change time MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 769 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-68

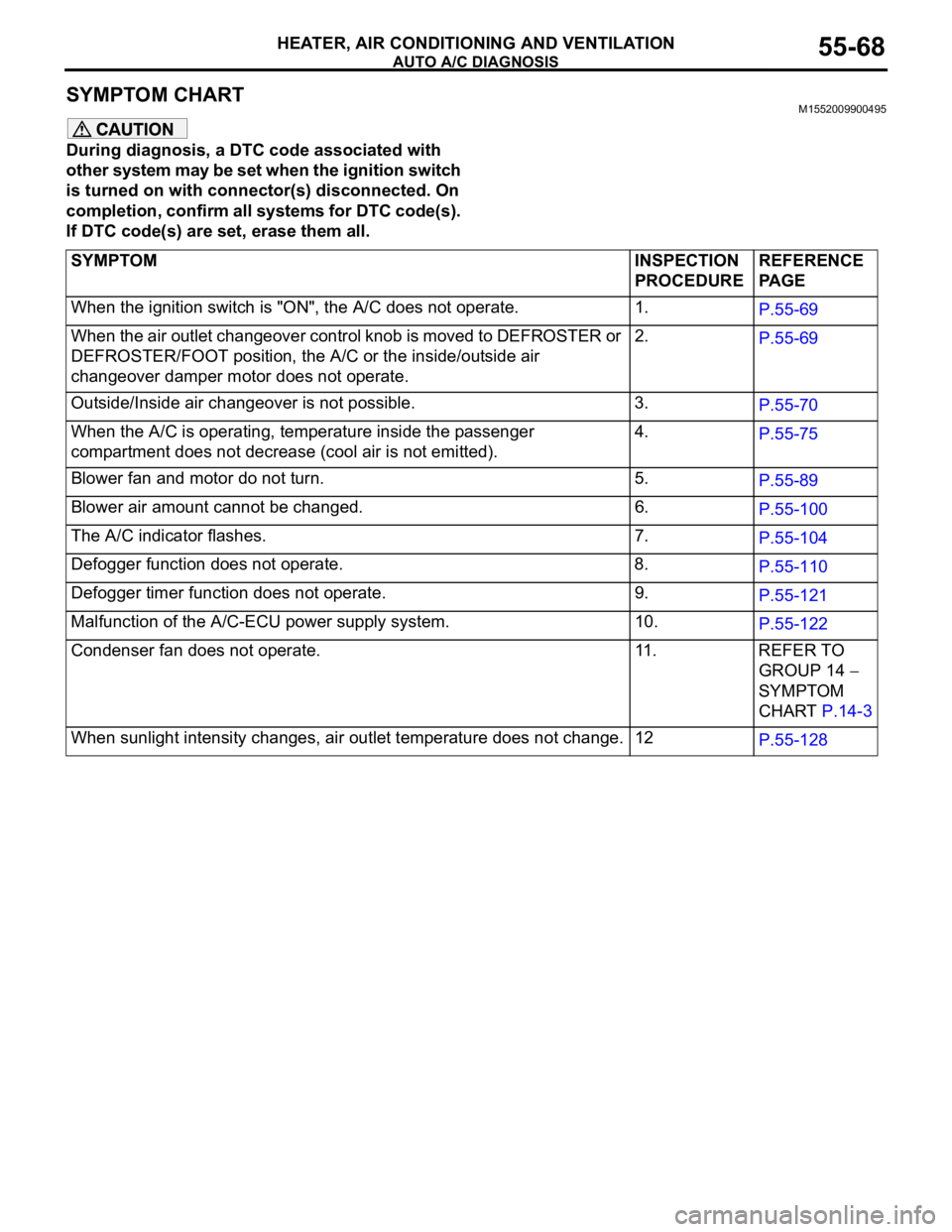

SYMPTOM CHART M1552009900495

During diagnosis, a DTC code associated with

other system may be set when the ignition switch

is turned on with connector(s) disconnected. On

completion, confirm all systems for DTC code(s).

If DTC code(s) are set, erase them all.

SYMPTOM INSPECTION

PROCEDUREREFERENCE

PA G E

When the ignition switch is "ON", the A/C does not operate. 1.

P.55-69

When the air outlet changeover control knob is moved to DEFROSTER or

DEFROSTER/FOOT position, the A/C or the inside/outside air

changeover damper motor does not operate.2.

P.55-69

Outside/Inside air changeover is not possible. 3.

P.55-70

When the A/C is operating, temperature inside the passenger

compartment does not decrease (cool air is not emitted).4.

P.55-75

Blower fan and motor do not turn. 5.

P.55-89

Blower air amount cannot be changed. 6.

P.55-100

The A/C indicator flashes. 7.

P.55-104

Defogger function does not operate. 8.

P.55-110

Defogger timer function does not operate. 9.

P.55-121

Malfunction of the A/C-ECU power supply system. 10.

