steering MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1271 of 1500

MAINTENANCE SERVICE

GENERAL00-50

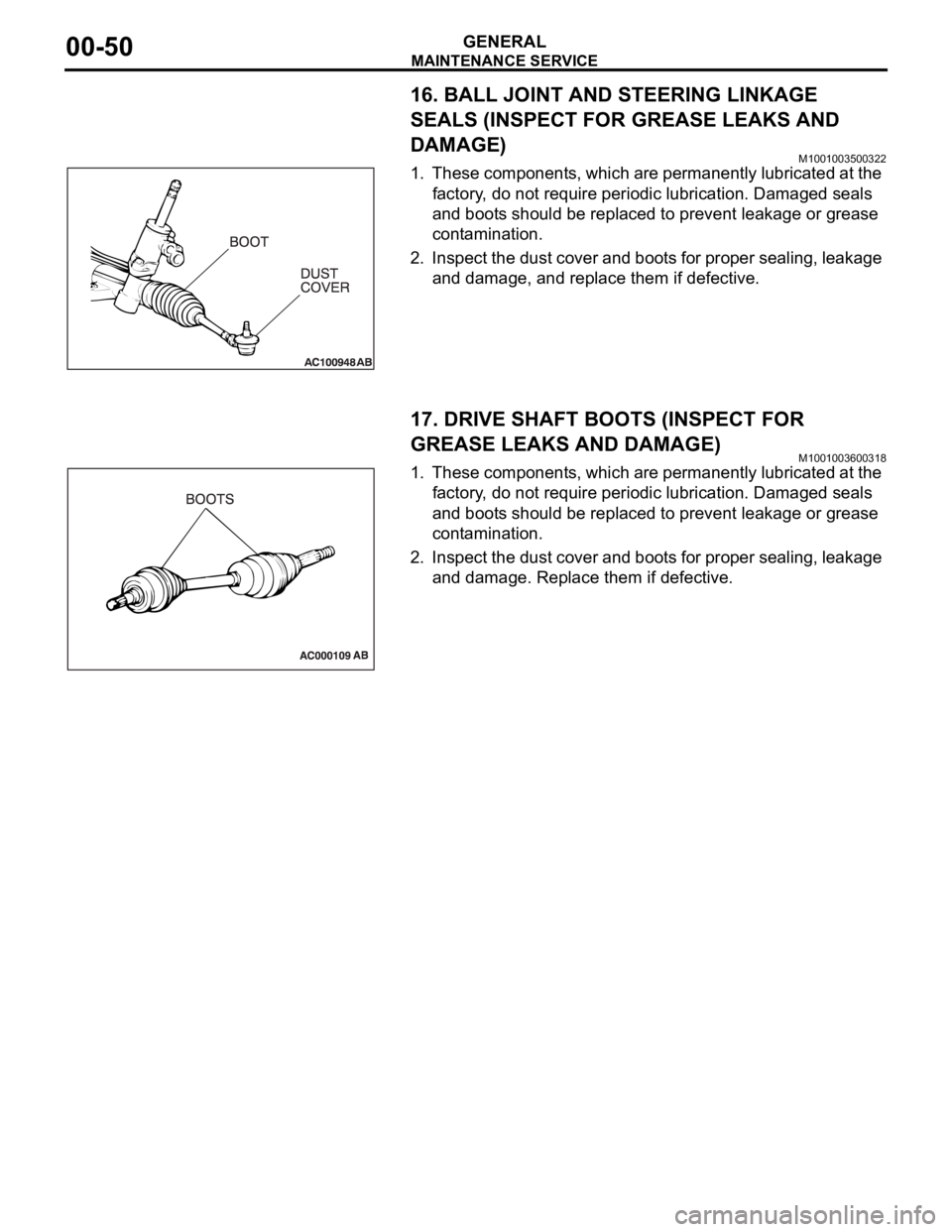

16. BALL JOINT AND STEERING LINKAGE

SEALS (INSPECT FOR GREASE LEAKS AND

DAMAGE)

M1001003500322

1. These components, which are permanently lubricated at the

factory, do not require periodic lubrication. Damaged seals

and boots should be replaced to prevent leakage or grease

contamination.

2. Inspect the dust cover and boots for proper sealing, leakage

and damage, and replace them if defective.

17. DRIVE SHAFT BOOTS (INSPECT FOR

GREASE LEAKS AND DAMAGE)

M1001003600318

1. These components, which are permanently lubricated at the

factory, do not require periodic lubrication. Damaged seals

and boots should be replaced to prevent leakage or grease

contamination.

2. Inspect the dust cover and boots for proper sealing, leakage

and damage. Replace them if defective.

