steering MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 970 of 1500

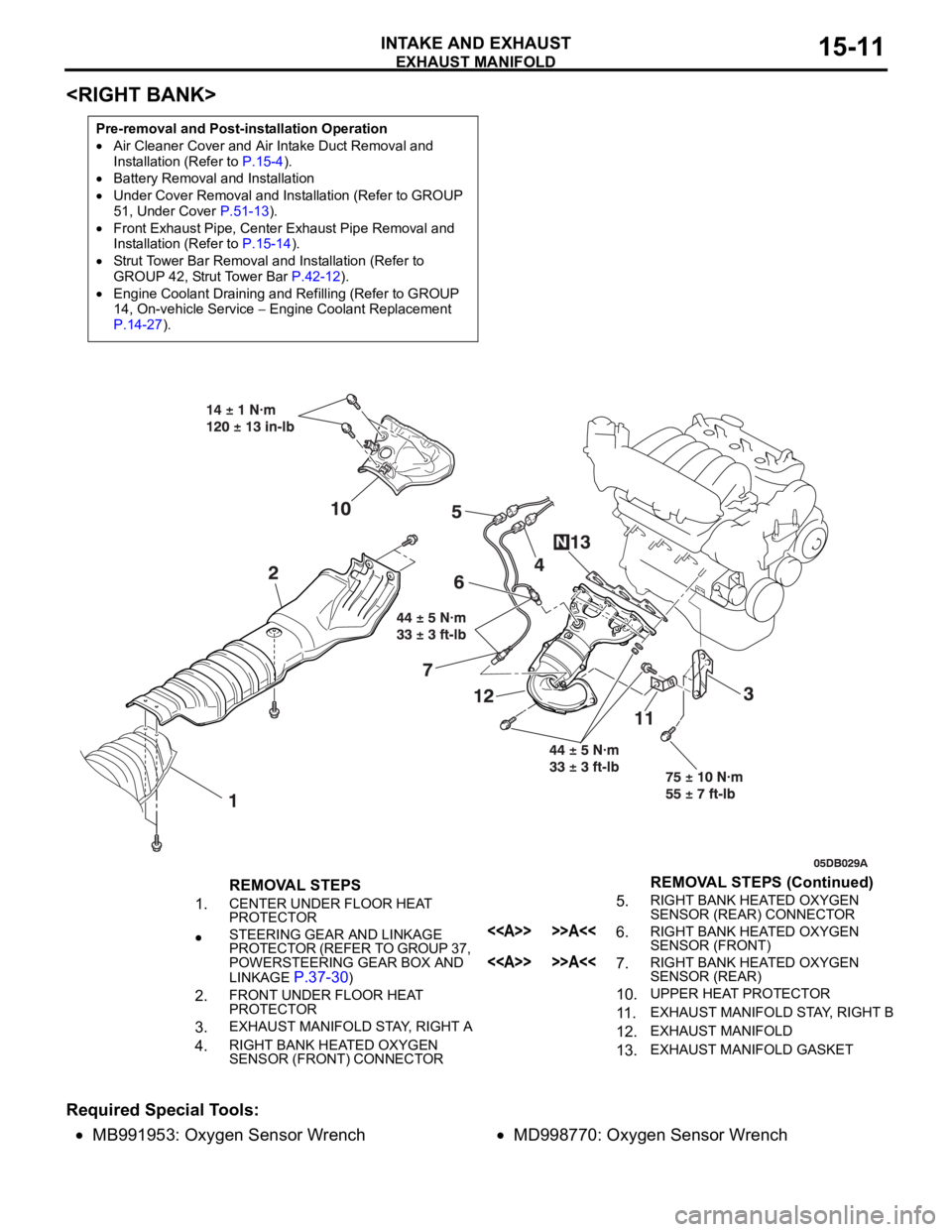

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-11

Required Special Tools:

MB991953: Oxygen Sensor WrenchMD998770: Oxygen Sensor Wrench

Pre-removal and Post-installation Operation

Air Cleaner Cover and Air Intake Duct Removal and

Installation (Refer to P.15-4).

Battery Removal and Installation

Under Cover Removal and Installation (Refer to GROUP

51, Under Cover P.51-13).

Front Exhaust Pipe, Center Exhaust Pipe Removal and

Installation (Refer to P.15-14).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar P.42-12).

Engine Coolant Draining and Refilling (Refer to GROUP

14, On-vehicle Service Engine Coolant Replacement

P.14-27).

REMOVAL STEPS

1.

