charging MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 846 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-145

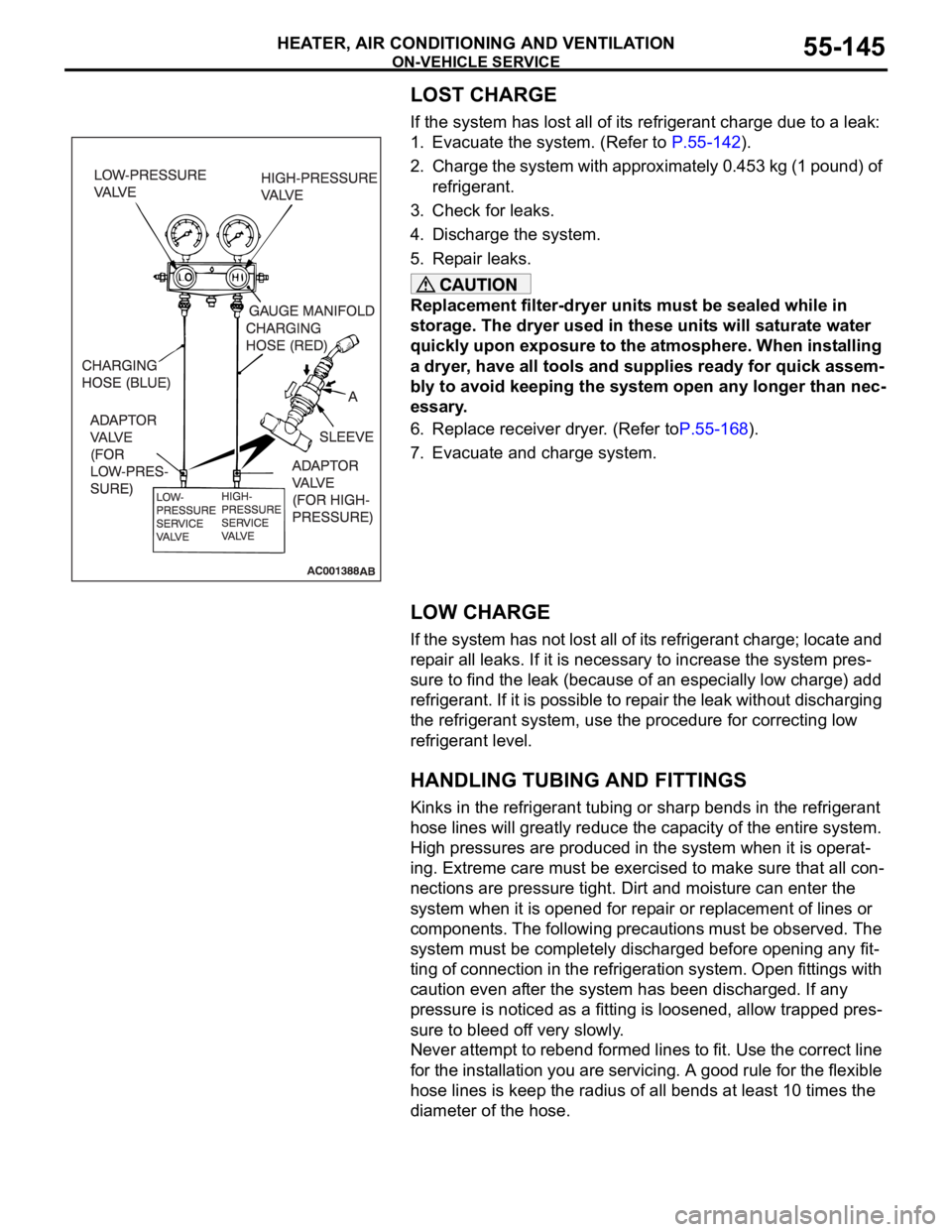

LOST CHARGE

If the system has lost all of its refrigerant charge due to a leak:

1. Evacuate the system. (Refer to P.55-142).

2. Charge the system with approximately 0.453 kg (1 pound) of

refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

Replacement filter-dryer units must be sealed while in

storage. The dryer used in these units will saturate water

quickly upon exposure to the atmosphere. When installing

a dryer, have all tools and supplies ready for quick assem-

bly to avoid keeping the system open any longer than nec-

essary.

