clock MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1268 of 1500

MAINTENANCE SERVICE

GENERAL00-47

6. Securely insert the dipstick.

NOTE: The transmission fluid should always be replaced

under the following conditions:

.

When troubleshooting the transaxle.

When overhauling the transaxle.

When the transmission fluid is noticeably dirty or burnt

(driving under severe conditions).

TRANSMISSION FLUID CHANGE

Refer to GROUP 23A, Automatic Transmission - On-vehicle

Service P.23A-296.

12. ENGINE COOLANT (CHANGE)M1001003100357

Check the cooling system parts such as the radiator, heater

and oil cooler hoses, thermostat and their connections for leak-

age and damage.

.

CHANGING COOLANT

1. Set the temperature control knob to the "HOT" position.

2. Run the engine until the engine coolant warms, and then

stop the engine.

When removing the radiator cap, use care to avoid

contact with hot coolant or steam. Place a shop towel

over the cap and turn the cap counterclockwise a lit-

tle to let the pressure escape through the vinyl tube.

After relieving the steam pressure, remove the cap by

slowly turning it counterclockwise.

3. Drain the water from the radiator, heater core and engine

after unplugging the radiator drain plug and removing the

radiator cap.

Page 1274 of 1500

MAINTENANCE SERVICE

GENERAL00-53

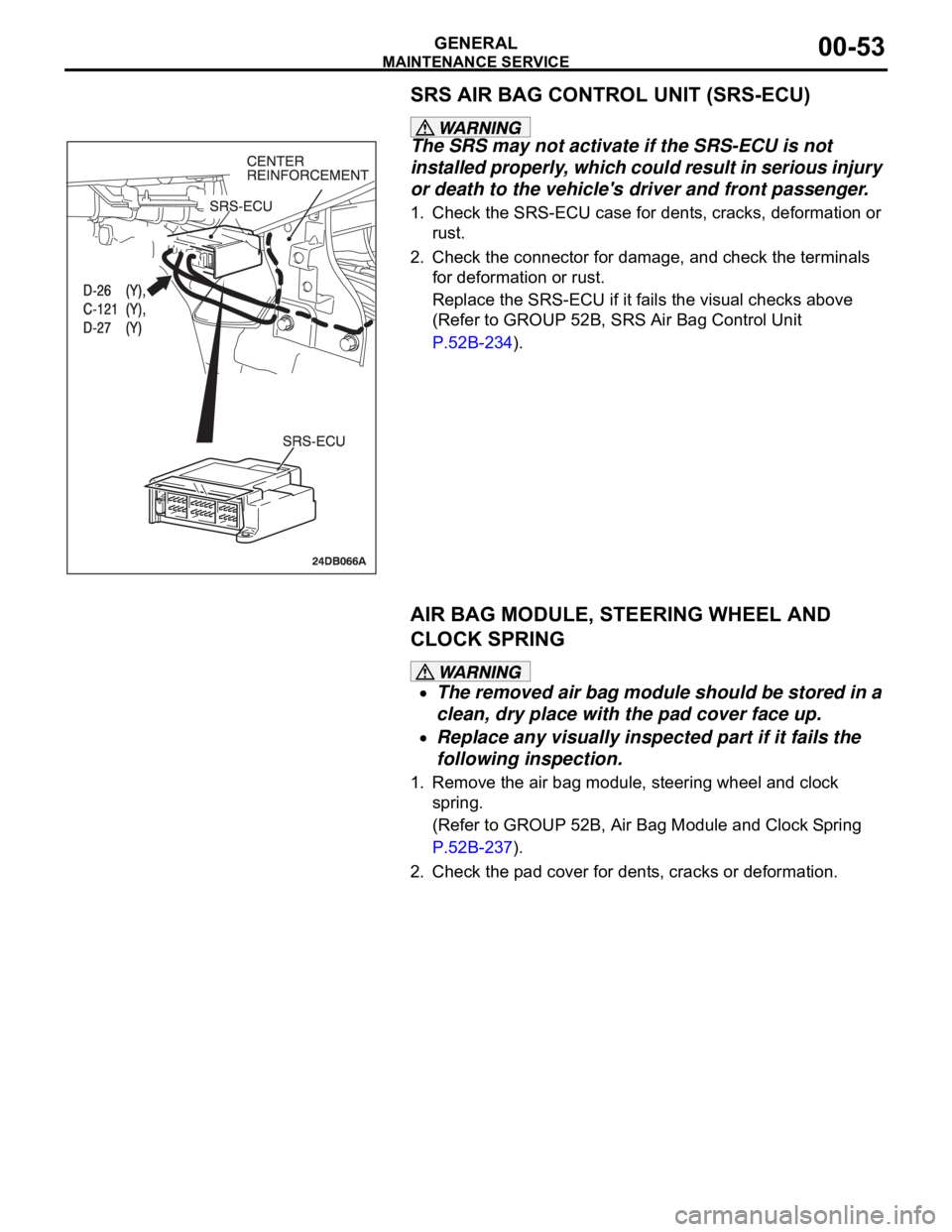

SRS AIR BAG CONTROL UNIT (SRS-ECU)

The SRS may not activate if the SRS-ECU is not

installed properly, which could result in serious injury

or death to the vehicle's driver and front passenger.