CENTER UNDER FLOOR HEAT

PROTECTOR

STEERING GEAR AND LINKAGE

PROTECTOR (REFER TO GROUP 37,

POWERSTEERING GEAR BOX AND

LINKAGE

P.37-30)

2.FRONT UNDER FLOOR HEAT

PROTECTOR

3.EXHAUST MANIFOLD STAY, RIGHT A

4.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5.RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

<> >>A<<6.RIGHT BANK HEATED OXYGEN

SENSOR (FRONT)

<> >>A<<7.RIGHT BANK HEATED OXYGEN

SENSOR (REAR)

10.UPPER HEAT PROTECTOR

11 .EXHAUST MANIFOLD STAY, RIGHT B

12.EXHAUST MANIFOLD

13.EXHAUST MANIFOLD GASKET

REMOVAL STEPS (Continued)

Page 977 of 1500

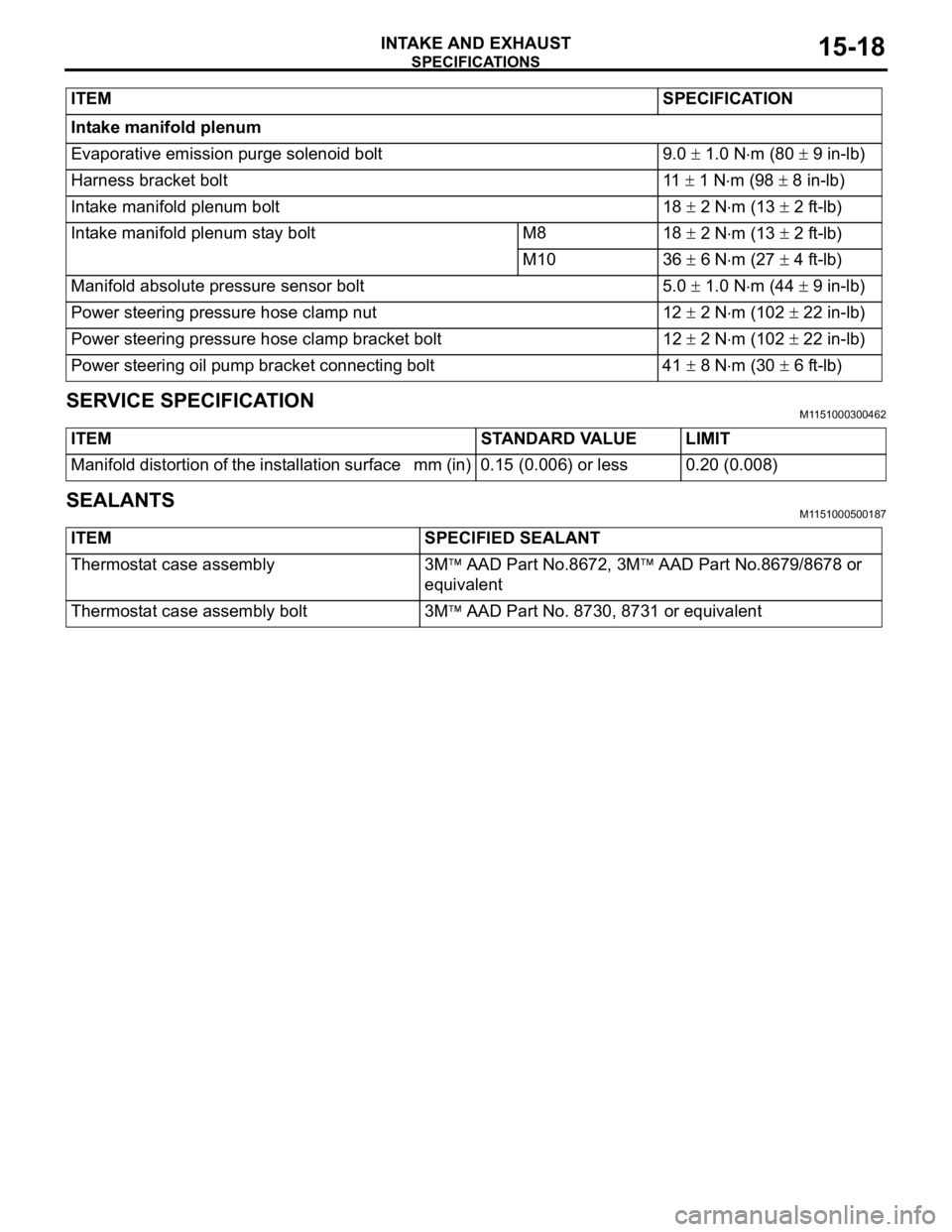

SPECIFICATIONS

INTAKE AND EXHAUST15-18

SERVICE SPECIFICATIONM1151000300462

SEALANTSM1151000500187

Intake manifold plenum

Evaporative emission purge solenoid bolt 9.0

1.0 Nm (80 9 in-lb)

Harness bracket bolt 11

1 Nm (98 8 in-lb)

Intake manifold plenum bolt 18

2 Nm (13 2 ft-lb)

Intake manifold plenum stay bolt M8 18

2 Nm (13 2 ft-lb)

M10 36

6 Nm (27 4 ft-lb)

Manifold absolute pressure sensor bolt 5.0

1.0 Nm (44 9 in-lb)

Power steering pressure hose clamp nut 12

2 Nm (102 22 in-lb)

Power steering pressure hose clamp bracket bolt 12

2 Nm (102 22 in-lb)

Power steering oil pump bracket connecting bolt 41

8 Nm (30 6 ft-lb) ITEMSPECIFICATION

ITEM STANDARD VALUE LIMIT

Manifold distortion of the installation surface mm (in) 0.15 (0.006) or less 0.20 (0.008)

ITEM SPECIFIED SEALANT

Thermostat case assembly 3M

AAD Part No.8672, 3M AAD Part No.8679/8678 or

equivalent

Thermostat case assembly bolt 3M