6. Replace receiver dryer. (Refer toP.55-168).

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge; locate and

repair all leaks. If it is necessary to increase the system pres-

sure to find the leak (because of an especially low charge) add

refrigerant. If it is possible to repair the leak without discharging

the refrigerant system, use the procedure for correcting low

refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the refrigerant

hose lines will greatly reduce the capacity of the entire system.

High pressures are produced in the system when it is operat-

ing. Extreme care must be exercised to make sure that all con-

nections are pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of lines or

components. The following precautions must be observed. The

system must be completely discharged before opening any fit-

ting of connection in the refrigeration system. Open fittings with

caution even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow trapped pres-

sure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the correct line

for the installation you are servicing. A good rule for the flexible

hose lines is keep the radius of all bends at least 10 times the

diameter of the hose.

Page 852 of 1500

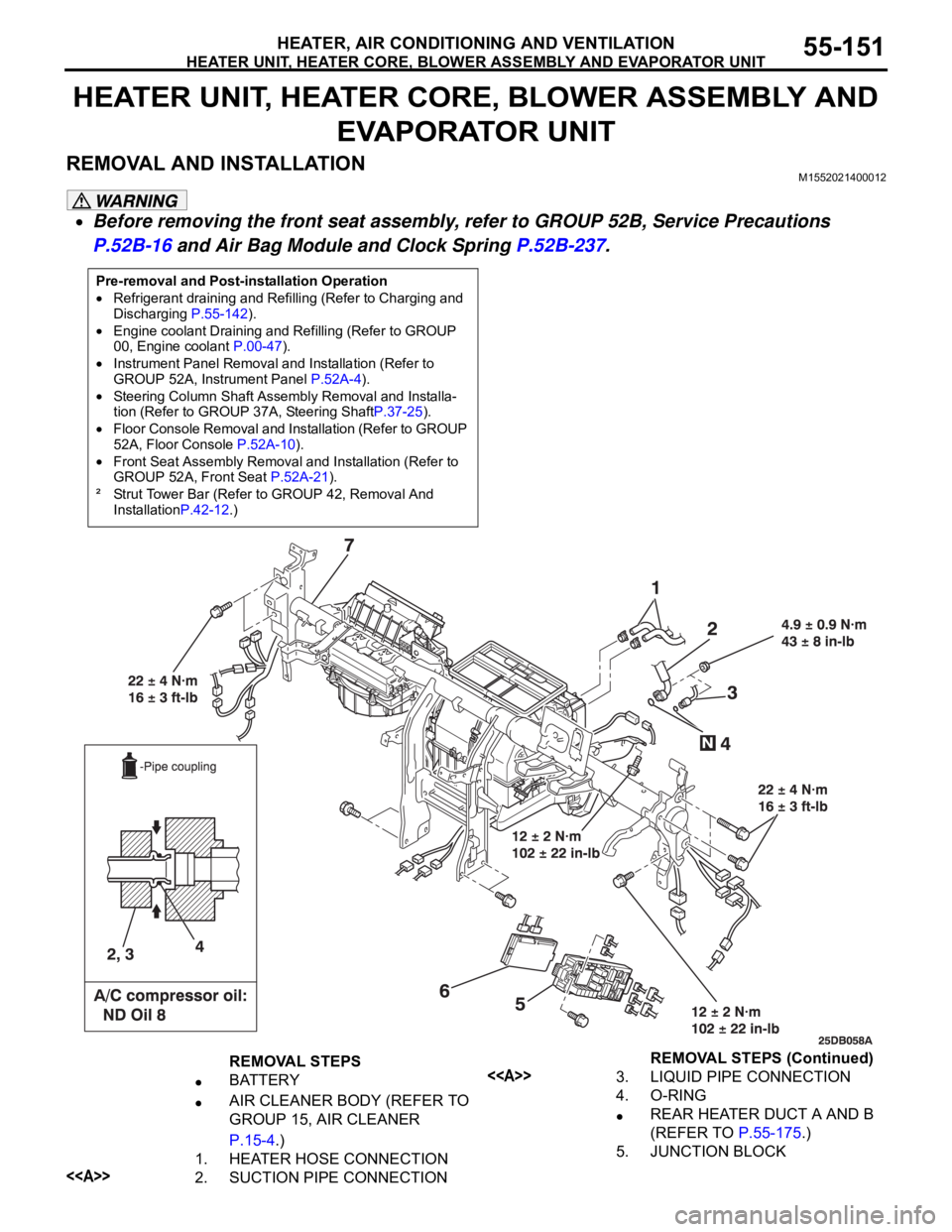

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-151

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND

EVAPORATOR UNIT

REMOVAL AND INSTALLATIONM1552021400012

Before removing the front seat assembly, refer to GROUP 52B, Service Precautions

P.52B-16 and Air Bag Module and Clock Spring P.52B-237.