1. Check the SRS-ECU case for dents, cracks, deformation or

rust.

2. Check the connector for damage, and check the terminals

for deformation or rust.

Replace the SRS-ECU if it fails the visual checks above

(Refer to GROUP 52B, SRS Air Bag Control Unit

P.52B-234).

AIR BAG MODULE, STEERING WHEEL AND

CLOCK SPRING

The removed air bag module should be stored in a

clean, dry place with the pad cover face up.

Replace any visually inspected part if it fails the

following inspection.

1. Remove the air bag module, steering wheel and clock

spring.

(Refer to GROUP 52B, Air Bag Module and Clock Spring

P.52B-237).

2. Check the pad cover for dents, cracks or deformation.

Page 1275 of 1500

MAINTENANCE SERVICE

GENERAL00-54

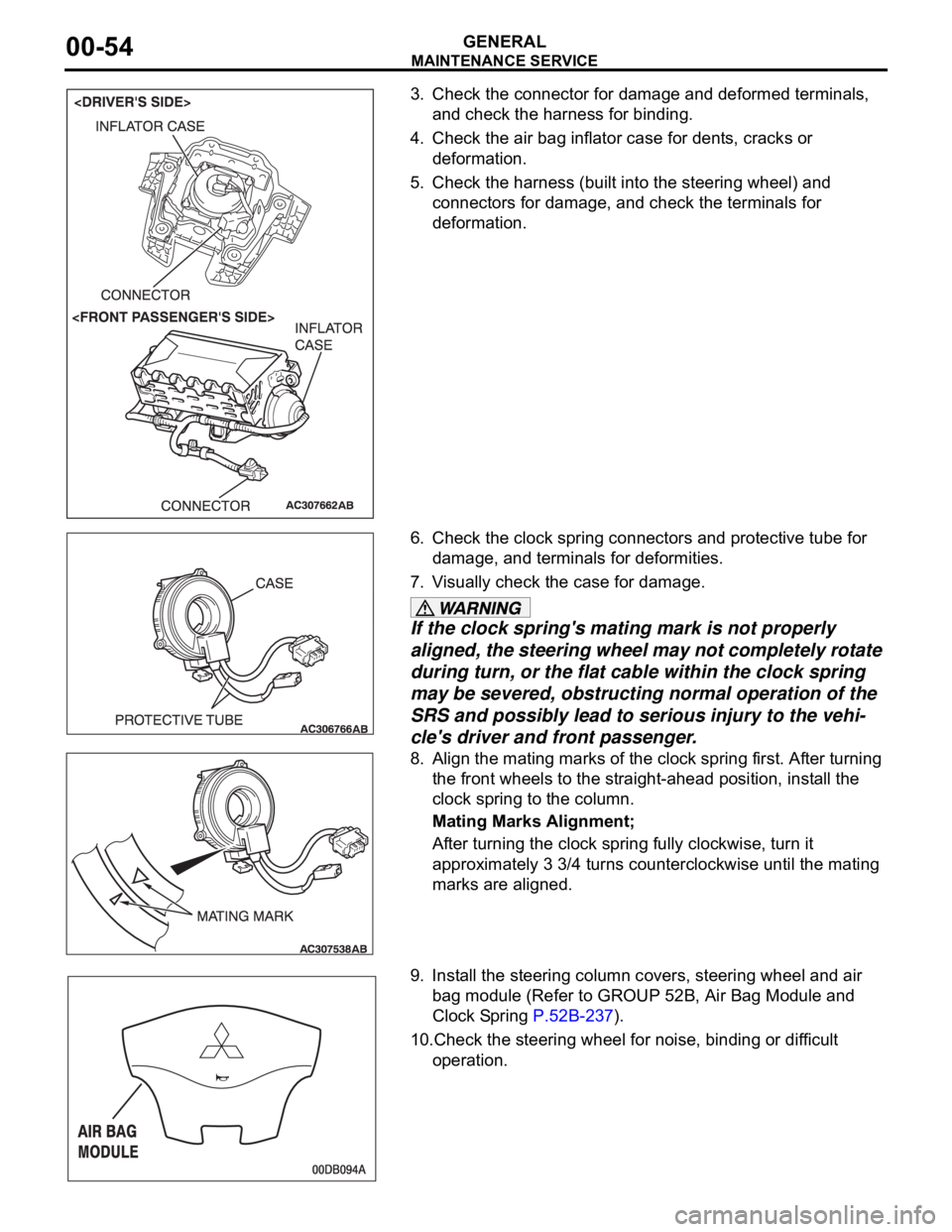

3. Check the connector for damage and deformed terminals,

and check the harness for binding.

