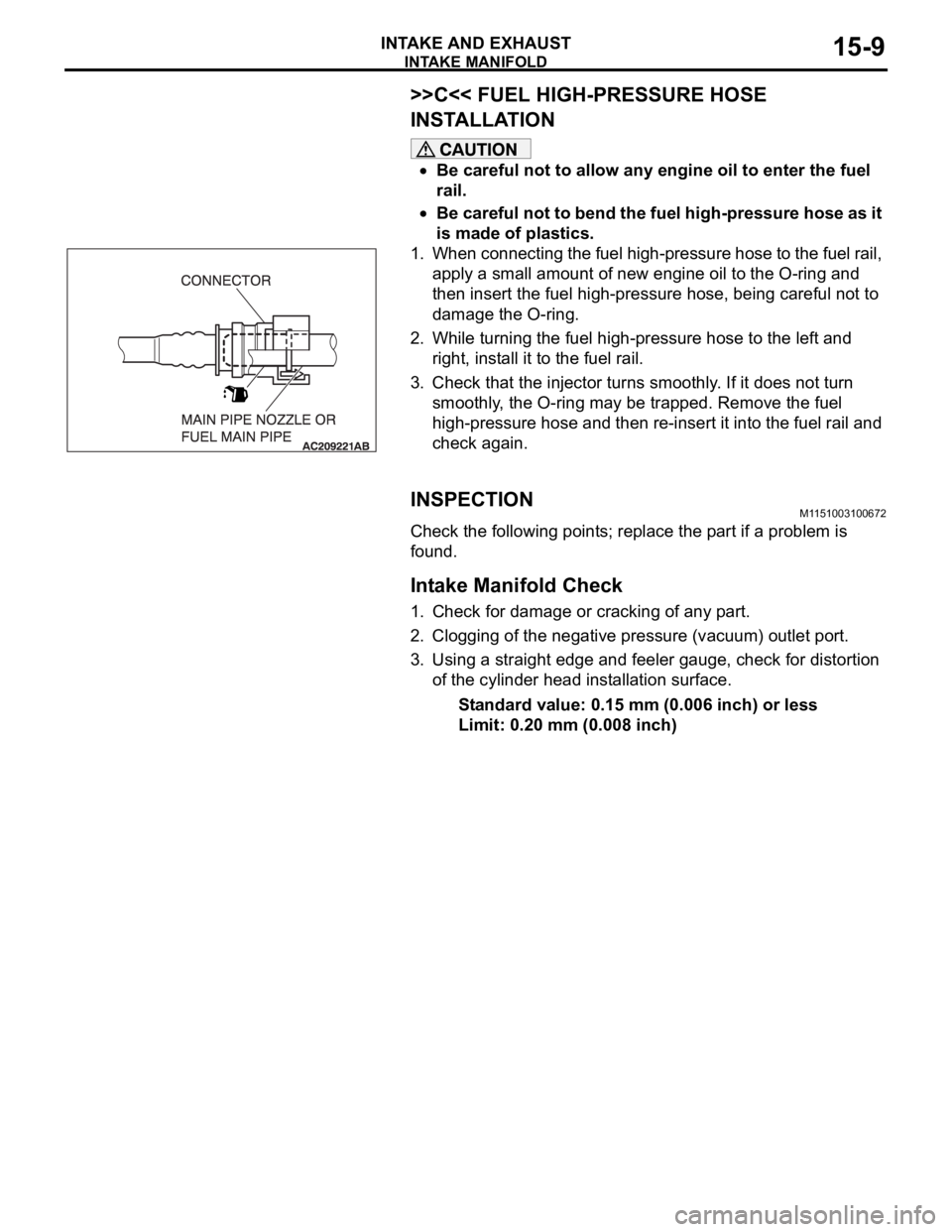

>>C<< FUEL HIGH-PRESSURE HOSE

INSTALLATION

Be careful not to allow any engine oil to enter the fuel

rail.

Be careful not to bend the fuel high-pressure hose as it

is made of plastics.

1. When connecting the fuel high-pressure hose to the fuel rail,

apply a small amount of new engine oil to the O-ring and

then insert the fuel high-pressure hose, being careful not to

damage the O-ring.

2. While turning the fuel high-pressure hose to the left and

right, install it to the fuel rail.

3. Check that the injector turns smoothly. If it does not turn

smoothly, the O-ring may be trapped. Remove the fuel

high-pressure hose and then re-insert it into the fuel rail and

check again.

INSPECTIONM1151003100672

Check the following points; replace the part if a problem is

found.

.

Intake Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port.