Pre-removal and Post-installation Operation

Refrigerant draining and Refilling (Refer to Charging and

Discharging P.55-142).

Engine coolant Draining and Refilling (Refer to GROUP

00, Engine coolant P.00-47).

Instrument Panel Removal and Installation (Refer to

GROUP 52A, Instrument Panel P.52A-4).

Steering Column Shaft Assembly Removal and Installa-

tion (Refer to GROUP 37A, Steering ShaftP.37-25).

Floor Console Removal and Installation (Refer to GROUP

52A, Floor Console P.52A-10).

Front Seat Assembly Removal and Installation (Refer to

GROUP 52A, Front Seat P.52A-21).

² Strut Tower Bar (Refer to GROUP 42, Removal And

InstallationP.42-12.)

REMOVAL STEPS

BATTERY

AIR CLEANER BODY (REFER TO

GROUP 15, AIR CLEANER

P.15-4.)

1. HEATER HOSE CONNECTION

<>2. SUCTION PIPE CONNECTION

<>3. LIQUID PIPE CONNECTION

4. O-RING

REAR HEATER DUCT A AND B

(REFER TO P.55-175.)

5. JUNCTION BLOCKREMOVAL STEPS (Continued)

Page 865 of 1500

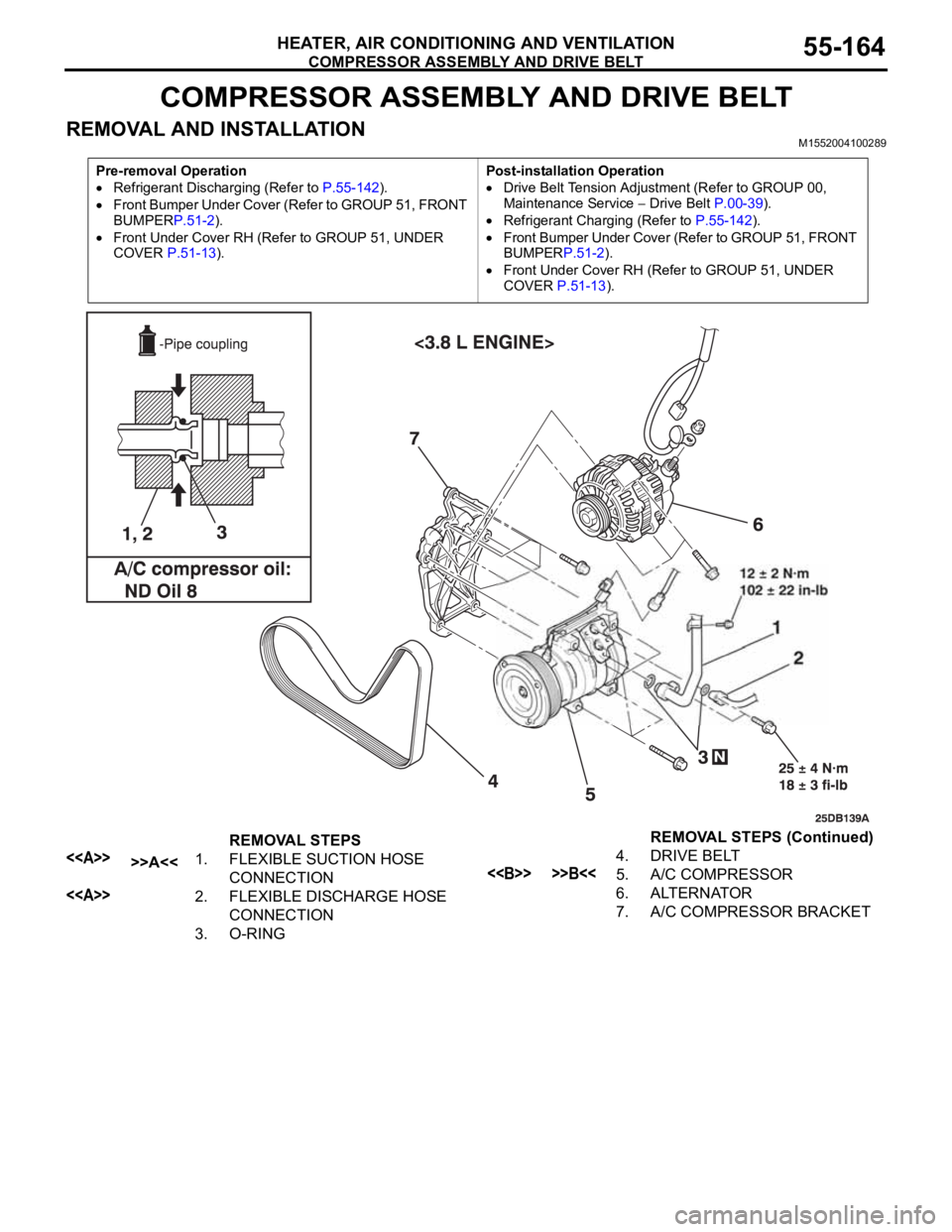

COMPRESSOR ASSEMBLY AND DRIVE BELT

HEATER, AIR CONDITIONING AND VENTILATION55-164

COMPRESSOR ASSEMBLY AND DRIVE BELT

REMOVAL AND INSTALLATIONM1552004100289

Pre-removal Operation

Refrigerant Discharging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).Post-installation Operation

Drive Belt Tension Adjustment (Refer to GROUP 00,

Maintenance Service

Drive Belt P.00-39).

Refrigerant Charging (Refer to P.55-142).

Front Bumper Under Cover (Refer to GROUP 51, FRONT

BUMPERP.51-2).

Front Under Cover RH (Refer to GROUP 51, UNDER

COVER P.51-13).

