brakes MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1199 of 1500

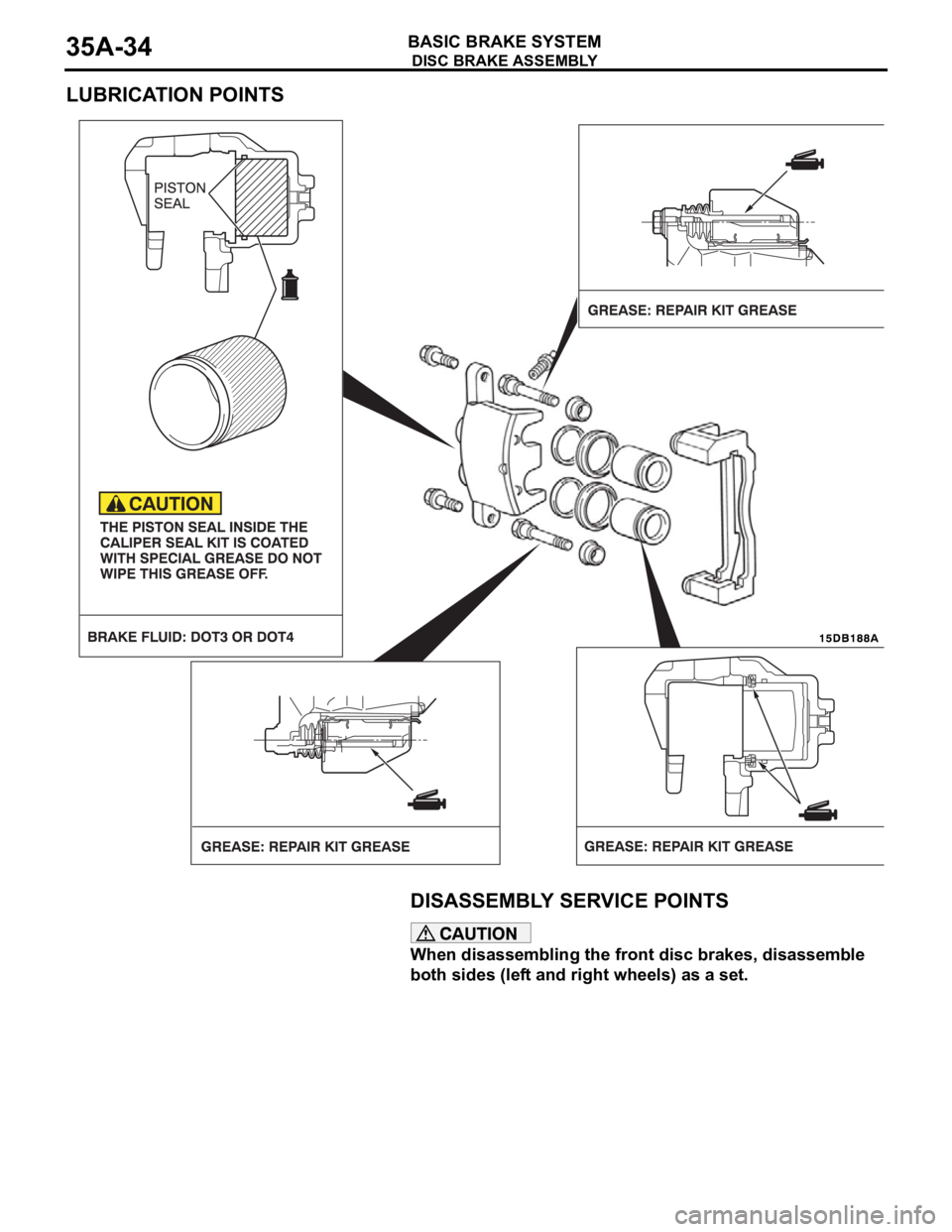

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-34

LUBRICATION POINTS

DISASSEMBLY SERVICE POINTS

When disassembling the front disc brakes, disassemble

both sides (left and right wheels) as a set.

.