P.55-122

Condenser fan does not operate. 11. REFER TO

GROUP 14

SYMPTOM

CHART P.14-3

When sunlight intensity changes, air outlet temperature does not change. 12

P.55-128

Page 843 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-142

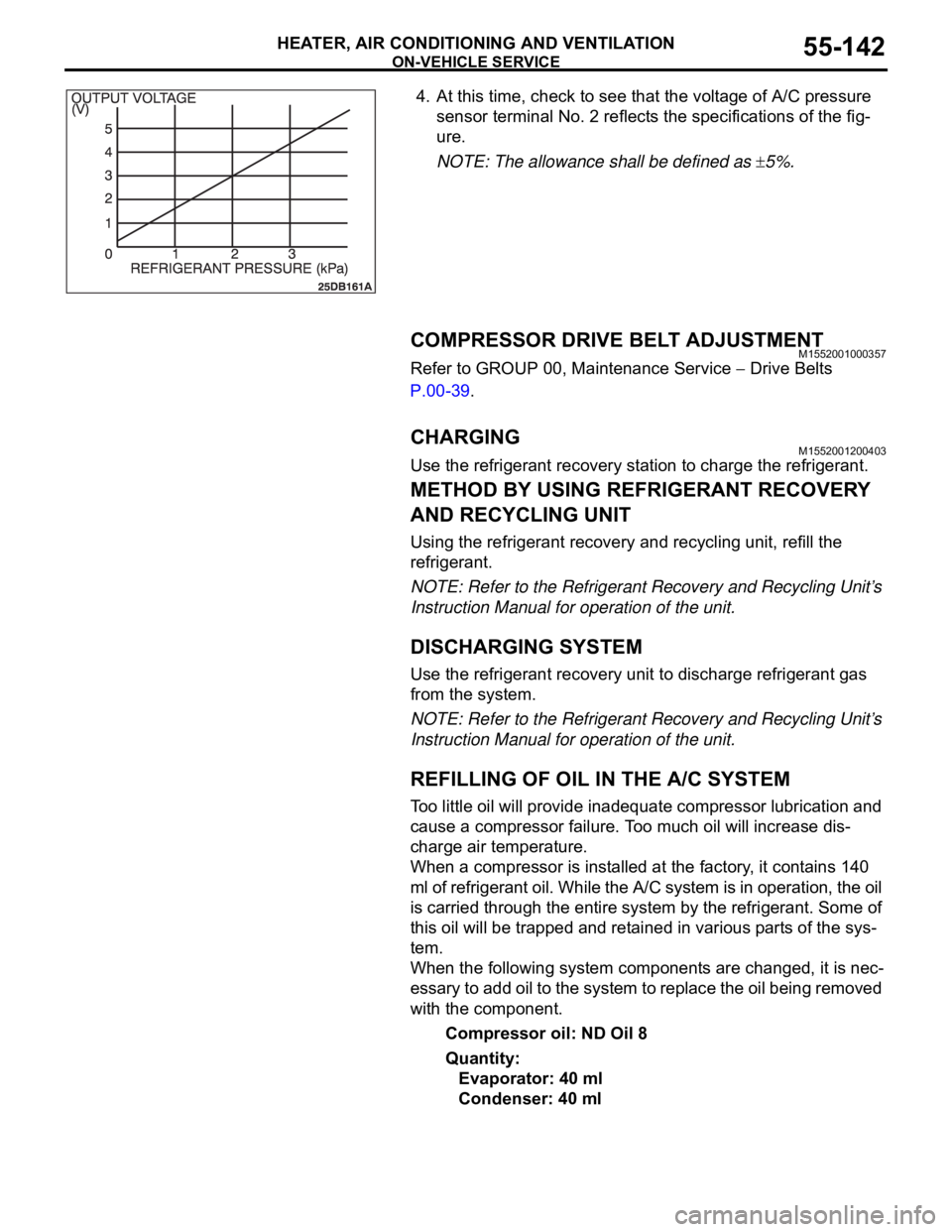

4. At this time, check to see that the voltage of A/C pressure

sensor terminal No. 2 reflects the specifications of the fig-

ure.

NOTE: The allowance shall be defined as

5%.

COMPRESSOR DRIVE BELT ADJUSTMENTM1552001000357

Refer to GROUP 00, Maintenance Service Drive Belts

P.00-39.

CHARGING M1552001200403

Use the refrigerant recovery station to charge the refrigerant.

METHOD BY USING REFRIGERANT RECOVERY

AND RECYCLING UNIT

Using the refrigerant recovery and recycling unit, refill the

refrigerant.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit’s

Instruction Manual for operation of the unit.

DISCHARGING SYSTEM

Use the refrigerant recovery unit to discharge refrigerant gas

from the system.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit’s

Instruction Manual for operation of the unit.

REFILLING OF OIL IN THE A/C SYSTEM

Too little oil will provide inadequate compressor lubrication and

cause a compressor failure. Too much oil will increase dis-

charge air temperature.

When a compressor is installed at the factory, it contains 140

ml of refrigerant oil. While the A/C system is in operation, the oil

is carried through the entire system by the refrigerant. Some of

this oil will be trapped and retained in various parts of the sys-

tem.

When the following system components are changed, it is nec-

essary to add oil to the system to replace the oil being removed

with the component.

Compressor oil: ND Oil 8

Quantity:

Evaporator: 40 ml

Condenser: 40 ml

Page 856 of 1500

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-155

INSPECTIONM1552014301157.