3. Using a straight edge and feeler gauge, check for distortion

of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 969 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-10

EXHAUST MANIFOLD

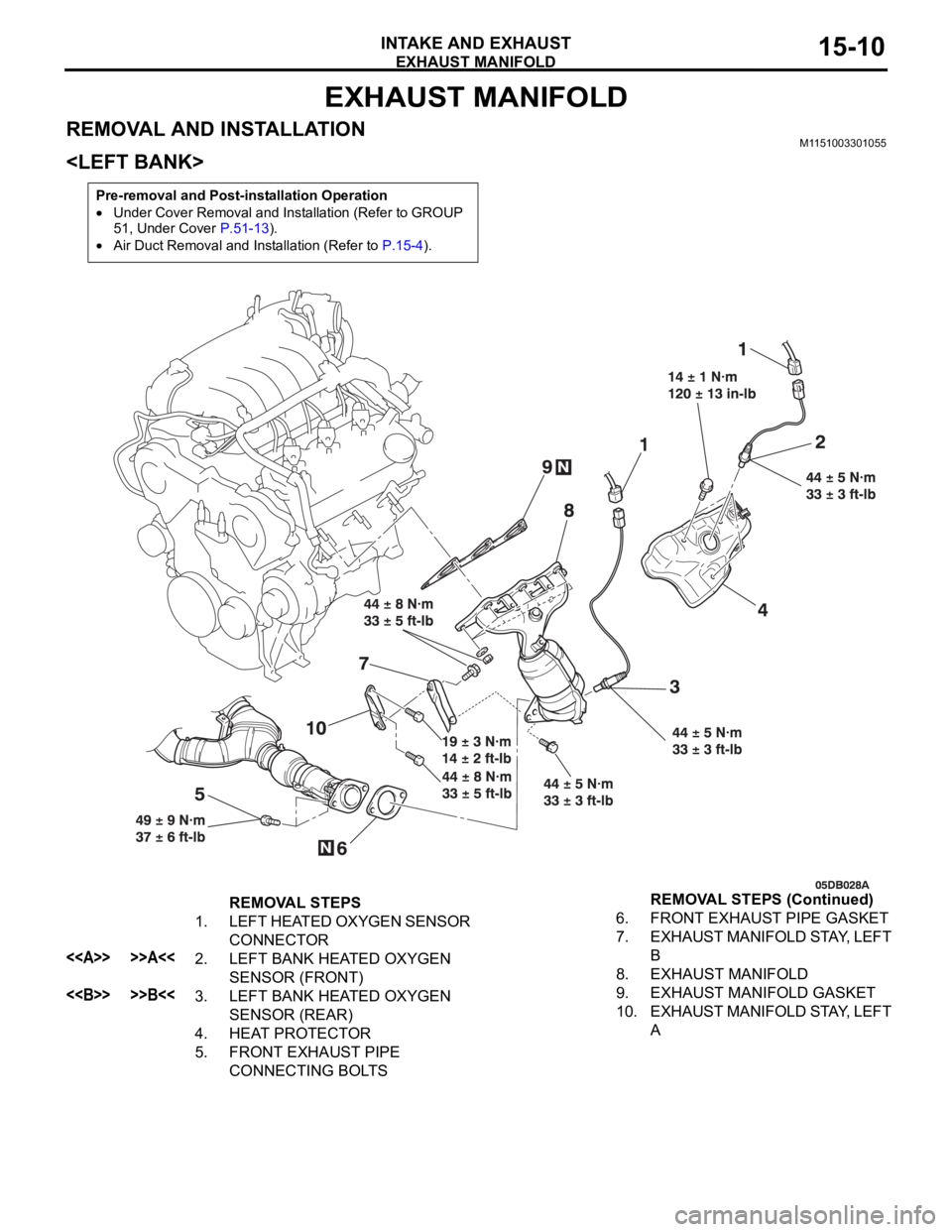

REMOVAL AND INSTALLATION M1151003301055

Pre-removal and Post-installation Operation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Air Duct Removal and Installation (Refer to P.15-4).

REMOVAL STEPS

1. LEFT HEATED OXYGEN SENSOR

CONNECTOR

<> >>A<<2. LEFT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>B<<3. LEFT BANK HEATED OXYGEN

SENSOR (REAR)

4. HEAT PROTECTOR

5. FRONT EXHAUST PIPE

CONNECTING BOLTS6. FRONT EXHAUST PIPE GASKET

7. EXHAUST MANIFOLD STAY, LEFT

B

8. EXHAUST MANIFOLD

9. EXHAUST MANIFOLD GASKET

10. EXHAUST MANIFOLD STAY, LEFT

A REMOVAL STEPS (Continued)

Page 970 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-11

Required Special Tools:

MB991953: Oxygen Sensor WrenchMD998770: Oxygen Sensor Wrench

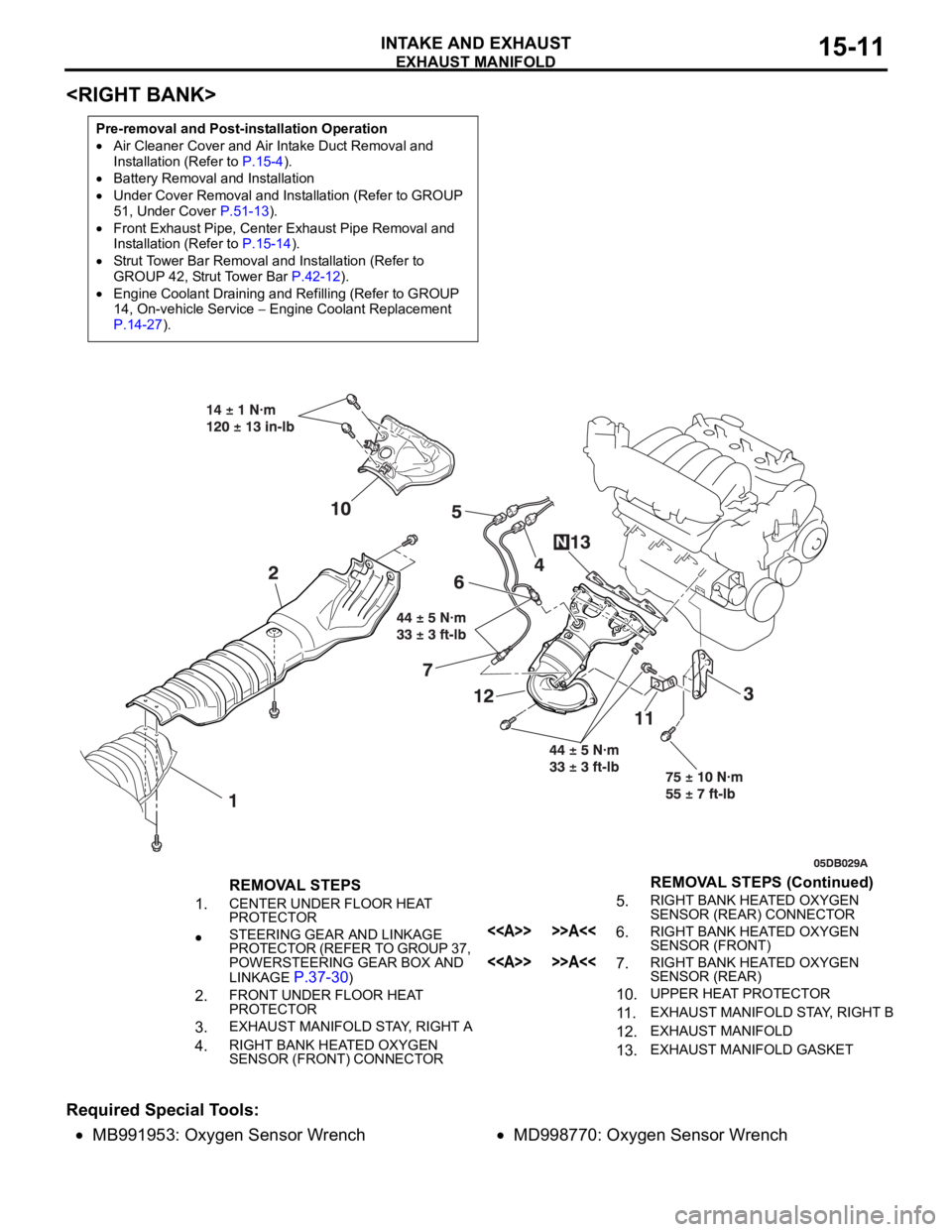

Pre-removal and Post-installation Operation

Air Cleaner Cover and Air Intake Duct Removal and

Installation (Refer to P.15-4).

Battery Removal and Installation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Front Exhaust Pipe, Center Exhaust Pipe Removal and

Installation (Refer to P.15-14).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar P.42-12).

Engine Coolant Draining and Refilling (Refer to GROUP

14, On-vehicle Service Engine Coolant Replacement

P.14-27).

REMOVAL STEPS

1.

CENTER UNDER FLOOR HEAT

PROTECTOR

STEERING GEAR AND LINKAGE

PROTECTOR (REFER TO GROUP 37,

POWERSTEERING GEAR BOX AND

LINKAGE

P.37-30)

2.FRONT UNDER FLOOR HEAT

PROTECTOR

3.EXHAUST MANIFOLD STAY, RIGHT A

4.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5.RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

<> >>A<<6.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>A<<7.RIGHT BANK HEATED OXYGEN

SENSOR (REAR)

10.UPPER HEAT PROTECTOR

11 .EXHAUST MANIFOLD STAY, RIGHT B

12.EXHAUST MANIFOLD

13.EXHAUST MANIFOLD GASKET

REMOVAL STEPS (Continued)