4. Check the air bag inflator case for dents, cracks or

deformation.

5. Check the harness (built into the steering wheel) and

connectors for damage, and check the terminals for

deformation.

6. Check the clock spring connectors and protective tube for

damage, and terminals for deformities.

7. Visually check the case for damage.

If the clock spring's mating mark is not properly

aligned, the steering wheel may not completely rotate

during turn, or the flat cable within the clock spring

may be severed, obstructing normal operation of the

SRS and possibly lead to serious injury to the vehi-

cle's driver and front passenger.

8. Align the mating marks of the clock spring first. After turning

the front wheels to the straight-ahead position, install the

clock spring to the column.

Mating Marks Alignment;

After turning the clock spring fully clockwise, turn it

approximately 3 3/4 turns counterclockwise until the mating

marks are aligned.

9. Install the steering column covers, steering wheel and air

bag module (Refer to GROUP 52B, Air Bag Module and

Clock Spring P.52B-237).

10.Check the steering wheel for noise, binding or difficult

operation.

Page 1276 of 1500

MAINTENANCE SERVICE

GENERAL00-55

The SRS may not activate if any of the above compo-

nents are not installed properly, which could result in

serious injury or death to the vehicle's driver and

front passenger.

11.Check the steering wheel for excessive free play.

Replace any part if it fails visual inspection (Refer to

GROUP 52B, Air Bag Module and Clock Spring P.52B-237).