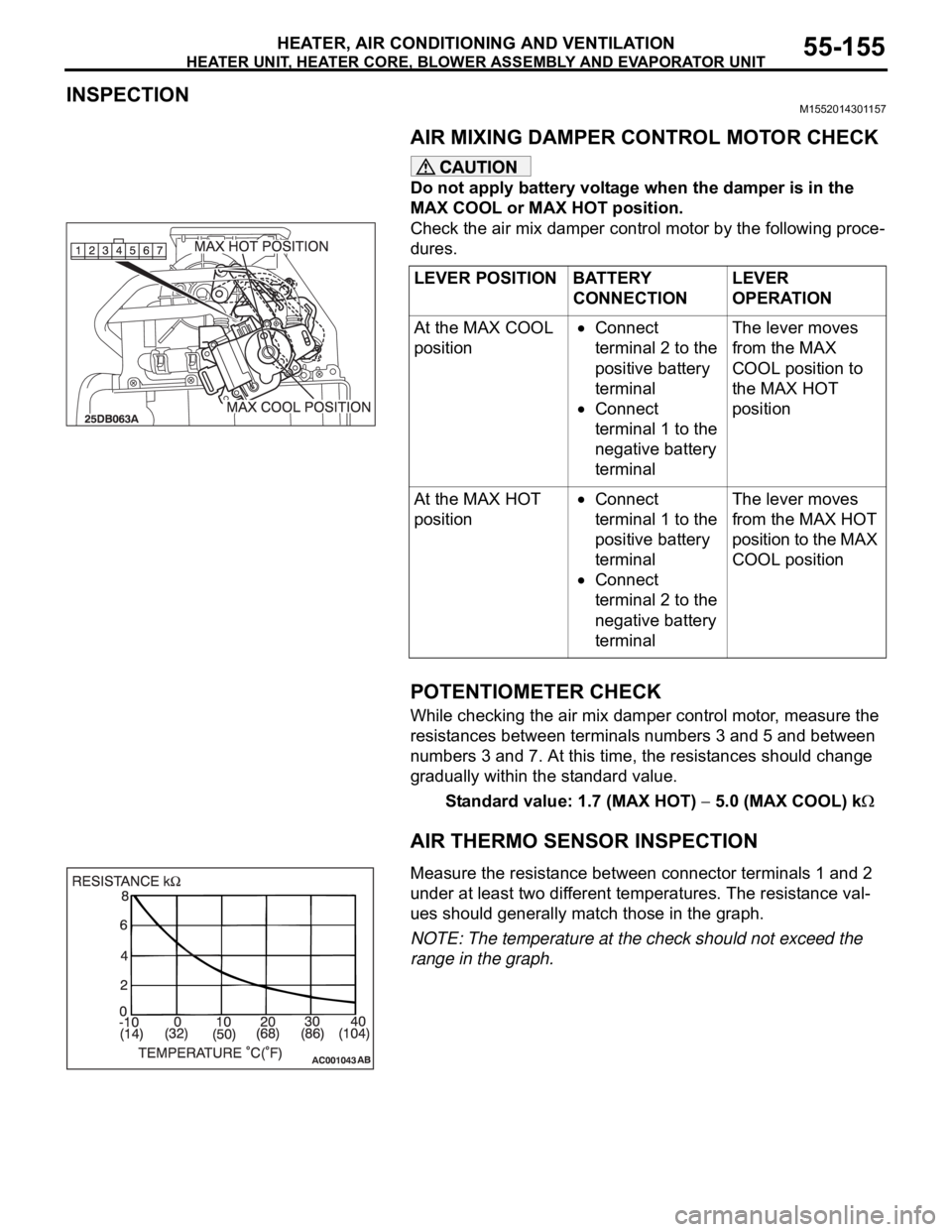

AIR MIXING DAMPER CONTROL MOTOR CHECK

Do not apply battery voltage when the damper is in the

MAX COOL or MAX HOT position.

Check the air mix damper control motor by the following proce-

dures.

.

POTENTIOMETER CHECK

While checking the air mix damper control motor, measure the

resistances between terminals numbers 3 and 5 and between

numbers 3 and 7. At this time, the resistances should change

gradually within the standard value.

Standard value: 1.7 (MAX HOT)

5.0 (MAX COOL) k

AIR THERMO SENSOR INSPECTION

.Measure the resistance between connector terminals 1 and 2

under at least two different temperatures. The resistance val-

ues should generally match those in the graph.

