Ignition circuit MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 64 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-64

STEP 1. Verify SWS monitor kit MB991813 for proper

connection.

Q: Is SWS monitor kit MB991813 connected with the

column switch properly?

YES : Go to Step 2.

NO : Connect SWS monitor kit MB991813 to the column

switch securely.

STEP 2. Verify the power supply circuit to the ETACS-ECU.

Q: Does the system communicate with diagnostic tool

MB991958 when the ignition switch is turned to the

"ON" position?

YES : Refer to Inspection Procedure A-3 "Communication

with the ETACS-ECU is not possible P.54B-74."

NO : Go to Step 3.

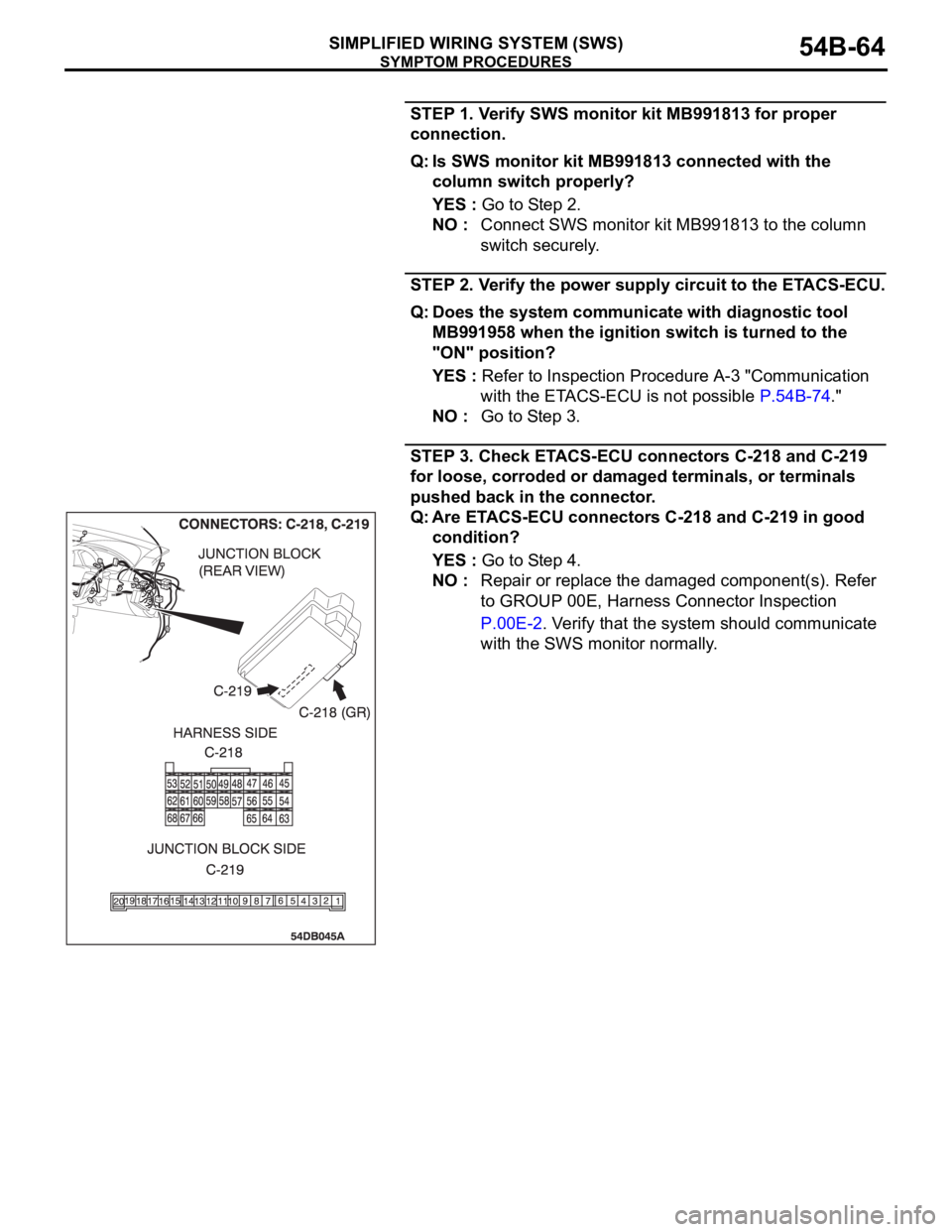

STEP 3. Check ETACS-ECU connectors C-218 and C-219

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Are ETACS-ECU connectors C-218 and C-219 in good

condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the system should communicate

with the SWS monitor normally.