Page 1202 of 1500

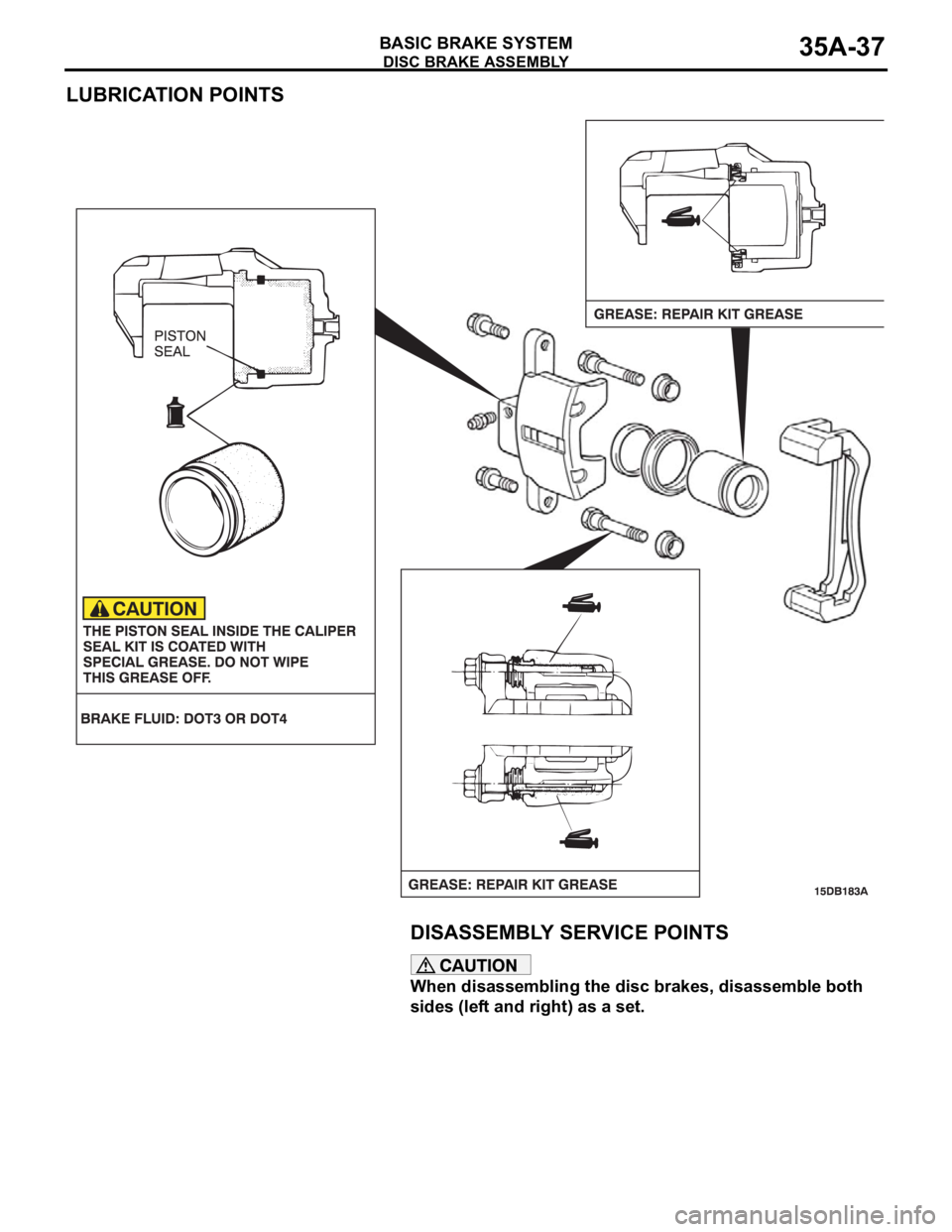

DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM35A-37

LUBRICATION POINTS

DISASSEMBLY SERVICE POINTS

When disassembling the disc brakes, disassemble both

sides (left and right) as a set.

.

Page 1205 of 1500

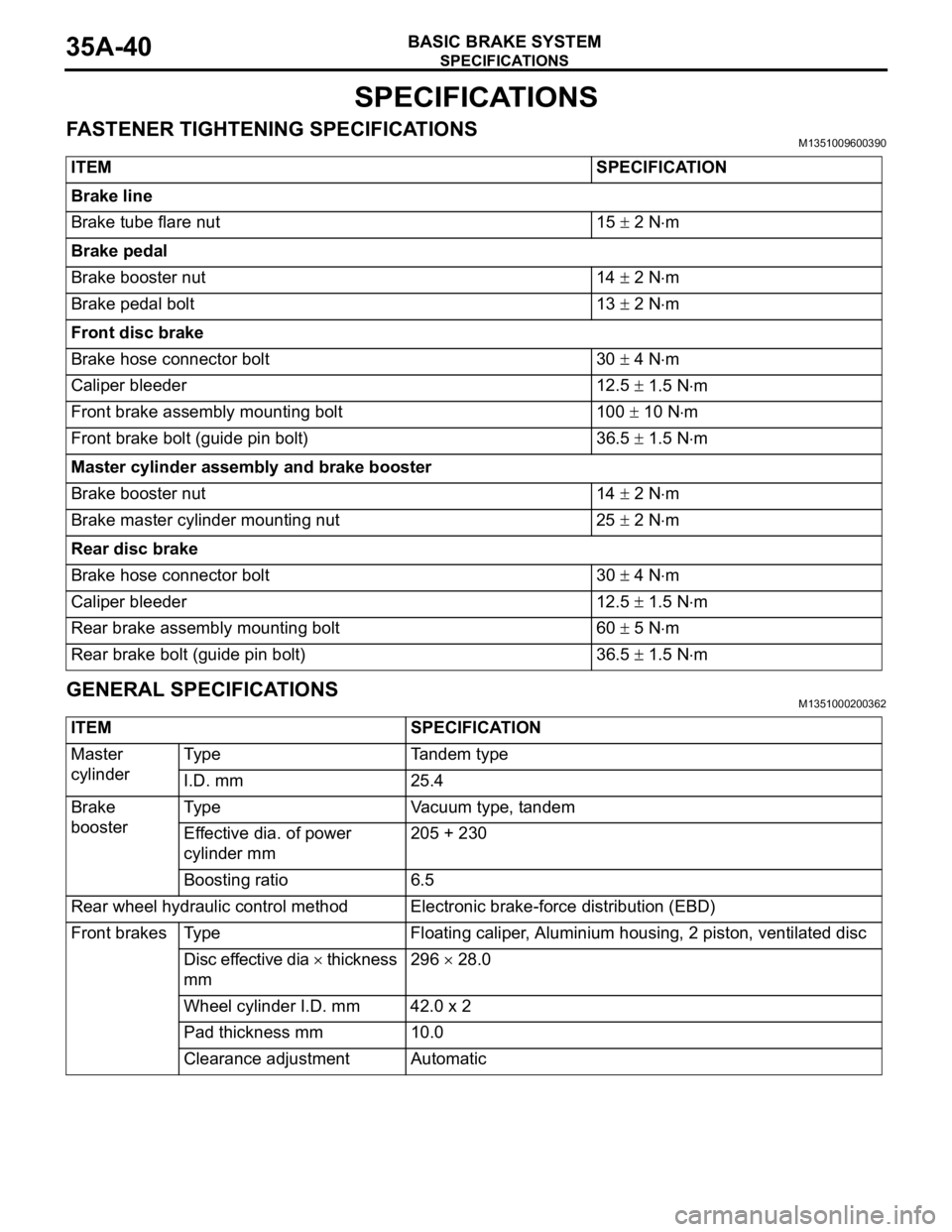

SPECIFICATIONS

BASIC BRAKE SYSTEM35A-40

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1351009600390

GENERAL SPECIFICATIONSM1351000200362

ITEM SPECIFICATION

Brake line

Brake tube flare nut 15

2 Nm

Brake pedal

Brake booster nut 14

2 Nm

Brake pedal bolt 13

2 Nm

Front disc brake

Brake hose connector bolt 30

4 Nm

Caliper bleeder 12.5

1.5 Nm

Front brake assembly mounting bolt 100

10 Nm

Front brake bolt (guide pin bolt) 36.5

1.5 Nm

Master cylinder assembly and brake booster

Brake booster nut 14

2 Nm

Brake master cylinder mounting nut 25

2 Nm

Rear disc brake

Brake hose connector bolt 30

4 Nm

Caliper bleeder 12.5

1.5 Nm

Rear brake assembly mounting bolt 60

5 Nm

Rear brake bolt (guide pin bolt) 36.5

1.5 Nm

ITEM SPECIFICATION

Master

cylinderType Tandem type

I.D. mm 25.4

Brake

boosterType Vacuum type, tandem

Effective dia. of power

cylinder mm 205 + 230

Boosting ratio 6.5

Rear wheel hydraulic control method Electronic brake-force distribution (EBD)