Page 971 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-12

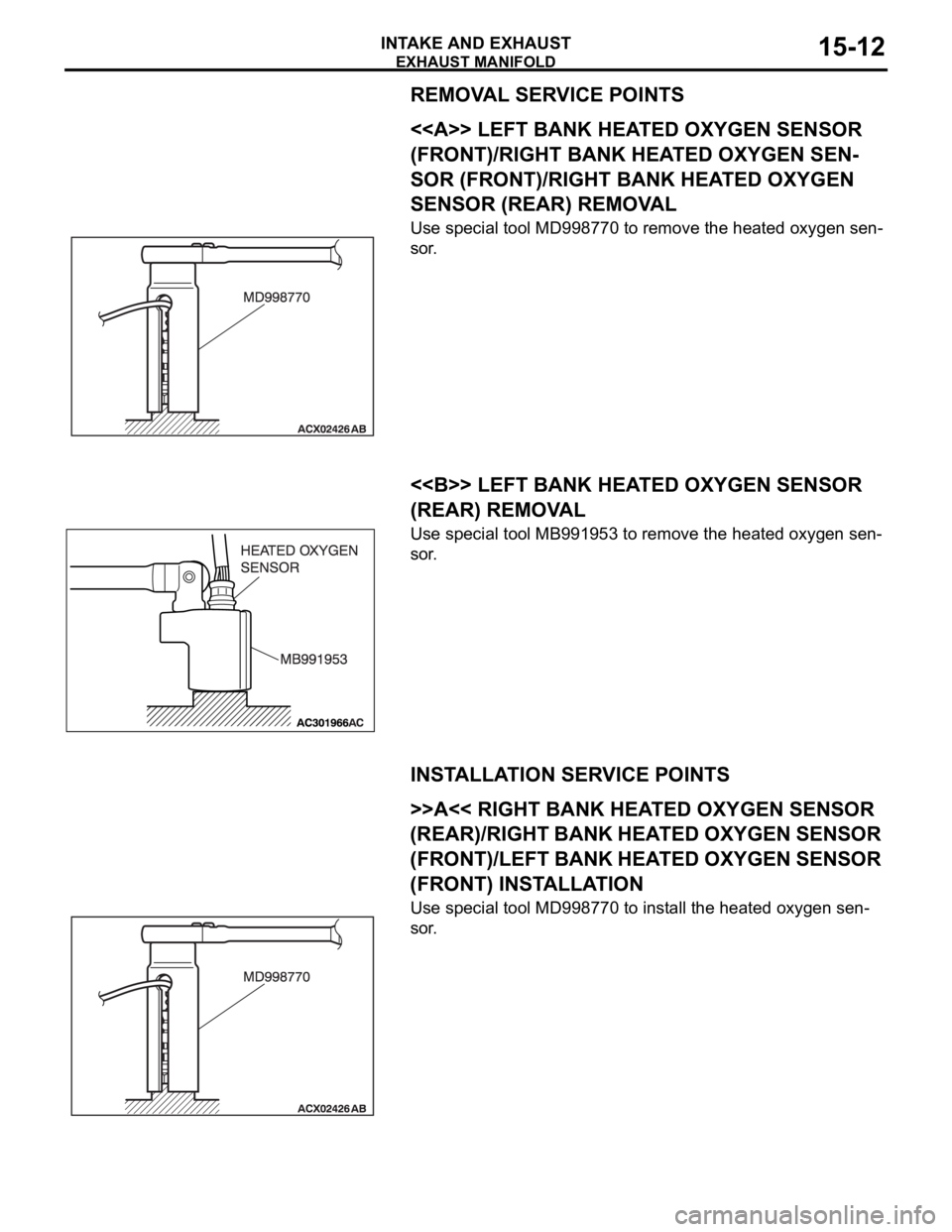

REMOVAL SERVICE POINTS

.

<> LEFT BANK HEATED OXYGEN SENSOR

(FRONT)/RIGHT BANK HEATED OXYGEN SEN-

SOR (FRONT)/RIGHT BANK HEATED OXYGEN

SENSOR (REAR) REMOVAL

Use special tool MD998770 to remove the heated oxygen sen-

sor.