REMOVAL STEPS

<>>>A<<1. FLEXIBLE SUCTION HOSE

CONNECTION

<>2. FLEXIBLE DISCHARGE HOSE

CONNECTION

3. O-RING4. DRIVE BELT

<> >>B<<5. A/C COMPRESSOR

6. ALTERNATOR

7. A/C COMPRESSOR BRACKETREMOVAL STEPS (Continued)

Page 871 of 1500

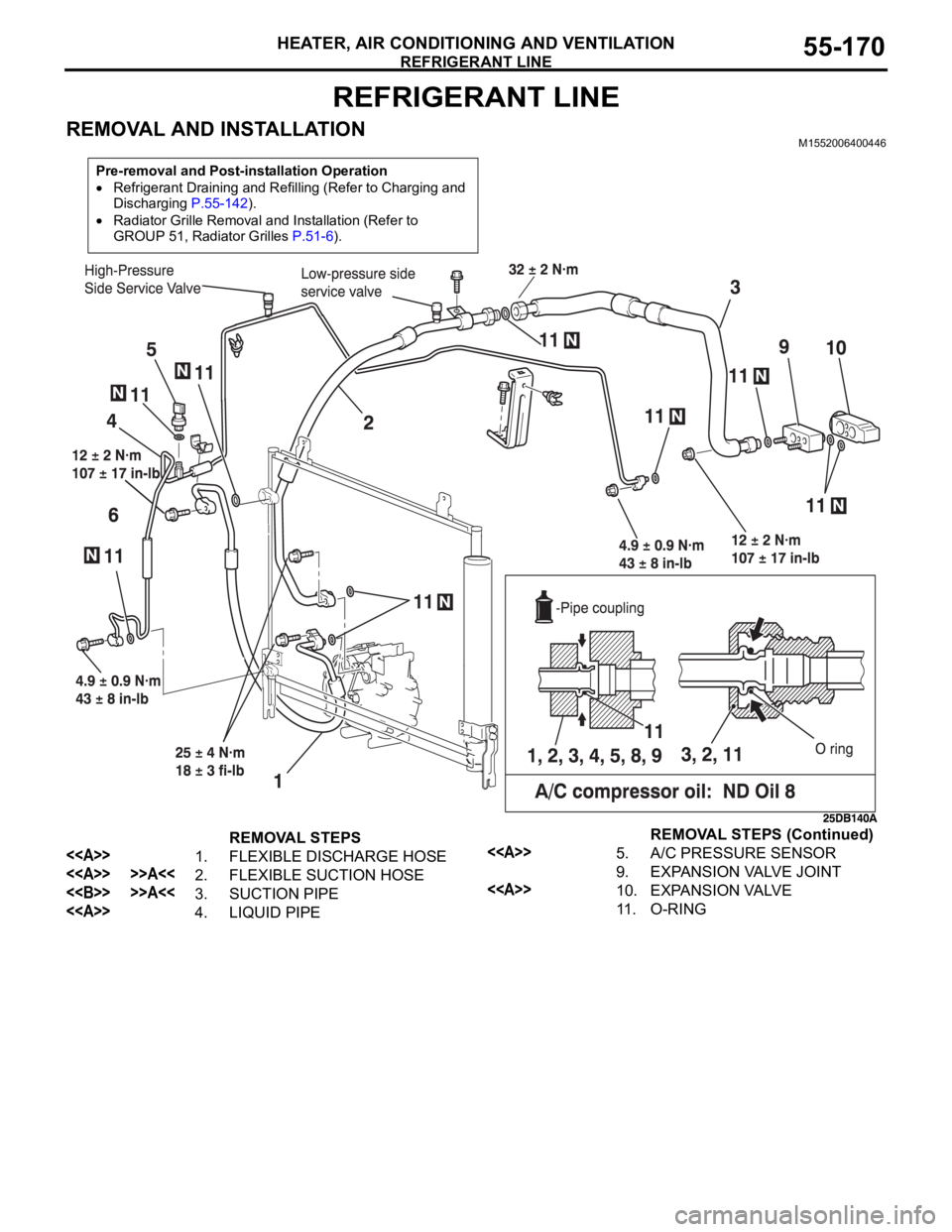

REFRIGERANT LINE

HEATER, AIR CONDITIONING AND VENTILATION55-170

REFRIGERANT LINE

REMOVAL AND INSTALLATIONM1552006400446

Pre-removal and Post-installation Operation

Refrigerant Draining and Refilling (Refer to Charging and

Discharging P.55-142).

Radiator Grille Removal and Installation (Refer to

GROUP 51, Radiator Grilles P.51-6).

REMOVAL STEPS

<>1. FLEXIBLE DISCHARGE HOSE

<> >>A<<2. FLEXIBLE SUCTION HOSE

<> >>A<<3. SUCTION PIPE

<>4. LIQUID PIPE

<>5. A/C PRESSURE SENSOR

9. EXPANSION VALVE JOINT

<>10. EXPANSION VALVE

11 . O - R I N GREMOVAL STEPS (Continued)

Page 978 of 1500

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .

16-2

GENERAL DESCRIPTION . . . . . .

16-2

CHARGING SYSTEM DIAGNOSIS16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-6

ON-VEHICLE SERVICE. . . . . . . . .16-7

ALTERNATOR OUTPUT WIRE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-7

OUTPUT CURRENT TEST . . . . . . . . . . 16-8

REGULATED VOLTAGE TEST . . . . . . . 16-10

WAVE PATTERN CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-11