AAD Part No. 8730, 8731 or equivalent

Page 980 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

CHARGING SYSTEM DIAGNOSISM1161000700427

TROUBLESHOOTING HINTS

Alternator malfunction light dose not go on when the ignition

switch is turned to ON, before the engine starts.

Check the bulb.

Alternator malfunction light dose not switch off after the engine

starts.

Check the IC voltage regulator inside the

alternatoralternator.

Discharged or overcharged battery.

Check the IC voltage regulator inside the alternator.

The alternator malfunction light illuminates dimly.

Check the diode (inside the combination meter) for a

short-circuit.

TROUBLESHOOTING GUIDE

The charging system troubleshooting guide is shown in the fol-

lowing steps.

STEP 1.

Q: Is the battery in good condition? (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

YES : Go to Step 2.

NO : Charge or replace the battery.

STEP 2.

Q: Is the alternator drive belt in good condition? (Refer to

GROUP 00, General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

YES : Go to Step 3.

NO : Adjust the belt tension or replace the belt.

STEP 3.

Q: Does the alternator malfunction light come on when the

ignition switch is turned on?

YES : Go to Step 4.

NO :

Check the ignition switch. (Refer to GROUP 54A,

Chassis Electrical

Ignition Switch Ignition

Switch

Inspection P.54A-44.)

Check for burnt-out alternator malfunction light.

Check the alternator. (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

Check the alternator malfunction light-related

circuits.