Front brakes Type Floating caliper, Aluminium housing, 2 piston, ventilated disc

Disc effective dia

thickness

mm 296 28.0

Wheel cylinder I.D. mm 42.0 x 2

Pad thickness mm 10.0

Clearance adjustment Automatic

Page 1206 of 1500

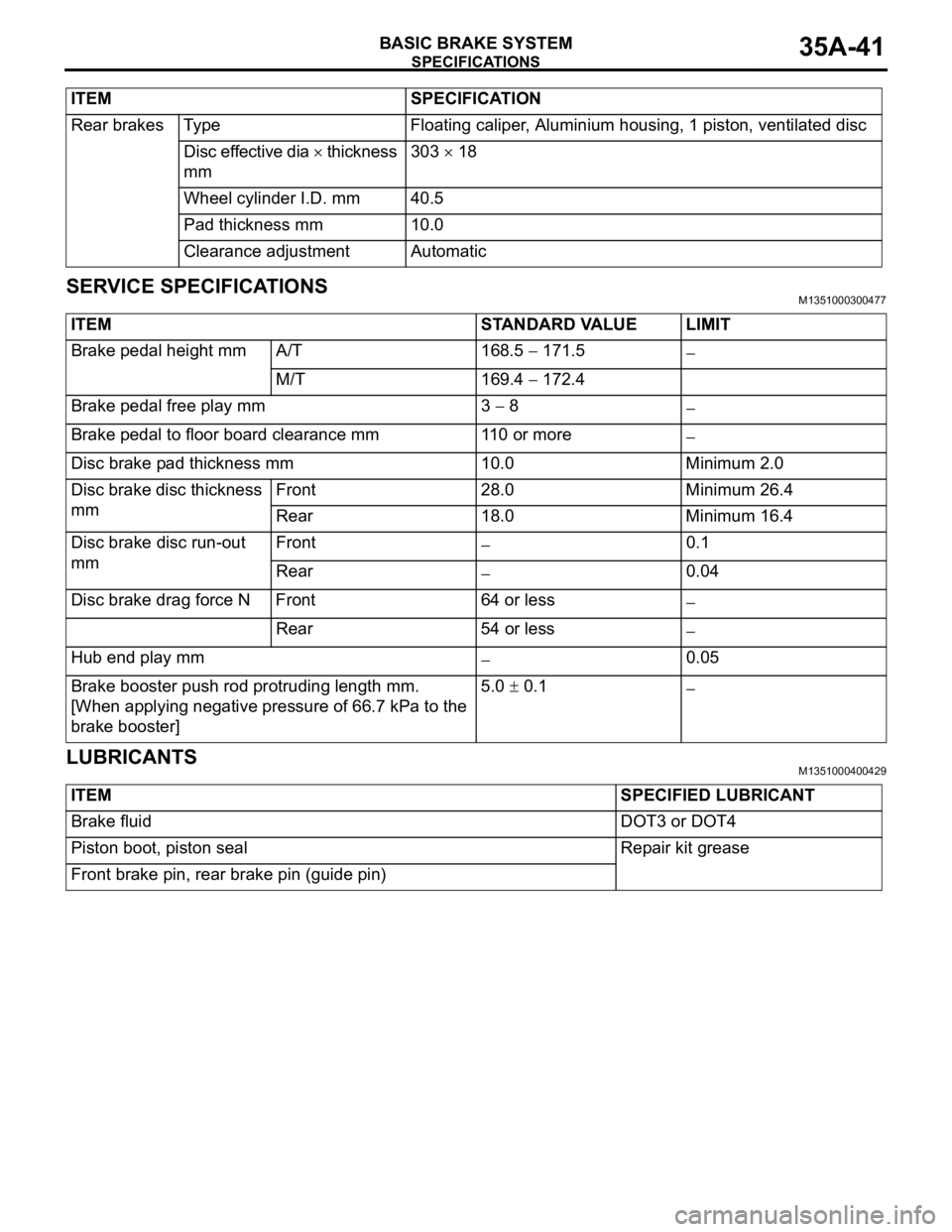

SPECIFICATIONS

BASIC BRAKE SYSTEM35A-41

SERVICE SPECIFICATIONSM1351000300477

LUBRICANTSM1351000400429

Rear brakes Type Floating caliper, Aluminium housing, 1 piston, ventilated disc

Disc effective dia

thickness

mm 303 18

Wheel cylinder I.D. mm 40.5

Pad thickness mm 10.0

Clearance adjustment Automatic ITEM SPECIFICATION

ITEM STANDARD VALUE LIMIT

Brake pedal height mm A/T 168.5

171.5

M/T 169.4 172.4

Brake pedal free play mm 3

8

Brake pedal to floor board clearance mm 110 or more

Disc brake pad thickness mm 10.0 Minimum 2.0

Disc brake disc thickness

mm Front 28.0 Minimum 26.4

Rear 18.0 Minimum 16.4

Disc brake disc run-out

mm Front

0.1

Rear

0.04

Disc brake drag force N Front 64 or less

Rear 54 or less

Hub end play mm 0.05

Brake booster push rod protruding length mm.