ALTERNATOR ASSEMBLY . . . . .16-14

REMOVAL AND INSTALLATION . . . . . 16-14

DISASSEMBLY AND ASSEMBLY. . . . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-20

GENERAL DESCRIPTION . . . . . .

16-20

STARTING SYSTEM DIAGNOSIS . . . . 16-21

STARTER MOTOR ASSEMBLY . .16-23

REMOVAL AND INSTALLATION . . . . . 16-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-24

DISASSEMBLY AND ASSEMBLY. . . . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-28

IGNITION SYSTEM . . . . . . . . . . . . . .16-30GENERAL DESCRIPTION . . . . . . .

16-30

SPECIAL TOOLS . . . . . . . . . . . . . .16-30

ON-VEHICLE SERVICE . . . . . . . . .16-31

KNOCK CONTROL SYSTEM CHECK . . 16-31

IGNITION COIL CHECK. . . . . . . . . . . . . 16-31

SPARK PLUG TEST . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING16-32

CAMSHAFT POSITION SENSOR CHECK16-32

CRANKSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-32

IGNITION COIL . . . . . . . . . . . . . . . .16-33

REMOVAL AND INSTALLATION . . . . . 16-33

CAMSHAFT POSITION SENSOR .16-34

REMOVAL AND INSTALLATION . . . . . 16-34

CRANKSHAFT POSITION SENSOR16-35

REMOVAL AND INSTALLATION . . . . . 16-35

KNOCK SENSOR . . . . . . . . . . . . . .16-36

REMOVAL AND INSTALLATION . . . . . 16-36

SPECIFICATIONS . . . . . . . . . . 16-38

FASTENER TIGHTENING

SPECIFICATIONS . . . . . . . . . . . . .