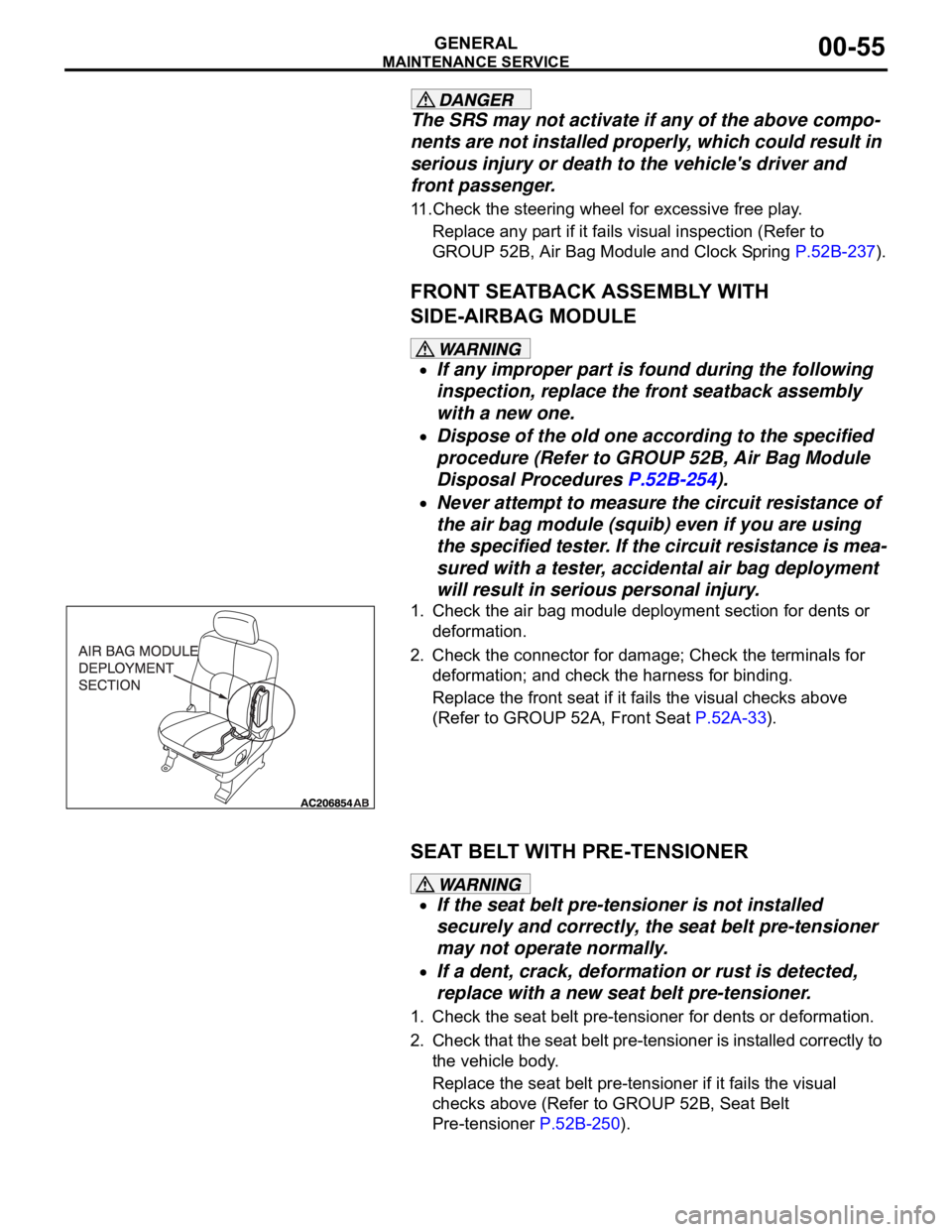

FRONT SEATBACK ASSEMBLY WITH

SIDE-AIRBAG MODULE

If any improper part is found during the following

inspection, replace the front seatback assembly

with a new one.

Dispose of the old one according to the specified

procedure (Refer to GROUP 52B, Air Bag Module

Disposal Procedures P.52B-254).

Never attempt to measure the circuit resistance of

the air bag module (squib) even if you are using

the specified tester. If the circuit resistance is mea-

sured with a tester, accidental air bag deployment

will result in serious personal injury.

1. Check the air bag module deployment section for dents or

deformation.

2. Check the connector for damage; Check the terminals for

deformation; and check the harness for binding.

Replace the front seat if it fails the visual checks above

(Refer to GROUP 52A, Front Seat P.52A-33).

SEAT BELT WITH PRE-TENSIONER

If the seat belt pre-tensioner is not installed

securely and correctly, the seat belt pre-tensioner

may not operate normally.

If a dent, crack, deformation or rust is detected,

replace with a new seat belt pre-tensioner.

1. Check the seat belt pre-tensioner for dents or deformation.

2. Check that the seat belt pre-tensioner is installed correctly to

the vehicle body.

Replace the seat belt pre-tensioner if it fails the visual

checks above (Refer to GROUP 52B, Seat Belt

Pre-tensioner P.52B-250).

Page 1352 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-21

CIRCUIT OPERATION

This circuit judges the signals of each switch

("COAST/SET", "ACC/RES" and "CANCEL") of the

auto-cruise control switch. The Engine ECU detects

the state of the auto-cruise control switch by sensing

the voltages shown below.

When all switches are OFF: 4.7 5.0 volts

When the "CRUISE" (MAIN) switch is "ON": 0

0.3 volt

When the "COAST/SET" switch is ON: 2.0 2.8

volts

When the "ACC/RES" switch is ON: 3.3 4.1

volts

When the "CANCEL" switch is ON: 0.8 1.5 volts

.

DTC SET CONDITIONS

Check Condition

The "CRUISE" indicator lamp illuminates.Judgement Criteria

If the auto-cruise control switch is operated, this

DTC will be set when the Engine ECU terminal

voltage is different from the standard value.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CASE:)

Malfunction of the auto-cruise control switch.

Malfunction of the clock spring.

Damaged harness or connector.

Malfunction of the Engine ECU.

Circuit drawings

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Refer to component locations GROUP-70

DIAGNOSIS

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991223: Harness Set

MB992044: ENGINE-ECU Check Harness

Page 1354 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-23

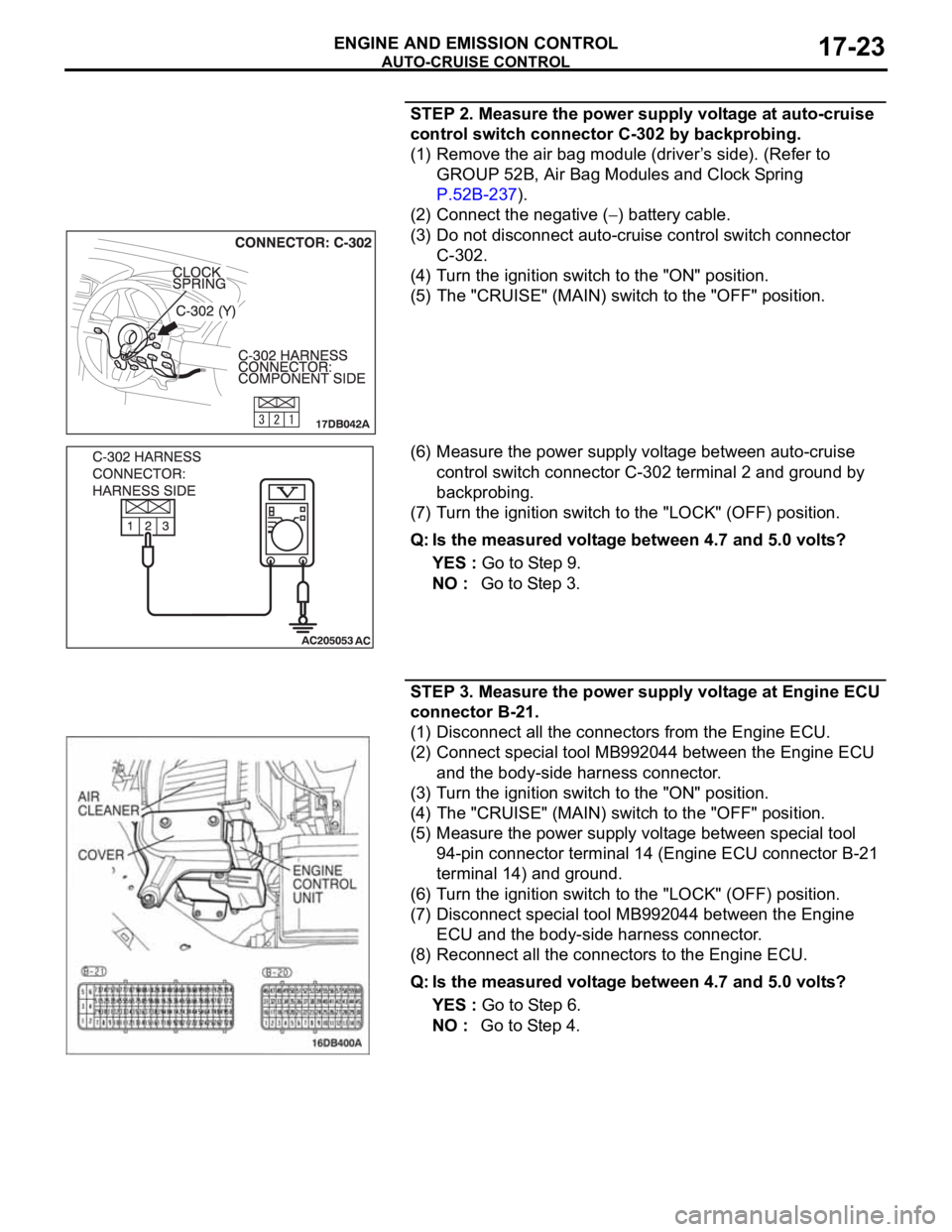

STEP 2. Measure the power supply voltage at auto-cruise

control switch connector C-302 by backprobing.

(1) Remove the air bag module (driver’s side). (Refer to

GROUP 52B, Air Bag Modules and Clock Spring

P.52B-237).

(2) Connect the negative (

) battery cable.

(3) Do not disconnect auto-cruise control switch connector

C-302.

(4) Turn the ignition switch to the "ON" position.

(5) The "CRUISE" (MAIN) switch to the "OFF" position.

(6) Measure the power supply voltage between auto-cruise

control switch connector C-302 terminal 2 and ground by

backprobing.

(7) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the measured voltage between 4.7 and 5.0 volts?

YES : Go to Step 9.

NO : Go to Step 3.