[When applying negative pressure of 66.7 kPa to the

brake booster]5.0

0.1

ITEM SPECIFIED LUBRICANT

Brake fluid DOT3 or DOT4

Piston boot, piston seal Repair kit grease

Front brake pin, rear brake pin (guide pin)

Page 1208 of 1500

36-1

GROUP 36

PARKING BRAKES

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .36-2

PARKING BRAKE DIAGNOSIS . . . .36-2

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . 36-2

TROUBLESHOOTING STRATEGY . . . . . . 36-2

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 36-2

SYMPTOM PROCEDURES . . . . . . . . . . . . 36-3

ON-VEHICLE SERVICE . . . . . . . . . . .36-3

PARKING BRAKE LEVER STROKE CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . . . . 36-3

PARKING BRAKE SWITCH CHECK . . . . . 36-5

PARKING BRAKE LINING SEATING

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 36-5

PARKING BRAKE LEVER . . . . . . . . .36-6

REMOVAL AND INSTALLATION . . . . . . . . 36-6

PARKING BRAKE CABLE . . . . . . . . .36-7

REMOVAL AND INSTALLATION . . . . . . . . 36-7

PARKING BRAKE LINING AND

DRUM . . . . . . . . . . . . . . . . . . . . . . . . .36-8

REMOVAL AND INSTALLATION . . . . . . . . 36-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 36-11

SPECIFICATIONS . . . . . . . . . . . . . . .36-12

FASTENER TIGHTENING SPECIFICATIONS36-12

SERVICE SPECIFICATIONS . . . . . . . . . . . 36-12

LUBRICANT . . . . . . . . . . . . . . . . . . . . . . . . 36-12

Page 1209 of 1500

GENERAL DESCRIPTION

PARKING BRAKES36-2

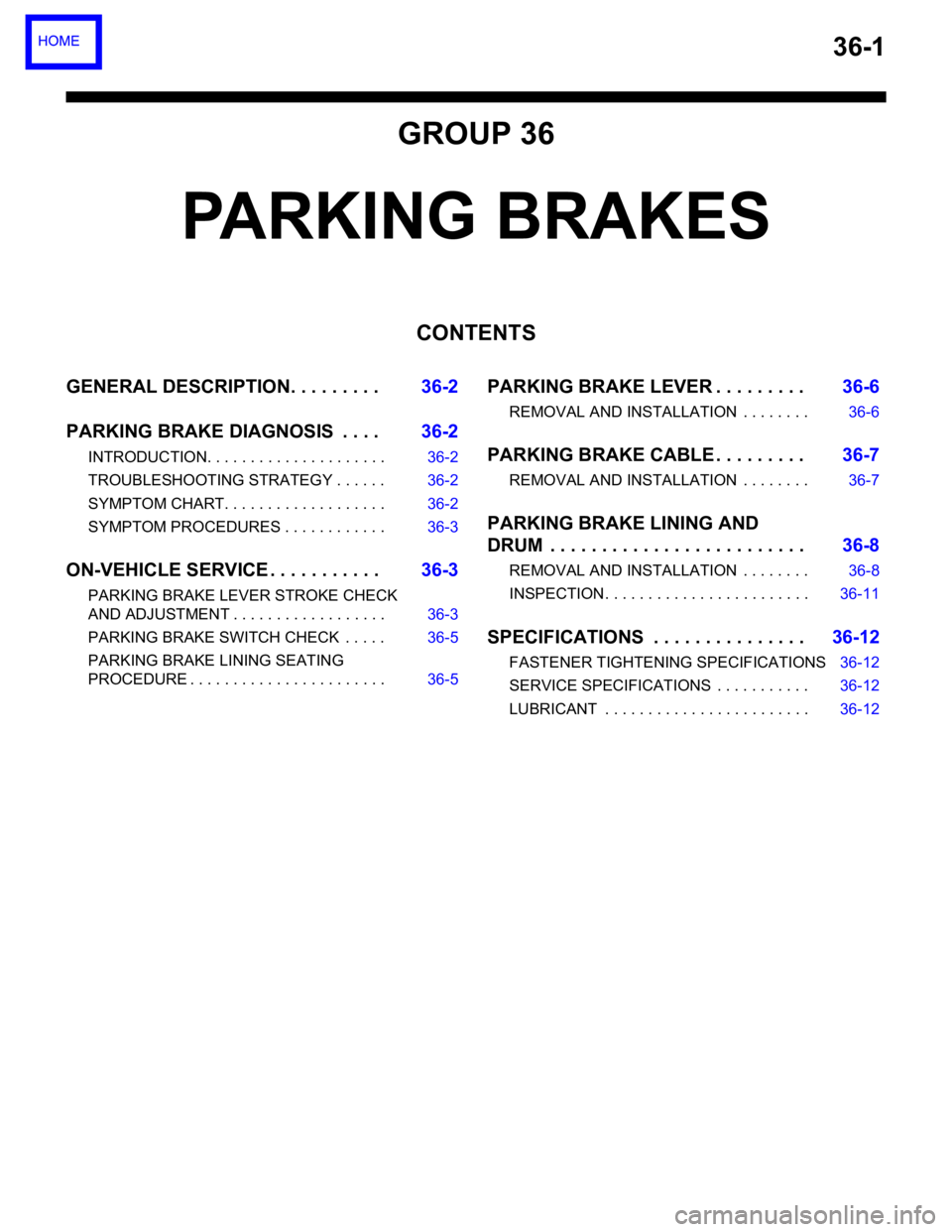

GENERAL DESCRIPTIONM1361000100344

The parking brakes are a mechanical rear wheel

brake design and controlled by a lever.

CONSTRUCTION DIAGRAM

PARKING BRAKE DIAGNOSIS

INTRODUCTIONM1361003700282

If the parking brake is faulty, parking brake effort will

become insufficient. The cause may be a malfunc-

tion of parking brake parts or the parking brake pedal

being out of adjustment.

TROUBLESHOOTING STRATEGYM1361003800290

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

parking brakes fault.