Page 984 of 1500

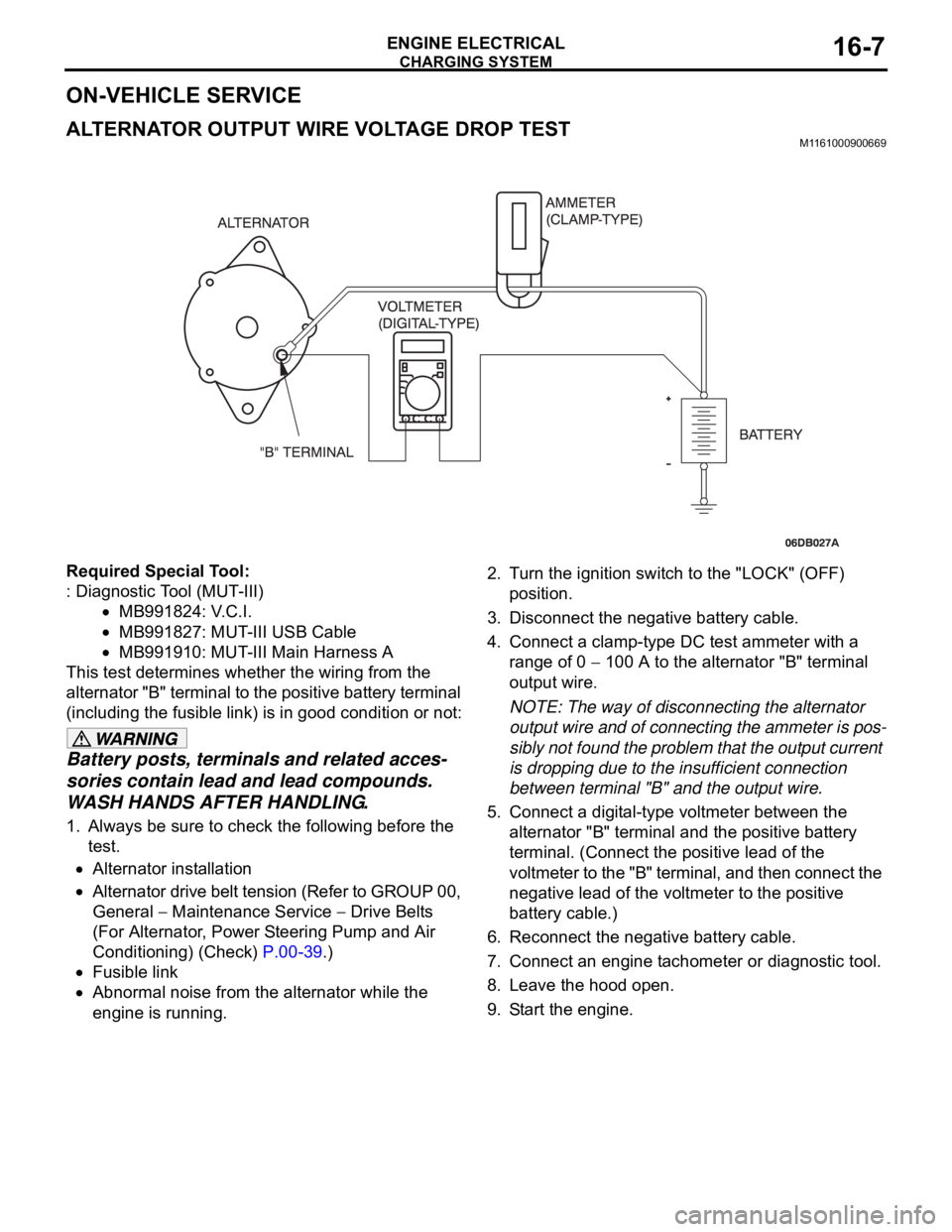

CHARGING SYSTEM

ENGINE ELECTRICAL16-7

ON-VEHICLE SERVICE

ALTERNATOR OUTPUT WIRE VOLTAGE DROP TESTM1161000900669

Required Special Tool:

: Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

This test determines whether the wiring from the

alternator "B" terminal to the positive battery terminal

(including the fusible link) is in good condition or not:

Battery posts, terminals and related acces-

sories contain lead and lead compounds.

WASH HANDS AFTER HANDLING.

1. Always be sure to check the following before the

test.

Alternator installation

Alternator drive belt tension (Refer to GROUP 00,

General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

Fusible link

Abnormal noise from the alternator while the

engine is running.2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0

100 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is pos-

sibly not found the problem that the output current

is dropping due to the insufficient connection

between terminal "B" and the output wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the positive battery

terminal. (Connect the positive lead of the

voltmeter to the "B" terminal, and then connect the

negative lead of the voltmeter to the positive

battery cable.)