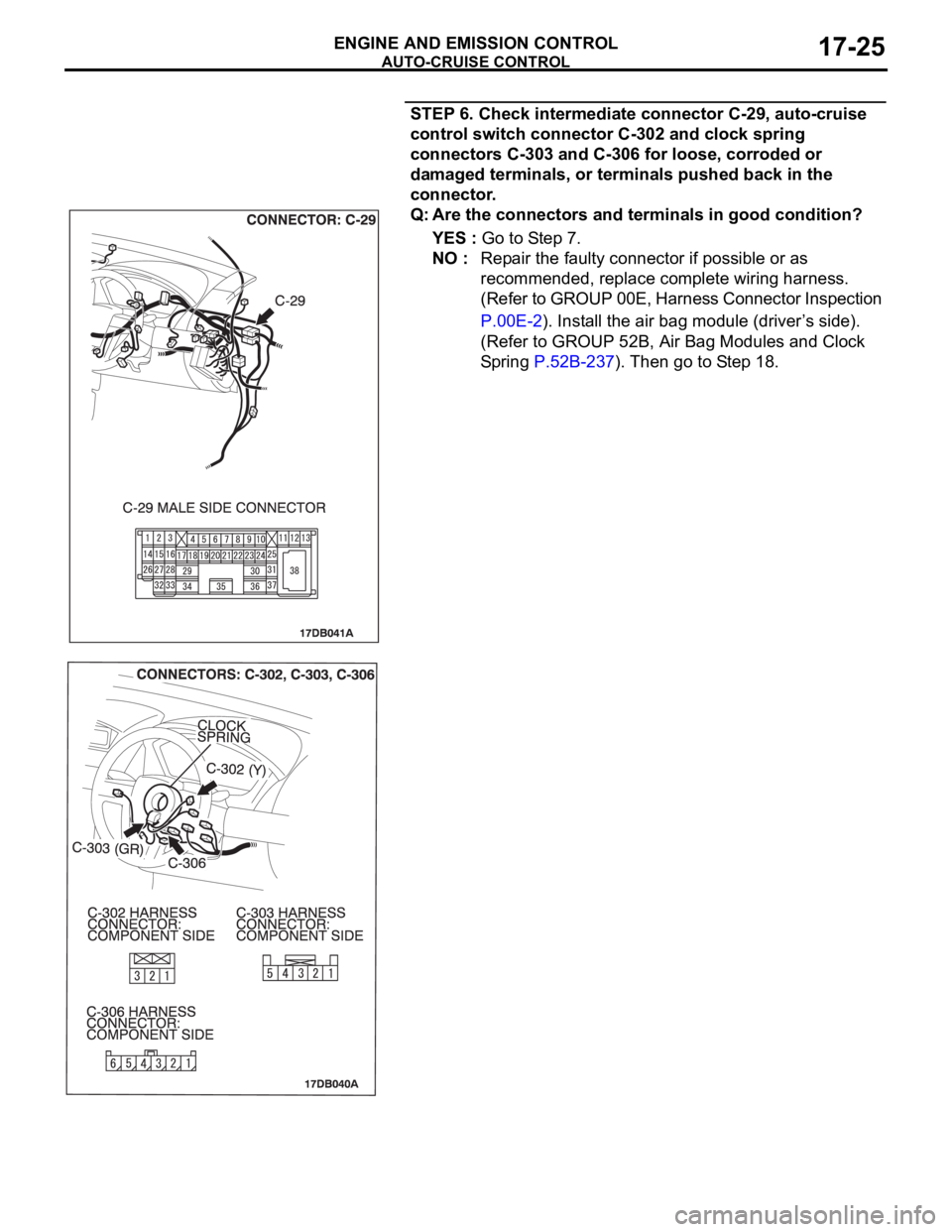

STEP 3. Measure the power supply voltage at Engine ECU

connector B-21.

(1) Disconnect all the connectors from the Engine ECU.

(2) Connect special tool MB992044 between the Engine ECU

and the body-side harness connector.

(3) Turn the ignition switch to the "ON" position.

(4) The "CRUISE" (MAIN) switch to the "OFF" position.

(5) Measure the power supply voltage between special tool

94-pin connector terminal 14 (Engine ECU connector B-21

terminal 14) and ground.

(6) Turn the ignition switch to the "LOCK" (OFF) position.

(7) Disconnect special tool MB992044 between the Engine

ECU and the body-side harness connector.

(8) Reconnect all the connectors to the Engine ECU.

Q: Is the measured voltage between 4.7 and 5.0 volts?

YES : Go to Step 6.

NO : Go to Step 4.

Page 1355 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-24

STEP 4. Check Engine ECU connector B-21 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Are the connector and terminals in good condition?

YES : Go to Step 5.

NO : Repair the faulty connector if possible or as

recommended, replace complete wiring harness.

(Refer to GROUP 00E, Harness Connector Inspection

P.00E-2). Install the air bag module (driver’s side).

(Refer to GROUP 52B, Air Bag Modules and Clock

Spring P.52B-237). Then go to Step 18.

STEP 5. Check the harness for short circuit to ground

between the Engine ECU connector B-21 terminal 14 and

the auto-cruise control switch connector C-302 terminal 2.

(1) Disconnect Engine ECU connector B-21 and measure at

the harness connector side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Measure the continuity between Engine ECU connector

B-21 terminal 14 and ground.

(4) Reconnect Engine ECU connector B-21.

Q: Is the measured continuity open circuit?

YES : Install the air bag module (driver’s side). (Refer to

GROUP 52B, Air Bag Modules and Clock Spring

P.52B-237). Then go to Step 17.

NO : Go to Step 6.

Page 1356 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-25

STEP 6. Check intermediate connector C-29, auto-cruise

control switch connector C-302 and clock spring

connectors C-303 and C-306 for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are the connectors and terminals in good condition?

YES : Go to Step 7.