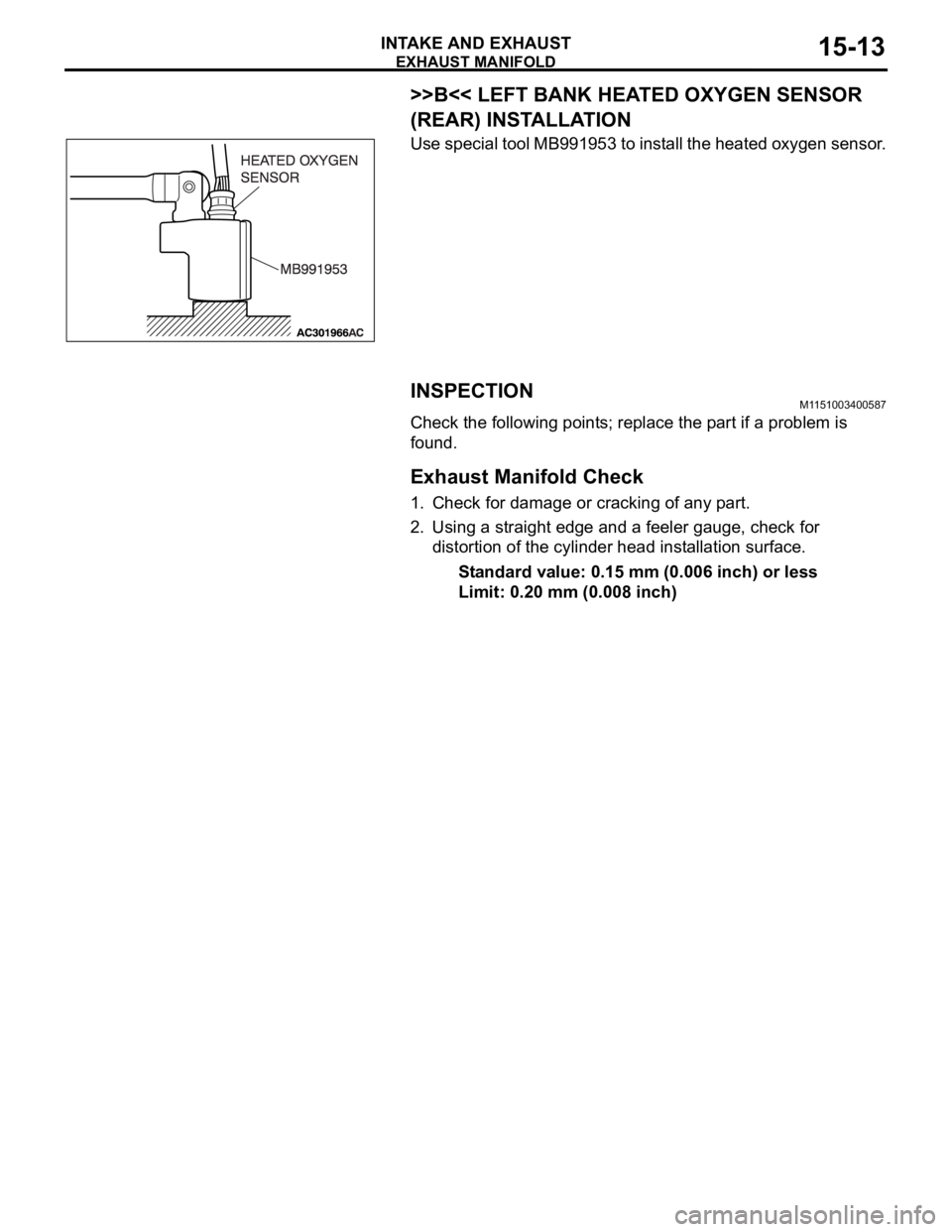

.

<> LEFT BANK HEATED OXYGEN SENSOR

(REAR) REMOVAL

Use special tool MB991953 to remove the heated oxygen sen-

sor.

INSTALLATION SERVICE POINTS

.

>>A<< RIGHT BANK HEATED OXYGEN SENSOR

(REAR)/RIGHT BANK HEATED OXYGEN SENSOR

(FRONT)/LEFT BANK HEATED OXYGEN SENSOR

(FRONT) INSTALLATION

Use special tool MD998770 to install the heated oxygen sen-

sor.

.

Page 972 of 1500

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-13

>>B<< LEFT BANK HEATED OXYGEN SENSOR

(REAR) INSTALLATION

Use special tool MB991953 to install the heated oxygen sensor.

INSPECTIONM1151003400587

Check the following points; replace the part if a problem is

found.

.