Page 68 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-68

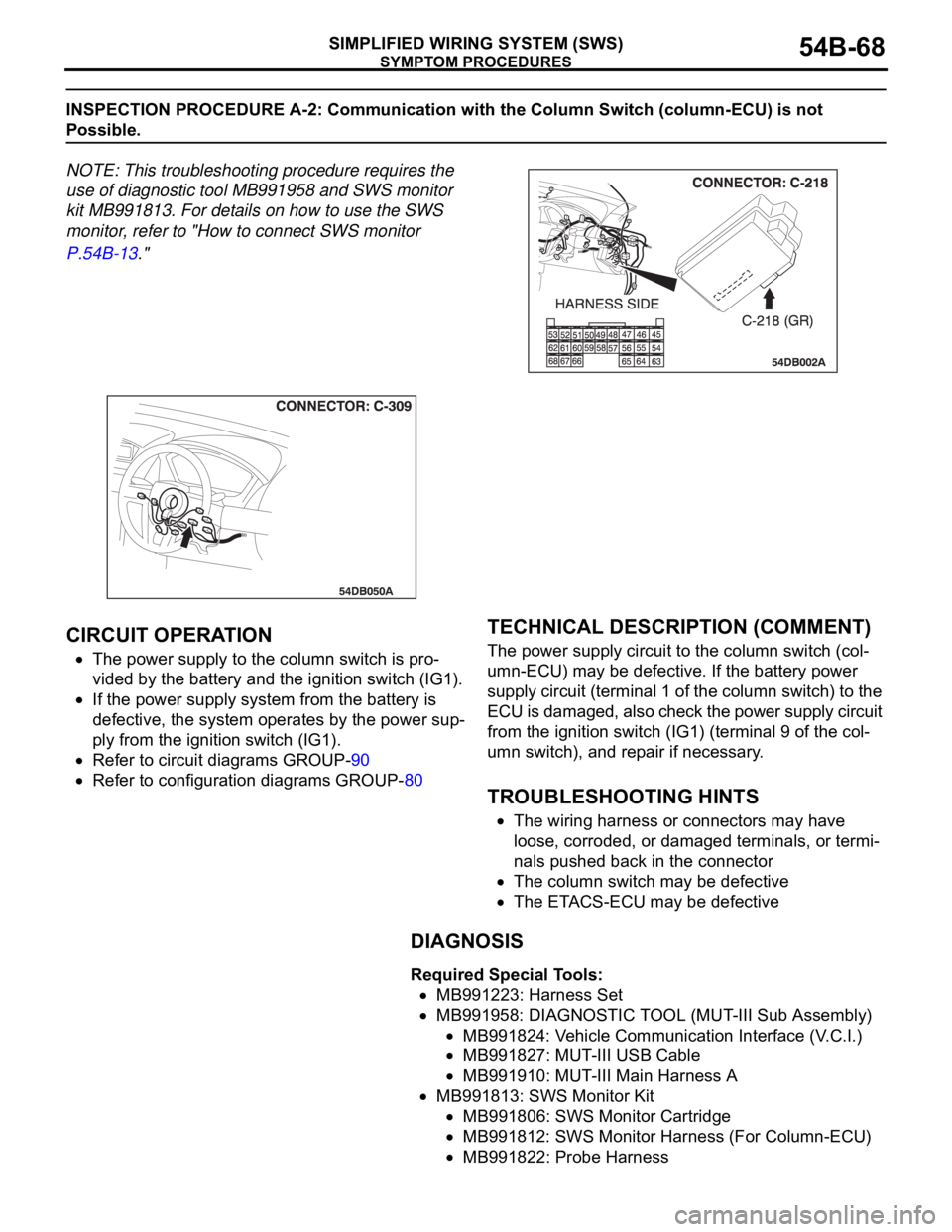

INSPECTION PROCEDURE A-2: Communication with the Column Switch (column-ECU) is not

Possible.

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The power supply to the column switch is pro-

vided by the battery and the ignition switch (IG1).

If the power supply system from the battery is

defective, the system operates by the power sup-

ply from the ignition switch (IG1).

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

.

TECHNICAL DESCRIPTION (COMMENT)

The power supply circuit to the column switch (col-

umn-ECU) may be defective. If the battery power

supply circuit (terminal 1 of the column switch) to the

ECU is damaged, also check the power supply circuit

from the ignition switch (IG1) (terminal 9 of the col-

umn switch), and repair if necessary.

.

TROUBLESHOOTING HINTS

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The column switch may be defective