6. Reconnect the negative battery cable.

7. Connect an engine tachometer or diagnostic tool.

8. Leave the hood open.

9. Start the engine.

Page 986 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-9

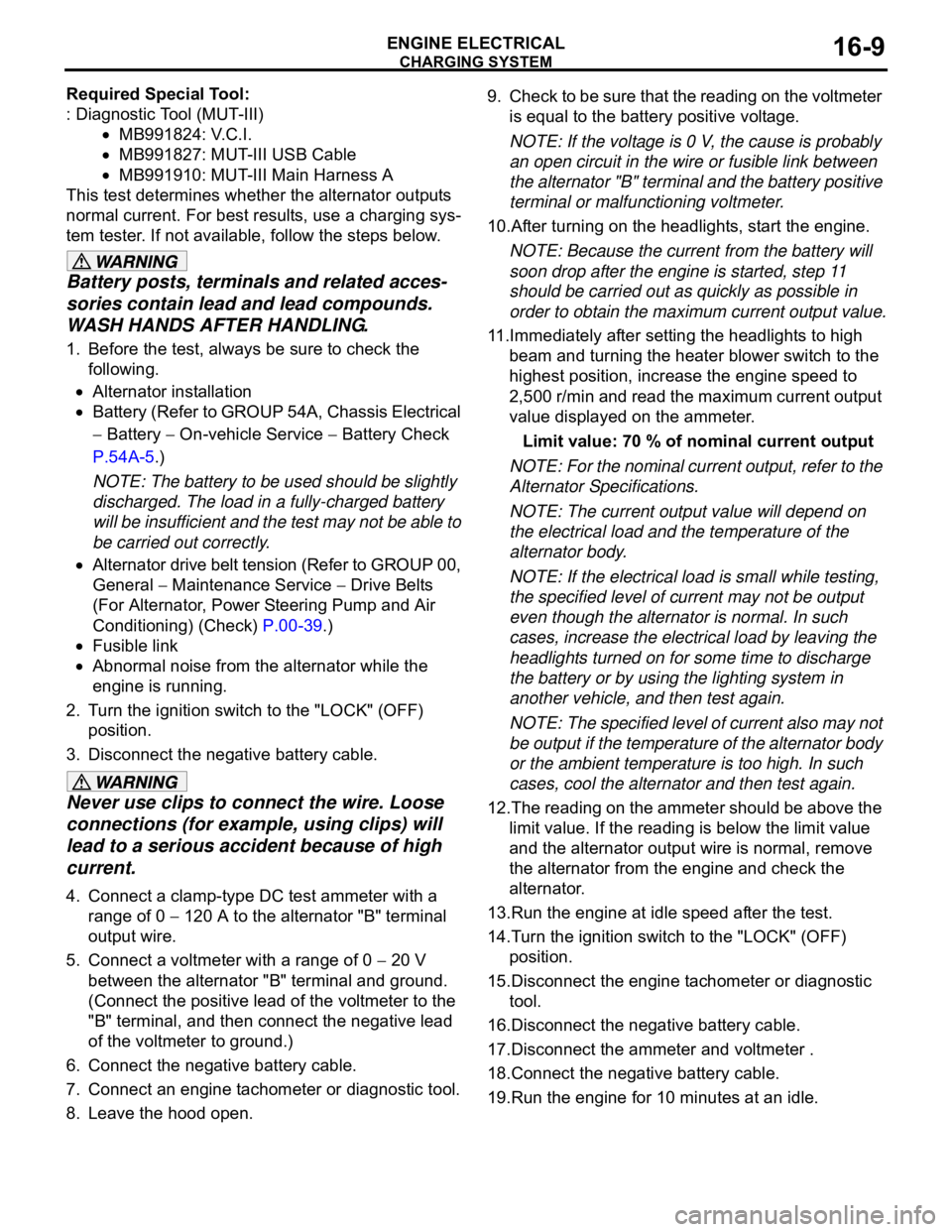

Required Special Tool:

: Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

This test determines whether the alternator outputs

normal current. For best results, use a charging sys-

tem tester. If not available, follow the steps below.

Battery posts, terminals and related acces-

sories contain lead and lead compounds.

WASH HANDS AFTER HANDLING.

1. Before the test, always be sure to check the

following.

Alternator installation

Battery (Refer to GROUP 54A, Chassis Electrical

Battery On-vehicle Service Battery Check

P.54A-5.)

NOTE: The battery to be used should be slightly

discharged. The load in a fully-charged battery

will be insufficient and the test may not be able to

be carried out correctly.

Alternator drive belt tension (Refer to GROUP 00,

General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

Fusible link

Abnormal noise from the alternator while the

engine is running.

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

Never use clips to connect the wire. Loose

connections (for example, using clips) will

lead to a serious accident because of high

current.

4. Connect a clamp-type DC test ammeter with a

range of 0

120 A to the alternator "B" terminal

output wire.

5. Connect a voltmeter with a range of 0

20 V

between the alternator "B" terminal and ground.

(Connect the positive lead of the voltmeter to the

"B" terminal, and then connect the negative lead

of the voltmeter to ground.)

6. Connect the negative battery cable.

7. Connect an engine tachometer or diagnostic tool.

8. Leave the hood open.9. Check to be sure that the reading on the voltmeter

is equal to the battery positive voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery positive

terminal or malfunctioning voltmeter.

10.After turning on the headlights, start the engine.

NOTE: Because the current from the battery will

soon drop after the engine is started, step 11

should be carried out as quickly as possible in

order to obtain the maximum current output value.

11.Immediately after setting the headlights to high

beam and turning the heater blower switch to the

highest position, increase the engine speed to

2,500 r/min and read the maximum current output

value displayed on the ammeter.

Limit value: 70 % of nominal current output

NOTE: For the nominal current output, refer to the

Alternator Specifications.

NOTE: The current output value will depend on

the electrical load and the temperature of the

alternator body.

NOTE: If the electrical load is small while testing,

the specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving the

headlights turned on for some time to discharge

the battery or by using the lighting system in

another vehicle, and then test again.

NOTE: The specified level of current also may not

be output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle speed after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Disconnect the engine tachometer or diagnostic

tool.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter .

18.Connect the negative battery cable.

19.Run the engine for 10 minutes at an idle.