Exhaust Manifold Check

1. Check for damage or cracking of any part.

2. Using a straight edge and a feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 973 of 1500

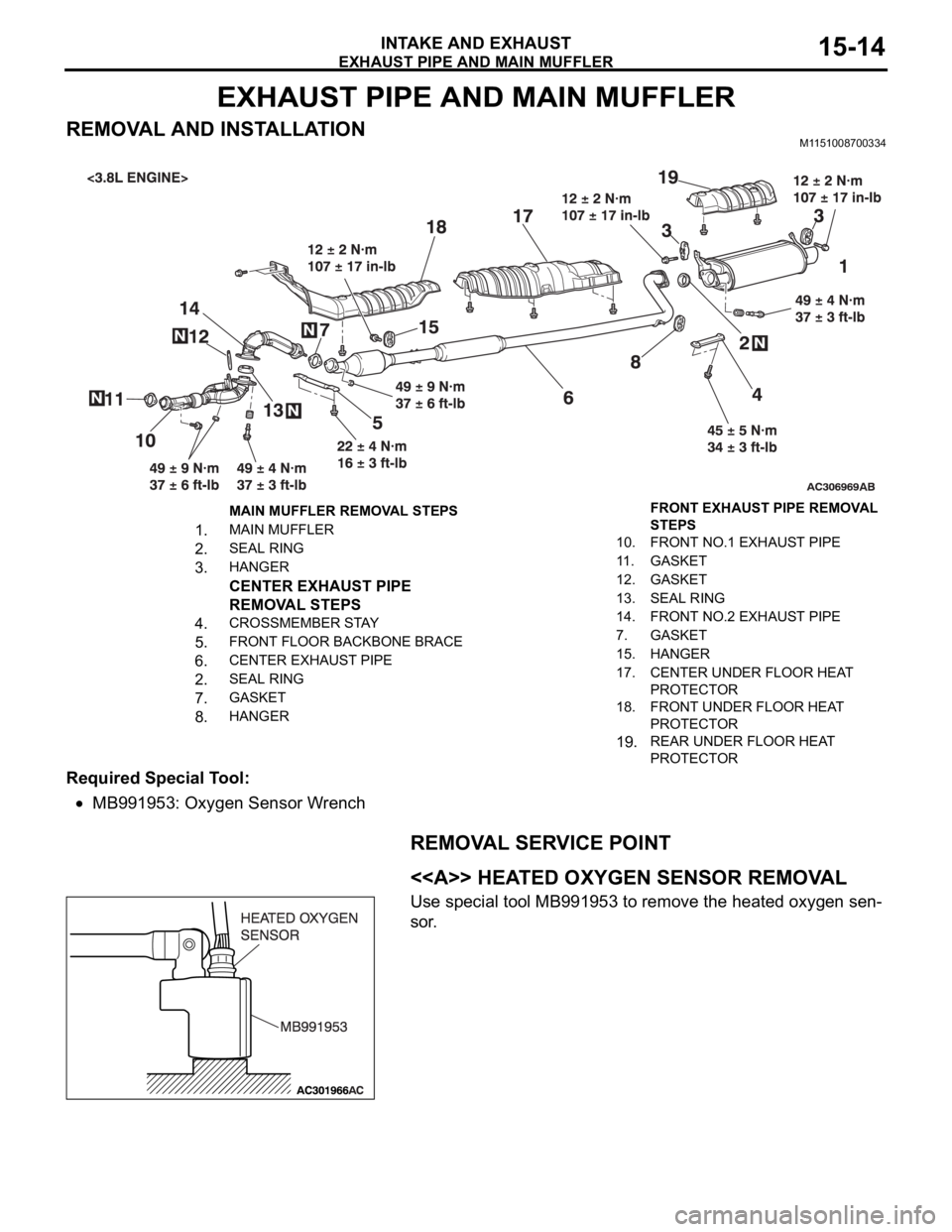

EXHAUST PIPE AND MAIN MUFFLER

INTAKE AND EXHAUST15-14

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATIONM1151008700334

Required Special Tool:

MB991953: Oxygen Sensor Wrench

REMOVAL SERVICE POINT

.

<> HEATED OXYGEN SENSOR REMOVAL

Use special tool MB991953 to remove the heated oxygen sen-

sor.

MAIN MUFFLER REMOVAL STEPS

1.MAIN MUFFLER

2.SEAL RING

3.HANGER

CENTER EXHAUST PIPE

REMOVAL STEPS

4.