The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Probe Harness

Page 74 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-74

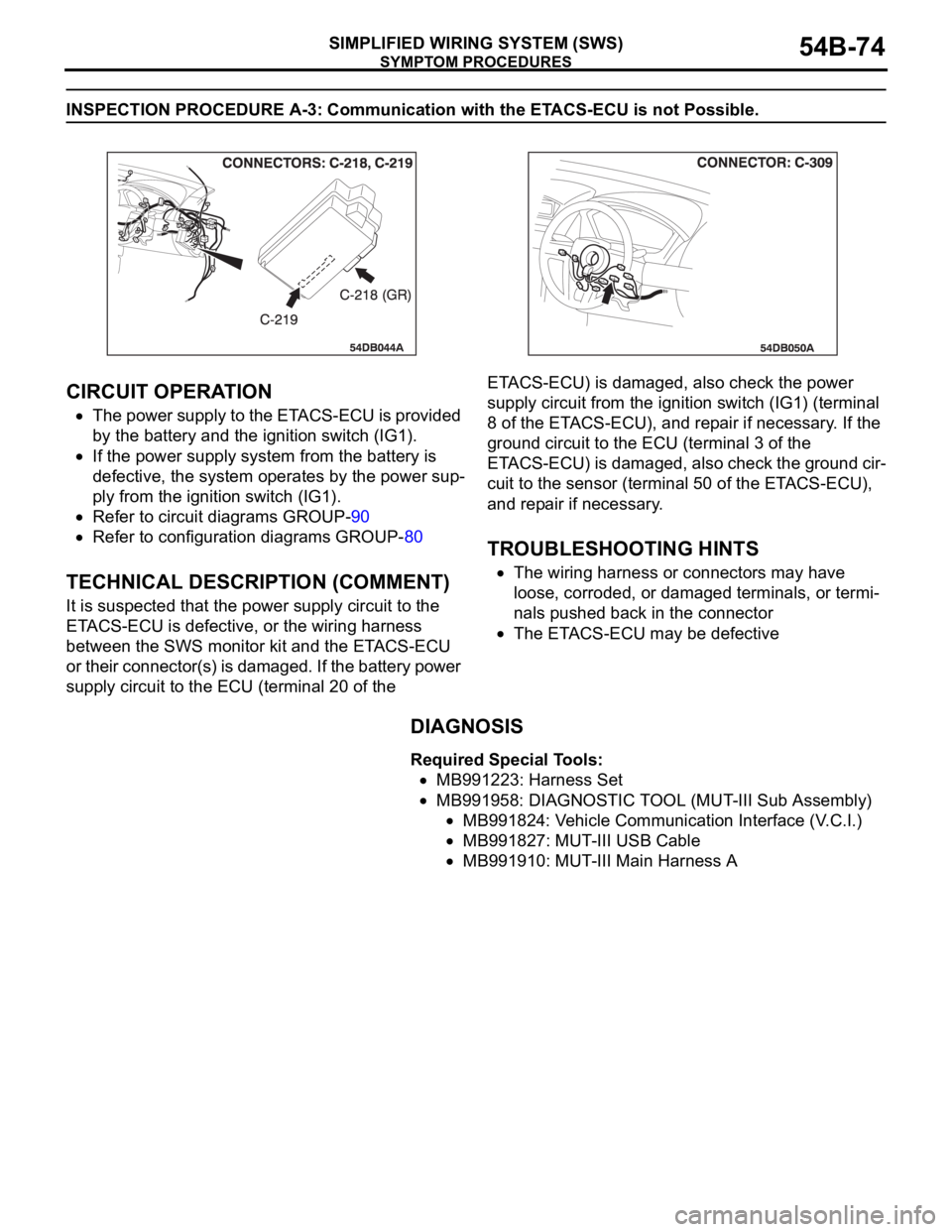

INSPECTION PROCEDURE A-3: Communication with the ETACS-ECU is not Possible.

.

CIRCUIT OPERATION

The power supply to the ETACS-ECU is provided

by the battery and the ignition switch (IG1).

If the power supply system from the battery is

defective, the system operates by the power sup-

ply from the ignition switch (IG1).

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

.

TECHNICAL DESCRIPTION (COMMENT)

It is suspected that the power supply circuit to the

ETACS-ECU is defective, or the wiring harness

between the SWS monitor kit and the ETACS-ECU

or their connector(s) is damaged. If the battery power

supply circuit to the ECU (terminal 20 of the ETACS-ECU) is damaged, also check the power

supply circuit from the ignition switch (IG1) (terminal

8 of the ETACS-ECU), and repair if necessary. If the

ground circuit to the ECU (terminal 3 of the

ETACS-ECU) is damaged, also check the ground cir-

cuit to the sensor (terminal 50 of the ETACS-ECU),

and repair if necessary.

.

TROUBLESHOOTING HINTS

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 80 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-80