1. Gather Information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

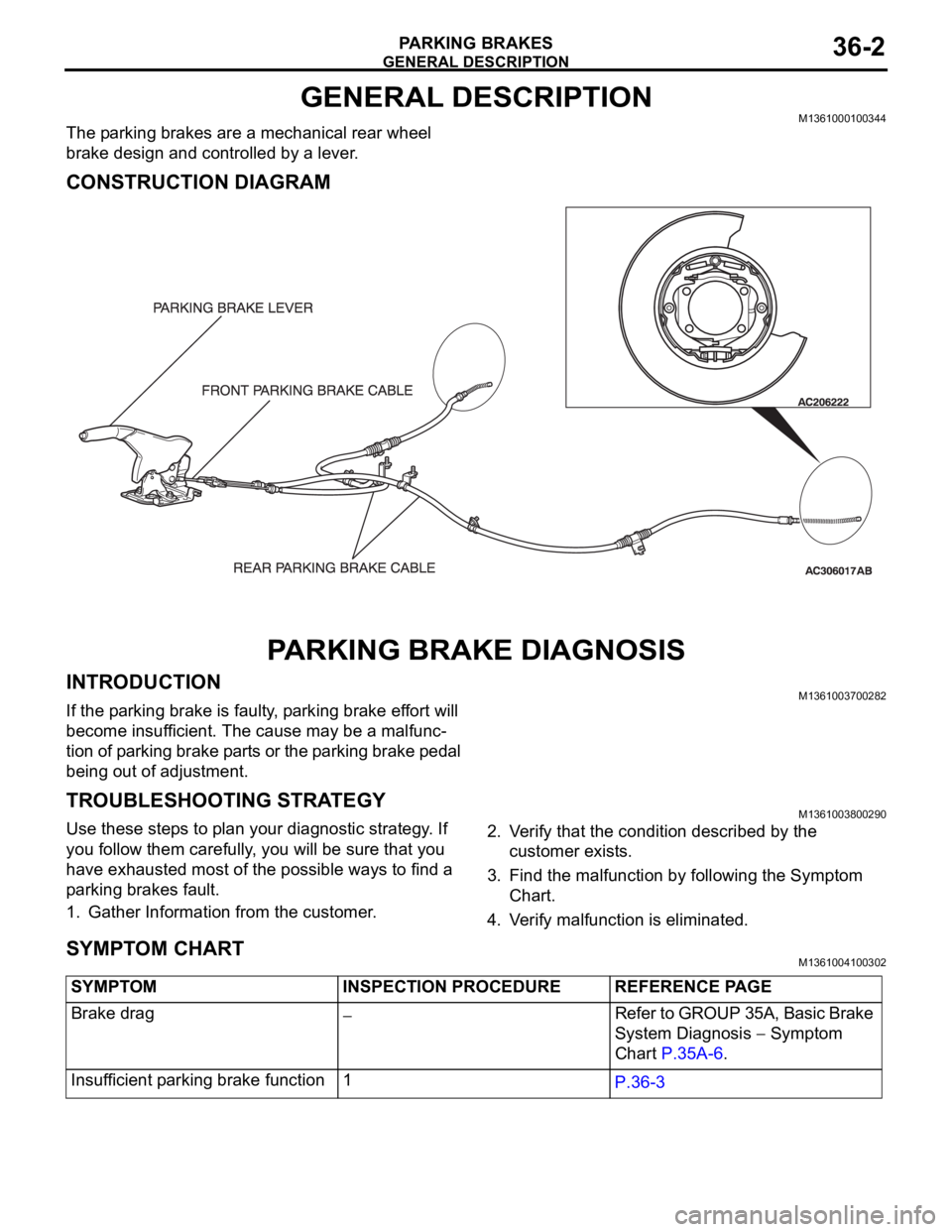

SYMPTOM CHARTM1361004100302

SYMPTOM INSPECTION PROCEDURE REFERENCE PAGE

Brake drag

Refer to GROUP 35A, Basic Brake

System Diagnosis

Symptom

Chart P.35A-6.

Insufficient parking brake function 1

P.36-3

Page 1210 of 1500

ON-VEHICLE SERVICE

PARKING BRAKES36-3

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Insufficient Parking Brake Function

DIAGNOSIS

STEP 1. Check the excessive parking brake lever

stroke.

Refer to P.36-3.

Q: Is the parking brake lever stroke adjusted

properly?

YES :

Go to Step 2.

NO : Adjust the parking brake lever stroke or

check the parking brake cable routing. Then

go to Step 5.

STEP 2. Check the parking brake cable for

sticking.

Q: Is the parking brake cable stuck?

YES :

Replace the cable. Then go to Step 5.

NO : Go to Step 3.

STEP 3. Check the brake lining and brake drum

for wear.

Refer to P.36-11.

Q: Is the brake lining thickness or brake drum inside

diameter outside of specification?

YES :

Replace the rear brake shoe assembly or

rear brake disc (Refer to P.36-8). Then go to

Step 5.

NO : Go to Step 4.

STEP 4. Check for oil, water, etc., on the lining

contact surfaces.

Q: Is oil, water, etc., on the lining contact surface?

YES :

Replace the part and determine and repair

source/cause of foreign material. Then go to

St e p 5.

NO : Carry out the parking brake lining seating

(Refer to P.36-5) and then go to Step 5.

STEP 5. Retest the system.

Q: Is the malfunction eliminated?

YES :

The procedure is complete.

NO : Recheck from Step 1.