Page 1274 of 1500

MAINTENANCE SERVICE

GENERAL00-53

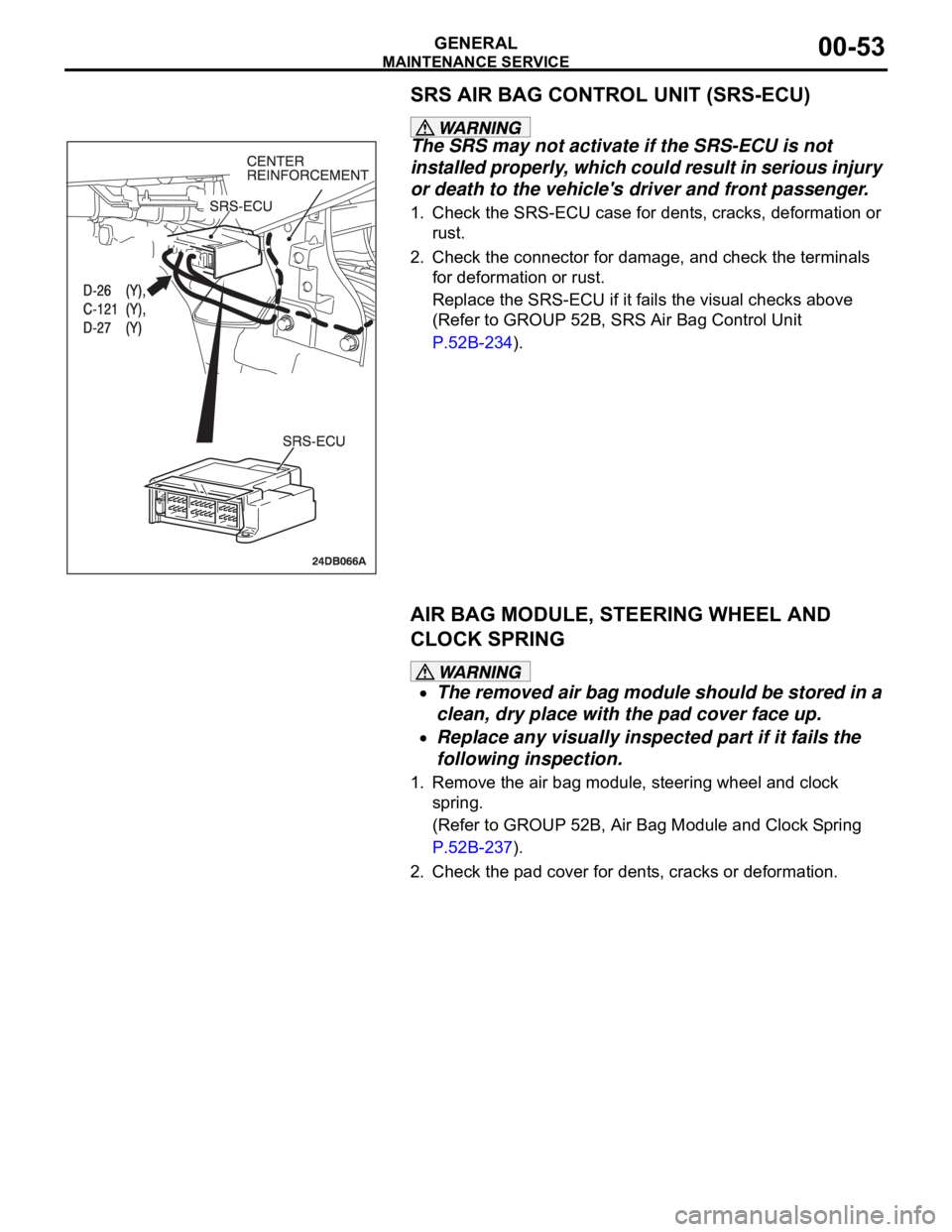

SRS AIR BAG CONTROL UNIT (SRS-ECU)

The SRS may not activate if the SRS-ECU is not

installed properly, which could result in serious injury

or death to the vehicle's driver and front passenger.

1. Check the SRS-ECU case for dents, cracks, deformation or

rust.

2. Check the connector for damage, and check the terminals

for deformation or rust.

Replace the SRS-ECU if it fails the visual checks above

(Refer to GROUP 52B, SRS Air Bag Control Unit

P.52B-234).

AIR BAG MODULE, STEERING WHEEL AND

CLOCK SPRING

The removed air bag module should be stored in a

clean, dry place with the pad cover face up.

Replace any visually inspected part if it fails the

following inspection.

1. Remove the air bag module, steering wheel and clock

spring.

(Refer to GROUP 52B, Air Bag Module and Clock Spring

P.52B-237).

