steering MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1030 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-13

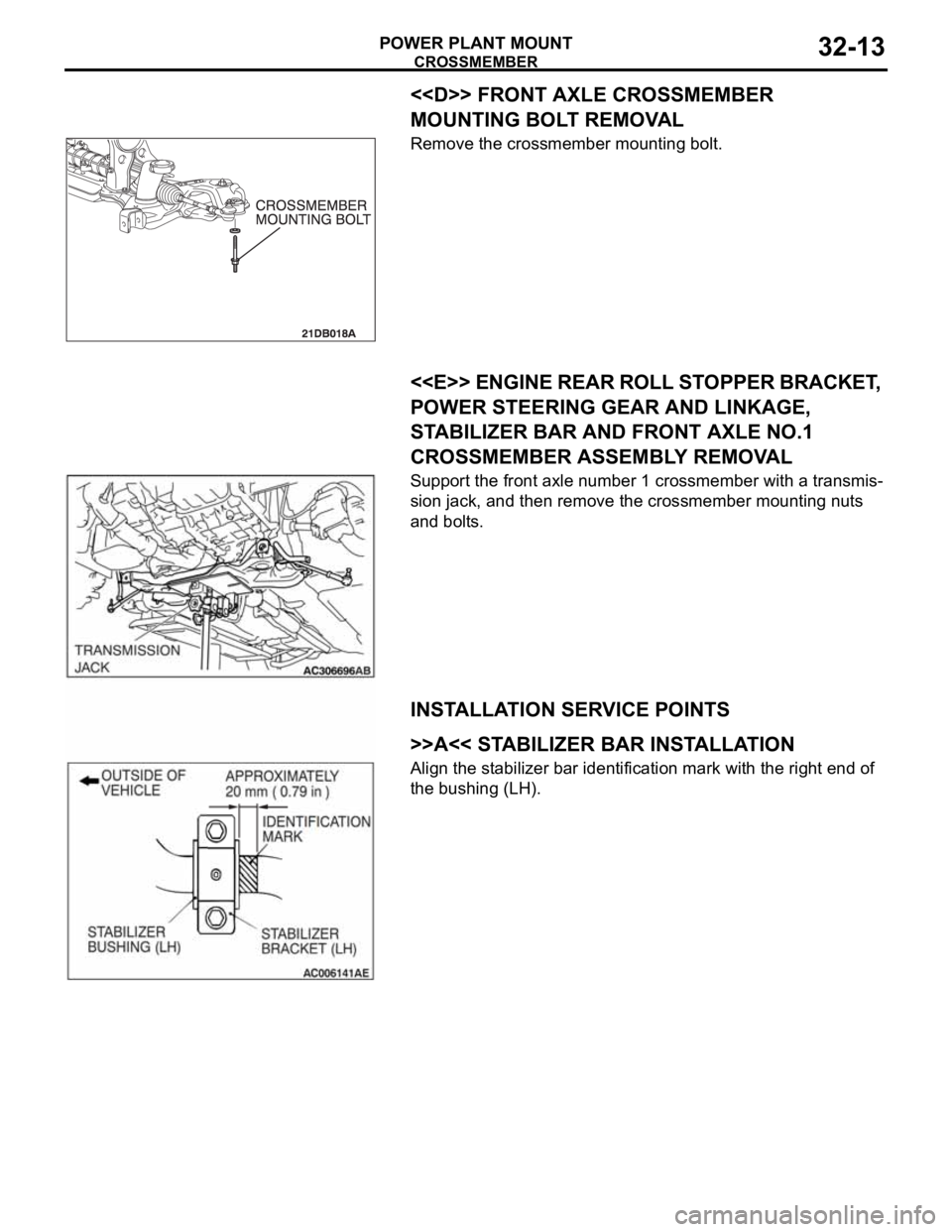

<

MOUNTING BOLT REMOVAL

Remove the crossmember mounting bolt.

.

<

POWER STEERING GEAR AND LINKAGE,

STABILIZER BAR AND FRONT AXLE NO.1

CROSSMEMBER ASSEMBLY REMOVAL

Support the front axle number 1 crossmember with a transmis-

sion jack, and then remove the crossmember mounting nuts

and bolts.

INSTALLATION SERVICE POINTS

.

>>A<< STABILIZER BAR INSTALLATION

Align the stabilizer bar identification mark with the right end of

the bushing (LH).

.

Page 1032 of 1500

SPECIFICATIONS

POWER PLANT MOUNT32-15

SPECIFICATIONS

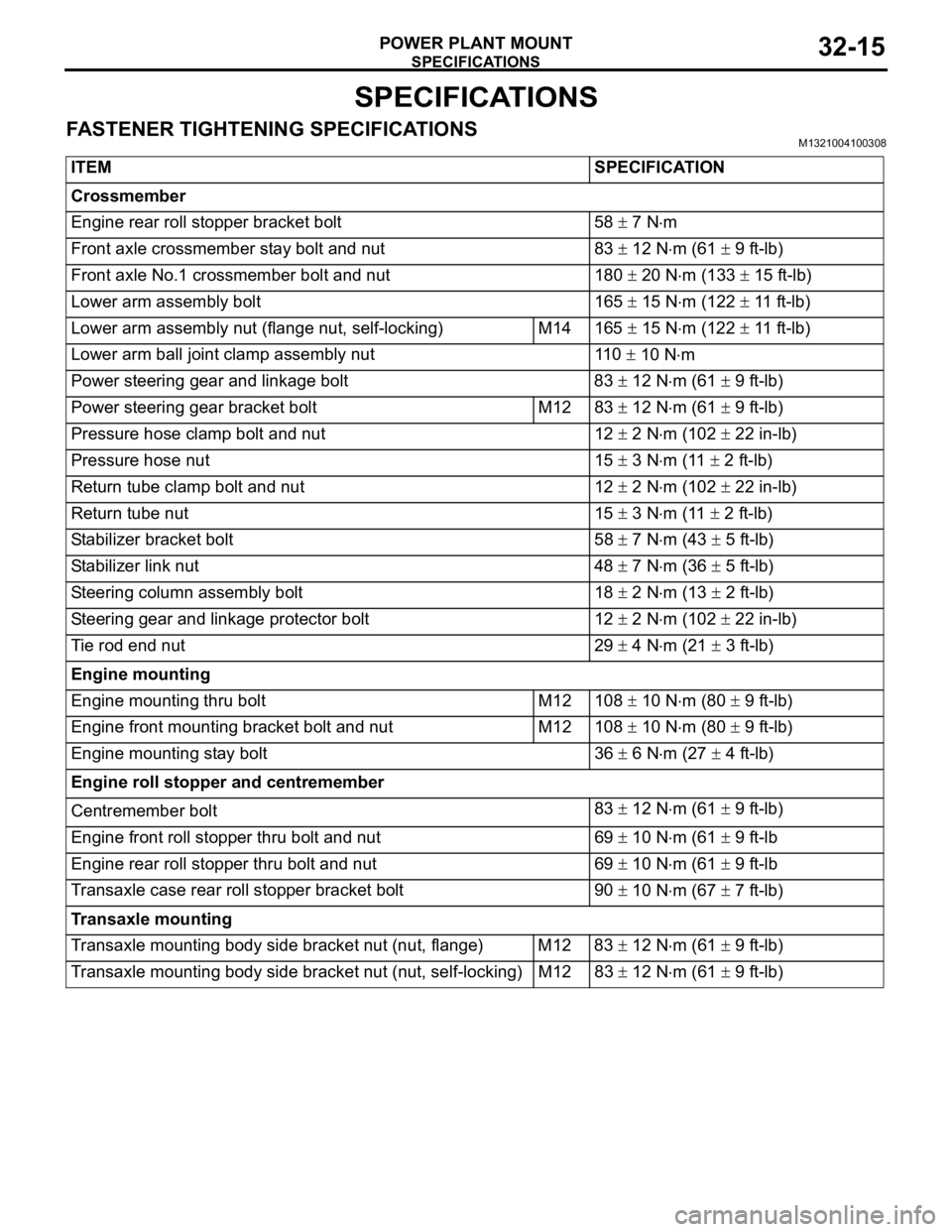

FASTENER TIGHTENING SPECIFICATIONSM1321004100308

ITEM SPECIFICATION

Crossmember

Engine rear roll stopper bracket bolt 58

7 Nm

Front axle crossmember stay bolt and nut 83

12 Nm (61 9 ft-lb)

Front axle No.1 crossmember bolt and nut 180

20 Nm (133 15 ft-lb)

Lower arm assembly bolt 165

15 Nm (122 11 ft-lb)

Lower arm assembly nut (flange nut, self-locking) M14 165

15 Nm (122 11 ft-lb)

Lower arm ball joint clamp assembly nut 110

10 Nm

Power steering gear and linkage bolt 83

12 Nm (61 9 ft-lb)

Power steering gear bracket bolt M12 83

12 Nm (61 9 ft-lb)

Pressure hose clamp bolt and nut 12

2 Nm (102 22 in-lb)

Pressure hose nut 15

3 Nm (11 2 ft-lb)

Return tube clamp bolt and nut 12

2 Nm (102 22 in-lb)

Return tube nut 15

3 Nm (11 2 ft-lb)

Stabilizer bracket bolt 58

7 Nm (43 5 ft-lb)

Stabilizer link nut 48

7 Nm (36 5 ft-lb)

Steering column assembly bolt 18

2 Nm (13 2 ft-lb)