16-38

GENERAL SPECIFICATIONS . . . .16-38

SERVICE SPECIFICATIONS . . . . .16-39

Page 979 of 1500

16-2

CHARGING SYSTEM

GENERAL DESCRIPTIONM1161000100629

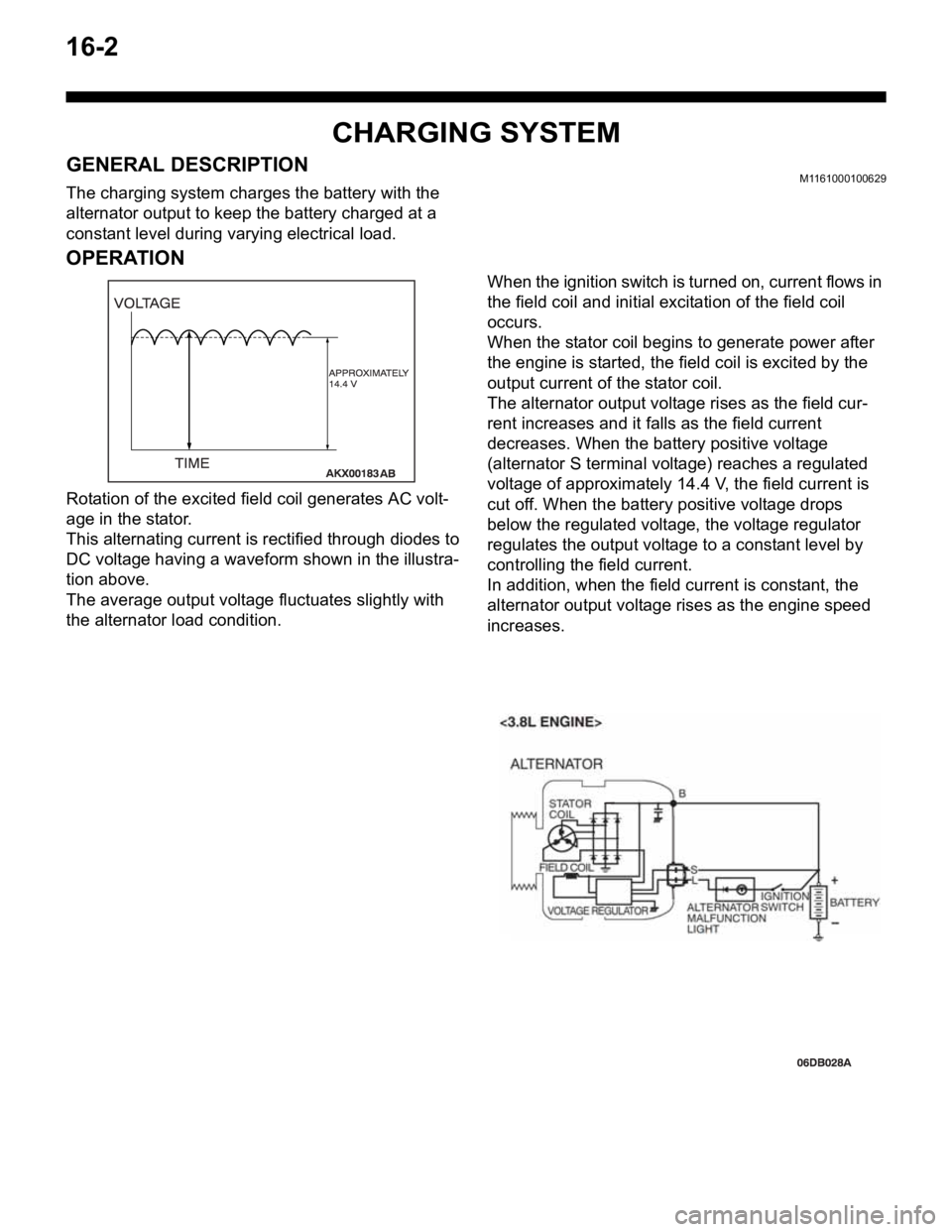

The charging system charges the battery with the

alternator output to keep the battery charged at a

constant level during varying electrical load.