2. Check the pad cover for dents, cracks or deformation.

Page 1275 of 1500

MAINTENANCE SERVICE

GENERAL00-54

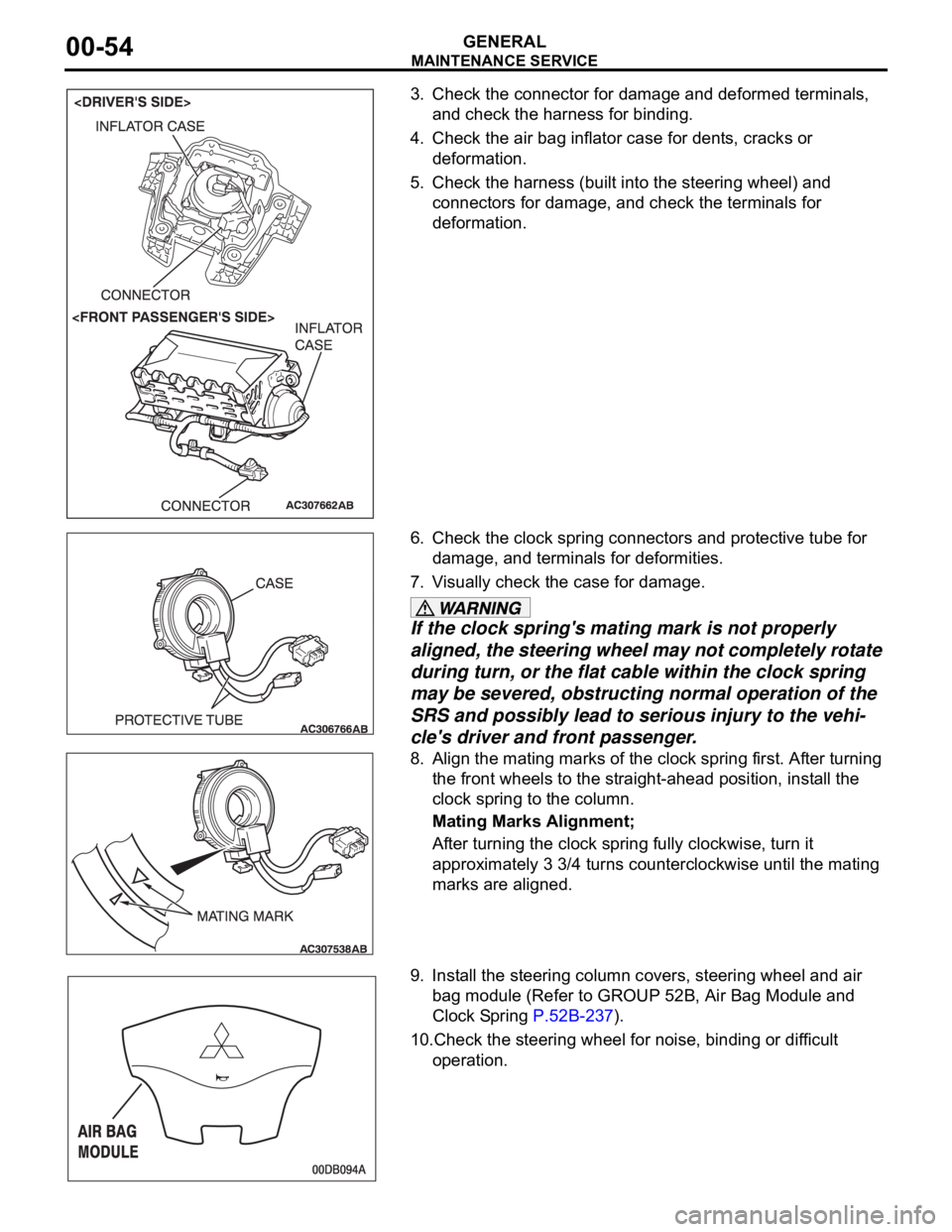

3. Check the connector for damage and deformed terminals,

and check the harness for binding.

4. Check the air bag inflator case for dents, cracks or

deformation.

5. Check the harness (built into the steering wheel) and

connectors for damage, and check the terminals for

deformation.

6. Check the clock spring connectors and protective tube for

damage, and terminals for deformities.

7. Visually check the case for damage.

If the clock spring's mating mark is not properly

aligned, the steering wheel may not completely rotate

during turn, or the flat cable within the clock spring

may be severed, obstructing normal operation of the

SRS and possibly lead to serious injury to the vehi-

cle's driver and front passenger.

8. Align the mating marks of the clock spring first. After turning

the front wheels to the straight-ahead position, install the

clock spring to the column.

Mating Marks Alignment;

After turning the clock spring fully clockwise, turn it

approximately 3 3/4 turns counterclockwise until the mating

marks are aligned.

9. Install the steering column covers, steering wheel and air

bag module (Refer to GROUP 52B, Air Bag Module and

Clock Spring P.52B-237).

10.Check the steering wheel for noise, binding or difficult

operation.

Page 1276 of 1500

MAINTENANCE SERVICE

GENERAL00-55

The SRS may not activate if any of the above compo-

nents are not installed properly, which could result in

serious injury or death to the vehicle's driver and

front passenger.

11.Check the steering wheel for excessive free play.

Replace any part if it fails visual inspection (Refer to

GROUP 52B, Air Bag Module and Clock Spring P.52B-237).