NOTE: The temperature at the check should not exceed the

range in the graph. LEVER POSITION BATTERY

CONNECTIONLEVER

OPERATION

At the MAX COOL

position

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 1 to the

negative battery

terminalThe lever moves

from the MAX

COOL position to

the MAX HOT

position

At the MAX HOT

position

Connect

terminal 1 to the

positive battery

terminal

Connect

terminal 2 to the

negative battery

terminalThe lever moves

from the MAX HOT

position to the MAX

COOL position

Page 859 of 1500

MOTORS AND TRANSISTOR

HEATER, AIR CONDITIONING AND VENTILATION55-158

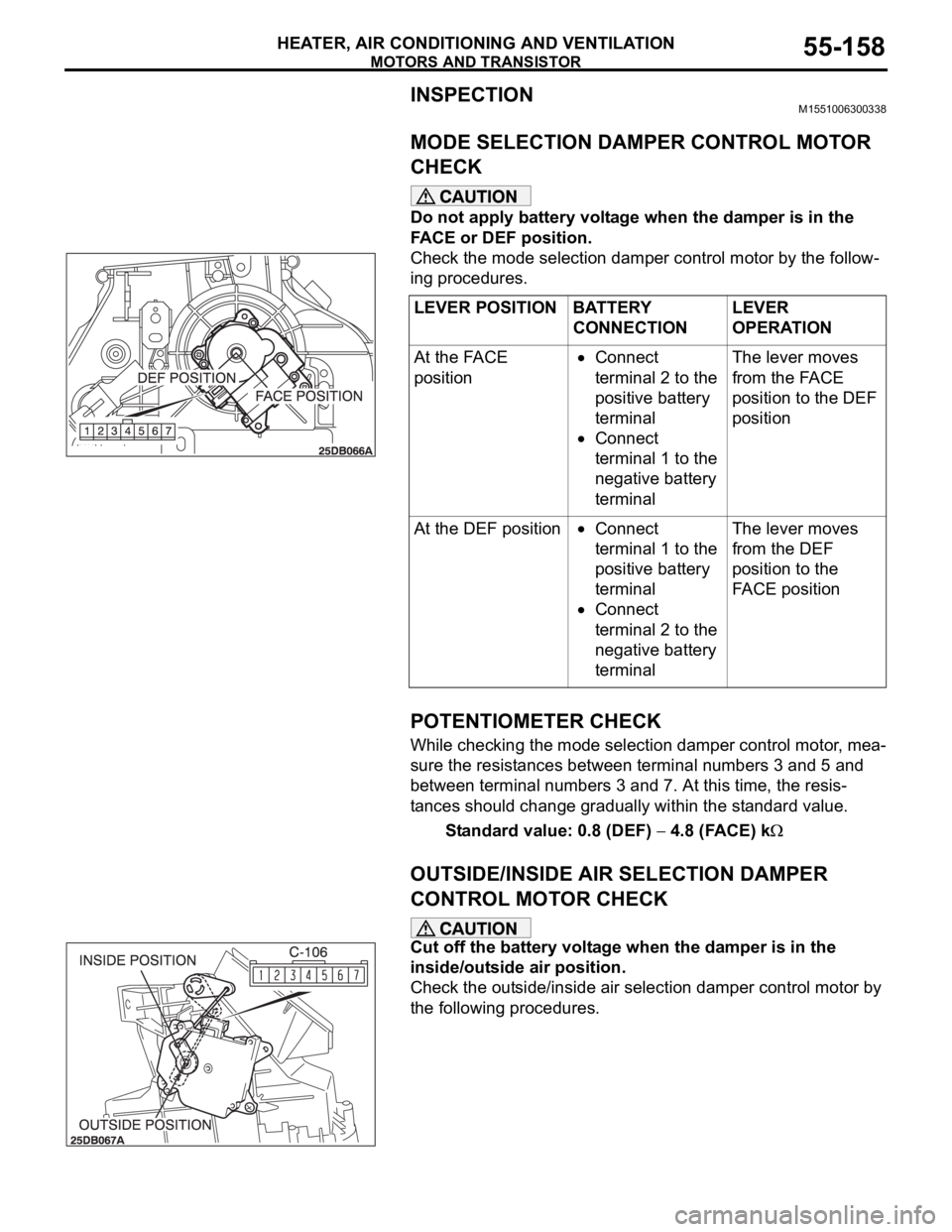

INSPECTIONM1551006300338.

MODE SELECTION DAMPER CONTROL MOTOR

CHECK

Do not apply battery voltage when the damper is in the

FACE or DEF position.

Check the mode selection damper control motor by the follow-

ing procedures.

.

POTENTIOMETER CHECK

While checking the mode selection damper control motor, mea-

sure the resistances between terminal numbers 3 and 5 and

between terminal numbers 3 and 7. At this time, the resis-

tances should change gradually within the standard value.

Standard value: 0.8 (DEF)

4.8 (FACE) k

.

OUTSIDE/INSIDE AIR SELECTION DAMPER

CONTROL MOTOR CHECK

Cut off the battery voltage when the damper is in the

inside/outside air position.