Steering gear and linkage protector bolt 12

2 Nm (102 22 in-lb)

Tie rod end nut 29

4 Nm (21 3 ft-lb)

Engine mounting

Engine mounting thru bolt M12 108

10 Nm (80 9 ft-lb)

Engine front mounting bracket bolt and nut M12 108

10 Nm (80 9 ft-lb)

Engine mounting stay bolt 36

6 Nm (27 4 ft-lb)

Engine roll stopper and centremember

Centremember bolt83

12 Nm (61 9 ft-lb)

Engine front roll stopper thru bolt and nut 69

10 Nm (61 9 ft-lb

Engine rear roll stopper thru bolt and nut 69

10 Nm (61 9 ft-lb

Transaxle case rear roll stopper bracket bolt 90

10 Nm (67 7 ft-lb)

Transaxle mounting

Transaxle mounting body side bracket nut (nut, flange) M12 83

12 Nm (61 9 ft-lb)

Transaxle mounting body side bracket nut (nut, self-locking) M1283

12 Nm (61 9 ft-lb)

Page 1167 of 1500

GENERAL DESCRIPTION

BASIC BRAKE SYSTEM35A-2

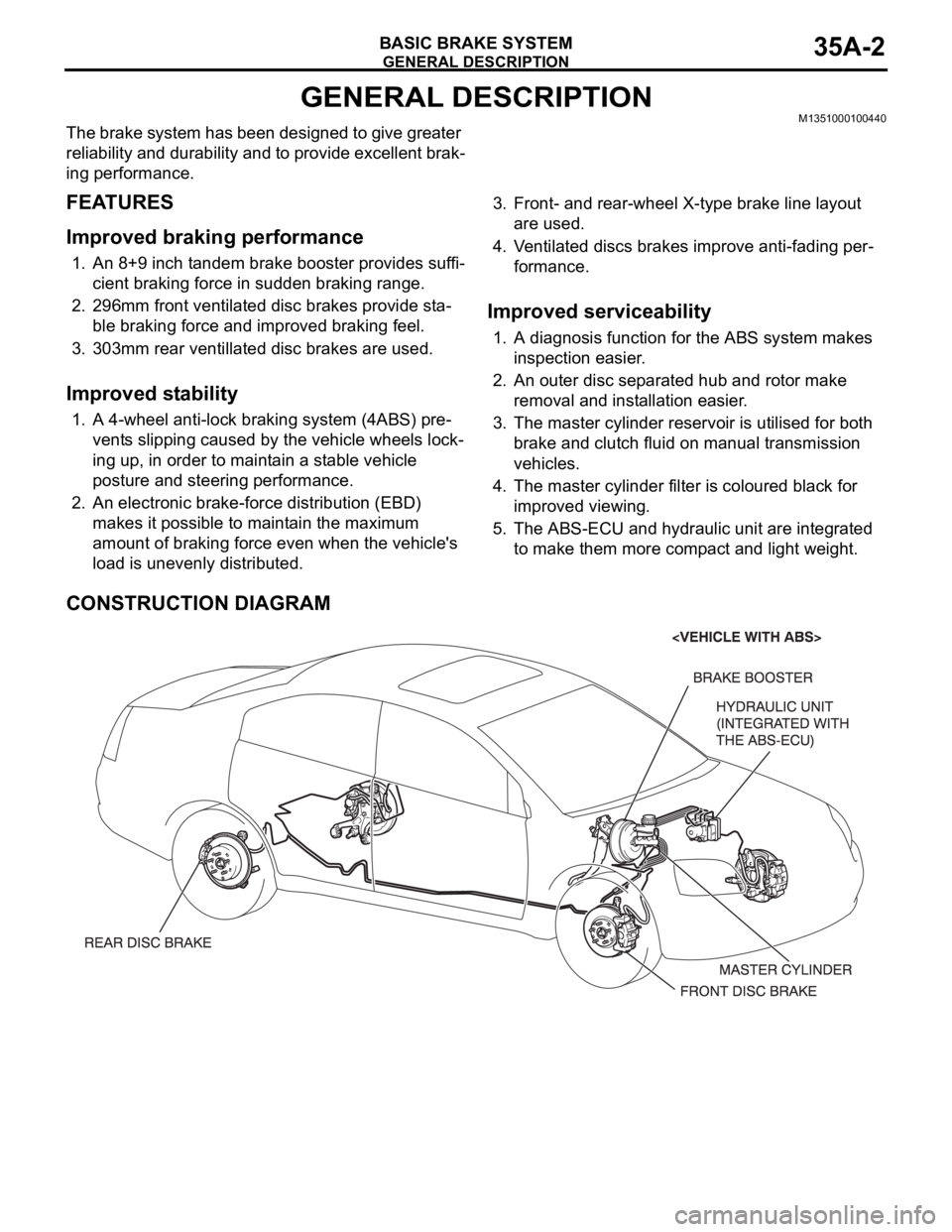

GENERAL DESCRIPTIONM1351000100440

The brake system has been designed to give greater

reliability and durability and to provide excellent brak-

ing performance.

FEATURES

.

Improved braking performance

1. An 8+9 inch tandem brake booster provides suffi-

cient braking force in sudden braking range.

2. 296mm front ventilated disc brakes provide sta-

ble braking force and improved braking feel.

3. 303mm rear ventillated disc brakes are used.

.

Improved stability

1. A 4-wheel anti-lock braking system (4ABS) pre-

vents slipping caused by the vehicle wheels lock-

ing up, in order to maintain a stable vehicle

posture and steering performance.

2. An electronic brake-force distribution (EBD)

makes it possible to maintain the maximum

amount of braking force even when the vehicle's

load is unevenly distributed. 3. Front- and rear-wheel X-type brake line layout

are used.

4. Ventilated discs brakes improve anti-fading per-

formance.

.

Improved serviceability

1. A diagnosis function for the ABS system makes

inspection easier.

2. An outer disc separated hub and rotor make

removal and installation easier.

3. The master cylinder reservoir is utilised for both

brake and clutch fluid on manual transmission

vehicles.

4. The master cylinder filter is coloured black for

improved viewing.

5. The ABS-ECU and hydraulic unit are integrated

to make them more compact and light weight.

CONSTRUCTION DIAGRAM

Page 1223 of 1500

GENERAL00-2

MAINTENANCE SERVICE . . . . . . . .00-37

1. FUEL SYSTEM (TANK, PIPE LINE AND

CONNECTION, AND FUEL TANK FILLER

TUBE CAP) (CHECK FOR LEAKS) . . . . . . 00-37

2. FUEL HOSES (CHECK CONDITION) . . 00-37

3. AIR CLEANER FILTER (REPLACE). . . . 00-37

4. EVAPORATIVE EMISSION SYSTEM

(EXCEPT EVAPORATIVE EMISSION

CANISTER) (CHECK FOR CLOGGING) . . 00-37

5. SPARK PLUGS (REPLACE). . . . . . . . . . 00-38

7. TIMING BELT (REPLACE) . . . . . . . . . . . 00-38

8. DRIVE BELTS (FOR ALTERNATOR, POWER

STEERING PUMP AND AIR CONDITIONING)

(CHECK) . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-39

9. EXHAUST SYSTEM (CONNECTIONS

PORTION OF MUFFLER, MUFFLER PIPES

AND CONVERTER HEAT SHIELDS) (CHECK

AND SERVICE AS REQUIRED) . . . . . . . . . 00-44

10. ENGINE OIL (CHANGE) . . . . . . . . . . . . 00-4411. ENGINE OIL FILTER (REPLACE) . . . . 00-44

12. TRANSMISSION FLUID . . . . . . . . . . . . 00-45

13. ENGINE COOLANT (CHANGE) . . . . . . 00-47

14. COOLANT HOSES (RADIATOR HOSE,

HEATER HOSE) (INSPECT). . . . . . . . . . . . 00-49

15. DISC BRAKE PADS, ROTORS

(INSPECT FOR WEAR) . . . . . . . . . . . . . . . 00-49

16. BRAKE HOSES (CHECK FOR

DETERIORATION OR LEAKS) . . . . . . . . . . 00-49

17. BALL JOINT AND STEERING LINKAGE

SEALS (INSPECT FOR GREASE LEAKS

AND DAMAGE) . . . . . . . . . . . . . . . . . . . . . . 00-50

18. DRIVE SHAFT BOOTS (INSPECT FOR

GREASE LEAKS AND DAMAGE) . . . . . . . . 00-50

19. SUSPENSION SYSTEM (INSPECT FOR

LOOSENESS AND DAMAGE) . . . . . . . . . . 00-51

20. SRS AIR BAG (INSPECT FOR SRS

SYSTEM). . . . . . . . . . . . . . . . . . . . . . . . . . . 00-51

21. TYRES (ROTATE). . . . . . . . . . . . . . . . . 00-58

Page 1243 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-22

ENGINE MODEL STAMPING

The engine model is stamped on the cylinder block.

The engine model number is as shown as follow.

The engine serial number is stamped near the engine model

number.

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)M1001011600056

1. Items to review when servicing SRS:

(1) Be sure to read GROUP 52B, Supplemental

Restraint System (SRS). For safe operation,

please follow the directions and heed all

warnings.

(2) Wait at least 60 seconds after disconnecting

the battery cable before doing any further

work. The SRS system is designed to retain

enough voltage to deploy the air bag even

after the battery has been disconnected.

Serious injury may result from unintended air

bag deployment if work is done on the SRS

system immediately after the battery cable is

disconnected.

(3) Warning labels must be heeded when

servicing or handling SRS components.

Warning labels can be found in the following

locations.

Front impact sensor

Hood

Sun visor

Instrument panel (passenger ’s side)

SRS-ECU

Steering wheel

Clock spring

Air bag module (Driver's or front

passenger's)

Side-airbag module (Driver's side or front

passenger's side)

Side impact sensor

Seat belt pre-tensioner

(4) Always use the designated special tools and

test equipment.(5) Store components removed from the SRS in a

clean and dry place. The air bag module

should be stored on a flat surface and placed

so that the pad surface is facing upward.

(6) Never attempt to disassemble or repair the

SRS components (SRS-ECU, air bag module

and clock spring). If there is a defect, replace

the defective part.

(7) Whenever you finish servicing the SRS, check

the SRS warning light operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing

of the air bag module or disposing of a vehicle

equipped with an air bag (Refer to GROUP

52B, Air Bag Module Disposal Procedures

P.52B-254).

2. Observe the following when carrying out

operations on places where SRS components are

installed, including operations not directly related

to the SRS air bag.

(1) When removing or installing parts, do not allow

any impact or shock to occur to the SRS

components.

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

a.SRS-ECU, air bag module, clock spring,

front impact sensor, the side impact sensor:

93

C (200F) or more

b.Seat belt pre-tensioner: 90

C (194F) or

more ENGINE MODEL ENGINE DISPLACEMENT

6G75 3828cc

Page 1245 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-24

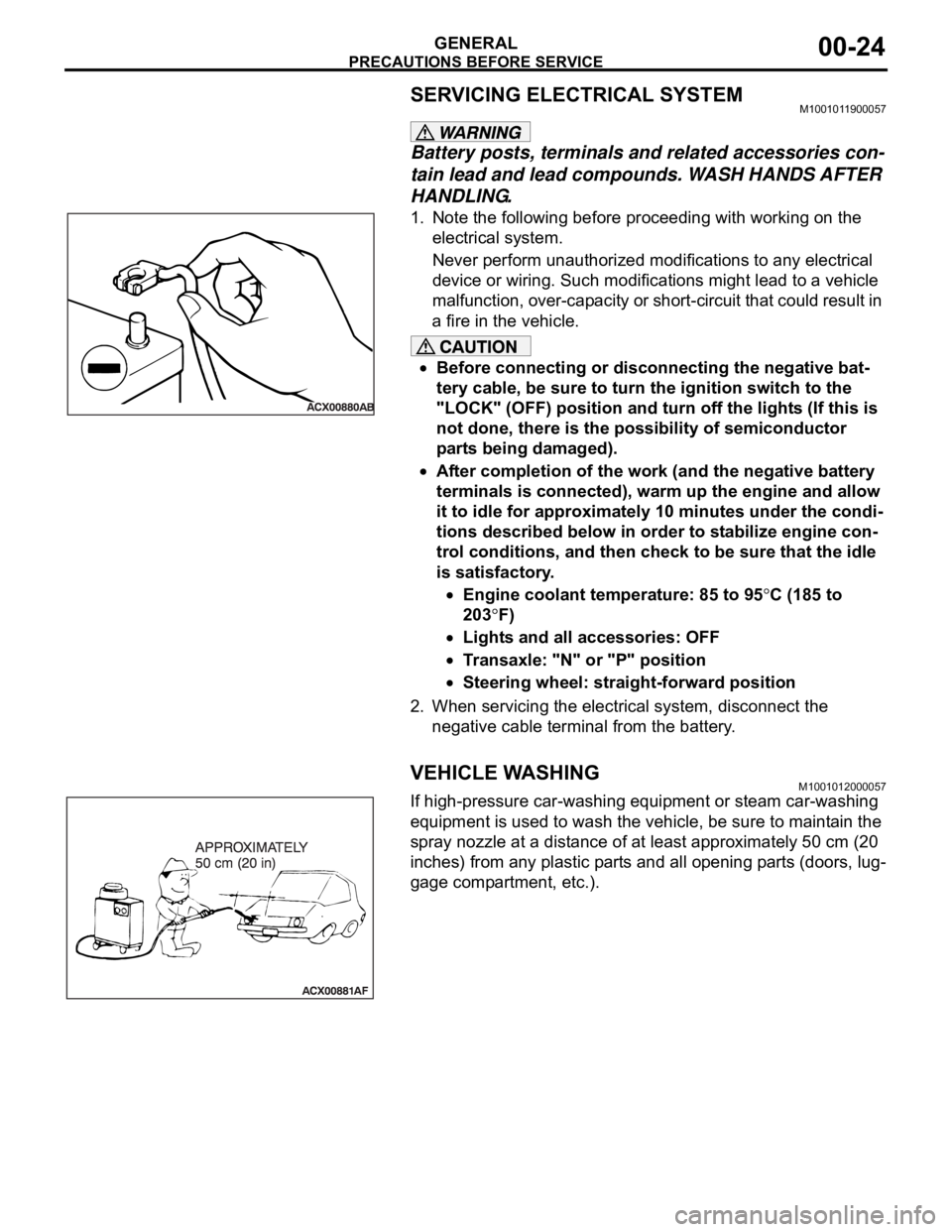

SERVICING ELECTRICAL SYSTEMM1001011900057

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Note the following before proceeding with working on the

electrical system.

Never perform unauthorized modifications to any electrical

device or wiring. Such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result in

a fire in the vehicle.

Before connecting or disconnecting the negative bat-

tery cable, be sure to turn the ignition switch to the

"LOCK" (OFF) position and turn off the lights (If this is

not done, there is the possibility of semiconductor

parts being damaged).

After completion of the work (and the negative battery

terminals is connected), warm up the engine and allow

it to idle for approximately 10 minutes under the condi-

tions described below in order to stabilize engine con-

trol conditions, and then check to be sure that the idle

is satisfactory.

Engine coolant temperature: 85 to 95C (185 to

203

F)

Lights and all accessories: OFF

Transaxle: "N" or "P" position

Steering wheel: straight-forward position

2. When servicing the electrical system, disconnect the

negative cable terminal from the battery.

VEHICLE WASHINGM1001012000057

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least approximately 50 cm (20

inches) from any plastic parts and all opening parts (doors, lug-

gage compartment, etc.).

Page 1248 of 1500

TOWING AND HOISTING

GENERAL00-27

TOWING WITH REAR WHEELS OFF THE

GROUND (TYPE B)

Place the gearshift lever in the "Neutral" position (M/T) or the

selector lever in the "N" (NEUTRAL) position (A/T). Turn the

ignition key to the "ACC" position and secure the steering

wheel in a straight-ahead position with a rope or tie-down strap.

Never place the ignition key in the "LOCK" position when tow-

ing.

Never tow an A/T vehicle with the rear wheels up (and

the front wheels on the ground) when the automatic

transmission fluid level is low. this may cause serious

and expensive damage to the transmission.

Do not use the steering column lock to secure the front

wheels for towing.

Make sure the transaxle is in Neutral if vehicle will have

drive wheels on the ground.

If these requirements cannot be met, the front wheels

must be placed on a tow dolly.

.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not avail-

able, the vehicle may be lifted and towed from the front, pro-

vided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle:

1. DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING

TO OR WRAPPING AROUND THE BUMPER.

2. Any loose, protruding, or damaged parts such as hoods,

doors, fenders, trim, etc. should be secured or removed

prior to moving the vehicle.

Page 1256 of 1500

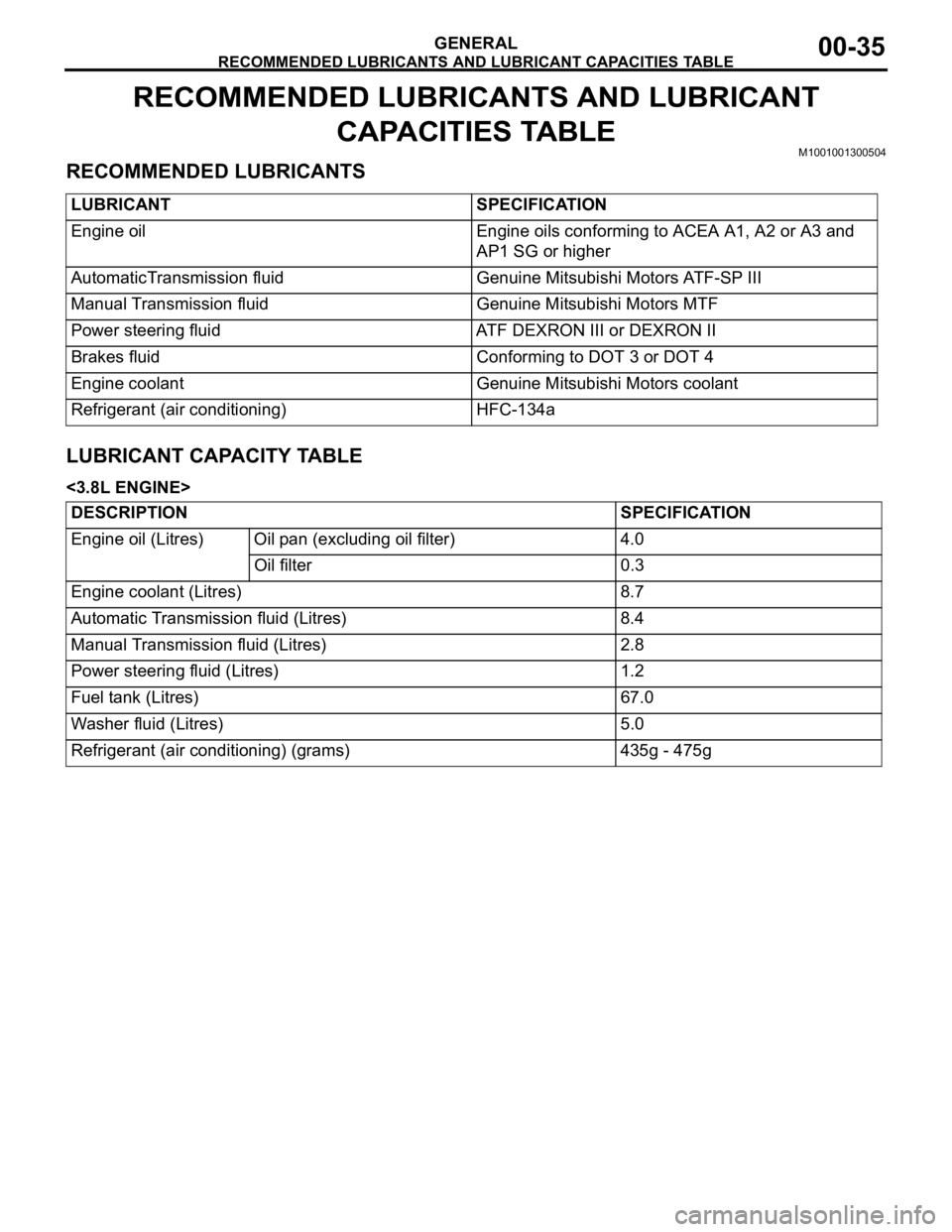

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE

GENERAL00-35

RECOMMENDED LUBRICANTS AND LUBRICANT

CAPACITIES TABLE

M1001001300504

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITY TABLE

<3.8L ENGINE>LUBRICANT SPECIFICATION

Engine oil Engine oils conforming to ACEA A1, A2 or A3 and

AP1 SG or higher

AutomaticTransmission fluid Genuine Mitsubishi Motors ATF-SP III

Manual Transmission fluid Genuine Mitsubishi Motors MTF

Power steering fluid ATF DEXRON III or DEXRON II

Brakes fluid Conforming to DOT 3 or DOT 4

Engine coolant Genuine Mitsubishi Motors coolant

Refrigerant (air conditioning) HFC-134a

DESCRIPTION SPECIFICATION

Engine oil (Litres) Oil pan (excluding oil filter) 4.0

Oil filter 0.3

Engine coolant (Litres) 8.7

Automatic Transmission fluid (Litres) 8.4

Manual Transmission fluid (Litres) 2.8

Power steering fluid (Litres) 1.2

Fuel tank (Litres) 67.0

Washer fluid (Litres) 5.0

Refrigerant (air conditioning) (grams) 435g - 475g

Page 1260 of 1500

MAINTENANCE SERVICE

GENERAL00-39

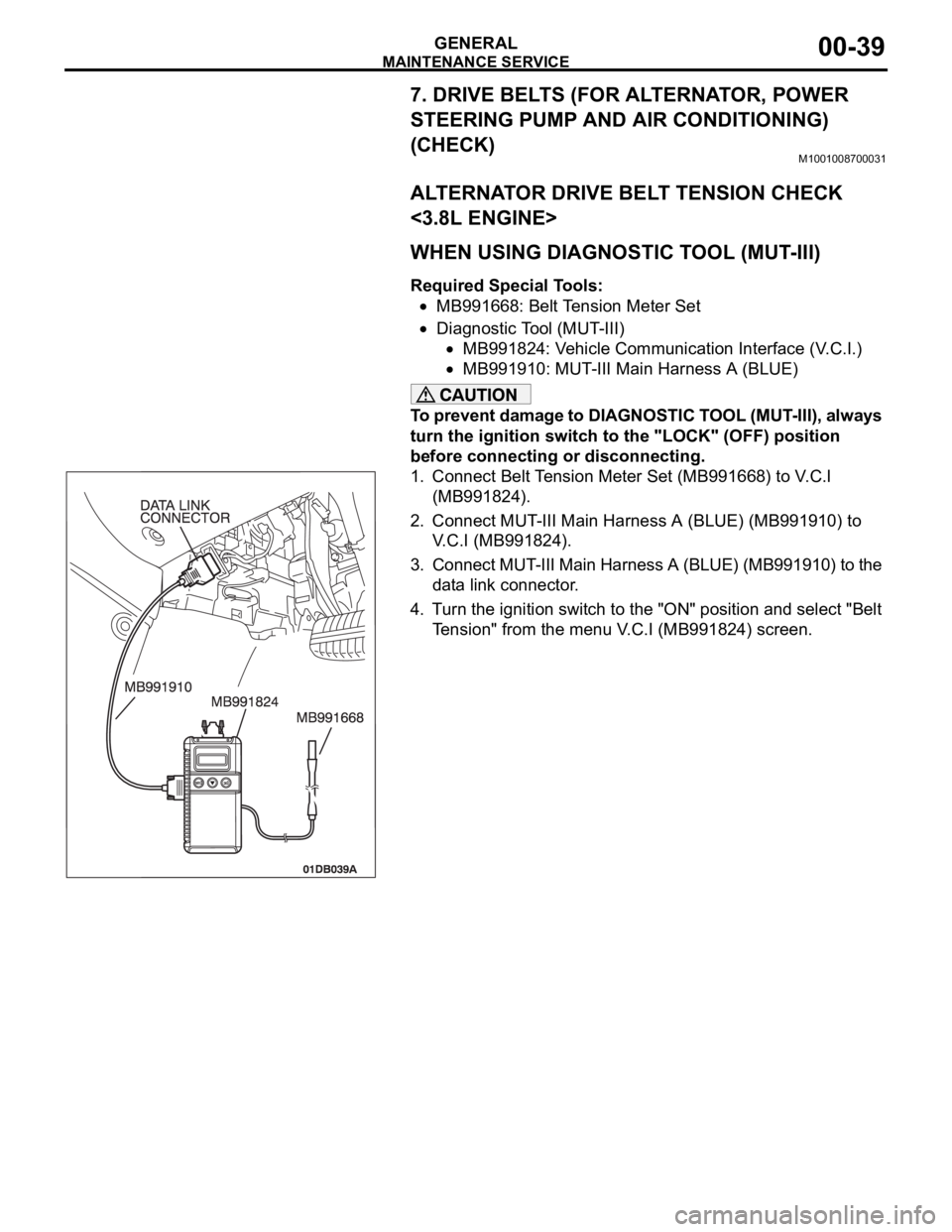

7. DRIVE BELTS (FOR ALTERNATOR, POWER

STEERING PUMP AND AIR CONDITIONING)

(CHECK)

M1001008700031

ALTERNATOR DRIVE BELT TENSION CHECK

<3.8L ENGINE>

.

WHEN USING DIAGNOSTIC TOOL (MUT-III)

Required Special Tools:

MB991668: Belt Tension Meter Set

Diagnostic Tool (MUT-III)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991910: MUT-III Main Harness A (BLUE)

To prevent damage to DIAGNOSTIC TOOL (MUT-III), always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting.

1. Connect Belt Tension Meter Set (MB991668) to V.C.I

(MB991824).

2. Connect MUT-III Main Harness A (BLUE) (MB991910) to

V.C.I (MB991824).

3. Connect MUT-III Main Harness A (BLUE) (MB991910) to the

data link connector.

4. Turn the ignition switch to the "ON" position and select "Belt

Tension" from the menu V.C.I (MB991824) screen.

Page 1263 of 1500

MAINTENANCE SERVICE

GENERAL00-42

ALTERNATOR DRIVE BELT TENSION

ADJUSTMENT

.1. Loosen the tensioner pulley fixing nut.

2. With the tensioner pulley fixing nut temporarily tightened to

15

5 Nm (11 4 ft-lb), set the belt tension or defection

amount to the standard value using the adjusting bolt.

Standard value:

3. Tighten the tension pulley fixing nut.

Tightening torque: 49

10 Nm (36 7 ft-lb)

POWER STEERING DRIVE BELT TENSION

CHECK

.

WHEN USING DIAGNOSTIC TOOL (MUT-III)

Required Special Tools:

MB991668: Belt Tension Meter Set

Diagnostic Tool (MUT-III)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991910: MUT-III Main Harness A (BLUE)

Gently tap the middle of the belt between the pulleys (the loca-

tion indicated by the arrow) with your finger as shown in the

illustration, and check that the vibration frequency of the belt is

within the standard value.

NOTE: Refer to P.00-39 for details on the method of measuring

the vibration frequency using the scan tool.

Standard value:

.

ITEMS DURING

ADJUSTMENTDURING

REPLACEMENT

Vibration

frequency Hz150

163 180 202

Tension N (lb) 539

637

(121

143)785

981

(176

221)

Deflection

(Reference value)

mm (in)8.9

10.1

(0.35

0.40)6.2

7.5

(0.24

0.30)

ITEM WHEN

CHECKEDDURING

ADJUSTME

NTDURING

REPLACEM

ENT

Vibration

frequency Hz124

160 134 151 160 189