Page 987 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-10

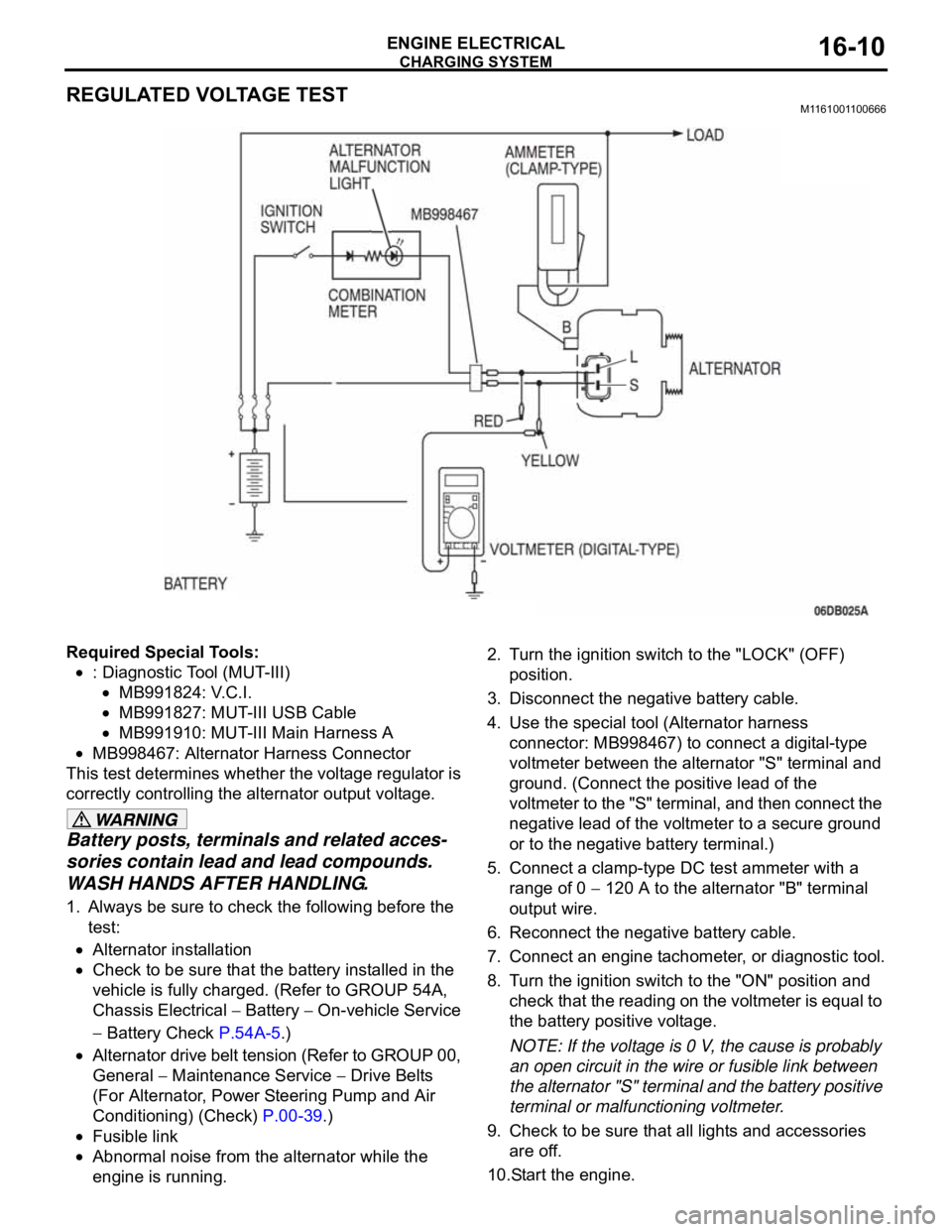

REGULATED VOLTAGE TESTM1161001100666

Required Special Tools:

: Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB998467: Alternator Harness Connector

This test determines whether the voltage regulator is

correctly controlling the alternator output voltage.

Battery posts, terminals and related acces-

sories contain lead and lead compounds.

WASH HANDS AFTER HANDLING.

1. Always be sure to check the following before the

test:

Alternator installation

Check to be sure that the battery installed in the

vehicle is fully charged. (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

Alternator drive belt tension (Refer to GROUP 00,

General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

Fusible link

Abnormal noise from the alternator while the

engine is running.2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Use the special tool (Alternator harness

connector: MB998467) to connect a digital-type

voltmeter between the alternator "S" terminal and

ground. (Connect the positive lead of the

voltmeter to the "S" terminal, and then connect the

negative lead of the voltmeter to a secure ground

or to the negative battery terminal.)

5. Connect a clamp-type DC test ammeter with a

range of 0

120 A to the alternator "B" terminal

output wire.

6. Reconnect the negative battery cable.

7. Connect an engine tachometer, or diagnostic tool.

8. Turn the ignition switch to the "ON" position and

check that the reading on the voltmeter is equal to

the battery positive voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "S" terminal and the battery positive

terminal or malfunctioning voltmeter.

9. Check to be sure that all lights and accessories

are off.

10.Start the engine.