Check the outside/inside air selection damper control motor by

the following procedures.LEVER POSITION BATTERY

CONNECTIONLEVER

OPERATION

At the FACE

position

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 1 to the

negative battery

terminalThe lever moves

from the FACE

position to the DEF

position

At the DEF position

Connect

terminal 1 to the

positive battery

terminal

Connect

terminal 2 to the

negative battery

terminalThe lever moves

from the DEF

position to the

FACE position

Page 907 of 1500

HOW TO DIAGNOSE

GENERAL

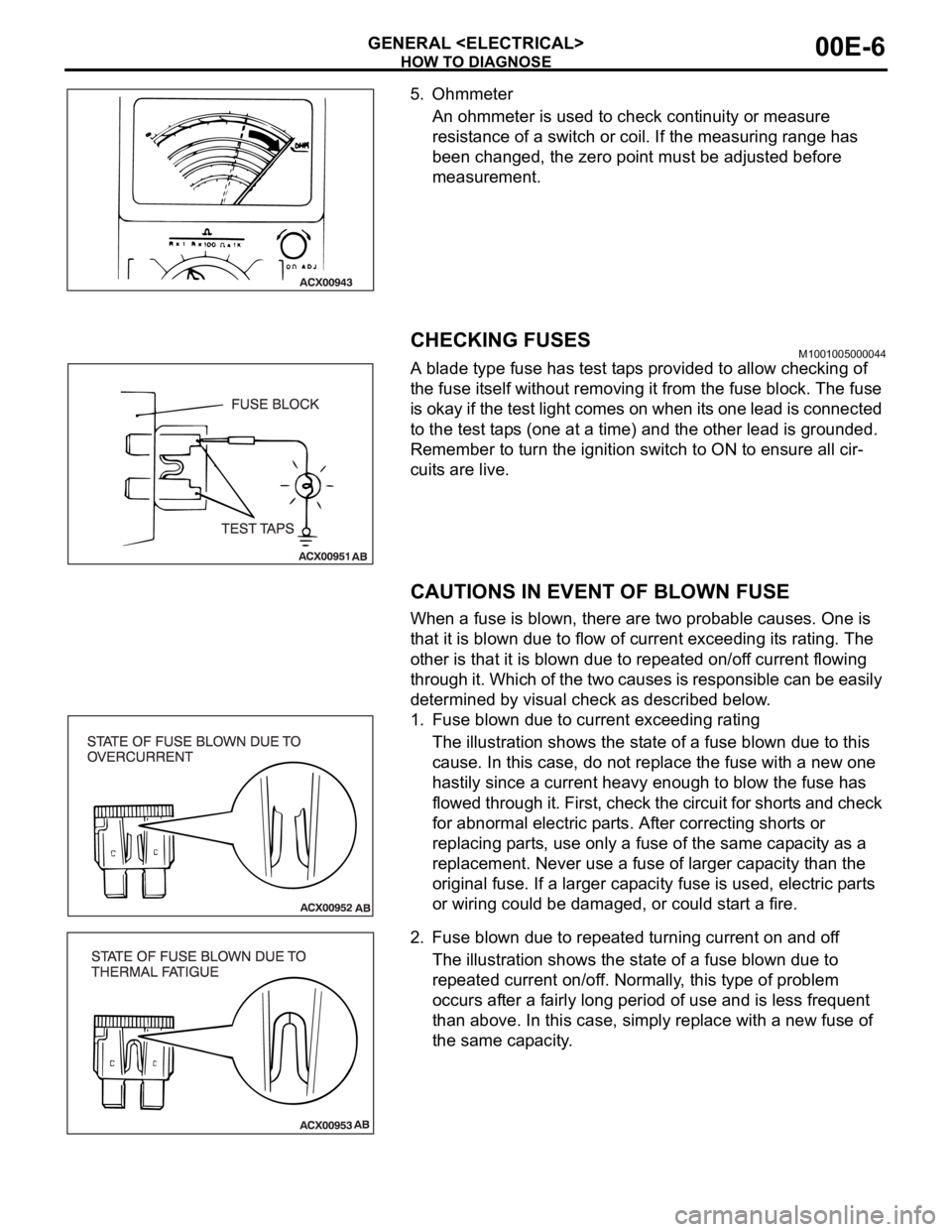

5. Ohmmeter

An ohmmeter is used to check continuity or measure

resistance of a switch or coil. If the measuring range has

been changed, the zero point must be adjusted before

measurement.

CHECKING FUSESM1001005000044

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The fuse

is okay if the test light comes on when its one lead is connected

to the test taps (one at a time) and the other lead is grounded.

Remember to turn the ignition switch to ON to ensure all cir-

cuits are live.

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes. One is

that it is blown due to flow of current exceeding its rating. The

other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

1. Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorts and check

for abnormal electric parts. After correcting shorts or

replacing parts, use only a fuse of the same capacity as a

replacement. Never use a fuse of larger capacity than the

original fuse. If a larger capacity fuse is used, electric parts

or wiring could be damaged, or could start a fire.

2. Fuse blown due to repeated turning current on and off

The illustration shows the state of a fuse blown due to

repeated current on/off. Normally, this type of problem

occurs after a fairly long period of use and is less frequent

than above. In this case, simply replace with a new fuse of

the same capacity.

Page 1047 of 1500

WINDSHIELD WIPER AND WASHER

EXTERIOR51-14

WINDSHIELD WIPER AND WASHER

GENERAL DESCRIPTIONM1511000100558

WINDSHIELD WIPER AND WASHER

OPERATION

.

WINDSHIELD LOW-SPEED (AND

HIGH-SPEED) WIPER OPERATION

If the windshield low-speed wiper switch is turned

to the ON position with the ignition switch at the

"ACC" or "ON" position, the column switch sends

a low-speed wiper ON and high-speed wiper OFF

signals to the front-ECU. This turns the wiper sig-

nal on and the wiper speed control relay off

(low-speed), causing the wipers to operate at

low-speed.

If the windshield high-speed wiper switch is

turned to the ON position, the column switch

sends a low-speed wiper OFF and high-speed

wiper ON signals to the front-ECU. This turns

both the wiper signal and the wiper speed control

relay on (high-speed), causing the wipers to

operate at high-speed.

NOTE: The windshield wiper speed is adjustable

with the built-in wiper speed control relay.

High-speed operations take place when the wiper

speed control relay is set to "ON" and low-speed

operations take place when the wiper speed control

relay is set to "OFF".

.

WINDSHIELD INTERMITTENT WIPER

OPERATION

The ETACS-ECU calculates the wiper operation

interval according to the voltage signal sent from the

column switch. Then the ETACS-ECU sends a signal

to the front-ECU. The front-ECU determines the

wiper operation interval and turns on the wiper relay

signal relay. This causes the wiper auto stop relay to

turn on. Then the wiper auto stop relay will turn off

after the wipers reach the park position. This causes

the wiper signal relay and then the wipers to turn off.

If the wiper signal relay remains off for the wiper

operation interval, the relay turns on again, causing

the wipers to operate in intermittent mode.

.