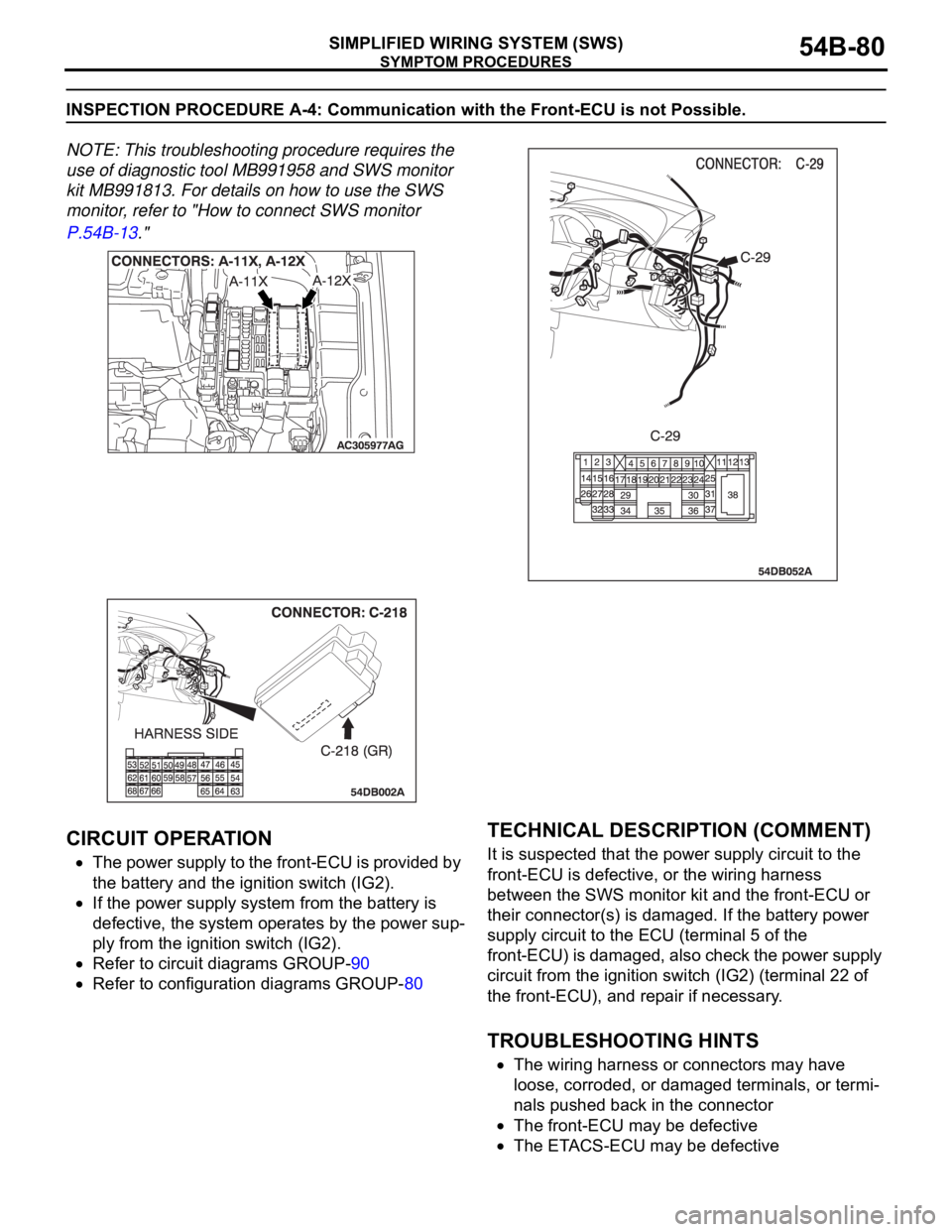

INSPECTION PROCEDURE A-4: Communication with the Front-ECU is not Possible.

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The power supply to the front-ECU is provided by

the battery and the ignition switch (IG2).

If the power supply system from the battery is

defective, the system operates by the power sup-

ply from the ignition switch (IG2).

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

.

TECHNICAL DESCRIPTION (COMMENT)

It is suspected that the power supply circuit to the

front-ECU is defective, or the wiring harness

between the SWS monitor kit and the front-ECU or

their connector(s) is damaged. If the battery power

supply circuit to the ECU (terminal 5 of the

front-ECU) is damaged, also check the power supply

circuit from the ignition switch (IG2) (terminal 22 of

the front-ECU), and repair if necessary.

.

TROUBLESHOOTING HINTS

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The front-ECU may be defective