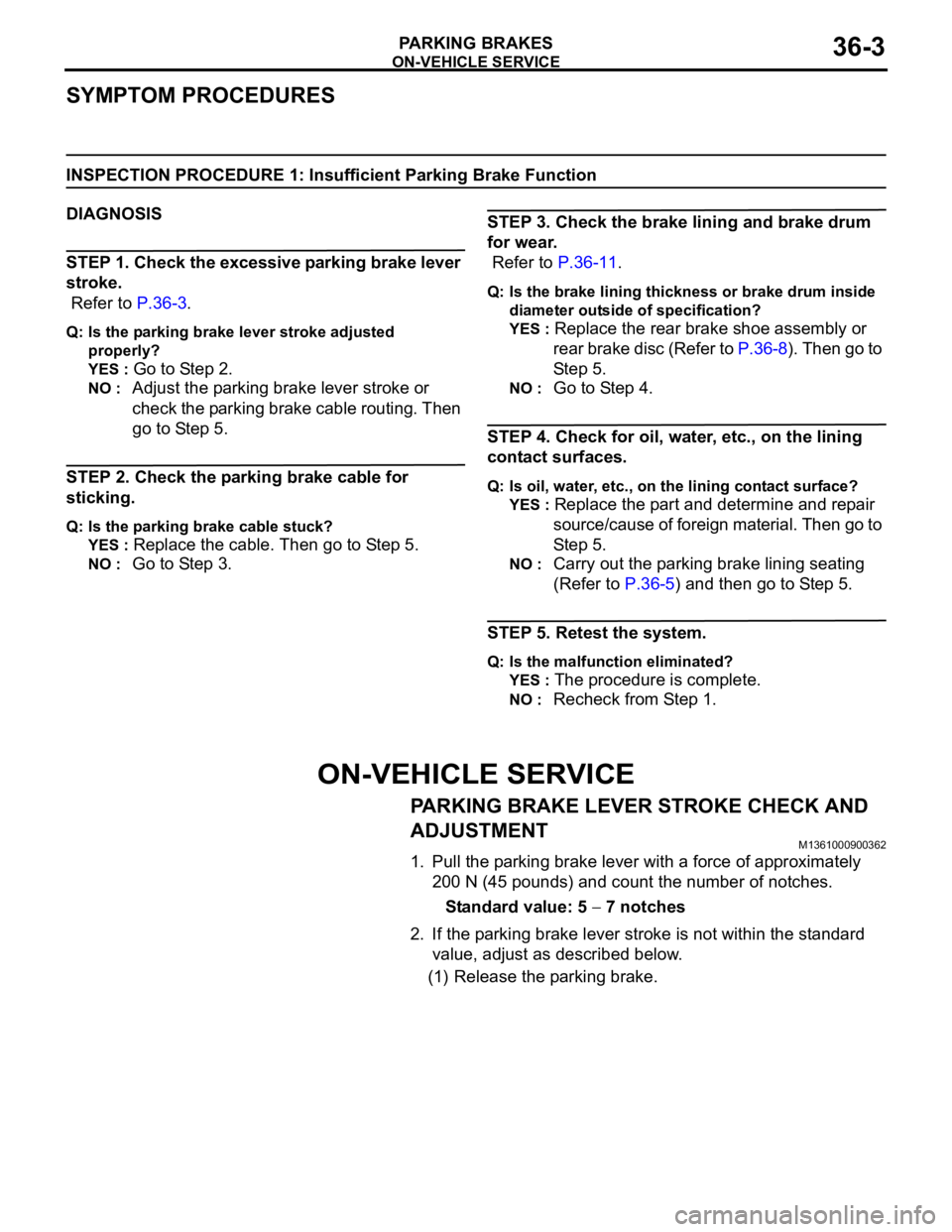

ON-VEHICLE SERVICE

PARKING BRAKE LEVER STROKE CHECK AND

ADJUSTMENT

M1361000900362

1. Pull the parking brake lever with a force of approximately

200 N (45 pounds) and count the number of notches.

Standard value: 5

7 notches

2. If the parking brake lever stroke is not within the standard

value, adjust as described below.

(1) Release the parking brake.