CROSSMEMBER STAY

5.FRONT FLOOR BACKBONE BRACE

6.CENTER EXHAUST PIPE

2.SEAL RING

7.GASKET

8.HANGERFRONT EXHAUST PIPE REMOVAL

STEPS

10. FRONT NO.1 EXHAUST PIPE

11. GASKET

12. GASKET

13. SEAL RING

14. FRONT NO.2 EXHAUST PIPE

7. GASKET

15. HANGER

17. CENTER UNDER FLOOR HEAT

PROTECTOR

18. FRONT UNDER FLOOR HEAT

PROTECTOR

19.REAR UNDER FLOOR HEAT

PROTECTOR

Page 974 of 1500

EXHAUST PIPE AND MAIN MUFFLER

INTAKE AND EXHAUST15-15

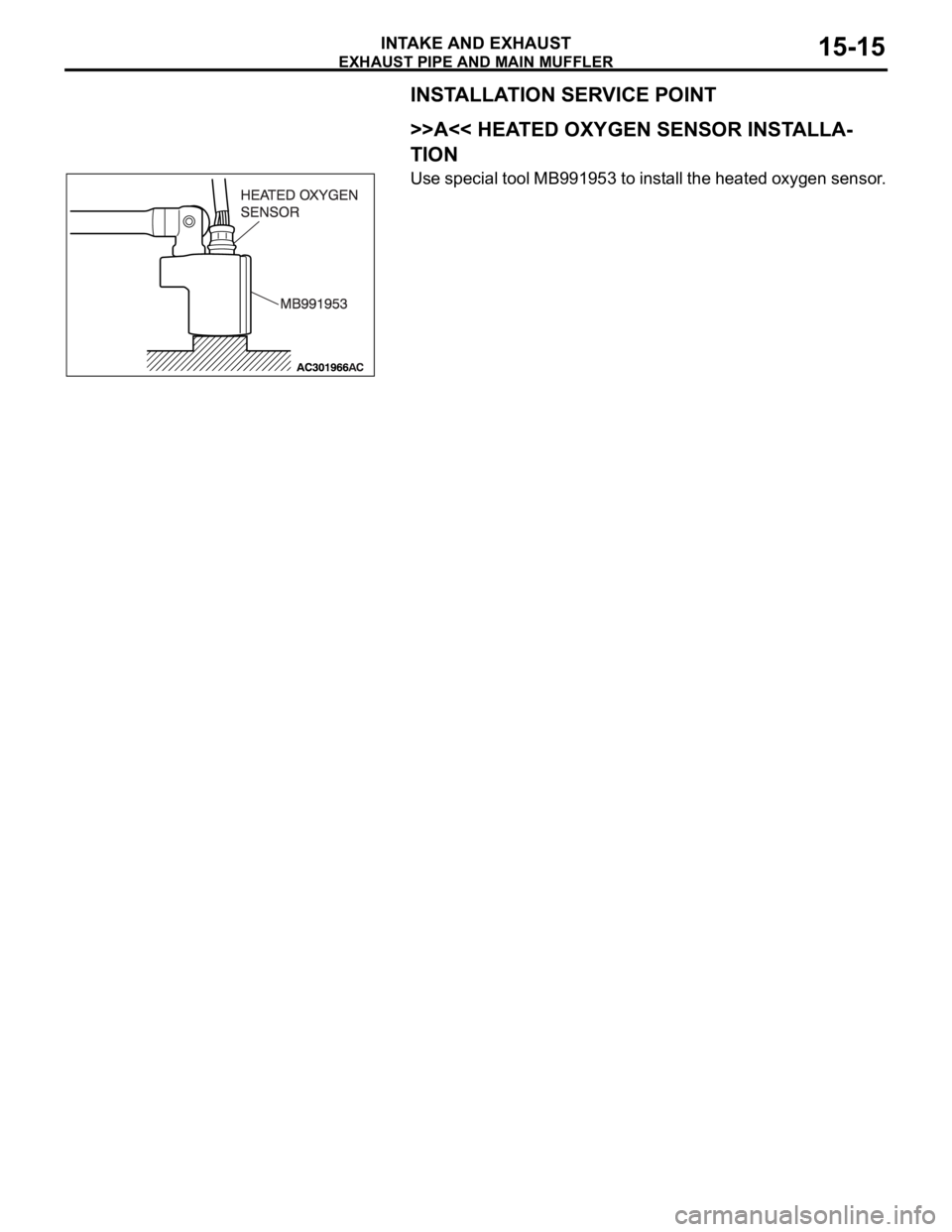

INSTALLATION SERVICE POINT

.

>>A<< HEATED OXYGEN SENSOR INSTALLA-

TION

Use special tool MB991953 to install the heated oxygen sensor.

