ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-15

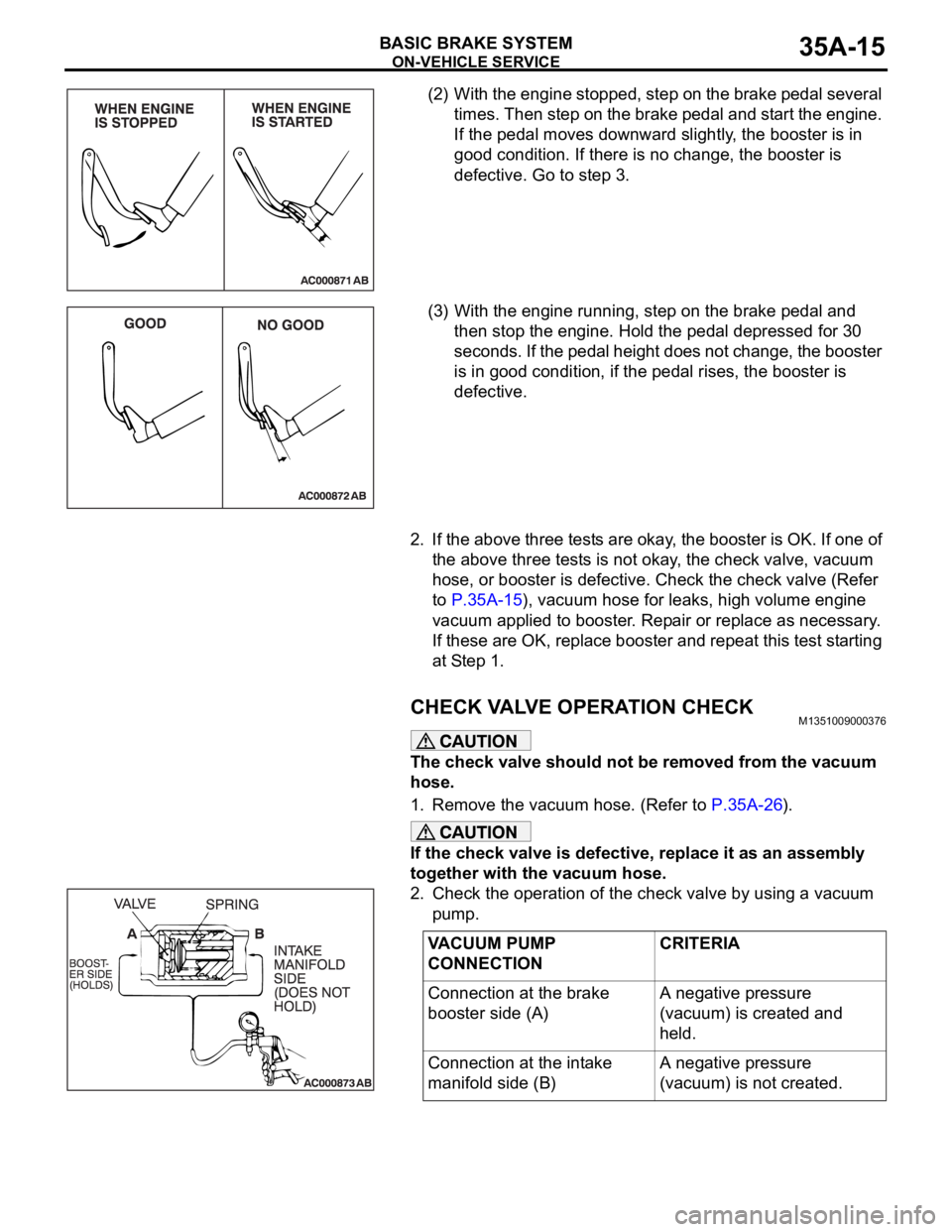

(2) With the engine stopped, step on the brake pedal several

times. Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is

defective. Go to step 3.

(3) With the engine running, step on the brake pedal and

then stop the engine. Hold the pedal depressed for 30

seconds. If the pedal height does not change, the booster

is in good condition, if the pedal rises, the booster is

defective.

2. If the above three tests are okay, the booster is OK. If one of

the above three tests is not okay, the check valve, vacuum

hose, or booster is defective. Check the check valve (Refer

to P.35A-15), vacuum hose for leaks, high volume engine

vacuum applied to booster. Repair or replace as necessary.

If these are OK, replace booster and repeat this test starting

at Step 1.

CHECK VALVE OPERATION CHECKM1351009000376

The check valve should not be removed from the vacuum

hose.

1. Remove the vacuum hose. (Refer to P.35A-26).

If the check valve is defective, replace it as an assembly

together with the vacuum hose.

2. Check the operation of the check valve by using a vacuum

pump.

VACUUM PUMP

CONNECTIONCRITERIA

Connection at the brake

booster side (A)A negative pressure

(vacuum) is created and

held.

Connection at the intake

manifold side (B)A negative pressure

(vacuum) is not created.

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-20

.