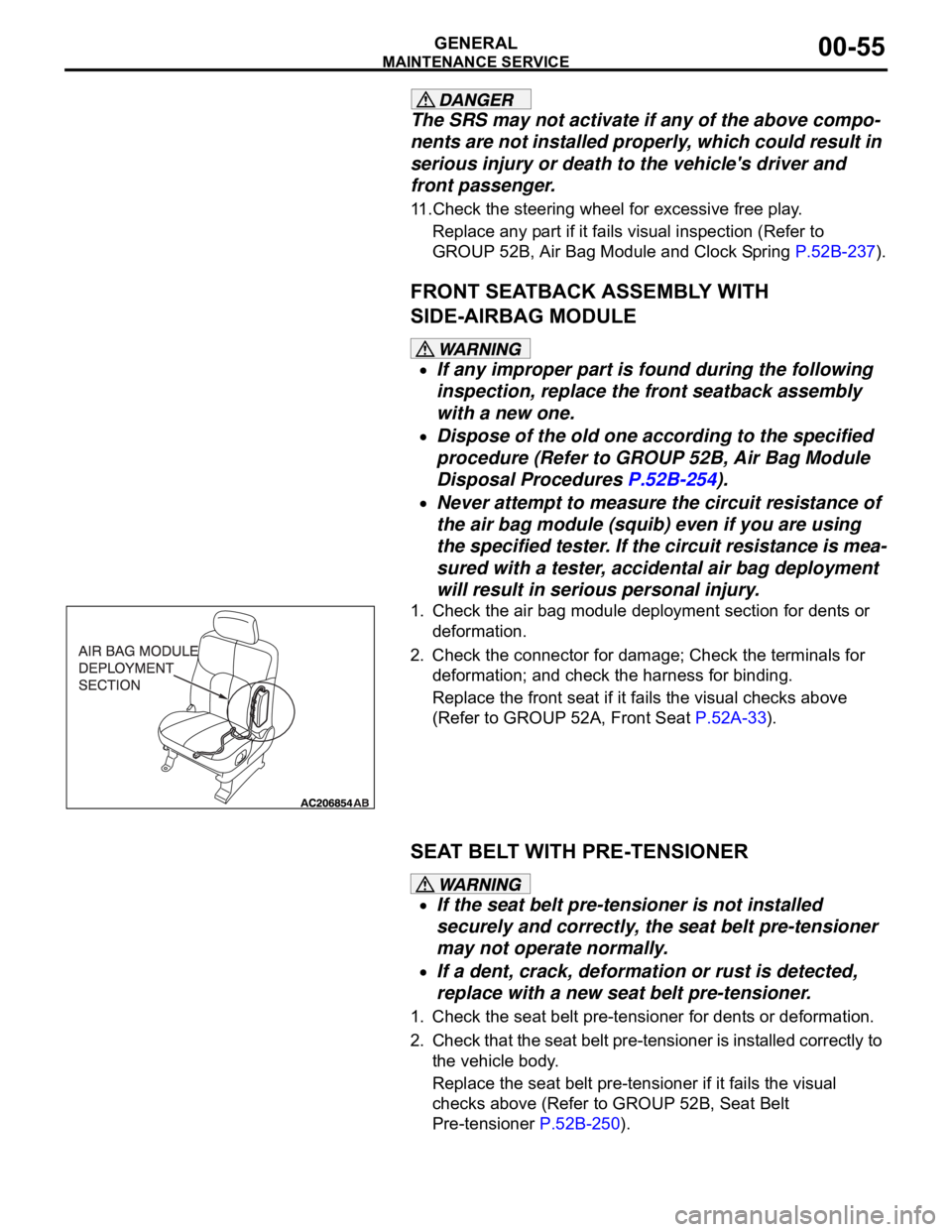

FRONT SEATBACK ASSEMBLY WITH

SIDE-AIRBAG MODULE

If any improper part is found during the following

inspection, replace the front seatback assembly

with a new one.

Dispose of the old one according to the specified

procedure (Refer to GROUP 52B, Air Bag Module

Disposal Procedures P.52B-254).

Never attempt to measure the circuit resistance of

the air bag module (squib) even if you are using

the specified tester. If the circuit resistance is mea-

sured with a tester, accidental air bag deployment

will result in serious personal injury.

1. Check the air bag module deployment section for dents or

deformation.

2. Check the connector for damage; Check the terminals for

deformation; and check the harness for binding.

Replace the front seat if it fails the visual checks above

(Refer to GROUP 52A, Front Seat P.52A-33).

SEAT BELT WITH PRE-TENSIONER

If the seat belt pre-tensioner is not installed

securely and correctly, the seat belt pre-tensioner

may not operate normally.

If a dent, crack, deformation or rust is detected,

replace with a new seat belt pre-tensioner.

1. Check the seat belt pre-tensioner for dents or deformation.

2. Check that the seat belt pre-tensioner is installed correctly to

the vehicle body.

Replace the seat belt pre-tensioner if it fails the visual

checks above (Refer to GROUP 52B, Seat Belt

Pre-tensioner P.52B-250).