Page 1211 of 1500

ON-VEHICLE SERVICE

PARKING BRAKES36-4

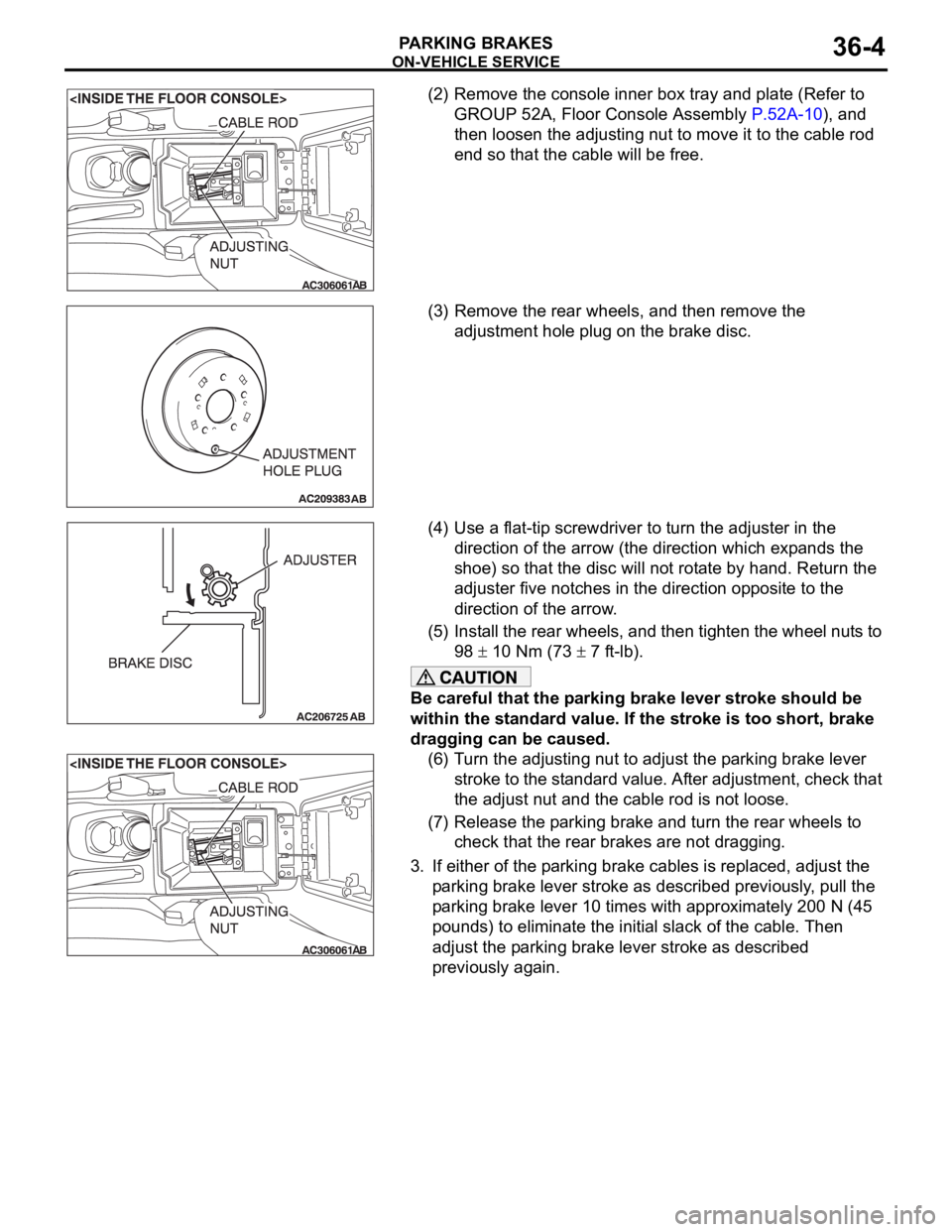

(2) Remove the console inner box tray and plate (Refer to

GROUP 52A, Floor Console Assembly P.52A-10), and

then loosen the adjusting nut to move it to the cable rod

end so that the cable will be free.

(3) Remove the rear wheels, and then remove the

adjustment hole plug on the brake disc.

(4) Use a flat-tip screwdriver to turn the adjuster in the

direction of the arrow (the direction which expands the

shoe) so that the disc will not rotate by hand. Return the

adjuster five notches in the direction opposite to the

direction of the arrow.

(5) Install the rear wheels, and then tighten the wheel nuts to

98

10 Nm (73 7 ft-lb).

Be careful that the parking brake lever stroke should be

within the standard value. If the stroke is too short, brake

dragging can be caused.

(6) Turn the adjusting nut to adjust the parking brake lever

stroke to the standard value. After adjustment, check that

the adjust nut and the cable rod is not loose.

(7) Release the parking brake and turn the rear wheels to

check that the rear brakes are not dragging.

3. If either of the parking brake cables is replaced, adjust the

parking brake lever stroke as described previously, pull the

parking brake lever 10 times with approximately 200 N (45

pounds) to eliminate the initial slack of the cable. Then

adjust the parking brake lever stroke as described

previously again.

Page 1212 of 1500

ON-VEHICLE SERVICE

PARKING BRAKES36-5

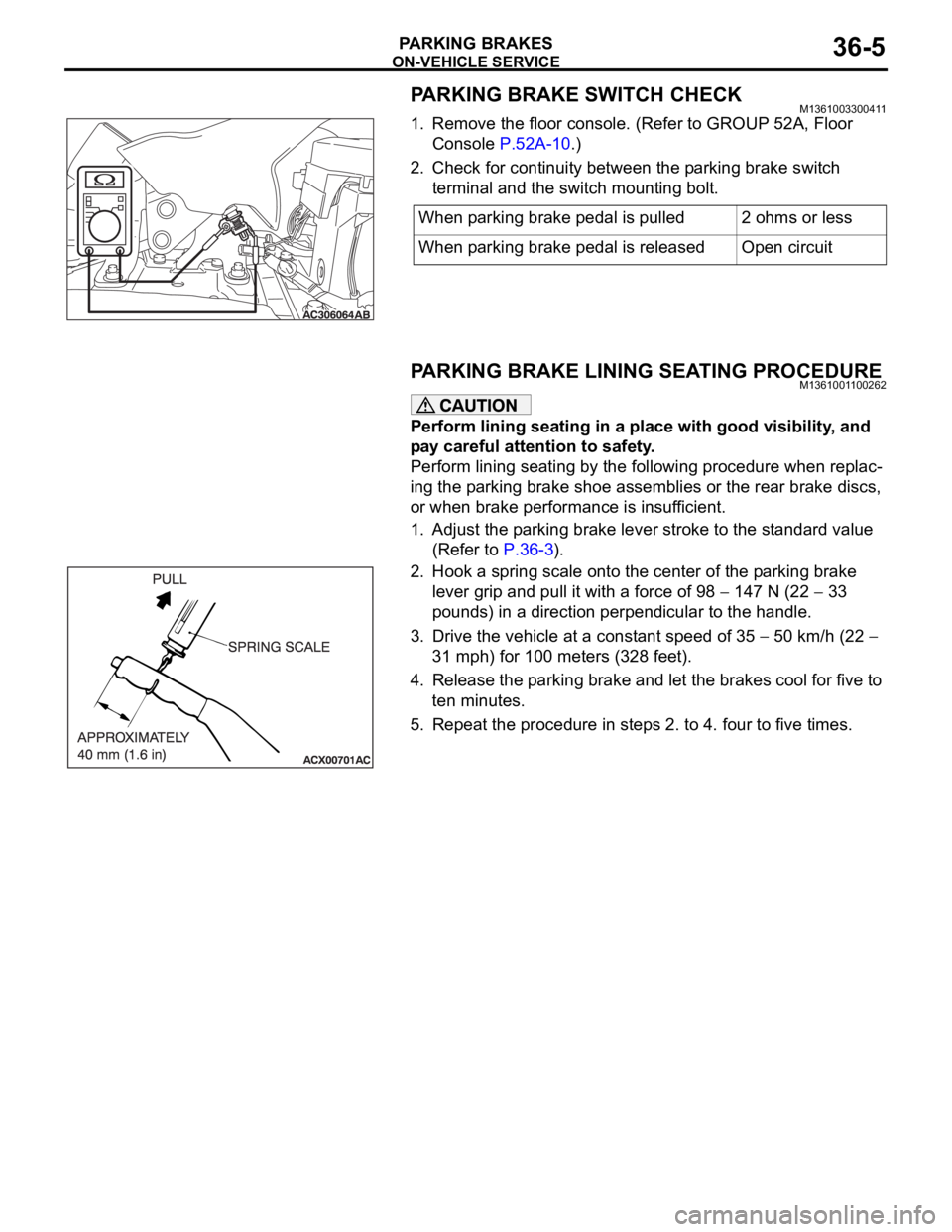

PARKING BRAKE SWITCH CHECKM1361003300411

1. Remove the floor console. (Refer to GROUP 52A, Floor

Console P.52A-10.)