Page 975 of 1500

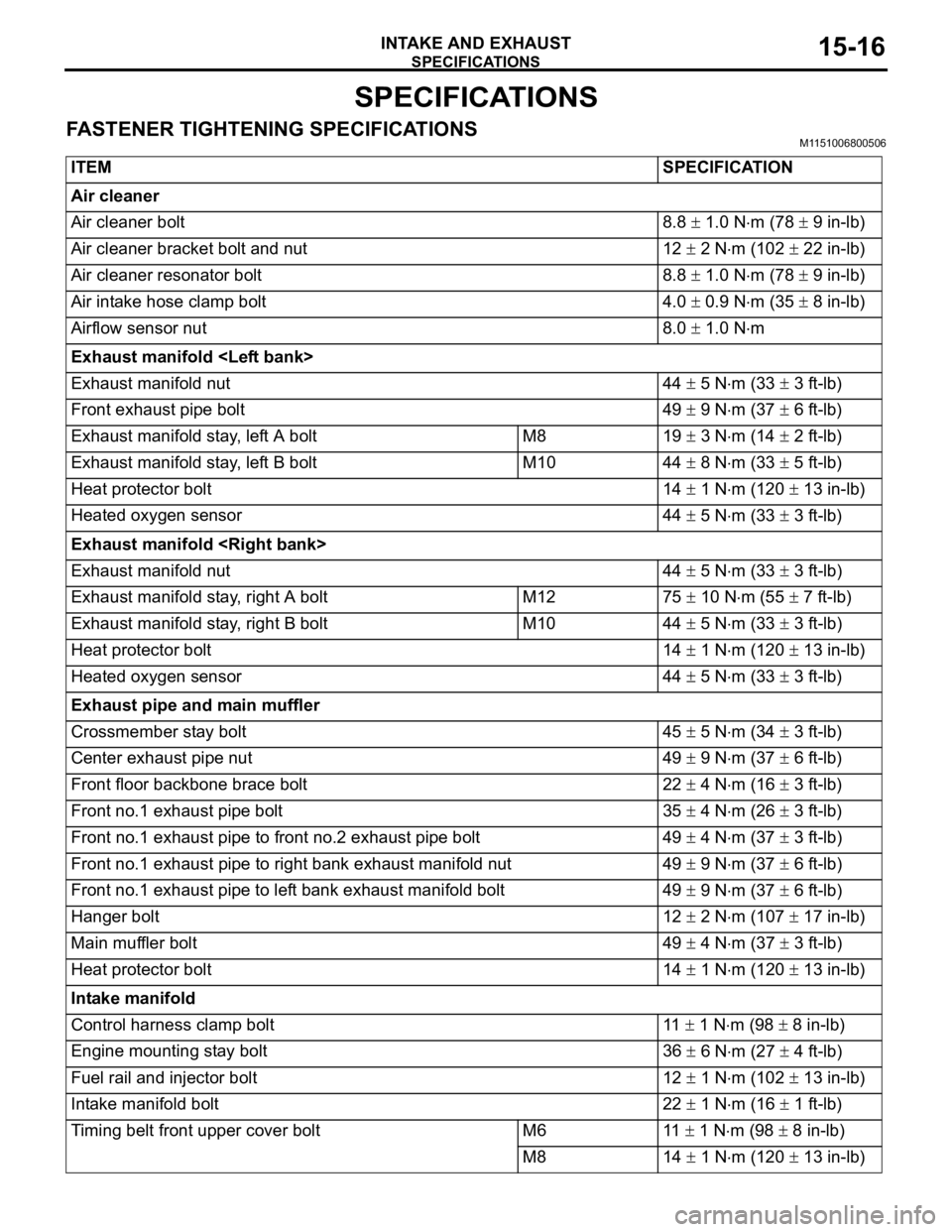

SPECIFICATIONS

INTAKE AND EXHAUST15-16

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1151006800506

ITEMSPECIFICATION

Air cleaner

Air cleaner bolt 8.8

1.0 Nm (78 9 in-lb)

Air cleaner bracket bolt and nut 12

2 Nm (102 22 in-lb)

Air cleaner resonator bolt 8.8

1.0 Nm (78 9 in-lb)

Air intake hose clamp bolt 4.0

0.9 Nm (35 8 in-lb)

Airflow sensor nut 8.0

1.0 Nm

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Front exhaust pipe bolt 49

9 Nm (37 6 ft-lb)

Exhaust manifold stay, left A bolt M8 19

3 Nm (14 2 ft-lb)

Exhaust manifold stay, left B bolt M10 44

8 Nm (33 5 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Exhaust manifold stay, right A bolt M12 75

10 Nm (55 7 ft-lb)

Exhaust manifold stay, right B bolt M10 44

5 Nm (33 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust pipe and main muffler

Crossmember stay bolt 45

5 Nm (34 3 ft-lb)

Center exhaust pipe nut 49

9 Nm (37 6 ft-lb)

Front floor backbone brace bolt 22

4 Nm (16 3 ft-lb)

Front no.1 exhaust pipe bolt 35

4 Nm (26 3 ft-lb)

Front no.1 exhaust pipe to front no.2 exhaust pipe bolt 49

4 Nm (37 3 ft-lb)

Front no.1 exhaust pipe to right bank exhaust manifold nut 49

9 Nm (37 6 ft-lb)

Front no.1 exhaust pipe to left bank exhaust manifold bolt 49

9 Nm (37 6 ft-lb)

Hanger bolt 12

2 Nm (107 17 in-lb)

Main muffler bolt 49

4 Nm (37 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Intake manifold

Control harness clamp bolt 11

1 Nm (98 8 in-lb)

Engine mounting stay bolt 36

6 Nm (27 4 ft-lb)

Fuel rail and injector bolt 12

1 Nm (102 13 in-lb)

Intake manifold bolt 22

1 Nm (16 1 ft-lb)

Timing belt front upper cover bolt M6 11

1 Nm (98 8 in-lb)

M8 14

1 Nm (120 13 in-lb)

Page 976 of 1500

SPECIFICATIONS

INTAKE AND EXHAUST15-17

Water pump bracket bolt 24 3 Nm (18 2 ft-lb) ITEMSPECIFICATION