NO : Repair the faulty connector if possible or as

recommended, replace complete wiring harness.

(Refer to GROUP 00E, Harness Connector Inspection

P.00E-2). Install the air bag module (driver’s side).

(Refer to GROUP 52B, Air Bag Modules and Clock

Spring P.52B-237). Then go to Step 18.

Page 1357 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-26

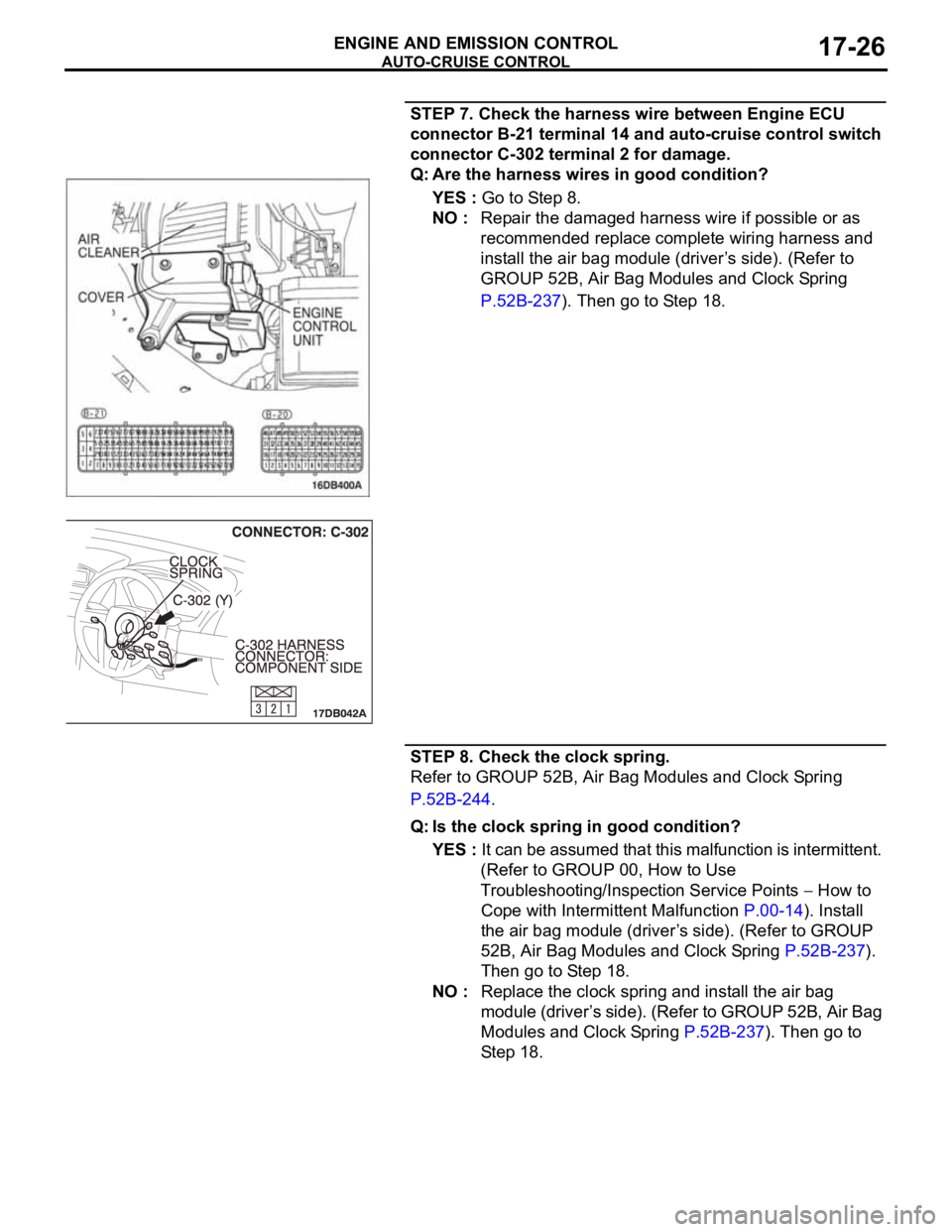

STEP 7. Check the harness wire between Engine ECU

connector B-21 terminal 14 and auto-cruise control switch

connector C-302 terminal 2 for damage.

Q: Are the harness wires in good condition?

YES : Go to Step 8.

NO : Repair the damaged harness wire if possible or as

recommended replace complete wiring harness and

install the air bag module (driver’s side). (Refer to

GROUP 52B, Air Bag Modules and Clock Spring

P.52B-237). Then go to Step 18.

STEP 8. Check the clock spring.

Refer to GROUP 52B, Air Bag Modules and Clock Spring

P.52B-244.