The ETACS-ECU may be defective

Page 87 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-87

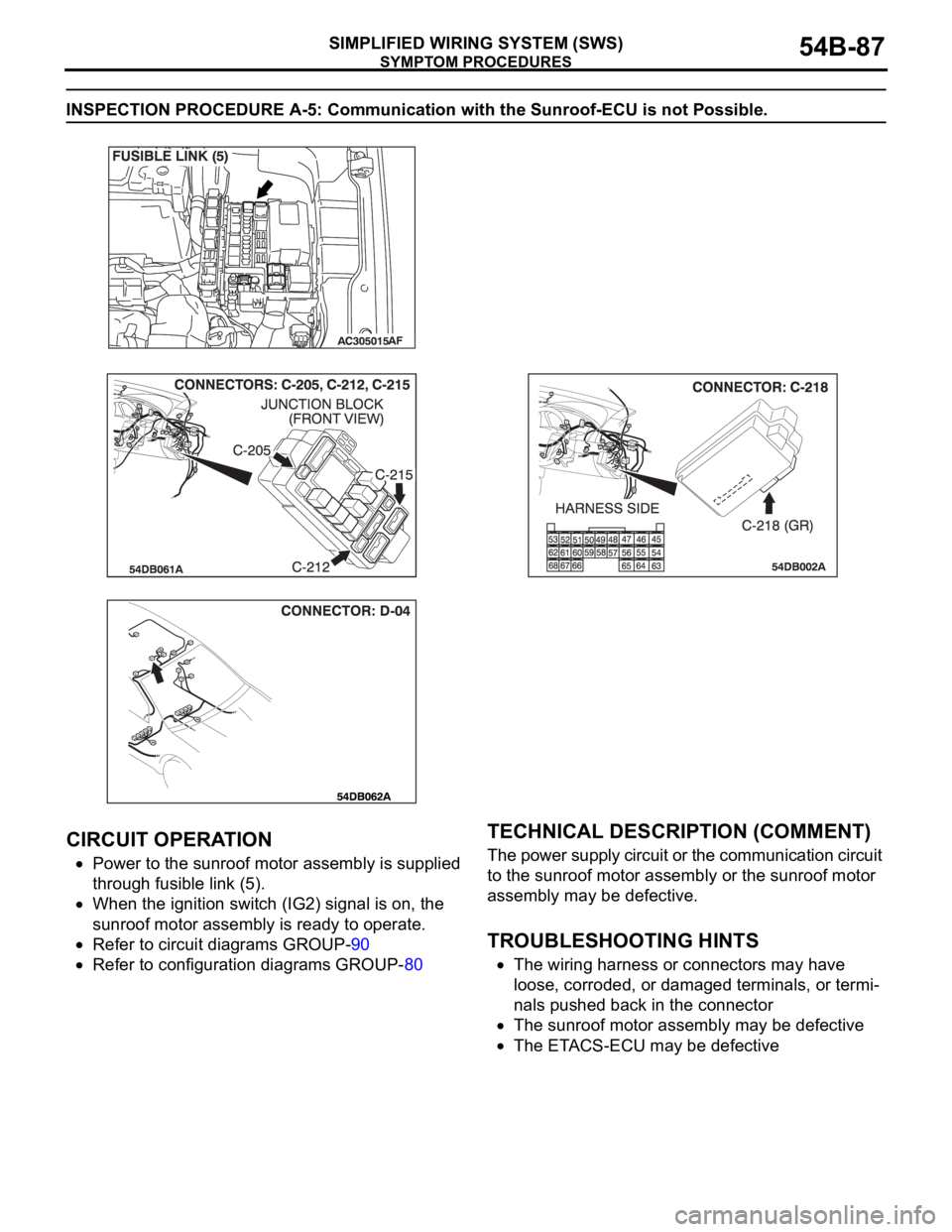

INSPECTION PROCEDURE A-5: Communication with the Sunroof-ECU is not Possible.

.

CIRCUIT OPERATION

Power to the sunroof motor assembly is supplied

through fusible link (5).

When the ignition switch (IG2) signal is on, the

sunroof motor assembly is ready to operate.

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

.

TECHNICAL DESCRIPTION (COMMENT)

The power supply circuit or the communication circuit

to the sunroof motor assembly or the sunroof motor

assembly may be defective.

.

TROUBLESHOOTING HINTS

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The sunroof motor assembly may be defective

The ETACS-ECU may be defective

Page 91 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-91

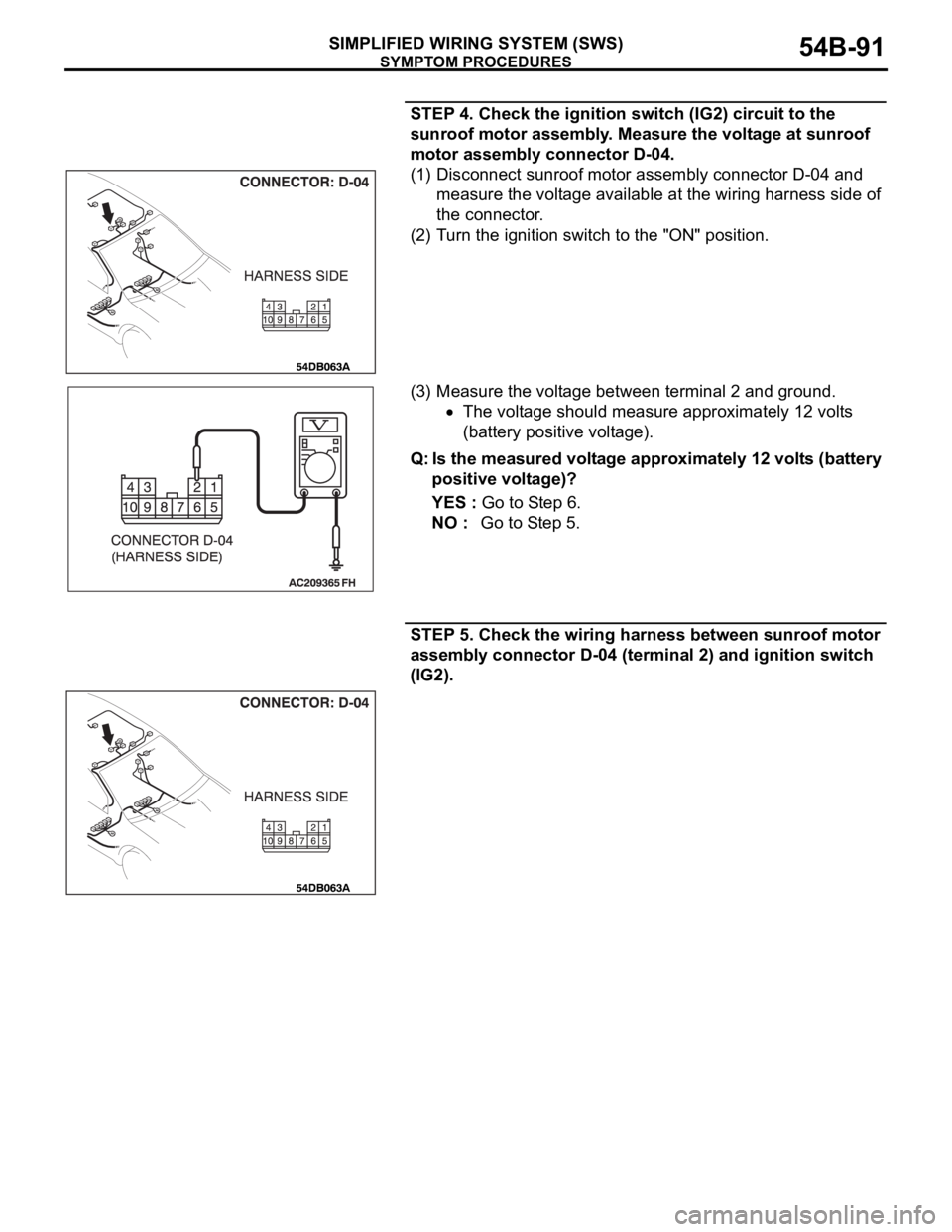

STEP 4. Check the ignition switch (IG2) circuit to the

sunroof motor assembly. Measure the voltage at sunroof

motor assembly connector D-04.