WINDSHIELD MIST WIPER OPERATION

If the windshield mist wiper switch is turned to the

ON position with the ignition switch at the "ACC"

or "ON" position, the mist wiper high-speed oper-

ation signal is sent to the front-ECU. This signal

turns on the wiper speed control relay, causing

the wipers to work at high-speed while the mist

switch is on.

While the windshield mist wiper switch remains

turned on when the intermittent mode is still work-

ing, the wipers work as the mist wiper. However,

the wipers return to the intermittent mode again

when the switch is changed back to "INT" posi-

tion.

To prevent the windshield mist wiper from operat-

ing when the windshield wiper switch is turned

OFF, the windshield mist wiper does not work for

0.5 second after the windshield intermittent wiper

switch, the windshield low-speed wiper switch

and the windshield high-speed wiper switch are

turned OFF.

.

WINDSHIELD WASHER OPERATION

If the windshield washer switch is turned to the

ON position with the ignition switch at "ACC" or

"ON" position, the windshield washer ON signal is

sent to the front-ECU. After 0.3 second, the wind-

shield wiper signal turns on. After the windshield

washer switch signal turns off, the windshield

wiper signal turns off in three seconds.

If the windshield washer switch is turned on while

the windshield wiper is at intermittent mode, and

the windshield washer switch is turned OFF

within 0.2 second, the wiper works only once to

perform mist operation. When the windshield

washer switch is turned on for more than 0.2 sec-

ond, the wiper performs the same movement as

normal condition from the time when 0.2 second

has elapsed, and then returns to intermittent

operation.

WINDSHIELD WIPER AND WASHER DIAGNOSISM1511000700389

The windshield wiper and washer are controlled by

the Simplified Wiring System (SWS). For trouble-

shooting, refer to GROUP 54B, SWS Diagnosis

P.54B-10.NOTE: Even when the ETACS-ECU has failed, the

windshield wiper can work at low speed as fail-safe

mode. (Normally, the windshield wiper operates

when the ignition switch is at the "ACC" position. But,

if it enters the fail-safe mode, the wiper can operate

only when the ignition switch is at the "ON" position.)

Page 1135 of 1500

KEYLESS ENTRY SYSTEM

BODY42-68

If none of the doors is opened or the ignition key

is not inserted in the ignition switch within 30 sec-

onds after the doors are unlocked using the

transmitter, the ETACS-ECU will relock the doors

automatically. This is called "Timer lock function."

This timer lock function prevents accidental

unlocking of doors. The adjustment function

allows you to change the timer lock period from 30 seconds (default setting) to 60, 120 or 180

seconds. For further details on using the

multi-center display (middle grade type) to adjust

the timer lock period, refer to GROUP 54B,

On-vehicle Service P.54B-486.

NOTE: The timer lock period begins when the doors

are unlocked, and ends when the doors is relocked

automatically.

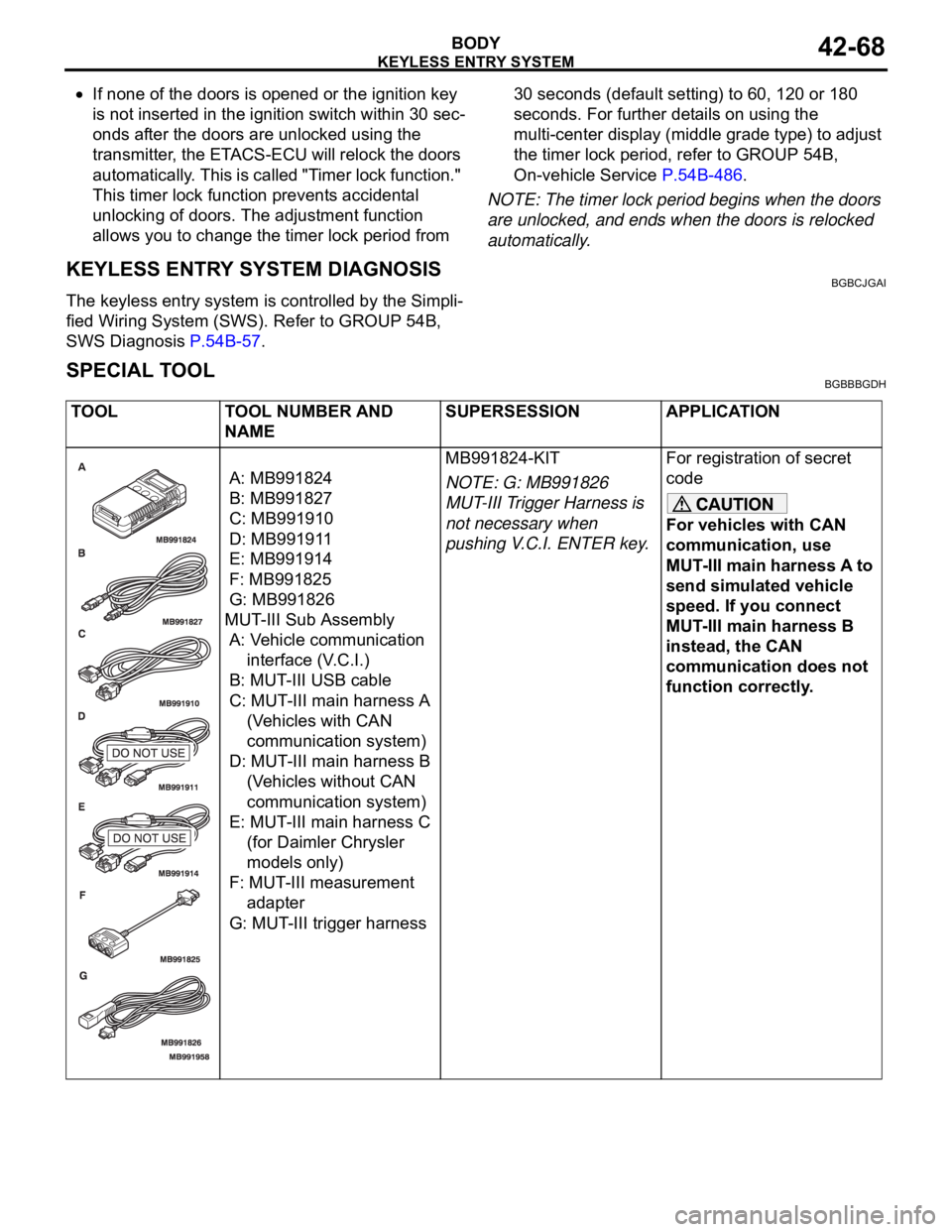

KEYLESS ENTRY SYSTEM DIAGNOSISBGBCJGAI

The keyless entry system is controlled by the Simpli-

fied Wiring System (SWS). Refer to GROUP 54B,

SWS Diagnosis P.54B-57.

SPECIAL TOOLBGBBBGDH

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III Sub Assembly

A: Vehicle communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness A

(Vehicles with CAN

communication system)

D: MUT-III main harness B

(Vehicles without CAN

communication system)

E: MUT-III main harness C

(for Daimler Chrysler

models only)

F: MUT-III measurement

adapter

G: MUT-III trigger harnessMB991824-KIT

NOTE: G: MB991826

MUT-III Trigger Harness is

not necessary when

pushing V.C.I. ENTER key.For registration of secret

code

For vehicles with CAN

communication, use

MUT-III main harness A to

send simulated vehicle

speed. If you connect

MUT-III main harness B

instead, the CAN

communication does not

function correctly.

Page 1138 of 1500

KEYLESS ENTRY SYSTEM

BODY42-71

KEYLESS ENTRY SYSTEM INSPECTIONBGBHCDAE

Check the following items. If defective, refer to GROUP 54B,

SWS Diagnosis P.54B-10).

1. Operate the transmitter to check that the doors can be

locked and unlocked.

NOTE: The adjustment function allows you to change the

unlock operation setting as follows. Prior to that check, con-

firm which setting is activated.

.

a. When the unlock button is pressed once, the driver's

door will be unlocked. Then when the button is pressed

once again, all the doors will be opened (initial setting).

b. When the unlock button is pressed only once, all the

doors will be opened.

2. Press the trunk lid button of transmitter twice (press once,

and then press again within 5 seconds) and confirm that the

trunk lid opens.

3. Operate the transmitter to check that the answerback

function works in response to doors locking/unlocking.

NOTE: The adjustment function allows you to change the

hazard answerback setting as follows. Prior to that check,

confirm which setting is activated.

.

a. Turn-signal lights: Flash once when doors are locked,

and twice when unlocked (initial setting)

b. Turn-signal lights: Flash once when doors are locked,

but does not flash when unlocked.

c. Turn-signal lights: Do not flash when doors are locked,

but flash twice when unlocked.

d. Turn-signal lights: Do not flash when doors are locked

and unlocked.

NOTE: The adjustment function allows you to change the

horn answerback setting as follows. Prior to that check, con-

firm which setting is activated.

.

a. Horn: Sounds once when the lock button is pressed.

b. Horn: Sounds once when the lock button is pressed (ini-

tial setting).

c. Horn: Does not sound.

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION

BGBEBDIA

If the doors are not locked within 30 seconds after the unlock

button is pressed, refer to GROUP 54B, SWS Diagnosis

P.54B-10.

NOTE: If either of the doors is opened or the key is inserted in

the ignition switch within that 30-second period, the timer lock

function will be cancelled.

Page 1139 of 1500

KEYLESS ENTRY SYSTEM

BODY42-72

NOTE: The adjustment function allows you to change the timer

lock period from 30 seconds (initial setting) to 60, 120 or 180

seconds. Prior to this inspection, confirm which setting is acti-

vated.

ENABLING/DISABLING THE ANSWERBACK

FUNCTION

BGBDGCGD

When the doors are locked or unlocked by using the transmit-

ter, the dome light will flash/illuminate, the turn-signal lights will

flash (hazard answerback), or the horn will sound (horn

answerback) to inform the driver.

The hazard answerback and horn answerback functions can be

enabled or disabled according to the following procedure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

.

How to adjust hazard answerback when the trans-

mitter is used to lock doors

1. Remove the ignition key.

2. Push the ”unlock” button and then push the ”lock“ button

within 4 seconds to 10 seconds.

3. Release the ”lock” button within 10 seconds after Step 2 and

then release the “unlock” button. The ETACS-ECU tone

alarm will sound, indicating that the hazard answerback

function can be enabled or disabled when the doors are

locked.

Enable the hazard answerback function when the

doors are locked: The ETACS-ECU tone alarm will

sound once.

Disable the hazard answerback function when the

doors are locked: The ETACS-ECU tone alarm will

sound twice.

.

How to adjust hazard answerback when the

transmitter is used to unlock doors

1. Remove the ignition key.

2. Push the ”unlock” button and then push the ”lock“ button

within 4 seconds to 10 seconds.