Page 1020 of 1500

SPECIAL TOOL

POWER PLANT MOUNT32-3

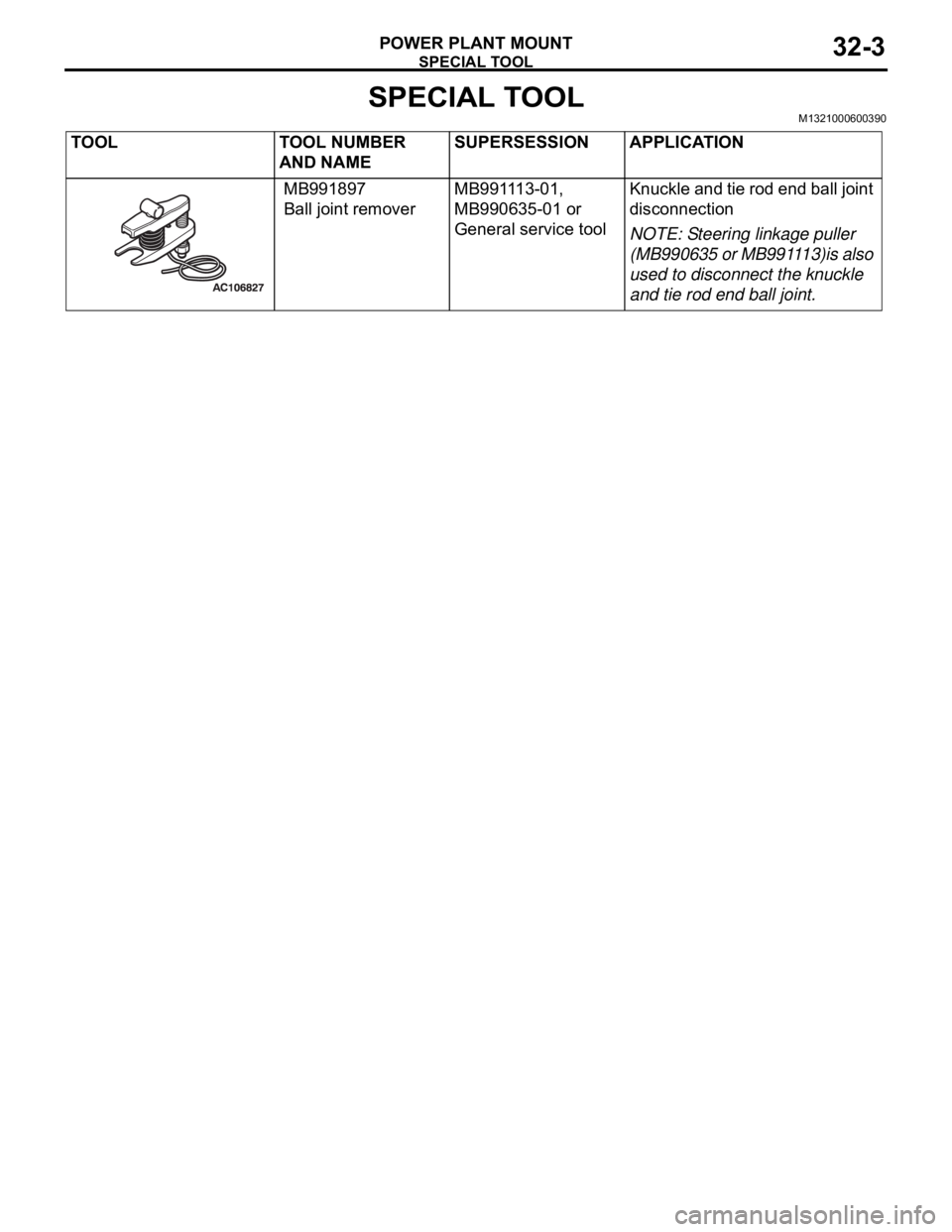

SPECIAL TOOLM1321000600390

TOOL TOOL NUMBER

AND NAMESUPERSESSION APPLICATION

MB991897

Ball joint removerMB991113-01,

MB990635-01 or

General service tool Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113)is also

used to disconnect the knuckle

and tie rod end ball joint.

Page 1026 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-9

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200551

Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions (P.52B-16), Air bag Module and Clock Spring (P.52B-237). Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the ground in the unladen condition.

Pre-removal Operation

Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Hoses Removal and Installation (Refer to

GROUP 37, Power Steering Hoses P.37A-57).

Air Bag Module and Steering Wheel Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-23).

Clock Spring Removal (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Floor Console Assembly Removal (Refer to GROUP 52A,

Floor Console Assembly P.52A-10).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Removal

(Refer to GROUP 52A, Trims P.52A-11).

Trunk Lid Release Handle Cover Removal (Refer to

GROUP 42, Trunk Lid P.42-63).

Accelerator Stopper Removal (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Front Floor Carpet Removal

Centremember Removal (Refer to P.32-7).Post-installation Operation

Centremember Installation (Refer to P.32-7).

Front Floor Carpet Installation

Accelerator Stopper Installation (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Trunk Lid Release Handle Cover Installation (Refer to

GROUP 42, Trunk Lid P.42-63).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Installa-

tion (Refer to GROUP 52A, Trims P.52A-11).