2. Check for continuity between the parking brake switch

terminal and the switch mounting bolt.

PARKING BRAKE LINING SEATING PROCEDUREM1361001100262

Perform lining seating in a place with good visibility, and

pay careful attention to safety.

Perform lining seating by the following procedure when replac-

ing the parking brake shoe assemblies or the rear brake discs,

or when brake performance is insufficient.

1. Adjust the parking brake lever stroke to the standard value

(Refer to P.36-3).

2. Hook a spring scale onto the center of the parking brake

lever grip and pull it with a force of 98

147 N (22 33

pounds) in a direction perpendicular to the handle.

3. Drive the vehicle at a constant speed of 35

50 km/h (22

31 mph) for 100 meters (328 feet).

4. Release the parking brake and let the brakes cool for five to

ten minutes.

5. Repeat the procedure in steps 2. to 4. four to five times.When parking brake pedal is pulled 2 ohms or less

When parking brake pedal is released Open circuit

Page 1213 of 1500

PARKING BRAKE LEVER

PARKING BRAKES36-6

PARKING BRAKE LEVER

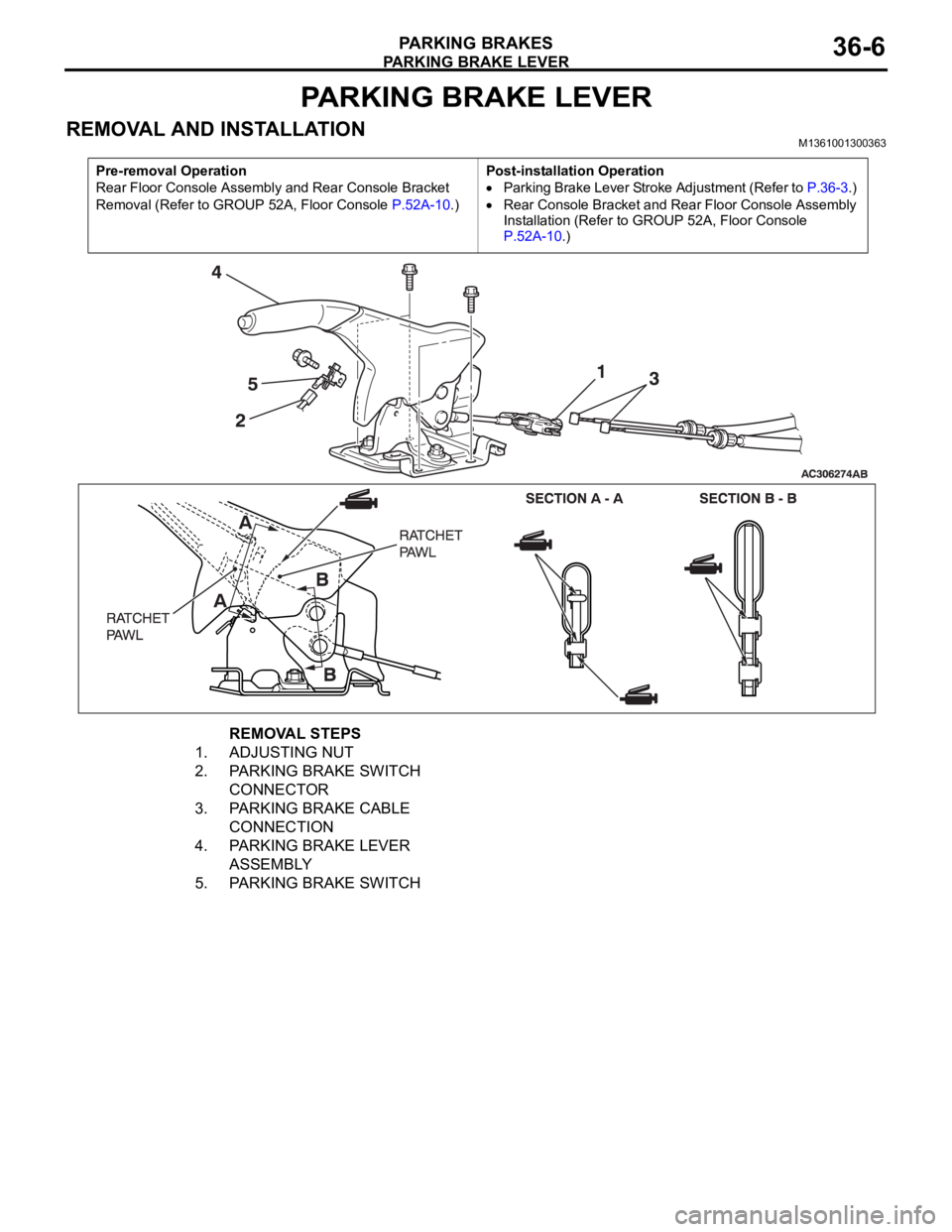

REMOVAL AND INSTALLATIONM1361001300363

Pre-removal Operation

Rear Floor Console Assembly and Rear Console Bracket

Removal (Refer to GROUP 52A, Floor Console P.52A-10.)Post-installation Operation

Parking Brake Lever Stroke Adjustment (Refer to P.36-3.)

Rear Console Bracket and Rear Floor Console Assembly

Installation (Refer to GROUP 52A, Floor Console

P.52A-10.)

REMOVAL STEPS

1. ADJUSTING NUT

2. PARKING BRAKE SWITCH

CONNECTOR

3. PARKING BRAKE CABLE

CONNECTION

4. PARKING BRAKE LEVER

ASSEMBLY

5. PARKING BRAKE SWITCH