Page 1406 of 1500

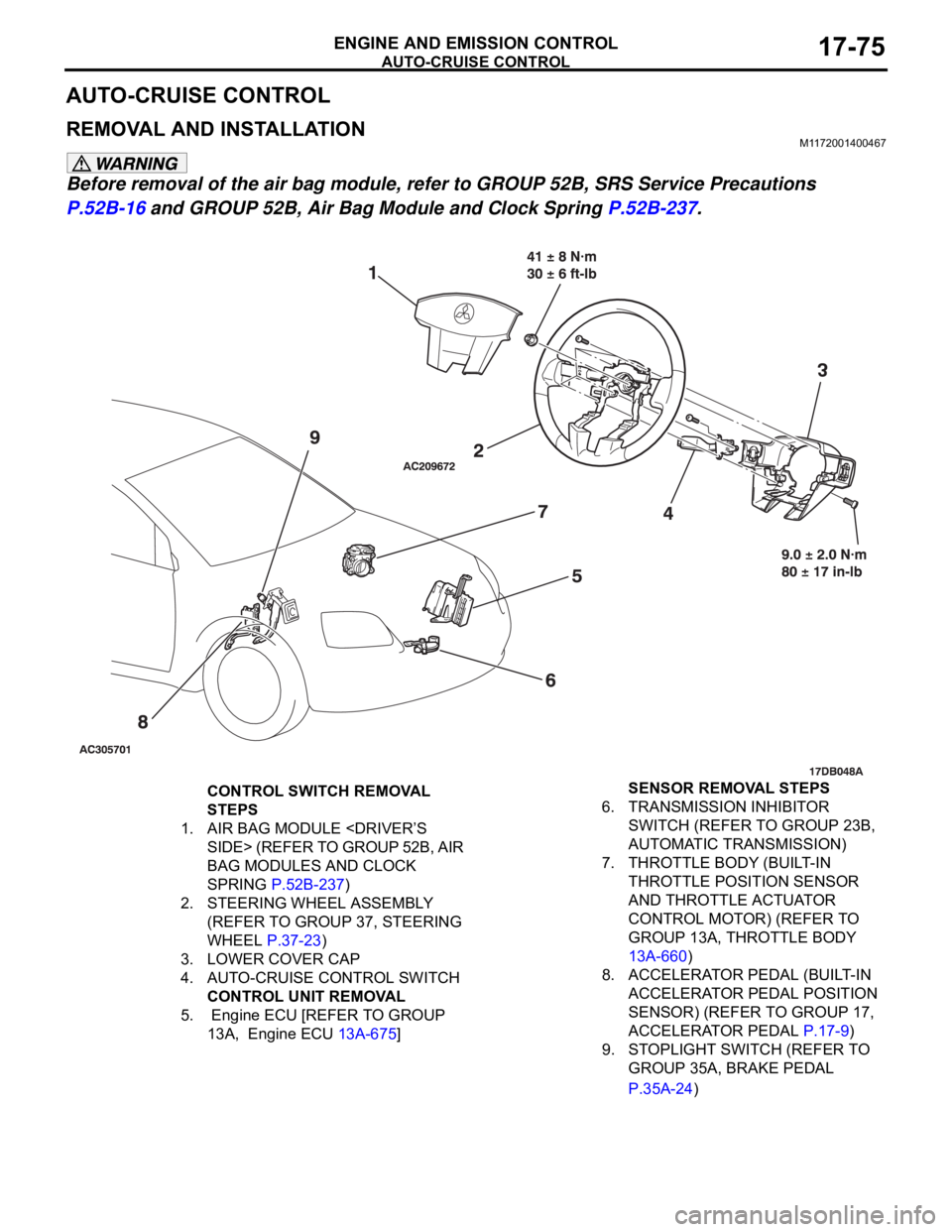

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-75

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATIONM1172001400467

Before removal of the air bag module, refer to GROUP 52B, SRS Service Precautions

P.52B-16 and GROUP 52B, Air Bag Module and Clock Spring P.52B-237.

CONTROL SWITCH REMOVAL

STEPS

1. AIR BAG MODULE

BAG MODULES AND CLOCK

SPRING P.52B-237)

2. STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37, STEERING

WHEEL P.37-23)

3. LOWER COVER CAP

4. AUTO-CRUISE CONTROL SWITCH

CONTROL UNIT REMOVAL

5. Engine ECU [REFER TO GROUP

13A, Engine ECU 13A-675] SENSOR REMOVAL STEPS

6. TRANSMISSION INHIBITOR

SWITCH (REFER TO GROUP 23B,

AUTOMATIC TRANSMISSION)

7. THROTTLE BODY (BUILT-IN

THROTTLE POSITION SENSOR

AND THROTTLE ACTUATOR

CONTROL MOTOR) (REFER TO

GROUP 13A, THROTTLE BODY

13A-660)