Floor Console Assembly Installation (Refer to GROUP

52A, Floor Console Assembly P.52A-10).

Clock Spring Installation (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Steering Wheel Assembly and Air Bag Module Installation

(Refer to P.37-23).

Check the dust cover for cracks or damage by pushing it

with your finger.

Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Fluid Line Bleeding (Refer to P.37-18).

Checking Steering Wheel Position with Wheels Straight

Ahead.

Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

Front Wheel Alignment Check and

Adjustment P.33-6).

Page 1027 of 1500

Page 1028 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-11

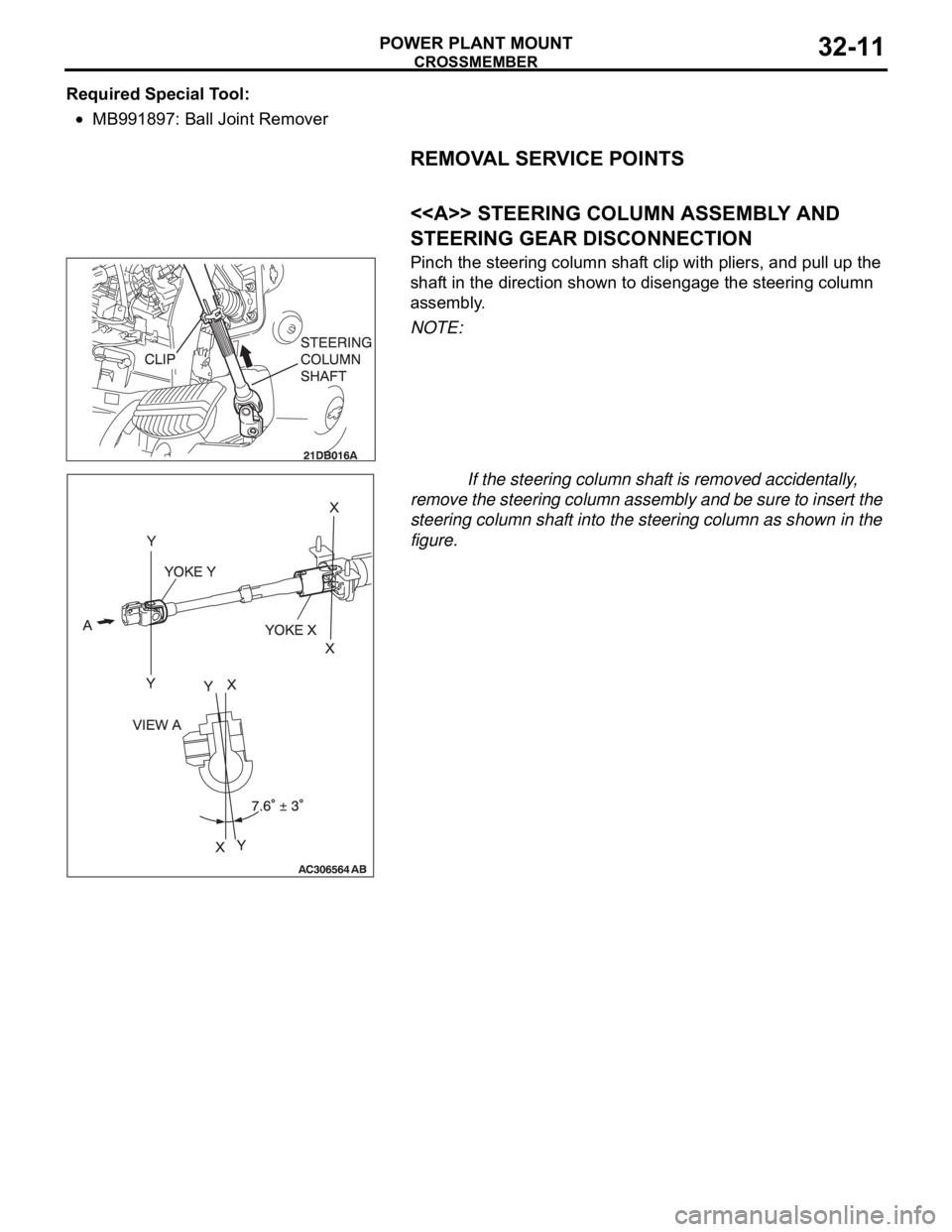

Required Special Tool:

MB991897: Ball Joint Remover

REMOVAL SERVICE POINTS

.

<> STEERING COLUMN ASSEMBLY AND

STEERING GEAR DISCONNECTION

Pinch the steering column shaft clip with pliers, and pull up the

shaft in the direction shown to disengage the steering column

assembly.

NOTE:

If the steering column shaft is removed accidentally,

remove the steering column assembly and be sure to insert the

steering column shaft into the steering column as shown in the

figure.

.