(1) Disconnect sunroof motor assembly connector D-04 and

measure the voltage available at the wiring harness side of

the connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 6.

NO : Go to Step 5.

STEP 5. Check the wiring harness between sunroof motor

assembly connector D-04 (terminal 2) and ignition switch

(IG2).

Page 92 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-92

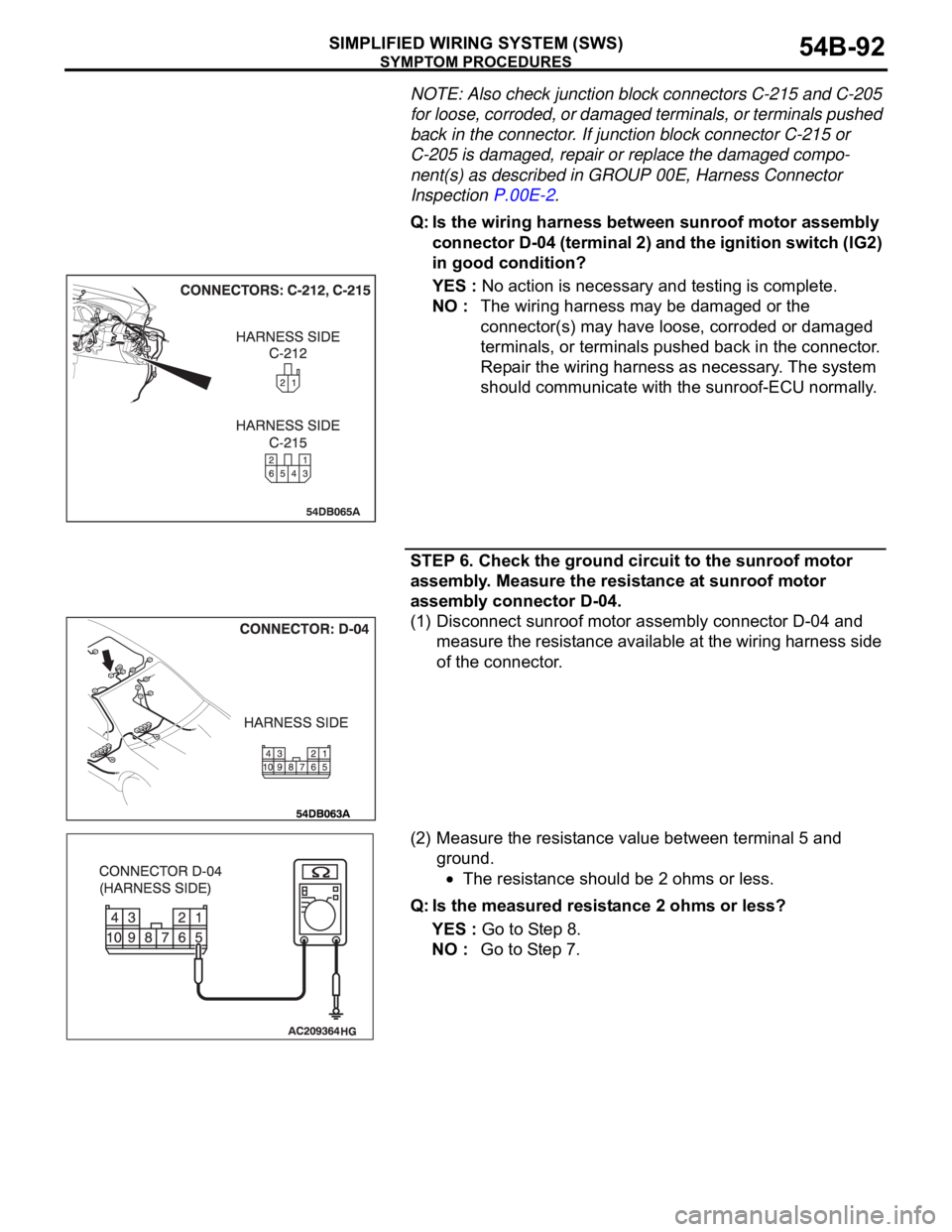

NOTE: Also check junction block connectors C-215 and C-205

for loose, corroded, or damaged terminals, or terminals pushed

back in the connector. If junction block connector C-215 or

C-205 is damaged, repair or replace the damaged compo-

nent(s) as described in GROUP 00E, Harness Connector

Inspection P.00E-2.

Q: Is the wiring harness between sunroof motor assembly

connector D-04 (terminal 2) and the ignition switch (IG2)

in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the sunroof-ECU normally.

STEP 6. Check the ground circuit to the sunroof motor

assembly. Measure the resistance at sunroof motor

assembly connector D-04.

(1) Disconnect sunroof motor assembly connector D-04 and

measure the resistance available at the wiring harness side

of the connector.

(2) Measure the resistance value between terminal 5 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 8.

NO : Go to Step 7.