3. Release the ”lock” button within 10 seconds after Step 2 and

then release the “unlock” button. The ETACS-ECU tone

alarm will sound, indicating that the hazard answerback

function can be enabled or disabled when the door are

unlocked.

Enable the hazard answerback function when the

doors are unlocked: The ETACS-ECU tone alarm

will sound once.

Disable the hazard answerback function when the

doors are unlocked: The ETACS-ECU tone alarm

will sound twice.

Page 1179 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-14

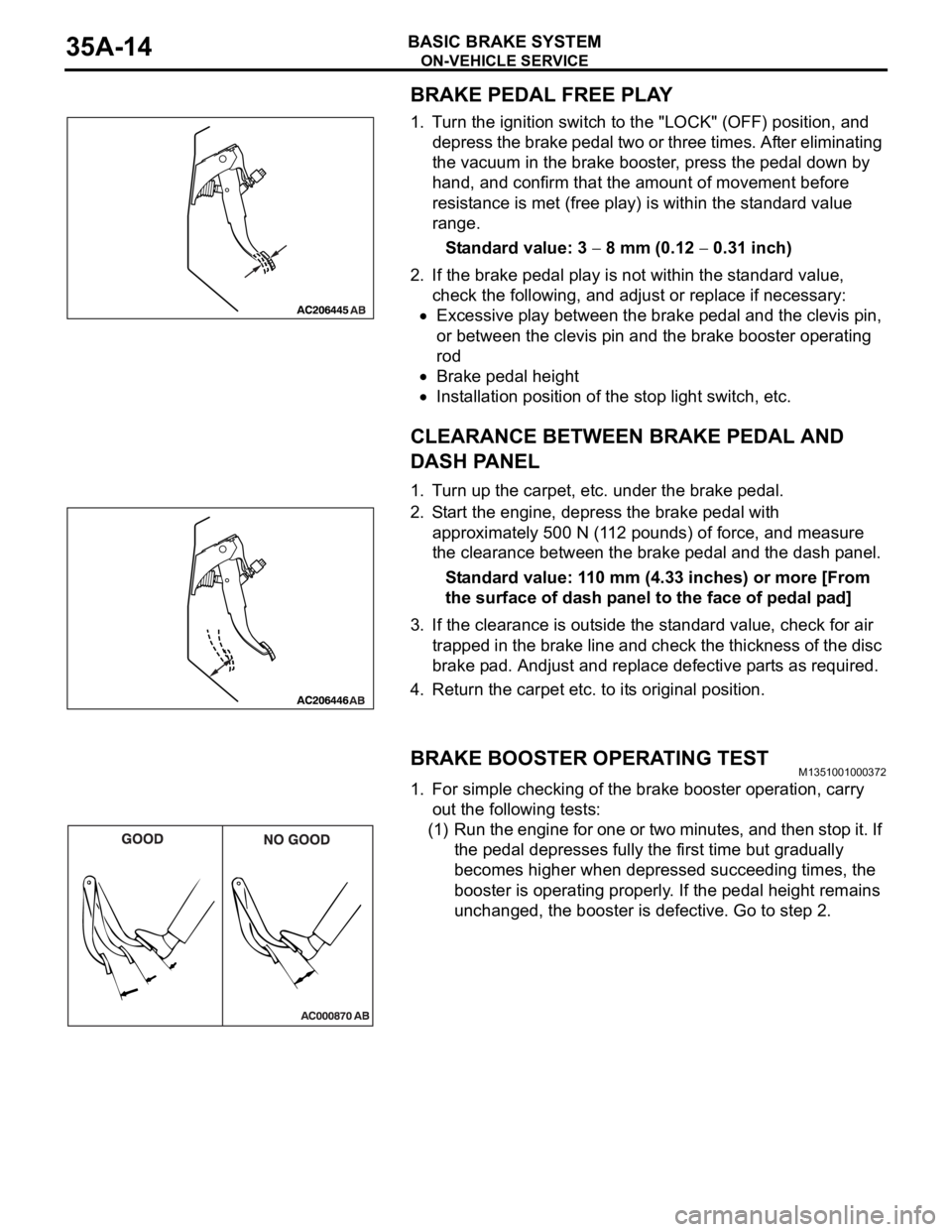

BRAKE PEDAL FREE PLAY

1. Turn the ignition switch to the "LOCK" (OFF) position, and

depress the brake pedal two or three times. After eliminating

the vacuum in the brake booster, press the pedal down by

hand, and confirm that the amount of movement before

resistance is met (free play) is within the standard value

range.

Standard value: 3

8 mm (0.12 0.31 inch)

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

Excessive play between the brake pedal and the clevis pin,

or between the clevis pin and the brake booster operating

rod

Brake pedal height

Installation position of the stop light switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND

DASH PANEL

1. Turn up the carpet, etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N (112 pounds) of force, and measure

the clearance between the brake pedal and the dash panel.

Standard value: 110 mm (4.33 inches) or more [From

the surface of dash panel to the face of pedal pad]

3. If the clearance is outside the standard value, check for air

trapped in the brake line and check the thickness of the disc

brake pad. Andjust and replace defective parts as required.

4. Return the carpet etc. to its original position.

BRAKE BOOSTER OPERATING TESTM1351001000372

1. For simple checking of the brake booster operation, carry

out the following tests:

(1) Run the engine for one or two minutes, and then stop it. If

the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective. Go to step 2.