8. ACCELERATOR PEDAL (BUILT-IN

ACCELERATOR PEDAL POSITION

SENSOR) (REFER TO GROUP 17,

ACCELERATOR PEDAL P.17-9)

9. STOPLIGHT SWITCH (REFER TO

GROUP 35A, BRAKE PEDAL

P.35A-24)

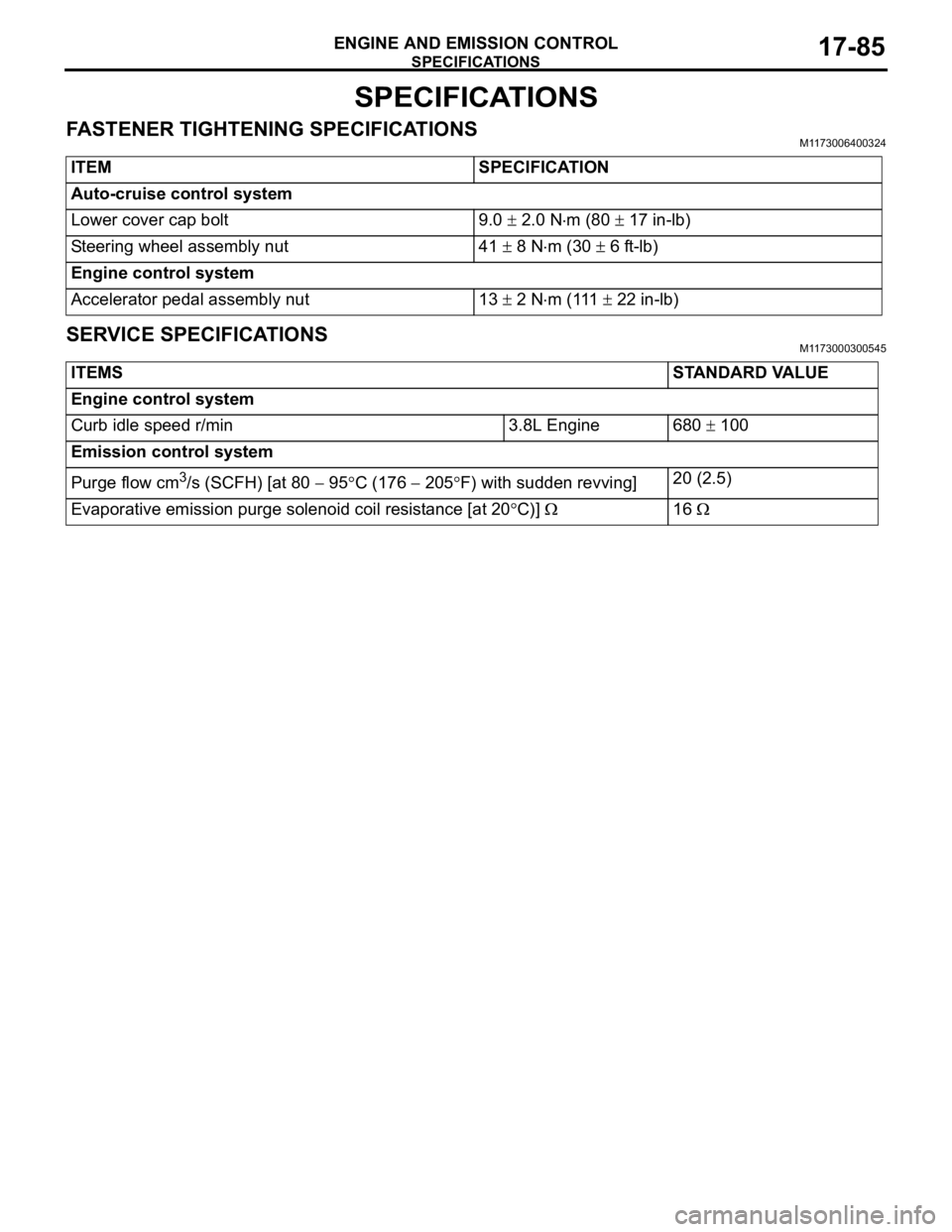

Page 1416 of 1500

SPECIFICATIONS

ENGINE AND EMISSION CONTROL17-85

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1173006400324

SERVICE SPECIFICATIONSM1173000300545

ITEM SPECIFICATION

Auto-cruise control system

Lower cover cap bolt 9.0

2.0 Nm (80 17 in-lb)

Steering wheel assembly nut 41

8 Nm (30 6 ft-lb)

Engine control system

Accelerator pedal assembly nut 13

2 Nm ( 111 22 in-lb)

ITEMSSTANDARD VALUE

Engine control system

Curb idle speed r/min 3.8L Engine 680

100

Emission control system

Purge flow cm

3/s (SCFH) [at 80 95C (176 205F) with sudden revving]20 (2.5)