Page 97 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-97

Door ajar warning buzzer

The buzzer is sounded 4 times by the ETACS-ECU to warn the

driver if any door is open when the ignition is switched ON and

the vehicle speed reaches 8 km/h (5 mph) or faster. The buzzer

will continue to sound for 4 times even if the ignition, door sta-

tus, or vehicle speed requirements are not maintained.

NOTE: The warning buzzer can be customized on vehicles

equipped with a multi center display. Refer to P.54B-486.

Multi center display operation tone

The ETACS-ECU sounds the buzzer when the buzzer signal is

sent from the center display.

Turn-signal lamp buzzer

The ETACS-ECU sounds the buzzer in sync with the turn-sig-

nal lamps or hazard warning lamps.

NOTE: The turn-signal lamp buzzer can be customized on

vehicles equipped with a multi center display (middle grade

type). Refer to P.54B-486.

General circuit diagram for lamp reminder tone alarm function. P.90-111

General circuit diagram for seat belt tone alarm function. P.90-113

Page 98 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-98

54B

INSPECTION PROCEDURE B-2: Tone Alarm: Light Reminder Tone Alarm Function does not Work

Normally.

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

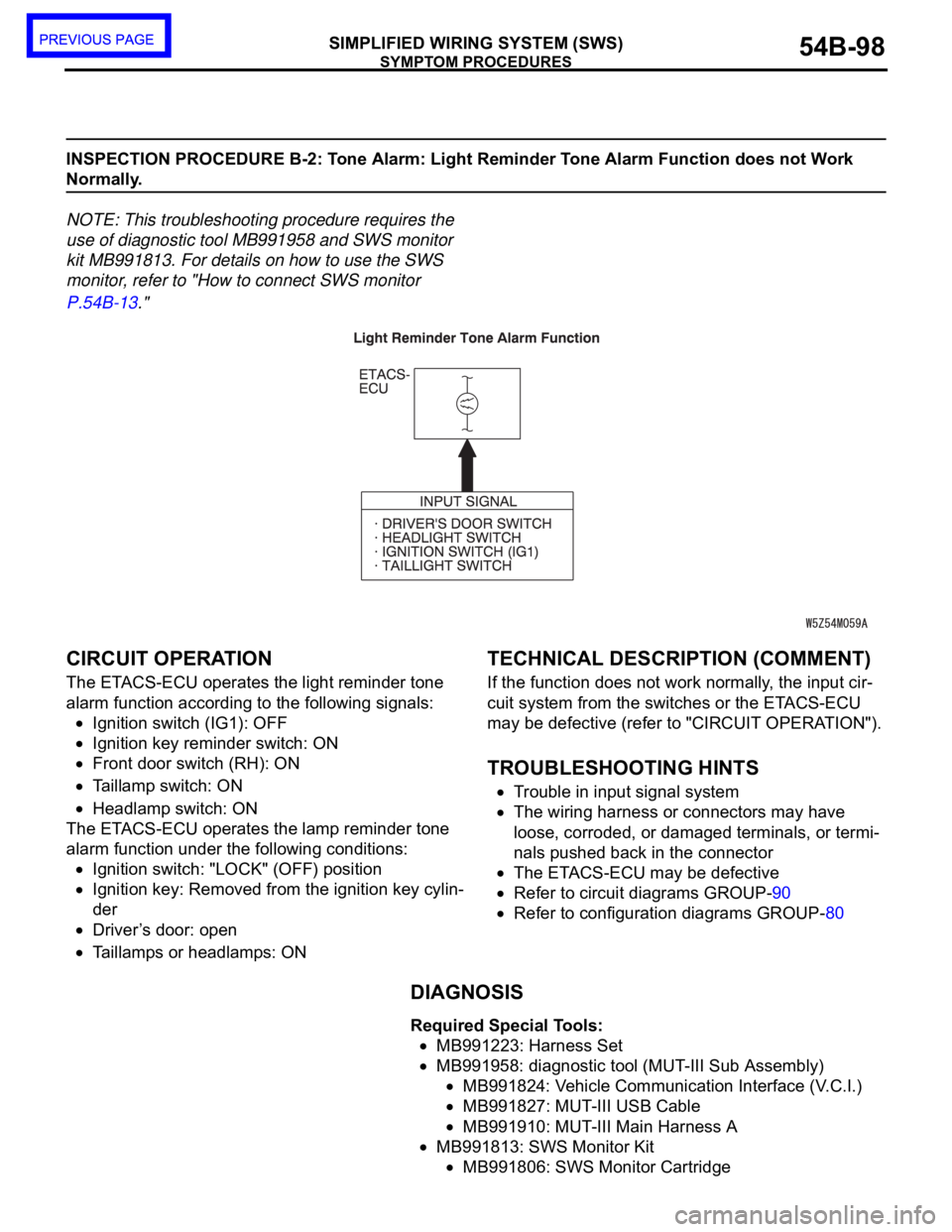

CIRCUIT OPERATION

The ETACS-ECU operates the light reminder tone

alarm function according to the following signals:

Ignition switch (IG1): OFF

Ignition key reminder switch: ON

Front door switch (RH): ON

Taillamp switch: ON

Headlamp switch: ON

The ETACS-ECU operates the lamp reminder tone

alarm function under the following conditions:

Ignition switch: "LOCK" (OFF) position

Ignition key: Removed from the ignition key cylin-

der

Driver’s door: open

Taillamps or headlamps: ON

.