OPERATION

Rotation of the excited field coil generates AC volt-

age in the stator.

This alternating current is rectified through diodes to

DC voltage having a waveform shown in the illustra-

tion above.

The average output voltage fluctuates slightly with

the alternator load condition.When the ignition switch is turned on, current flows in

the field coil and initial excitation of the field coil

occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by the

output current of the stator coil.

The alternator output voltage rises as the field cur-

rent increases and it falls as the field current

decreases. When the battery positive voltage

(alternator S terminal voltage) reaches a regulated

voltage of approximately 14.4 V, the field current is

cut off. When the battery positive voltage drops

below the regulated voltage, the voltage regulator

regulates the output voltage to a constant level by

controlling the field current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

Page 980 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

CHARGING SYSTEM DIAGNOSISM1161000700427

TROUBLESHOOTING HINTS

Alternator malfunction light dose not go on when the ignition

switch is turned to ON, before the engine starts.

Check the bulb.

Alternator malfunction light dose not switch off after the engine

starts.

Check the IC voltage regulator inside the

alternatoralternator.

Discharged or overcharged battery.

Check the IC voltage regulator inside the alternator.

The alternator malfunction light illuminates dimly.

Check the diode (inside the combination meter) for a

short-circuit.

TROUBLESHOOTING GUIDE

The charging system troubleshooting guide is shown in the fol-

lowing steps.

STEP 1.

Q: Is the battery in good condition? (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

YES : Go to Step 2.

NO : Charge or replace the battery.

STEP 2.

Q: Is the alternator drive belt in good condition? (Refer to

GROUP 00, General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

YES : Go to Step 3.

NO : Adjust the belt tension or replace the belt.

STEP 3.

Q: Does the alternator malfunction light come on when the

ignition switch is turned on?

YES : Go to Step 4.

NO :

Check the ignition switch. (Refer to GROUP 54A,

Chassis Electrical

Ignition Switch Ignition

Switch

Inspection P.54A-44.)

Check for burnt-out alternator malfunction light.

Check the alternator. (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

Check the alternator malfunction light-related

circuits.

Page 981 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

STEP 4.

Q: Does the alternator malfunction light go out after

starting the engine?

YES : Go to Step 5.

NO : Check the alternator (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

STEP 5.

Q: Is an oscilloscope available?

YES : Go to Step 6.

NO : Go to Step 7.

STEP 6.

Q: Does the oscilloscope show a normal wave pattern?

(Refer to Charging System

On-vehicle Service Wave

Pattern Check Using an Oscilloscope P.16-11.)

YES : Go to Step 7.

NO : Check the alternator. (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

STEP 7.

Engine: 2,500 r/min

Headlight: ON (high beam)

Voltage between alternator terminal B and the positive bat-

tery terminal

OK: 0.5 V or less

Voltage between the negative battery terminal and

alternator body

OK: 0.5 V or less

Q: Are the alternator output wire and ground wire in good

condition?

YES : Go to Step 8.

NO : Check the alternator output wire and ground wire.

STEP 8.

Q: Is the output current normal? (Refer to Charging

System

On-vehicle Service Output Current Test

P.16-8.)

YES : Go to Step 9.

NO : Check the alternator (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

Page 982 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-5

STEP 9.

Q: Is the regulated voltage normal? (Refer to Charging

System

On-vehicle Service Regulated Voltage Test

P.16-10.)

YES : Go to Step 10.

NO : Check the alternator (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

STEP 10.

Q: Is the voltage drop in the alternator output wire normal?

YES : Alternator is normal. Check other systems.

NO : Check the output wire.