Q: Is the clock spring in good condition?

YES : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14). Install

the air bag module (driver’s side). (Refer to GROUP

52B, Air Bag Modules and Clock Spring P.52B-237).

Then go to Step 18.

NO : Replace the clock spring and install the air bag

module (driver’s side). (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-237). Then go to

Step 18.

Page 1359 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-28

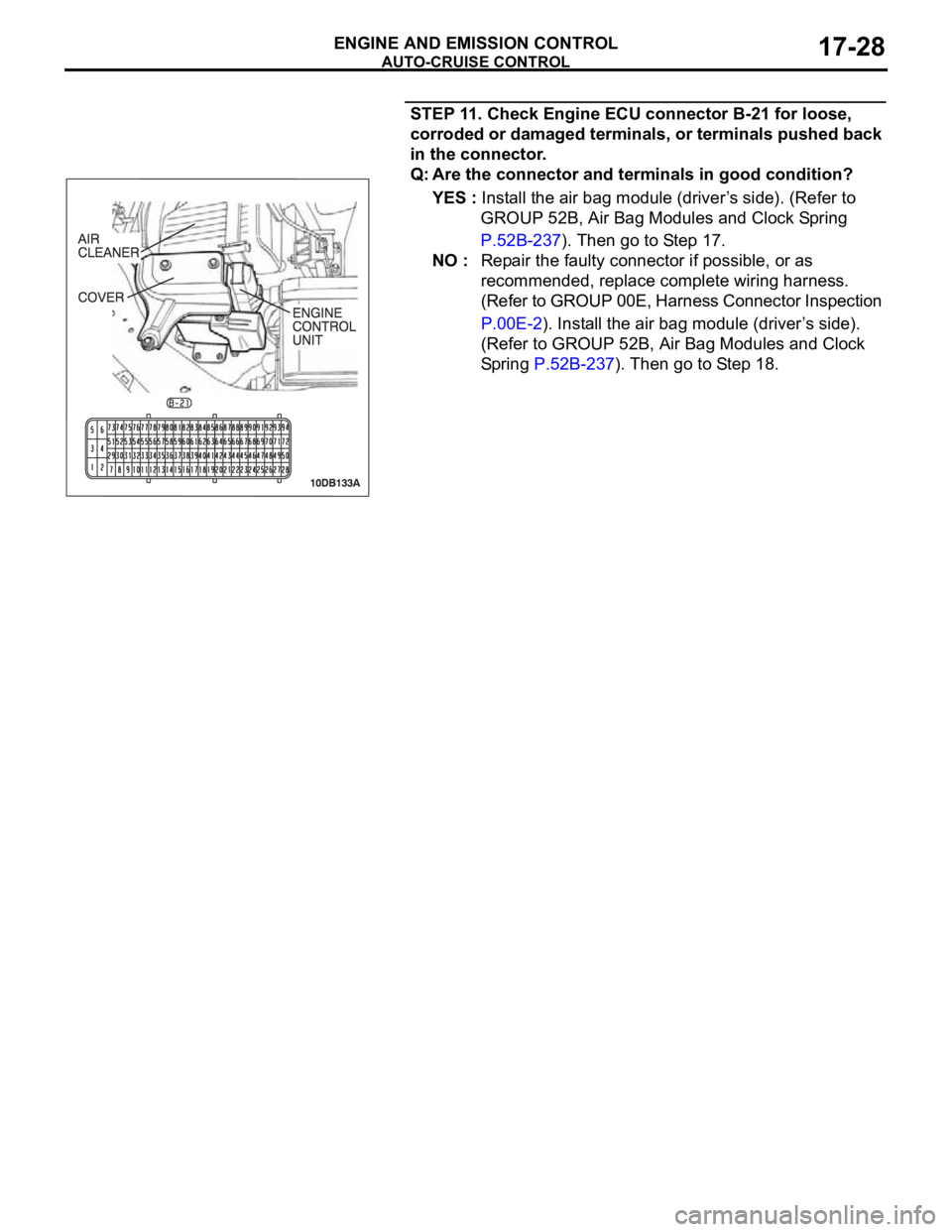

STEP 11. Check Engine ECU connector B-21 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Are the connector and terminals in good condition?

YES : Install the air bag module (driver’s side). (Refer to

GROUP 52B, Air Bag Modules and Clock Spring

P.52B-237). Then go to Step 17.

NO : Repair the faulty connector if possible, or as

recommended, replace complete wiring harness.

(Refer to GROUP 00E, Harness Connector Inspection

P.00E-2). Install the air bag module (driver’s side).

(Refer to GROUP 52B, Air Bag Modules and Clock

Spring P.52B-237). Then go to Step 18.