Evaporative emission purge solenoid coil resistance [at 20

C)] 16

Page 1421 of 1500

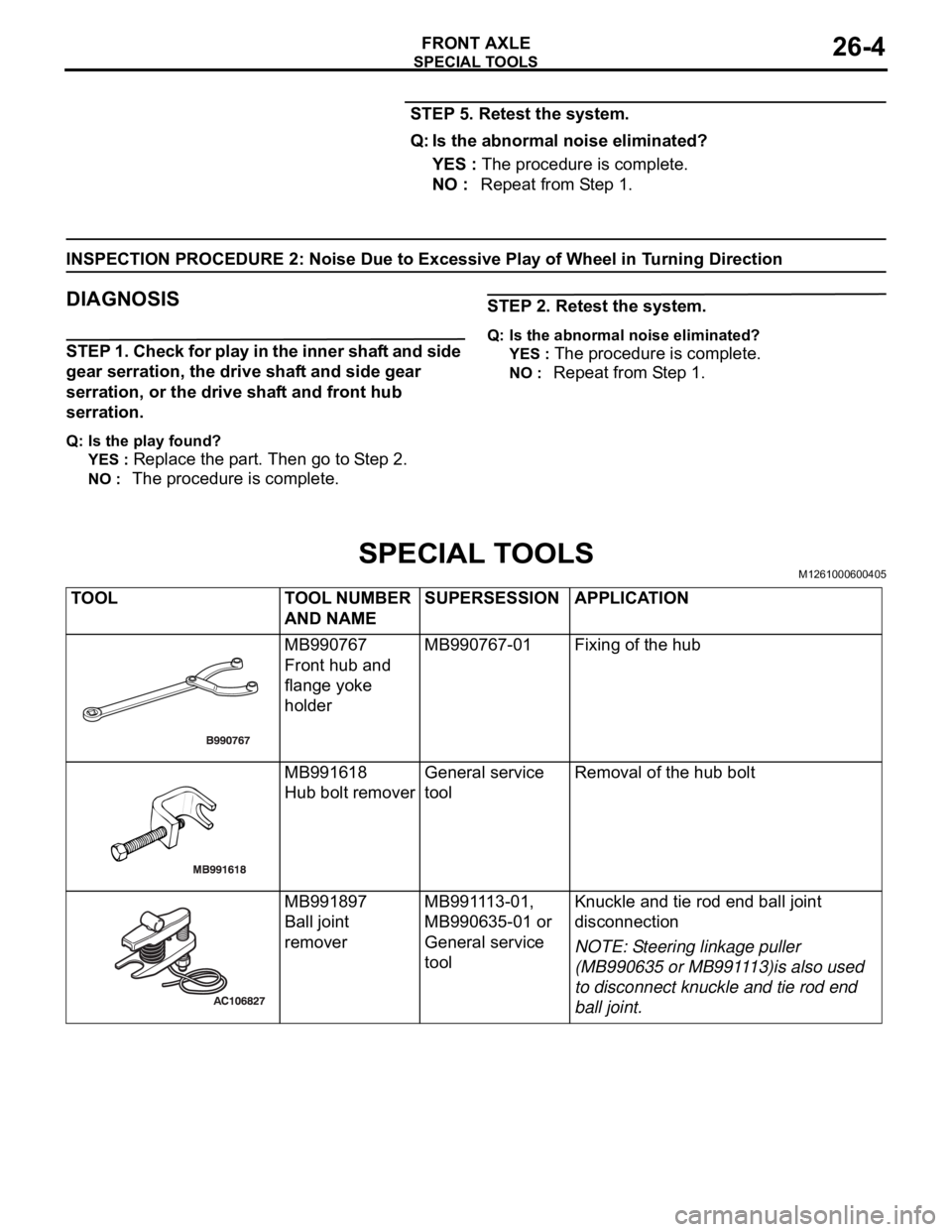

SPECIAL TOOLS

FRONT AXLE26-4

STEP 5. Retest the system.

Q: Is the abnormal noise eliminated?

YES : The procedure is complete.

NO : Repeat from Step 1.

INSPECTION PROCEDURE 2: Noise Due to Excessive Play of Wheel in Turning Direction

DIAGNOSIS

STEP 1. Check for play in the inner shaft and side

gear serration, the drive shaft and side gear

serration, or the drive shaft and front hub

serration.

Q: Is the play found?

YES :

Replace the part. Then go to Step 2.

NO : The procedure is complete.

STEP 2. Retest the system.

Q: Is the abnormal noise eliminated?

YES :

The procedure is complete.

NO : Repeat from Step 1.

SPECIAL TOOLSM1261000600405

TOOL TOOL NUMBER

AND NAMESUPERSESSION APPLICATION

MB990767

Front hub and

flange yoke

holderMB990767-01 Fixing of the hub

MB991618

Hub bolt removerGeneral service

toolRemoval of the hub bolt

MB991897

Ball joint

removerMB991113-01,

MB990635-01 or

General service

tool Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113)is also used

to disconnect knuckle and tie rod end

ball joint.

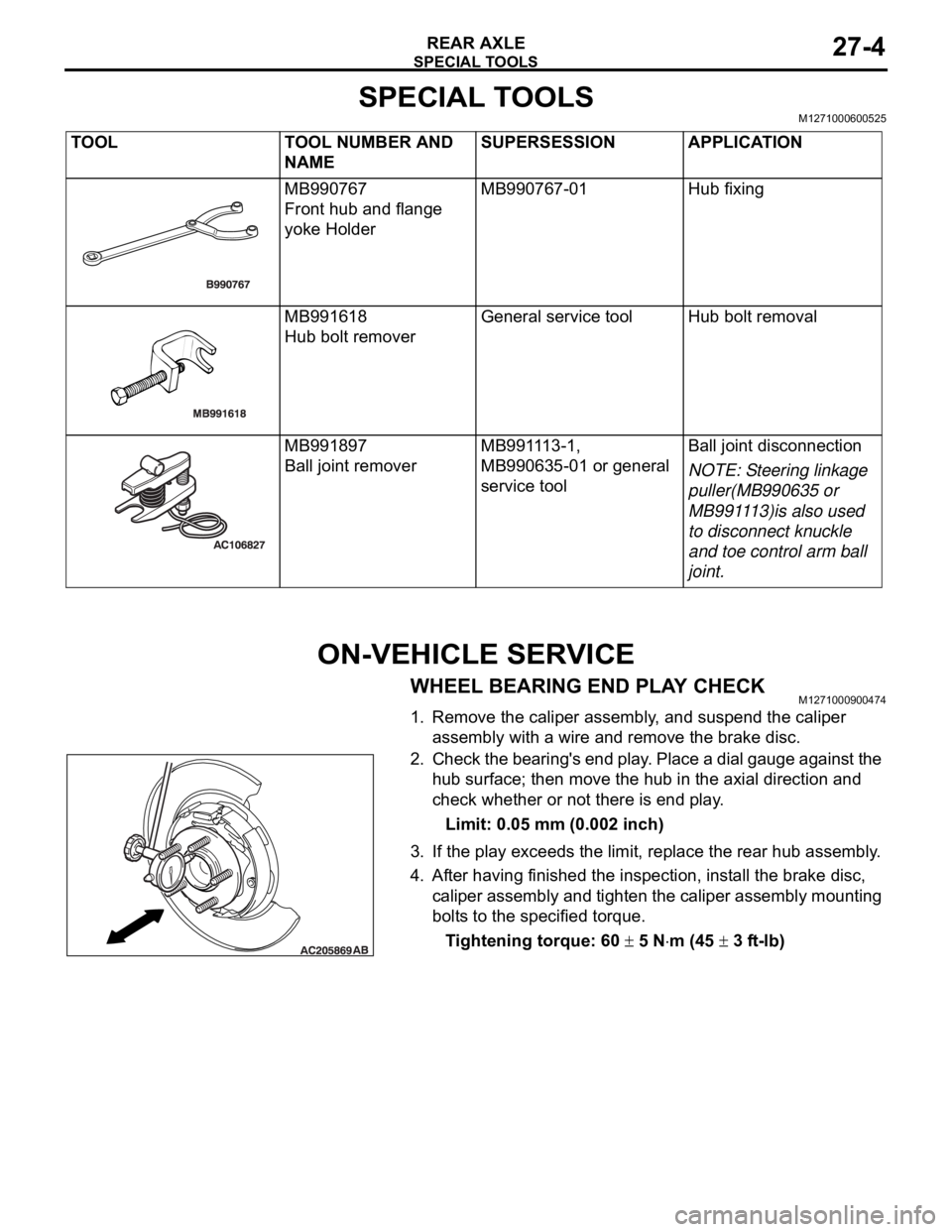

Page 1451 of 1500

SPECIAL TOOLS

REAR AXLE27-4

SPECIAL TOOLSM1271000600525

ON-VEHICLE SERVICE

WHEEL BEARING END PLAY CHECKM1271000900474

1. Remove the caliper assembly, and suspend the caliper

assembly with a wire and remove the brake disc.

2. Check the bearing's end play. Place a dial gauge against the

hub surface; then move the hub in the axial direction and

check whether or not there is end play.

Limit: 0.05 mm (0.002 inch)

3. If the play exceeds the limit, replace the rear hub assembly.

4. After having finished the inspection, install the brake disc,

caliper assembly and tighten the caliper assembly mounting

bolts to the specified torque.

Tightening torque: 60

5 Nm (45 3 ft-lb) TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB990767

Front hub and flange

yoke HolderMB990767-01 Hub fixing

MB991618

Hub bolt removerGeneral service tool Hub bolt removal

MB991897

Ball joint removerMB991113-1,

MB990635-01 or general

service toolBall joint disconnection

NOTE: Steering linkage

puller(MB990635 or

MB991113)is also used

to disconnect knuckle

and toe control arm ball

joint.