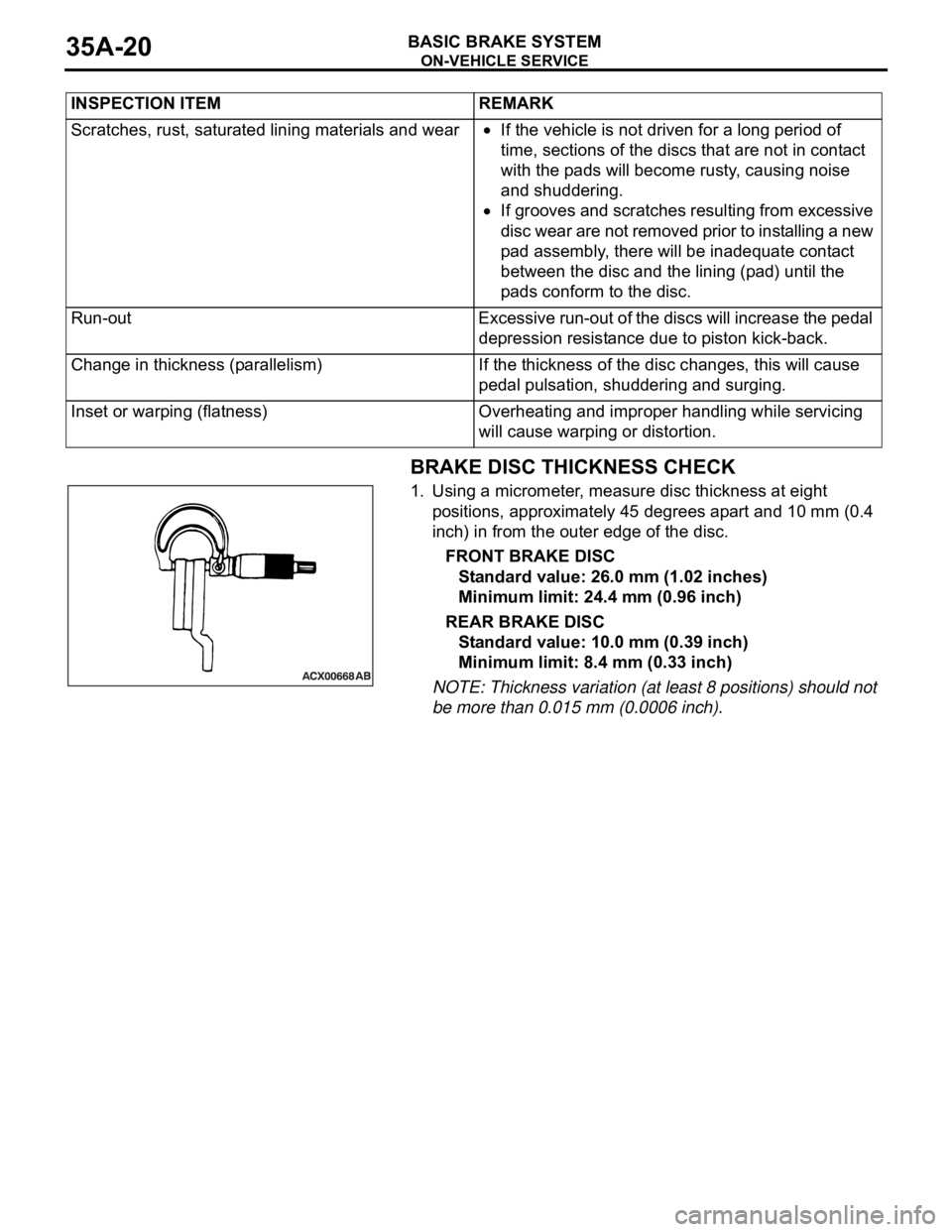

BRAKE DISC THICKNESS CHECK

1. Using a micrometer, measure disc thickness at eight

positions, approximately 45 degrees apart and 10 mm (0.4

inch) in from the outer edge of the disc.

FRONT BRAKE DISC

Standard value: 26.0 mm (1.02 inches)

Minimum limit: 24.4 mm (0.96 inch)

REAR BRAKE DISC

Standard value: 10.0 mm (0.39 inch)

Minimum limit: 8.4 mm (0.33 inch)

NOTE: Thickness variation (at least 8 positions) should not

be more than 0.015 mm (0.0006 inch). INSPECTION ITEM REMARK

Scratches, rust, saturated lining materials and wear

If the vehicle is not driven for a long period of

time, sections of the discs that are not in contact

with the pads will become rusty, causing noise

and shuddering.

If grooves and scratches resulting from excessive

disc wear are not removed prior to installing a new

pad assembly, there will be inadequate contact

between the disc and the lining (pad) until the

pads conform to the disc.

Run-out Excessive run-out of the discs will increase the pedal

depression resistance due to piston kick-back.

Change in thickness (parallelism) If the thickness of the disc changes, this will cause

pedal pulsation, shuddering and surging.

Inset or warping (flatness) Overheating and improper handling while servicing

will cause warping or distortion.