Page 983 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

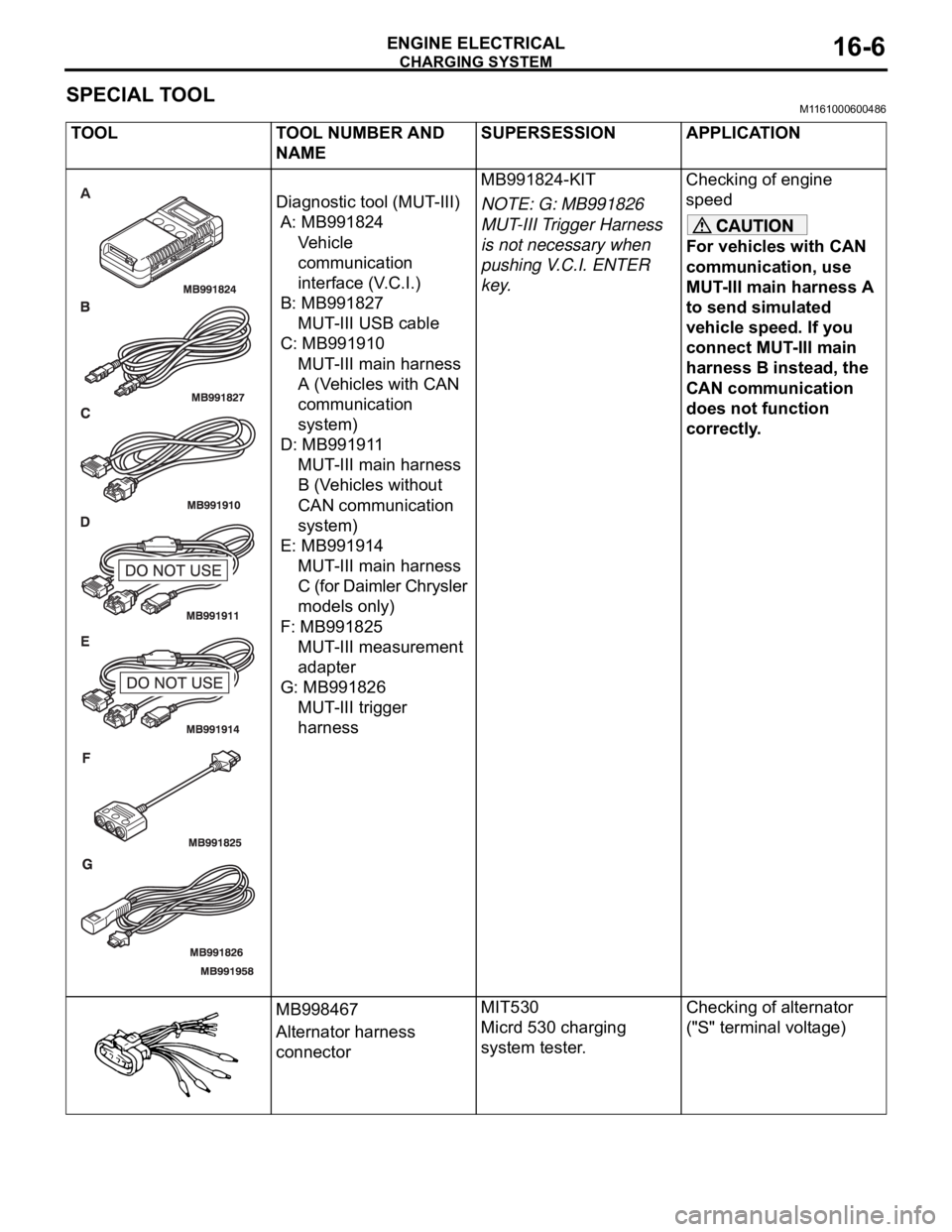

SPECIAL TOOLM1161000600486

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

Diagnostic tool (MUT-III)

A: MB991824

Ve h i c l e

communication

interface (V.C.I.)

B: MB991827

MUT-III USB cable

C: MB991910

MUT-III main harness

A (Vehicles with CAN

communication

system)

D: MB991911

MUT-III main harness

B (Vehicles without

CAN communication

system)

E: MB991914

MUT-III main harness

C (for Daimler Chrysler

models only)

F: MB991825

MUT-III measurement

adapter

G: MB991826

MUT-III trigger

harnessMB991824-KIT

NOTE: G: MB991826

MUT-III Trigger Harness

is not necessary when

pushing V.C.I. ENTER

key.Checking of engine

speed

For vehicles with CAN

communication, use

MUT-III main harness A

to send simulated

vehicle speed. If you

connect MUT-III main

harness B instead, the

CAN communication

does not function

correctly.

MB998467

Alternator harness

connectorMIT530

Micrd 530 charging

system tester.Checking of alternator

("S" terminal voltage)