TECHNICAL DESCRIPTION (COMMENT)

If the function does not work normally, the input cir-

cuit system from the switches or the ETACS-ECU

may be defective (refer to "CIRCUIT OPERATION").

.

TROUBLESHOOTING HINTS

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: diagnostic tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

Page 101 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-101

Normal condition is not displayed for "FRONT DOOR

SW" : Refer to Inspection Procedure M-4 "ETACS-ECU

does not receive any signal from the front door

switches P.54B-413."

Normal condition is not displayed for "H/L AUTO-CUT" :

Refer to Inspection Procedure H-9 "Headlamp

automatic shutoff function does not work normally

P.54B-305."

Normal condition is not displayed for "BUZZER" :

Replace the ETACS-ECU. The lamp reminder tone

alarm function should now work normally.

INSPECTION PROCEDURE B-3: Tone Alarm: Seat Belt Tone Alarm Function does not Work Normally.

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

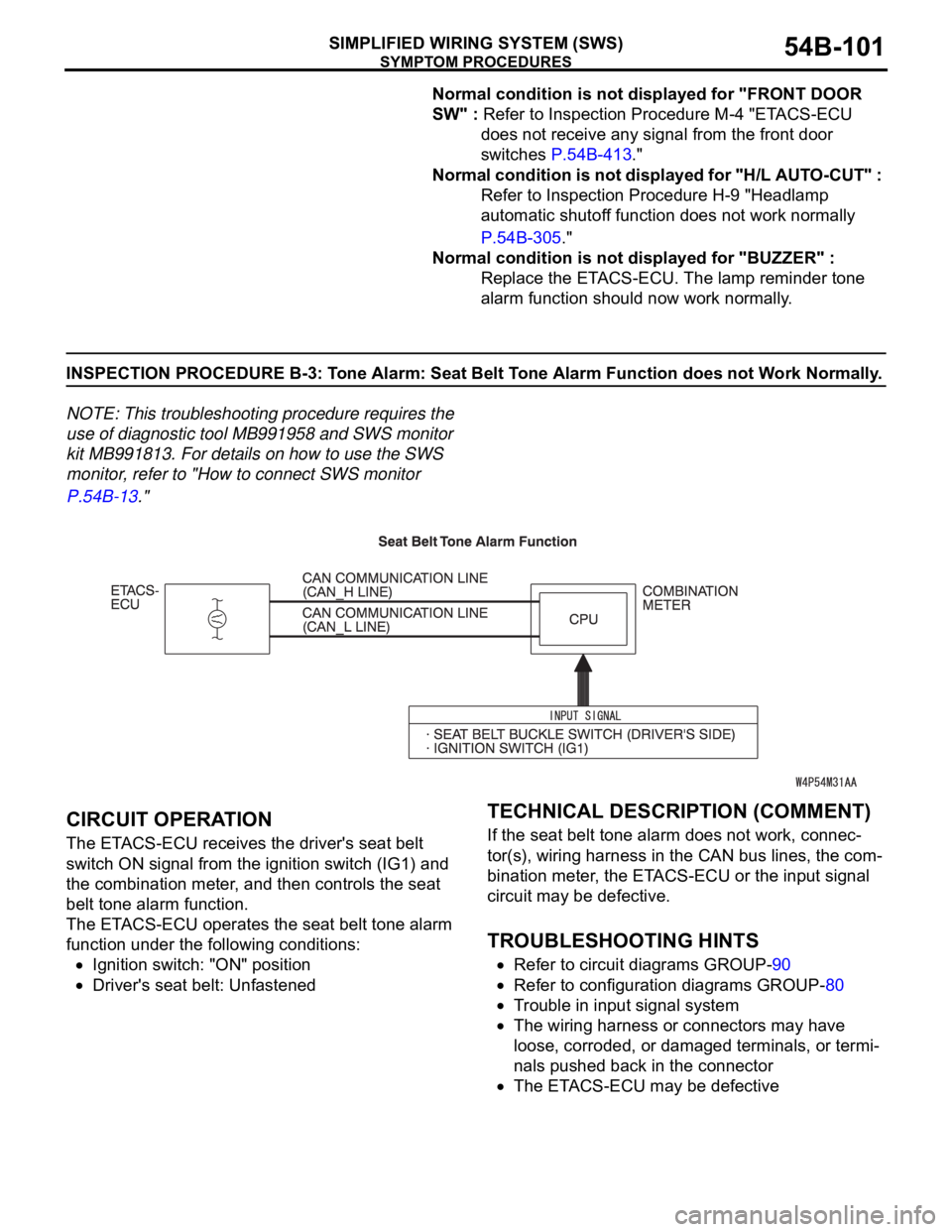

CIRCUIT OPERATION

The ETACS-ECU receives the driver's seat belt

switch ON signal from the ignition switch (IG1) and

the combination meter, and then controls the seat

belt tone alarm function.

The ETACS-ECU operates the seat belt tone alarm

function under the following conditions:

Ignition switch: "ON" position

Driver's seat belt: Unfastened

.

TECHNICAL DESCRIPTION (COMMENT)

If the seat belt tone alarm does not work, connec-

tor(s), wiring harness in the CAN bus lines, the com-

bination meter, the ETACS-ECU or the input signal

circuit may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective